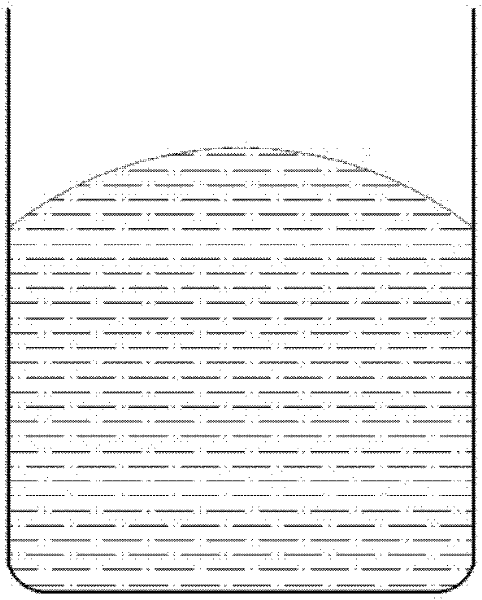

Double-crucible experimental apparatus for high-temperature experiment

An experimental device, double crucible technology, applied in the equilibrium experiment between pyrometallurgical slag-metal-gas phase, new crucible design field

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] The cylindrical ceramic crucible is made of Al 2 o 3 Cylindrical crucible, containing molten steel; molten steel will not corrode Al 2 o 3 Ceramic crucible. The waisted metal crucible is made of metal Mo, which is used to convert CaO-SiO 2 -Al 2 o 3 -MgO-TiO 2 The slag is held together, and the slag does not corrode the metal Mo.

[0017] Before the experiment, the required steel shavings were packed in Al 2 o 3 In a cylindrical crucible, and flatten the surface. The proportion of CaO and SiO that meet the experimental requirements 2 、Al 2 o 3 , MgO and TiO 2 After the powder is mixed evenly, it is filled in a Mo crucible and compacted. Then, the filled CaO, SiO 2 、Al 2 o 3 , MgO and TiO 2 The Mo crucible of the mixture powder was put into the Al 2 o 3 in a cylindrical crucible.

[0018] Put the above-mentioned double crucible with the reaction raw materials into the high-temperature furnace for equilibrium reaction. After the experiment, the Ti co...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com