Rolling process for improving surface corrosion resistance of 6061 aluminum alloy

A technology of aluminum alloy surface and corrosion resistance, which is applied in the field of aluminum alloy manufacturing, can solve the problems that stainless steel materials cannot be replaced, and the corrosion resistance of 6061-T651 alloy thick plates cannot meet the application requirements of semiconductor parts, so as to improve mechanics and durability Effects of corrosion performance, fine grain structure, and composition optimization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0030] A rolling process for improving the corrosion resistance of the 6061 aluminum alloy surface, comprising the following steps:

[0031] A. Ingredients: Calculate the amount of each aluminum alloy raw material and prepare the aluminum alloy raw material according to the ratio. The mass percentage ratio of each element of the 6061 aluminum alloy raw material is as follows:

[0032] Si Fe Cu mn Mg Cr Ni Zn Ti Impurities Al content 0.58 0.14 0.28 0.07 0.96 0.21 0.003 0.007 0.02 0.06 margin

[0033] B. Melting and casting: Put the configured aluminum alloy raw materials into the melting furnace for melting in turn, and use flux to refine and cover. After feeding, start stirring when aluminum water appears in the furnace. After stirring evenly, it will be melted into liquid aluminum alloy. The melting temperature is 730 ℃, pour the smelted aluminum alloy melt into the refining furnace for refining, the refining temperature is 7...

Embodiment 2

[0044] The difference between Example 2 and Example 1 is that the number of rolling passes in step F is 19, and 3 passes of large deformation rolling are introduced in the 10th to 12th passes to ensure that the deformation in a single pass is not less than 50mm. Before the start of the 13th pass, the temperature of the plate was measured, and the temperature was 472°C. The rolling was suspended, and the temperature was lowered to 370°C by spraying the emulsion. Then switch to small deformation pass rolling, real-time emulsion spraying mode according to the rolling situation and the plate feedback temperature, control the plate temperature, and the plate final rolling temperature is 205°C. Among them, Table 2 of hot rolling passes of aluminum alloy ingots is as follows:

[0045]

[0046]

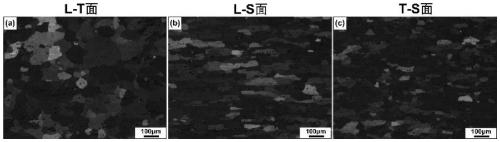

[0047] The grain structure of 6061-T651 plate in embodiment 2 is as follows figure 2 shown.

PUM

| Property | Measurement | Unit |

|---|---|---|

| elongation | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com