Crucible for reappearance of metal-carbon high-temperature eutectic point

A eutectic point and crucible technology, applied in crucibles and other directions, can solve the problems of eutectic pollution, easy extrusion damage, and many geometric constraints, and achieve the effects of reducing thermal stress, improving reliability and convenient installation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

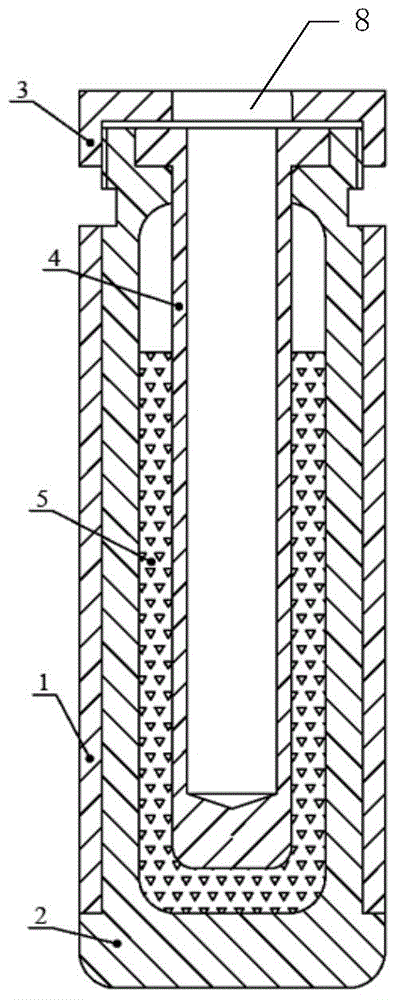

[0030] The metal-carbon high temperature eutectic point reappearance crucible in the present embodiment, its material is graphite; Its structure is as follows figure 1 As shown, it includes: a crucible shell 1, a crucible lining 2, a crucible upper cover 3 and a thermometer well 4.

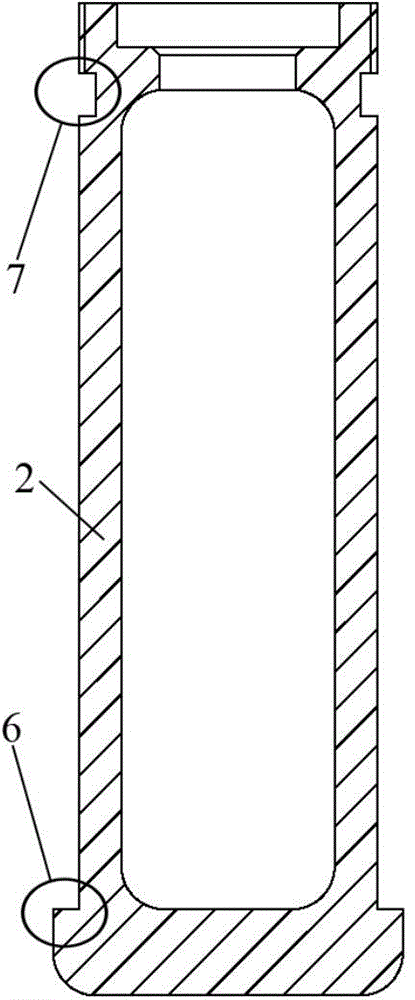

[0031] The structure of the crucible lining 2 is as figure 2 As shown, the upper port has an external thread, and the lower end of the crucible lining 2 is designed with a flange 6 . A neck structure 7 with a diameter smaller than the upper port is designed under the external thread of the upper port of the crucible lining 2, which is convenient for clamping and moving the uncooled crucible with crucible tongs.

[0032] Both the bottom of the inner cavity of the crucible lining 2 and the bottom of the flange 6 adopt a rounded corner transition design, the purpose of whic...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com