Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

103results about How to "Improve high temperature corrosion resistance" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

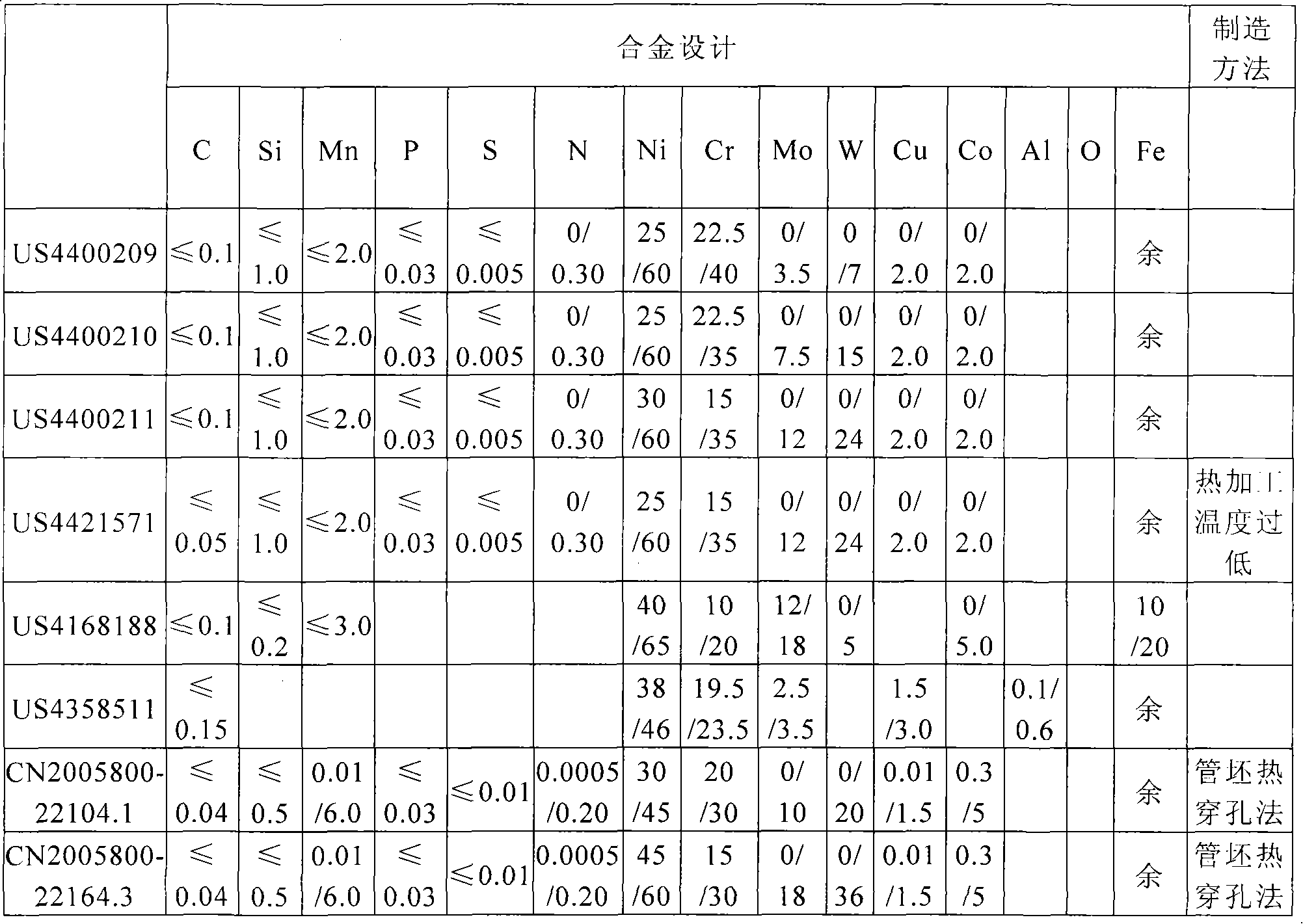

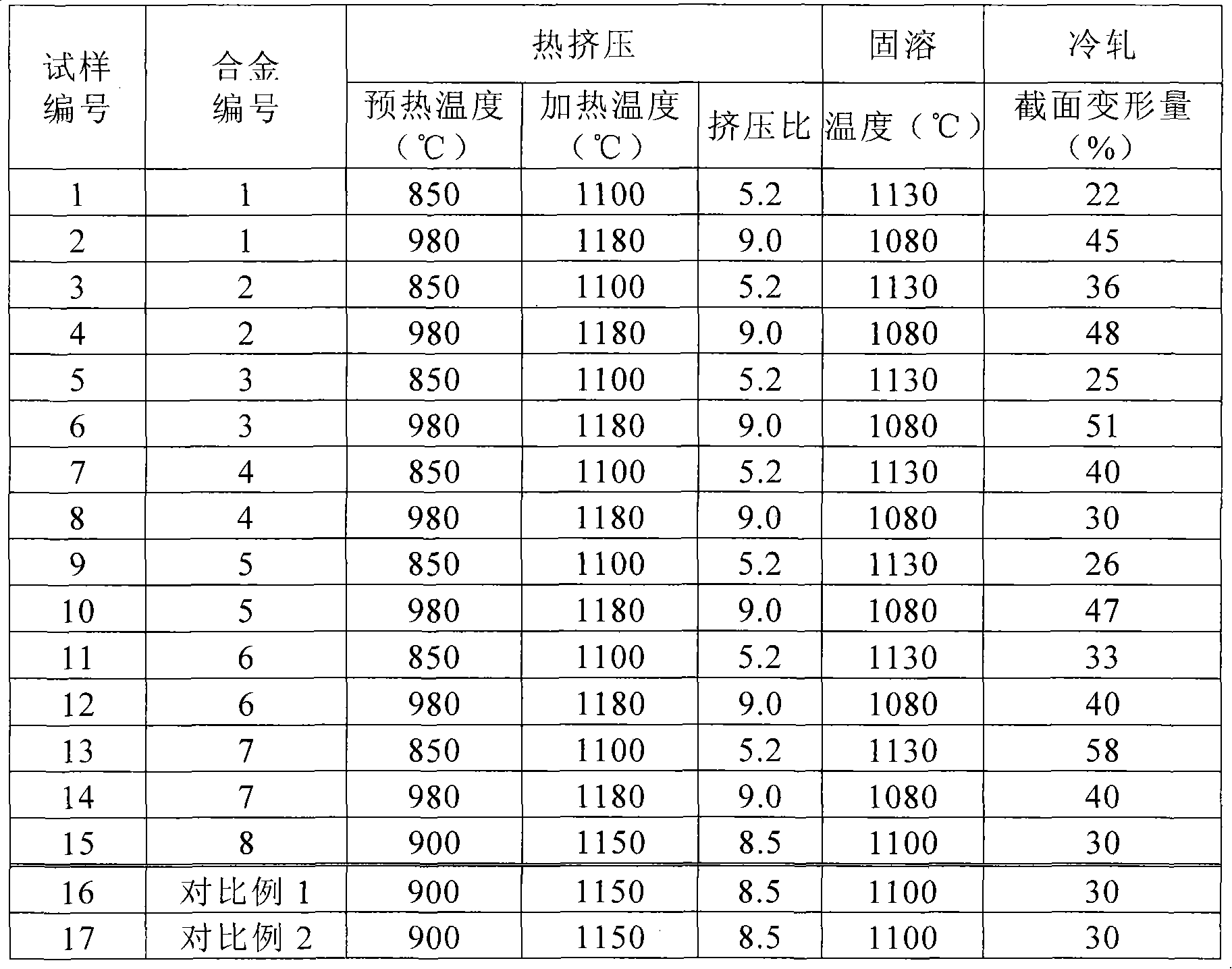

Ni-based alloy oil sleeve and manufacturing method for high-acidity deep well

ActiveCN101613833ALow costImprove high temperature corrosion resistanceDrilling rodsRoll mill control devicesSolution treatmentImpurity

The invention relates to a Ni-based alloy oil sleeve for a high-acidity deep well, which comprises the following components in percentage by mass: less than or equal to 0.02 percent of C, less than or equal to 0.03 percent of P, less than or equal to 0.03 percent of S, less than or equal to 0.5 percent of Si, less than or equal to 1.0 percent of Mn, 40 to 60 percent of Ni, 20 to 30 percent of Cr, 1 to 10 percent of Mo, 1 to 5 percent of W, 0 to 5 percent of Co, 0.1 to 3.0 percent of Cu, 0.01 to 0.5 percent of Al, less than or equal to 0.01 percent of O, less than or equal to 1.5 percent of Ti, and the balance of Fe and inevitable impurities. In the invention, the thermal extrusion processing performance and corrosion resisting performance of the alloy are effectively ensured by controlling the contents of the Al and O. The 90 to 140 ksi steel-grade Ni-based alloy oil sleeve meeting different well depth requirements of high-acidity oil fields and gas fields is manufactured by thermal extrusion, 1,050-1,150 DEG C of solution treatment and cold rolling of the smelted and forged blanks.

Owner:BAOSHAN IRON & STEEL CO LTD

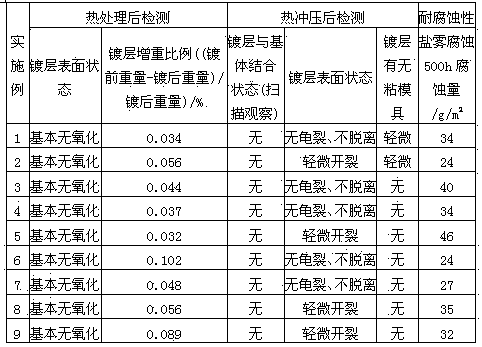

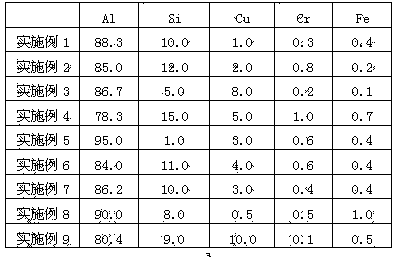

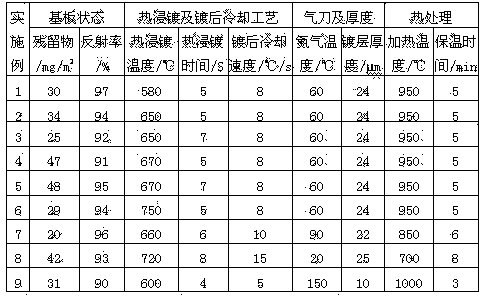

High-temperature oxidation resistant plating layer material and hot dipping method for hot stamping formed steel

ActiveCN104233149AImprove high temperature oxidation resistanceImprove corrosion resistanceHot-dipping/immersion processesHot stampingSheet steel

The invention discloses a high-temperature oxidation resistant plating layer material and a hot dipping method for hot stamping formed steel. A hot stamping formed steel plate enters a plating solution for hot dipping and then is subjected to cooling and heat treatment so that a hot dipping steel plate can be obtained, wherein the plating solution comprises the following components in percentage by mass: 1.0%-15.0% of Si, 0.5%-10.0% of Cu, 0.1%-1.0% of Cr, less than or equal to 1.0% of Fe and the balance of Al and inevitable impurities. According to the method, the Cu element and Al element which are contained in a plating layer form a high-melting point intermetallic compound in a cooling process after the hot dipping, and Cr is gathered on the surface of the plating layer to form a compact oxidation film, so that the high-temperature oxidation resistant property of the plating layer is greatly enhanced; the Cu element is enriched on the surface of the plating layer, so that the corrosion-resisting property of the plating layer is greatly enhanced. The high-temperature oxidation resistance and the high-temperature corrosion resistance of the plating layer are enhanced by utilizing the intermetallic compounds formed among Al, Si, Cr, Cu and Fe; and the obtained plating layer has the advantages of reasonability in structure, tight combination with a substrate and good high-temperature oxidation resistance and corrosion-resisting property.

Owner:HEBEI IRON AND STEEL

Preparation method of submicron particle-reinforced aluminum-based composite material

InactiveCN102134667AImprove high temperature resistanceExtended service lifeAluminum matrix compositesMetal matrix composite

The invention provides a preparation method of a submicron particle-reinforced aluminum-based composite material, belonging to the technical field of preparation of metal-based composite materials. The method comprises the steps of: refining an aluminum melt or an aluminum alloy melt and then adjusting to a reaction starting temperature; adding a reactant which can have in-situ reaction with the aluminum melt or the aluminum alloy melt to generate particle phase so as to carry out synthetic reaction; applying high-energy ultrasound and low-frequency stirring magnetic field during the synthetic reaction; and standing to a pouring temperature and carrying out pouring after the reaction is finished, wherein the high-energy ultrasound and low-frequency stirring magnetic field are applied at the same time and the high-energy ultrasound is applied intermittently. When an intermittent application manner is adopted, the service life of a amplitude transformer can be prolonged and the quality deterioration of the melt caused by the introduction of impurity elements due to the corrosion of the amplitude transformer is prevented; and the size of the generated particles is smaller than that generated by other manners so that the manner has the function of thinning and reinforcing the particles and is beneficial to improvement of the mechanical property of the submicron particle-reinforced aluminum-based composite material.

Owner:江苏中欧材料研究院有限公司 +1

High-temperature alloy, alloy hood manufactured from same and manufacturing technology of alloy hood

ActiveCN103173692AHigh hardnessImprove high temperature oxidation resistanceChemical/physical processesManufacturing technologyHardness

The invention provides a high-temperature alloy which comprises the components such as C, Cr, Ni, Mo, Mn, Si, Nb, RE, N, Ti, B, Zr and the like, wherein the optimal content of each component is selected after reasonable analysis and repeated tests so that the components of the alloy realize the best interaction effect; and the tests prove that the high-temperature alloy provided by the invention is obviously superior to 25-20 steel and 316 steel in terms of average hardness, high-temperature oxidation resistance, high-temperature corrosion resistance and high-temperature washout resistance, and has good high-temperature comprehensive performance.

Owner:浙江科得力新材料有限公司

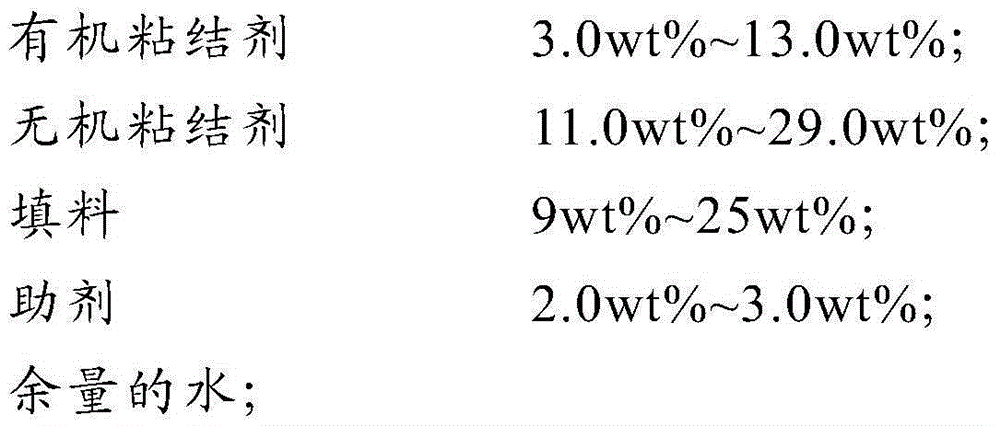

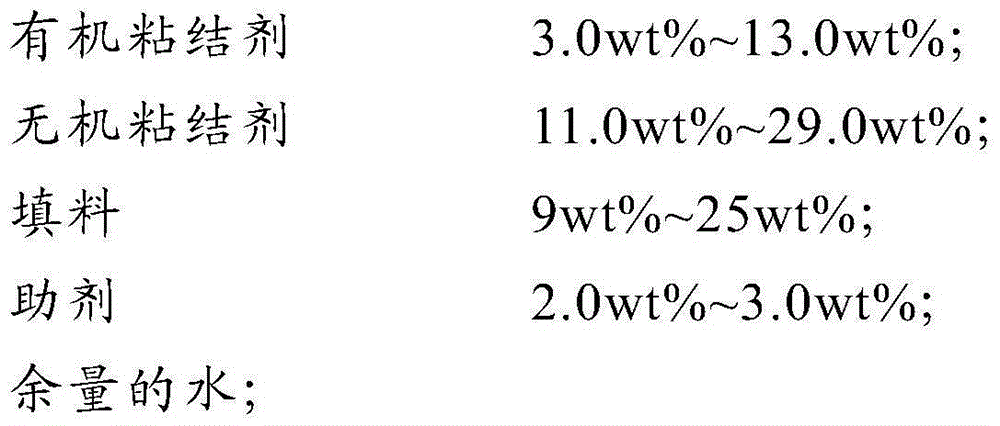

Ceramic paint and application thereof

The invention provides a ceramic paint which comprises 3.0-13.0 wt% of organic binder, 11.0-29.0 wt% of inorganic binder, 8.6-25 wt% of filler, 2.0-3.0 wt% of assistant and the balance of water. The organic binder is a pure acrylic emulsion, the inorganic binder is sodium water glass, and the filler comprises rare-earth oxide, graphite and boron nitride. The invention also provides application of the ceramic paint in industrial furnaces. Under the synergistic actions of the components, the ceramic paint has favorable comprehensive properties when being used as a ceramic coating.

Owner:铜陵兆山科技有限公司

Powder core wire as well as preparation method and application thereof

ActiveCN104032251AEnhanced Amorphous Formation AbilityImprove corrosion resistanceMolten spray coatingVulcanizationSand blasting

The invention discloses a powder core wire as well as a preparation method and application thereof. The powder core wire is prepared by coating a powder core in a stainless steel strip; the powder core is prepared by mixing seven element powder in percentage by weight: 30-50% of Cr, 2-10% of B, 1-5% of Al, 1-5% of Si, 3-15% of Nb, 2-10% of Mo and the rest amount of Fe; the skin of the powder core wire selects the stainless steel strip; the weight ratio of the powder core to the stainless steel strip is (0.43-0.67): 1; when a coating layer is prepared by adopting an electric arc spraying technology, oil and rust on the surface of a matrix are removed firstly; and then, the pretreatment such as sand blasting is performed. The powder core wire can obtain the coating layer with low porosity, high hardness and excellent high-temperature oxidization and sulphuration corrosion resistance, and is suitable for such high-temperature structural members as a boiler pipe, a roller and an engine cylinder body.

Owner:HOHAI UNIV

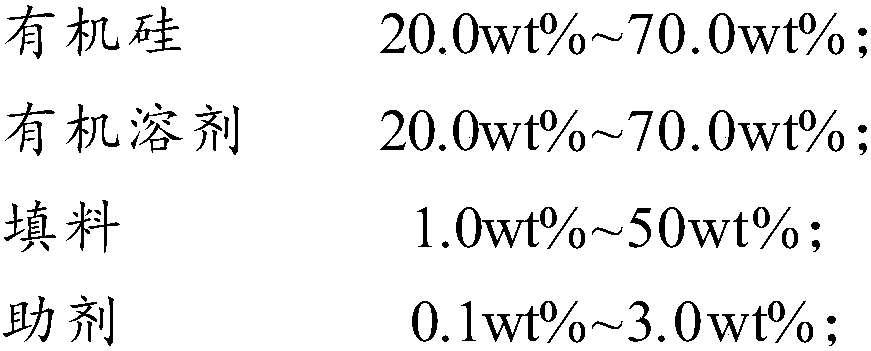

Ceramic surface material and surface coating

ActiveCN108531078AImprove toughnessImprove thermal stabilityFireproof paintsAnti-corrosive paintsRare earthButyl carbitol

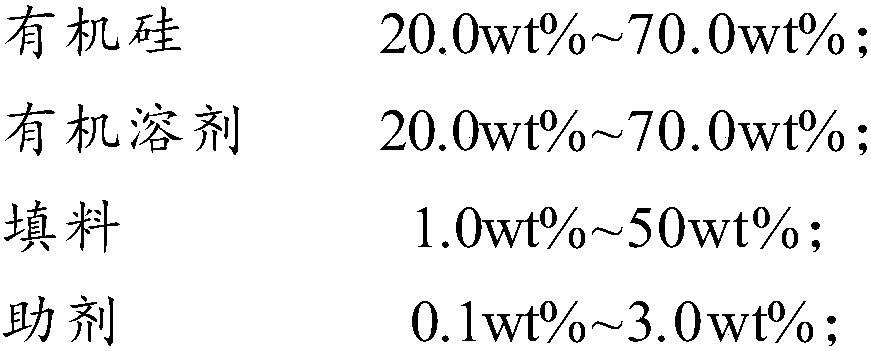

The invention provides a ceramic surface material. The ceramic surface material comprises 20.0wt%-70.0wt% of organosilicone, 20.0wt%-70.0wt% of an organic solvent, 10wt%-50wt% of filler and 0.1wt%-3.0wt% of an auxiliary, wherein the organic solvent is selected from one or more of butyl acetate, dimethylbenzene, n-butyl ether, butyl carbitol acetate, hexahydrotoluene, normal octane and butyl titanate; and the filler consists of graphene, graphite, transition group metallic oxide, composite silicate, rare earth oxide, nonmetal and metal. The components in the ceramic surface material cooperatively interact, and the ceramic surface material has good overall performance when used as a coating.

Owner:ZHAOSHAN TECH BEIJING CO LTD

Method for producing alumina homogenization material

ActiveCN101121604AImprove high temperature corrosion resistanceImprove fire resistanceGrain growthMaterials science

The present invention discloses a preparation method for bauxite material; which uses the aluminium bauxite mineral with loose structure and incapable of baking directly, and is formed through the following steps including matching, grilling, de-iron, filtering, molding and drying and baking. The main crystal phase of the bauxite material is Alpha- Al2O3, whose section is caesious with compact texture and inerratic crystal grain growth; most of the material is more than 15um; each physical index reaches or even exceeds the bauxite material produced in domestic; compared with the existing technology, the material has the advantages of lower baking temperature and shorter baking time and so on.

Owner:PUYANG REFRACTORIES GRP CO LTD

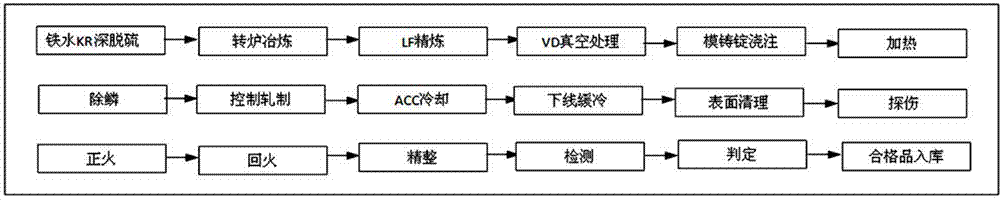

Extra-thick hydrogen present 15CrMoR steel plate and production method thereof

InactiveCN103045970AImprove performanceImprove purityHeat treatment process controlTemperingUltimate tensile strength

The invention discloses an extra-thick hydrogen present 15CrMoR steel plate and a production method thereof. The steel plate comprises the following elements in percentage by weight: 0.12-0.17 percent of C, less than or equal to 0.20 percent of Si, 0.40-0.70 percent of Mn, less than or equal to 0.008 percent of P, less than or equal to 0.003 percent of S, 0.14-0.18 percent of Ni, 0.80-1.20 percent of Cr, less than or equal to 0.10 percent of Cu, 0.45-0.60 percent of Mo, 0.025-0.050 percent of Al, less than or equal to 0.016 percent of As, ess than or equal to 0.008 percent of Sn, less than or equal to 0.003 percent of Sb and Fe and unavoidable impurities in balancing weight. The production method comprises the steps of converter smelting, LF (Ladle Furnace) refining, vacuum refining, pouring, heating, rolling, cooling control, slow cooling, heat treatment and the like. According to the invention, the chemical elements of the steel plate are designed via the Cr-Mo taken as the basic alloy element, through the converter smelting, the LF refining, VD (Vacuum Degassing) furnace vacuum degasification, plate rolling, crack detection, normalization, tempering, steel plate finishing operation, performance inspection, as well as rolling control, cooling control, normalization and tempering, the particle size of steel is more than 8.0, and the elements are organized to a tempering sorbite; and through the effective implement of the measurements, the hydrogen present steel plate with a thickness of 120 mm to 150 mm and good corrosion resistance is successfully produced, and the steel plate is provided with higher intensity and good tenacity, and has favorable welding performance.

Owner:NANYANG HANYE SPECIAL STEEL CO LTD

Steel plate made of pressure vessel steel ASTMA387CL11Gr2 and production method thereof

InactiveCN104561837AImprove performanceImprove high temperature corrosion resistanceAlloy elementSteel quality

The invention discloses a steel plate made of pressure vessel steel ASTMA387CL11Gr2, which can meet the use requirements of equipment, and a production method thereof. The steel plate made of the pressure vessel steel ASTMA387CL11Gr2 comprises the following chemical components in percentage by mass: 0.10 to 0.17 percent of C, less than or equal to 0.55 percent of Si, 0.40 to 0.65 percent of Mn, less than or equal to 0.008 percent of P, less than or equal to 0.003 percent of S, less than or equal to 0.20 percent of Ni, 1.20 to 1.50 percent of Cr, less than or equal to 0.10 percent of Cu, 0.45 to 0.65 percent of Mo, 0.025 to 0.050 percent of Al, less than or equal to 0.016 percent of As, less than or equal to 0.005 percent of Sn, less than or equal to 0.003 percent of Sb, less than or equal to 0.003 percent of O, less than or equal to 0.008 percent of N, less than or equal to 0.0002 percent of H and the balance of Fe and unavoidable impurities. According to the invention, the chemical components of the steel plate are designed by using Cr-Mo as the basic alloy elements; by the process route of converter steelmaking, LF (low frequency) furnace refining, VD (vacuum degassing) furnace vacuum degassing, rolling, fault detection, normalizing, tempering, steel plate finishing and performance examination, the suitable internal controlled composition is made, the fluctuation range of the chemical components is strictly controlled and stability of performance of the steel plate is ensured; the LF and VD processes are adopted to ensure cleanness of the steel; blending control and smelting operation are reinforced; the content of harmful elements such as Sn, Sb, As, O, N and H is effectively controlled; the temper embrittlement tendency is reduced; the high-temperature corrosion resistance of the steel is improved.

Owner:NANYANG HANYE SPECIAL STEEL CO LTD

Ceramic paint and application thereof

The invention provides ceramic paint. The ceramic paint comprises 3.0wt%-6.8wt% of organic binders, 15.0wt%-45.0wt% of inorganic binders, 7wt%-35wt% of packing, 2.0wt%-3.0wt% of auxiliaries and the balance water. The organic binders are made of silicone emulsion, the inorganic binders are made of sodium water glass, and the packing comprises rare-earth oxide, graphite, mica, kaolin, copper chromite black, zirconia and chromium oxide. The invention further provides application of the ceramic paint to industrial furnaces. The ceramic paint and the application have the advantages that mutual synergistic effects can be realized by components in the ceramic paint, and accordingly the ceramic paint is excellent in comprehensive performance when used as a ceramic coating.

Owner:铜陵兆山科技有限公司

High-entropy alloy composite coating layer for surface protection for aluminum die-casting die

ActiveCN110846618ADense tissueEnhanced interface bindingVacuum evaporation coatingSputtering coatingHigh entropy alloysAlloy composite

The invention discloses a high-entropy alloy composite coating layer for surface protection for an aluminum die-casting die. The essential of the technical scheme is as follows: the high-entropy alloycomposite coating layer for surface protection for the aluminum die-casting die comprises a Ti priming layer, a CrAlN barrier layer, a CrAlNbN-CrAlSiN support layer with a gradient structure, and a CrAlNbSiON function layer which are sequentially deposited on the surface of the aluminum alloy die-casting die, wherein the CrAlNbN-CrAlSiN support layer with the gradient structure is a multi-periodcoating layer forming a cycle period from a CrAlNb layer to a CrAlSi layer; and the content of Nb element in the CrAlNbN-CrAlSiN support layer with the gradient structure is gradually increased from the CrAlN barrier layer to the CrAlNbSiON function layer, and the content of Si element is gradually reduced. The high-entropy alloy composite coating layer is compact in structure, good in interface bonding, not liable to crack and peel off, and good in anti-crack effect; and on top of increasing the hardness of the coating layer, Nb is beneficial to compaction for the coating layer, and further improves the toughness, the high-temperature corrosion resistance, the oxidation resistance and other performance of the coating layer.

Owner:振金镀膜(温州)有限公司

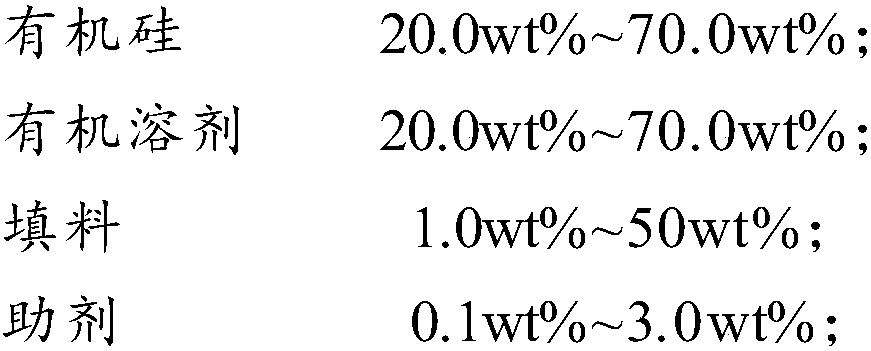

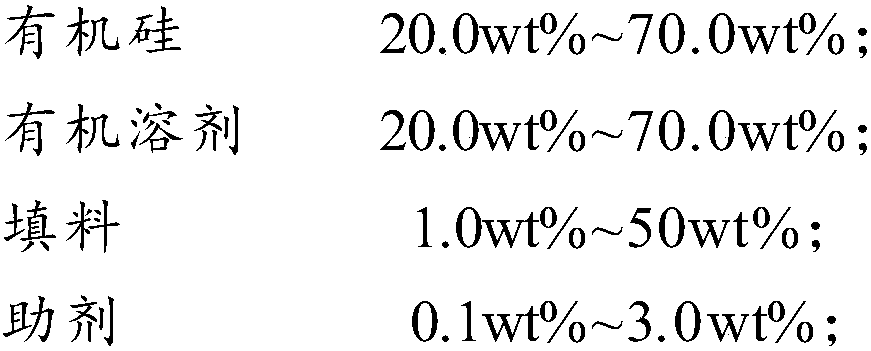

Ceramic surface material and surface coating

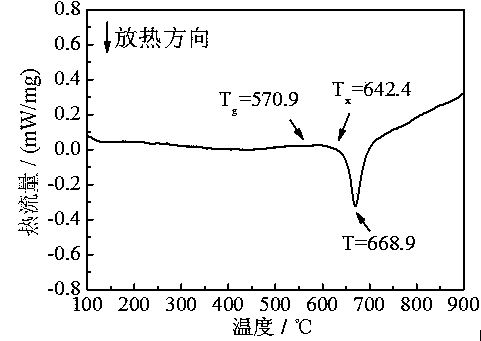

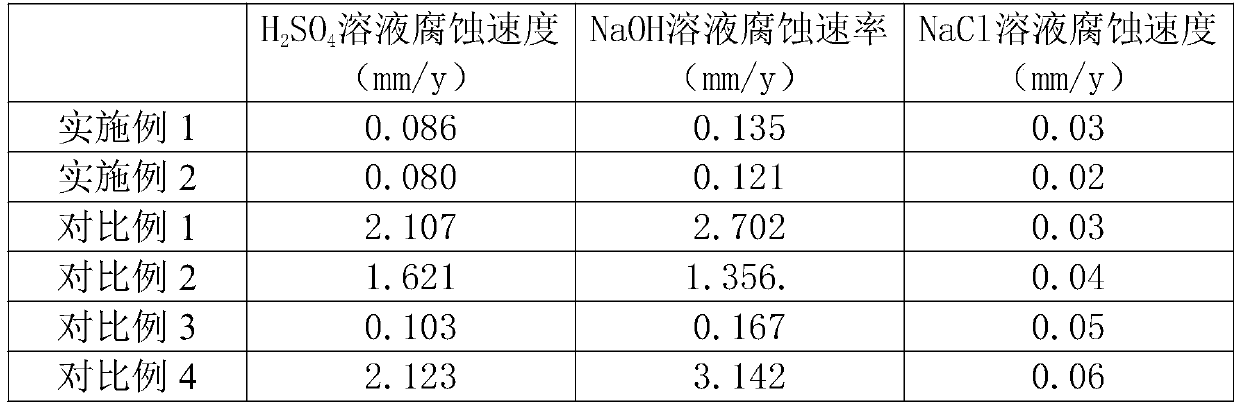

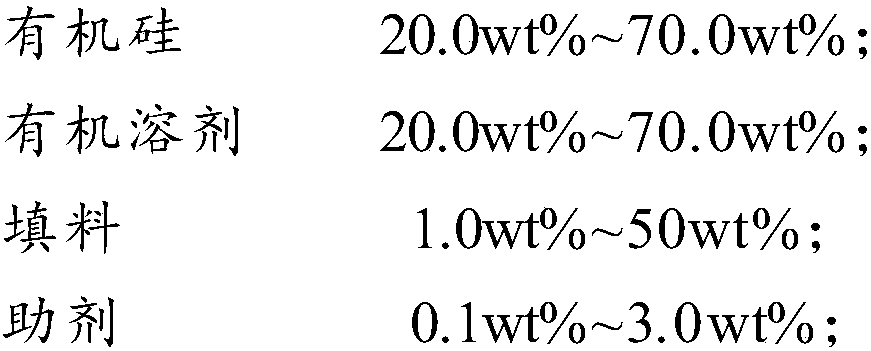

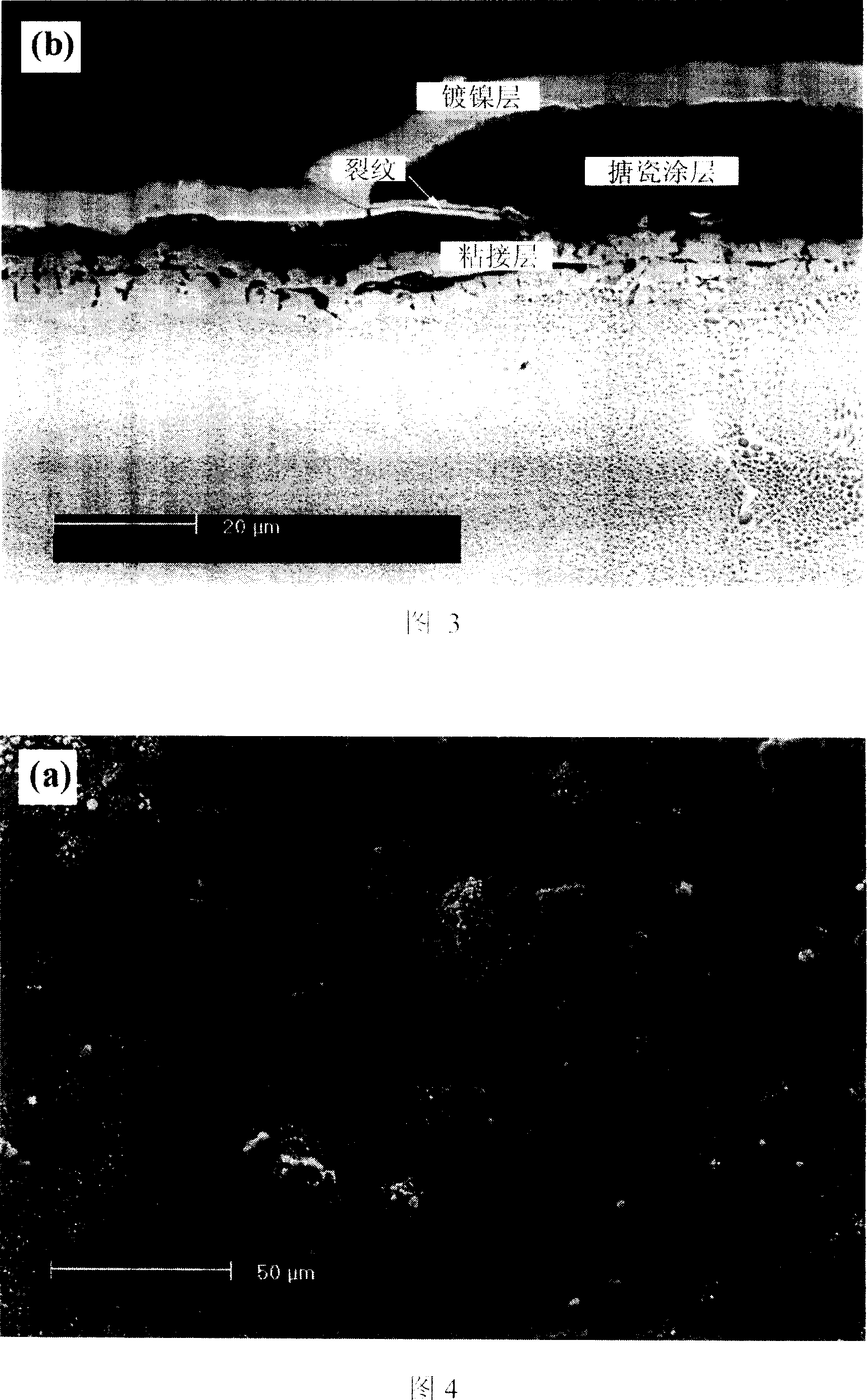

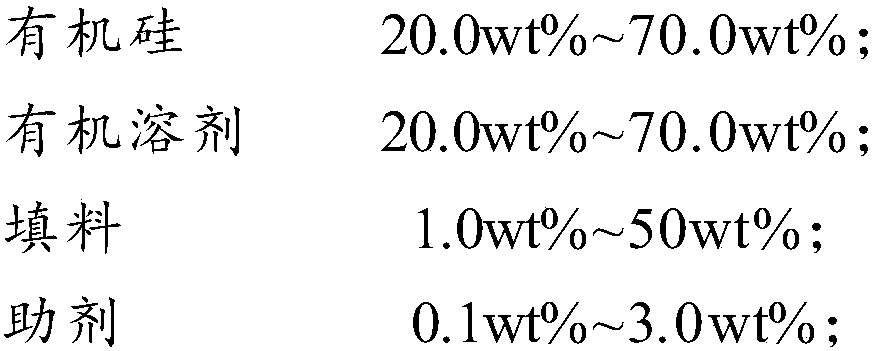

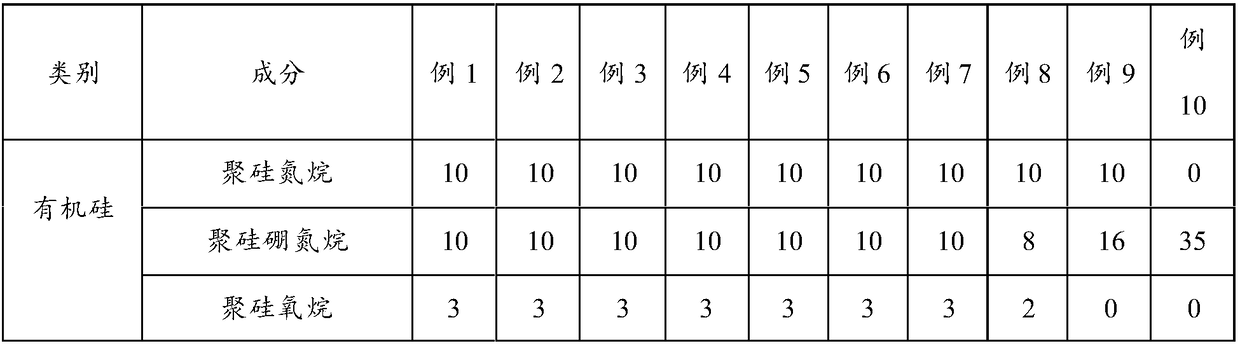

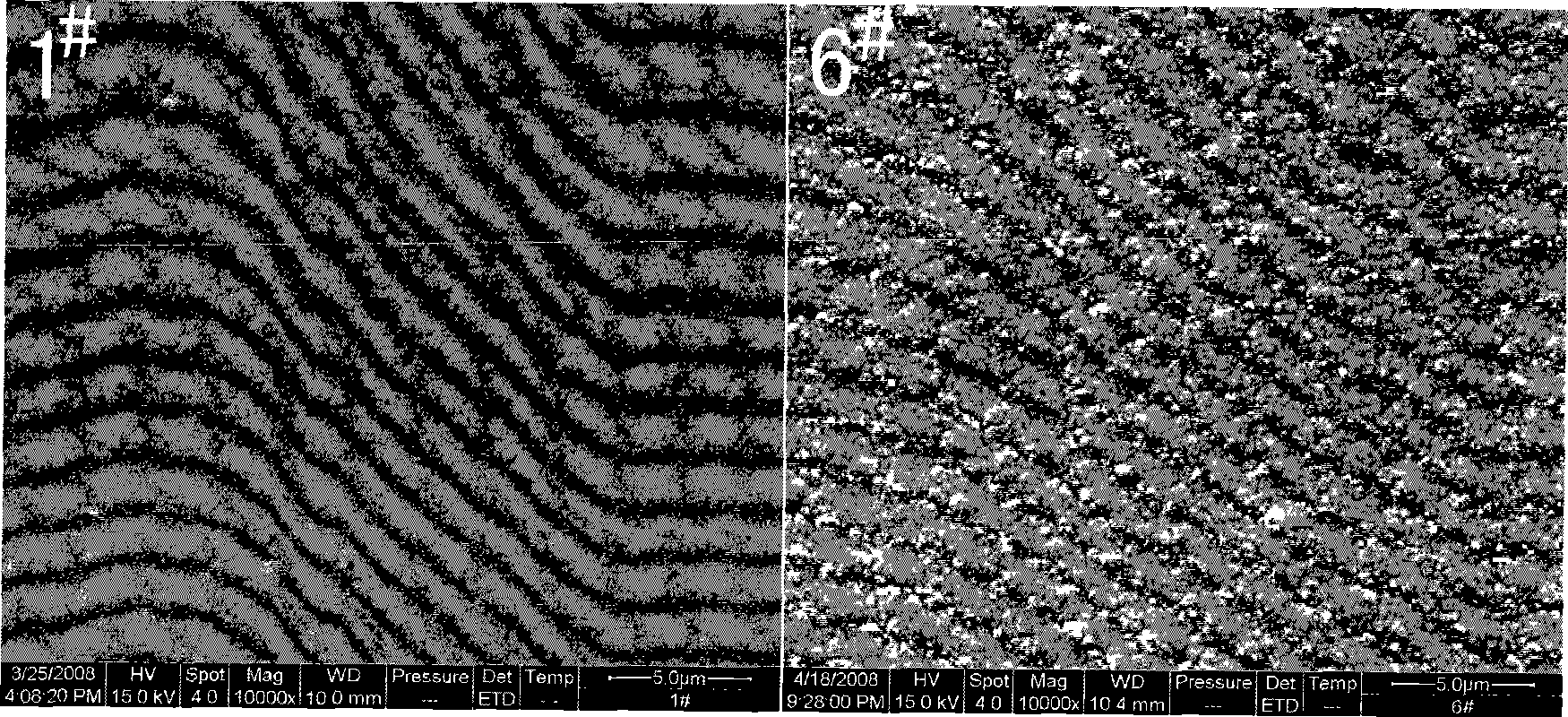

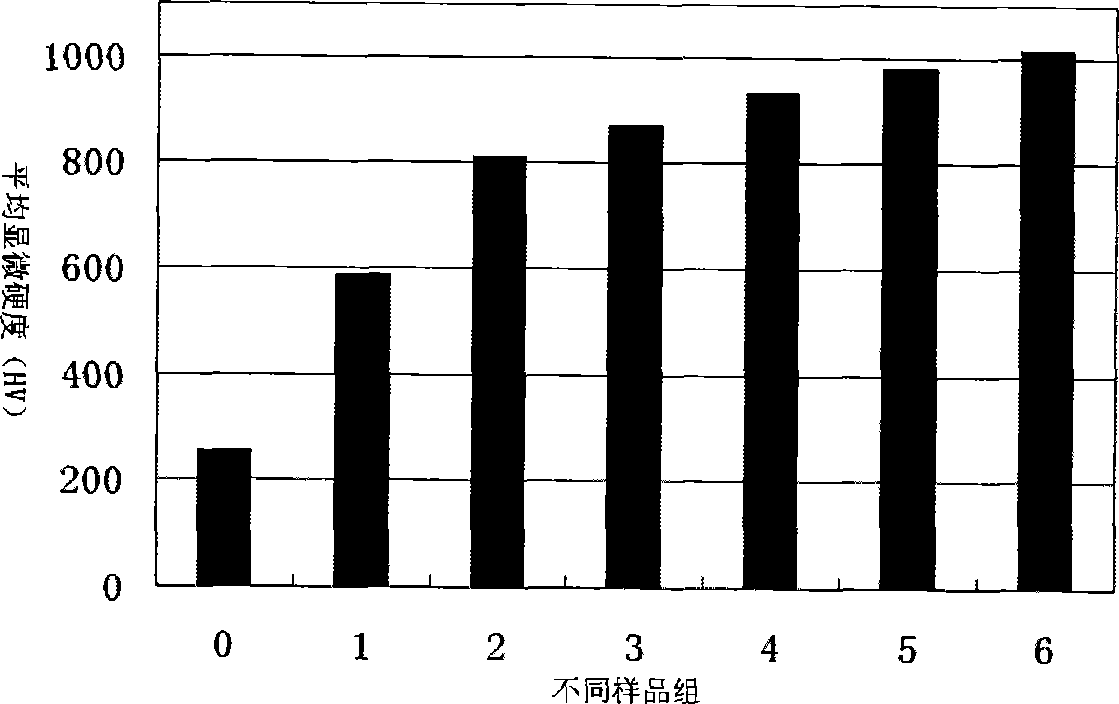

ActiveCN108587458AImprove thermal stabilityImprove high temperature corrosion resistanceFireproof paintsAntifouling/underwater paintsSurface coatingTransition metal

The invention provides a ceramic surface material, which is prepared from 20.0 to 70.0 weight percent of organic silicon, 20.0 to 70.0 weight percent of organic solvents, 1.0 to 50 weight percent of filling materials and 0.1 to 3.0 weight percent of auxiliary agents, wherein the organic solvents are selected from one or several kinds of materials from butyl acetate, xylene, n-butyl ether, di-ethylenhje glycol mono butyl ether acetate, methylcyclohexane, normal octane and butyl titanate; the filling materials are prepared from graphene, graphite, transition metal oxide, compound silicate, rareearth oxides, nonmetal, nonmetal compounds, transition metal boride and metal. The ingredients in the ceramic surface material achieve the mutual cooperated effects, so that the better comprehensive performance is realized when the ceramic surface material is used as a coating.

Owner:ZHAOSHAN TECH BEIJING CO LTD

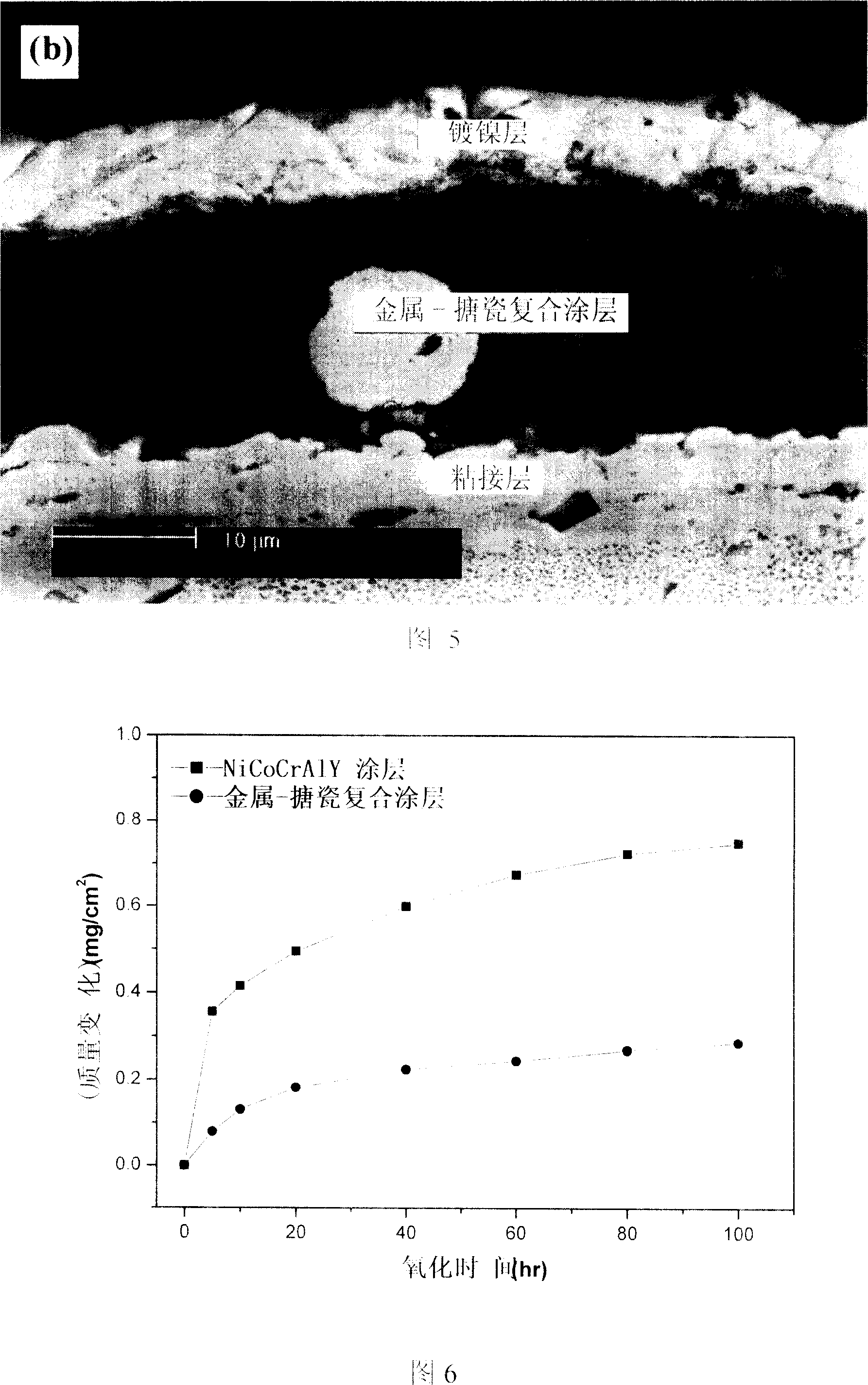

High-temperature alloy protecting coating and method of preparing the same

InactiveCN101109086AImprove thermal shock resistanceImprove thermal shock performanceThermal expansionSuperalloy

A protection coating for a hi-temp alloy is characterized in that, the coating is a compound coating of metal and enamel formed by spreading some metallic powder on an enamel substrate. Wherein, the metallic powder is MCrAlY powder of high thermal expansion rate coefficient and good resistance to hi-temp corrosion, M is one from Ni, Co, NiCo or any combination of them. Way for preparing the protection coating for hi-temp alloy is: first of all the metallic powder is fully mixed with the enamel powder, then the mixed powder is sprayed on the surface of a specimen, still then a metal-enamel compound coating spread on the enamel substrate is formed by high temperature sintering. The metal-enamel compound coating prepared by the invention is not only furnished with excellent resistance to hi-temp corrosion, but also highly improved thermal expansion rate coefficient because of the addition of plastic metallic powder, and greatly improved thermal vibration property.

Owner:INST OF METAL RESEARCH - CHINESE ACAD OF SCI

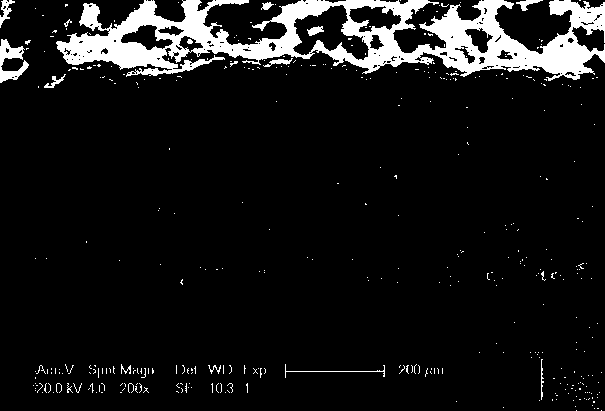

Preparation and application of rare earth-containing nickel-based powder core wire material and coating

ActiveCN103924182AHeat and corrosion resistantGood heat and corrosion resistanceMolten spray coatingThermal sprayingRare earth

The invention discloses preparation and application of a rare earth-containing nickel-based powder core wire material and a coating, belonging to the field of thermal spraying in the material machining engineering. A core the following components in percentage by mass: 20-35% of pure metal chromium powder, 10-31% of nickel boron powder, 0.1-0.3% of rare earth and the balance of nickel, wherein the outer skin of the powder core wire material is made of a 80Ni-20Cr strip; the filling rate of the powder core wire material is 32%; when the rare earth-containing nickel-based coating is prepared in an electric arc spraying mode, a substrate needs to be pretreated; the spraying parameters are as follows: the voltage is 28-34V, the current is 160-220A, the spraying distance is 190-210mm, and the pressure of compressed air is 0.5-0.6MPa. A coating which is good in thermal conversion property and corrosion resistance can be obtained, and the service stability of a water-cooling wall tube and a superheater tube in a waste resource WTE (Waste To Energy) garbage incinerator is improved.

Owner:唐山宝航机械制造有限公司

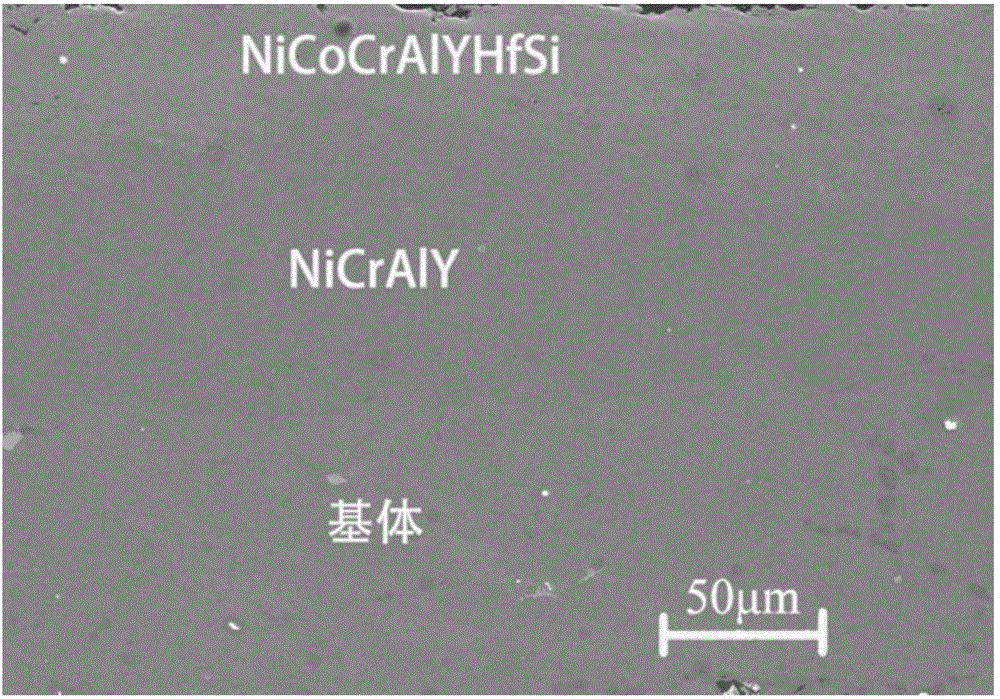

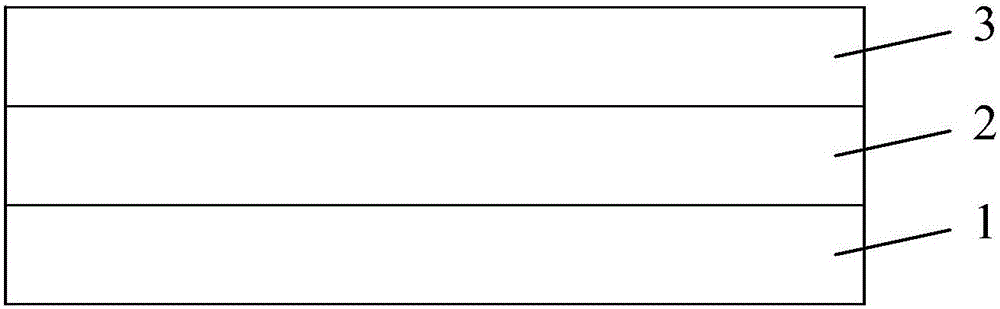

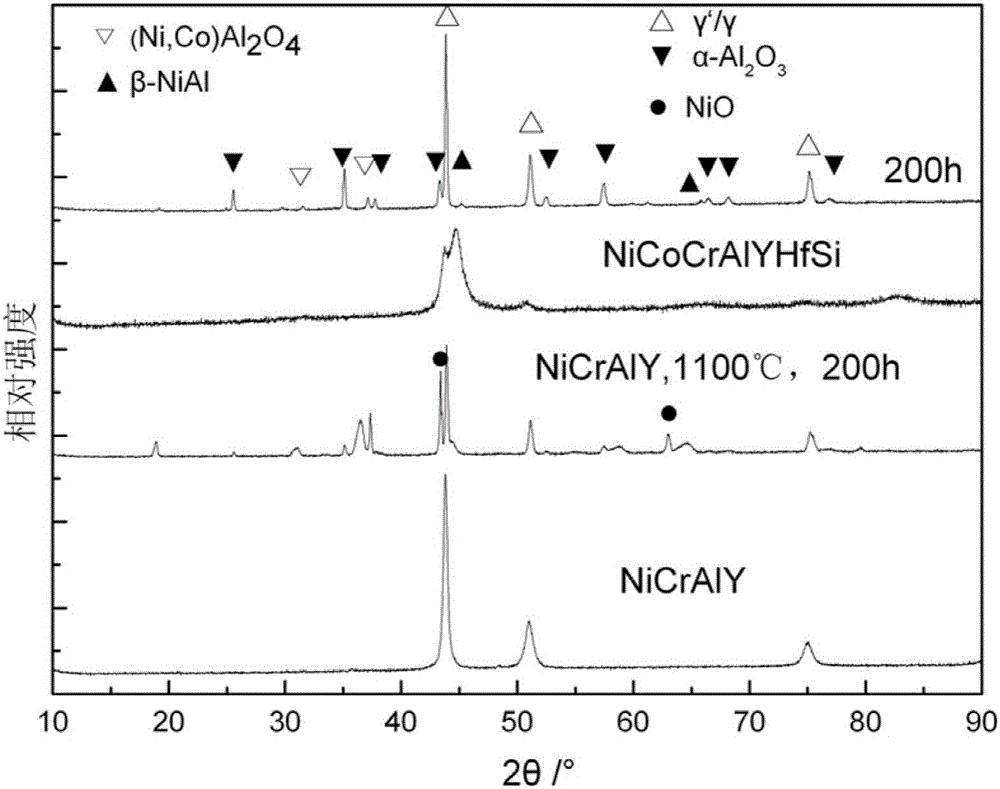

Bilayer-structure bonding coating on surface of single crystal alloy and preparation method of bilayer-structure bonding coating

ActiveCN105951030AReduce harmful precipitatesReduce defectsMolten spray coatingBond coatingSingle crystal

The invention discloses a bilayer-structure bonding coating on the surface of single crystal alloy and a preparation method of the bilayer-structure bonding coating. The bilayer-structure bonding coating on the surface of the single crystal alloy comprises a single crystal alloy matrix and a bilayer-structure bonding coating body. The bilayer-structure bonding coating body comprises a bonding coating bottom layer and a bonding coating top layer. The bonding coating bottom layer is formed on the surface of the single crystal alloy matrix, the thickness of the bonding coating bottom layer is 50-80 microns, the bonding coating bottom layer contains Ni, Cr, Al and Y, and the weight ratio of Al in the bonding coating bottom layer is 4%-6%. The bonding coating top layer is formed on the other surface, opposite to the single crystal alloy matrix, of the bonding coating bottom layer, the thickness of the bonding coating top layer is 50-80 microns, the bonding coating top layer contains Ni, Co, Cr, Al, Y, Hf and Si, the weight ratio of Al in the bonding coating top layer is 11%-13%, and the thickness ratio of the bonding coating bottom layer and the bonding coating top layer is 8:2-6:4. According to the bilayer-structure bonding coating on the surface of single crystal alloy and the preparation method of the bilayer-structure bonding coating, the influence of the coating on the fatigue performance of the alloy can be reduced, the high-temperature-resistant oxidation performance of the coating on the surface of the alloy is improved, and the high-temperature endurance life of the alloy is prolonged.

Owner:CHINESE ACAD OF AGRI MECHANIZATION SCI +1

Ceramic surface material and surface coating

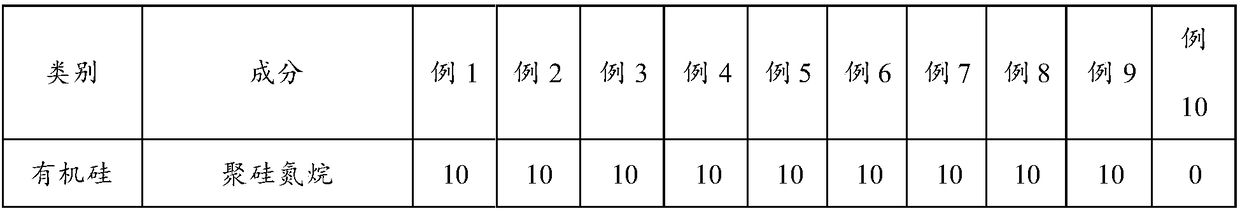

ActiveCN108641594AImprove toughnessImprove thermal stabilityFireproof paintsAntifouling/underwater paintsOrganosiliconEther

The invention provides a ceramic surface material. The ceramic surface material comprises 20.0-70.0 wt% of organosilicon, 20.0-70.0 wt% of an organic solvent, 1.0-50 wt% of a filler and 0.1-3.0 wt% ofan assistant, wherein the organic solvent is one or more selected from butyl acetate, xylene, n-butyl ether, diethylene glycol butylether acetate, methylcyclohexane, n-octane and butyl titanate; andthe filler is composed of graphene, graphite, transition metal oxide, composite silicate, rare earth oxide, nonmetal, a nonmetallic compound and metal. Components in the ceramic surface material havesynergistic effects, so the ceramic surface material has good comprehensive performances as a coating layer.

Owner:ZHAOSHAN TECH BEIJING CO LTD

Ni-W-nano CeF3 composite coating for glass mould surface, electroplating method and electroplating solution

InactiveCN101462819ACompact structureIncreased microhardnessElectrolytic coatingsGlass pressing apparatusTungstateFrictional coefficient

The invention provides a Ni-W-nanometer CeF3 composite plating used on the surface of a glass die. The composite plate has a Ni-W basal body interlarded with nanometer CeF3 micro-particles. The invention also provides a method for electroplating the Ni-W-nanometer CeF3 composite plating onto the surface of the glass dire and the electrolyte thereof. Na tungstates and Ni sulphamates are taken as the main salts of the electrolyte; nanometer CeF3 powder is added to form the bath; and the Ni-W-nanometer CeF3 composite plating is obtained through controlling the content of the Na tungstates, the Ni sulphamates and the CeF3, the variety and content of codeposition promoters, the pH value and the current density, and stirring the bath. The composite plating has a simple process, little pollution, safety, low overall cost, high plating hardness, corrosion resistance, wear resistance and high temperature resistance, and good self lubrication performance. When the Ni-W-nanometer CeF3 composite plating is ground with fused glass, the Ni-W-nanometer CeF3 composite plating has a lower frictional coefficient, thereby bringing about good demoldability of the die.

Owner:TSINGHUA UNIV

Automobile corrosion-resistant die-casting aluminum alloy and preparation method thereof

The invention discloses an automobile corrosion-resistant die-casting aluminum alloy and a preparation method thereof, and belongs to the field of aluminum alloy die-casting processing. The automobilecorrosion-resistant die-casting aluminum alloy comprises, by weight, 6.5%-7.6% of Si, 1.4%-2.1% of Mg, 0.8%-1.3% of Cu, 0.05%-0.11% of Sr, 0.4%-0.9%of Zn, 0.4%-0.8% of Mn, 0.2%-0.6% of Fe, 0.2%-0.5%of Y, 0.03%-0.05% of Er, less than or equal to 0.5% of other metals and non-metals, and the balance Al. The automobile corrosion-resistant die-casting aluminum alloy is prepared by the steps of melting, refining, standing, die casting, solid solution quenching treatment, aging treatment and the like. The aluminum alloy has the advantages that the corrosion resistance is greatly improved, the tensile property at high temperature is good, the toughness is high, and the extrusion resistance is good; and the preparation method is simple and feasible in process, and has the advantages of being highin safety and low in production process cost, and the produced aluminum alloy casting meets the use requirements of the workpiece needing to bear a large dynamic load.

Owner:广西平果铝合金精密铸件有限公司

Fireproof repairing agent for industrial kiln

The invention relates to the technical field of high temperature refractories, in particular to a fireproof repairing agent for an industrial kiln. The fireproof repairing agent includes alumina micropowder, nano silica, kyanite powder, nano zirconia, ceramic fiber, polyvinyl alcohol, aluminum silicon sol, deionized water, metal quantum dot composite, carboxymethyl cellulose sodium, polyethylene glycol and dispersing agent, wherein the alumina micropowder is alpha type alumina with a grain size of 20-40 nm; the dispersing agent is one of ammonium polyacrylate, sodium tripolyphosphate and sodium hexametaphosphate; the ceramic fiber is selected from a group consisting of a high alumina fiber, an aluminum oxide polycrystalline fiber and aluminum silicate fiber; and the ceramic fiber has a fiber length of 2-4 mm. The repairing agent has the advantages of high refractoriness, good adhesion, large bonding strength, good thermal expansion and outstanding erosion resistance.

Owner:来安县瑞傲源新材料有限公司

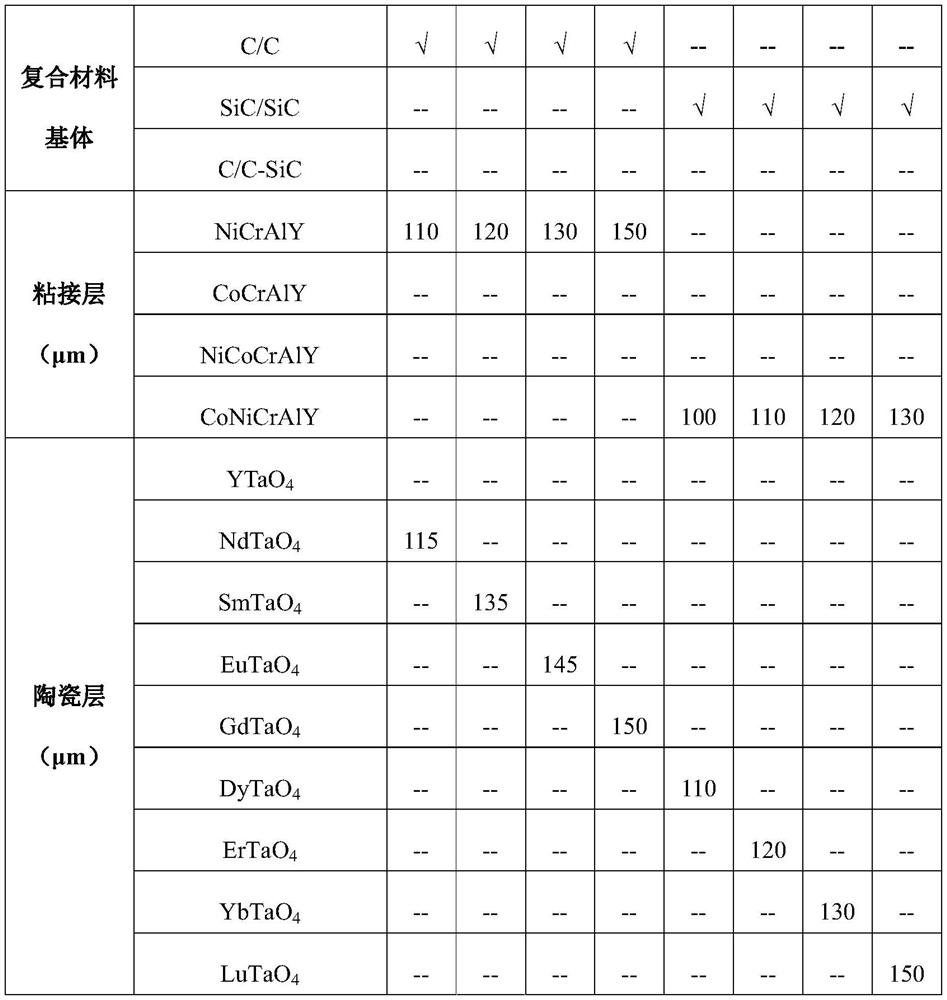

Ultrahigh-temperature corrosion-resistant composite material and preparation method thereof

The invention relates to the technical field of composite materials, and discloses an ultrahigh-temperature corrosion-resistant composite material and a preparation method thereof. The composite material comprises a composite material base body, a bonding layer and a ceramic layer are sequentially deposited on the composite material base body, and the ceramic layer is formed by mixing one or two of rare earth tantalate (RETaO4) and rare earth niobate (RENbO4) in proportion. The prepared composite material can adapt to various severe corrosion environments, the service time of the C / C, SiC / SiC,C / C-SiC and other composite materials can be effectively prolonged, material and energy waste caused by corrosion is greatly reduced, and economic benefits are generated.

Owner:KUNMING UNIV OF SCI & TECH +1

Ceramic surface material and surface coating

ActiveCN108485516AImprove toughnessImprove thermal stabilityFireproof paintsAntifouling/underwater paintsRare earthMaterials science

The invention provides a ceramic surface material, which comprises the following components: 20.0wt%-70wt% of organic silicon, 20.0wt%-70wt% of organic solvent, 1.0wt%-50wt% of filler, and 0.1wt%-3wt%of auxiliary agent, wherein the organic solvent is selected from one or more of butyl acetate, xylene, n-butyl ether, diethylene glycol monobutyl ether acetate, methylcyclohexane, n-octane and butyltitanate; the filler is composed of graphene, graphite, transition metal oxide, composite silicate, rare earth oxide and metal. The components in the ceramic surface material cooperate with each other, so that the ceramic surface material has better comprehensive performance when being used as a coating.

Owner:ZHAOSHAN TECH BEIJING CO LTD

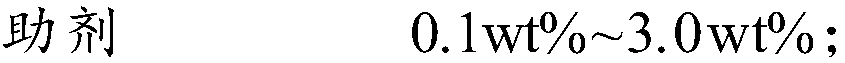

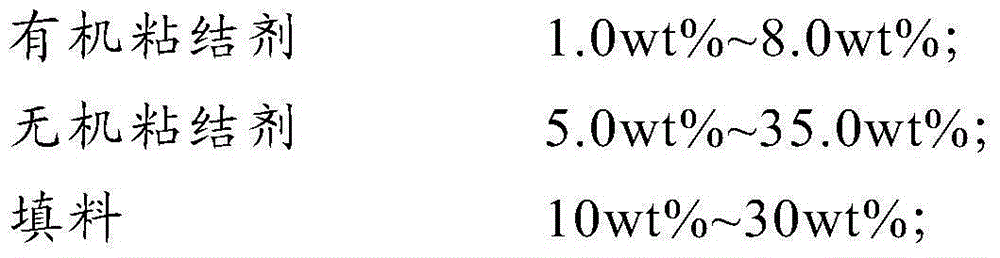

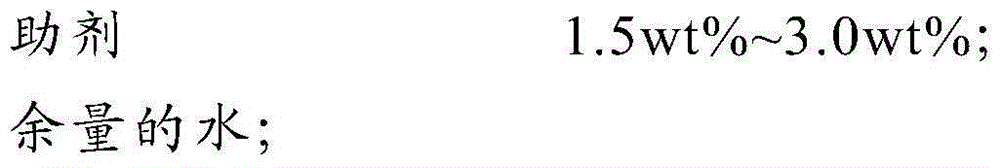

Ceramic paint and application thereof

The invention provides ceramic paint. The ceramic paint comprises 1.0wt%-8.0wt% of organic binders, 5.0wt%-35.0wt% of inorganic binders, 10wt%-30wt% of packing, 1.5wt%-3.0wt% of auxiliaries and the balance water. The organic binders are made of ethyl alcohol, the inorganic binders are made of aluminum dihydrogen phosphate, boehmite, phosphoric acid and nitric acid, and the packing comprises rare-earth oxide and zirconia. The invention further provides application of the ceramic paint to industrial furnaces. The ceramic paint and the application have the advantages that mutual synergistic effects are realized by components in the ceramic paint, and accordingly the ceramic paint is excellent in comprehensive performance when used as a ceramic coating.

Owner:ZHAOSHAN TECH BEIJING CO LTD

Ceramic surface material and surface coating

ActiveCN108610960AImprove toughnessImprove thermal stabilityFireproof paintsAntifouling/underwater paintsRare earthMaterials science

The invention provides a ceramic surface material which comprises the following components in percentage by weight: 20-70% of organosilicone, 20-70% of an organic solvent, 1.0-50% of fillers and 0.1-3.0% of an aid, wherein the organic solvent is selected from one or more of butyl acetate, xylene, n-butyl ether, diethylene glycol monobutyl ether acetate, methyl cyclohexane, normal octane and butyltitanate; the filler is composed of grapheme, graphite, transition metal oxides, composite silicate, rare earth oxides, nonmetals, nonmetallic compounds, transition group metal borides, whiskers and metals. The components in the ceramic surface material achieve mutual synergistic effects, so that the ceramic surface material serving as a coating has excellent overall performance.

Owner:ZHAOSHAN TECH BEIJING CO LTD

Composite ceramic coating containing precious metal intermediate layer and preparation process thereof

ActiveCN108588771AImprove fracture toughnessHigh bonding strengthElectrolytic inorganic material coatingMicro nanoComposite ceramic

The invention provides a preparation process of a composite ceramic coating containing a precious metal intermediate layer. The preparation process comprises the following steps that (1) surface oxides of a titanium-based alloy substrate are removed, and washing and drying are carried out; (2) a precursor solution A is prepared by sulfuric acid and a platinum compound; (3) the titanium-based alloyis used as a working electrode, metal platinum or graphite is used as a counter electrode, the titanium-based alloy and the metal platinum or graphite are placed in the precursor solution A for electro deposition, washing and drying are carried out, and a platinum-plated titanium-based alloy is obtained; (4) anhydrous ethanol, a sodium nitrate solution and precursor alkyl silicate are prepared into a mixed solution, the pH value of the mixed solution is adjusted with acid, stirring is carried out, and a precursor solution B is obtained; (5) the platinum-plated titanium-based alloy is used asa working electrode, and metal platinum or graphite is used as a counter electrode, the platinum-plated titanium-based alloy and the metal platinum or graphite are placed in the precursor solution B for secondary electro deposition, washing and drying are carried out, and a micro-nano-oxide coating on the surface of the substrate is obtained; and (6) the platinum-plated titanium-based alloy with the micro-nano-oxide coating on the surface is subjected to heat treatment, and the composite ceramic coating containing the precious metal intermediate layer is obtained on the surface of the substrate after the heat treatment.

Owner:ZHEJIANG UNIV OF TECH

Additive for pouring box dry vibrating material and preparation method and application thereof

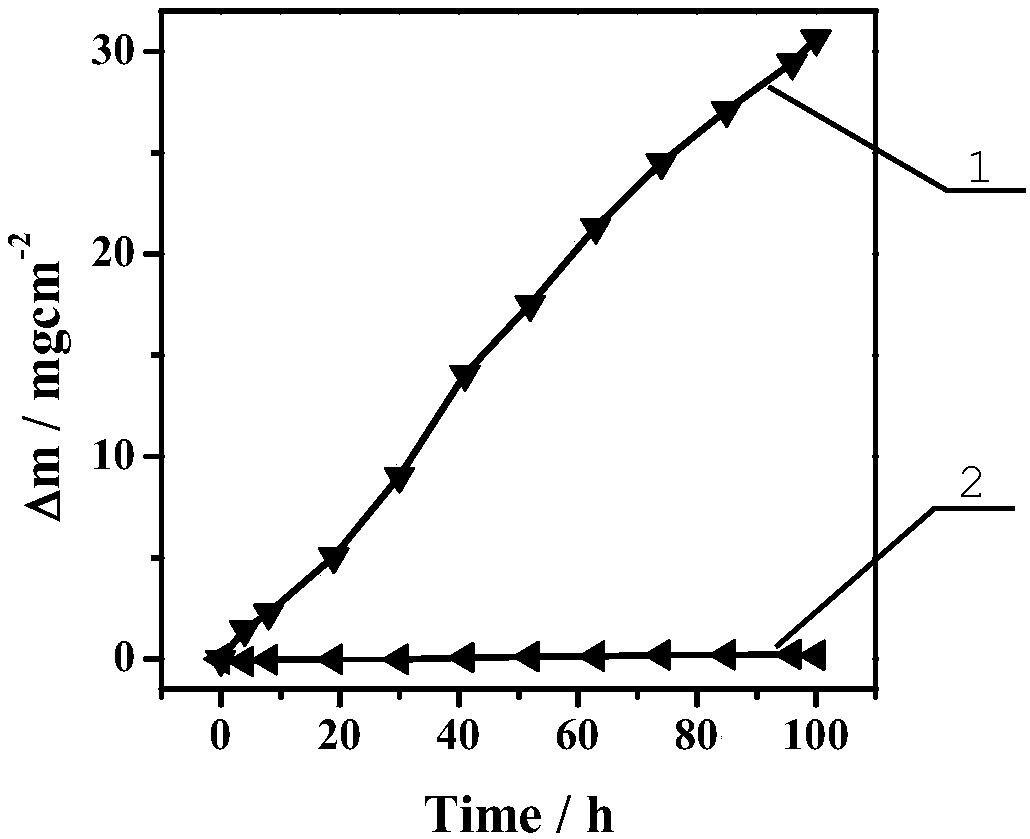

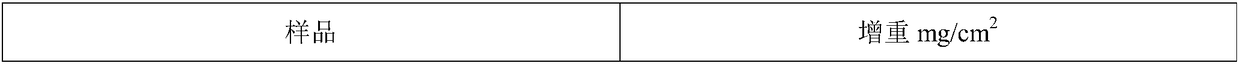

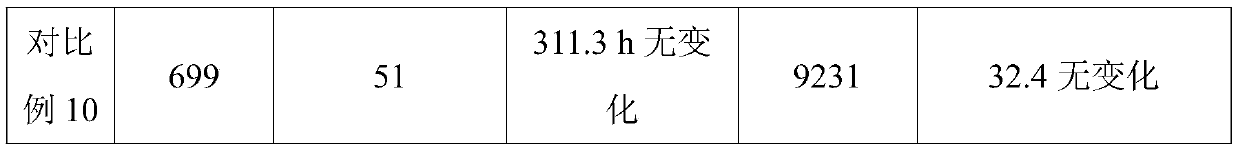

The invention relates to an additive for a pouring box dry vibrating material, which is used in the continuous steel casting process of a large-sized steel making enterprise, and a preparation method and application thereof, belonging to the technical field of steel making. The first technical problem to the solved of the invention is to provide an additive for the pouring box dry vibrating material, which is used for solving the problem of sintering intensity of the dry vibrating material and meeting the requirement of continuous steel casting. The technical scheme of the invention is that: the additive consists of the following components in parts by weight: 50-80 parts of magnesia-chromite brick powder, 10-30 parts of borax and 10-25 parts of ferric oxide powder. When the additive is applied to the pouring box dry vibrating material, the problems of poor medium-temperature sintering of a product, low pressure resistance (the pressure resistance is enhanced from 10 MPa to 15 MPa by 5 MPa at the temperature of 1,100 DEG C), poor corrosion resistance at high temperature (the molten slag corrosion thickness is reduced from 20-30 millimeters to 15-20 millimeters by 8 millimeters on average) and severe sintering are solved, and a new thought is provided for technical personnel in the field.

Owner:PANZHIHUA GANGCHENG GROUP

Preparation method of AlFeCoNiCr high-entropy coating on surface of stainless steel

ActiveCN112281155AAchieve metallurgical bondingImprove bindingMetallic material coating processesSS - Stainless steelOxidation resistant

The invention discloses a preparation method of an AlFeCoNiCr high-entropy coating on the surface of stainless steel. The method comprises the following steps of 1, preparing materials; 2, mixing thematerials; 3, preparing mixed slurry; 4, coating the mixed slurry on the surface of the stainless steel and drying; 5, carrying out pre-sintering to form an AlFeCoNiC pre-sintered coating; and 6, preparing the AlFeCoNiC high-entropy coating on the surface of the stainless steel by adopting an electron beam cladding process. According to the preparation method, a powder pre-sintering method and anelectron beam cladding process are combined, metallurgical bonding of the AlFeCoNiCr high-entropy coating and a stainless steel base body is achieved, the bonding force of the AlFeCoNiCr high-entropycoating and the stainless steel base body is effectively improved, then the abrasion resistance, hardness, oxidation resistance and high-temperature corrosion resistance of the AlFeCoNiCr high-entropycoating on the surface of the stainless steel are improved, and the service life is prolonged. The preparation method is easy to implement and low in cost, and the adaptability of the AlFeCoNiCr high-entropy coating in an extreme environment is improved.

Owner:NORTHWEST INSTITUTE FOR NON-FERROUS METAL RESEARCH

Anti-corrosion composite heat preservation cover felt for industrial vacuum furnace and preparation method thereof

ActiveCN111038022AReduce damageReduce thermal stress gradient changesNon-macromolecular adhesive additivesLayered productsCarbon coatingVacuum furnace

The invention discloses an anti-corrosion composite heat preservation cover felt for an industrial vacuum furnace and a preparation method thereof. The anti-corrosion composite heat preservation coverfelt sequentially comprises a graphite foil or an antipyretic carbon coating, a carbon / silicon carbide porous layer and a graphite felt layer from the surface to the interior, and the layers are bonded through a carbon-based silicon binder or a carbon-based / ceramic binder at high temperature. In the using process, the surface graphite foil or the antipyretic carbon coating and the silicon steam are used for in-situ production of the silicon carbide surface, and the silicon carbide layer and the carbon / silicon carbide layer are combined to provide efficient corrosion resistance. Compared witha traditional heat preservation cover material, the added carbon / silicon carbide layer not only improves physical strength, but also optimizes matching of thermal expansion coefficients and hardness of surface silicon carbide and a base body, and the service life of the cover felt under oxidation and silicon steam corrosion is remarkably prolonged. The cover felt is mainly damaged on the surface and a part of the carbon / silicon carbide layer, and can be maintained and renovated by polishing and re-coating. The cover felt is low in cost, long in service life and suitable for industrial production.

Owner:GANSU HAOSHI CARBON FIBER

High-performance silicon-containing ferrite/martensitic steel

PendingCN113235014AImprove mechanical propertiesImprove high temperature corrosion resistanceMetallic materialsIngot

The invention discloses high-performance silicon-containing ferrite / martensitic steel, and relates to the technical field of metal materials. The high-performance silicon-containing ferrite / martensitic steel comprises, by weight: 0.11 to 0.13 percent of C, 8.5 to 10 percent of Cr, 1.3 to 1.7 percent of W, 0.4 to 0.6 percent of Mn, 0.05 to 0.15 percent of Ta, 0.15 to 0.25 percent of V, 0.005 to 0.015 percent of Zr, 0.7 to 1.2 percent of Si, and the balance Fe and inevitable impurities. A preparation method comprises the following steps: smelting and pouring according to the formula of the alloy steel components to obtain a steel cast ingot, and carrying out equal-channel angular extrusion treatment on the steel cast ingot, specifically, annealing treatment is carried out after each pass of extrusion treatment. The chemical components and the processing process of the F / M alloy steel are improved, the microstructure of 9Cr-F / M steel, including the type, size and distribution of precipitated phases, is regulated and controlled, and the comprehensive mechanical property of the alloy steel is improved.

Owner:HEFEI INSTITUTES OF PHYSICAL SCIENCE - CHINESE ACAD OF SCI +2

Stamping die surface phosphating processing method

InactiveCN110042376AExcellent high temperature corrosion resistanceGood adhesionMetallic material coating processesHigh-temperature corrosionHot Temperature

The invention discloses a stamping die surface phosphating processing method, and relates to the technical field of mold processing. The stamping die surface phosphating processing method includes thefollowing steps of polishing, heating, phosphating, twice soaking and twice drying processing and pressurizing processing. By means of the stamping die surface phosphating processing method, a uniform and compact phosphating film can be formed on the surface of a stamping die, the surface of the stamping die can be better protected, and the processed stamping die has excellent high-temperature corrosion-resistant performance.

Owner:长沙而道新能源科技有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com