Hot stamping mould steel and method for manufacturing same

A technology of hot stamping dies and manufacturing methods, which is applied in the field of hot work die steel and its manufacturing, can solve the problems of reduction and cost increase, and achieve the effects of improving comprehensive performance, reducing costs and increasing thermal conductivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1-5

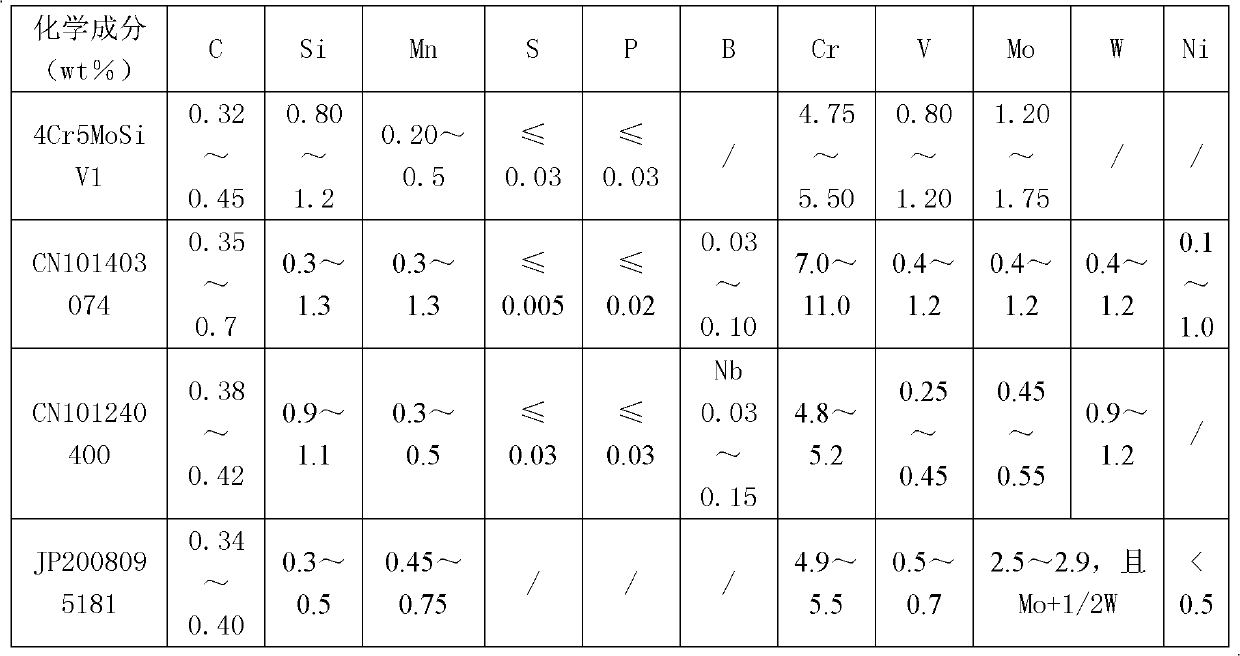

[0046] The specific steps of manufacturing hot stamping die steel are as follows (the chemical composition of each steel grade is shown in Table 1 in this case embodiment 1-5):

[0047] (1) Smelting: electric arc furnace smelting, the tapping temperature of molten steel is 1545~1555℃;

[0048] (2) Casting: casting into φ400mm~φ450mm electrode rod;

[0049] (3) Electroslag remelting: the voltage of the electric system is 57-59V, the current is 11000-12000A, and the electroslag is remelted into an electroslag ingot of 2000-3000kg;

[0050] (4) Put the electroslag ingot into the heating furnace of the radial forging machine with a furnace temperature of 700-800°C, heat it to 1230-1260°C at a heating rate of 80-120°C / h, and then keep it warm for 3-5 hours;

[0051] (5) Diameter forging machine forging: the forging start temperature is 1100-1150°C, and the stop forging temperature is 850-900°C;

[0052] (6) Put the electroslag ingot into an annealing furnace at 740-830°C for 14-1...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com