High-temperature eutectic pre-fused eutectic pouring crucible

A technology of eutectic point and crucible, which is applied in the direction of crucible, can solve the problems of wall thickness that is easy to break, pre-eutectic container cannot be reused, and pre-eutectic container cannot be removed, so as to save pouring cost, reduce the risk of rupture, Avoid the effect of sticking

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

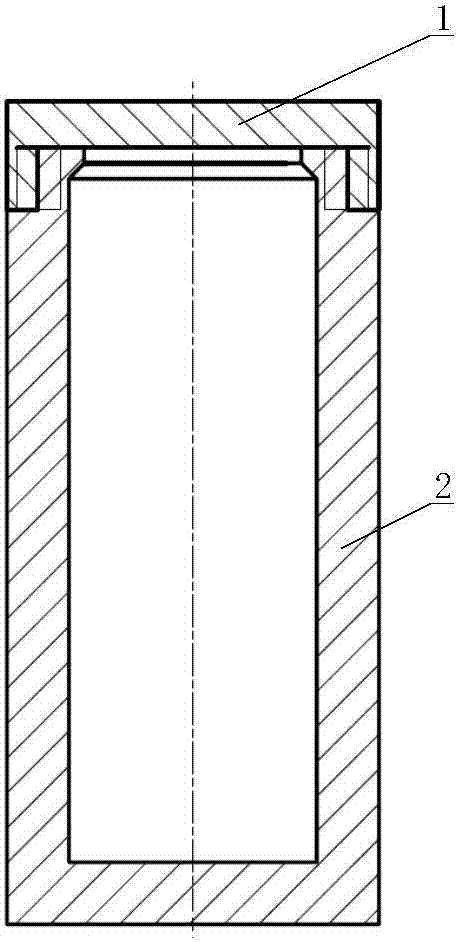

[0020] A high temperature eutectic point pre-eutectic perfusion crucible, such as figure 1 As shown, the shape is cylindrical, including a pre-eutectic crucible cover 1 and a pre-eutectic crucible main body 2 . The connection relationship is: a male thread is processed on the main body of the pre-eutectic crucible, and a matching female thread is processed on the cover of the pre-eutectic crucible, and the two are connected by threads.

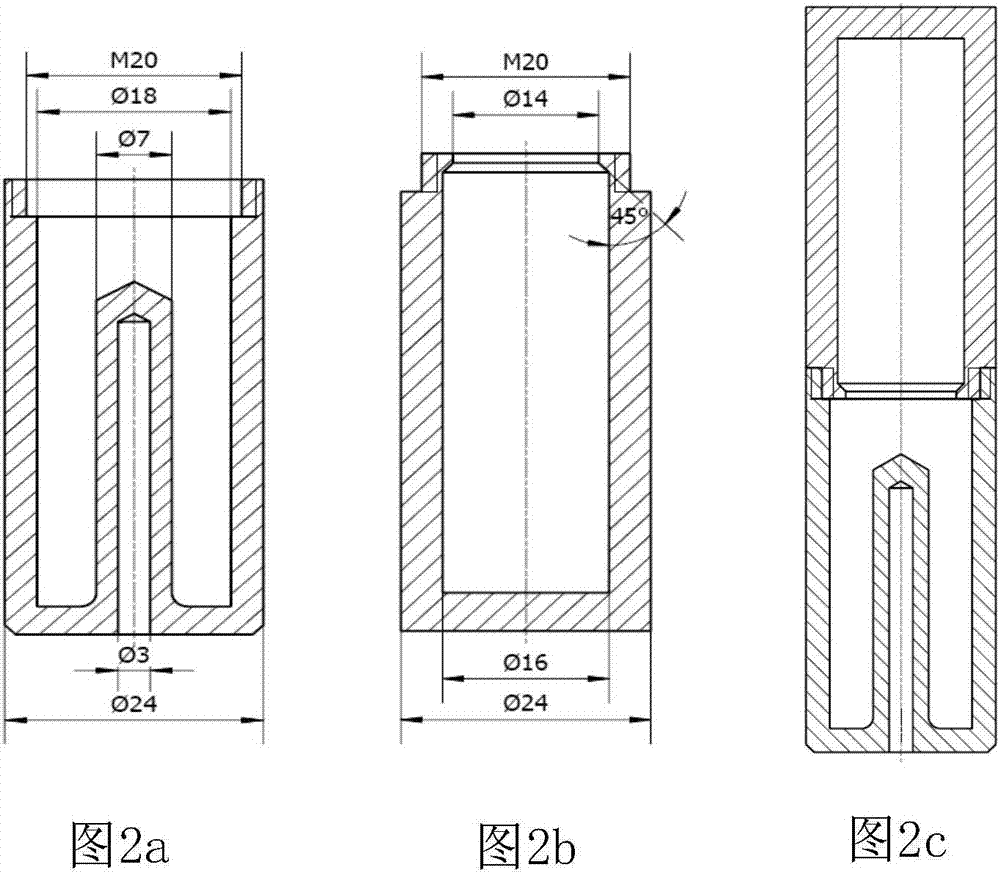

[0021] figure 2 Eutectic crucibles and pre-eutectic crucibles of a conventional diameter. figure 2 a is a eutectic point crucible with a conventional diameter, figure 2 b is a pre-eutectic crucible main body of a high-temperature eutectic point pre-eutectic pouring crucible designed in the present invention.

[0022] In order to prevent the metal-carbon eutectic from being contaminated by impurities, the eutectic point crucible is usually made of high-purity graphite. Therefore, the pre-eutectic crucible should also be made of graphite ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com