Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

143results about How to "Uniform grain structure" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Preparation method of magnesium alloy strip for cell phone shell

InactiveCN102352459AHigh strengthImprove plasticityRoll mill control devicesMetal rolling arrangementsImpurityMagnesium alloy

The invention discloses a preparation method of a magnesium alloy strip for a cell phone shell. The preparation method is characterized in that the magnesium alloy comprises the following components by weight percent: 2%-4.5% of Al, 0.5%-0.8% of Si, 0.7%-1.2% of Cu, 0.5%-1.0% of Mn, 0.1%-0.8% of Zn, 0.2%-0.3% of Ti and the balance of Mg and inevitable impurities. The preparation method comprises the following steps: smelting, performing homogenizing annealing, performing hot rolling and performing cold rolling. The tensile strength of the magnesium alloy strip is 190MPa-210MPa, the elongation at break is 8.0%-10.0%, and the earring rate is 2%-3%; and the magnesium alloy strip can meet the thin stretching and punching forming requirement of the cell phone shell.

Owner:YONGXIN PRECISION MATERIAL WUXI

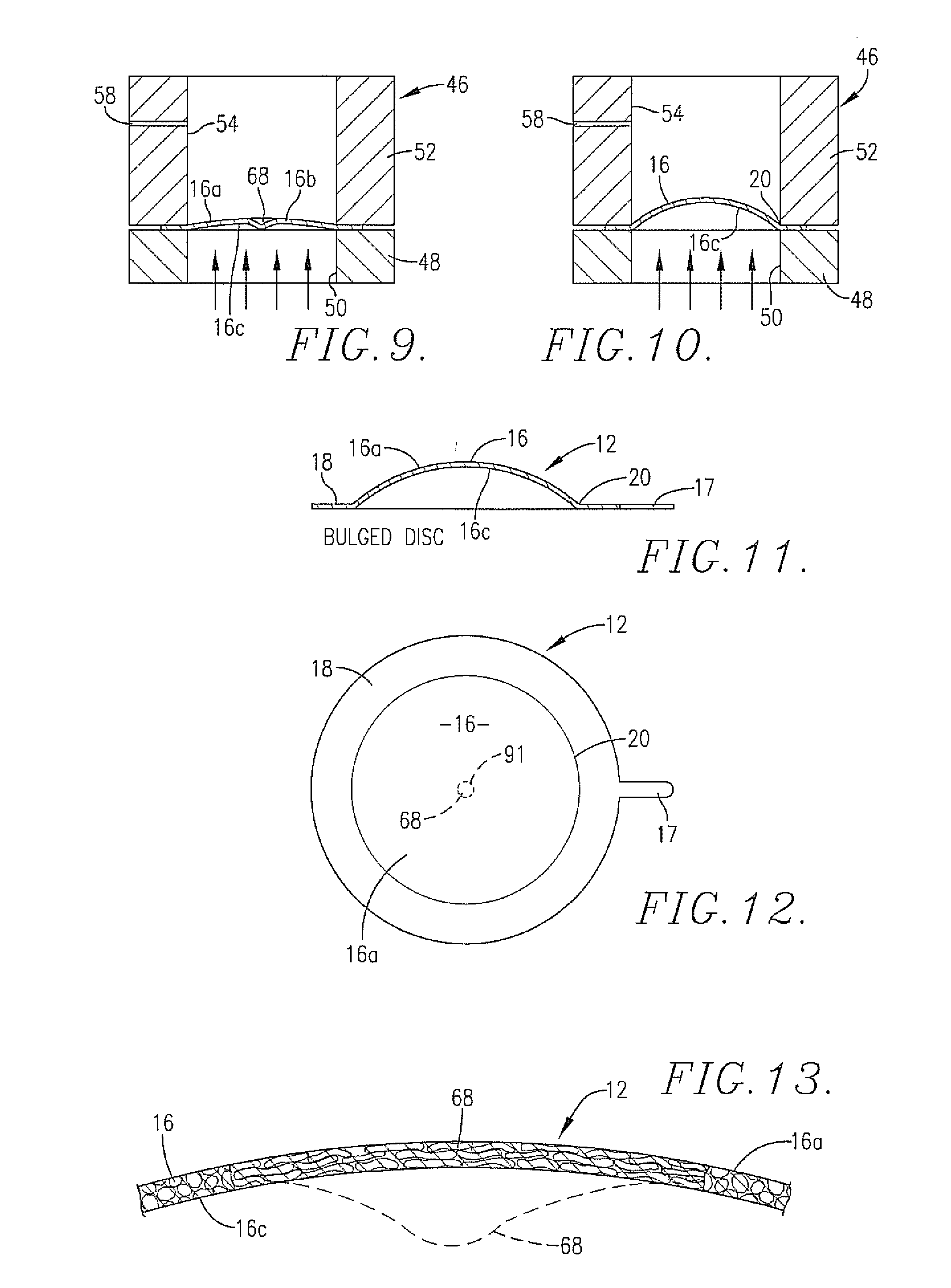

Rupture disc with machined line of opening

ActiveUS20090302035A1Uniform grain structureLarge containersEqualizing valvesMilling cutterGrain structure

A reverse acting rupture disc and methods of forming the same are provided. Generally, the rupture disc comprises a bulged portion and a circumscribing flange area surrounding the bulged portion. The bulged portion includes a mechanically formed line-of-opening recess comprising a singular channel. In certain embodiments, the mechanical process by which the recess is formed utilizes a high-speed mill which removes a portion of metal from the bulged portion of the disc without disrupting the substantially uniform metallic grain structure of the metal adjacent the channel.

Owner:FIKE CORP

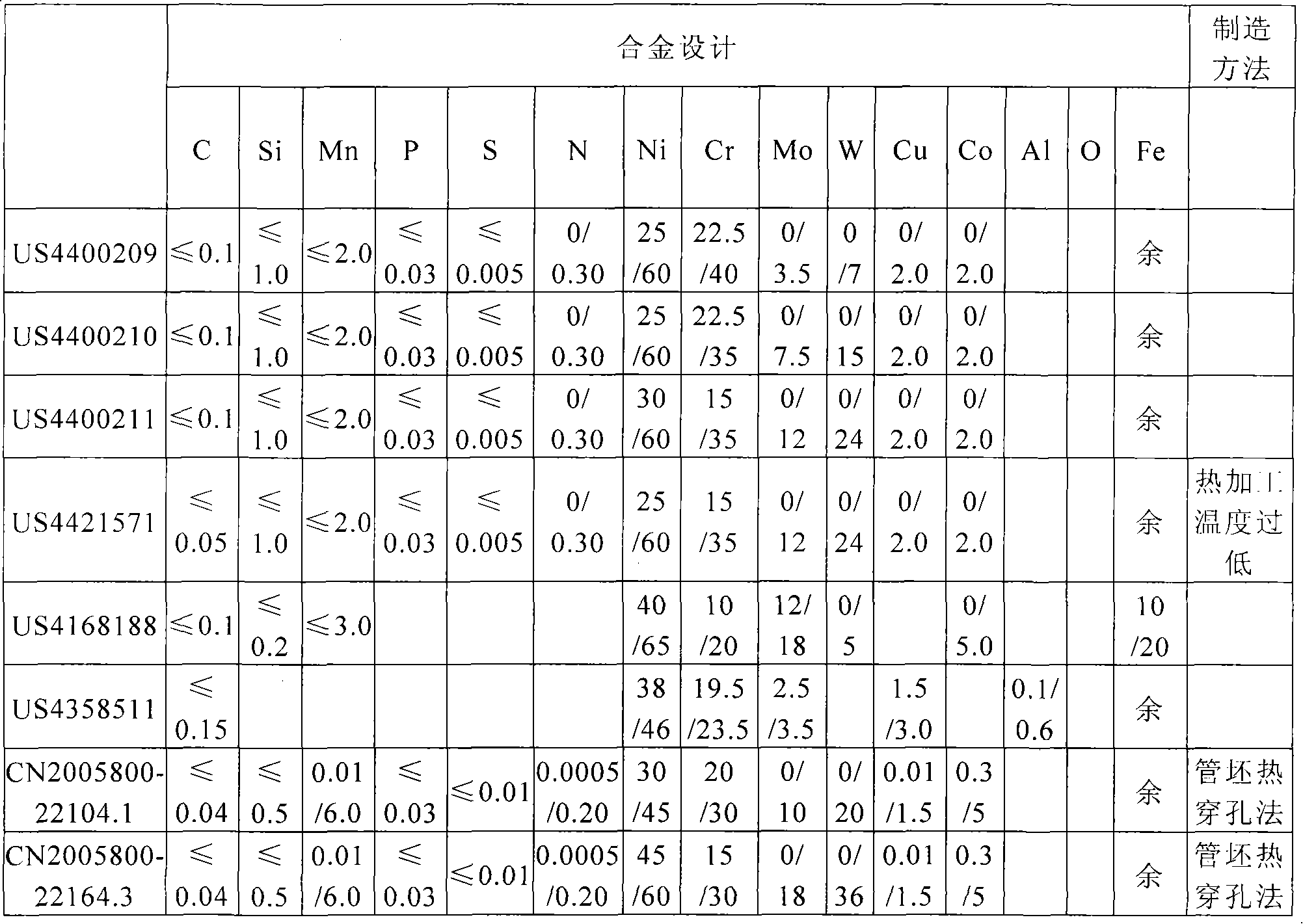

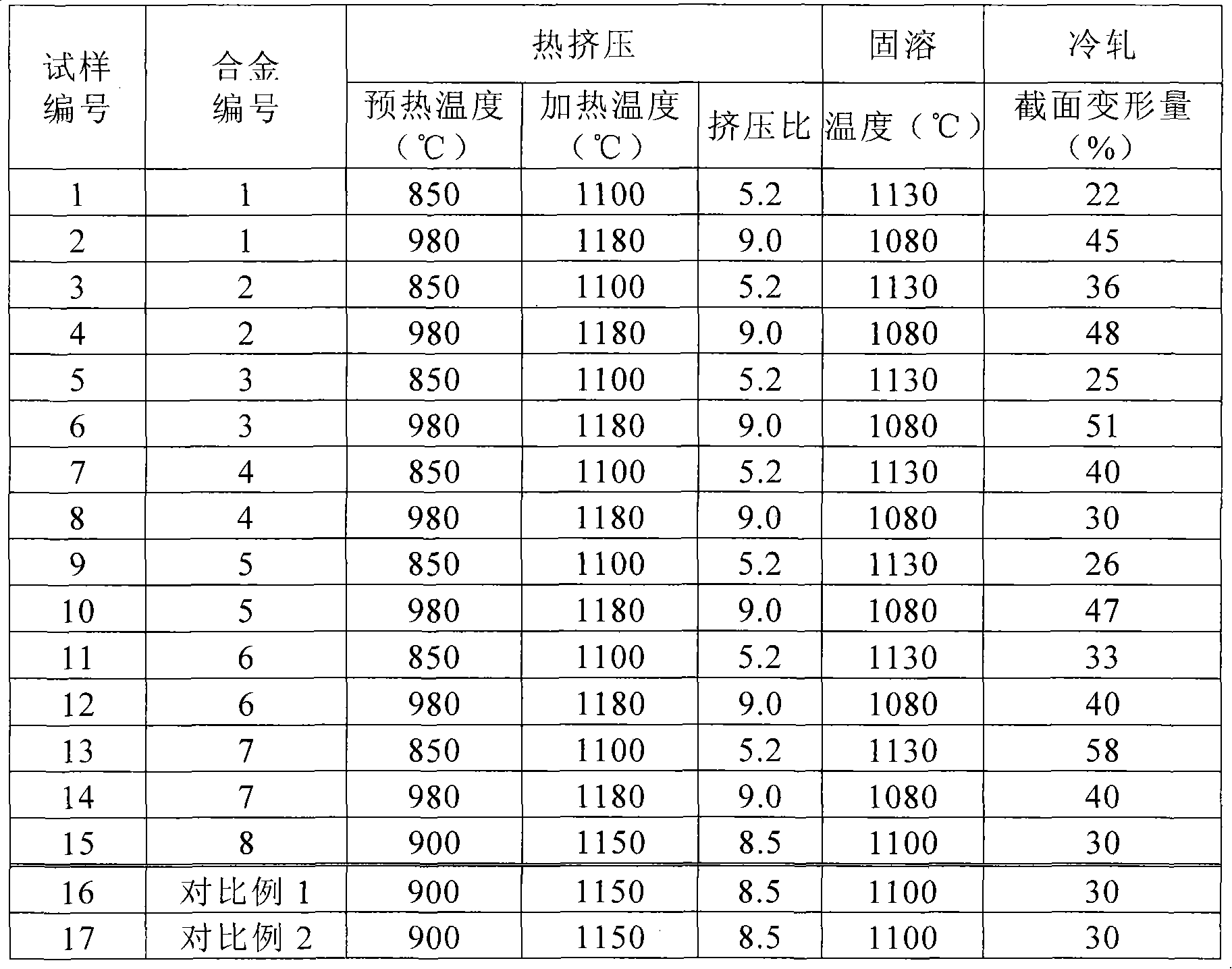

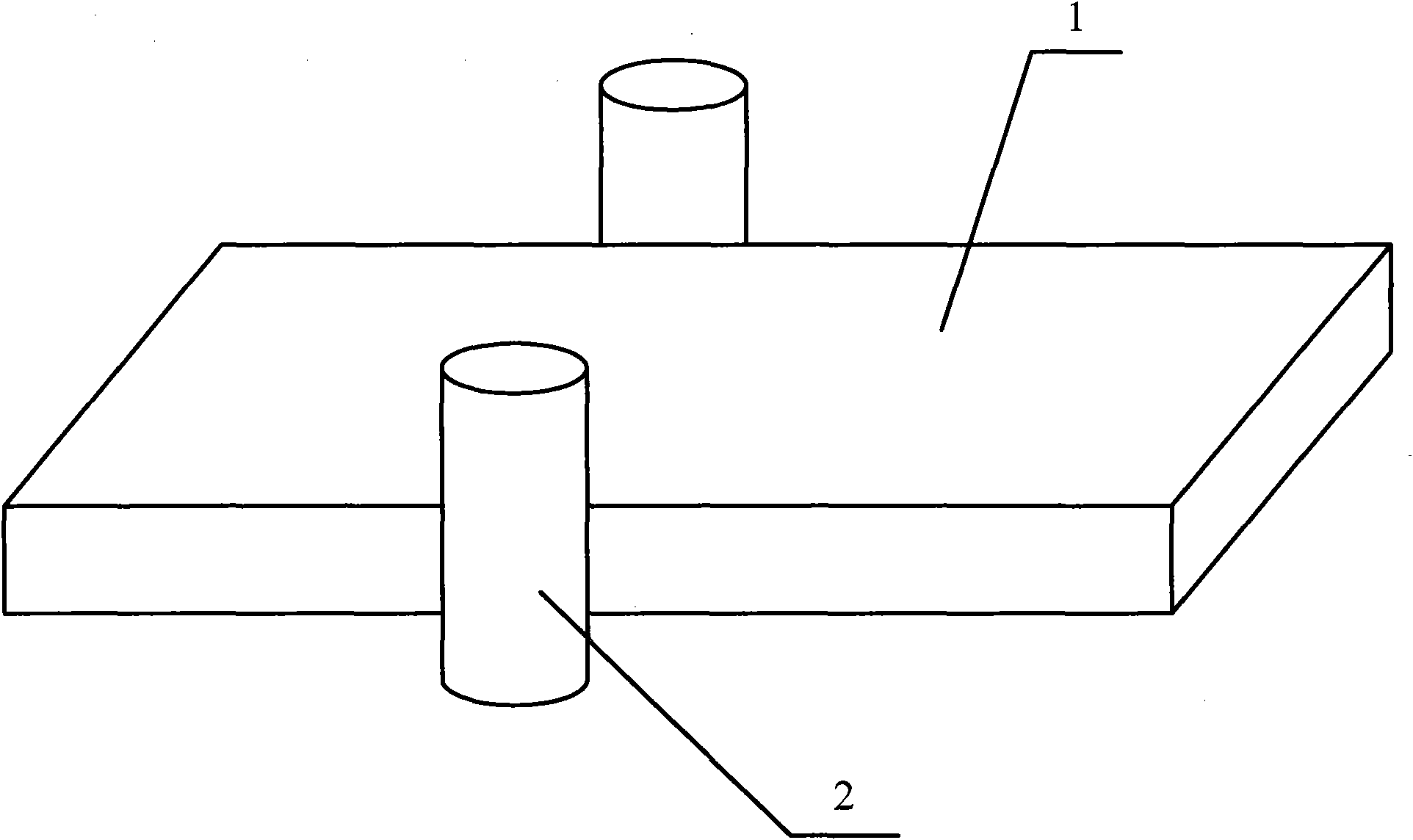

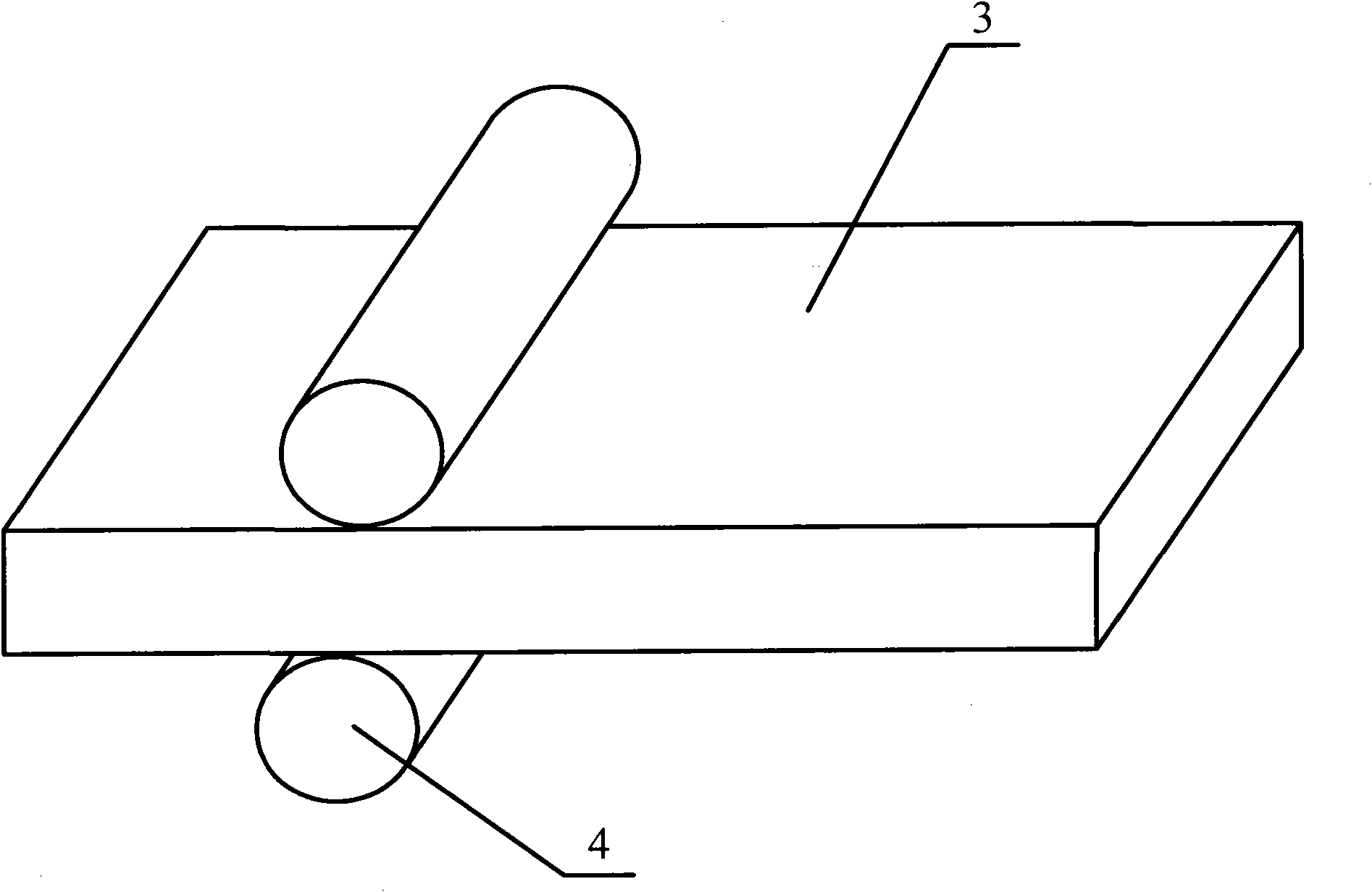

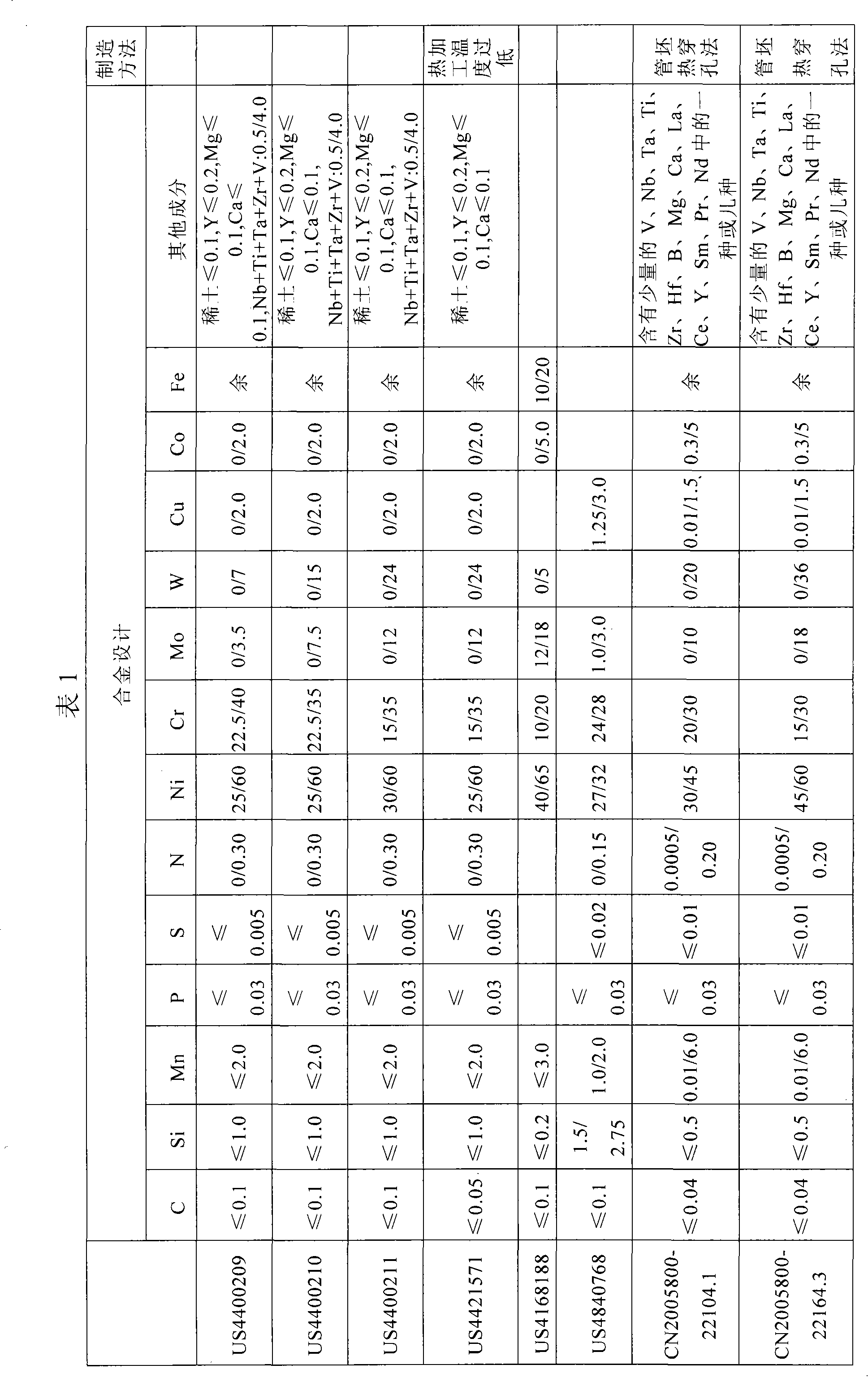

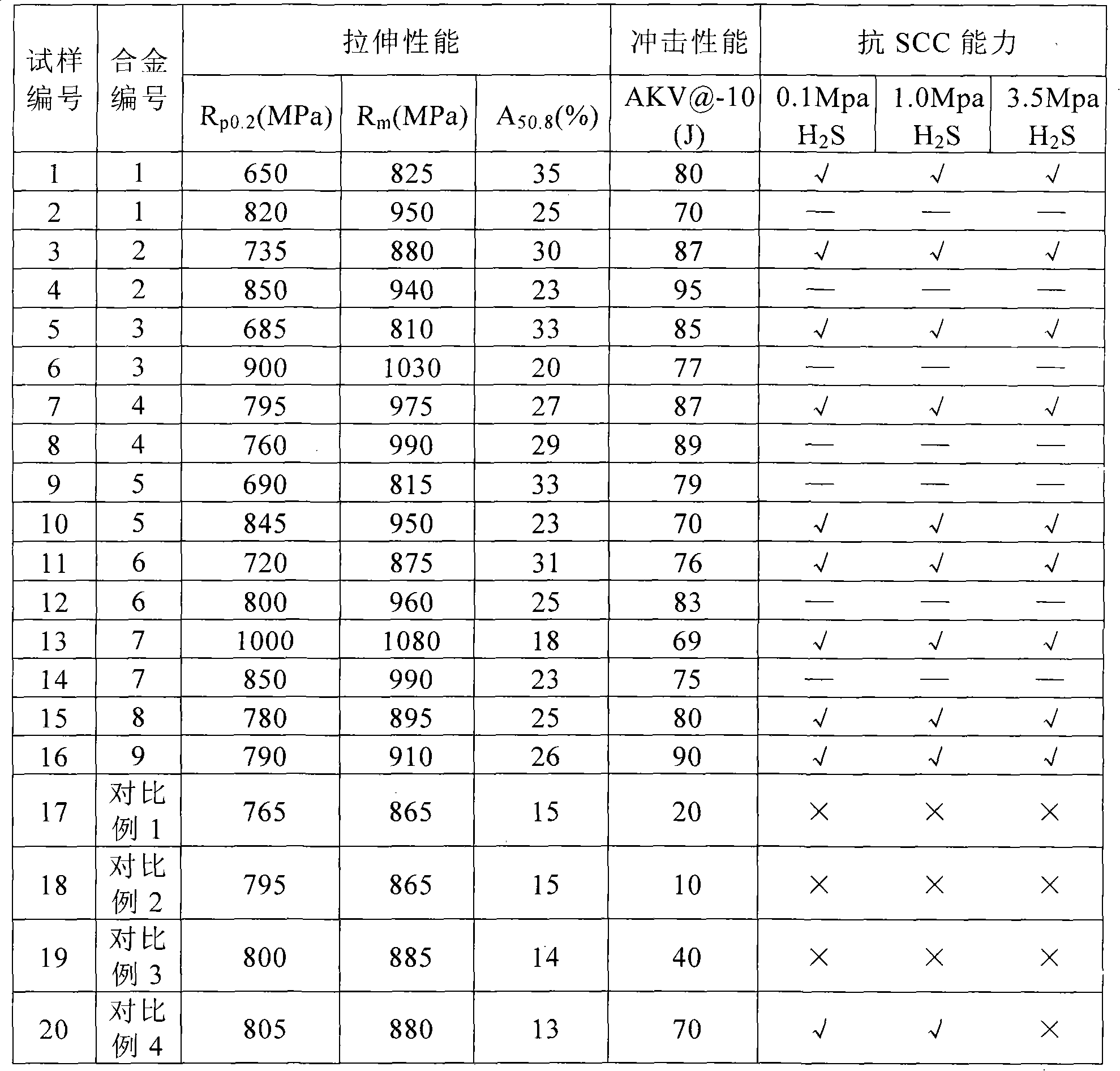

Ni-based alloy oil sleeve and manufacturing method for high-acidity deep well

ActiveCN101613833ALow costImprove high temperature corrosion resistanceDrilling rodsRoll mill control devicesSolution treatmentImpurity

The invention relates to a Ni-based alloy oil sleeve for a high-acidity deep well, which comprises the following components in percentage by mass: less than or equal to 0.02 percent of C, less than or equal to 0.03 percent of P, less than or equal to 0.03 percent of S, less than or equal to 0.5 percent of Si, less than or equal to 1.0 percent of Mn, 40 to 60 percent of Ni, 20 to 30 percent of Cr, 1 to 10 percent of Mo, 1 to 5 percent of W, 0 to 5 percent of Co, 0.1 to 3.0 percent of Cu, 0.01 to 0.5 percent of Al, less than or equal to 0.01 percent of O, less than or equal to 1.5 percent of Ti, and the balance of Fe and inevitable impurities. In the invention, the thermal extrusion processing performance and corrosion resisting performance of the alloy are effectively ensured by controlling the contents of the Al and O. The 90 to 140 ksi steel-grade Ni-based alloy oil sleeve meeting different well depth requirements of high-acidity oil fields and gas fields is manufactured by thermal extrusion, 1,050-1,150 DEG C of solution treatment and cold rolling of the smelted and forged blanks.

Owner:BAOSHAN IRON & STEEL CO LTD

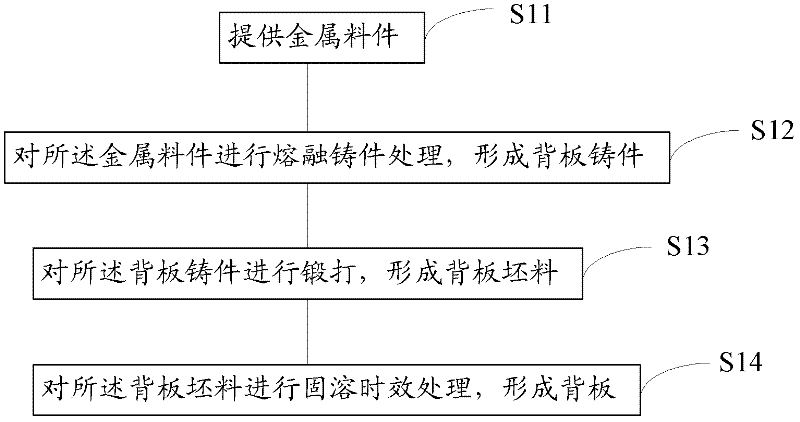

Backboard fabricating method

ActiveCN102534518AUniform grain refinementAvoid distortionVacuum evaporation coatingSputtering coatingSiliconDistortion

The invention discloses a backboard fabricating method, comprising the following steps of: providing a backboard casting piece; forging the backboard casting piece at a temperature of 800-1000 DEG C so as to form a backboard blank; and processing the backboard blank so as to form a backboard. According to the backboard fabricating method disclosed by the invention, the backboard with a finer and more uniform inner organization structure can be obtained, so that the backboard is prevented from distortion and deformation. On one hand, a deviation between each part of a target and a silicon wafer substrate is reduced, and the quality of a coating film is improved; and on the other hand, the service life of a sputtering target assembly is prolonged.

Owner:KONFOONG MATERIALS INTERNATIONAL CO LTD

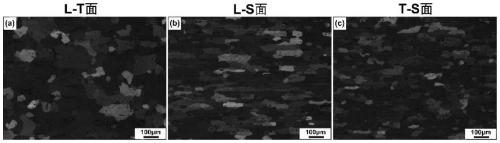

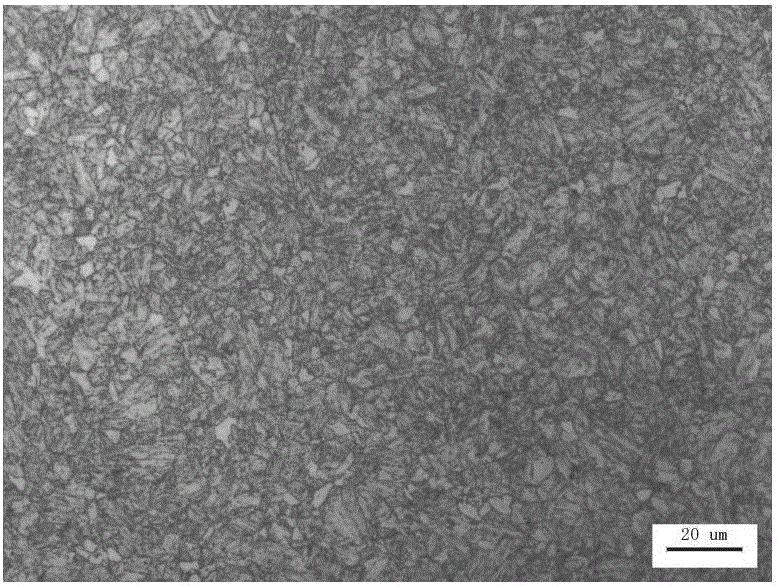

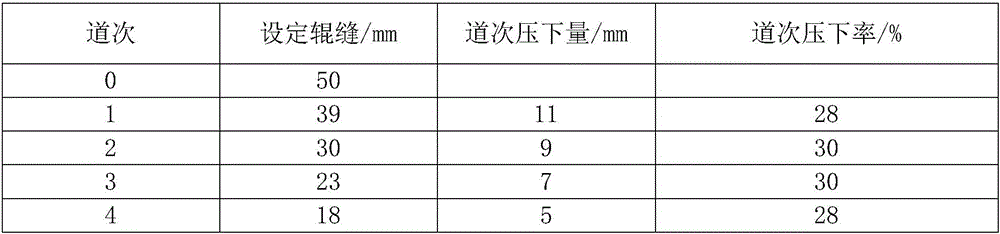

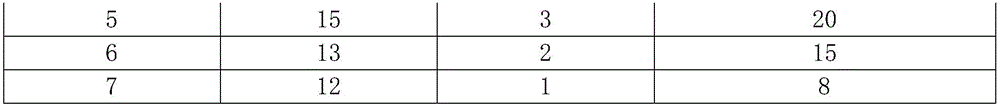

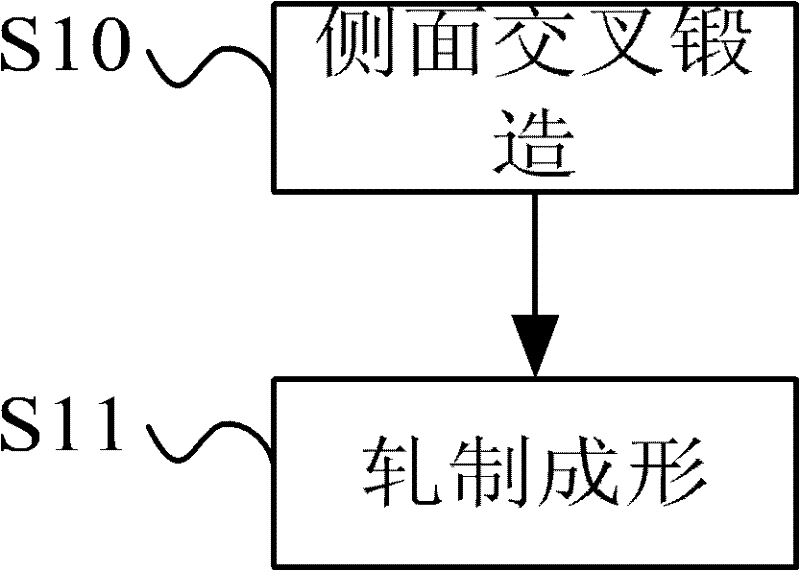

Aluminum alloy strip for mobile phone battery shell and manufacturing method thereof

The invention provides an aluminum alloy strip for a mobile phone battery shell and a manufacturing method thereof, relates to an alloy strip and a manufacturing method thereof, and solves the problems of low tensile strength, high elongation after breakage and high earing rate of a conventional 3003-H14 aluminum alloy strip applied to the mobile phone battery shell, and uneven grain structures of alloys prepared by the conventional manufacturing method. The aluminum alloy strip is made from Si, Fe, Cu, Mn, Mg, Zn, Ti and Al. The tensile strength of the aluminum alloy strip is between 190MPa and 210MPa, the elongation after breakage of the aluminum alloy strip is between 2.0 and 4.0 percent, and the earing rate of the aluminum alloy strip is between 3 and 4 percent. The manufacturing method comprises the following steps of: mixing the materials; melting, casting, homogenizing annealing, hot rolling, and cold rolling to obtain the aluminum alloy strip for the mobile phone battery shell. The aluminum alloy strip for the mobile phone battery shell can improve the strength of the mobile phone battery shell and reduce wall thickness at the same time so as to improve the capacity of the battery shell.

Owner:NORTHEAST LIGHT ALLOY CO LTD

Silver target manufacturing method

The invention relates to the field of target manufacturing and particularly relates to a silver target manufacturing method. The silver target manufacturing method comprises the following steps: selecting a silver raw material with purity of over 4N, fusing the silver raw material by utilizing the atmosphere smelting or vacuum smelting method, casting the melt and then cooling to form an ingot blank; immediately carrying out thermal insulation heat treatment on the ingot blank, i.e., carrying out thermal insulation homogenization within the temperature range of 400 to 900 DEG C and then carrying out hot rolling or forging by an air hammer to form a silver blank, wherein the thermal insulation time is over 0.5h; carrying out cold rolling on the silver blank to form a cold-rolled blank; and carrying out annealing heat treatment on the cold-rolled blank for 0.5 to 3 hours at the annealing heat treatment temperature of 350 to 700 DEG C to obtain a silver target blank with fine and uniform crystal grains and finally, machining by a machine tool to obtain a large-size silver target. The process is higher in machining efficiency and can produce the lower-cost large-size silver target with high quality.

Owner:济源豫金靶材科技有限公司

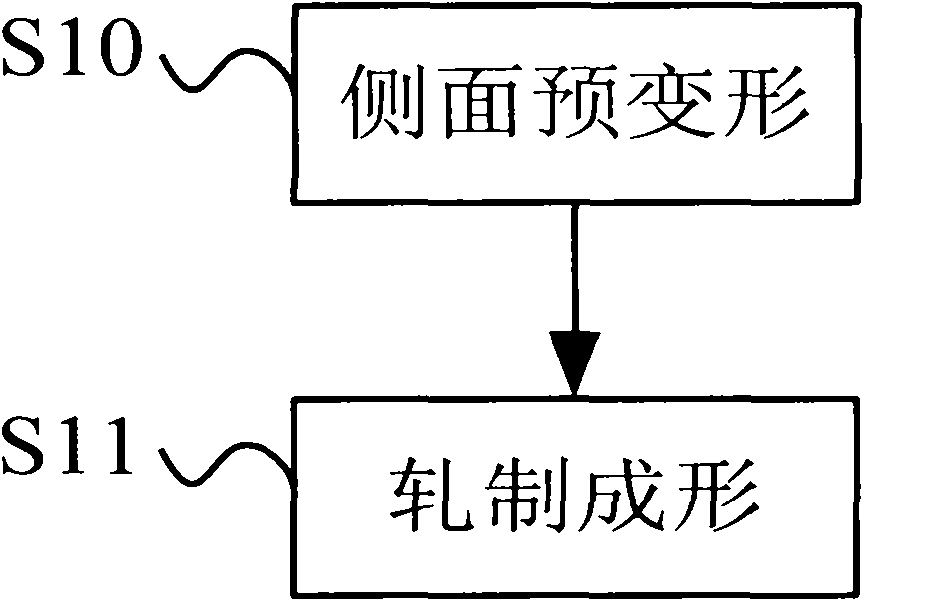

Rolling method of magnesium alloy plate and auxiliary rolling method thereof

InactiveCN102039308AReduce processing costsReasonable cost controlMetal rolling arrangementsCrystallitePre treatment

Owner:CHONGQING UNIV

Fe-based austenite alloy oil sleeve and manufacturing method for high-acidity deep well

InactiveCN101613834ALow head lifeIncrease production costDrilling rodsRoll mill control devicesSolution treatmentChemical composition

The invention relates to a Fe-based austenite alloy oil sleeve, which comprises the following components in percentage by mass: less than or equal to 0.03 percent of C, less than or equal to 0.03 percent of P, less than or equal to 0.03 percent of S, 0.01 to 1.0 percent of Si, 0.01 to 3.0 percent of Mn, 25 to 40 percent of Ni, 20 to 35 percent of Cr, 1 to 5 percent of Mo, 0.1 to 1.5 percent of Cu, 0.01 to 0.5 percent of Al, less than or equal to 0.01 percent of O, and the balance of Fe and inevitable impurities. The 90 to 140 ksi steel-grade Fe-based alloy oil sleeve meeting different well depth requirements of high-acidity oil fields and gas fields is manufactured by thermal extrusion, 1,050-1,180 DEG C of solution treatment and cold rolling of the smelted and forged blanks.

Owner:BAOSHAN IRON & STEEL CO LTD

Manufacturing method of high-strength oxidable aluminum alloy plate strip

The invention discloses a manufacturing method of a high-strength oxidable aluminum alloy plate strip. The manufacturing method of the high-strength oxidable aluminum alloy plate strip comprises the following steps that (1) molten aluminum alloy is prepared, specifically, chemical elements are determined, and the aluminum alloy comprises, by mass, 0.6%-0.9% of Si, 0.1%-1.4% of Fe, 0.6%-0.9% of Cu, 0.2%-0.3% of Mn, 0.9%-1.1% of Mg, 0-0.05% of Cr, 0-0.05% of Zn, 0-0.05% of Ti, 0-0.05% of single impurities, 0-0.15% of blended impurities, and the balance Al; (2) casting is conducted; (3) hot rolling is conducted; (4) intermediate annealing is conducted; (5) cold rolling and finish rolling are conducted; and (6) continuous pull-correcting or predrawing is conducted. The aluminum alloy plate strip manufactured through the method has high strength, the tensile strength T.S(delta b / MPa) is equal to or higher than 350 MPa, the yield strength Y.S(delta 0.2 / MPa) is equal to or higher than 320 MPa, the extensibility (theta / %) is equal to or higher than 8%, and the surface hardness HV is equal to or higher than 120. The type of the aluminum alloy plate strip manufactured through the method is TY62-T651, the aluminum alloy plate strip is high in supporting strength and surface strength and oxidable when used for a side key of a mobile phone support, continuous punching can be achieved, and the production efficiency is high.

Owner:昆山灿鑫精密电子科技有限公司

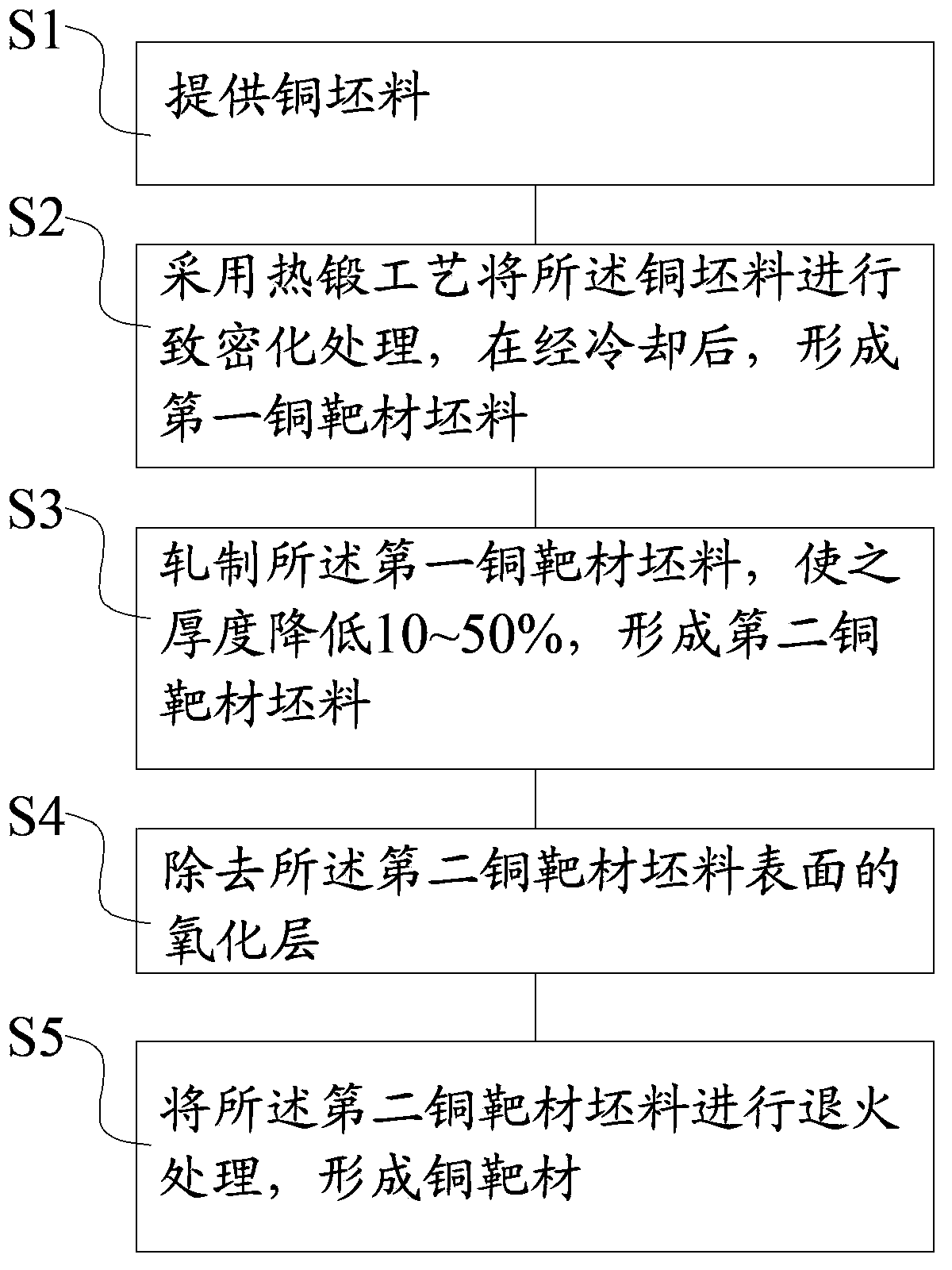

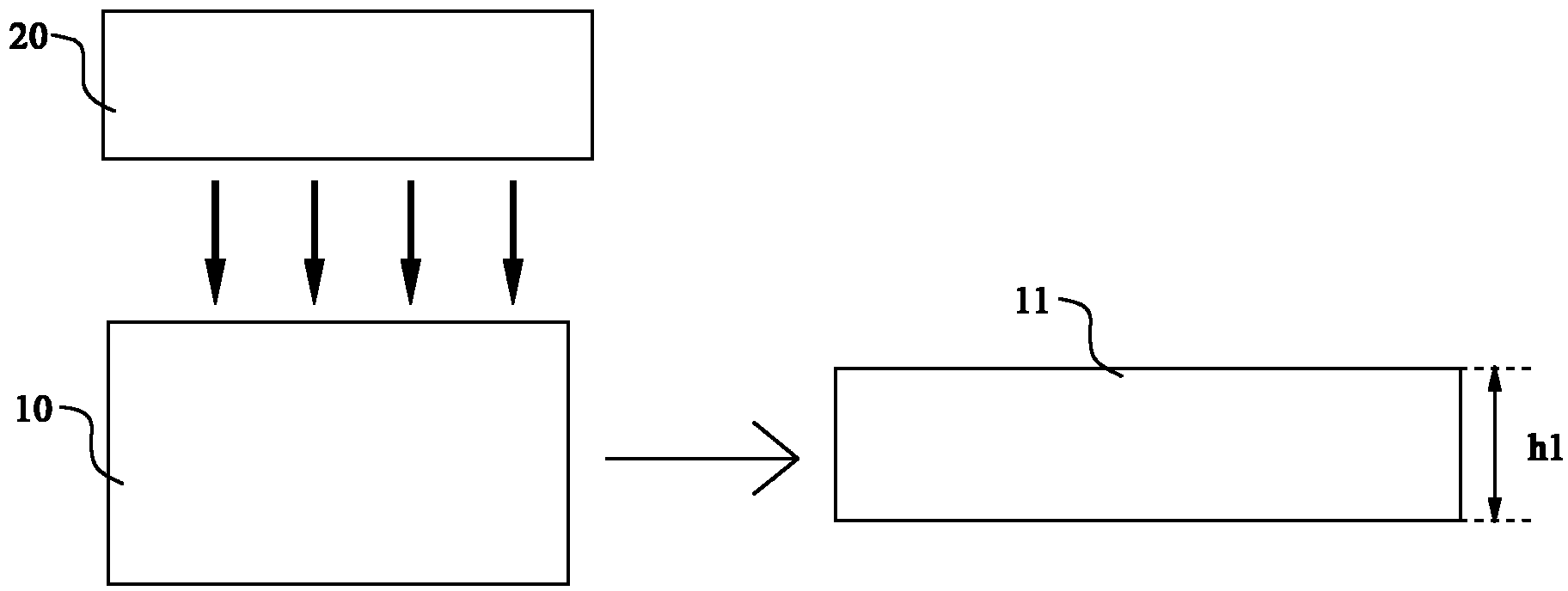

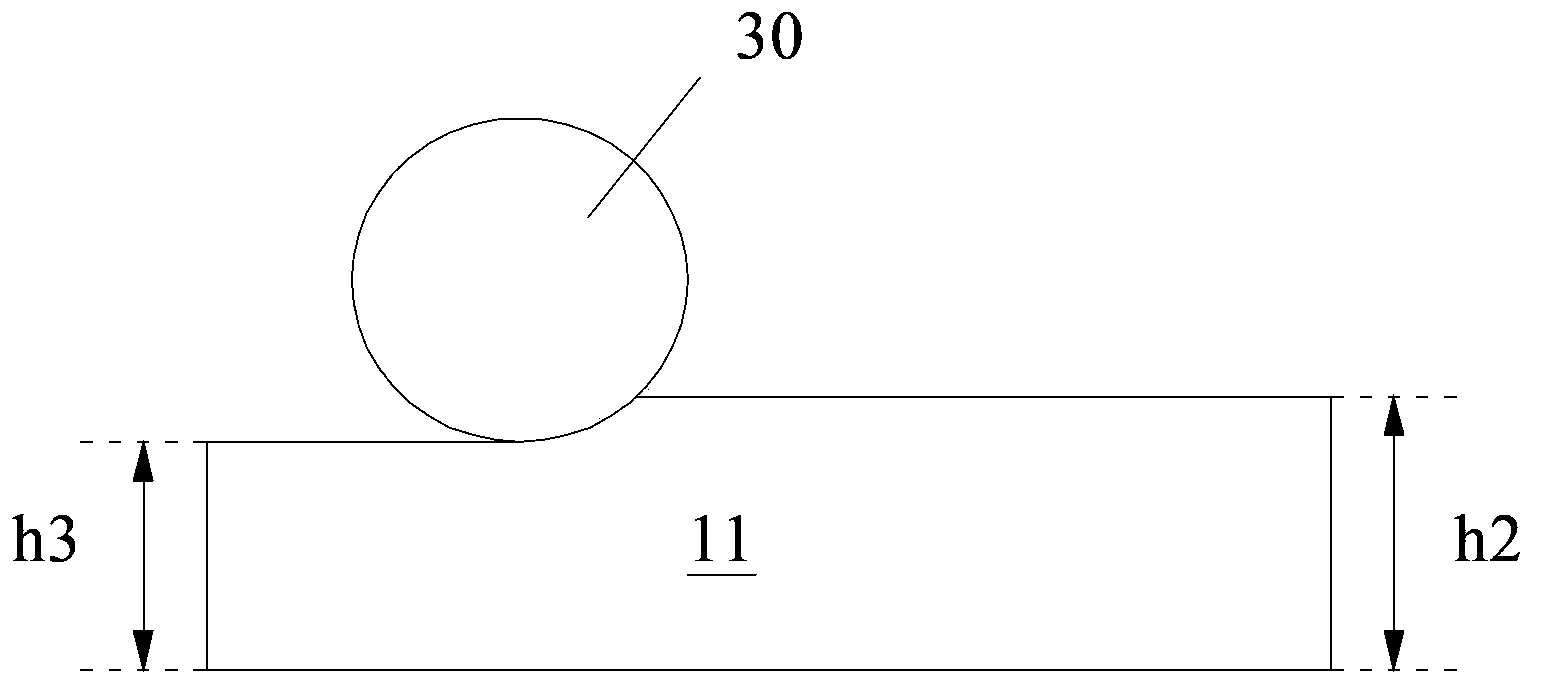

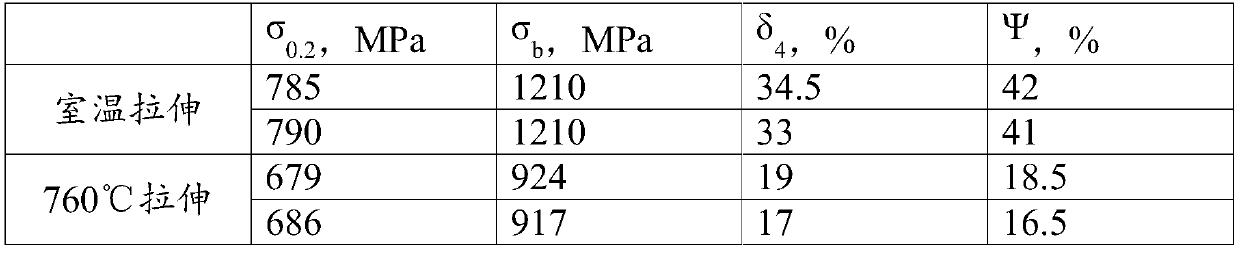

Preparation method of copper target

The invention provides a preparation method of a copper target. The preparation method comprises the following steps: firstly, the compaction treatment is performed for a copper blank by adopting a hot forging process; a first copper target blank is formed after the copper blank is cooled; the first copper target blank is rolled to reduce the thickness by 10-50% to form a second copper target blank; and the second copper target blank is annealed to form the copper target. The preparation method can prepare the copper target with fine grains, compacter grain structure and 90-130 HV of hardness.

Owner:KONFOONG MATERIALS INTERNATIONAL CO LTD

High-strength and high-toughness heat-treatment-free aluminum alloy material and preparation method thereof

PendingCN113755722AReasonably control the range of elementsGood mechanical propertiesMold fillingUltimate tensile strength

The invention discloses a high-strength and high-toughness heat-treatment-free aluminum alloy material and a preparation method, and belongs to the technical field of aluminum alloy casting. The high-strength and high-toughness heat-treatment-free aluminum alloy material comprises the following components in percentage by mass: 8.0-10.5% of Si, less than or equal to 0.15% of Fe, 0.05-0.3% of Mg, 0.05-0.3% of Zn, 0.3-0.6% of Mn, less than or equal to 0.1% of Cu, 0.05-0.15% of Ti, less than or equal to 0.005% of Ca, 0.005-0.030% of Sr, 0.1-0.3% of Zr, 0.01-0.1% of Mo, 0.01-0.3% of V, less than or equal to 0.02% of Cr, less than or equal to 0.002% of Na, less than or equal to 0.002% of P, less than or equal to 0.01% of Cd, less than or equal to 0.001% of Li, less than or equal to 0.0025% of B, less than or equal to 0.05% of Ga, and the balance Al and inevitable impurities. The alloy does not need to be subjected to heat treatment, and has excellent casting performance and mold filling capacity and good tensile strength, yield strength and toughness.

Owner:隆达铝业(顺平)有限公司 +2

GH4780 alloy billet and forged piece and preparing method thereof

ActiveCN110592506AUniform grain structureUniform tissueMetal-working apparatusCrystalliteGas turbines

The invention provides a GH4780 alloy billet and forged piece and a preparing method thereof. The method includes the following steps of breaking columnar crystals of a GH4780 alloy ingot at 900-1160DEG C, and conducting at least two heating numbers of drawing out and upsetting until the deformation reaches 10-50% to obtain the GH4780 alloy billet. The GH4780 alloy billet prepared through coggingand forging through the method is uniform in grain structure and has the average grain size of ASTM4 grade or higher after thermal treatment. By means of the preparing method of the GH4780 alloy forged piece, the GH4780 alloy forged piece can be prepared, the GH4780 alloy forged piece with the uniform structure is obtained, and the material support is provided for the development of aero-enginesand gas turbines. The GH4780 alloy forged piece is uniform in grain structure and has the average grain size of ASTM4 grade or higher after thermal treatment.

Owner:BEIJING CISRI GAONA TECH +3

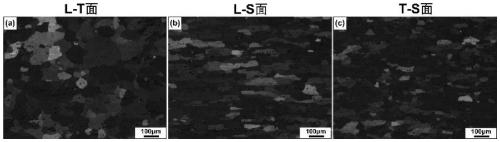

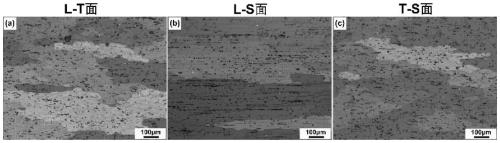

Rolling process for improving surface corrosion resistance of 6061 aluminum alloy

ActiveCN111334677AImprove corrosion resistanceImprove mechanical propertiesAnodisationTemperature controlThick plate

The invention belongs to the technical field of aluminum alloy manufacturing, and relates to a rolling process for improving surface corrosion resistance of 6061 aluminum alloy. The aluminum alloy comprises, by weight, 0.50%-0.65% of Si, less than or equal to 0.2% of Fe, 0.25%-0.35% of Cu, less than or equal to 0.10% of Mn, 0.9%-1.1% of Mg, 0.13%-0.26% of Cr, less than or equal to 0.05% of Ni, less than or equal to 0.04% of Zn, less than or equal to 0.15% of Ti, less than or equal to 0.05% of single impurities while less than or equal to 0.15% of the total impurities, and the balance Al. In the hot rolling procedure, the hot rolling process combining large-deformation rolling and small-deformation temperature control rolling is adopted, a 6061-T651 alloy thick plate with the excellent corrosion resistance is prepared, the grain structure of the plate is fine and uniform, and under the condition that the mechanical property is not lost, the corrosion resistance of the plate in the acidenvironment is greatly improved.

Owner:TIANJIN ZHONGWANG ALUMINUM IND CO LTD

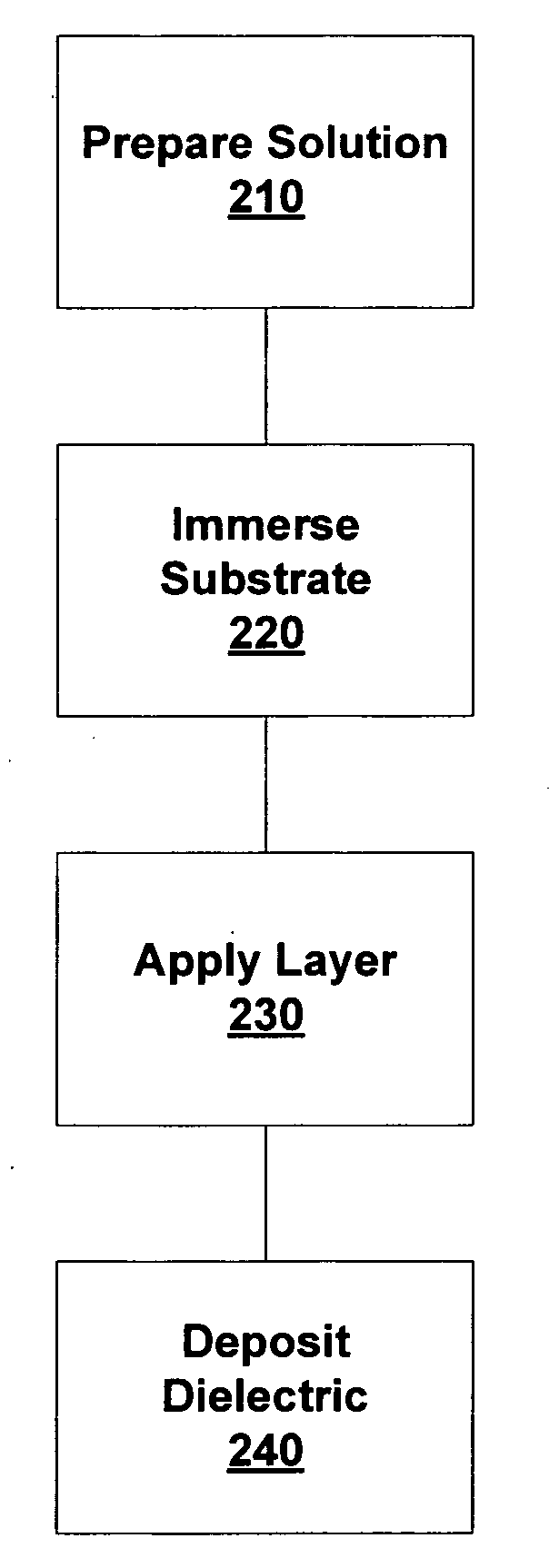

Electroless deposition of cobalt alloys

ActiveUS20080152822A1Improved grain morphologyUniform grain structureLiquid surface applicatorsAnti-corrosive paintsDielectricCopper

Systems and methods for electroless deposition of a cobalt-alloy layer on a copper surface include a solution characterized by a low pH. This solution may include, for example, a cobalt(II) salt, a complexing agent including at least two amine groups, a pH adjuster configured to adjust the pH to below 7.0, and a reducing agent. In some embodiments, the cobalt-alloy is configured to facilitate bonding and copper diffusion characteristics between the copper surface and a dielectric in an integrated circuit.

Owner:LAM RES CORP

Acidic corrosion-resistant X65 seamless steel pipeline and manufacturing method thereof

InactiveCN106319361AMeet the mechanical performance requirementsControl sulfur and phosphorus contentThermal insulationSteel pipeline

The invention discloses an acidic corrosion-resistant X65 seamless steel pipeline and a manufacturing method thereof. The acidic corrosion-resistant X65 seamless steel pipeline comprises, by weight, 0.08-0.16% of C, 0.15-0.35% of Si, 1.0-1.6% of Mn, 0.02-0.05% of Al, 0.03-0.049% of V, 0.01-0.04% of Ti, 0.20-0.30% of Cu, 0.20-0.30% of Ni, less than or equal to 0.015% of P and less than or equal to 0.005% of S. When C content is less than or equal to 0.12%, CE<Pcm> is less than or equal to 0.25 and when C content is greater than 0.12%, CE<IIW> is less than or equal to 0.42. According to the manufacturing method of the acidic corrosion-resistant X65 seamless steel pipeline, a continuous rolling method is used, a pipe blank is heated to a temperature of 1200-1300 DEG C through an annular furnace, a tube knockout temperature is in a range of 1190-1240 DEG C and a sizing temperature is in a range of 820-850 DEG C, in quenching and tempering treatment, a quenching heating temperature is in a range of 890-910 DEG C, a quenching medium is water, thermal insulation time is greater than or equal to 30min, a tempering temperature is in a range of 580-620 DEG C, thermal insulation time is greater than or equal to 50min, and heating straightening and flaw detection examination are carried out at a temperature greater than or equal to 400 DEG C.

Owner:ANGANG STEEL CO LTD

Method for preparing welding wire made of nickel base alloy

ActiveCN103949805AEasy to processImprove antioxidant capacityWelding/cutting media/materialsSoldering mediaHydrogenSlag

The invention relates to a method for preparing a welding wire made of nickel base alloy. The welding wire comprises the following components by mass percent: 0.4-0.45% of C, 1.0-1.5% of Mn, 0.15-1.2% of Si, less than or equal to 0.025% of P, less than or equal to 0.02% of S, 28-30% of Cr, 49-51% of Ni, less than or equal to 0.1% of Co, less than or equal to 0.1% of Mo, less than or equal to 0.1% of Ti, less than or equal to 0.1% of Al, 4.0-5.0% of W and the balance of Fe. The method for preparing the welding wire comprises the steps of smelting the alloy, remelting electro-slag, carrying out hot forging and cogging down, carrying out hot rolling and annealing, carrying out acid pickling, polishing, carrying out cold drawing and removing hydrogen, wherein a CaF2, Al2O3 or CaO slag system is adopted in the step of remelting the electro-slag. The thinner welding wire can be prepared by the method for preparing the welding wire made of the nickel base alloy, the performances of the welding wire meet the requirements, and the welding wire is high in yield.

Owner:JIANGSU TOLAND ALLOY

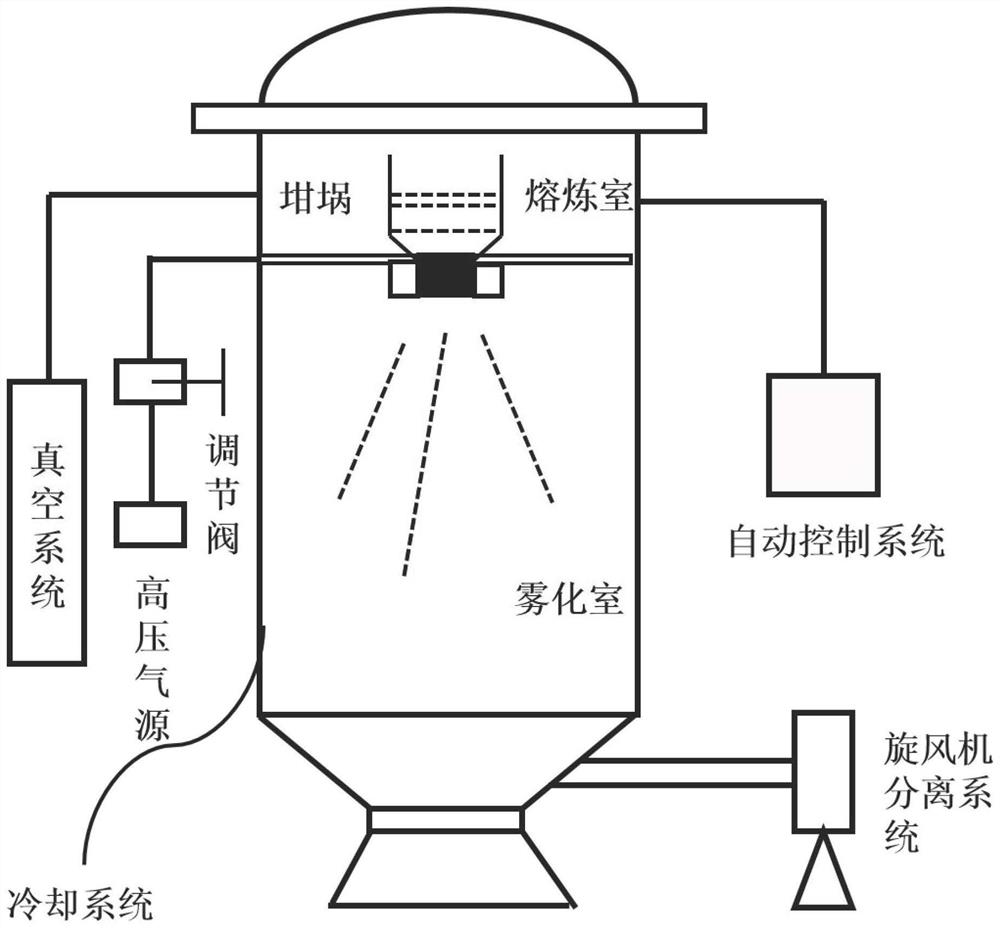

Preparation method of aluminum-scandium alloy sputtering target material

InactiveCN111636054AReduce oxygen contentHigh degree of densificationVacuum evaporation coatingSputtering coatingGrain structureHot isostatic pressing

The invention provides a preparation method of an aluminum-scandium alloy sputtering target material, and relates to the technical field of target material preparation. The preparation method of the aluminum-scandium alloy sputtering target material comprises the following steps that an aluminum source and a scandium source are mixed, and vacuum melting is conducted on an obtained aluminum-scandium alloy ingredient to obtain a molten aluminum-scandium alloy liquid; vacuum gas atomization is conducted on the molten aluminum-scandium alloy liquid by using an inert gas flow to obtain aluminum-scandium alloy powder; outer sheathing and hot isostatic pressing molding are sequentially conducted on the aluminum-scandium alloy powder to obtain an aluminum-scandium alloy sputtering target blank; and the aluminum-scandium alloy sputtering target blank is bound and machined to obtain an aluminum-scandium alloy sputtering target material. According to the method, the vacuum gas atomization is conducted by using the inert gas flow, contact between the molten aluminum-scandium alloy liquid and oxygen is isolated, the prepared aluminum-scandium alloy powder is high in sphericity degree, low in oxygen content, and uniform in grain structure, particle size and microstructure, and the aluminum-scandium alloy sputtering target material obtained by utilizing hot isostatic pressing molding is highin density, uniform in chemical component, and free of the defects such as segregation.

Owner:FUJIAN ACETRON NEW MATERIALS CO LTD

Corrosion resistance aluminum alloy plate for aviation and preparation method of corrosion resistance aluminum alloy plate

InactiveCN111926225AImproves corrosion performance and toughnessGood overall performanceCorrosionAluminium alloy

The invention relates to the technical field of aluminum alloy processing, in particular to a preparation method of an aluminum alloy plate for aviation. The aluminum alloy comprises the following chemical components of, in percentage by mass, 0.05%-0.2% of zirconium, 0.05%-0.2% of scandium, 3.0%-6.0% of zinc, 3.0%-6.0% of magnesium, 3.0%-4.0% of copper, 0.2%-0.4% of silver, 0.05%-0.2% of lithium,1.0%-1.5% of manganese, 0.8%-1.5% of silicon, 0.20%-0.40% of titanium, 0.05%-0.1% of ruthenium, and the balance aluminum and inevitable impurities, and the content of the impurities is controlled tobe 0.15% or below; and an aluminum alloy melt is prepared according to pre-prepared materials, ultrasonic vibration is adopted in a refining process to refine grains, and then the aluminum alloy platefor the aviation is obtained through pouring, homogenization, extrusion, solid solution treatment, pre-stretching and three-stage aging treatment. According to the corrosion resistance aluminum alloyplate for the aviation and the preparation method of the corrosion resistance aluminum alloy plate, the Vickers hardness of the prepared aluminum alloy plate ranges from 175 Hv to 190 Hv, the yield strength ranges from 520 MPa to 562 MPa, the tensile strength ranges from 605 MPa to 656 MPa, the elongation ranges from 9.4% to 12%, the overall performance is excellent, and the aluminum alloy plateis particularly suitable for being used in the aerospace field.

Owner:湖南恒佳新材料科技有限公司

Method for manufacturing commercial pure titanium plate through twice-heating production process by using heavy and medium plate mill

ActiveCN106623423AImprove performance qualityImprove surface qualityMetal rolling arrangementsStructure propertyMetallurgy

The invention discloses a method for manufacturing a commercial pure titanium plate through a twice-heating production process by using a heavy and medium plate mill. The method sequentially comprises the following steps of casting a blank, forging, primarily heating, primarily dephosphorizing, primarily rolling, cooling, secondarily heating, secondarily dephosphorizing, secondarily rolling, annealing, and postprocessing; the blank is obtained after the forging operation; an intermediate slab with the thickness of 35-60 mm is obtained after the primary rolling operation, and the titanium plate with the thickness of 9-40 mm is obtained after the secondary rolling. The invention aims at providing the method for manufacturing the commercial pure titanium plate through the twice-heating production process by using the heavy and medium plate mill. The problems of relatively low surface quality and structure property of the heavy and medium titanium plate in the one-time heating production are solved, and if the scheme is adopted to produce the heavy and medium titanium plate, the invested production cost is low, the production efficiency is high, the surface quality is high, and the property meets and is higher than the national standard requirement.

Owner:GUANGDONG POLYTECHNIC NORMAL UNIV

Electroless deposition of cobalt alloys

ActiveUS7794530B2Improved grain morphologyUniform grain structureLiquid surface applicatorsAnti-corrosive paintsDielectricCopper

Owner:LAM RES CORP

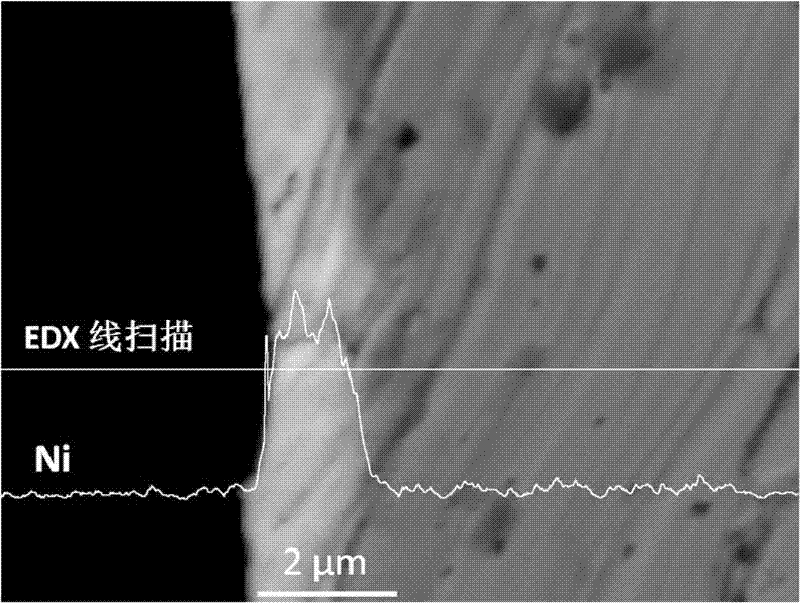

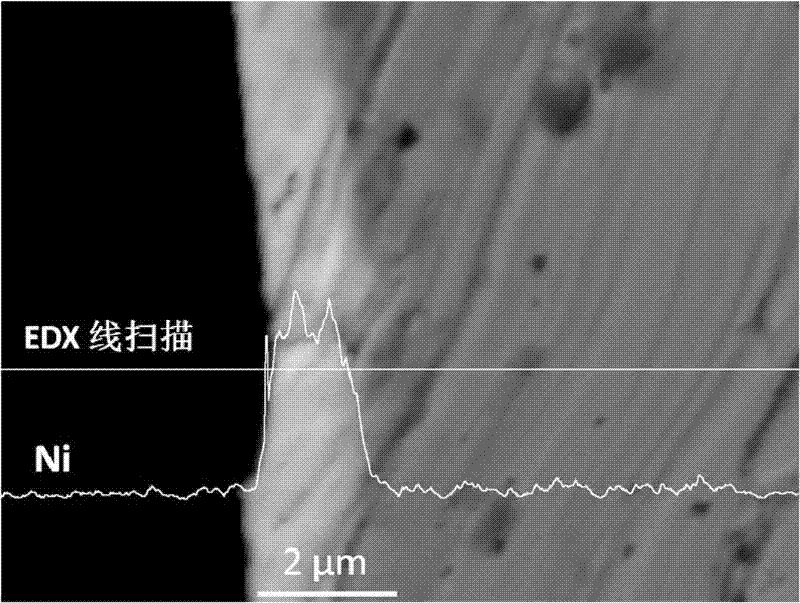

Pulse electrochemical deposition and tissue adjustment processes for nickel plating copper belt

The invention discloses pulse electrochemical deposition and tissue adjustment processes for a nickel plating copper belt. The process comprises the following steps of: performing pulse plating on a nickel coating; performing subsequent cold machining deformation and vacuum heat treatment processes, and the like. By the pulse electrochemical deposition process, the thickness of the nickel coating deposited on the copper belt and the uniformity of a microscopic structure can be effectively ensured; and by the subsequent cold machining deformation and vacuum heat treatment processes, the comprehensive mechanical property, particularly the bending resistance and the physical property of the nickel plating copper belt can be improved, so that high-quality nickel plating copper belts required in industries such as electronics, batteries, electrovacuum, electric light sources and the like can be possibly processed. The pulse nickel plating and tissue adjustment process is low in required equipment investment, has a simple method, is convenient to operate and is suitable for industrial production.

Owner:CHANGSHA STORM ENERGY TTECH

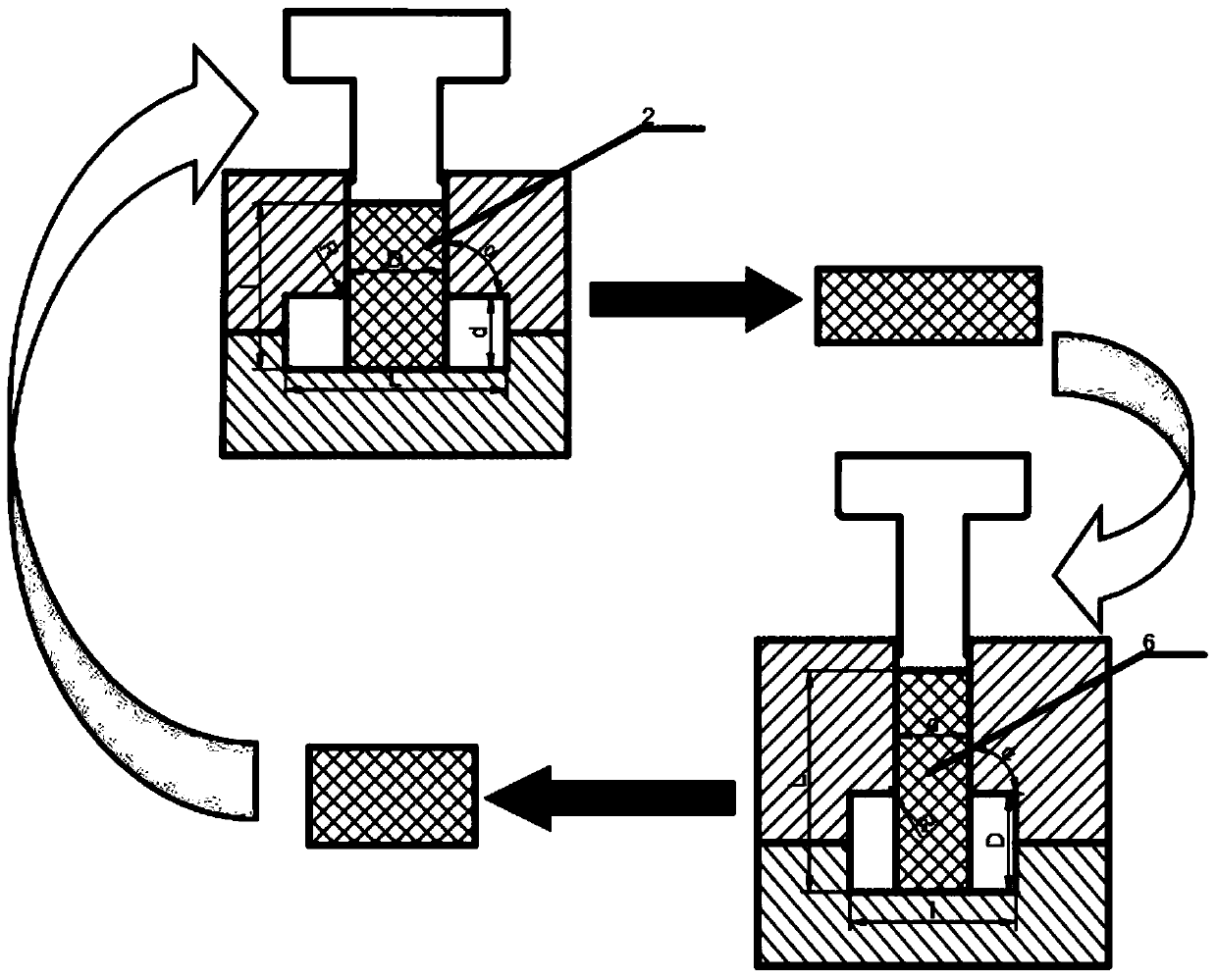

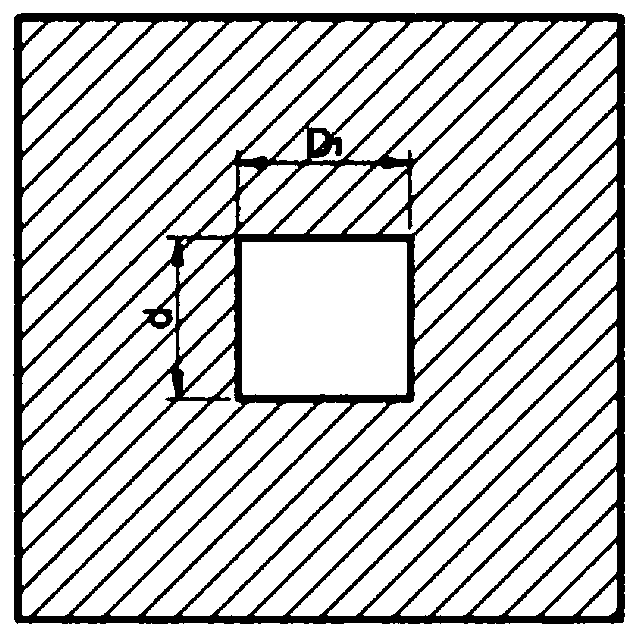

Device for preparing high-performance magnesium alloy through large plastic deformation and preparation method

ActiveCN110000322AControl upsetting deformationSmall machining allowanceExtrusion diesForging/hammering/pressing machinesCrystal structurePlastic property

The invention discloses a device for preparing a high-performance magnesium alloy through large plastic deformation and a preparation method. The device comprises a die I and a die II which have the same structure; each die comprises a male die, an upper female die and a lower female die; a cuboid-shaped extrusion channel is horizontally formed between each upper female die and the corresponding lower female die; the upper female die is vertically penetrated to be provided with a male die channel; the male die channel communicates with the extrusion channel and is matched with the male die; the width of the male die channel of the die I is equal to the height of the extrusion channel of the die II, and the width of the male die channel of the die II is equal to the height of the extrusionchannel of the die I; and the thicknesses of the male die channels and the extrusion channels are equal. According to the device for preparing the high-performance magnesium alloy through the large plastic deformation and the preparation method, the magnesium alloy is repeatedly upset and extruded by replacing the dies to continuously accumulate strain, so that mass points of the magnesium alloy are expected to uniformly generate corner shearing, expansion and upsetting deformation, and finally a texture is weakened while forming a uniform fine crystal structure so as to prepare the high-performance magnesium alloy.

Owner:HUNAN UNIV OF SCI & TECH

Method for forging and cogging magnesium alloy sheet

InactiveCN102513484AQuality improvementReduce processing costsMetal-working apparatusSingle processProcessing cost

The invention discloses a method for forging and cogging a magnesium alloy sheet, comprising the following steps: forging the side with a low temperature and a small stress in a cross way, namely, carrying out multi-process forging to the sheet from the side in a cross way along horizontal direction and vertical direction of the sheet, and forging with a relatively low process stress. By adopting the forging and cogging, the material undergoes large cold deformation at a low temperature, and twin refined crystal grains are effectively excited, so as to form a structure type that is helpful for consequent rolling shaping by refining the crystal grain size of the cast sheet and by effectively utilizing the twin divided crystal grains. Therefore, the single-process maximum pressing amount and continuous deforming property are greatly improved in the consequent rolling process, the rolling times and the intermediate annealing times are decreased, so that the processing cost of the magnesium alloy sheet is reduced. At the same time, the magnesium alloy sheet prepared by the method has more even and thinner crystal grain tissue and excellent mechanical property; the break tendency of the side of the sheet is greatly improved, so that the quality of the magnesium alloy sheet is improved.

Owner:CHONGQING UNIV

Preparation method of molybdenum tube

InactiveCN110000391AGood deformabilityEasy to processVacuum evaporation coatingSputtering coatingHigh densityVolumetric Mass Density

The invention discloses a preparation method of a molybdenum tube for a rotating target material. The method comprises the following steps: 1, carrying out filling and hot isostatic pressing treatmenton molybdenum powder to obtain a molybdenum tube blank; and 2, extruding and annealing the molybdenum tube blank to obtain the molybdenum tube. The method has the advantages of few process steps, short production period and the like; and the molybdenum tube prepared by the method has high density and fine and uniform crystal grain structure, specifically, the density is greater than or equal to 99% of theoretical density, the average crystal grain size is smaller than or equal to 40 [mu]m, the maximum length can exceed 4 meters, and the molybdenum tube can well meet the sputtering coating requirements in the industries of plane display, solar photovoltaic and the like.

Owner:ZHUZHOU HARD ALLOY GRP CO LTD

Nickel base alloy welding wire with diameter smaller than 3 mm

ActiveCN103962747AEasy to processHigh strengthWelding/cutting media/materialsSoldering mediaHydrogenSlag

The invention relates to a nickel base alloy welding wire. Alloy of the nickel base alloy welding wire comprises, by mass, 0.4%-0.45% of C, 1.0%-1.5% of Mn, 0.15%-1.2% of Si, 0.025% or less of P, 0.02% or less of S, 28%-30% of Cr, 49%-51% of Ni, 0.1% or less of Co, 0.1% or less of Mo, 0.1% or less of Ti, 0.1% or less of Al, 4.0%- 5% of W and the balance being Fe. A method for preparing the nickel base alloy welding wire includes the steps of alloy smelting, electroslag remelting, hot forging and blooming, hot rolling and annealing, acid pickling and coping, cold drawing and hydrogen withdrawing. A CaF2 slag system, an Al2O3 slag system and a CaO slag system are adopted in electroslag remelting. Through the method for preparing the nickel base alloy welding wire, the thin welding wire with the performance meeting requirements can be prepared, and the yield is high.

Owner:JIANGSU TOLAND ALLOY

High-strength Al-Mg-Si aluminum alloy bar for automobile chassis and manufacturing method

The invention discloses a high-strength Al-Mg-Si aluminum alloy bar for an automobile chassis and a manufacturing method of the high-strength Al-Mg-Si aluminum alloy bar, and relates to an aluminum alloy bar and a manufacturing method thereof. The invention aims to solve the problems that the existing 6082 aluminum alloy bar is low in tensile strength and yield strength, and the requirement for the bearing capacity of the automobile chassis in the future is difficult to meet are solved. The high-strength Al-Mg-Si aluminum alloy bar for the automobile chassis is composed of Si, Cu, Mn, Mg, Zn,Ti, Zr and Al. The manufacturing method comprises the steps of first, weighing; second, smelting; third, casting an aluminum alloy round cast ingot; fourth, conducting homogenizing annealing treatment; fifth, extruding a finished bar; and sixth, performing solid solution and aging treatment. The scheme is mainly applied to the high-strength Al-Mg-Si aluminum alloy bar for the automobile chassis and the manufacturing of the high-strength Al-Mg-Si aluminum alloy bar.

Owner:NORTHEAST LIGHT ALLOY CO LTD

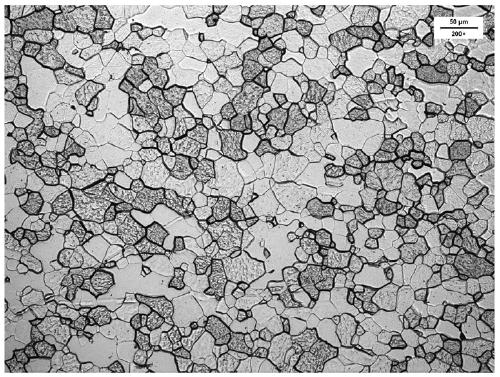

Preparation method of titanium-aluminum alloy target material

ActiveCN111101105AReduce manufacturing costSimple production process controlTransportation and packagingMetal-working apparatusTitaniumHot isostatic pressing

The invention discloses a preparation method of a titanium-aluminum alloy target material. The preparation method comprises a powder mixing step, a filling step, a cold isostatic pressing step, a welding sheath degassing step, a hot isostatic pressing step, a slitting step, an alloying diffusion heat treatment step and a machining finishing step. The preparation method is simple in control, low inprocessing cost and high in processing efficiency.

Owner:东莞市欧莱溅射靶材有限公司

Machining process of zinc-copper with mechanical properties controlled by machining rate

InactiveCN103397288AImprove ductilityUniform and fully recrystallized structureCupronickelGrain structure

The invention discloses a machining process of zinc-copper with mechanical properties controlled by a machining rate. The process comprises the following steps of: smelting and casting; milling surfaces; roughly rolling and cogging; thickening and cutting edges; carrying out intermediate annealing; degreasing and washing; rolling a backing material; carrying out intermediate annealing; degreasing and washing; rolling a finished product; annealing the finished product; stretching the bent part and straightening; washing the finished product; splitting into bars and warehousing. The zinc-copper backing material is rolled at a machining rate of 35-65% in the step of rolling the backing material; before the step of intermediate annealing, the zinc-copper backing material is unrolled and then heated to 500-600 DEG C, and the temperature is preserved for 7-12 hours and heat treatment is carried out; the finished product is rolled at a machining rate of 10-50% in the step of rolling the finished product; in the step of annealing the finished product, the rolled finished product is subjected to low-temperature recovery heat treatment through an annealing furnace, the temperature is controlled to be 300-400 DEG C, and the temperature is preserved for 3-7 hours. A final zinc-copper product has uniform and good crystal grain structure, the internal residual stress of a material is small, the mechanical property fluctuation is small, and the finished product rate is high.

Owner:ANHUI XINKE NEW MATERIALS

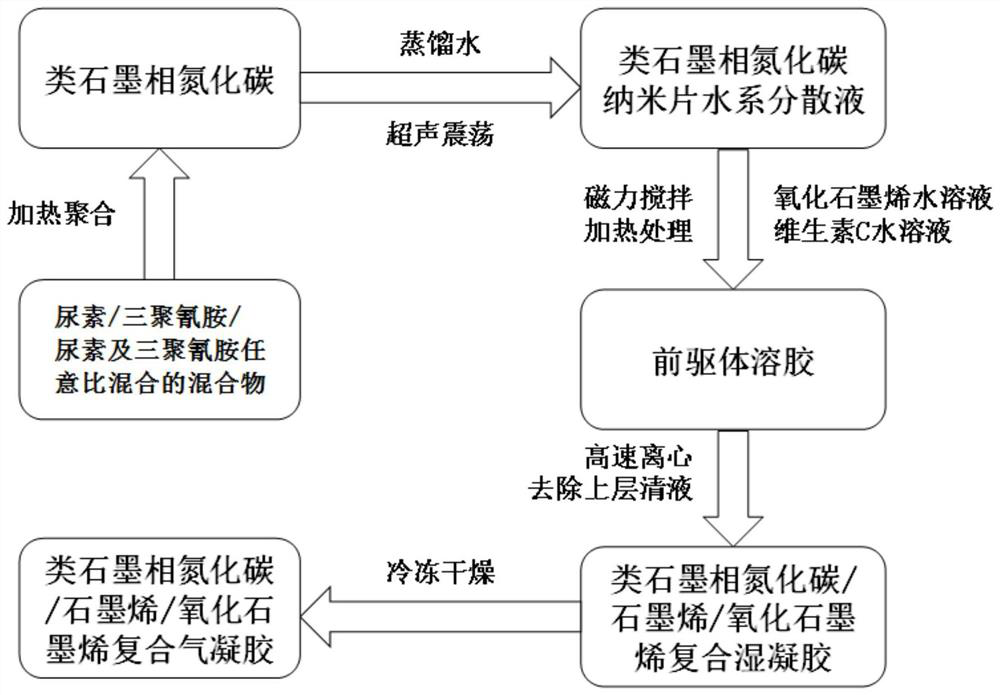

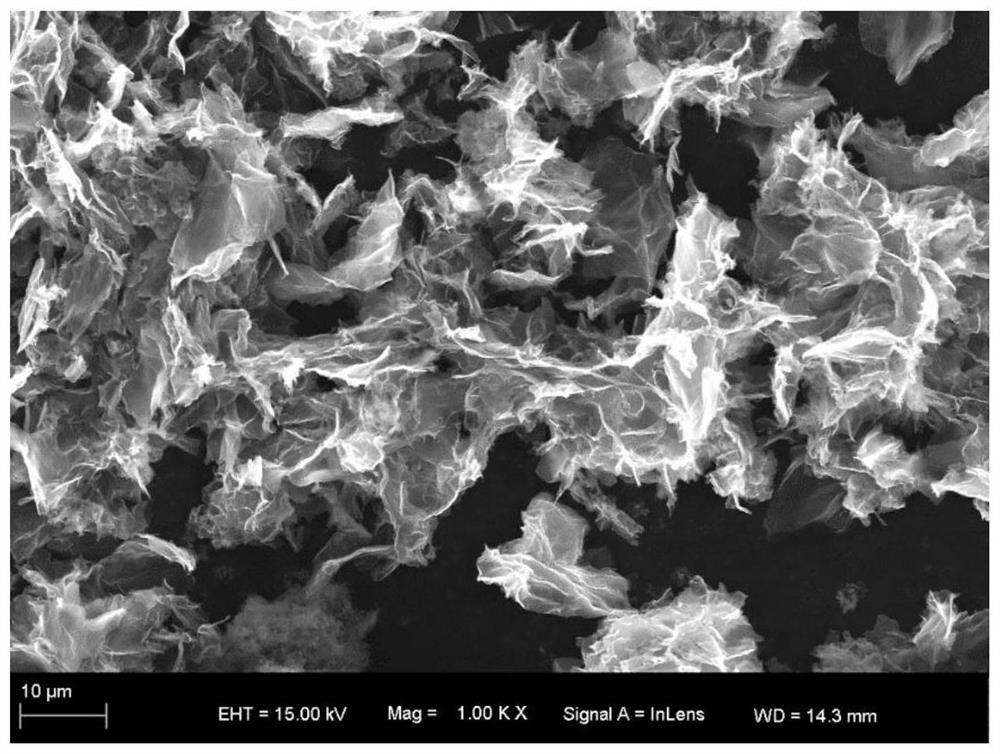

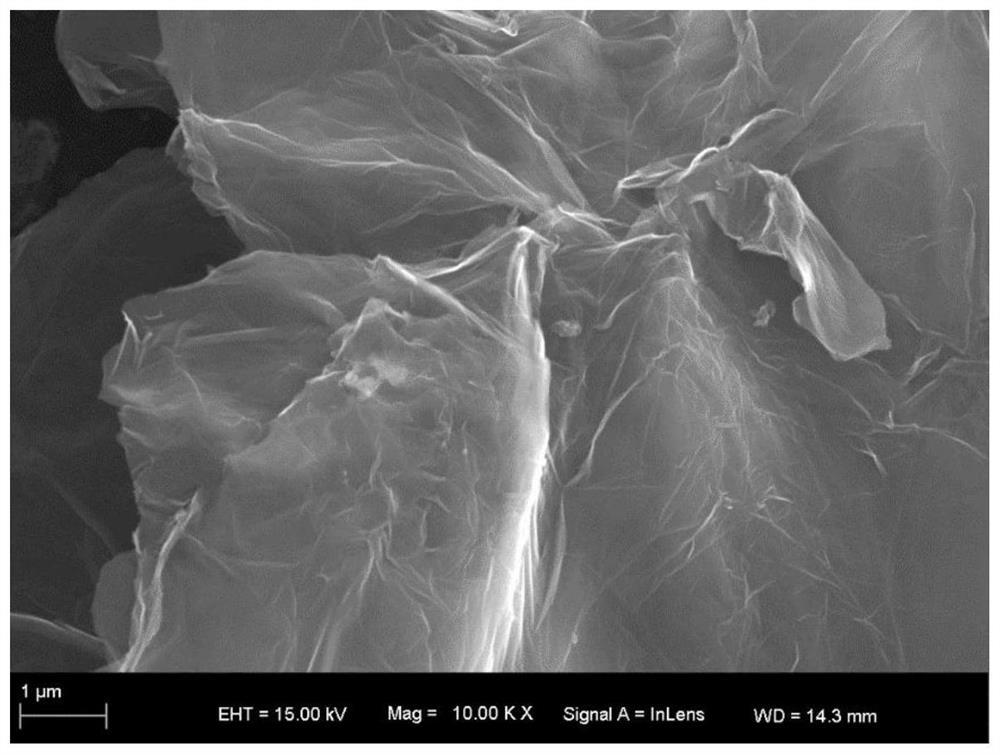

Graphite-like carbon nitride/graphene/graphene oxide composite aerogel and preparation method thereof

PendingCN113617351ASolve the problem of low photocatalytic efficiencyUniform grain structureWater/sewage treatment by irradiationWater treatment compoundsVitamin COrganic dye

The invention discloses a preparation method of graphite-like carbon nitride / graphene / graphene oxide composite aerogel. The preparation method specifically comprises the following steps: step 1, grinding urea or melamine or a mixture formed by mixing urea and melamine in any ratio into powder, and heating to prepare graphite-like carbon nitride; step 2, mixing the graphite-like phase carbon nitride obtained in the step 1 with distilled water; step 3, uniformly mixing the graphite-like phase carbon nitride nanosheet aqueous dispersion liquid with a graphene oxide aqueous solution and a vitamin C aqueous solution; step 4, performing high-speed centrifugation on the precursor sol; and step 5, drying the wet gel by using a freeze dryer to obtain the graphite-like carbon nitride / graphene / graphene oxide composite aerogel. The invention also provides the graphite-like carbon nitride / graphene / graphene oxide composite aerogel prepared by the method. Compared with graphite-like carbon nitride, the graphite-like carbon nitride / graphene / graphene oxide composite aerogel has the advantage that the degradation efficiency and degradation rate of organic dye degraded by a photocatalytic material are improved.

Owner:XIAN UNIV OF TECH

Seamless steel tube heat treatment process

ActiveCN107236856AImprove stabilityUniform grain structureFurnace typesHeat treatment furnacesQuenchingMuffle furnace

The invention discloses a seamless steel tube heat treatment process. The process comprises the following steps that (1) annealing is conducted, specifically, a semi-finished seamless steel tube is conveyed into a muffle furnace for annealing treatment; (2) quenching is conducted, specifically, the annealed seamless steel tube is conveyed into a quenching furnace for quenching treatment through a first heating stage, a second heating stage and a soaking stage; (3) quenching bath pouring soaking is conducted, specifically, the seamless steel tube is discharged from the quenching furnace after quenching is completed and soaked in quenching bath with the temperature being 15-25 DEG C, and the quenching time is 45-55 s; and (4) tempering is conducted, specifically, finally, the seamless steel tube is conveyed into a tempering furnace for tempering treatment, and the seamless steel tube is discharged from the tempering furnace and air-cooled to the room temperature after tempering is completed. Through the heat treatment process, the stability of the performance of the seamless steel tube can be improved, and meanwhile, the phenomenon that seamless steel tubes cannot be straightened and corrected due to bending and nonuniform mechanical performance caused by heat treatment is avoided.

Owner:安徽华飞机械铸锻有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com