Composite molybdenum crucible, and preparation method and application thereof

A molybdenum crucible and composite technology, which is applied in the crucible, coating, metal material coating process, etc., can solve problems such as cracking and molybdenum crucible leakage, and achieve corrosion reduction, high temperature corrosion resistance, and uniform microstructure Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0052] The invention provides a method for preparing a composite molybdenum crucible, comprising the following steps:

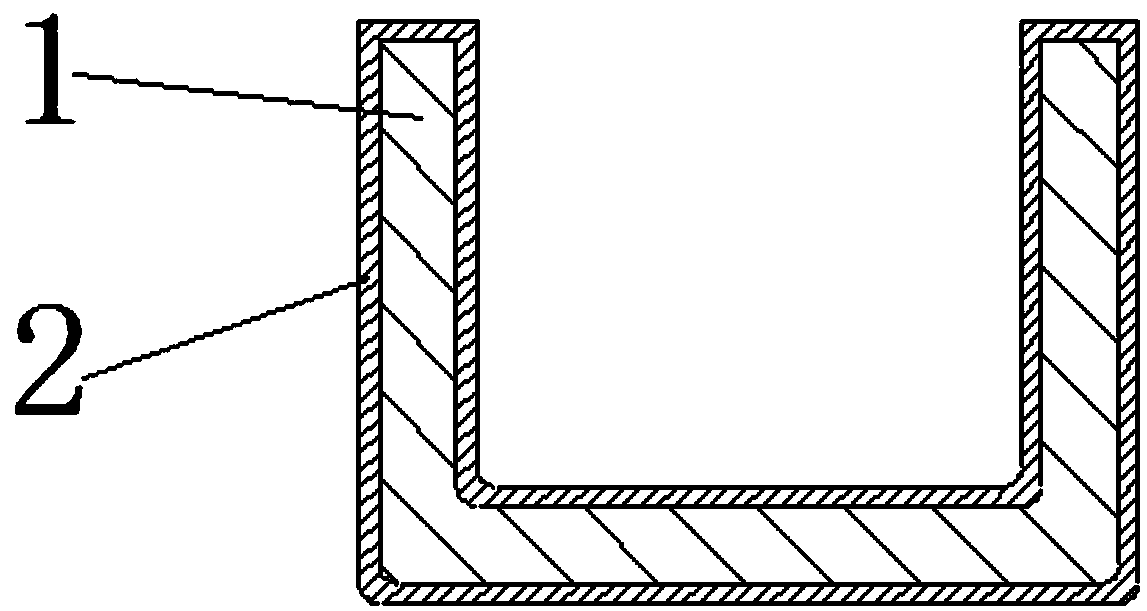

[0053] (1) Prepare a U-shaped matrix pure molybdenum crucible with a hollow bottom and a hollow bottom, the size of which is 300mm in outer diameter, 300mm in height, 20mm in wall thickness, 25mm in bottom thickness, and a density of 9.5g / cm 3 ;

[0054] (2) Assembly of base molybdenum crucible components: evenly lay graphite powder on the bottom of the graphite crucible, lay graphite plate on the graphite powder, place the bottom surface of the base molybdenum crucible on the graphite plate, and keep the other surfaces of the base molybdenum crucible away from the graphite powder. contact, leave a gap between the base molybdenum crucible and the graphite crucible, and then cover the graphite cover to obtain the assembled base molybdenum crucible assembly, specifically as Figure 4 shown;

[0055] (3) High-temperature carburizing treatment: move the assembl...

Embodiment 2

[0059] The invention provides a method for preparing a composite molybdenum crucible, comprising the following steps:

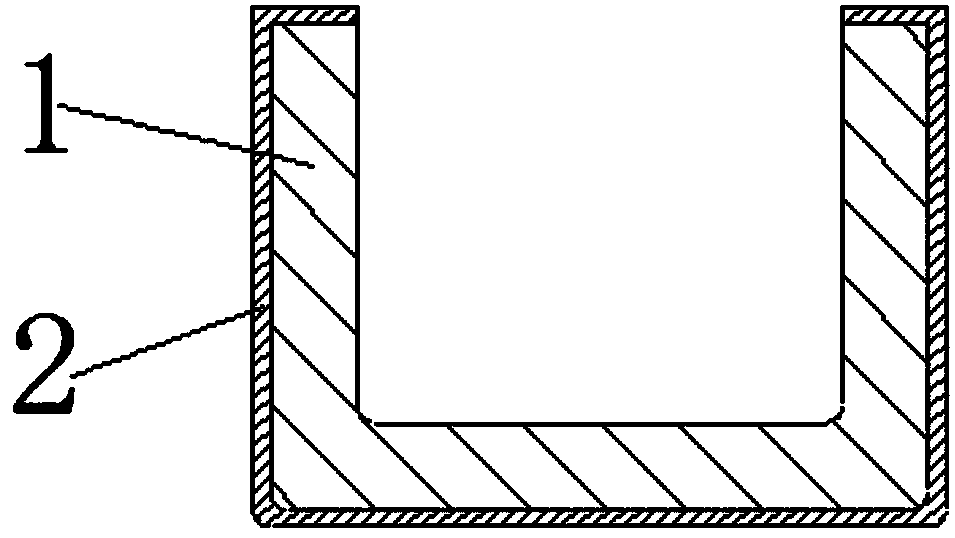

[0060] (1) Prepare a U-shaped matrix molybdenum alloy crucible whose longitudinal section shape is hollow with a bottom. The doping element of the molybdenum alloy crucible is 0.8% (mass percentage) cerium oxide, and its size is 100mm in outer diameter, 100mm in height, and 100mm in wall thickness. 5mm, bottom thickness 5mm, density 9.4g / cm 3 ;

[0061] (2) Assembly of matrix molybdenum alloy crucible components: lay graphite powder evenly on the bottom of graphite crucible, graphite powder is provided with graphite hard felt, matrix molybdenum alloy crucible is placed on graphite hard felt, matrix molybdenum alloy crucible is installed inside and inside Molybdenum alloy crucible with internal protection matching the surface shape and size. Only the outer bottom of the base molybdenum alloy crucible is in contact with the graphite hard felt. The base molybde...

Embodiment 3

[0066] The invention provides a method for preparing a composite molybdenum crucible, comprising the following steps:

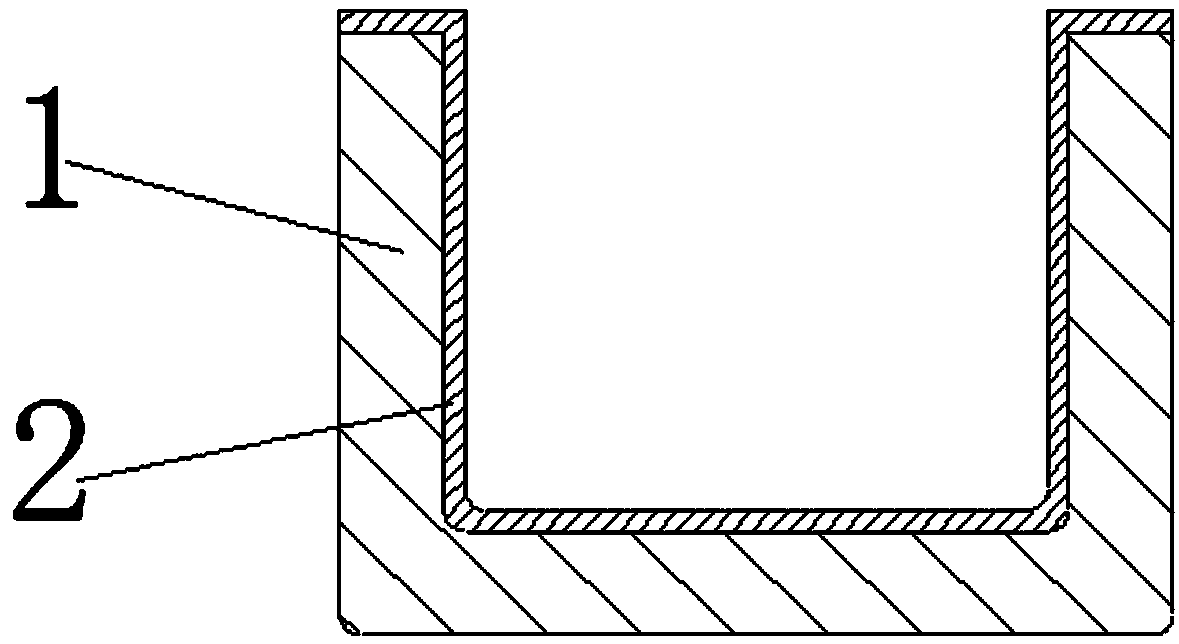

[0067] (1) Prepare the U-shaped matrix molybdenum alloy crucible whose longitudinal section shape is hollow with bottom, the doping element of the molybdenum alloy crucible is 1.0% (mass percentage) lanthanum oxide, and its size is 170mm in outer diameter, 110mm in height, and 10mm, bottom thickness 10mm, density 9.6g / cm 3 ;

[0068] (2) Assembly of matrix molybdenum alloy crucible components: lay graphite powder evenly on the bottom of graphite crucible, graphite powder is provided with graphite soft felt, matrix molybdenum alloy crucible is placed on graphite soft felt, matrix molybdenum alloy crucible is installed on the outside The outer protective pure molybdenum crucible with matching surface shape and size, only the outer bottom of the outer protective pure molybdenum crucible is in contact with the graphite soft felt, the matrix molybdenum alloy cruc...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Outer diameter | aaaaa | aaaaa |

| Height | aaaaa | aaaaa |

| Wall thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com