Preparation method of polyvinyl alcohol/hydroxyapatite (PVA/HA) composite microspheres

A technology of hydroxyapatite and composite microspheres, which is applied in the direction of microsphere preparation, microcapsule preparations, skin care preparations, etc., can solve performance limitations and other problems, and achieve easy operation, high degree of spheroidization, and high dispersion Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

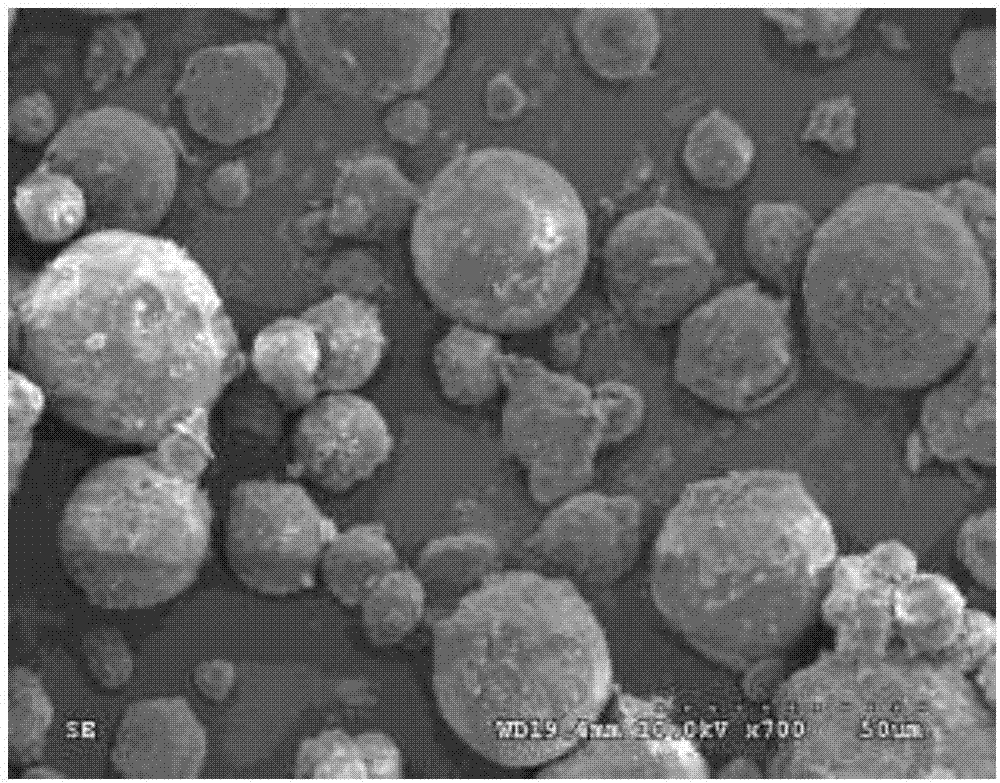

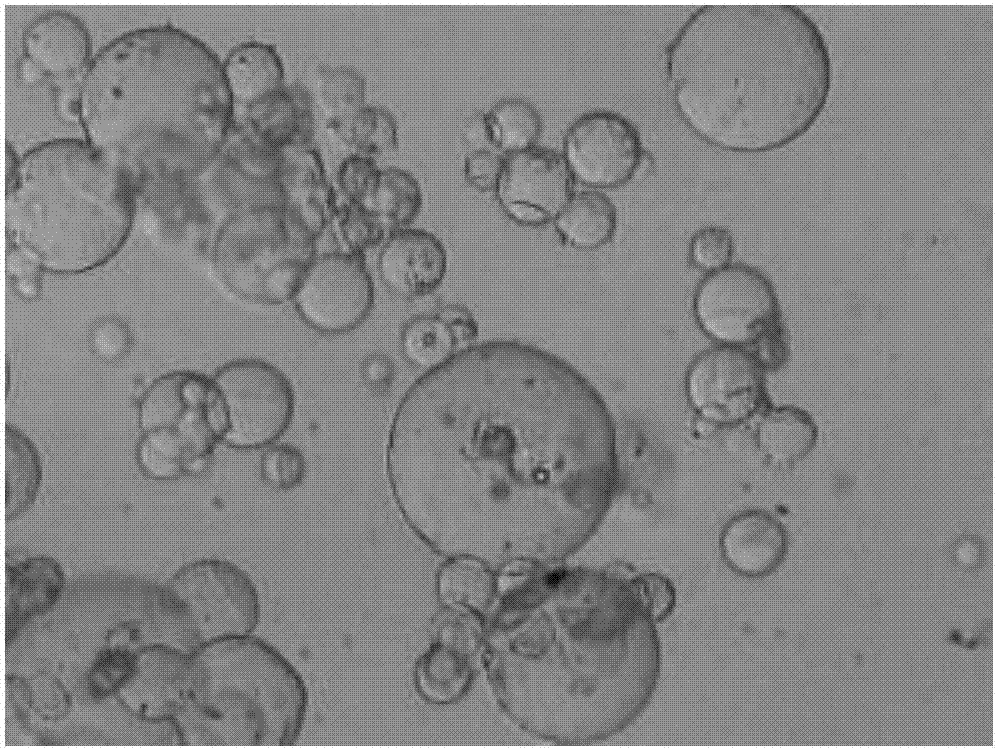

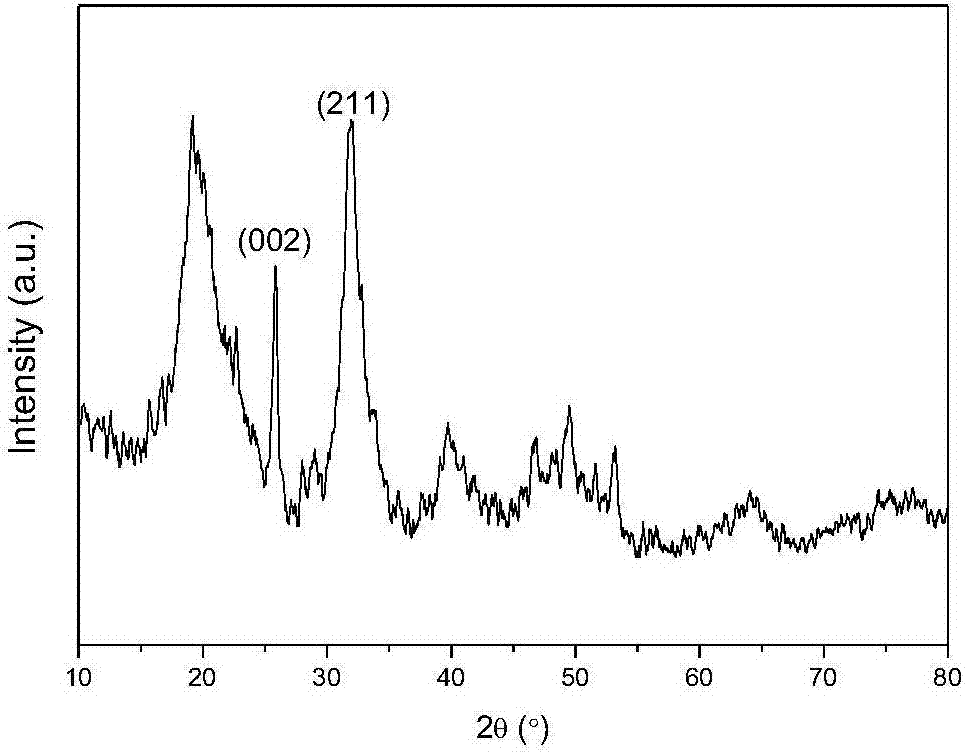

[0068] Under the condition of water bath at 90°C, dissolve the PVA124 particles in 10mL deionized water to prepare a 7% PVA solution. After cooling the solution to room temperature, 0.175 g of hydroxyapatite powder and an appropriate amount of concentrated hydrochloric acid were added thereto. Stir well at room temperature to completely dissolve the hydroxyapatite. The resulting solution was added dropwise to 100 mL of soybean oil containing Span 80 as a surfactant for dispersion, followed by adding glutaraldehyde for crosslinking. After 1 hour of cross-linking, an appropriate amount of NaOH solution was added to the emulsion system, and the stirring was continued for 2 hours to regenerate HA and deposit it into the PVA matrix in situ. The obtained product is centrifuged, washed repeatedly with acetone and water, and then placed in the air at room temperature to obtain PVA / HA composite microspheres with a theoretical content of HA of 20%.

Embodiment 2

[0070] Under the condition of water bath at 90°C, dissolve the PVA124 particles in 5mL deionized water to prepare a 6% PVA solution. After the solution was cooled to room temperature, 0.176g of calcium nitrate tetrahydrate, 0.16g of disodium hydrogen phosphate dodecahydrate and concentrated nitric acid were added thereto, and an acidic PVA solution containing calcium ions and phosphate ions was formed after thorough stirring. The resulting solution was added dropwise to 100 mL of liquid paraffin containing Span 85 as a surfactant for dispersion, followed by adding glutaraldehyde for crosslinking. After 2 hours of cross-linking, an appropriate amount of ammonia water was added to the emulsion system, and the stirring reaction was continued for 4 hours, so that HA was generated and deposited into the PVA matrix in situ. The obtained product is centrifuged, washed repeatedly with ethanol and water, and then placed in the air at room temperature to obtain PVA / HA composite microsph...

Embodiment 3

[0072] Dissolve PVA1750 particles in 10 mL of deionized water at 80°C in a water bath to prepare a 10% PVA solution. After the solution was cooled to room temperature, 0.473g of calcium chloride, 0.338g of diammonium hydrogen phosphate and concentrated hydrochloric acid were added thereto, fully stirred to dissolve it completely, and an acidic PVA solution containing calcium ions and phosphate ions was formed. The solution was added dropwise to 100 mL of olive oil containing Span80-Tween 80 (mass ratio 8:2) for dispersion, and then glutaraldehyde was added for cross-linking. After cross-linking for 2 hours, add an appropriate amount of NaOH solution to the emulsion system and continue to stir for 2 hours to generate HA and deposit it into the PVA matrix in situ. The obtained product is centrifuged, washed repeatedly with acetone and water, and then placed in the air at room temperature to obtain a PVA / HA composite microsphere with a theoretical content of HA of 30%.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com