Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

126results about "Crucibles" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

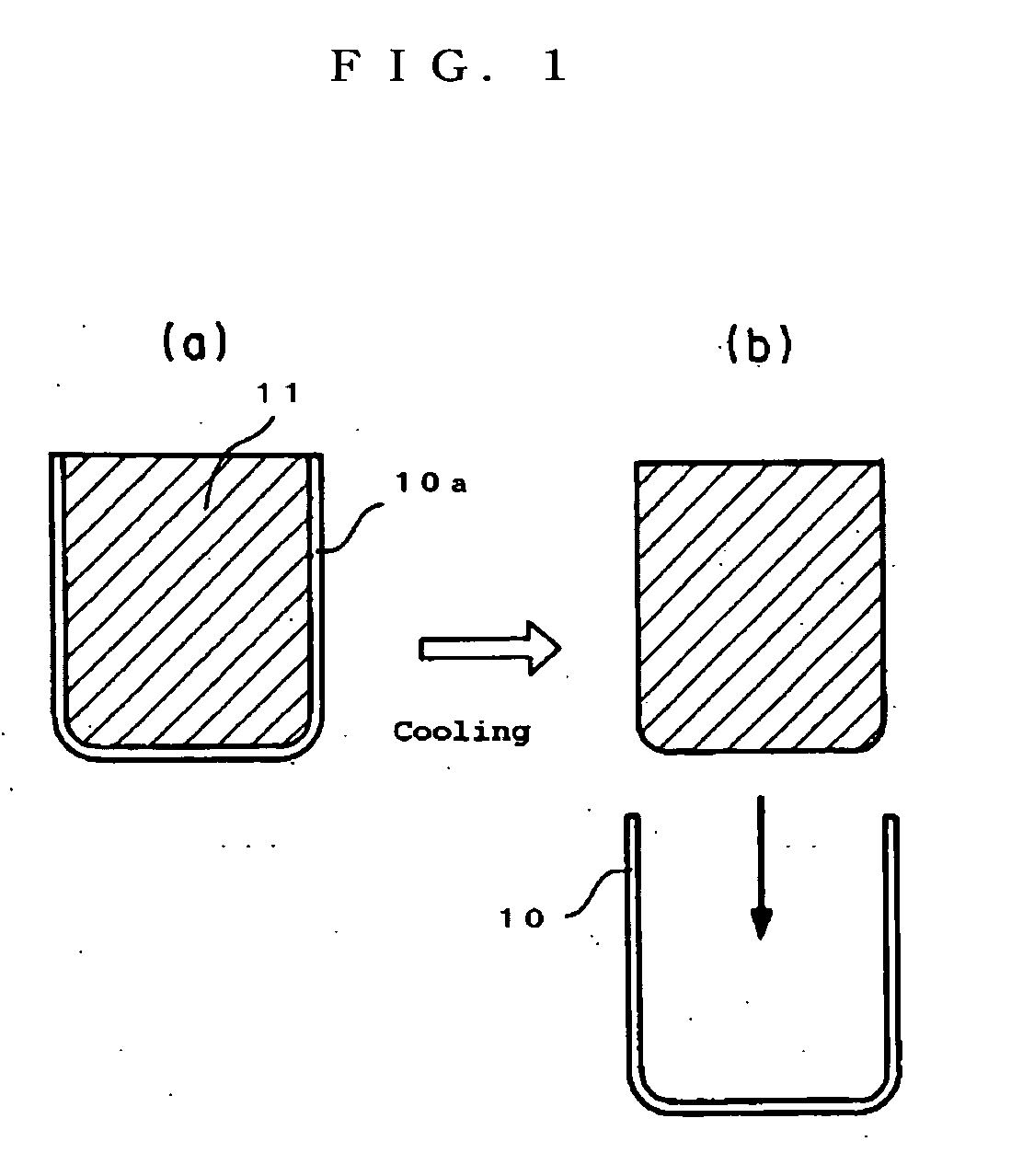

PCR method for amplifying a gene using metallic sample container having inner surface coated with a resin or metal oxide

InactiveUS6140613ABioreactor/fermenter combinationsHeating or cooling apparatusPcr methodMaterials science

A sample container for heating a sample stored therein includes a resin layer on the whole inner surface of the container made of metal having a thickness ranging from 0.02 mm to 1.0 mm and the resin layer having a thickness ranging from 1 mu m to 100 mu m. A sample container for heating a sample stored therein includes a metal oxide layer on at least the whole inner surface of the container made of metal having a thickness ranging from 0.02 mm to 1.0 mm.

Owner:NGK INSULATORS LTD

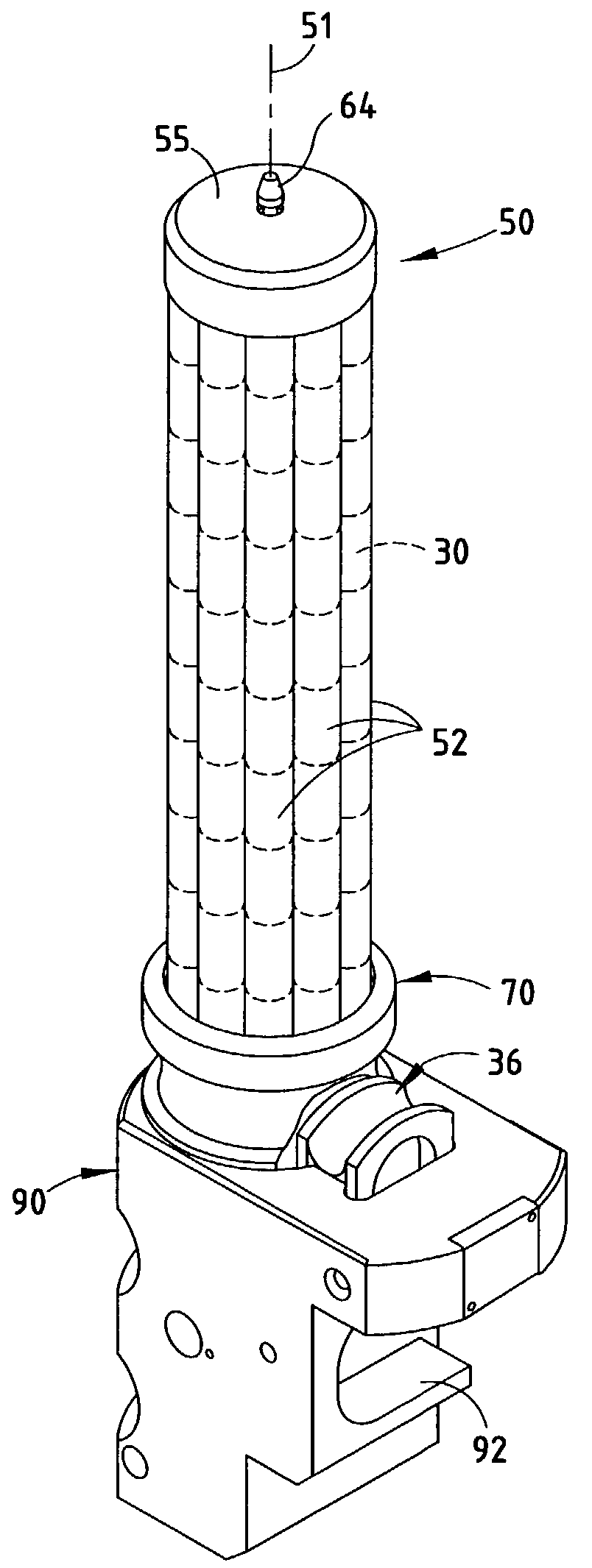

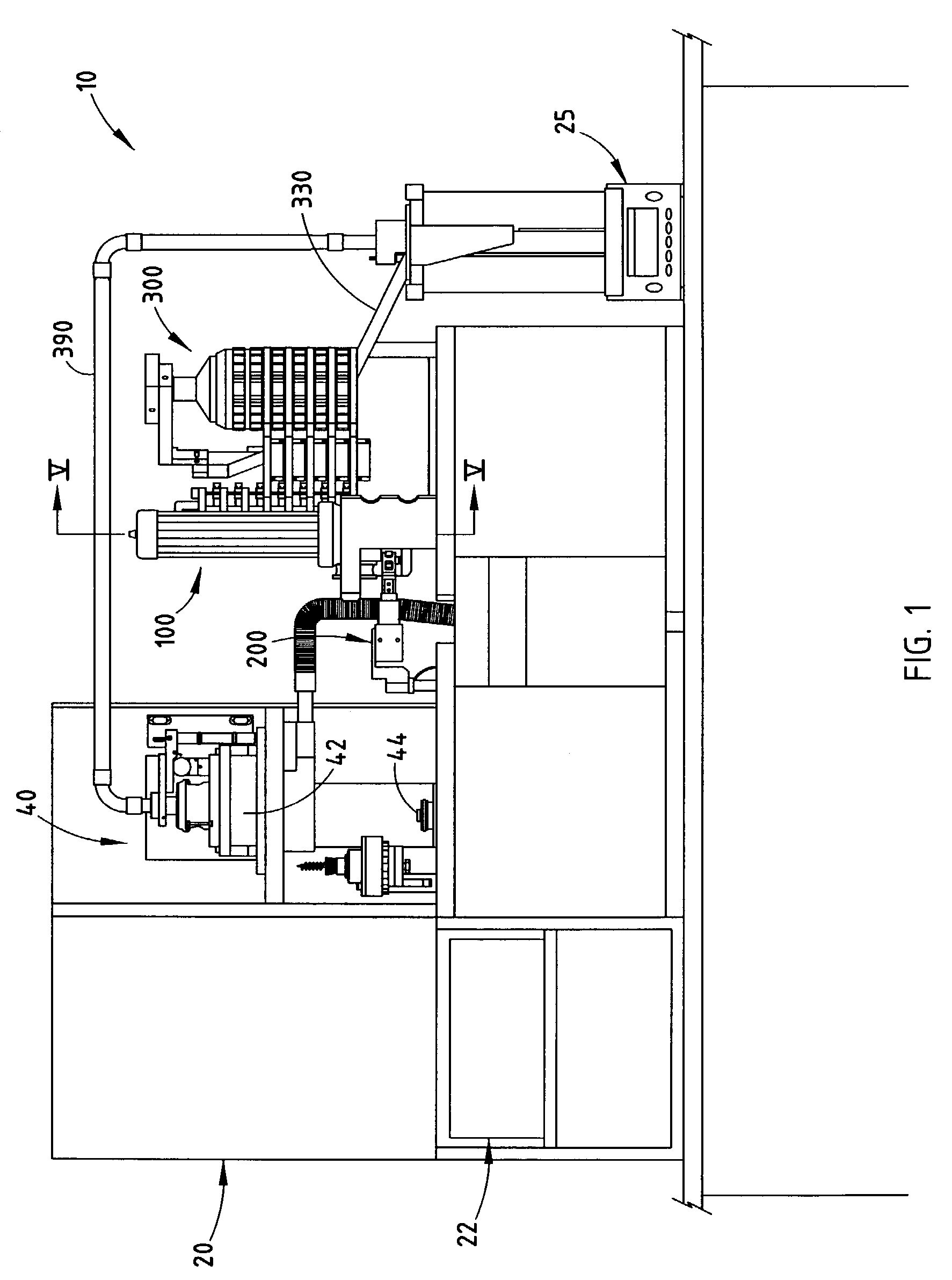

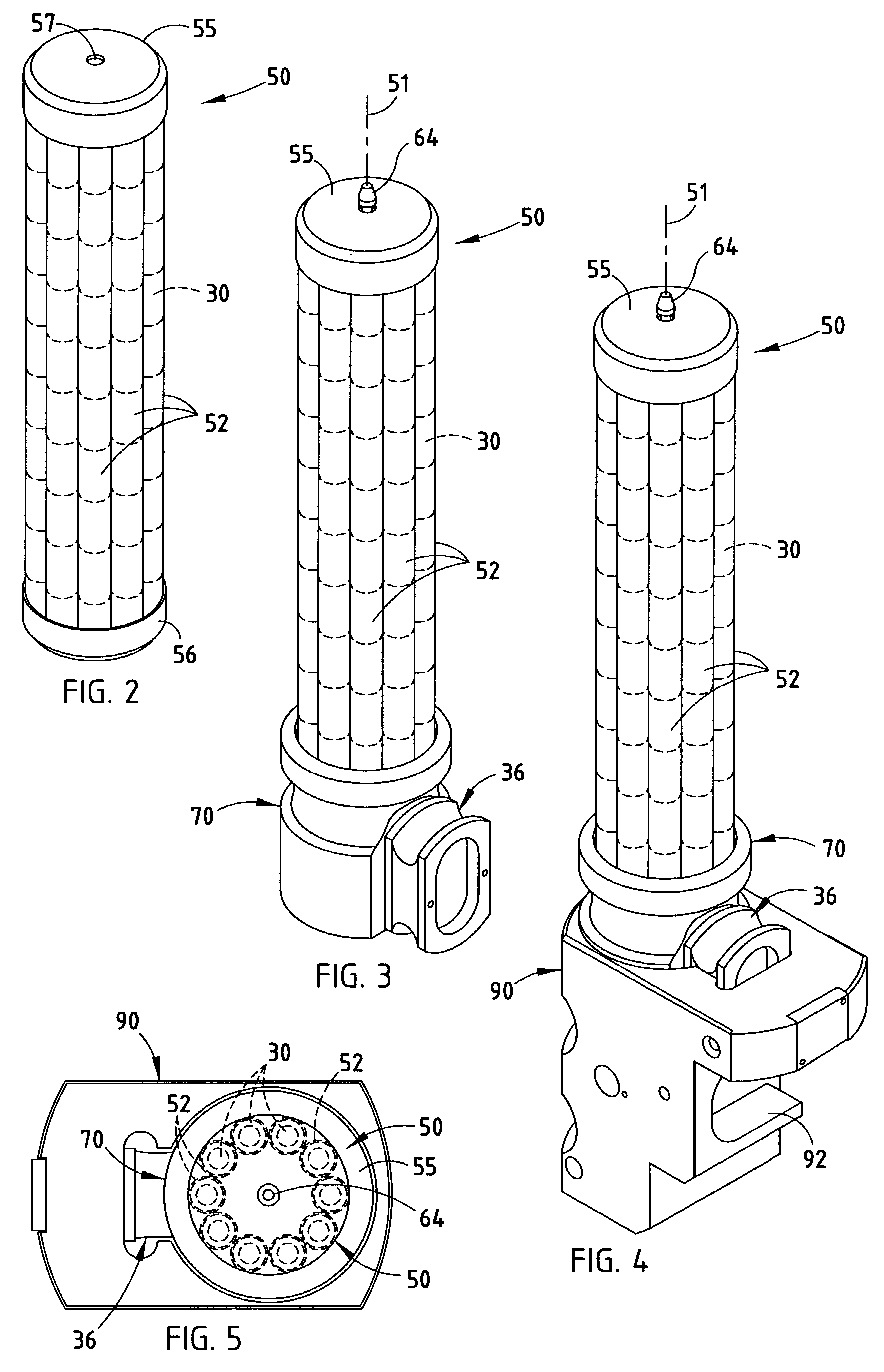

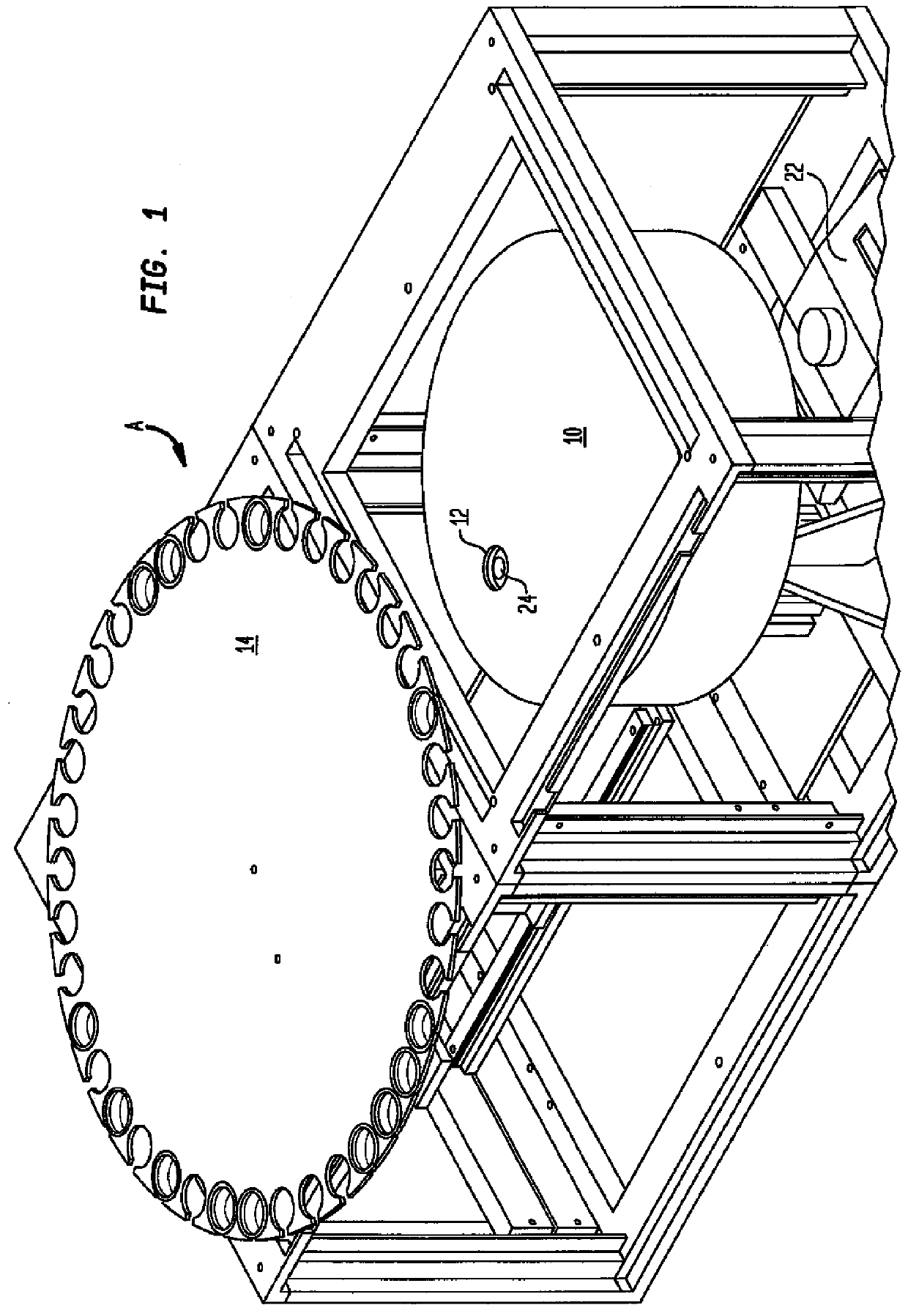

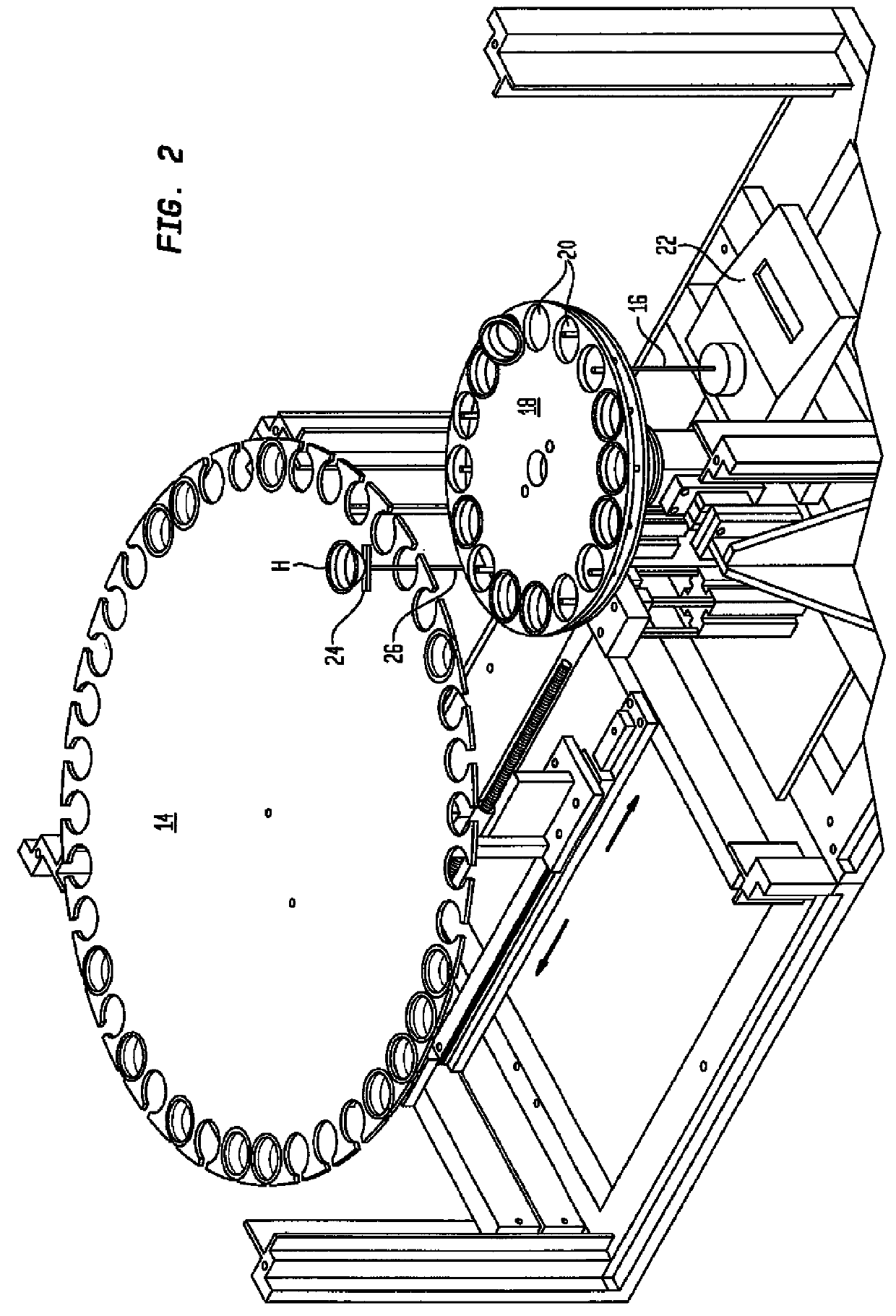

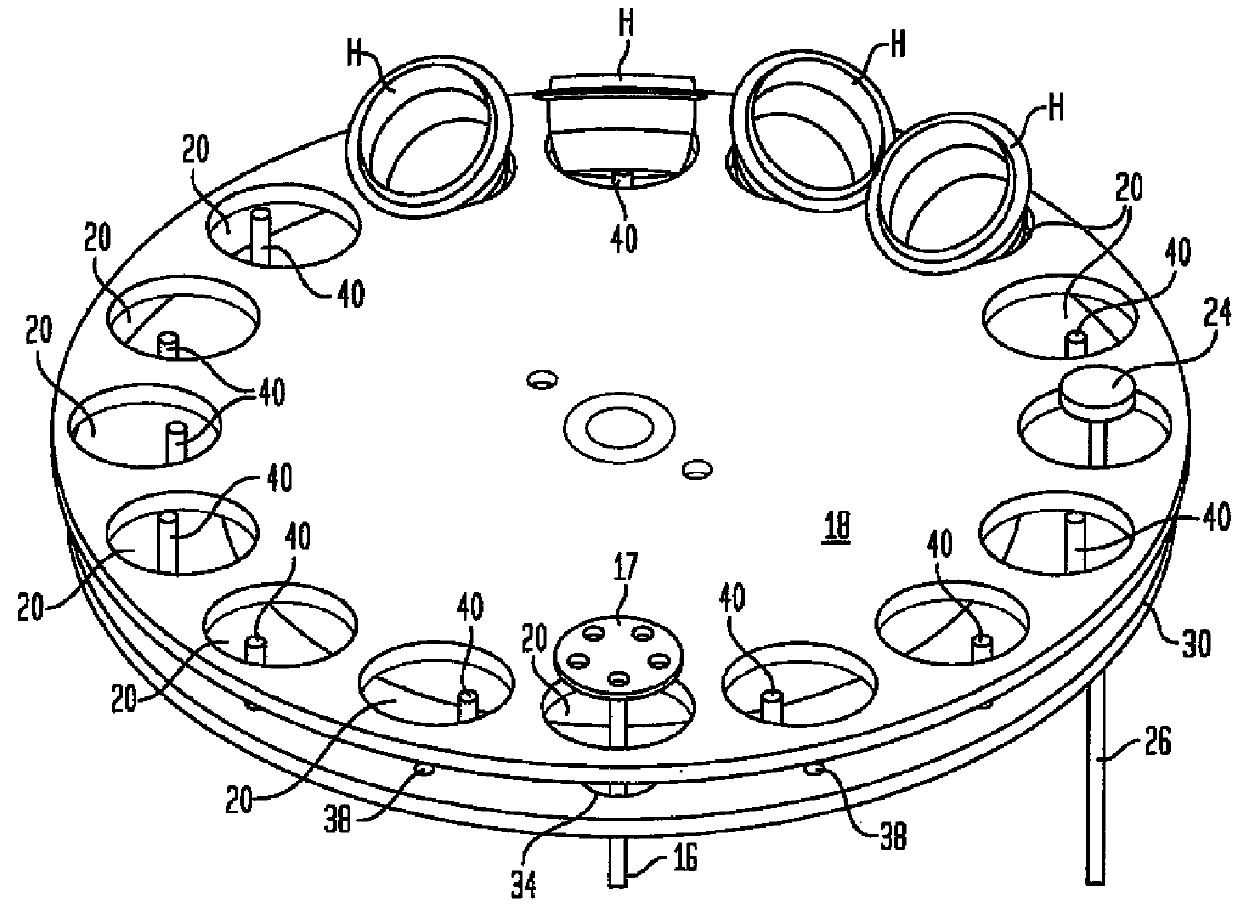

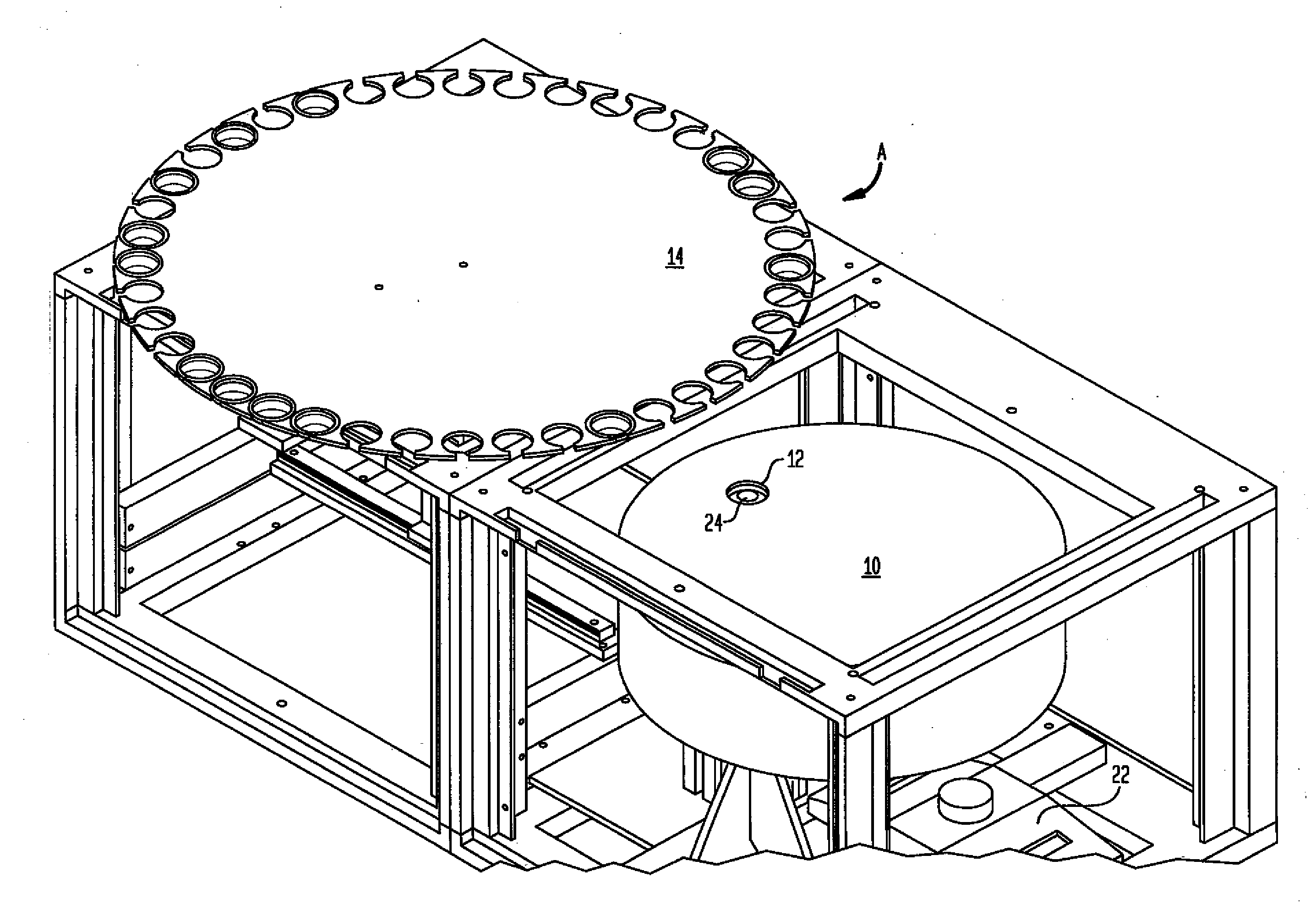

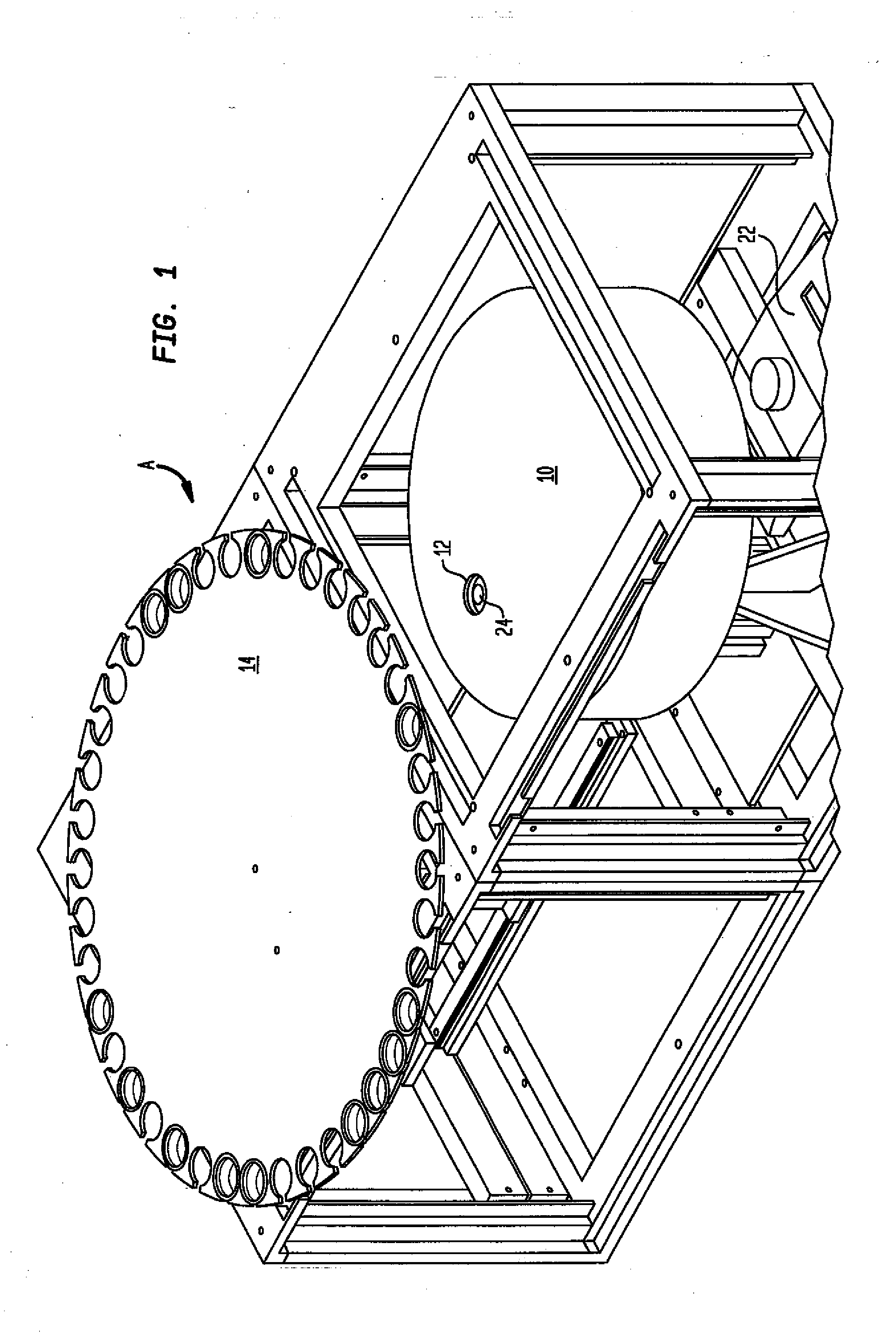

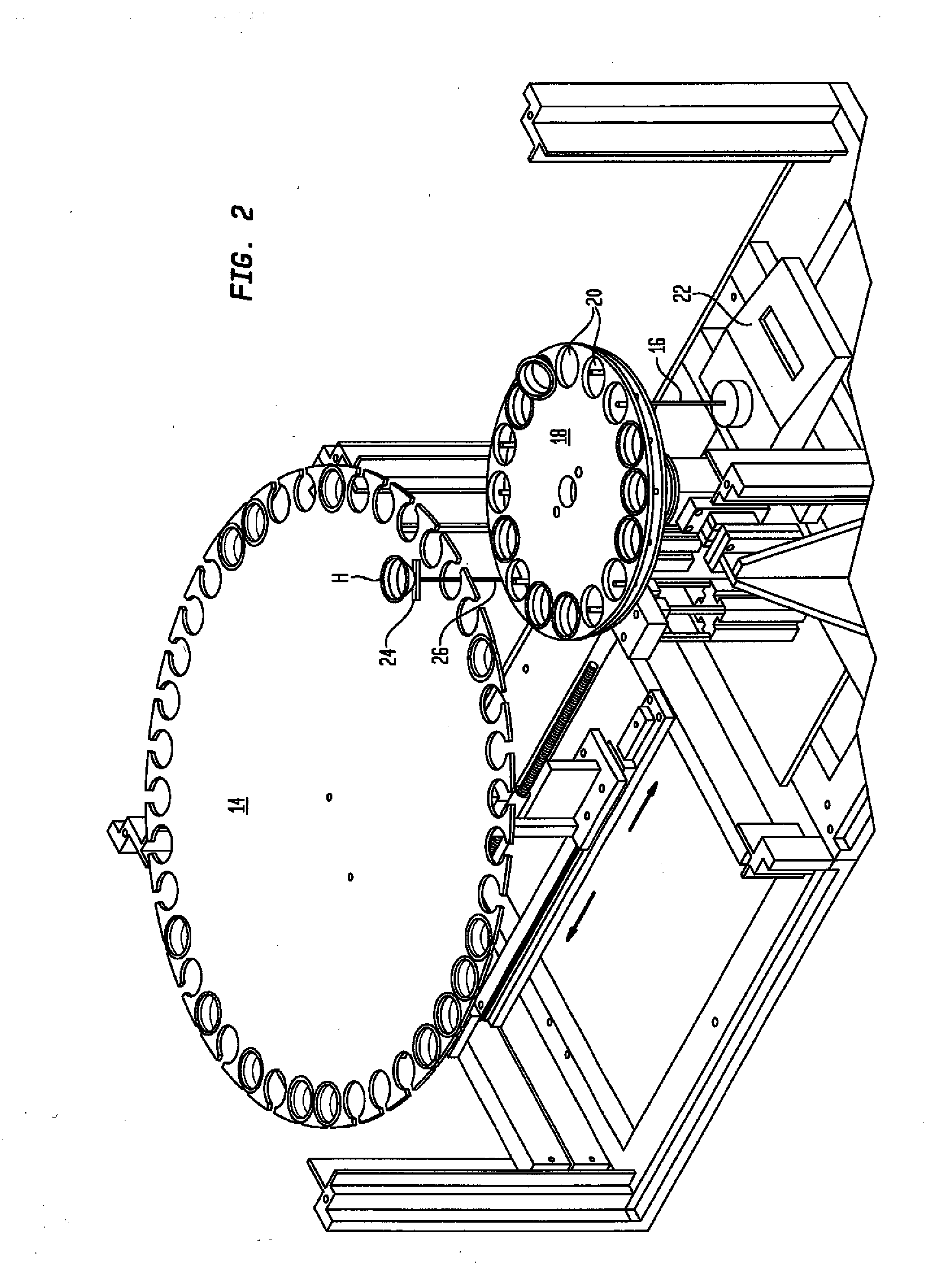

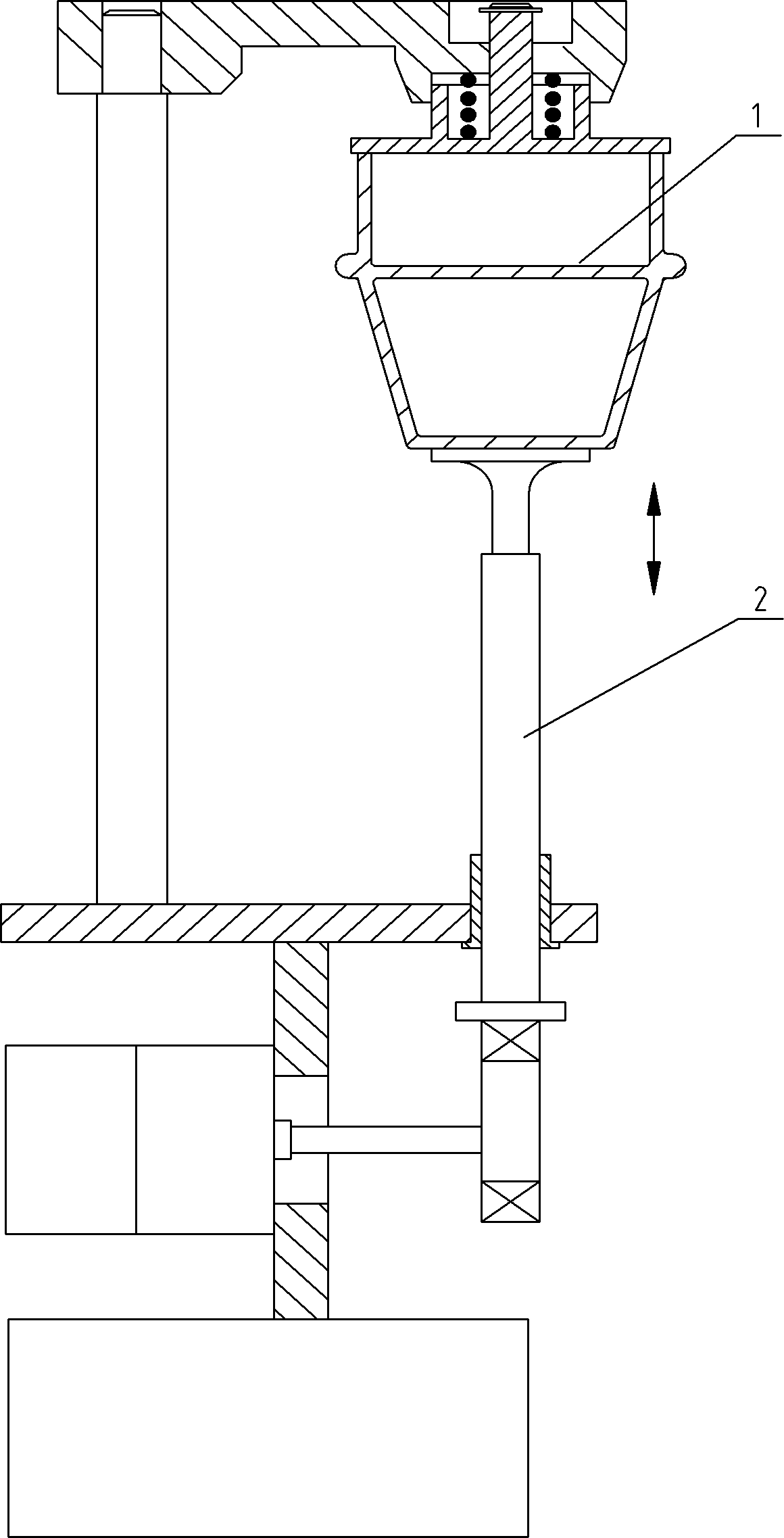

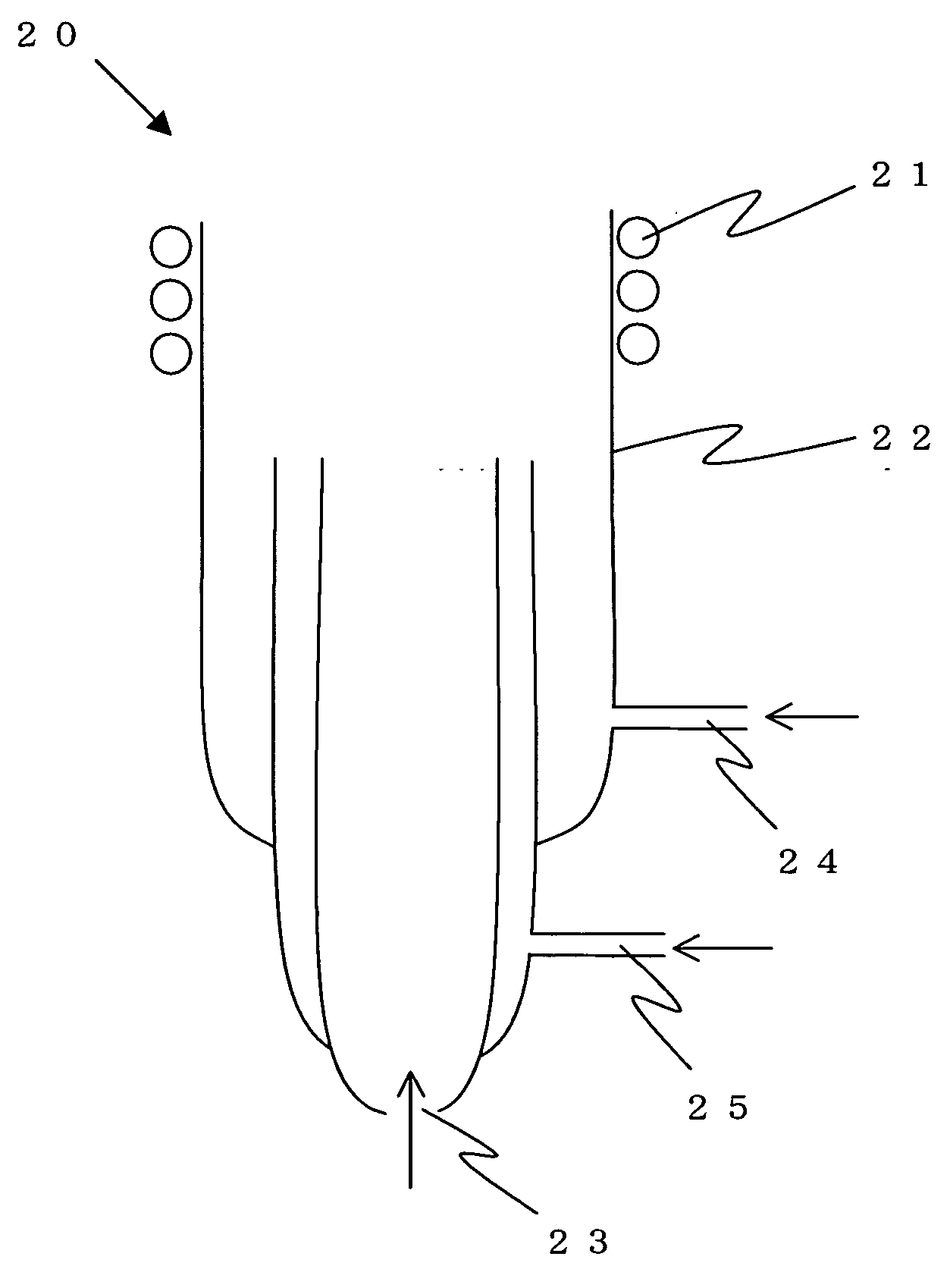

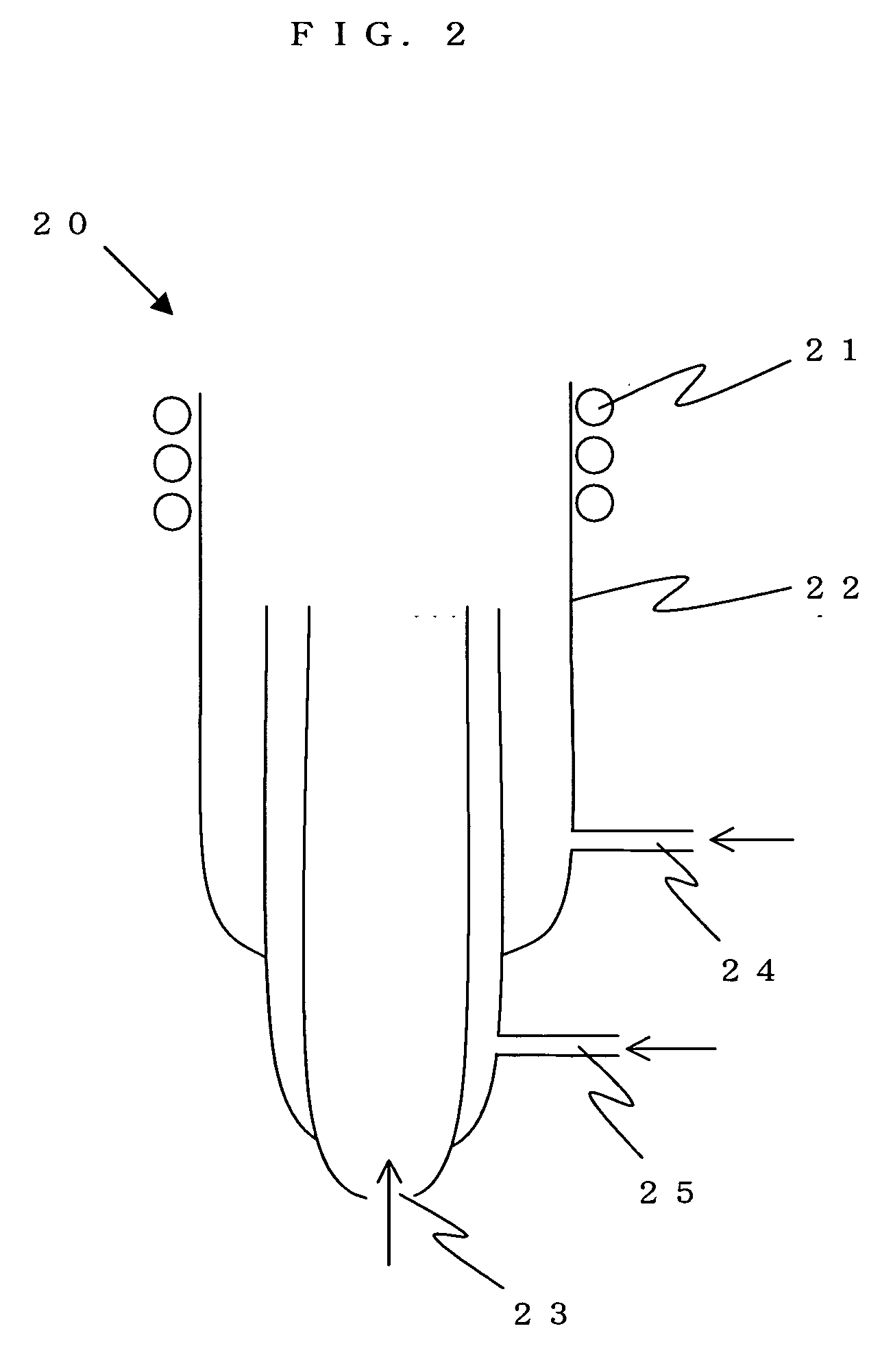

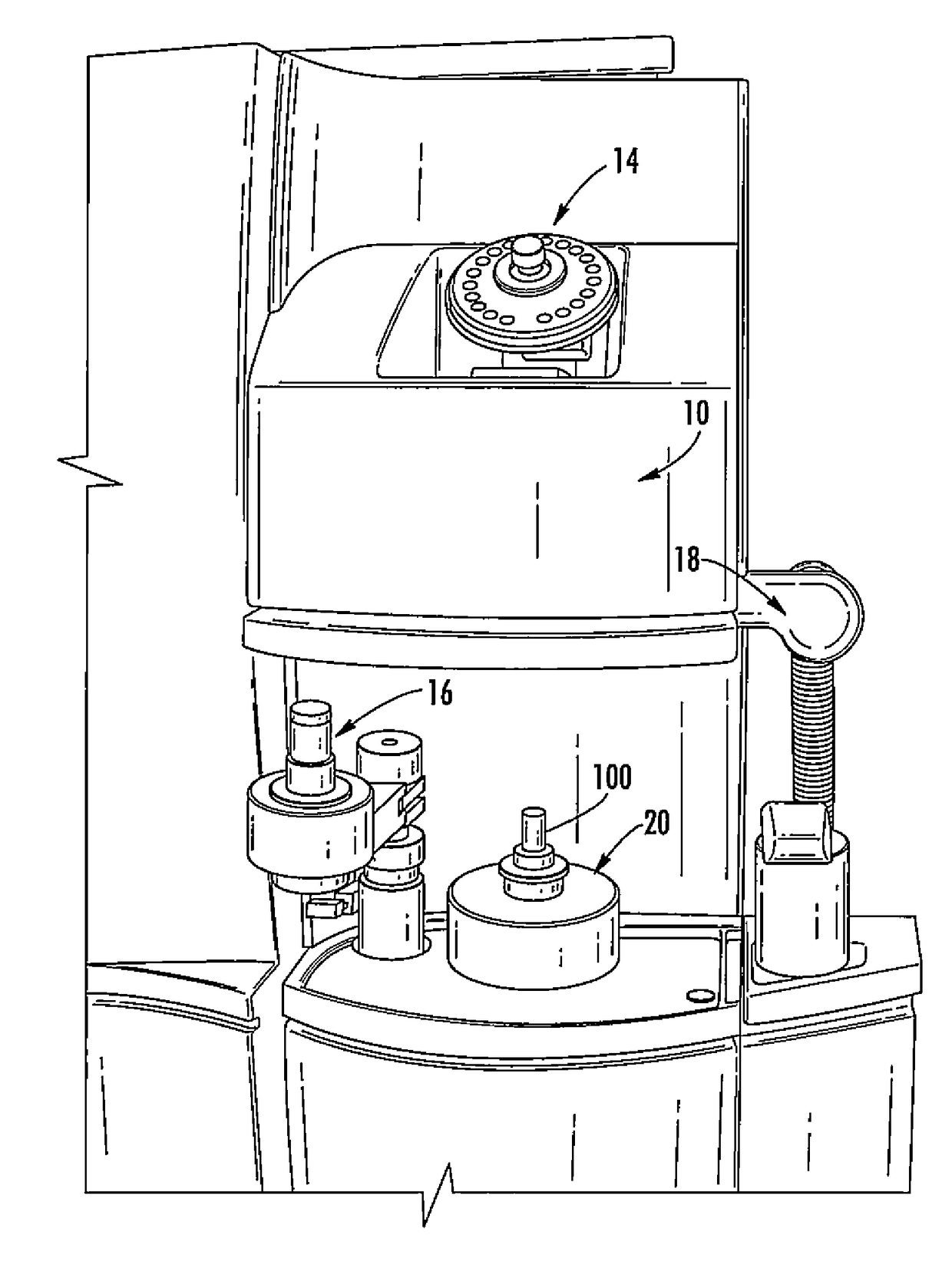

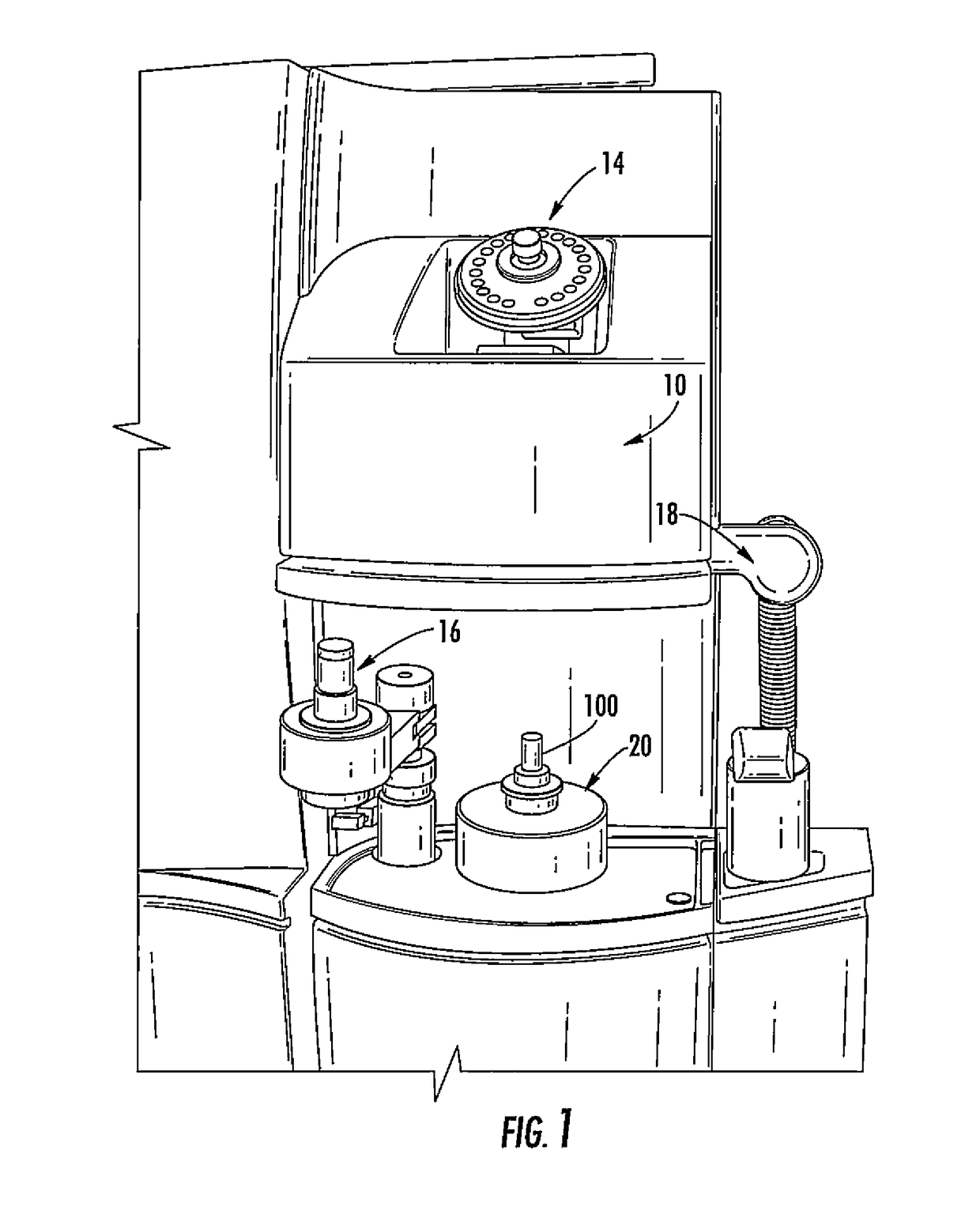

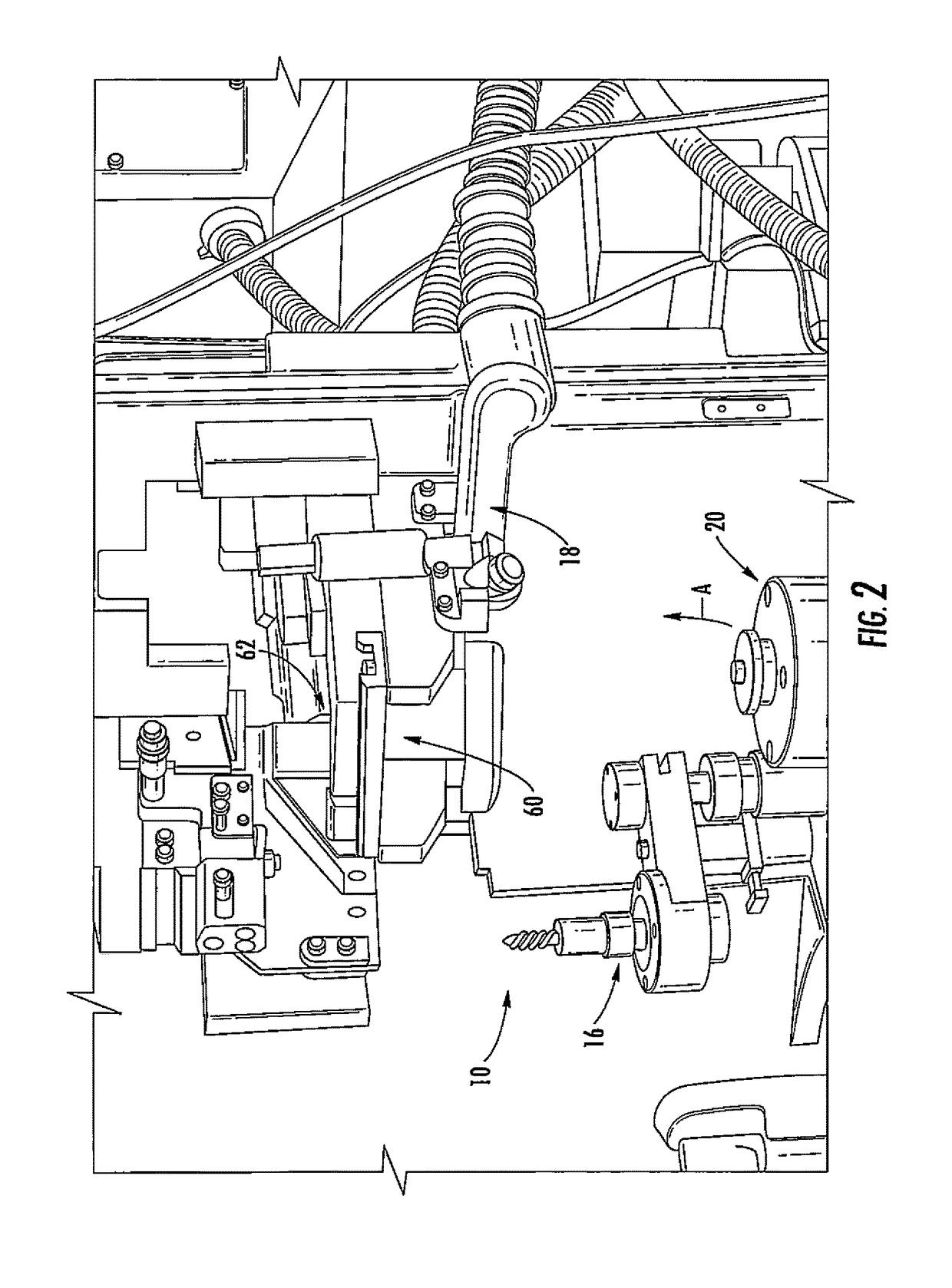

Automatic crucible and sample loading system and method

InactiveUS7402280B2Increase the number ofEliminate needCoin-freed apparatus detailsMaterial analysis by optical meansCombustionCrucible

A crucible and sample handling system and method provides a crucible-holding cartridge which is prepackaged to hold a plurality of crucibles. Upon removal of an end cap exposing an exit aperture, it is loaded onto a crucible delivery assembly which discharges individual crucibles from the cartridge onto a platform where a pick-and-place arm assembly places the crucible in a combustion furnace. Individual samples are dropped from stacked sample holding carousels onto a balance and, after weighing, are pneumatically drawn from the balance and introduced into the furnace and crucible for combustion.

Owner:LECO CORPORATION

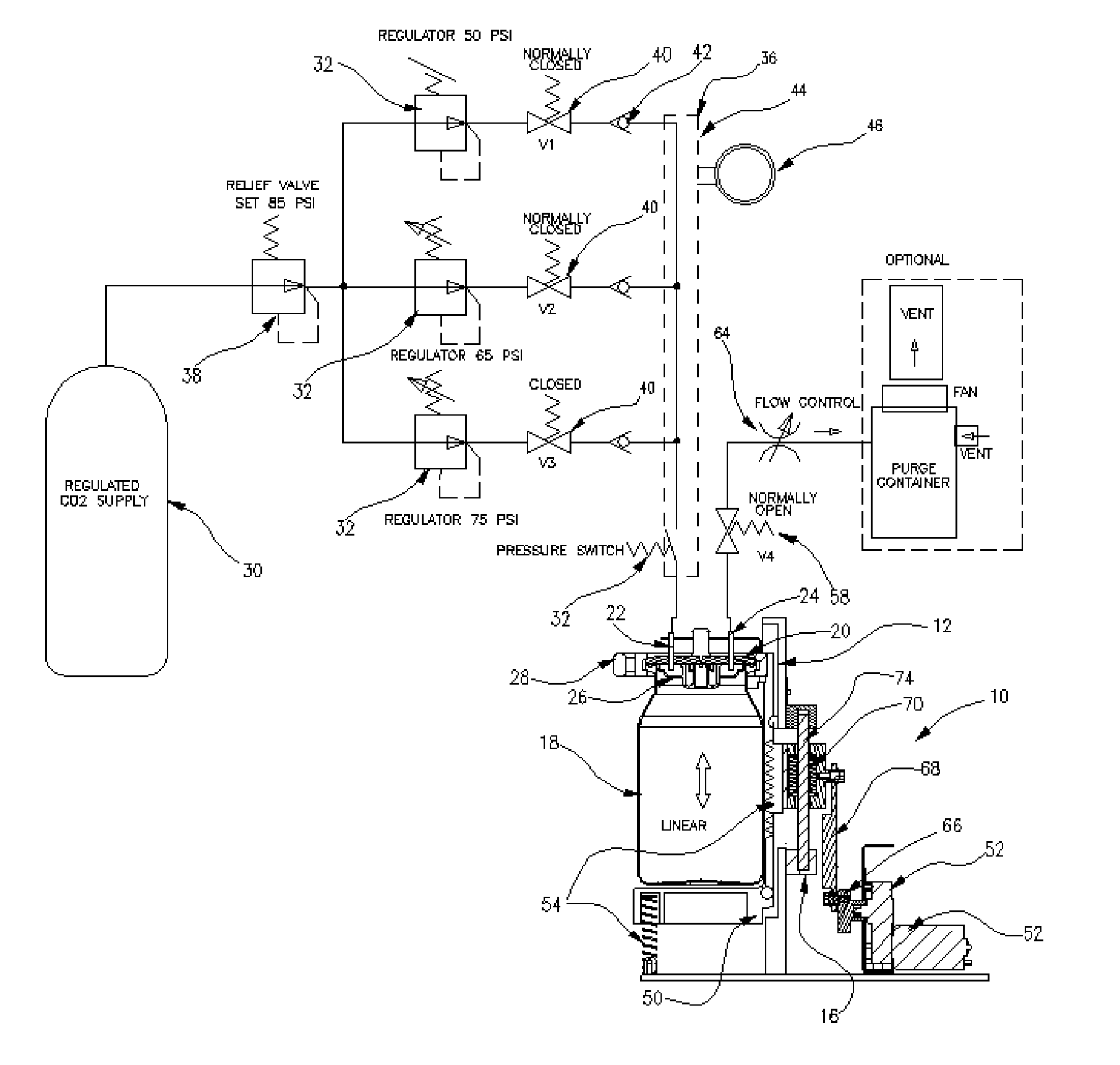

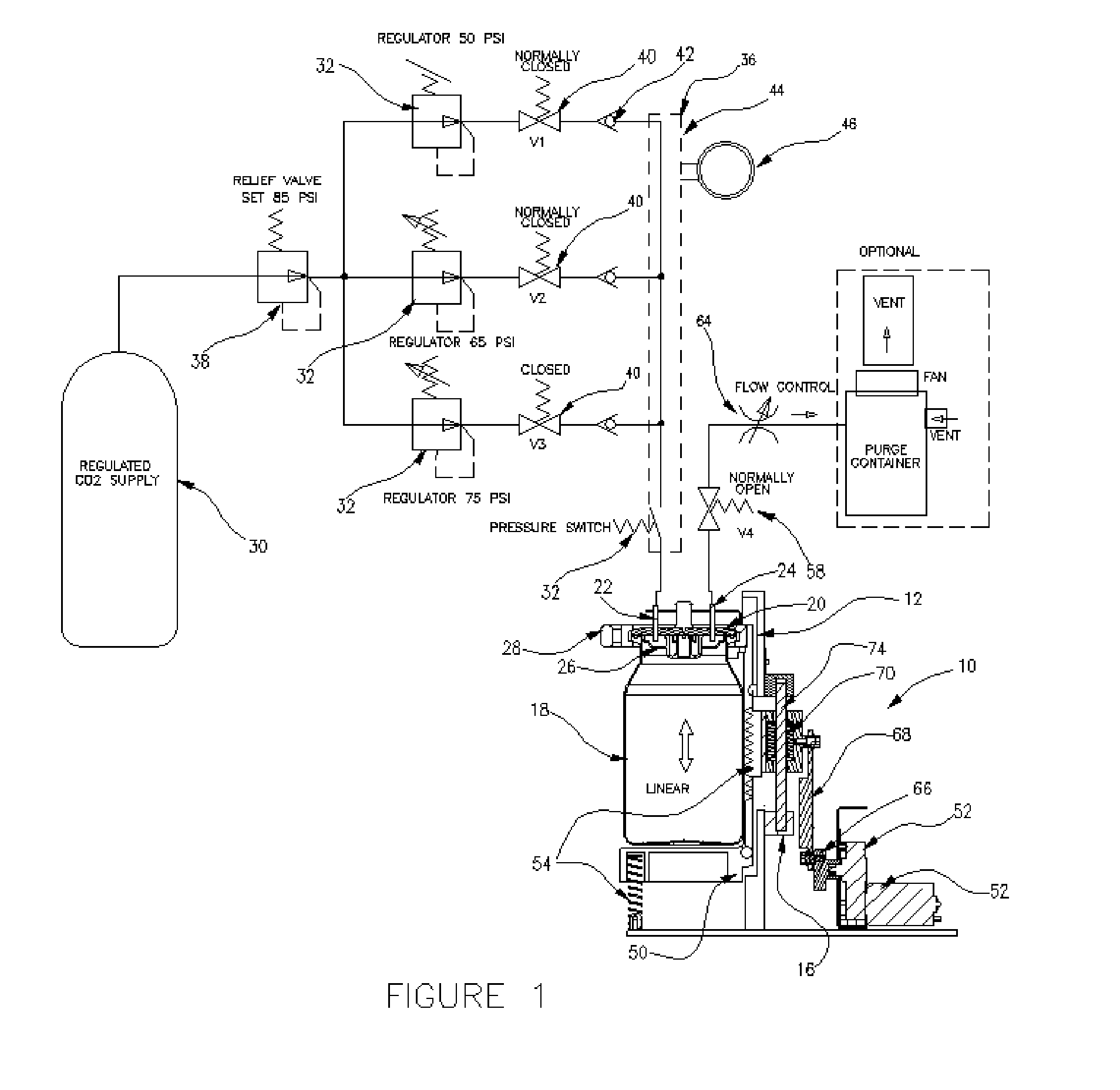

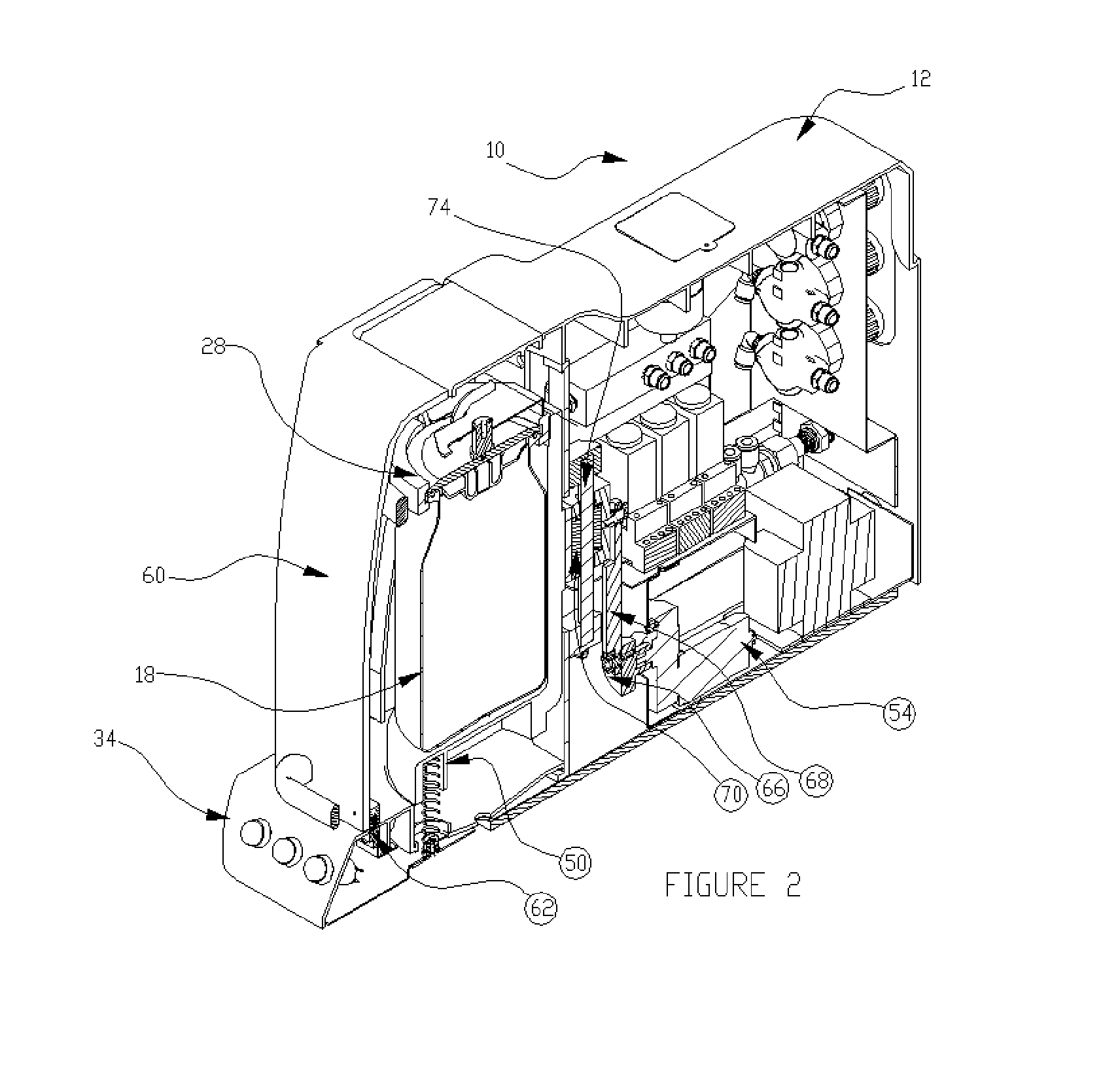

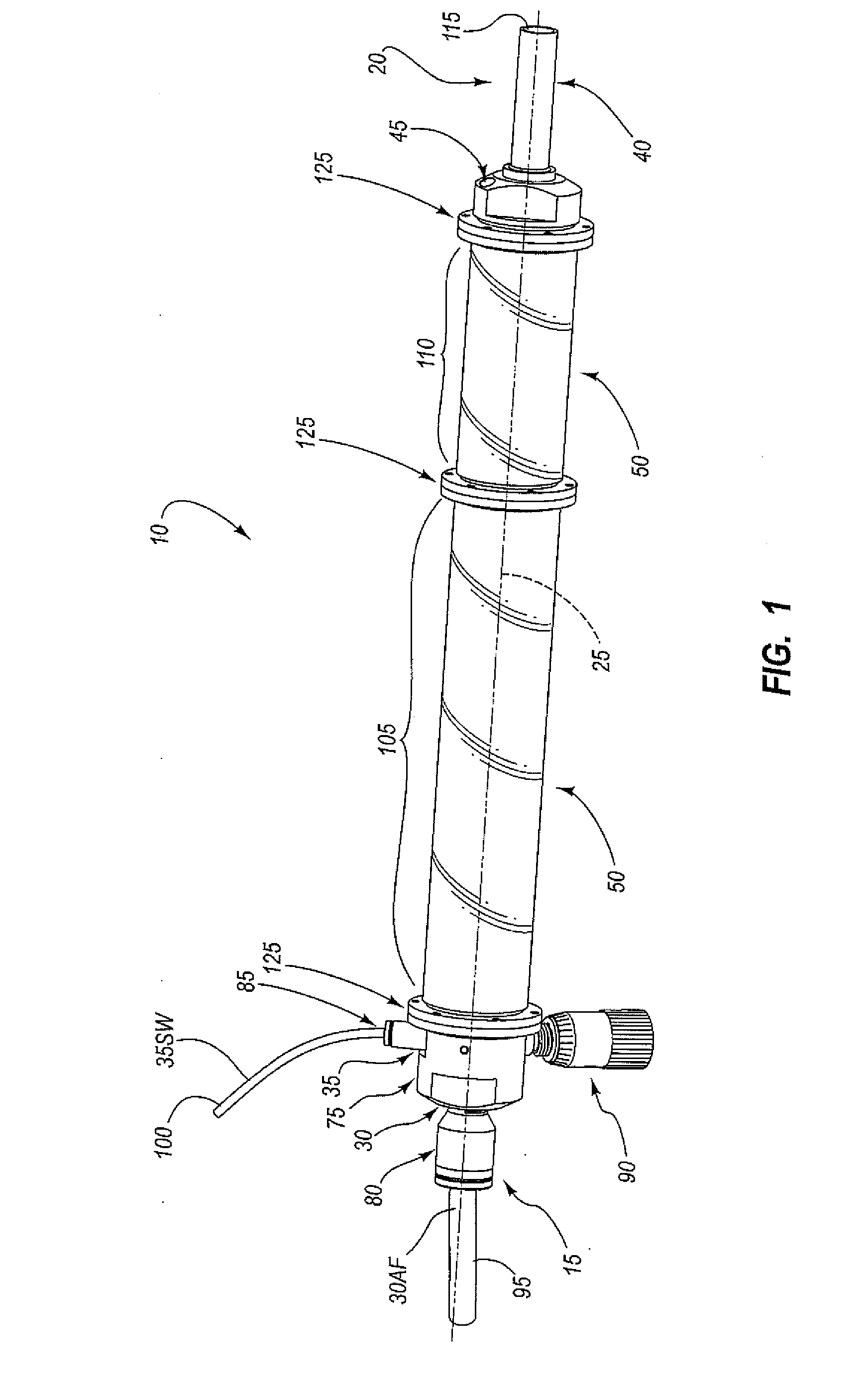

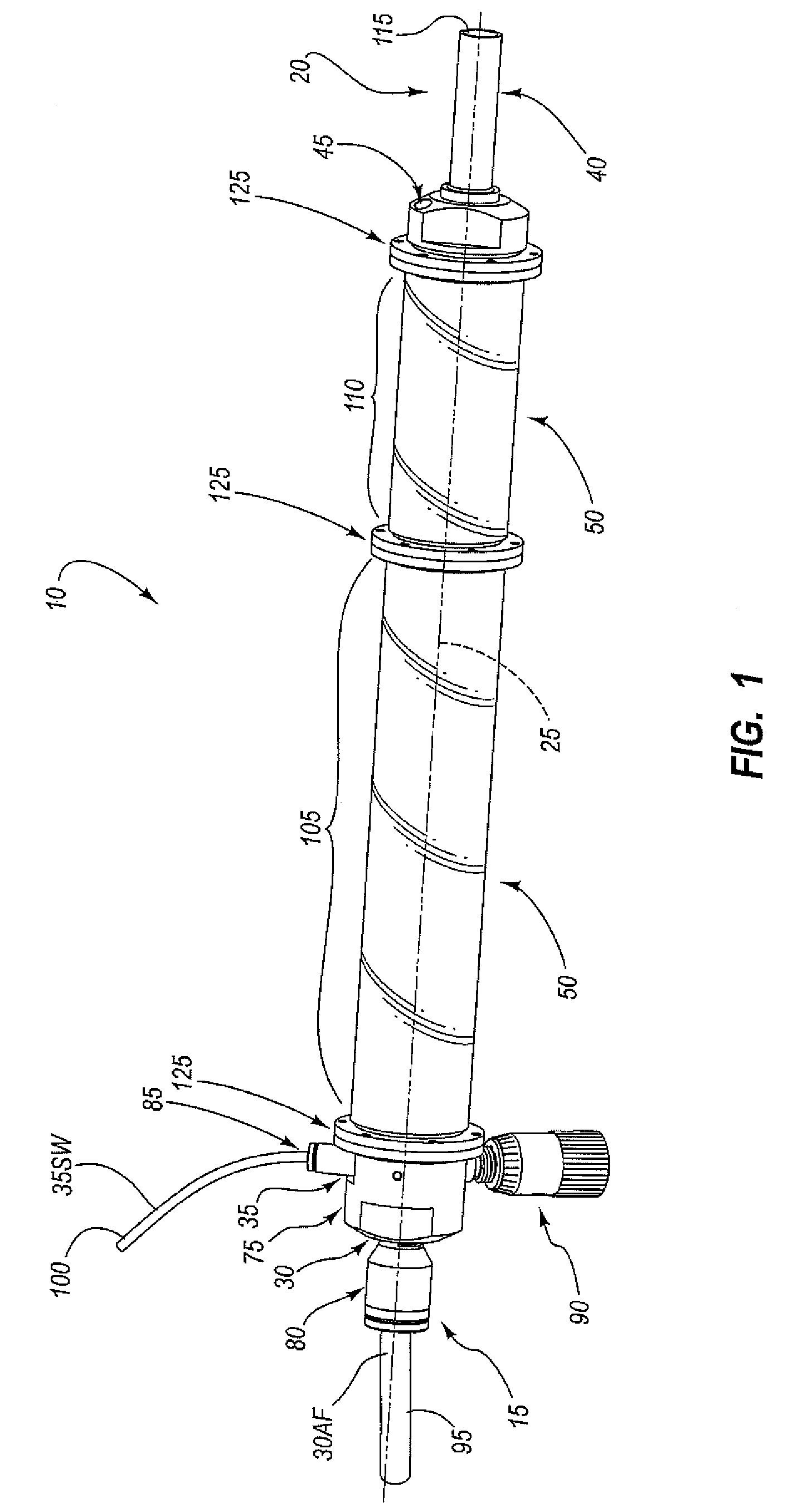

Batch carbonator and method of forming a carbonated beverage

InactiveUS9114368B2Shaking/oscillating/vibrating mixersTransportation and packagingLocking mechanismEngineering

A batch carbonation apparatus includes a housing defining a vessel cavity. The housing includes an agitation mechanism. The pressure vessel includes a cap that has a CO2 inlet and a CO2 outlet is provided. The pressure vessel also includes a seal. The pressure vessel is moveable into an out of the vessel cavity. A locking mechanism is provided and is attached to the agitation mechanism to removably lock the cap and seal relative to the pressure vessel. A CO2 source is connected to a plurality of valves where each valve has a differing pressure. A selection toggle is attached to the housing. A control mechanism is coupled to the plurality of valves. A user selects a desired carbonation level using the selection toggle and CO2 is introduced to the pressure vessel at a specified pressure wherein the agitation mechanism agitates liquid within the pressure vessel forming a carbonated beverage having a selected carbonation level. Also disclosed is a process of forming a carbonated beverage in a batch.

Owner:MARMON FOODSERVICE TECH INC

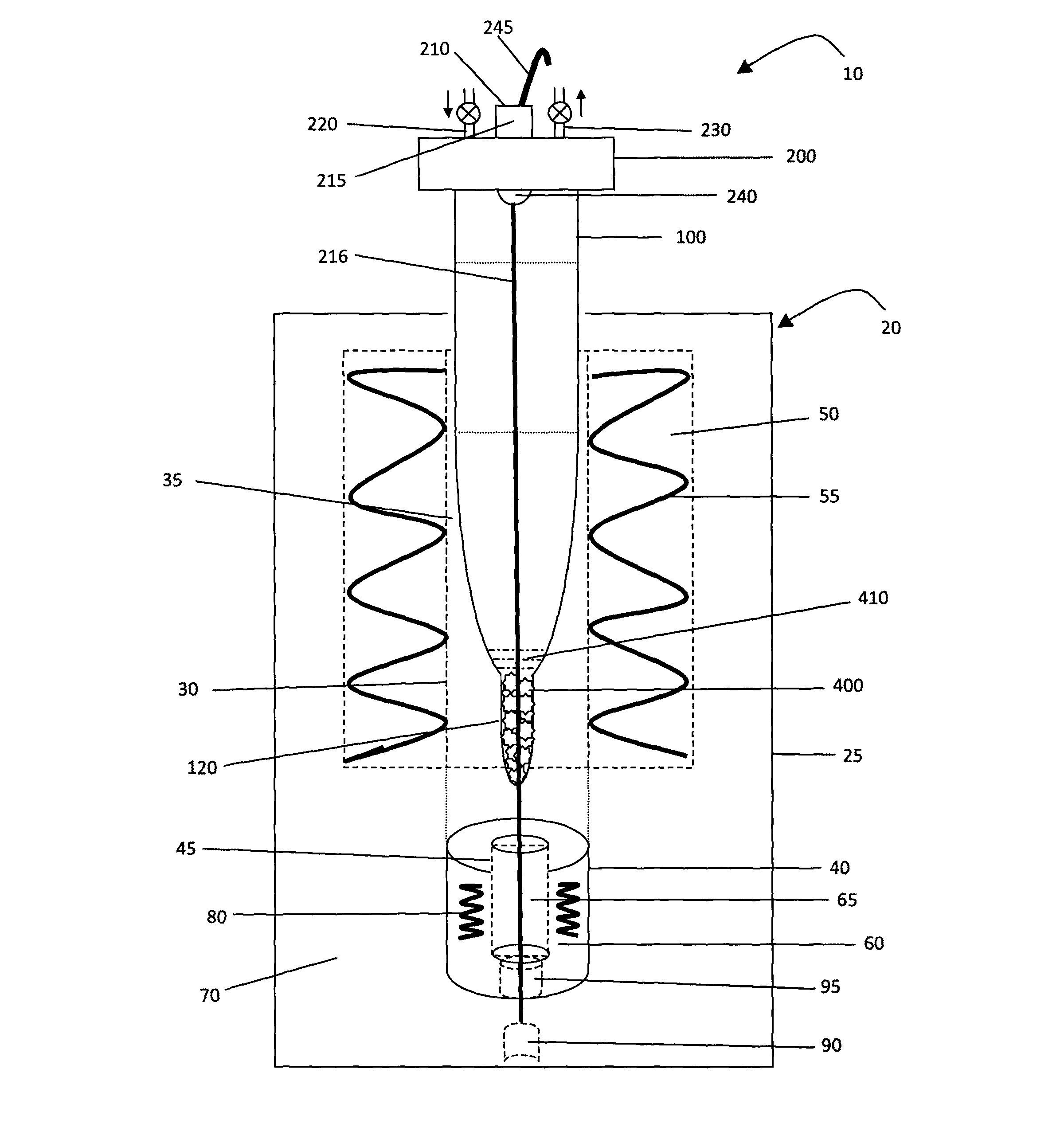

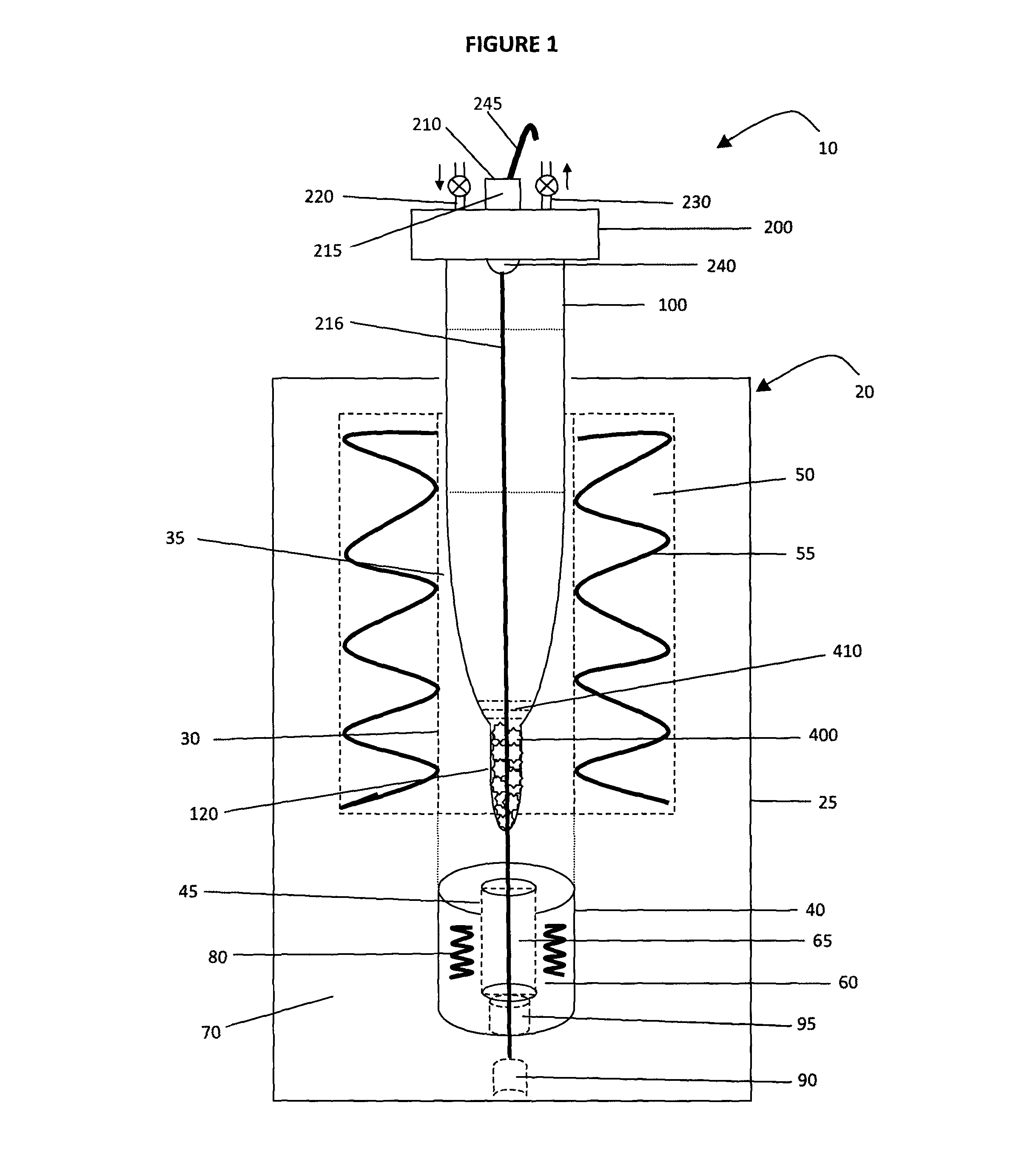

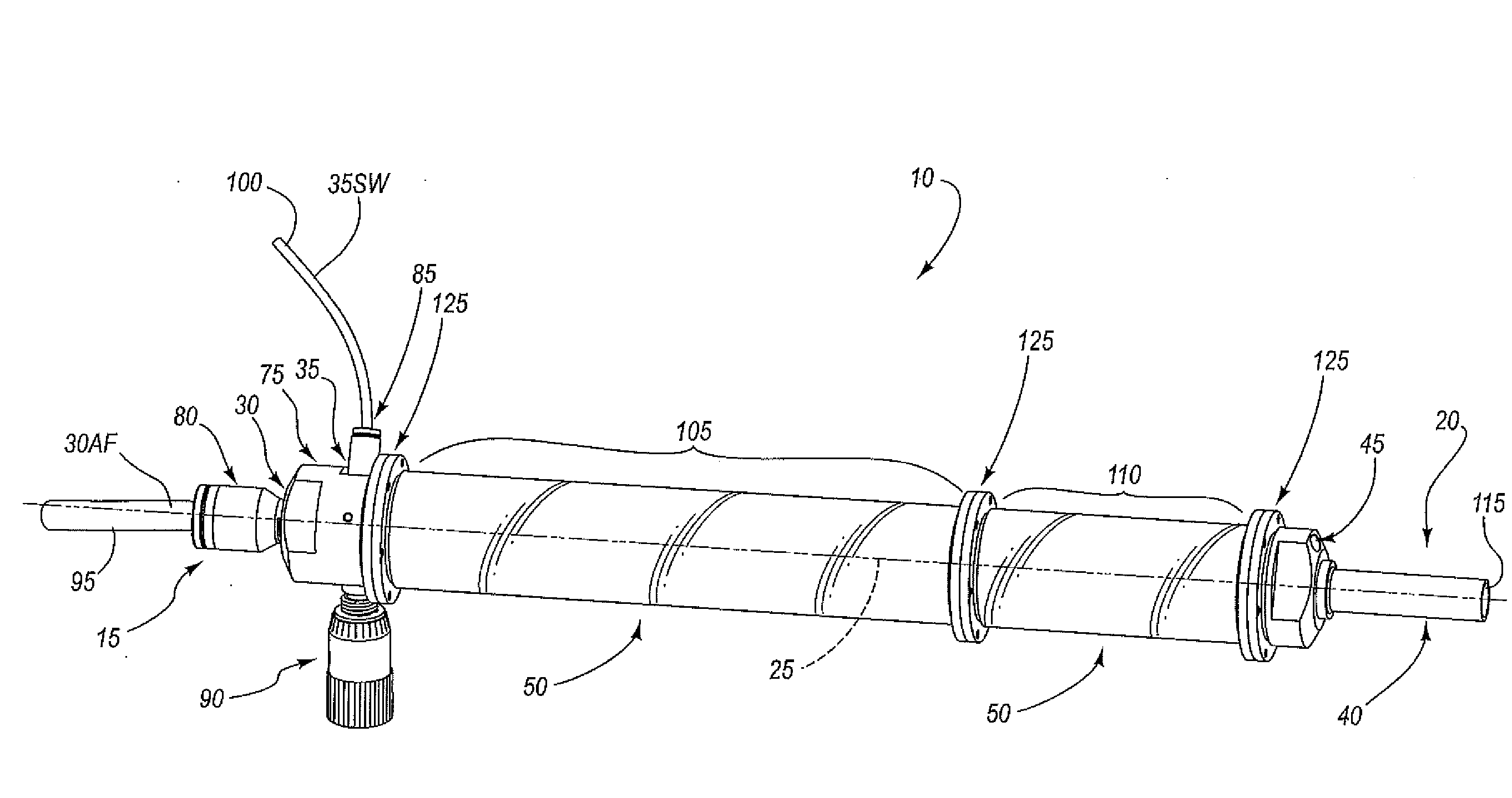

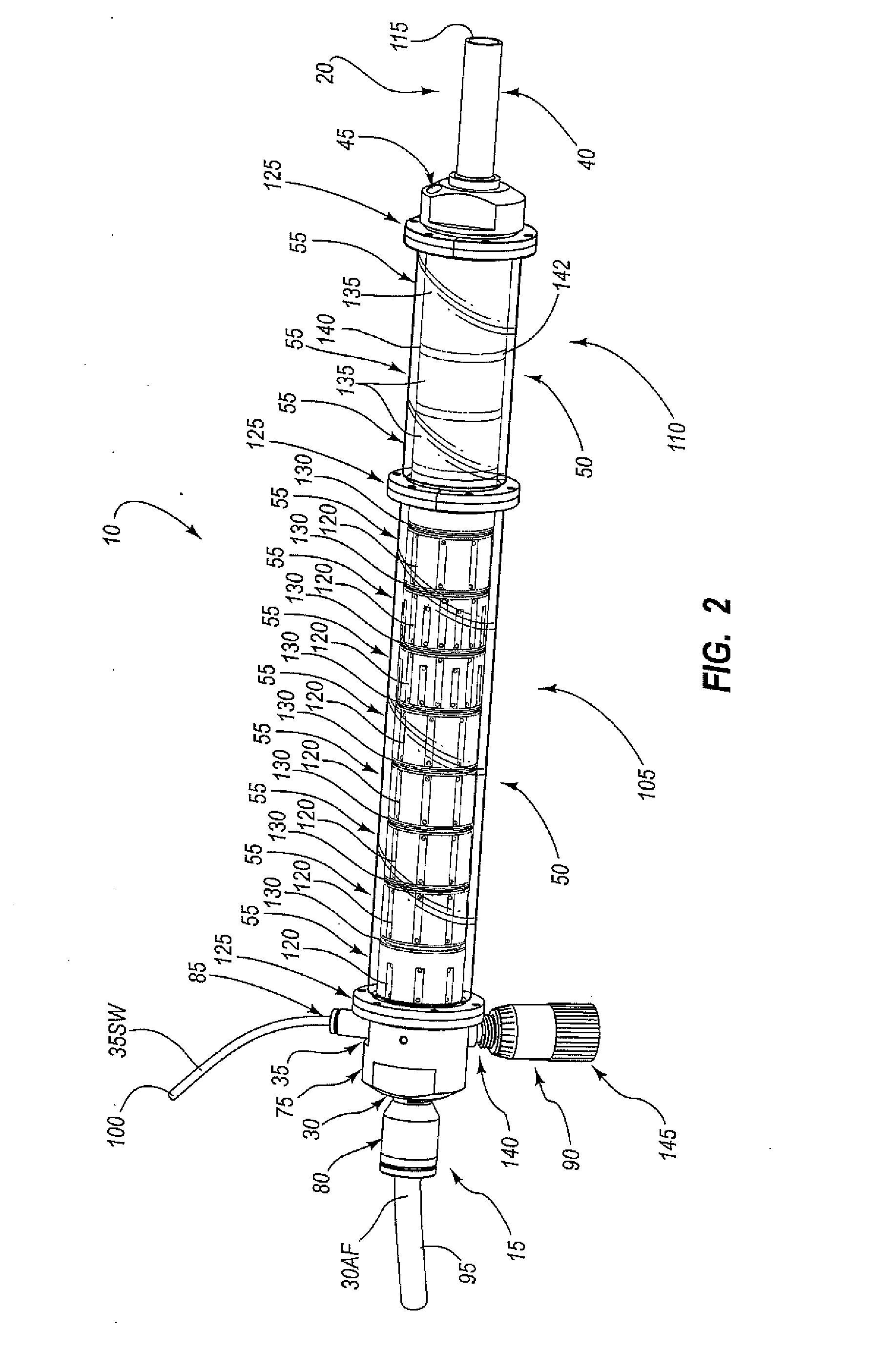

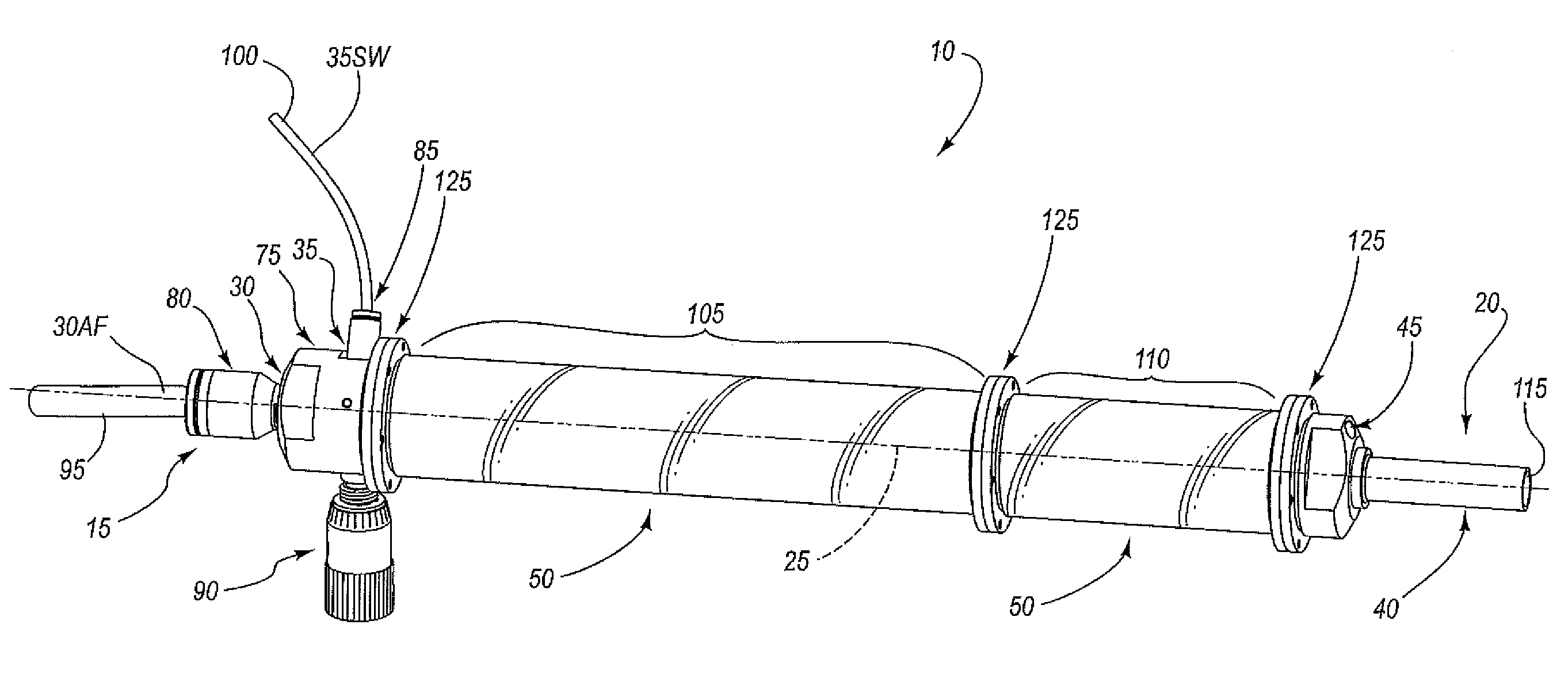

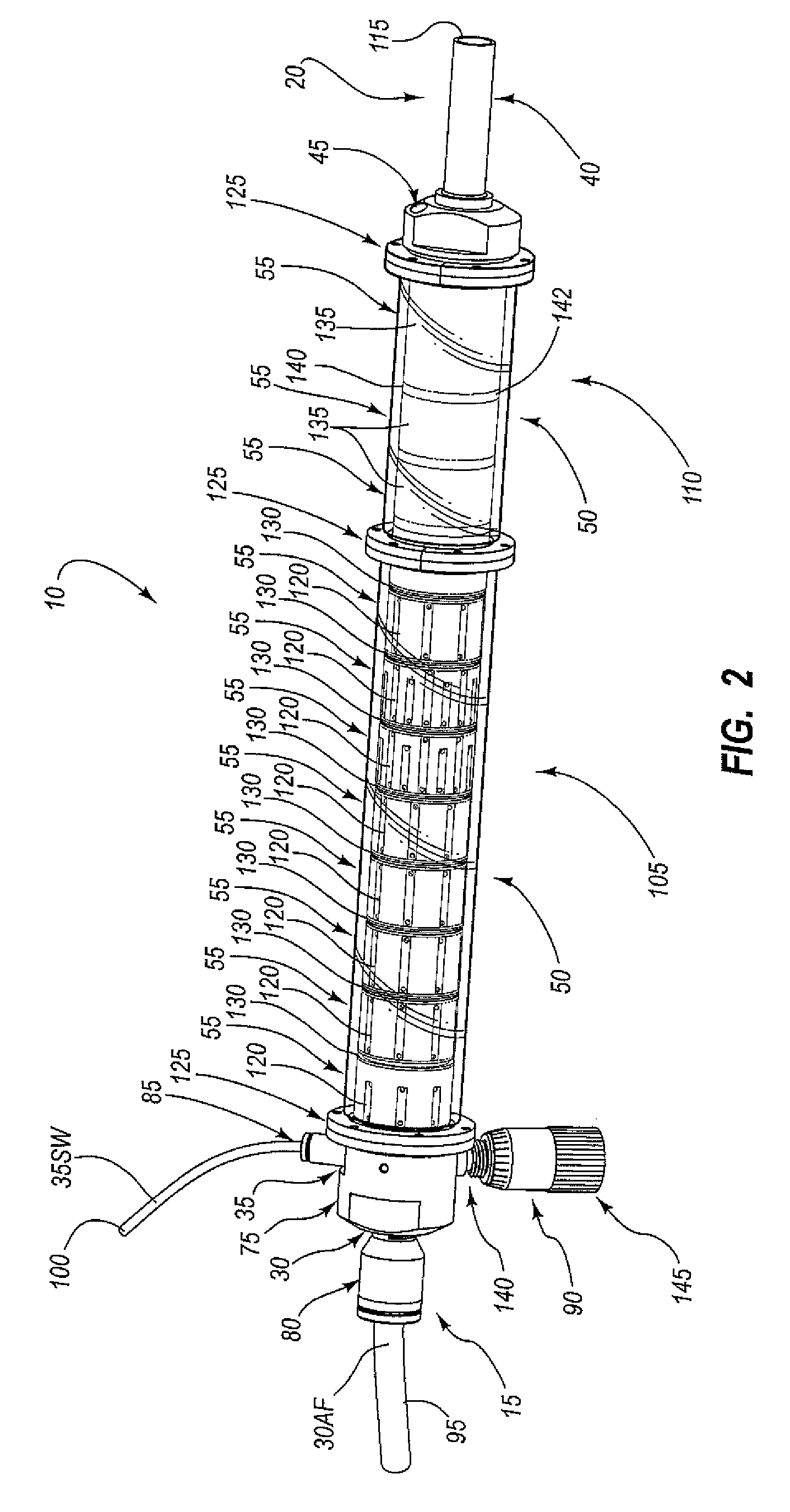

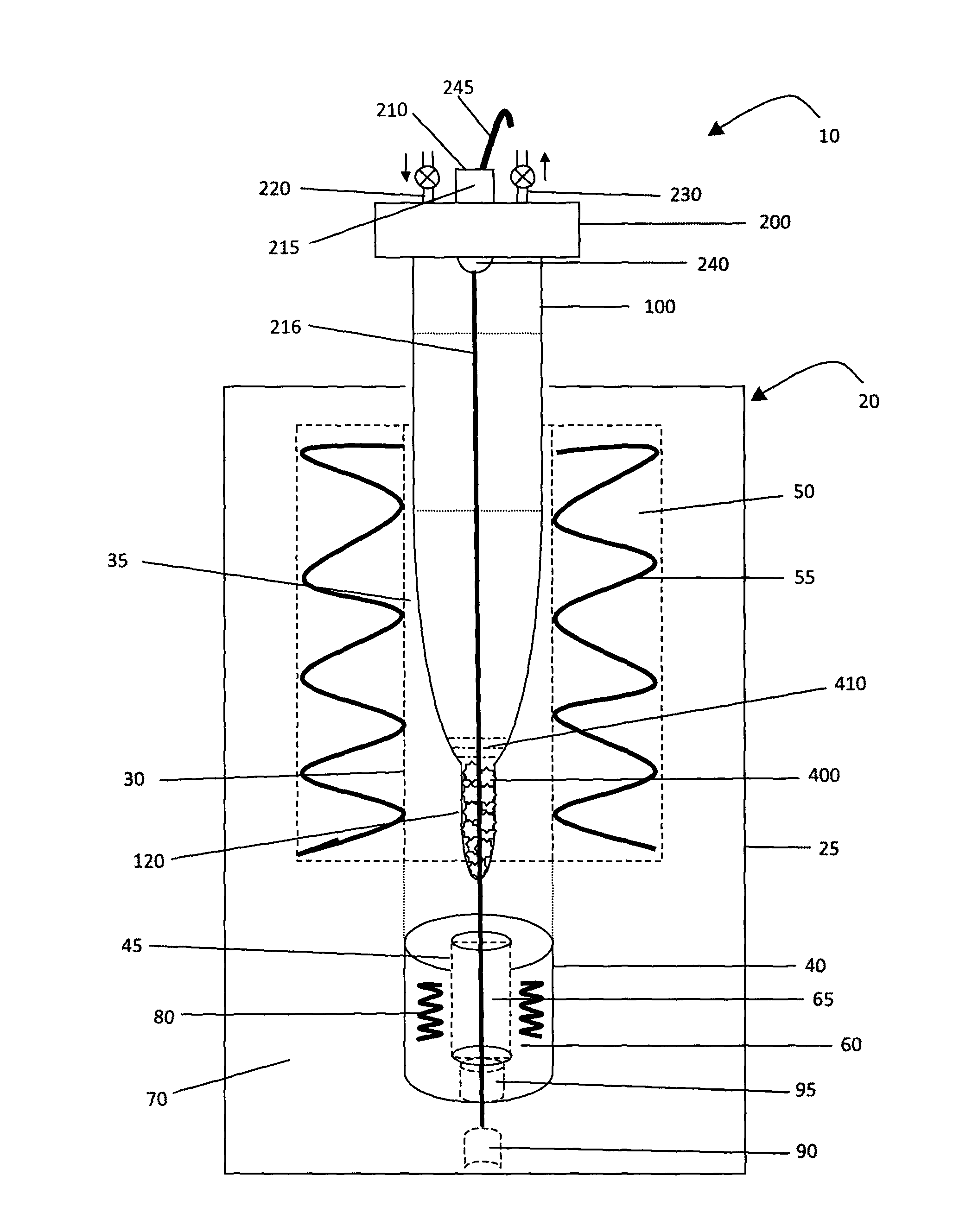

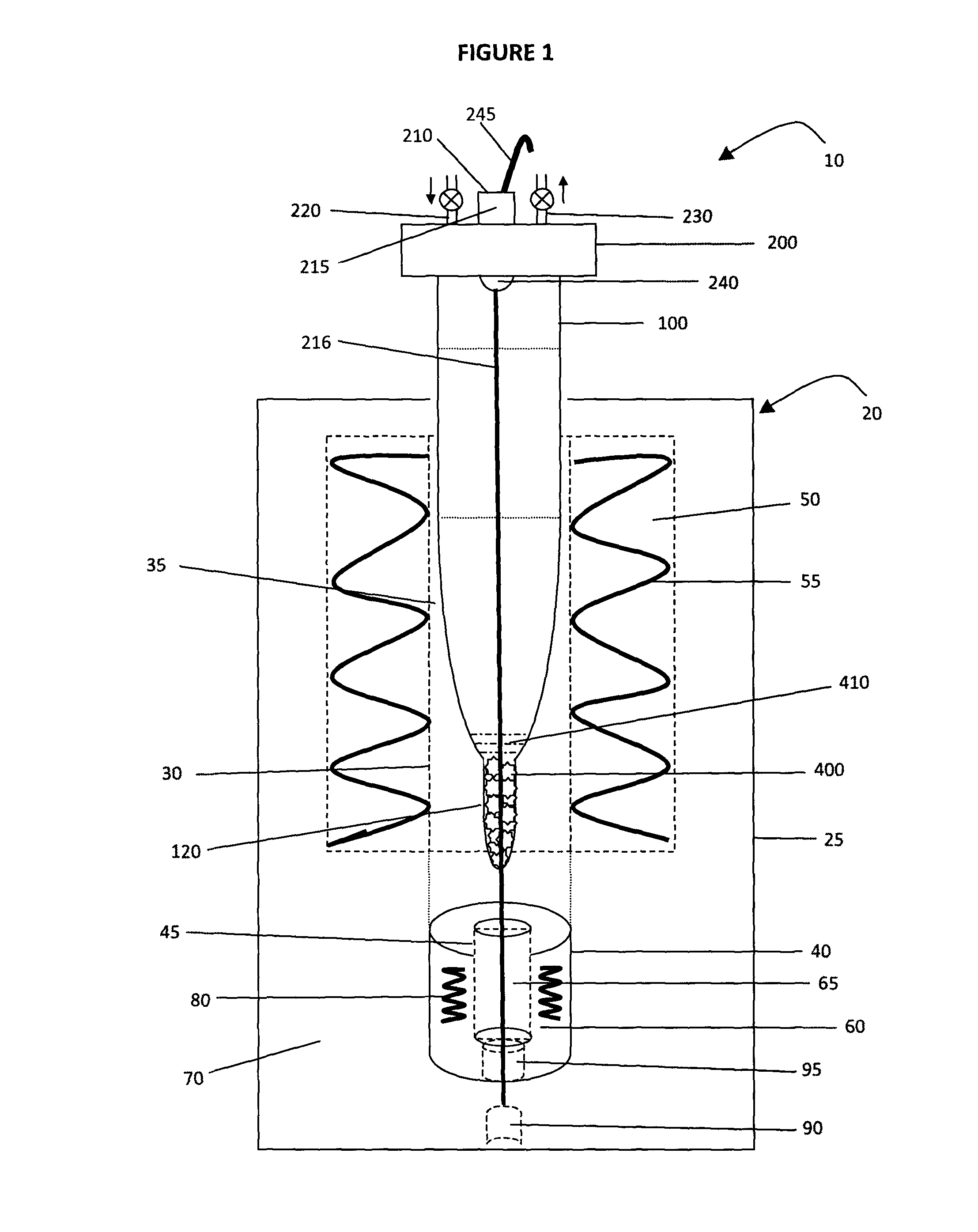

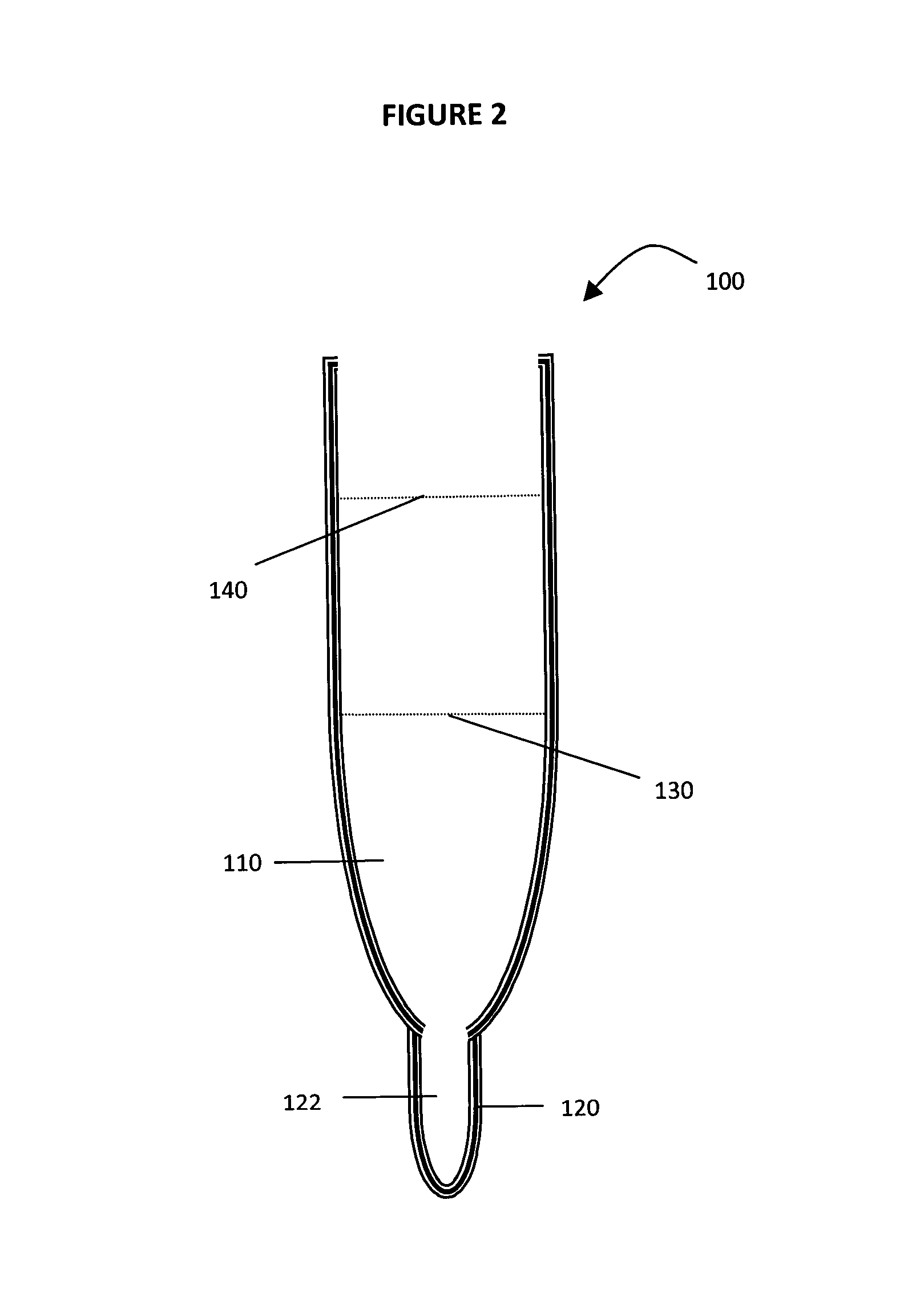

Systems and methods for preparing samples for chemical analysis

A system for preparing samples for chemical analysis comprises at least one sample container, and a container receptacle apparatus for receiving the sample container. The sample container comprises an elongate tubular body having a crucible portion proximal to a closed end for receiving a sample therein, and an expansion portion proximal to an open end. The container receptacle apparatus comprising a housing having a heating compartment, a cooling compartment spaced apart from the heating compartment, and an insulating region located between the heating compartment and the cooling compartment. The heating compartment is shaped to receive the crucible portion of the sample container, and the cooling compartment is shaped to receive the expansion portion of the sample container. The apparatus also includes a heating mechanism for heating the sample within the crucible portion of the sample container, and a cooling mechanism for cooling the expansion portion of the sample container.

Owner:COLDBLOCK TECH INC

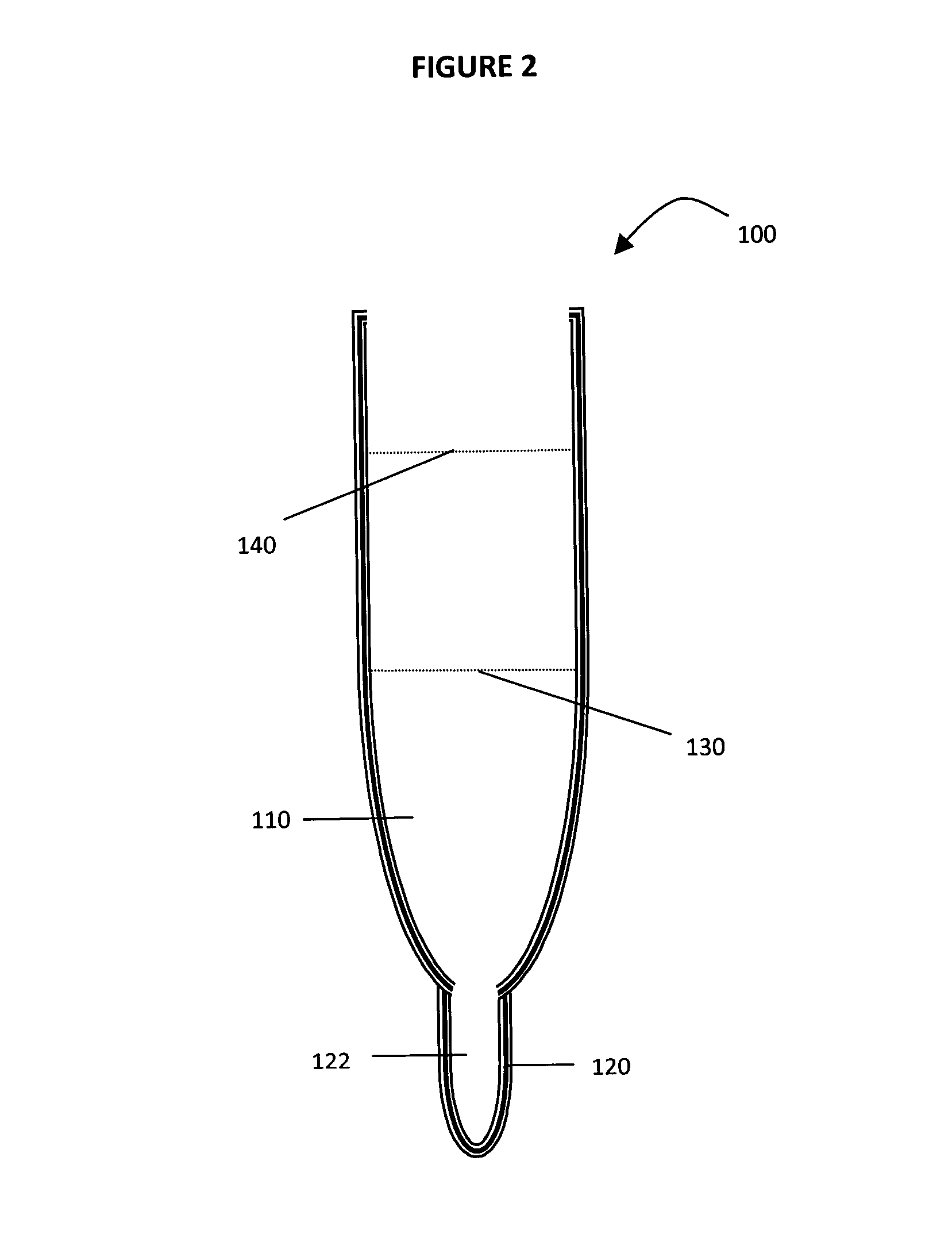

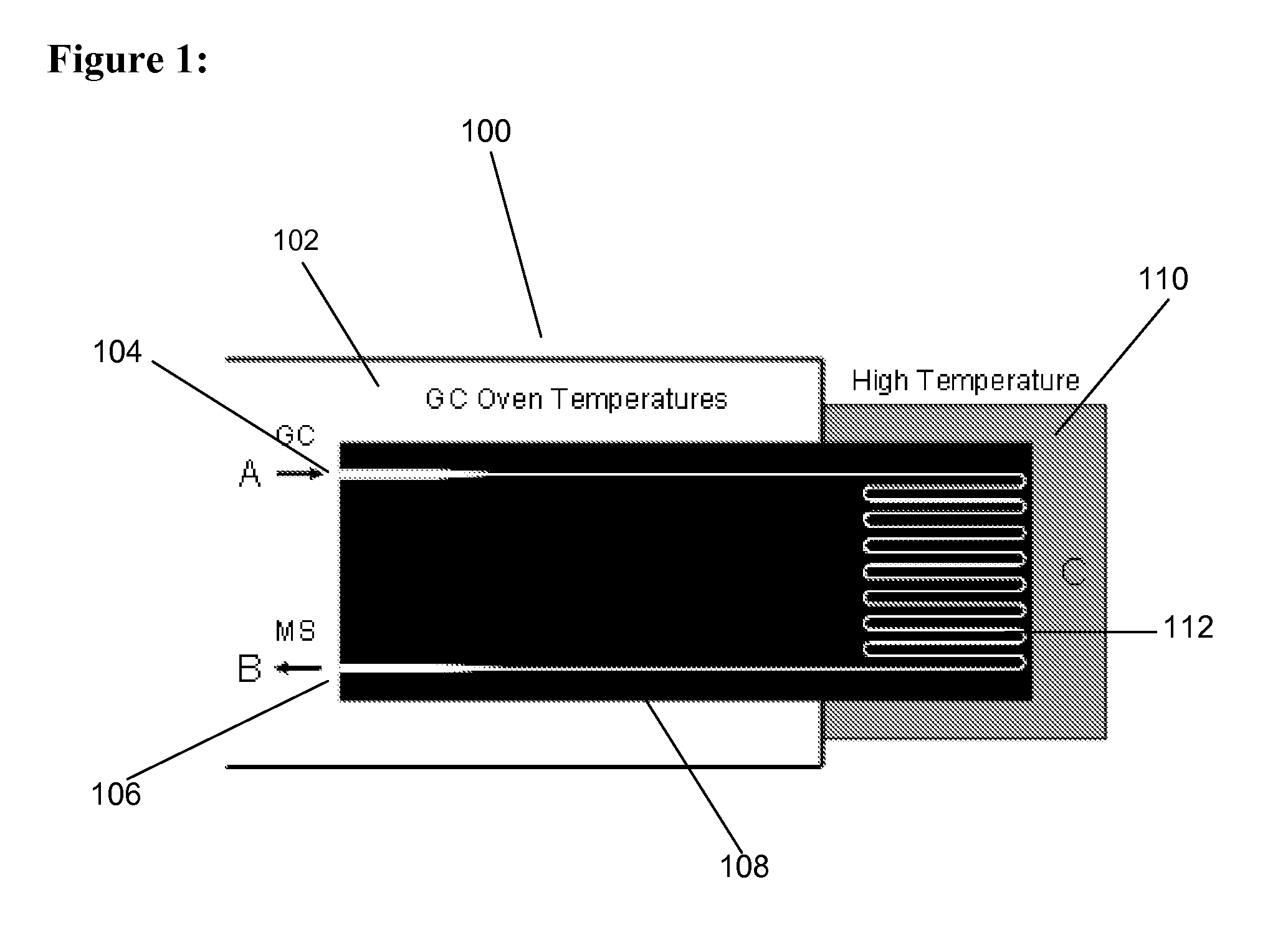

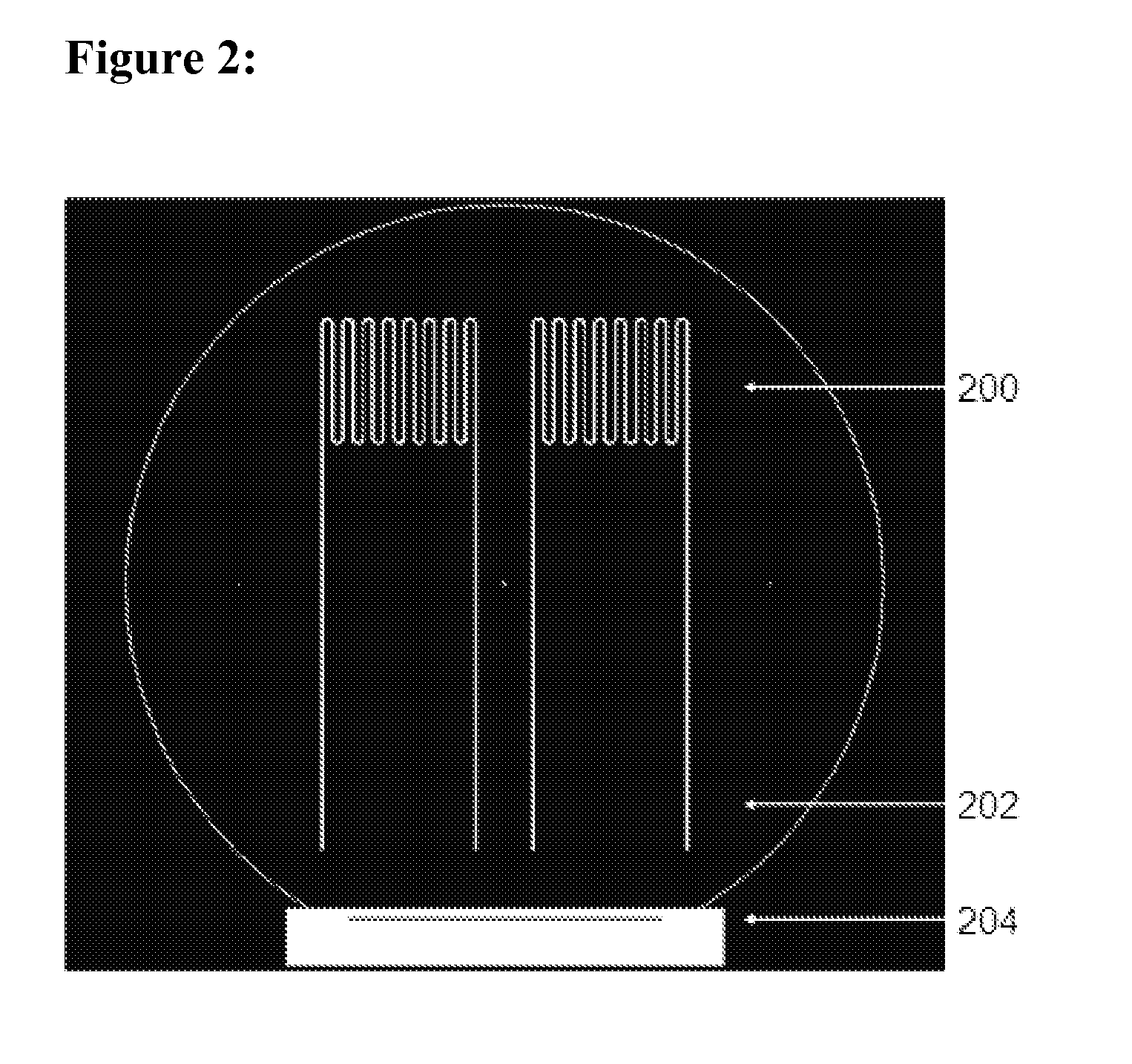

Microfabrication of high temperature microreactors

InactiveUS20120142118A1Stable isotopic compositional analysisGuaranteed uptimeHeating or cooling apparatusComponent separationMicroreactorMicrofabrication

Microreactors, methods of fabricating, and using such microreactors comprises a substrate having an outer periphery and composing two monolithic sections, each of said monolithic sections comprising two opposed main surfaces and one or more edges extending between the main opposed surfaces. One of the main surfaces from each of the monolithic sections are joined together at a substantially planar junction. The microreactor further comprises at least one microcapillary flow passage defined by surfaces within said substrate and having first and second ends. One or more inlets connect the outer periphery of said substrate with the first end of said microcapillary flow passage. One or more outlets connect the outer periphery of said substrate with the second end of said microcapillary flow passage, which may narrowingly taper. The substrate can be made from high purity fused silica. A metallic reagent and / or catalyst can be incorporated in the micro capillary passage.

Owner:CORNELL UNIVERSITY

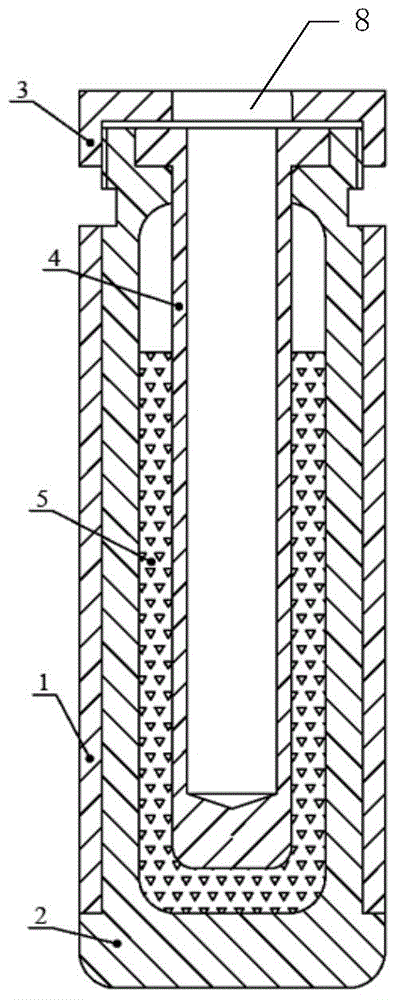

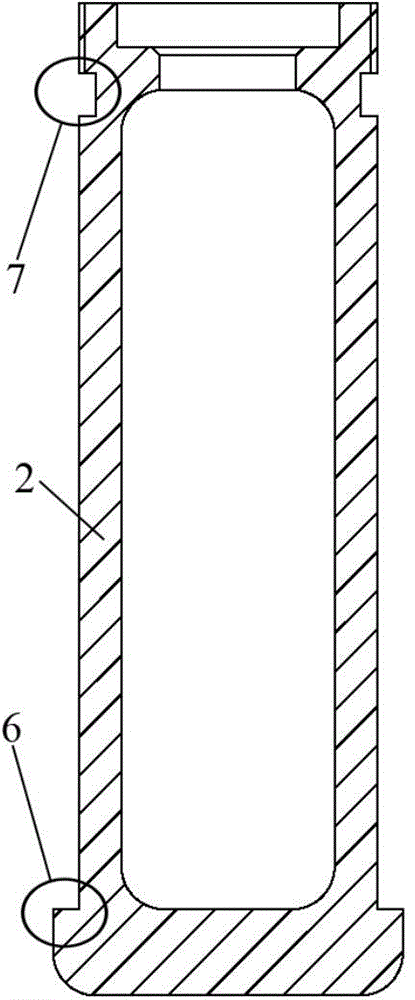

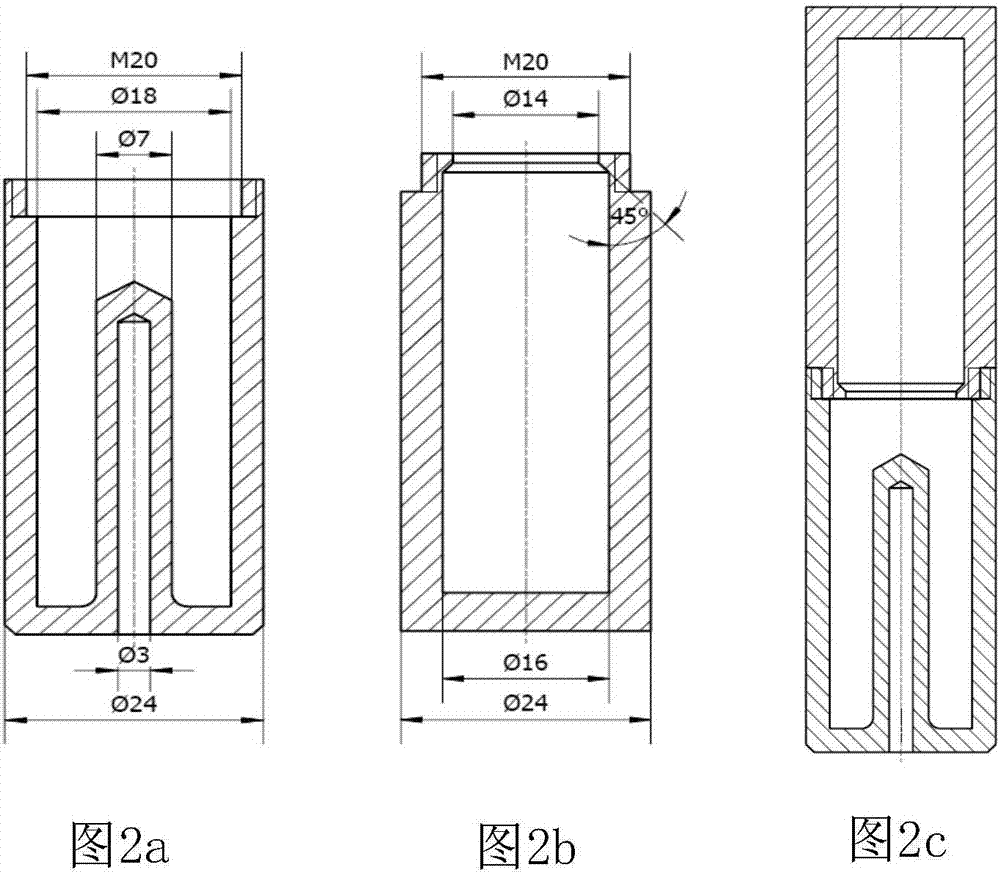

Crucible for reappearance of metal-carbon high-temperature eutectic point

The invention relates to a crucible for reappearance of a metal-carbon high-temperature eutectic point and belongs to the field of high-temperature thermocouple verification or verification. The crucible is made from graphite and mainly comprises a crucible housing, a crucible lining, a crucible upper cover and a thermometer well. A flange is arranged at the bottom of the crucible lining, and the crucible lining can be directly sleeved with the crucible housing which is located above the flange, so that the mounting is convenient during use. The crucible housing prevents the phenomenon that the crucible lining cracks when the crucible is used at a high temperature so that a metal-carbon eutectic substance flows out, thereby playing a dual protection effect. Meanwhile, when the crucible lining deforms at a high temperature, the bottom of the crucible lining is not restrained by the crucible housing any more, thermal stress is reduced, and the reliability in use of the whole crucible is increased.

Owner:BEIJING CHANGCHENG INST OF METROLOGY & MEASUREMENT AVIATION IND CORP OF CHINA

Method and apparatus for multiple sample preparation and simultaneous loss of ignition/gain on ignition analysis, for use in X-ray fluorescence spectrometry

ActiveUS9377419B2Good reproducibilityHuge savingsWeighing by removing componentShaking/oscillating/vibrating mixersEngineeringSample plane

The analyzer mixes the material to be analyzed and the flux in sample holders supported by a movable platform within the furnace. A tilt member is provided having multiple stations. Each station has an upstanding pin offset from the center point of the station in a different direction. The platform is indexed relative to the tilt member such that the sample holder aligns with each station, in sequence. As the sample holder aligns with each station, the platform is moved toward the tilt member such that the pin of the aligned station abuts and tilts the sample holder in a different direction. The repeated tilting of the sample holder in different directions mixes the material and flux. The contents of the sample holder may also be agitated by rapidly moving the platform back and forth with sudden stops. The analyzer can be used with a special sample holder.

Owner:LAS NAVAS GARCIA JOSE MARIA

Desalinization apparatus and method

There is disclosed a desalinization apparatus, and methods related to desalinization. In an embodiment, a desalinization apparatus includes at least one port for receiving airflow therethrough, at least one port for receiving salt water therethrough, at least one output for providing outflow of pure water vapor, and at least one output for proving outflow of a mixture of water, salt and air; and a plurality of chambers for evaporating the salt water into the airflow, at least one of the chambers forming a plurality of ports arranged in a plurality of rows. In an embodiment, a method includes providing airflow to a desalinization apparatus; providing salt water to the desalinization apparatus; forming a vortex in the airflow to evaporate water vapor from the salt water; and providing the water vapor in the airflow to a condenser so as to obtain pure water.

Owner:LYTESYDE LLC

A graphite crucible for manufacturing c/sic ceramic matrix composite brake discs

The invention relates to a graphite crucible for manufacturing brake disks of C / SiC ceramic matrix composite materials. The graphite crucible comprises a graphite crucible body, on which evenly distributed small holes are opened, the inner wall of the graphite crucible is coated with a boron nitride (BN) coating, and the boron nitride (BN) coating is laid There is graphite paper. The graphite crucible of the invention has a long service life, and the material is easy to clean up during use, so that the temperature uniformity in the high-temperature vacuum furnace can be improved. The graphite crucible of the invention can also be used in the preparation of other ceramic matrix composite materials by the reactive melt infiltration method.

Owner:NORTHWESTERN POLYTECHNICAL UNIV

Method and apparatus for multiple sample preparation and simultaneous loss of ignition/gain on ignition analysis, for use in x-ray fluorescence spectrometry

ActiveUS20140161150A1Good reproducibilityHuge savingsMaterial analysis using wave/particle radiationShaking/oscillating/vibrating mixersEngineeringElectrical and Electronics engineering

The analyzer mixes the material to be analyzed and the flux in sample holders supported by a movable platform within the furnace. A tilt member is provided having multiple stations. Each station has an upstanding pin offset from the center point of the station in a different direction. The platform is indexed relative to the tilt member such that the sample holder aligns with each station, in sequence. As the sample holder aligns with each station, the platform is moved toward the tilt member such that the pin of the aligned station abuts and tilts the sample holder in a different direction. The repeated tilting of the sample holder in different directions mixes the material and flux. The contents of the sample holder may also be agitated by rapidly moving the platform back and forth with sudden stops. The analyzer can be used with a special sample holder.

Owner:LAS NAVAS GARCIA JOSE MARIA

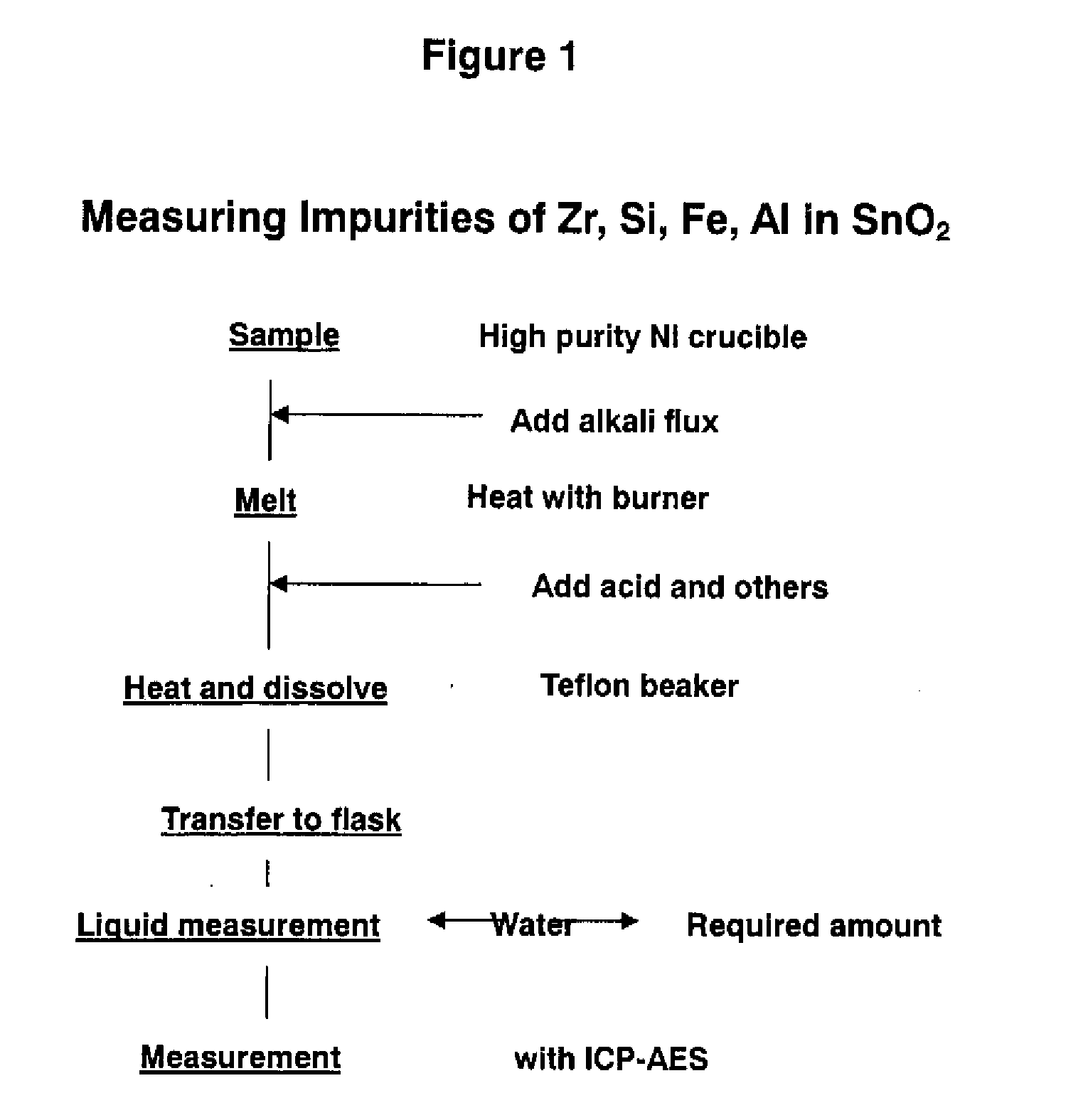

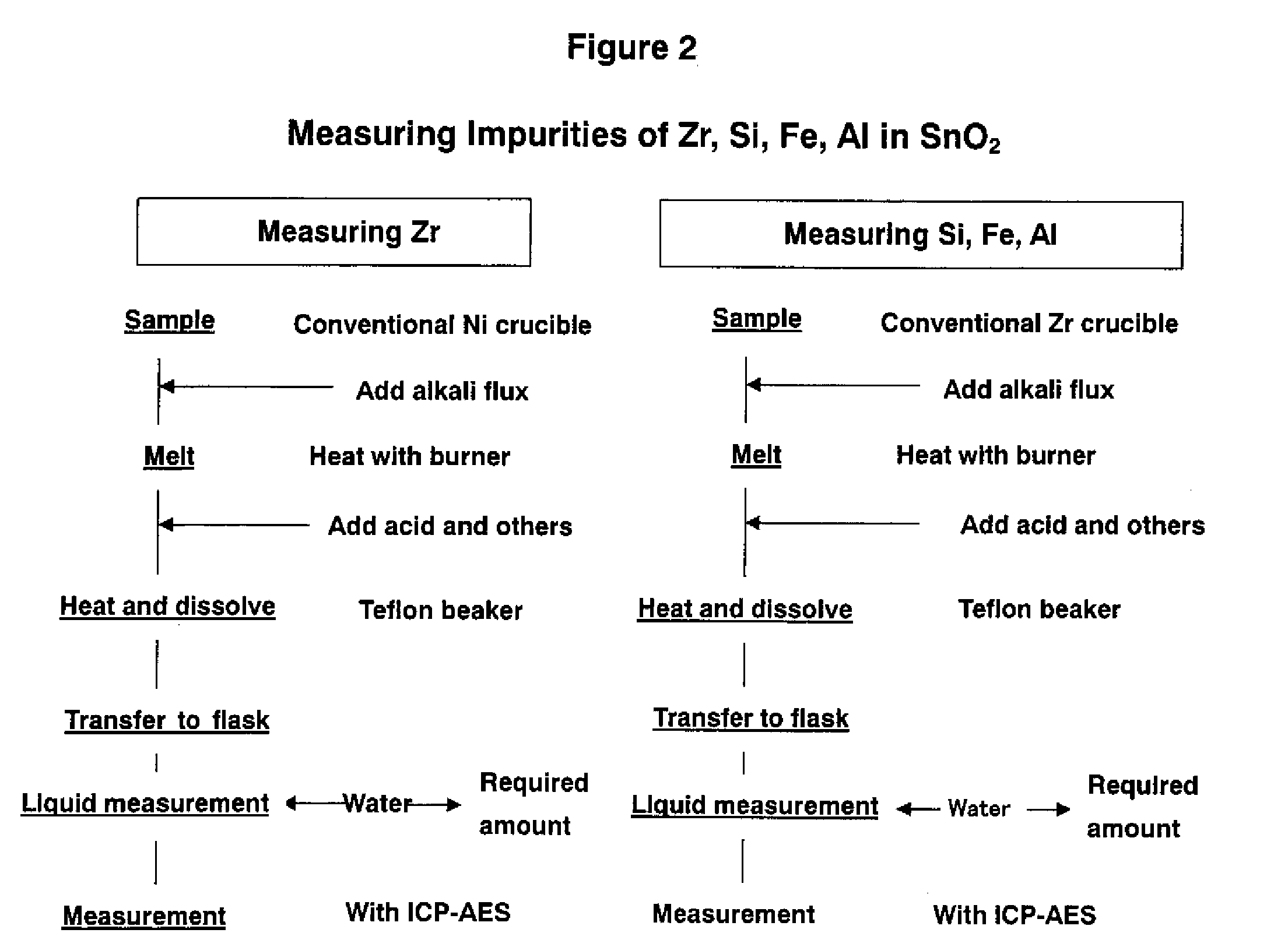

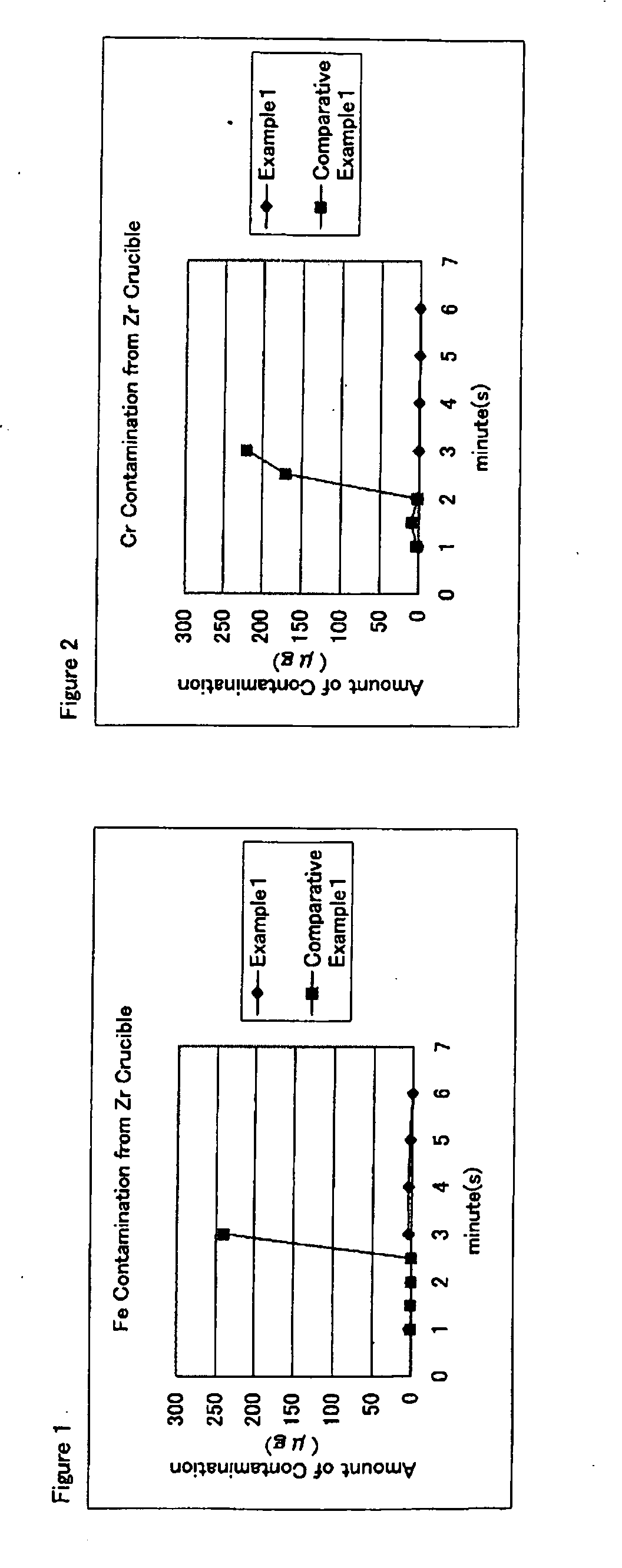

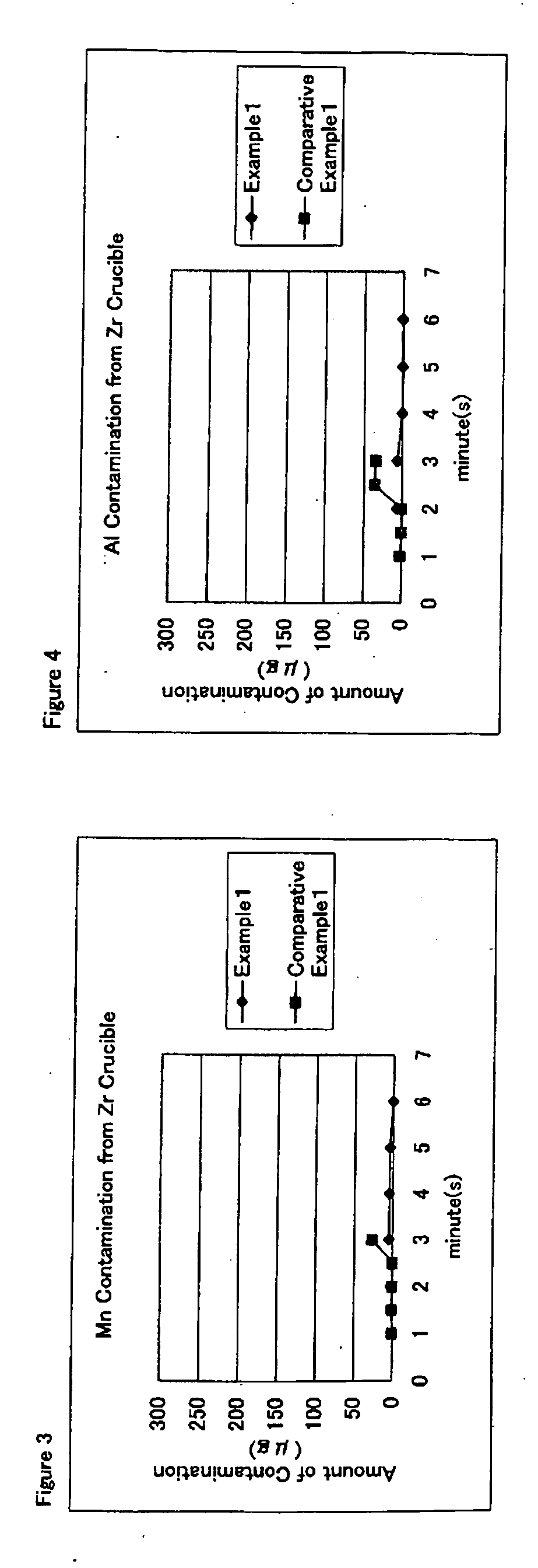

Zirconium Crucible

ActiveUS20090053112A1Save labor timeReduce the amount requiredPigmenting treatmentAnalysis using chemical indicatorsCrucibleImpurity

In light of the recent analytical technology demanded of fast and accurate measurement of high purity materials, a zirconium crucible is provided for melting an analytical sample and is capable of inhibiting the inclusion of impurities from the crucible by using a high-purity crucible, improving the durability of high-purity zirconium as an expensive crucible material, and increasing the number of times that the zirconium crucible can be used. With this zirconium crucible used for melting an analytical sample in the pretreatment of the analytical sample, the purity excluding gas components is 3N or higher, and the content of carbon as a gas component is 100 mass ppm or less.

Owner:JX NIPPON MINING& METALS CORP

Ceramic crucible for microwave heating molten metal

InactiveCN101261077AZirconium oxygen bond strengthPrevent immersionCrucible furnacesCruciblesMicrowaveCrucible

The invention provides a ceramic copple for microwave heating and melting metal, belonging to the advanced ceramic technical field. The copple adopts the sub-micron and the micro-sized stabilized zirconia powder to form certain grain composition; the component of La-monazite is added, the pulp is made by the ball milling and mixing and the copple shape is formed by grunting and is baked at a temperature of 1600 to 1700 DEG C. The copple has the advantages of heat resistance performance, heat insulation performance and resistance to heat shocks, is not stuck with high temperature molten metal and has the function of microwave absorption.

Owner:TIANJIN UNIV

Composite molybdenum crucible, and preparation method and application thereof

InactiveCN109321870AUniform microstructureReduce corrosionSolid state diffusion coatingCruciblesElectrolysisRare earth

The invention discloses a composite molybdenum crucible, and a preparation method and an application thereof, and belongs to the field of refractory metal product manufacturing. The composite molybdenum crucible is composed of a substrate molybdenum crucible and a molybdenum carbide coating on the surface of the substrate molybdenum crucible, and the outside surface and / or the inside surface of the composite molybdenum crucible is the molybdenum carbide coating. The surface of the composite molybdenum crucible is provided with the compact molybdenum carbide coating generated through in-situ reaction, and the composite molybdenum crucible not only reserves the characteristics that molybdenum is high in strength and is not liable to break at high temperature, but also has the characteristicsthat the high temperature chemical properties of the composite molybdenum are stable and the high temperature corrosion resistance is high. The composite molybdenum crucible is applicable for rare earth metal or alloy with a molten salt electrolysis preparation method, and the service life of the crucible can be prolonged greatly; precious molybdenum resources are saved, and the product quality of the rare earth metal or alloy is improved; and the production cost can be further reduced. The composite molybdenum crucible has the advantages of simple preparation technology, easy control over the thickness of the molybdenum carbide coating, high density of the molybdenum carbide coating, high binding strength with a substrate, high thermal shock resistance, the stable structure and low preparation cost.

Owner:ZHUZHOU HARD ALLOY GRP CO LTD

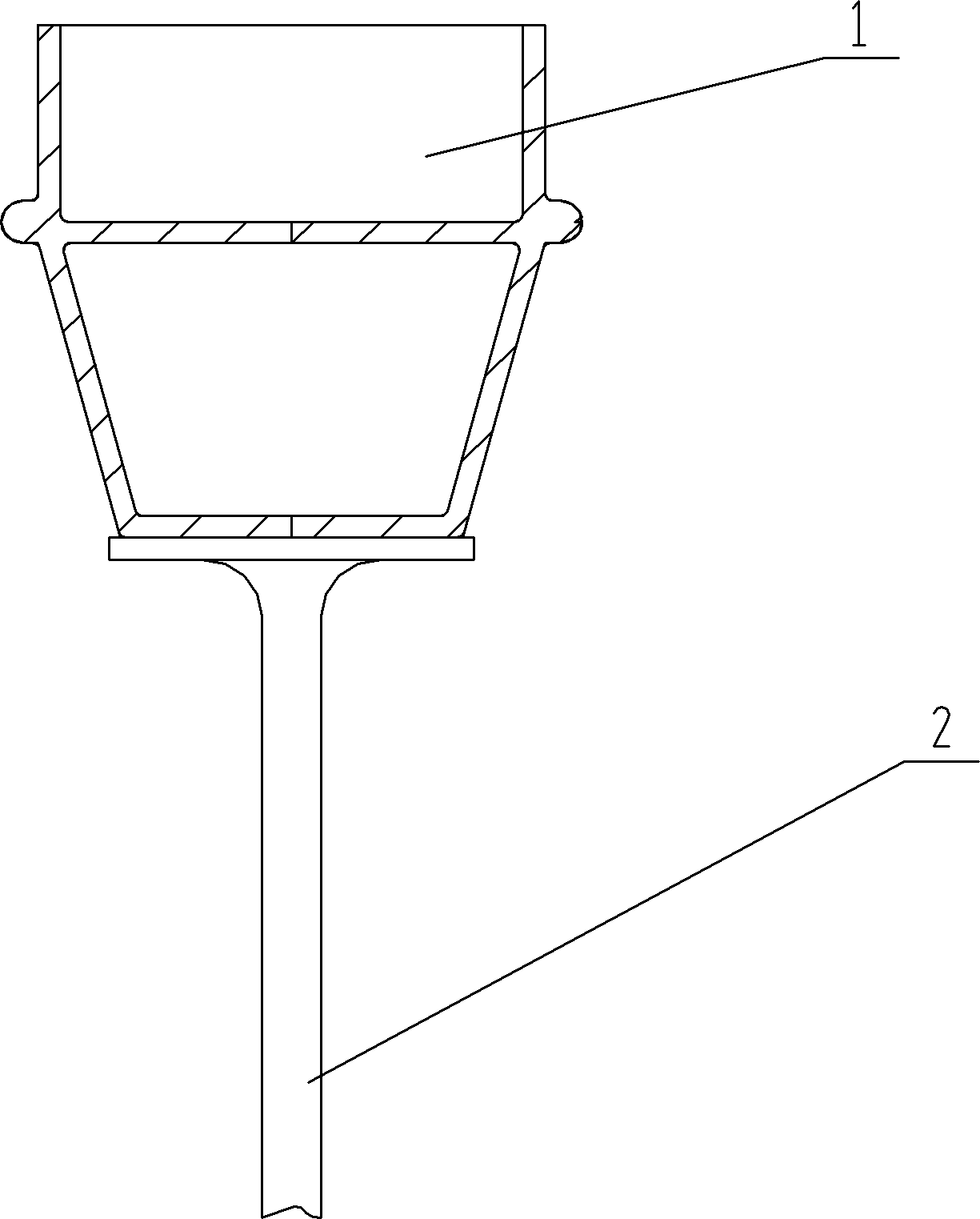

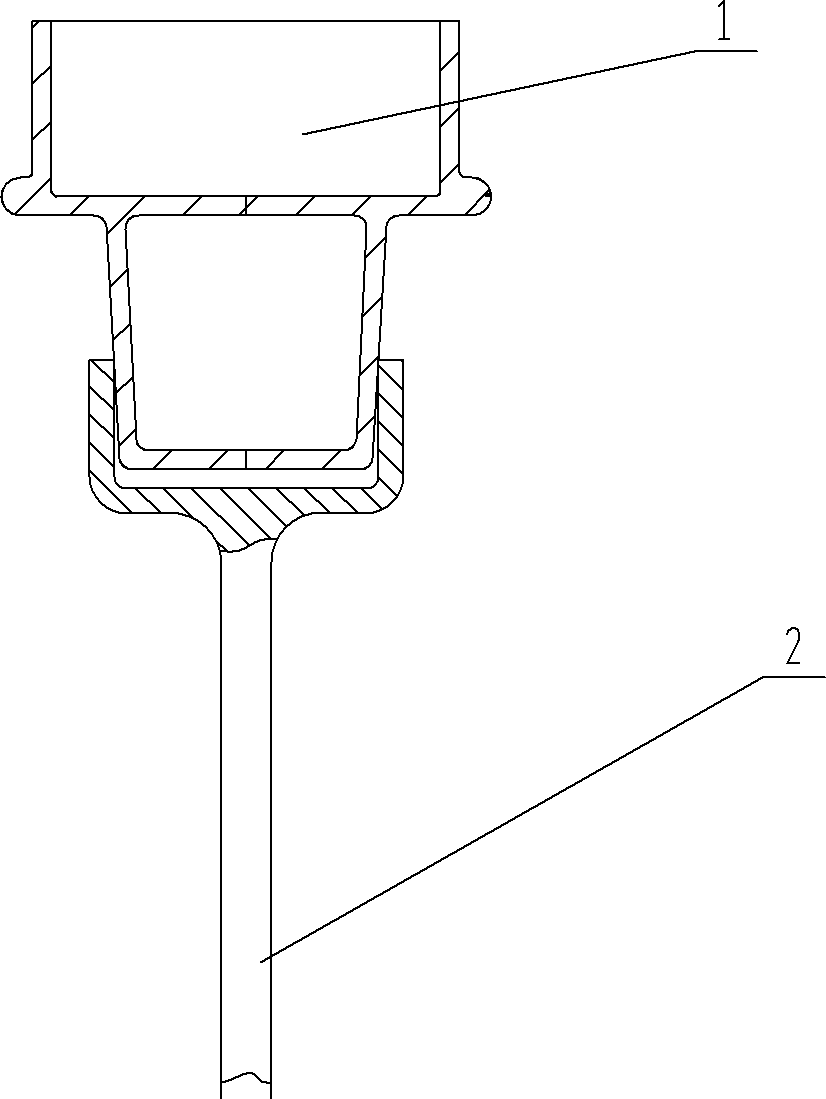

Crucible

The invention discloses a crucible which comprises a crucible main body, and at least two spacing bodies axially distributed along the crucible main body are arranged on the crucible main body. For the crucible provided by the invention, at least two spacing bodies are arranged on the crucible main body so as to ensure that a mechanical claw can be spaced through one of the spacing bodies to clamp the crucible, and the other spacing body is used as a spacing component for clamping the crucible on a sample placing disc. The crucible provided by the invention can be applicable to horizontal clamping, the problems of smoothness and reliability in movement can be solved through the spacing of the two spacing bodies, sample rejection turning can be realized, an automatic instrument mechanism can be simplified, and the crucible is beneficial to increasing mechanism strength and reducing instrument size and is economical and applicable.

Owner:CHANGSHA KAIYUAN INSTR

Vessel for pretreatment of elementary analysis, method for analyzing elements, inductively coupled plasma torch and apparatus for elementary analysis

InactiveUS20050040342A1Less pollutionEasy to analyzeWithdrawing sample devicesPreparing sample for investigationHeat resistanceElement analysis

There is disclosed a vessel for pretreatment of elementary analysis wherein the vessel is a ceramic vessel produced by chemical vapor deposition (CVD) method. And there is disclosed an inductively coupled plasma torch that has at least an induction coil and a nozzle and is used in an apparatus for elementary analysis by ICP method, wherein the nozzle is a ceramic nozzle produced by CVD method. Thus, there can be provided a vessel for pretreatment of elementary analysis that excels in heat resistance and chemical resistance such as acid resistance, and has high purity. There can be also provided an inductively coupled plasma torch used in an apparatus for analysis by ICP method that enables accurate elementary analysis and excels in durability, and an apparatus for elementary analysis by ICP method having this.

Owner:SHIN ETSU CHEM IND CO LTD

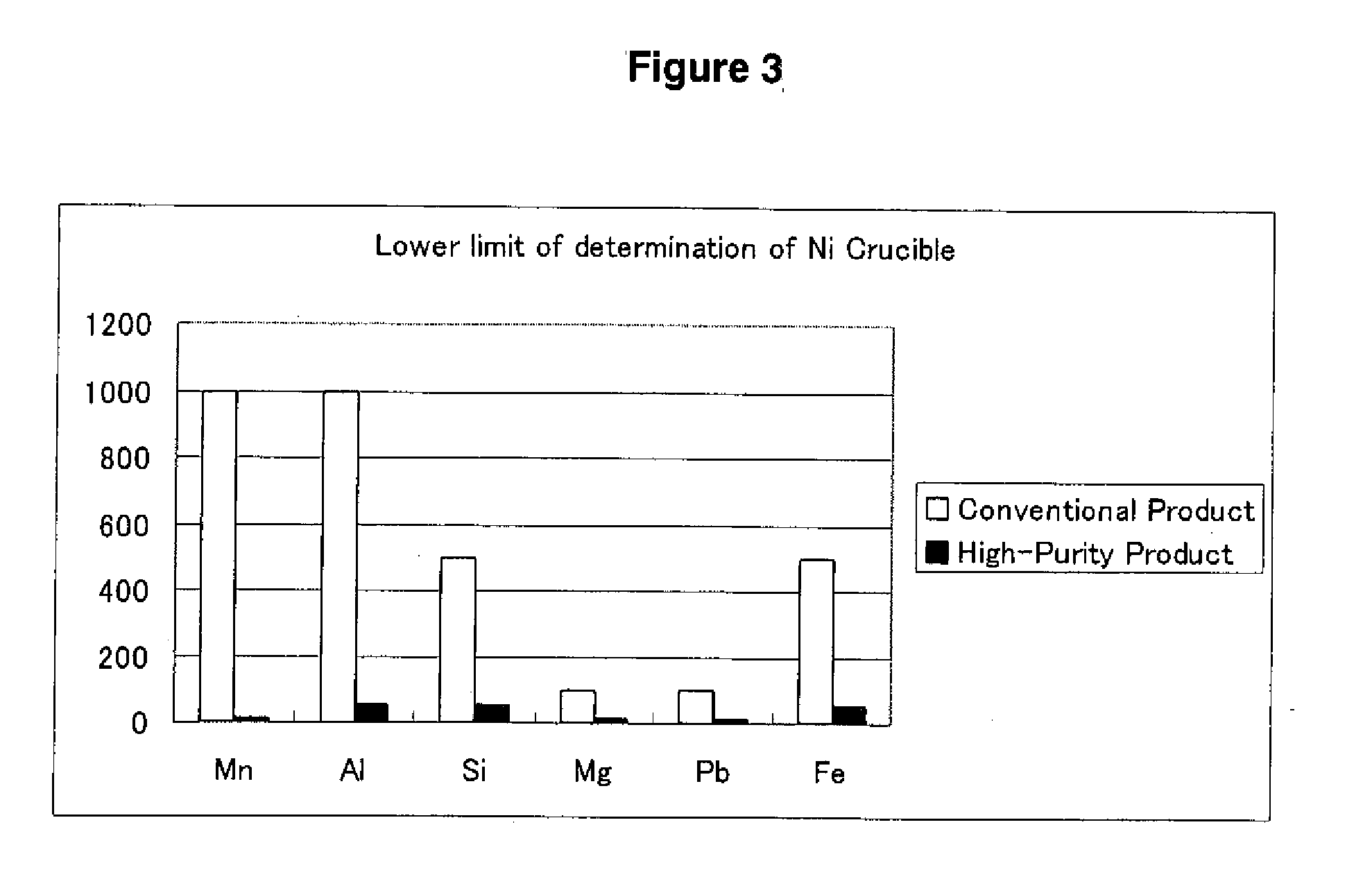

Nickel Crucible for Melting Analytical Sample, Method of Preparing Analytical Sample and Method of Analysis

ActiveUS20100167407A1High precision analysisFast and accurate measurement of high purity materialsAnalysis using chemical indicatorsWithdrawing sample devicesLower limitCrucible

A nickel crucible used for melting an analytical sample in the pretreatment of the analytical sample, characterized in that the purity of the nickel crucible is 99.9999 wt % or higher. Also provided is a method of analysis, comprising melting a sample by the use of the nickel crucible for melting having a purity of 99.9999 wt % or higher, and analyzing the melt to thereby obtain an analytical result in which the respective lower limits of determination of Mn, Al, Si, Mg, Pb, Fe, Co, Ti, Cu, Cr, Zr, Mo, and W are Mn: 5 wtppm, Al: 10 wtppm, Si: 10 wtppm, Mg: 5 wtppm, Pb: 5 wtppm, Fe: 5 wtppm, Co: 5 wtppm, Ti: 20 wtppm, Cu: 20 wtppm, Cr: 10 wtppm, Zr: 5 wtppm, Mo: 2 wtppm, and W:10 wtppm. In light of the recent analytical technology demanded of fast and accurate measurement of high purity materials, high purity analysis is attained through inhibition of mixing of impurities from the crucible.

Owner:JX NIPPON MINING& METALS CORP

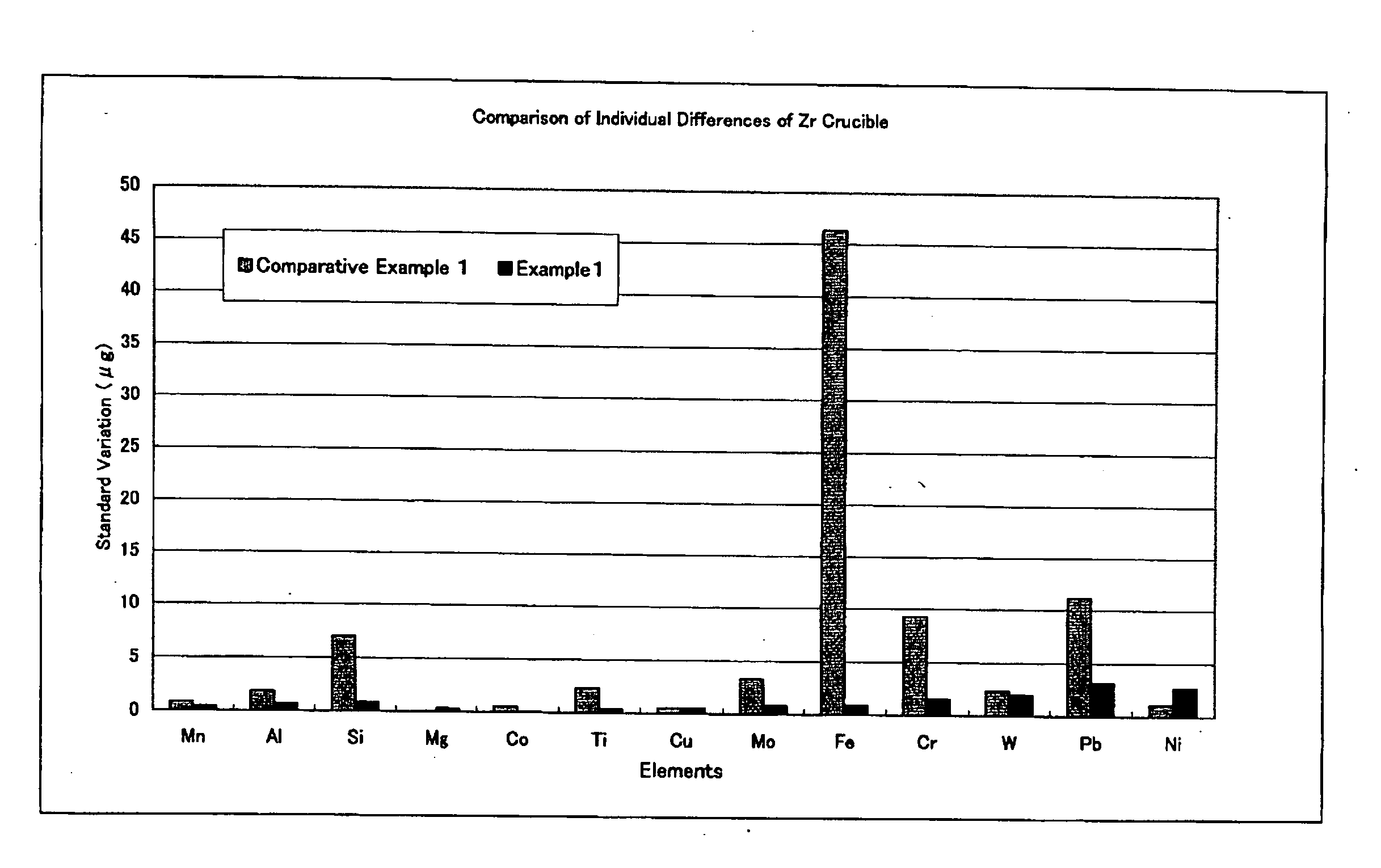

Zirconium Crucible for Melting Analytical Sample, Method of Preparing Analytical Sample and Method of Analysis

ActiveUS20090104082A1Reduce the amount requiredSave labor timeLiquid surface applicatorsMolten spray coatingCrucibleAnalysis method

Proposed is a zirconium crucible used for melting an analytical sample in the pretreatment of the analytical sample, wherein the purity of the zirconium crucible is 99.99 wt % or higher. in light of the recent analytical technology demanded of fast and accurate measurement of high purity materials, the present invention provides a zirconium crucible for melting an analytical sample, a method of preparing such analytical sample, and a method of analysis that enables the analysis of high purity materials by inhibiting the inclusion of impurities from the crucible regardless of difference in the analysts and their skill.

Owner:JX NIPPON MINING & METALS CORP

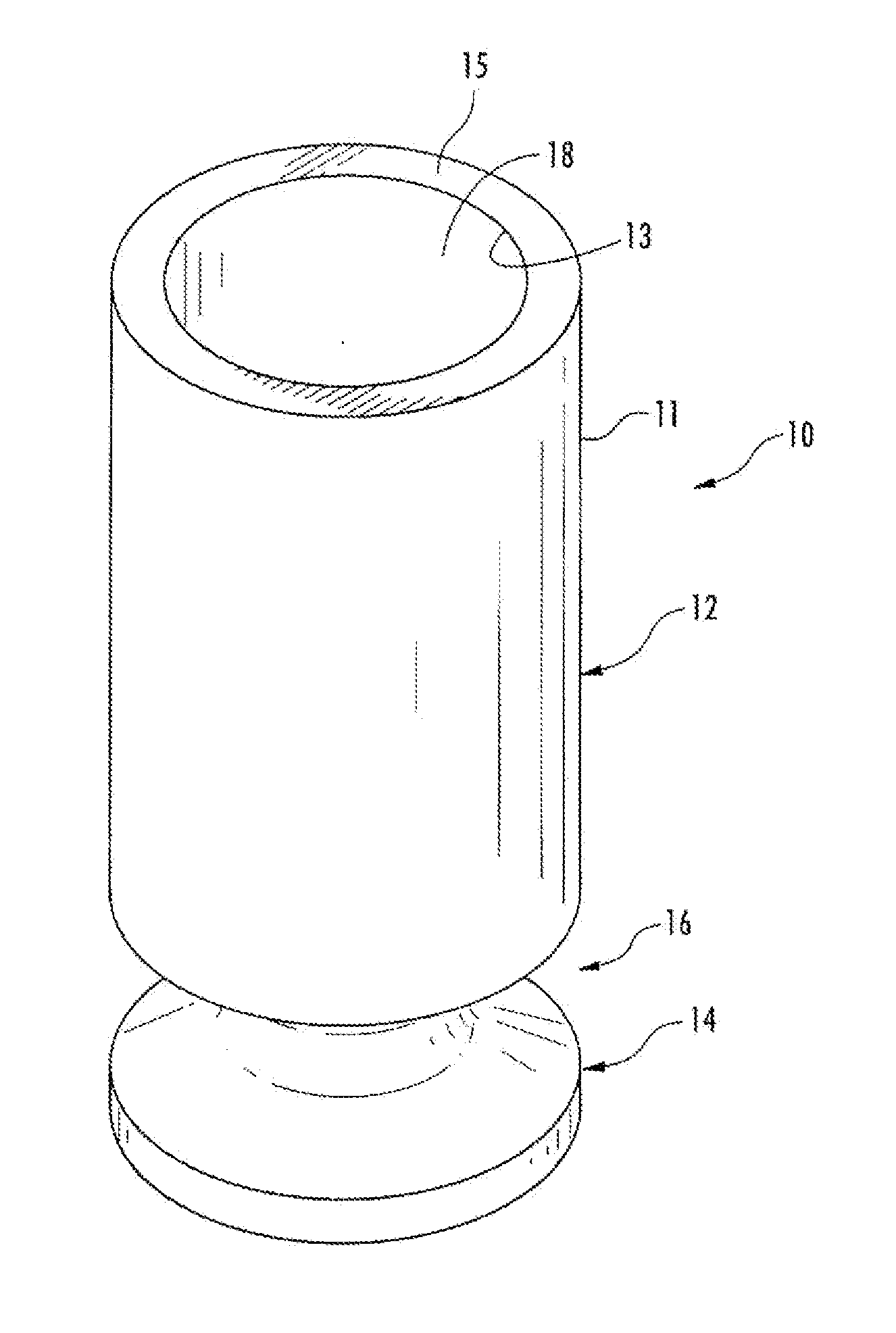

Resistance analytical furnace

ActiveUS9808797B2Prolong lifeReduced Power RequirementsChemical analysis using combustionHeater elementsCrucibleCoolant flow

A resistance furnace provides an improved upper and lower electrode construction with significantly increased coolant flow. The lower electrode has a tip design that significantly lowers the electrode tip temperature during an analysis. The upper and lower electrodes also cooperate with an improved crucible design to significantly reduce the power required to fuse a specimen contained in the crucible. The furnace uniformly heats the floor and lower side walls of a crucible, which lowers the power requirement for specimen fusion and provides higher structural benefits to provide consistent analysis and manufacturing yields. The crucible has a cylindrical body and pedestal base with an annular smoothly curved concave indentation therebetween.

Owner:LECO CORPORATION

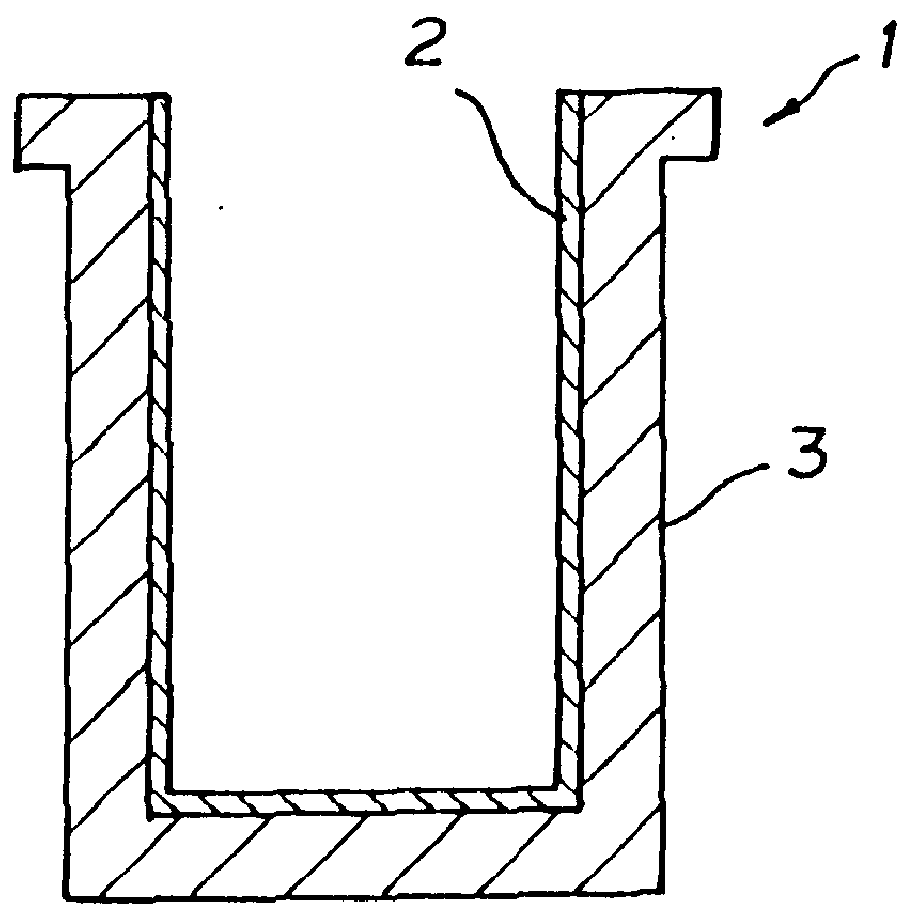

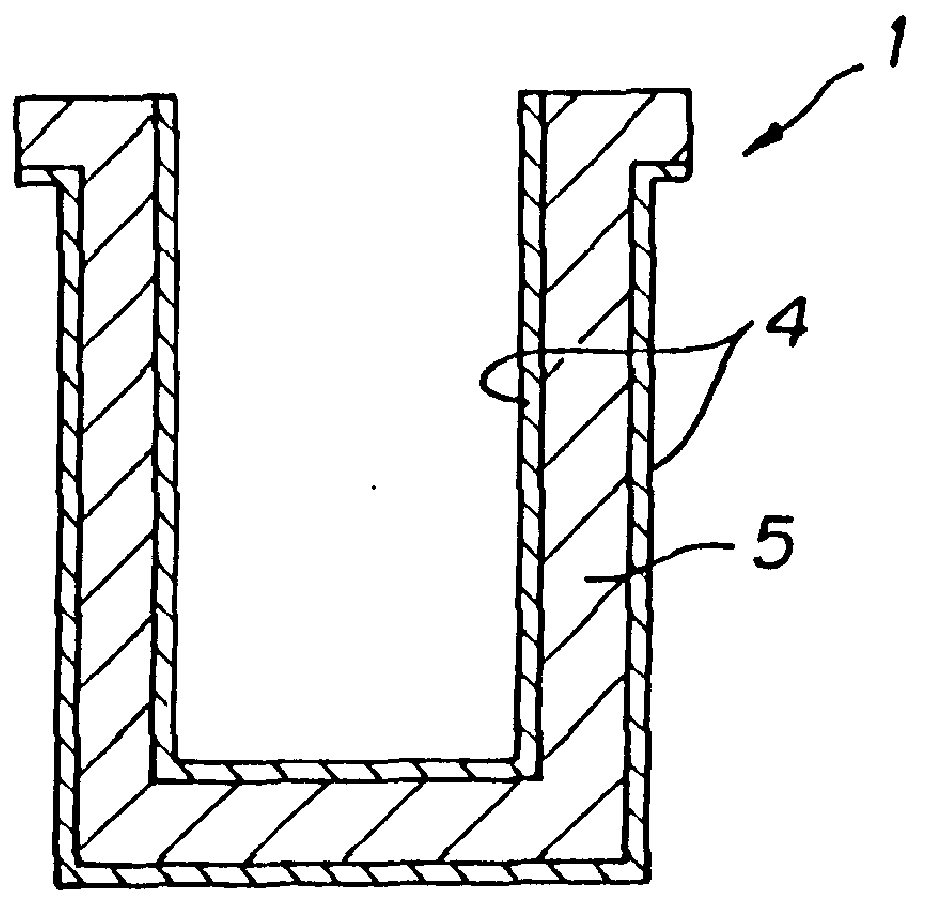

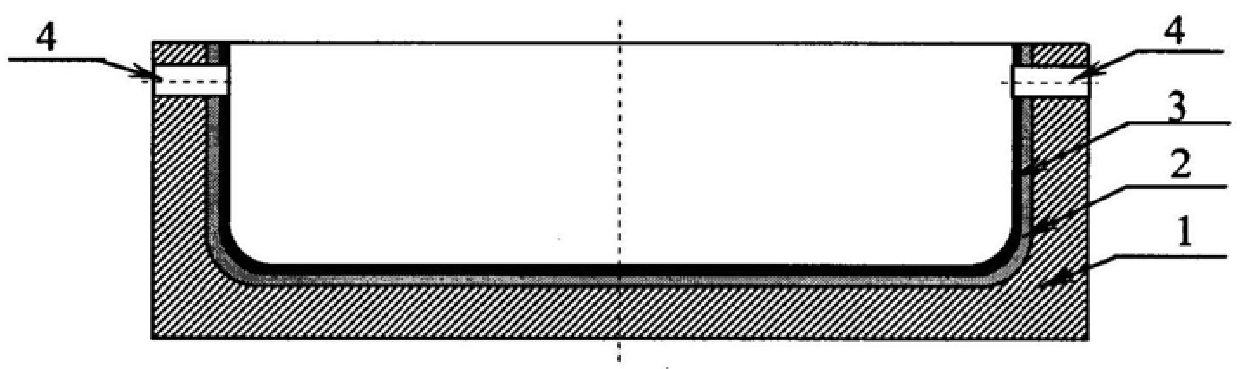

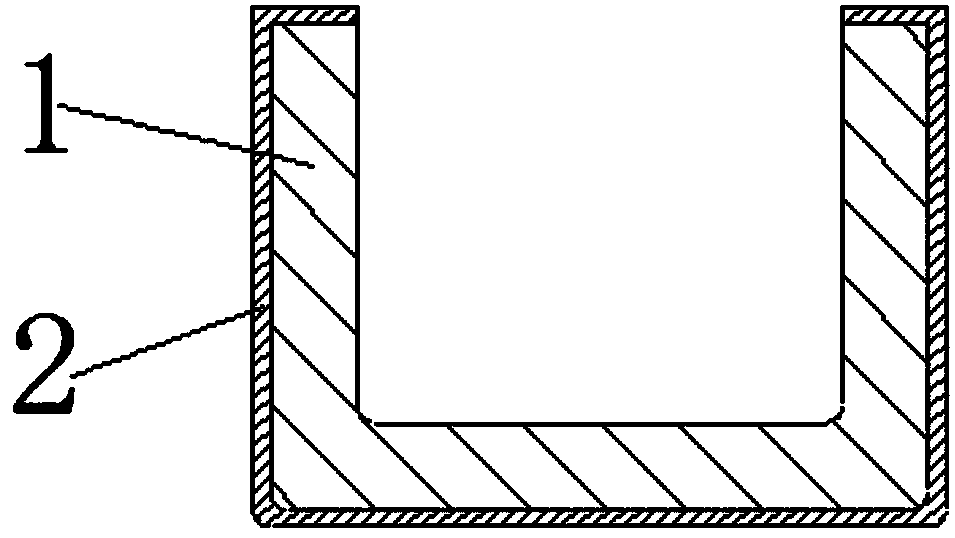

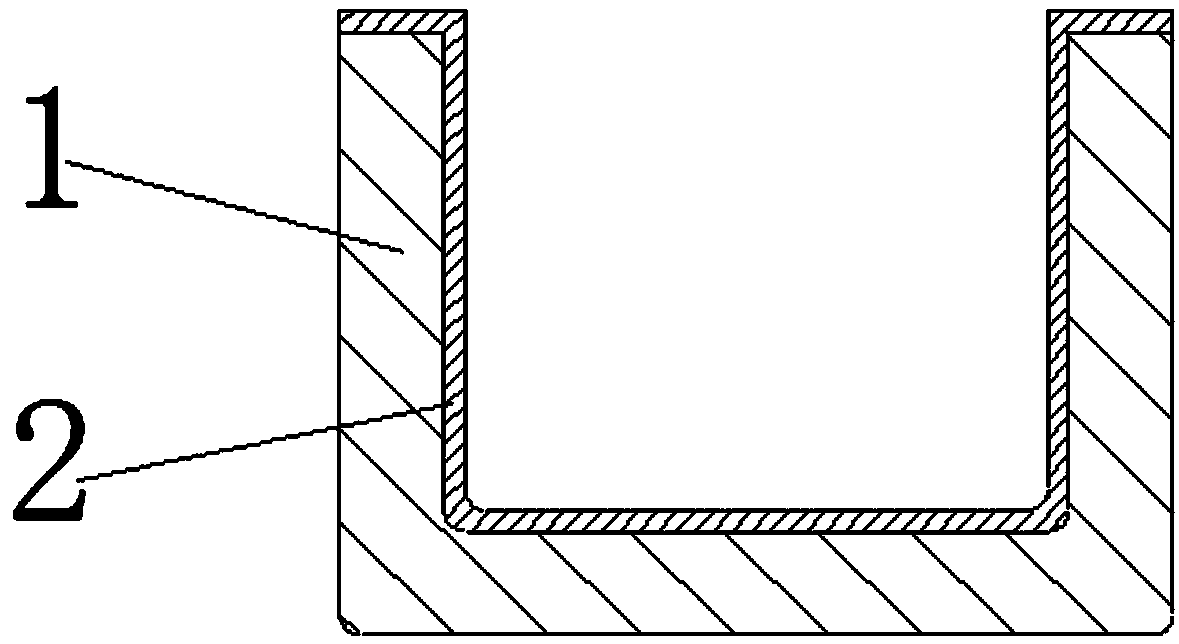

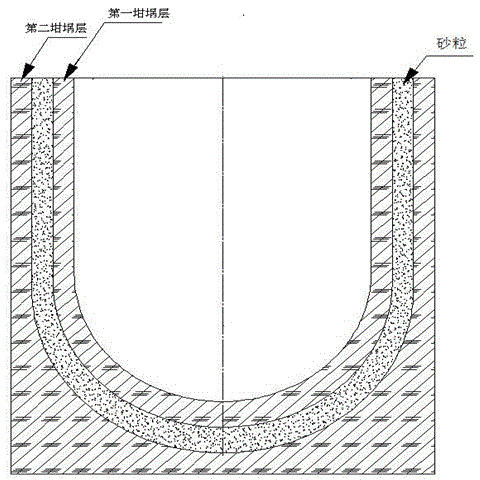

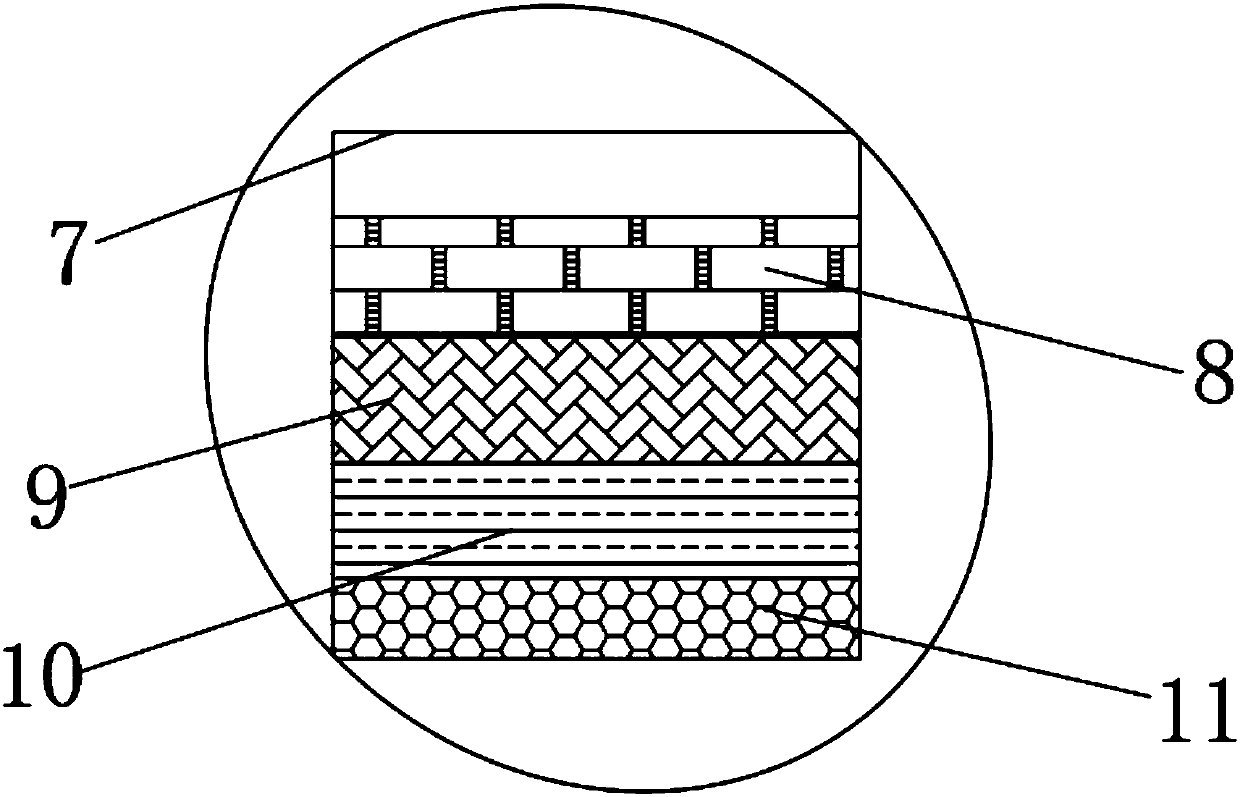

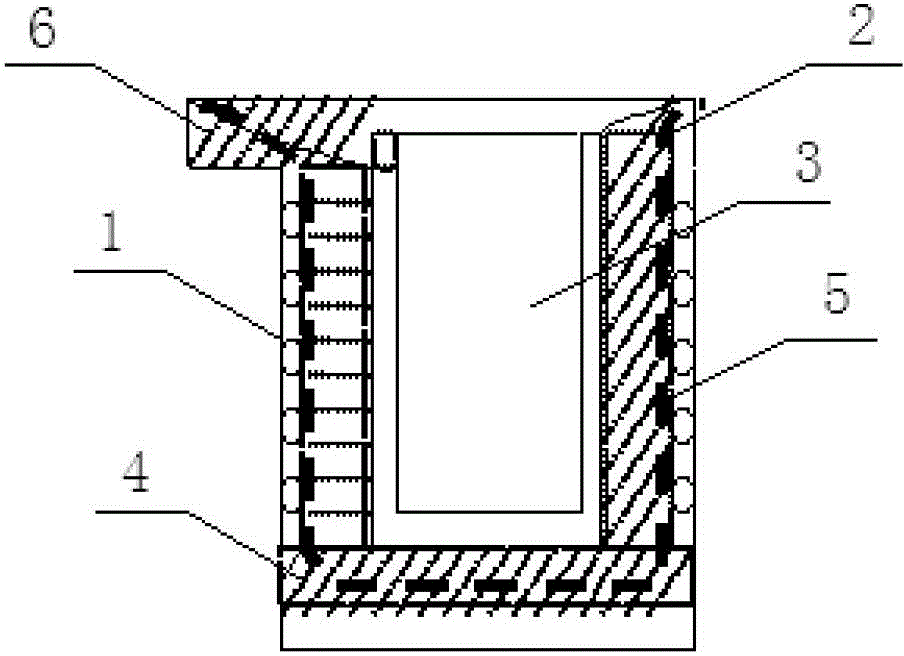

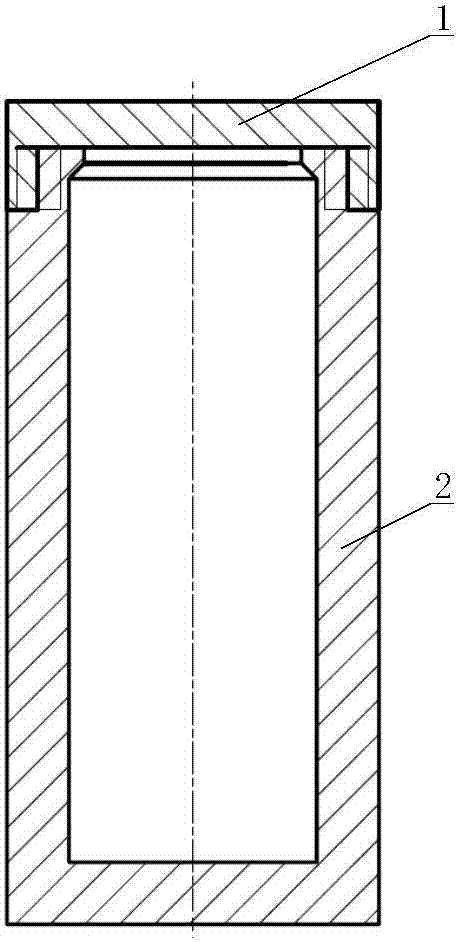

Multilayered homogeneous crucible and installation method thereof

The invention discloses a multilayered homogeneous crucible and an installation method thereof. The multilayered homogeneous crucible is provided with a plurality of crucible layers, wherein fine sand made of the same material is filled in gaps between every two adjacent crucible layers, and the crucible layers are made of the same materials as the sand. The multilayered homogeneous crucible has the advantages that the multilayered homogeneous crucible can effectively achieve high temperature resistance and fusion resistance consumption and strength required by heating, fusing, boiling and evaporating of substances with a high fusing-boiling point; different crucible layers have different functions, sand layers between two crucible layers are made of the same materials as the crucible layers, therefore, inner-layer products and the crucible are not contaminated, two crucible layers can be buffered, the crucible on another layer can not be influenced when the crucible on some layer goes wrong, and using effect of the crucible is improved well.

Owner:JIANGSU BOQIAN NEW MATERIALS

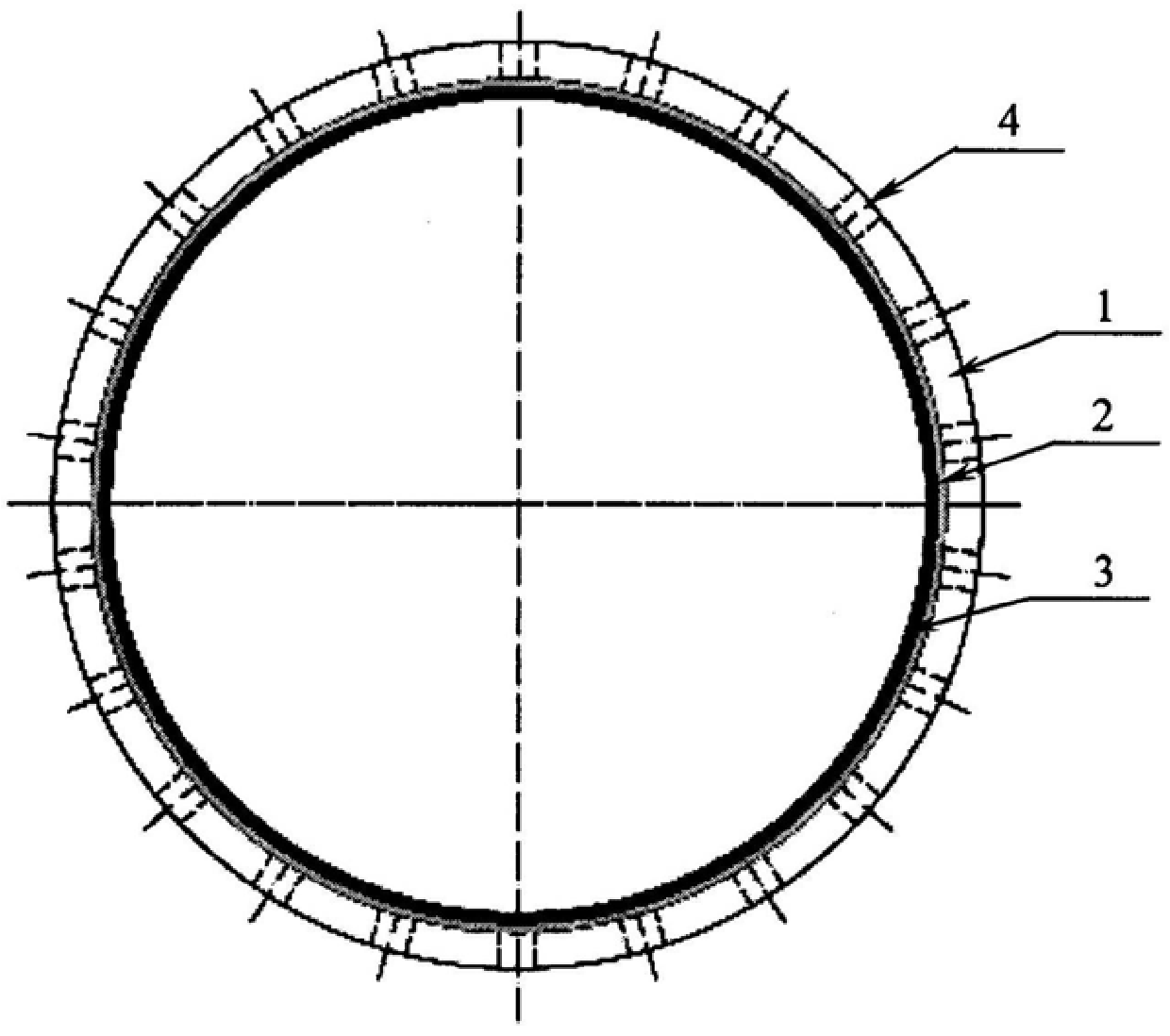

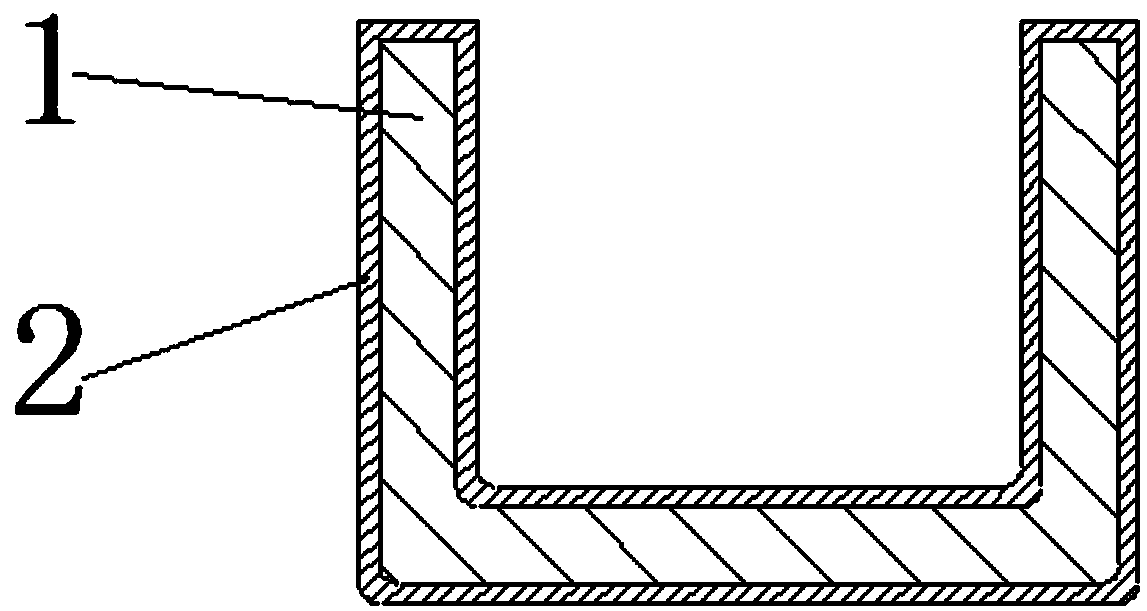

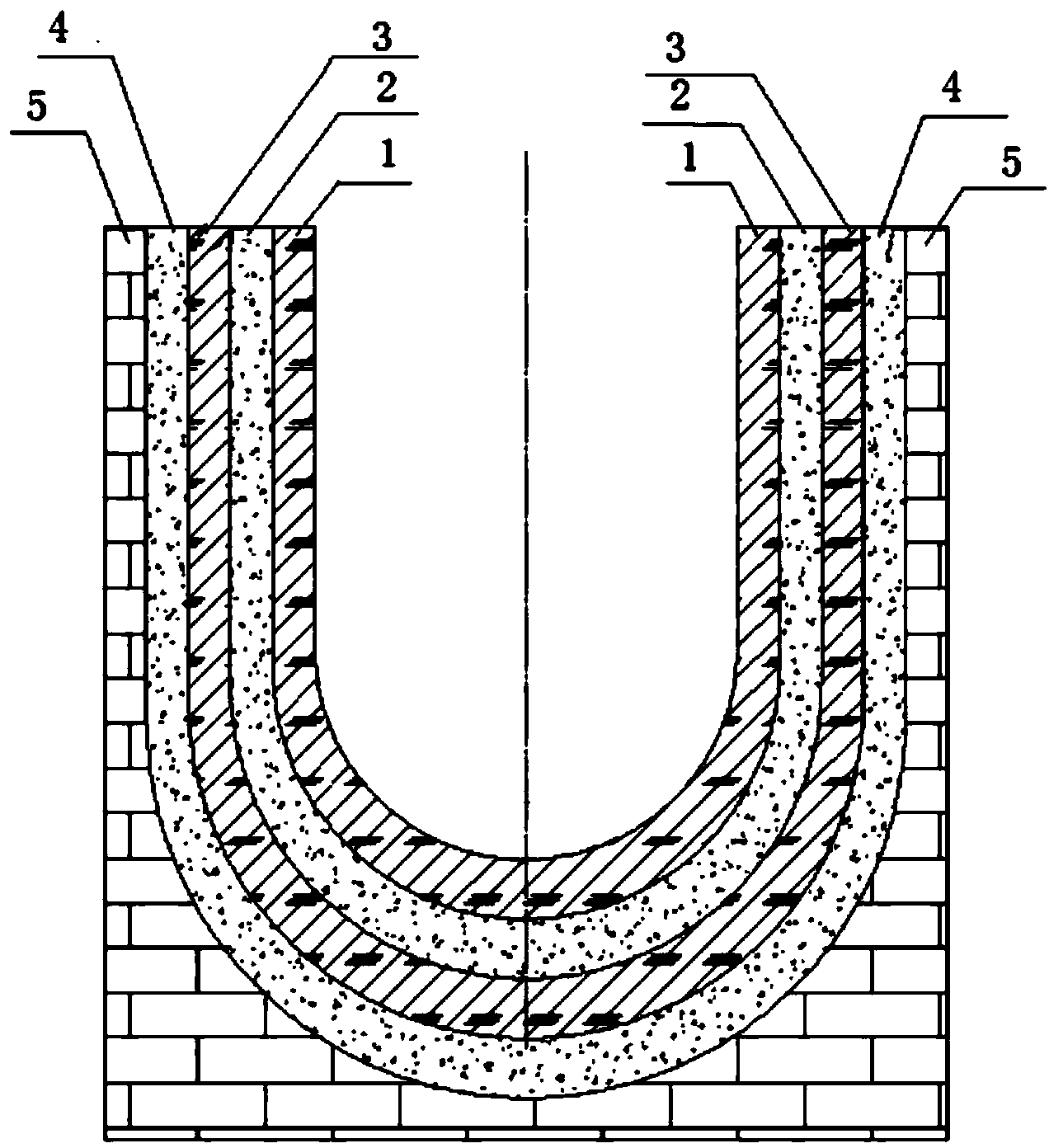

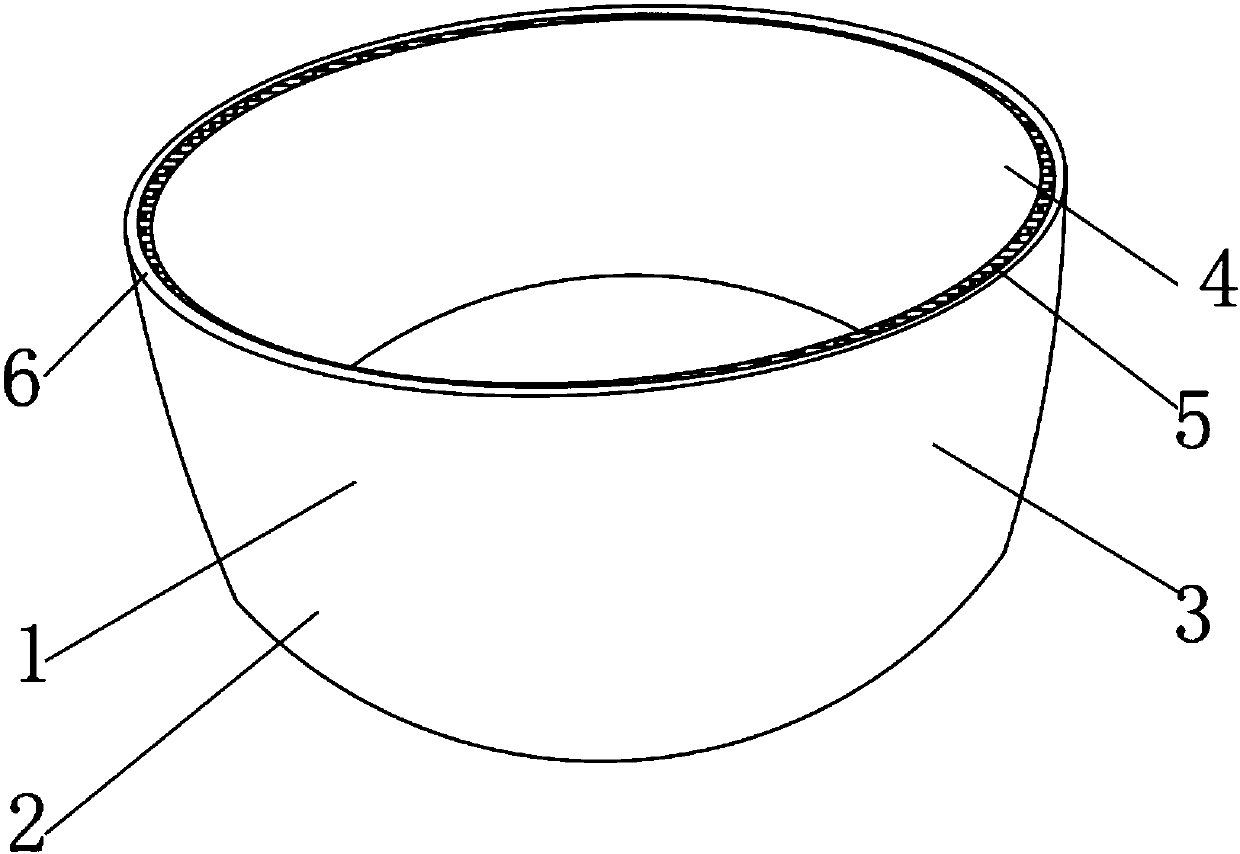

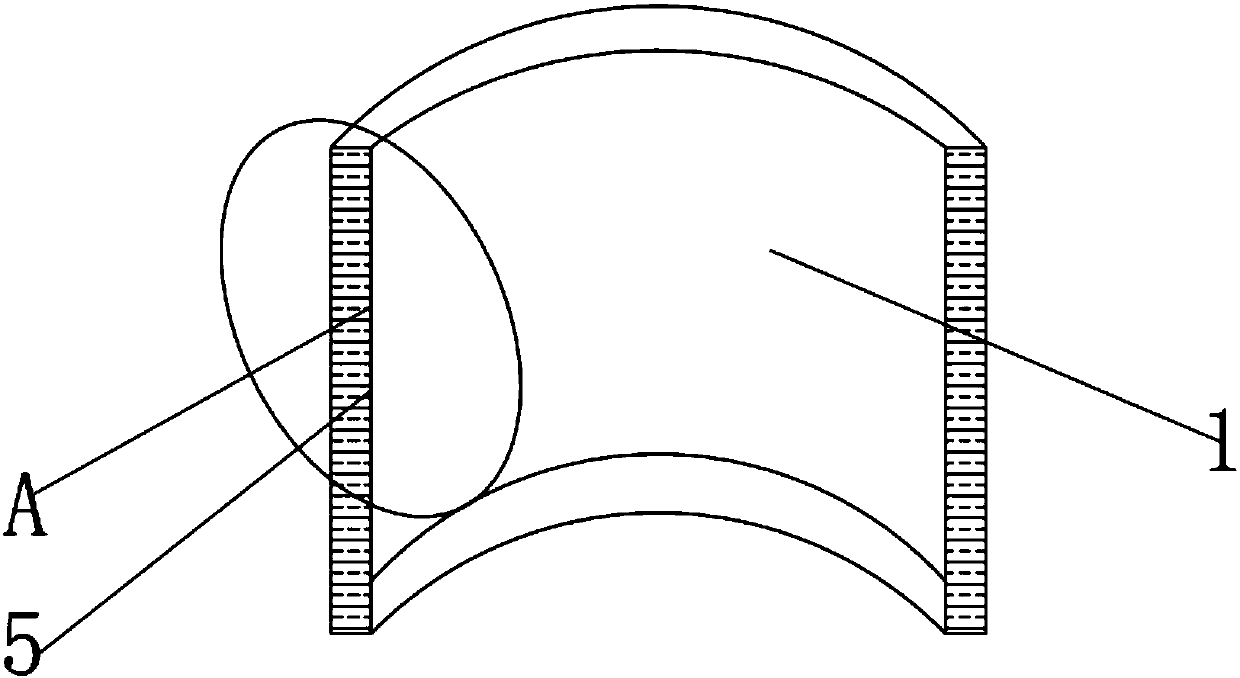

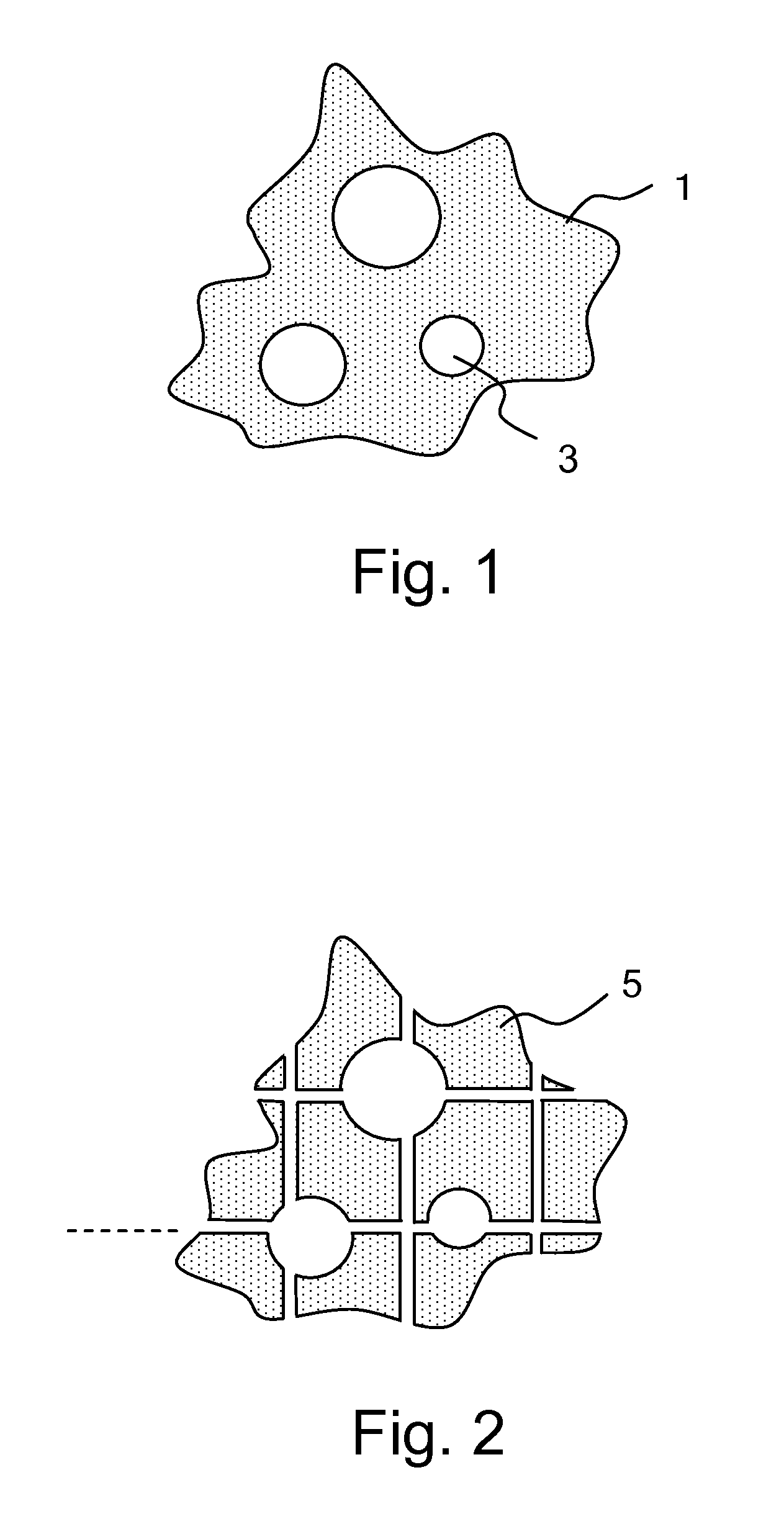

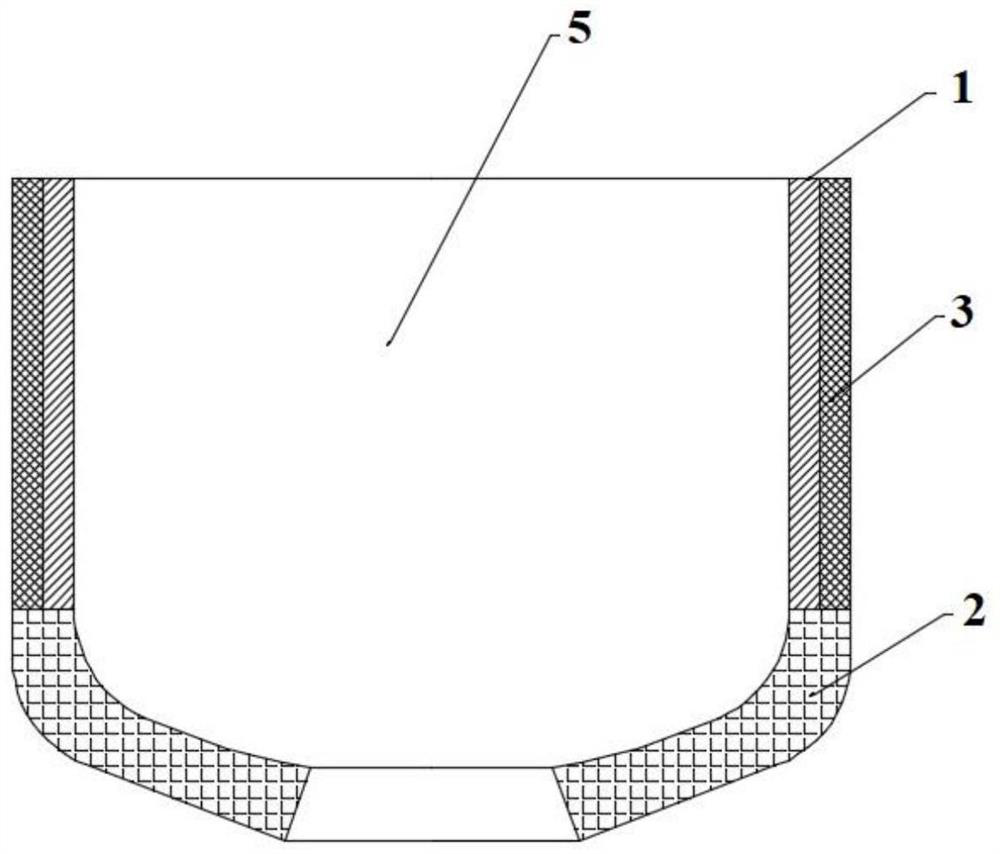

Heterogeneous multi-layer crucible

The invention discloses a heterogeneous multi-layer crucible. The heterogeneous multi-layer crucible comprises a plurality of crucible layers made of different materials, and a sand filling layer is arranged between every two adjacent crucible layers. The heterogeneous multi-layer crucible further comprises a first crucible layer (1), a second crucible layer (3) and a third crucible layer (5), wherein a sand filling layer I (2) is arranged between the first crucible layer (1) and the second crucible layer (3), and a sand filling layer II (4) is arranged between the second crucible layer (3) and the third crucible layer (5). Compared with the prior art, the heterogeneous multi-layer crucible is characterized in that the crucible has multiple layers and is made of different materials, the material with the melting point slightly lower than the boiling point of a material to be heated can be used, the material with a high melting point is not needed, production cost is lowered, and the problems of vessels needed by heating, melting, boiling and volatilization of materials with a high melting point and a high boiling point is resolved. The number of layers and materials of the crucible can be increased and selected according to the needs, the service life is prolonged, and industrial production is facilitated.

Owner:JIANGSU BOQIAN NEW MATERIALS

Desalinization apparatus and method

ActiveUS8361281B2Drying using combination processesGeneral water supply conservationWater vaporSalt water

Owner:LYTESYDE LLC

Quartz crucible excellent in heat preservation effect

InactiveCN110302854AImprove insulation effectHigh melting pointAfter-treatment apparatusPolycrystalline material growthHoneycombPolystyrene

The invention discloses a quartz crucible excellent in heat preservation effect. The quartz crucible comprises a quartz crucible body and is characterized a crucible bottom is fixedly mounted at the lower end of the quartz crucible body, a crucible body part is arranged in the middle of the quartz crucible body, the inner surface of the crucible body part is provided with an inner wall, the outersurface of the inner wall is provided with an outer wall, a graphite heat preservation sleeve is fixedly mounted on the outer surface of the outer wall, and a position, close to the inner surface of the inner wall, inside the outer wall is provided with a transparent layer. The quartz crucible has the advantages that the quartz crucible is provided with the graphite heat preservation sleeve, an extruded polystyrene board and a honeycomb core, so that the quartz crucible is resistant to high temperature, and the heat preservation effect of the quartz crucible is improved; meanwhile, graphite heat preservation sleeve dampness can be prevented at the same time to prolong the service life of the graphite heat preservation sleeve; the weight of the graphite heat preservation sleeve is reduced while hardness lowering is avoided; the quartz crucible is convenient for people to use and promising in application prospect.

Owner:连云港科拓信息科技有限公司

Method of manufacturing granulated silica powder, method of manufacturing vitreous silica crucible

ActiveUS20120137732A1Facilitated releaseEasy to manufactureSilicaGlass shaping apparatusCrucibleSilicon dioxide

The present invention provides a method of manufacturing a vitreous silica crucible having a transparent layer by use of waste vitreous silica, and silica powder suitable for the manufacturing. According to the present invention, there is provided a method of manufacturing granulated silica powder comprising a process for pulverizing waste vitreous silica generated in the manufacturing process of a crucible to form silica fine powder having an average particle diameter of 100 μm or less, and a process for granulating the silica fine powder to obtain granulated silica powder having an average particle diameter of 50 μm or more under helium atmosphere.

Owner:SUMCO CORP

Crucible for the treatment of molten silicon

A crucible for the treatment of molten silicon includes a basic body with a bottom surface and lateral walls defining an inner volume. The basic body comprises at least 65% by weight of silicon carbide, and from 12 to 30% by weight of a constituent selected from silicon oxide or nitride. Moreover, the basic body comprises at least one silicon oxide and / or nitride coating, at least on the surfaces defining the inner volume of the crucible.

Owner:VESUVIUS CRUCIBLE CO

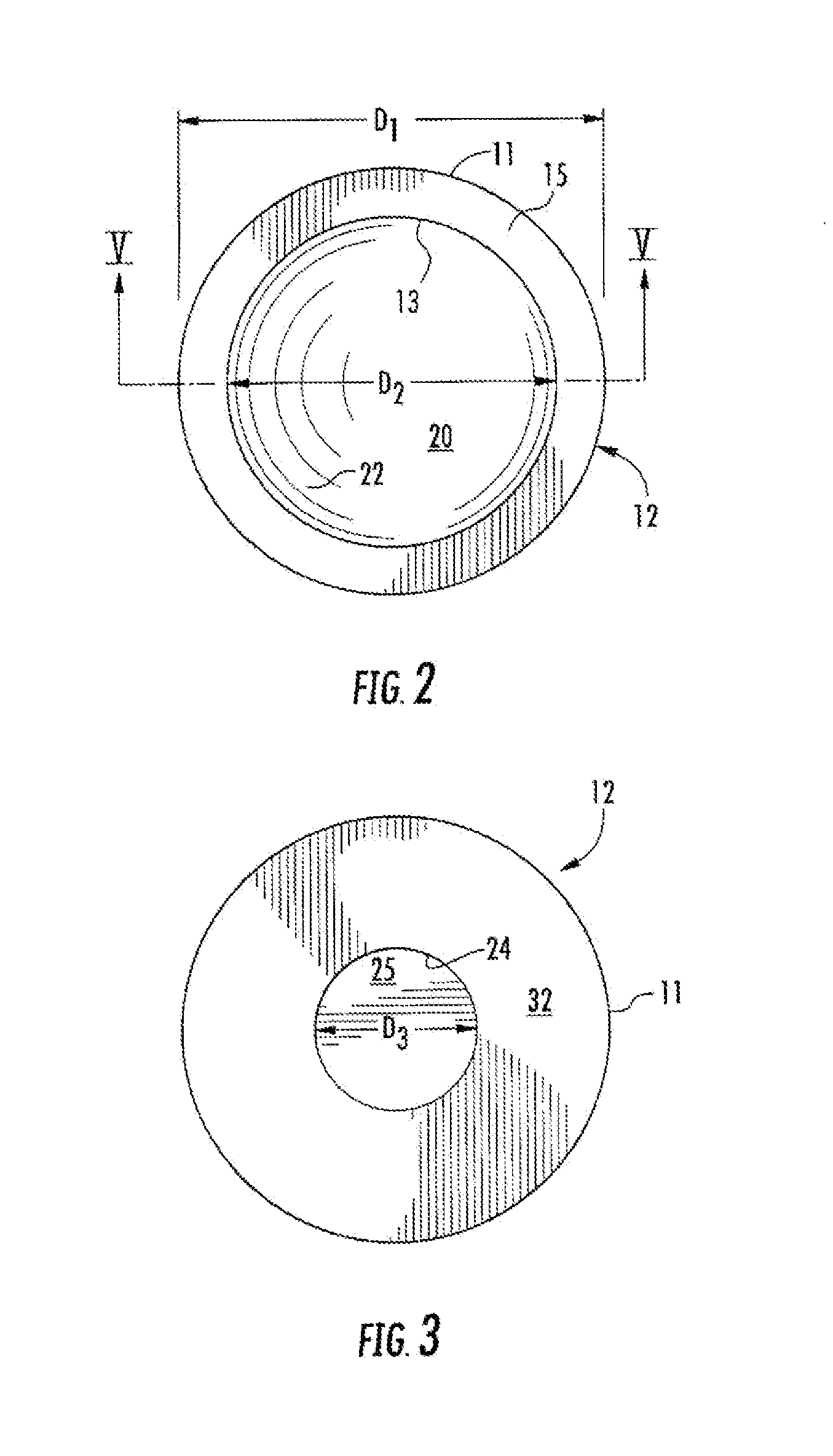

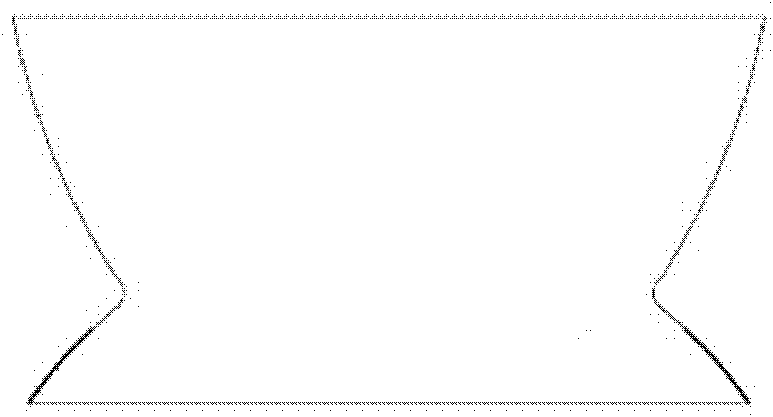

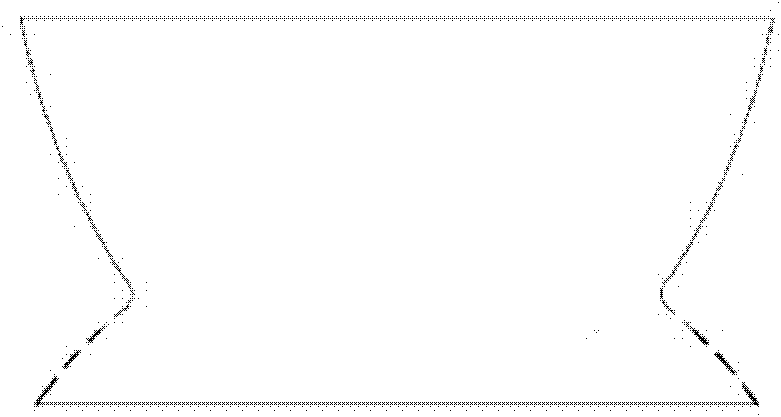

Crucible

ActiveUS20130337396A1Easily withstands compressive forceLess powerCrucible furnacesCruciblesEngineeringMechanical engineering

A graphite crucible has a cylindrical body with an upper opening for receiving a sample for analysis and a disk-shaped pedestal base. The pedestal base includes a bottom surface with a centrally formed circular indentation. An inwardly projecting concave arcuate annular indentation extends between the body and pedestal base with a smoothly curved radius of curvature. The upper and lower walls of the arcuate indentation diverge outwardly at an angle of from about 56 to about 60°. The pedestal base includes a bottom surface with a centrally formed circular indentation.

Owner:LECO CORPORATION

Systems and methods for preparing samples for chemical analysis

A system for preparing samples for chemical analysis comprises at least one sample container, and a container receptacle apparatus for receiving the sample container. The sample container comprises an elongate tubular body having a crucible portion proximal to a closed end for receiving a sample therein, and an expansion portion proximal to an open end. The container receptacle apparatus comprising a housing having a heating compartment, a cooling compartment spaced apart from the heating compartment, and an insulating region located between the heating compartment and the cooling compartment. The heating compartment is shaped to receive the crucible portion of the sample container, and the cooling compartment is shaped to receive the expansion portion of the sample container. The apparatus also includes a heating mechanism for heating the sample within the crucible portion of the sample container, and a cooling mechanism for cooling the expansion portion of the sample container.

Owner:COLDBLOCK TECH INC

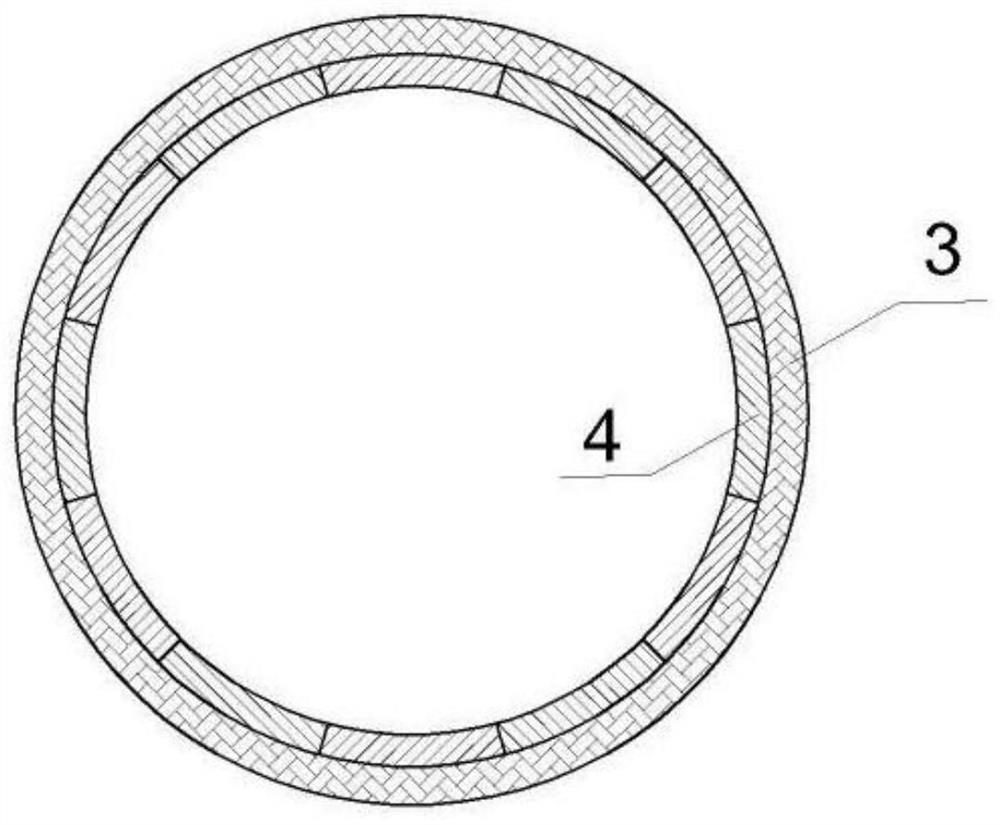

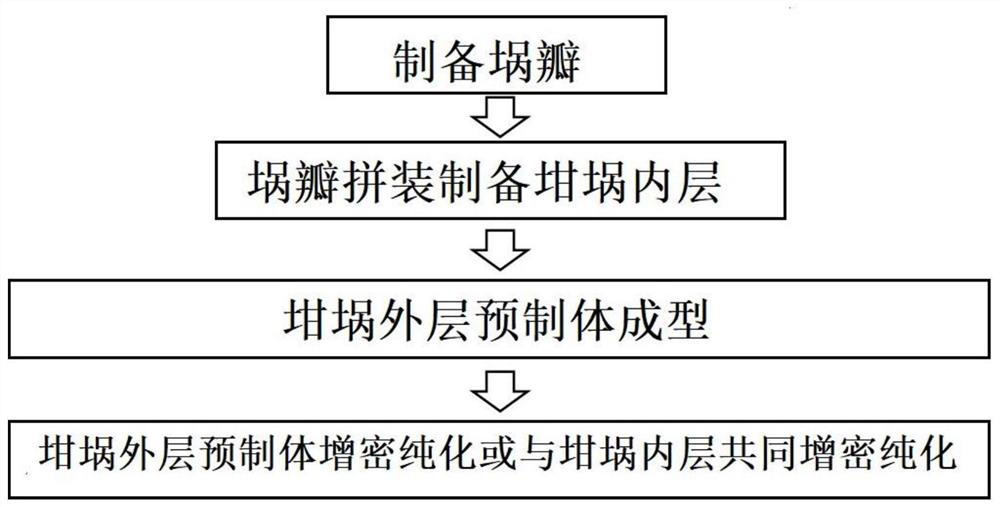

Carbon/carbon crucible and manufacturing method thereof

ActiveCN112341232AIncrease productivityIncrease the strength of the hoop structureLiquid-phase epitaxial-layer growthBy zone-melting liquidsCarbon compositesCrucible

The invention discloses a carbon / carbon crucible. The carbon / carbon crucible is composed of a crucible inner layer and a crucible outer layer covering the outer surface of the crucible inner layer, wherein the crucible inner layer is formed by splicing a plurality of crucible petals, or is formed by splicing a crucible bottom and a plurality of crucible petals; and the crucible inner layer and thecrucible outer layer are both made of carbon / carbon composite materials. The invention further discloses a manufacturing method of the carbon / carbon crucible. The whole crucible inner layer or a partof the crucible inner layer of the carbon / carbon crucible is of a split structure, so the utilization rate of equipment required by crucible preparation is greatly increased, raw material waste is avoided, the production efficiency of the crucible is improved, the manufacturing cost of the crucible is reduced; and meanwhile, the outer surface of the crucible inner layer is covered with the crucible outer layer which is rapidly prepared and formed and serves as a reinforcing layer, so the circumferential structural strength and the mechanical properties of the crucible are improved, the erosion resistance of the crucible is improved, and the service life of the crucible is prolonged. The manufacturing method is simple in process and easy to implement.

Owner:XIAN CHAOMA SCI TECH

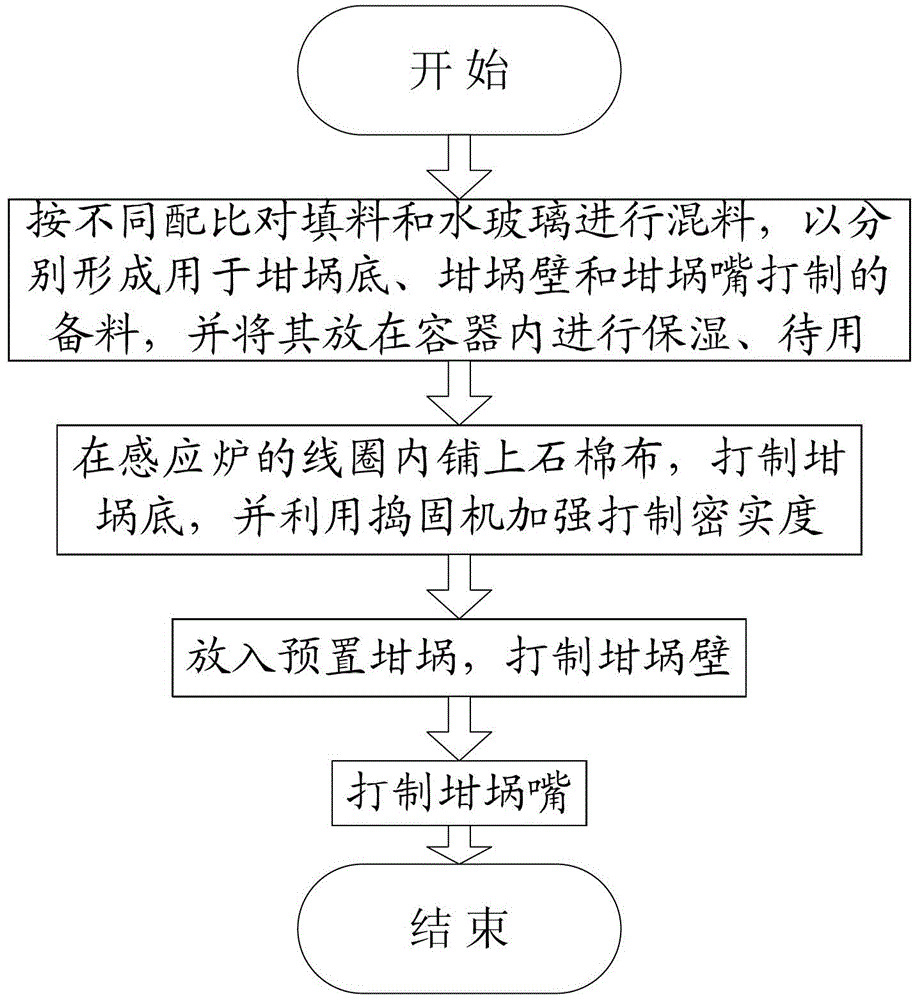

Wet type and semi-automatic method for forging crucible

The invention discloses a wet type and semi-automatic method for forging a crucible. Specifically, the method comprises a step of mixing fillers and water glass according to different proportions to form standby materials for forging crucible bottom, crucible wall and crucible mouth, putting the standby materials in a container, and preserving moisture for use; a step of laying asbestos cloth in coils of an induction furnace, forging the crucible and reinforcing forging compactness by using a tamping machine; a step of putting a pre-set crucible and forging the crucible; and a step of forging the crucible mouth. The wet type and semi-automatic method for forging the crucible is simple and reasonable in steps. A stirrer is used for mixing materials instead of labor, and the compactness is reinforced by using the tamping machine while forging the crucible bottom and the crucible wall, so that uniformity of mixing the materials and forging compactness are increased; the service life of the crucible and work efficiency for forging the crucible are increased; and workload is alleviated.

Owner:SINO MAGNETICS TECH

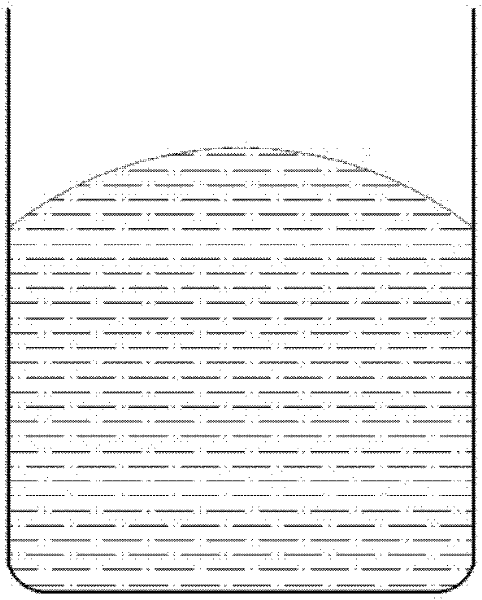

Double-crucible experimental apparatus for high-temperature experiment

InactiveCN102247902ASolve erosionOvercome the pitfalls of separate studiesCruciblesThermodynamicsSlag

The invention discloses a double-crucible experimental apparatus for a high-temperature experiment, which belongs to the field of high-temperature metallurgical experiments, is used for a slag-molten metal-gas phase balance experiment of high-temperature metallurgy and can solve the problem of erosion of crucibles by slag and molten metal in a high-temperature metallurgical residue / metal reactionexperiment. Unique metal crucible design is utilized, and a metal crucible is combined with a ceramic crucible. The ceramic crucible is used for holding molten metal; and the slag is collected up by using a convex liquid surface which is formed by waist-reduced drum-shaped metal crucible and molten metal, so that the ceramic crucible is not eroded by the slag during the experiment, and the slag does not react with the waist-reduced drum-shaped metal crucible. The vertical double-crucible experimental apparatus does not affect an experimental atmosphere and is not limited to the experimental atmosphere, and the high-temperature experiment can be performed under required atmosphere. Since the problem of erosion of the crucible by a reactant is solved, the thermodynamic properties of the slag and the molten metal can be simultaneously researched, the obtained thermodynamic data is more accurate and reliable, and the experiment difficulty and cost are also reduced.

Owner:UNIV OF SCI & TECH BEIJING

High-temperature eutectic pre-fused eutectic pouring crucible

The invention relates to a high-temperature eutectic pre-fused eutectic pouring crucible, and belongs to the technical field of high-temperature eutectics. The crucible is cylindrical in appearance, and comprises a pre-fused eutectic crucible cover and a pre-fused eutectic crucible main body, wherein the pre-fused eutectic crucible main body is provided with a male thread; the pre-fused eutectic crucible cover is provided with a female thread which is matched with the male thread; the pre-fused eutectic crucible main body is in a threaded connection with the pre-fused eutectic crucible cover. After an eutectic is formed in a pre-fused eutectic crucible, the eutectic is connected to the eutectic crucible in an inverted way, changes into a molten state after being heated, and flows into the eutectic crucible under the action of gravity in order to realize pouring of the eutectic crucible. By adopting the high-temperature eutectic pre-fused eutectic pouring crucible, the breaking risk of the pre-fused eutectic crucible is lowered, the eutectic is prevented from adhering to a joint between the pre-fused eutectic crucible and the eutectic crucible, the pre-fused eutectic crucible can be reused, the problem that an existing pre-fused eutectic container can only be used once is solved, and the pouring cost is lowered.

Owner:BEIJING CHANGCHENG INST OF METROLOGY & MEASUREMENT AVIATION IND CORP OF CHINA

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com