Carbon/carbon crucible and manufacturing method thereof

A technology for crucibles and prefabricated bodies, applied in crucibles, crucible furnaces, chemical instruments and methods, etc., can solve problems such as poor integrity of crucibles, damaged connection structures, and parts falling apart, so as to avoid waste of raw materials, reduce costs, and improve overall performance. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

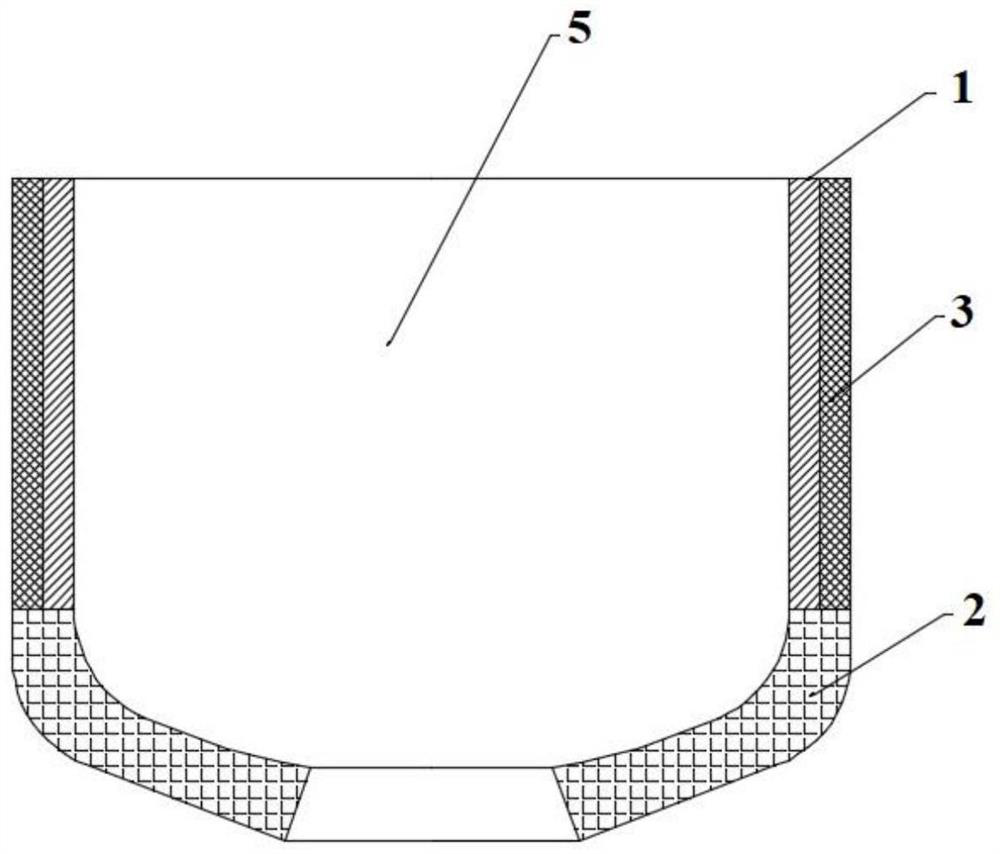

[0040] Such as figure 1 with figure 2 As shown, the first charcoal / charcoal crucible of this embodiment is composed of a crucible inner layer 1 and a crucible outer layer 3 that surrounds and covers part of the outer surface of the crucible inner layer 1. The crucible inner layer 1 is composed of a crucible bottom 2 It is assembled with 14 crucible petals 4, and the surrounding centers of the 14 crucible petals 4 are located on the axis line of the carbon / charcoal crucible, and the crucible bottom 2 and the 14 crucible petals 4 form an accommodation cavity 5, and the inside of the crucible The materials of layer 1 and outer layer 3 of the crucible are both carbon / carbon composite materials.

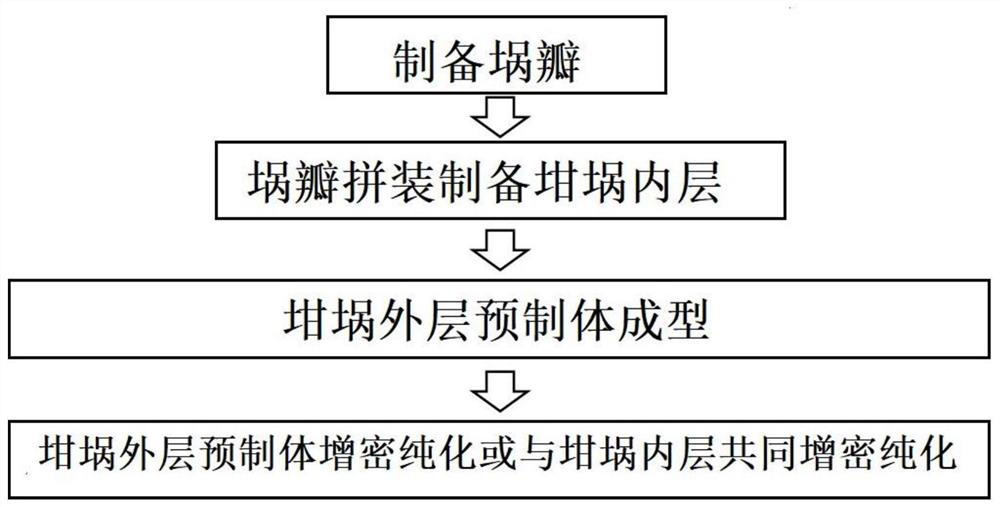

[0041] Such as image 3 with Figure 4 Shown, the concrete manufacturing process of first kind of charcoal / charcoal crucible of the present invention is:

[0042] Step 1. Choose a density greater than 1.3g / cm 3 The square material machine adds a long plate with a bevel on the side t...

Embodiment 2

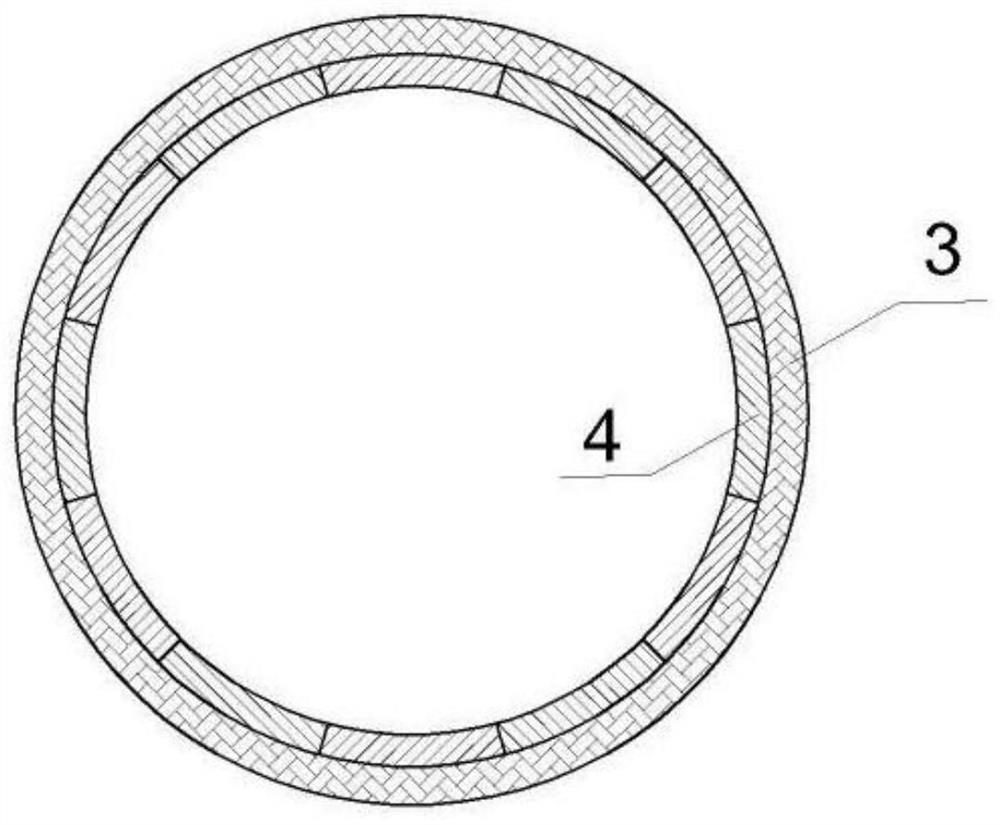

[0053] Such as Figure 5 with Image 6 As shown, the second charcoal / charcoal crucible of the present invention is composed of a crucible inner layer 1 and a crucible outer layer 3 covering the outer surface of the crucible inner layer 1, and the crucible inner layer 1 is composed of three crucible flaps 4 assembled, 4 The surrounding center of the crucible petals 4 is located on the axis of the crucible, and the three crucible petals 4 form an accommodating cavity 5, and the materials of the crucible inner layer 1 and the crucible outer layer 3 are carbon / carbon composite materials, so The central angles corresponding to the circular arcs of the cross section of the crucible flap 4 along the horizontal direction are all 120°.

[0054] The concrete manufacturing process of second kind of charcoal / charcoal crucible of the present invention is:

[0055] Step 1. Select the petal-shaped profiling blank of carbon / carbon composite material to obtain the crucible petal 4 through ma...

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com