A graphite crucible for manufacturing c/sic ceramic matrix composite brake discs

A technology of graphite crucibles and composite materials, applied in the direction of crucibles, etc., can solve the problems of increasing manufacturing costs, reducing the service life of crucibles, poor temperature uniformity, etc.

Uniformity, the effect of lengthening the uniform temperature zone

Active Publication Date: 2010-03-10

NORTHWESTERN POLYTECHNICAL UNIV

View PDF0 Cites 7 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

graphite crucible, it is easy to cause the raw material to react with the graphite crucible, which seriously reduces the service life of the crucible, increases the manufacturing cost, and

It is difficult to clean the material and other problems; at the same time, because the graphite crucible and the raw material have a large heat capacity, and the channel for the energy transfer generated by the heating element

Due to limited channels, the temperature uniformity in the furnace is poor, which cannot meet the requirements of mass production of brake discs

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment Construction

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Login to View More

Abstract

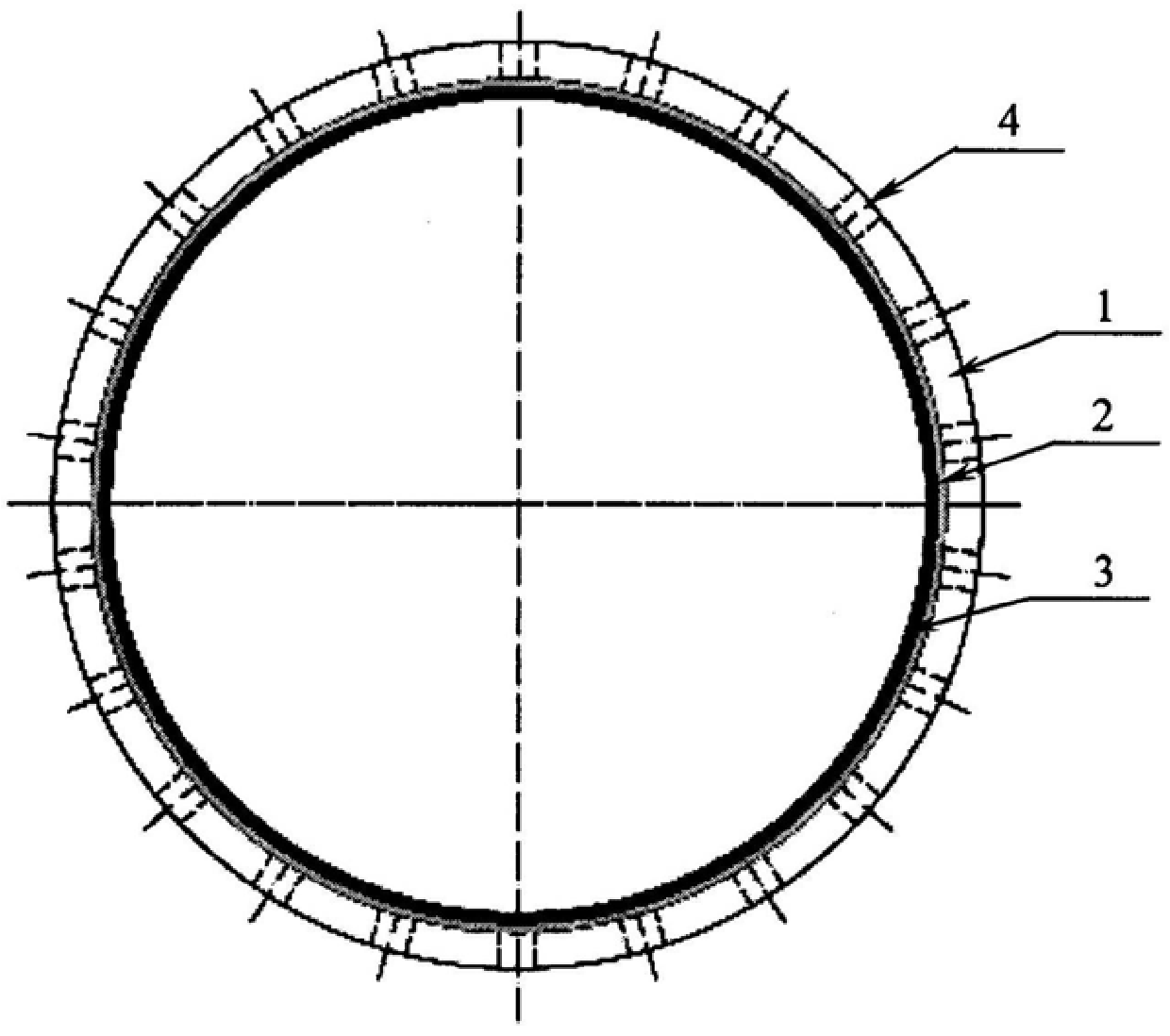

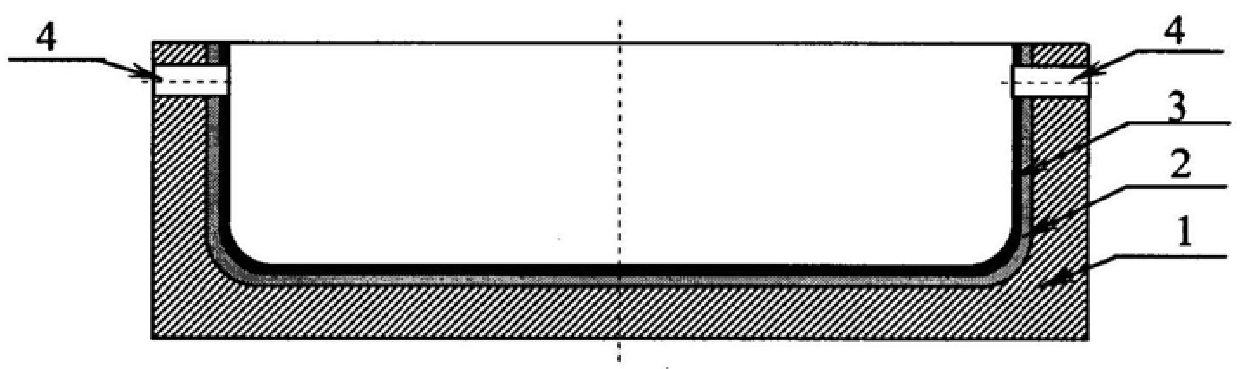

The invention relates to a graphite crucible for manufacturing brake disks of C / SiC ceramic matrix composite materials. The graphite crucible comprises a graphite crucible body, on which evenly distributed small holes are opened, the inner wall of the graphite crucible is coated with a boron nitride (BN) coating, and the boron nitride (BN) coating is laid There is graphite paper. The graphite crucible of the invention has a long service life, and the material is easy to clean up during use, so that the temperature uniformity in the high-temperature vacuum furnace can be improved. The graphite crucible of the invention can also be used in the preparation of other ceramic matrix composite materials by the reactive melt infiltration method.

Description

A graphite crucible for manufacturing C / SiC ceramic matrix composite brake discs technical field The present invention relates to a kind of graphite crucible, particularly relate to a kind of manufacture C / SiC ceramic matrix composite material brake disk graphite crucible. Background technique The manufacture method of carbon / silicon carbide ceramic matrix composite material (C / SiC) brake disc is to adopt chemical vapor infiltration method (CVI) combined with reactive melt infiltration (RMI). Firstly, three-dimensional needle-punched carbon (C) fibers were fabricated by chemical vapor infiltration (CVI). Deposit a pyrolytic carbon (C) interface layer on the dimensional preform, and then adjust the flow ratio of propylene and diluent gas as well as the deposition temperature. Now CVI is rapidly deposited to make carbon / carbon (C / C) porous composites; finally, it is processed by reactive melt infiltration (RMI) at high temperature The carbon / silicon carbide (C / SiC) ...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More Patent Type & Authority Patents(China)

IPC IPC(8): B01L3/04

Inventor 徐永东张立同成来飞王东刘小瀛涂建勇陈旭付志强

Owner NORTHWESTERN POLYTECHNICAL UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com