Oil sleeve resistant to hydrogen sulfide stress corrosion cracking and manufacturing method thereof

A technology of stress corrosion cracking and hydrogen sulfide resistance, which is applied in the field of oil casing and its manufacturing, can solve problems such as economic losses, safety hazards, stress corrosion cracking, etc., achieve good high strength, refine grains, and increase supercooling Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

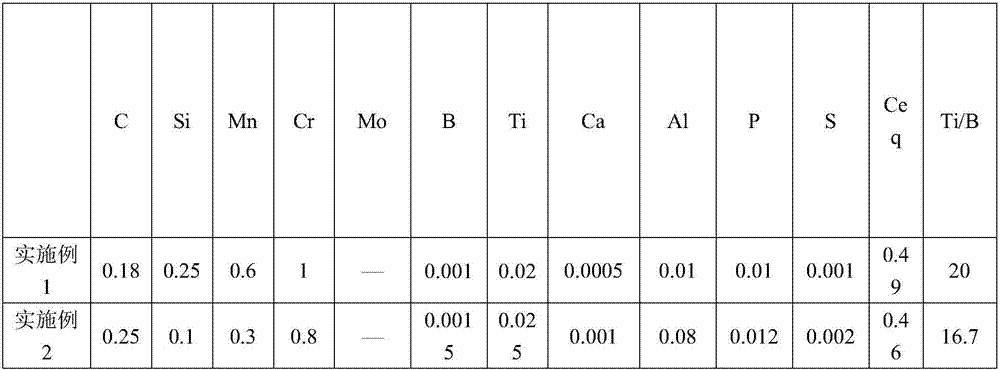

Embodiment 1-5 and comparative example 1-4

[0043] The oil casing pipe of embodiment 1-5 and the pipe steel of comparative example 1-4 adopt following steps to make:

[0044] (1) Smelting and casting by using the mass percentage ratio in Table 1 to obtain a tube blank, wherein the degree of superheat is controlled to be ≤30°C, and the casting speed is 1.6-2m / min;

[0045] (2) Rolling: the tube billet is soaked at 1210-1240°C, and then pierced. The piercing temperature is 1190-1240°C; the final rolling temperature is controlled at 900-950°C, and the sizing temperature is 850-900°C;

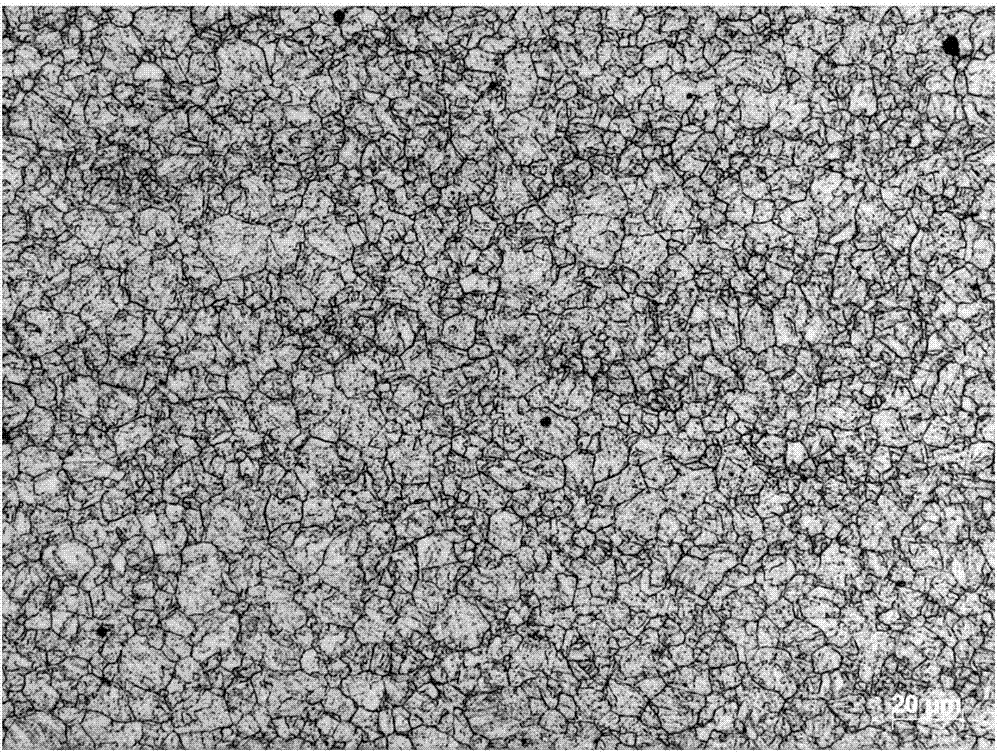

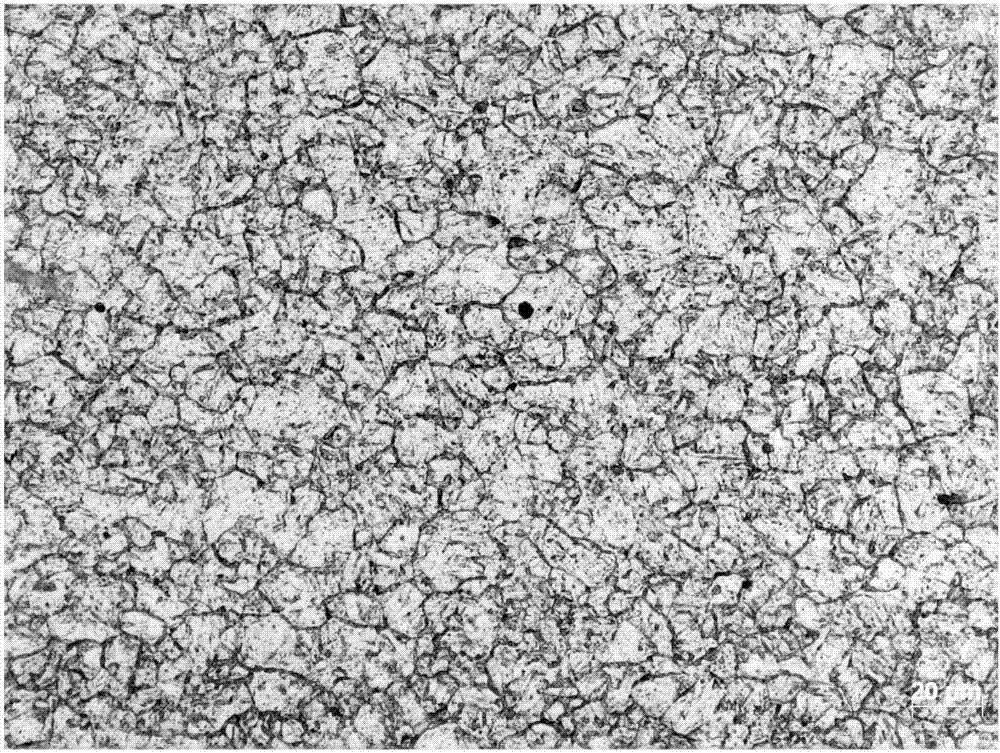

[0046] (3) Controlled cooling: water-cool the outer walls of the casings of Examples 1-5 and Comparative Examples 1-3, and cool them to 100-400°C at a cooling rate of 30-50°C / s, so that the structure of the steel pipes becomes shellfish. Tensite or martensite; (wherein, comparative example 4 adopts air cooling to 50 ℃, and cooling rate is 1.5 ℃ / s);

[0047] (4) Heat treatment: Quenching first: heat the steel pipe to 880-920°C, keep it warm ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| yield strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

| elongation | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com