Rolling method of magnesium alloy plate and auxiliary rolling method thereof

A technology for magnesium alloys and plates, applied in the field of material rolling and forming, can solve the problems of restricting the production and application of magnesium alloy plates, low yield and increasing rolling passes.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

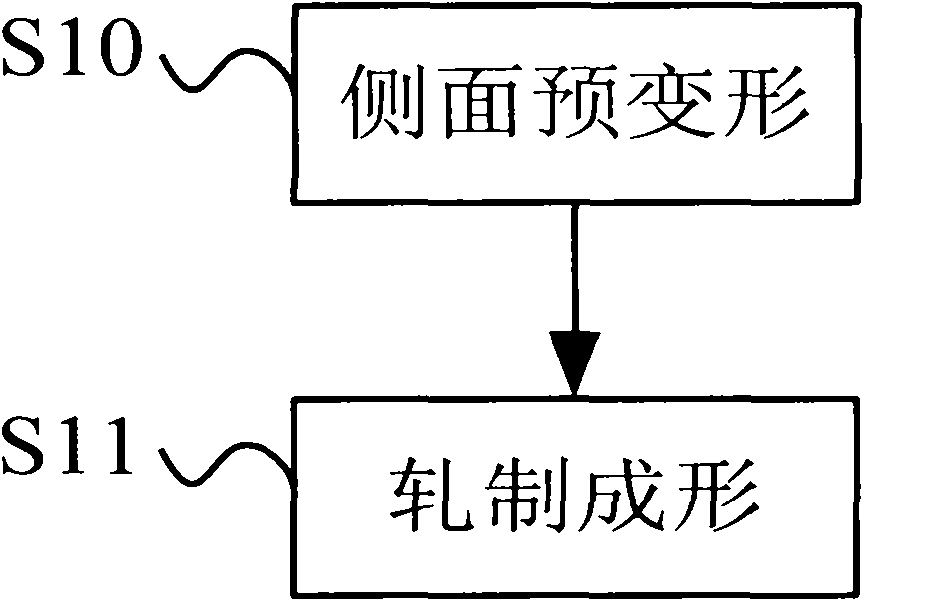

Method used

Image

Examples

Example Embodiment

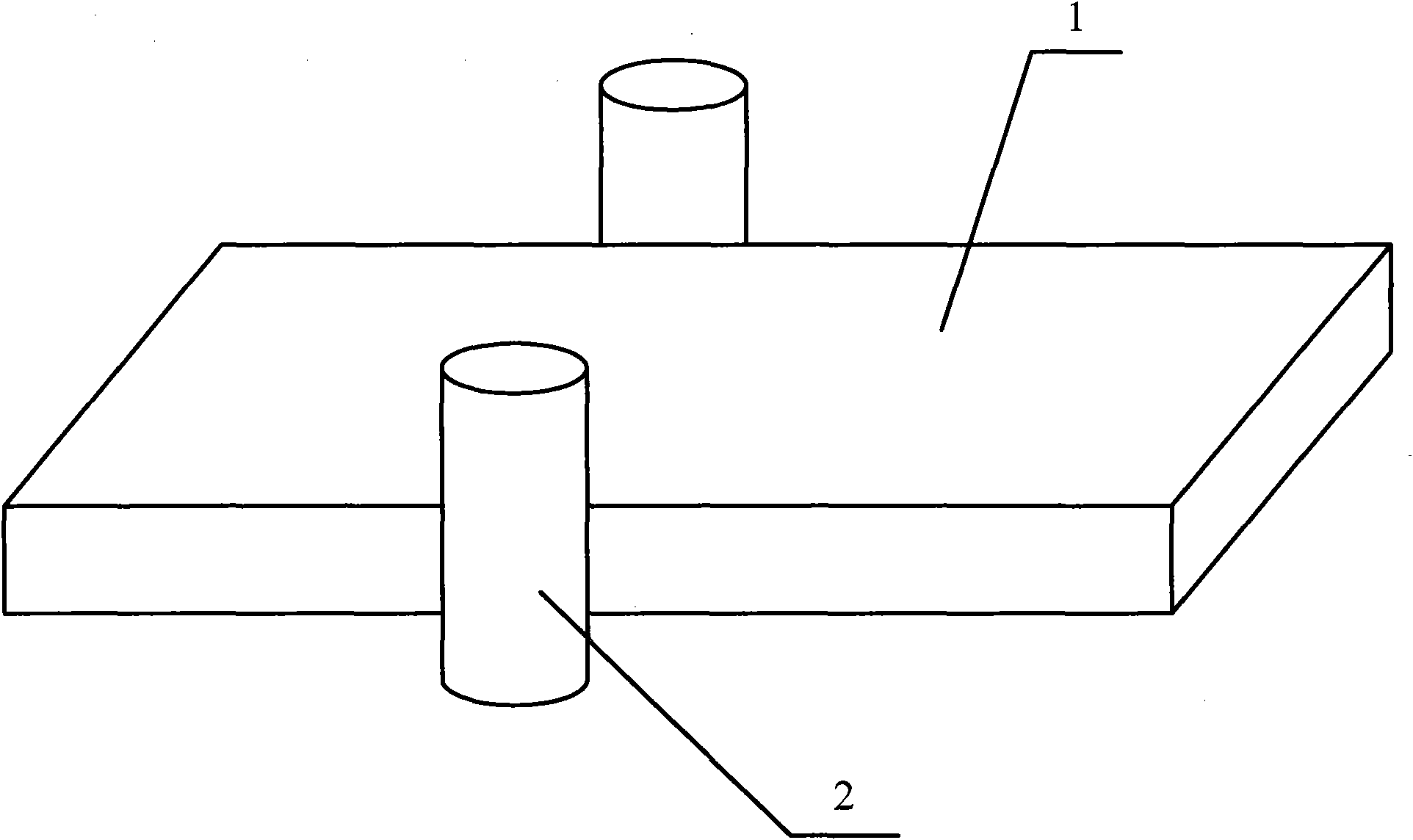

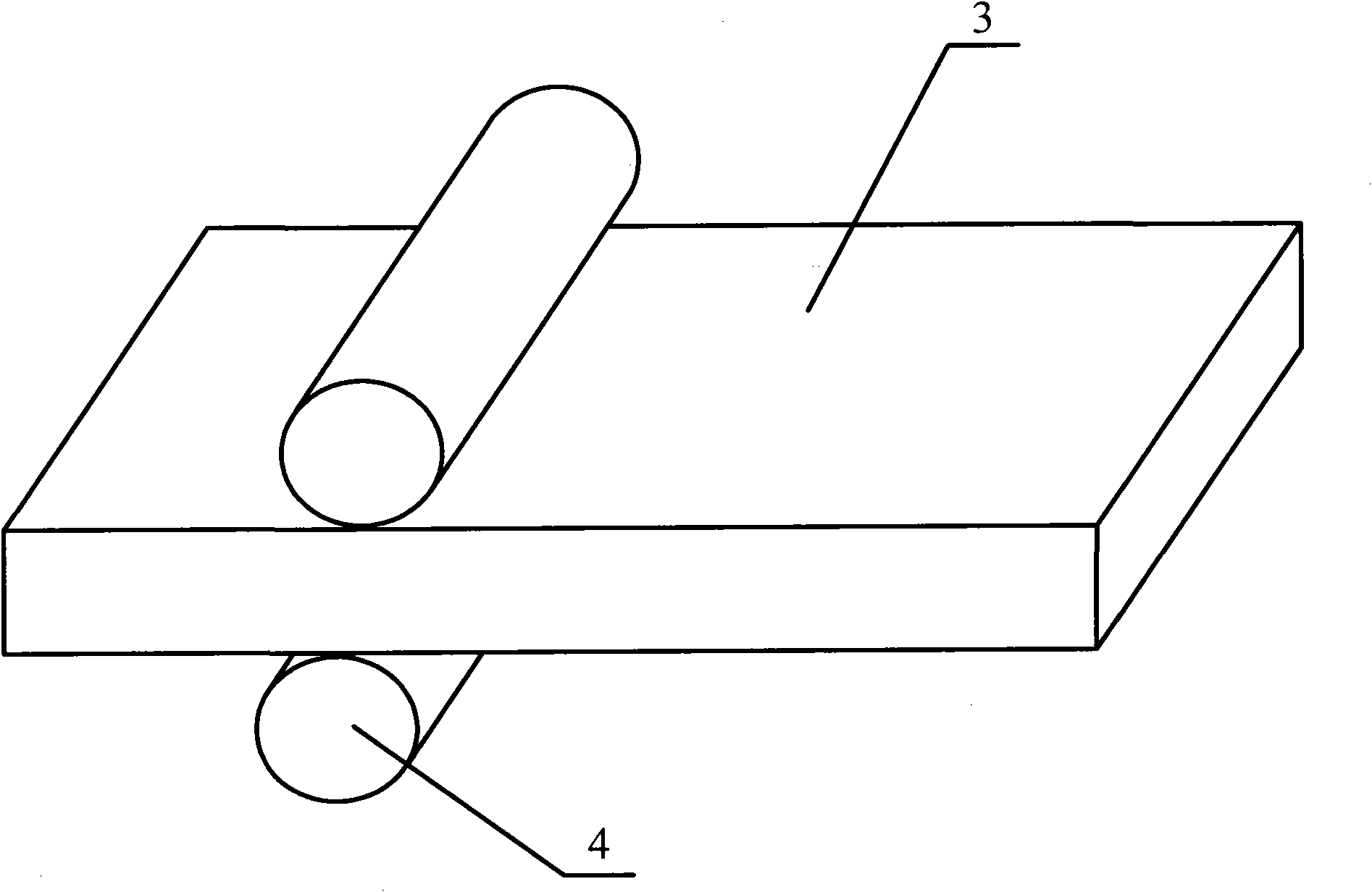

[0034] Example one

[0035] The initial size of the hot-rolled slab is 150×70×15mm, of which the thickness is 15mm. After rolling 5% on the side of the vertical roll at room temperature (20℃), the thickness of the plate is about 16mm at this time, and it is kept in the heating furnace to 300 Flat roll rolling is carried out after ℃, which can achieve a reduction of more than 50% in a single pass without edge cracks. The thickness of the plate after rolling is about 8mm. Similarly, if the plate is deformed without side rolling, a single pass without cracks can only achieve a reduction of about 20%.

Example Embodiment

[0036] Example two

[0037] The initial size of the hot-rolled slab is 150×70×15mm, and the slab with a thickness of 15mm is rolled 10% on the side of the vertical roll at room temperature. At this time, the thickness of the plate is about 16mm. After it is kept at 400℃ in a heating furnace Flat-roll rolling can achieve a single-pass reduction of more than 60% and basically no cracks at the edges. The thickness of the plate after rolling is about 6.4mm.

Example Embodiment

[0038] Example three

[0039] The initial size of the hot-rolled slab is 150×75×15mm. The slab with a thickness of 15mm is side-rolled at 100°C for 15%, and then flat-rolled at room temperature to achieve a single pass reduction of 25% or more. The thickness of the plate after rolling is about 12mm, and without pre-deformed samples, the single pass can only reach 15% without cracks.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com