Preparation method of copper target

A copper target and copper billet technology, which is applied in the field of semiconductor sputtering, can solve the problems of difficulty in controlling the film formation rate, easy deformation, and the inability to increase the target area.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

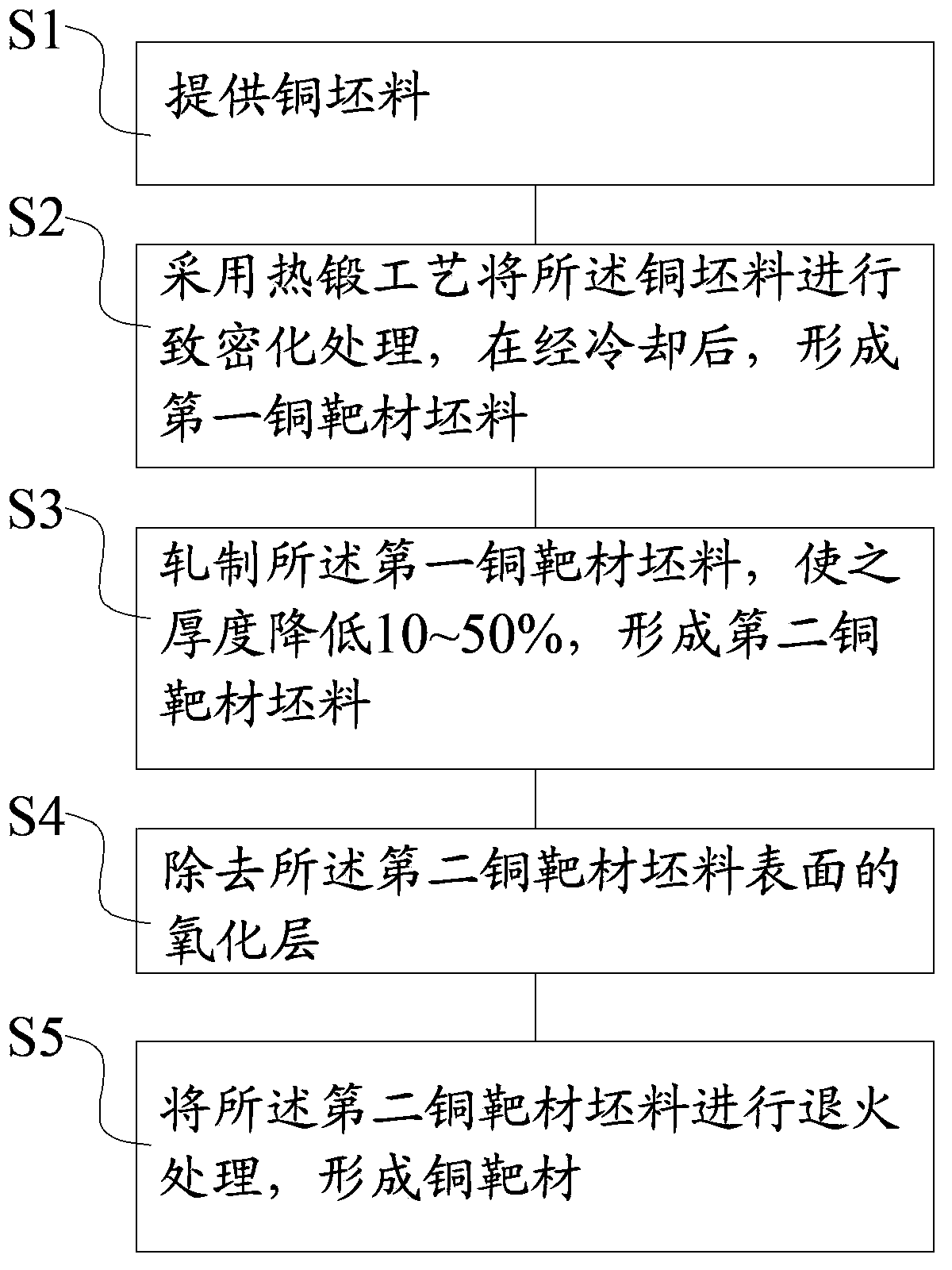

[0028] As mentioned in the background technology, in view of the ever-increasing demand for the coating area of magnetron sputtering, the area of the target material used for magnetron sputtering also increases accordingly, and at the same time, the requirements for the control of the film formation rate of magnetron sputtering also increase. more stringent. Correspondingly, higher requirements are also put forward for the hardness of the target. However, the hardness of metal copper is small, and the hardness of the target obtained through the existing preparation process is not enough to meet the requirements of magnetron sputtering for large-area targets. For this reason, the present invention provides a kind of preparation method of copper target material, refer to figure 1 As shown, the preparation method of the copper target of the present invention comprises steps:

[0029] S1: provide copper blank;

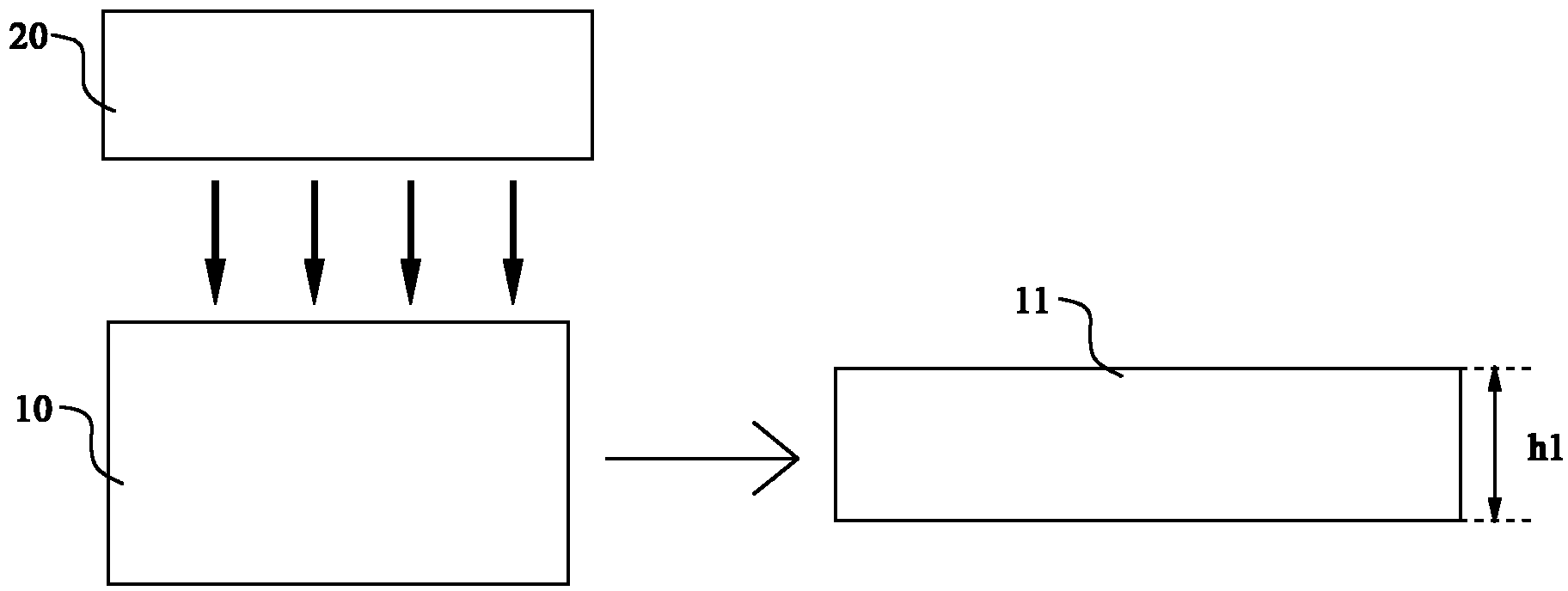

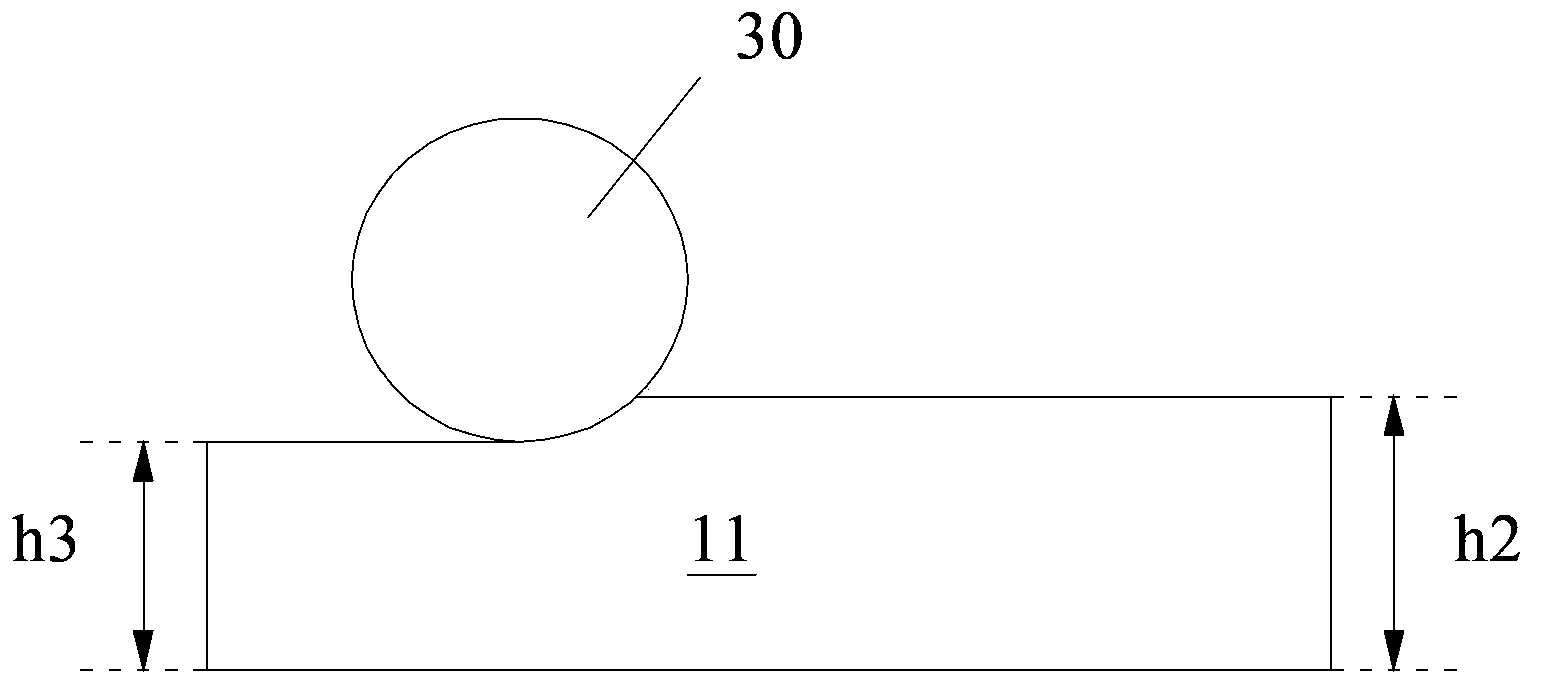

[0030] S2: Densifying the copper blank by using a hot forging ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| hardness | aaaaa | aaaaa |

| hardness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com