Stamping die surface phosphating processing method

A technology of stamping die and processing method, which is applied in the field of phosphating treatment on the surface of stamping die to achieve the effect of firm adhesion of coating, smooth surface and improved quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

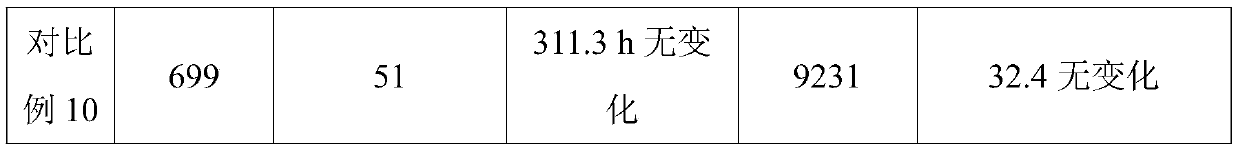

Examples

Embodiment 1

[0050] A method for phosphating the surface of a stamping die, comprising the following steps in sequence:

[0051] (1) Grinding the stamping mold, using sandpaper to polish the surface of the stamping mold, specifically using sandpaper to polish the surface of the mold is as follows: respectively use 200 mesh, 600 mesh, 1200 mesh, and 1800 mesh sandpaper on the surface of the stamping mold Grinding, each grinding time is 40min;

[0052] (2) Heat the stamping die processed in step (1) to 700°C, keep it warm for 7 minutes, then cool it down to room temperature naturally, immerse it in absolute ethanol for 10 minutes at a temperature of 85°C, take it out, and clean it with deionized water. Then dry to constant weight, get final product;

[0053] (3) soak the stamping die after step (2) processing in the phosphating solution, soak for 6min, then take out, the surface adopts deionized water to clean to neutrality, then dry, and described phosphating solution comprises following r...

Embodiment 2

[0061] A method for phosphating the surface of a stamping die, comprising the following steps in sequence:

[0062](1) Grinding the stamping mold, using sandpaper to polish the surface of the stamping mold, specifically using sandpaper to polish the surface of the mold is as follows: respectively use 200 mesh, 600 mesh, 1200 mesh, and 1800 mesh sandpaper on the surface of the stamping mold Grinding, each grinding time is 30min;

[0063] (2) Heat the stamping die processed in step (1) to 800°C, keep it warm for 5 minutes, then cool it down to room temperature naturally, immerse it in absolute ethanol for 10 minutes at a temperature of 90°C, then take it out and clean it with deionized water. Then dry to constant weight, get final product;

[0064] (3) soak the stamping die after step (2) processing in the phosphating solution, soak for 5min, then take out, the surface adopts deionized water to clean to neutrality, then dry, and described phosphating solution comprises followin...

Embodiment 3

[0072] A method for phosphating the surface of a stamping die, comprising the following steps in sequence:

[0073] (1) Grinding the stamping mold, using sandpaper to polish the surface of the stamping mold, specifically using sandpaper to polish the surface of the mold is as follows: respectively use 200 mesh, 600 mesh, 1200 mesh, and 1800 mesh sandpaper on the surface of the stamping mold Grinding, each grinding time is 50min;

[0074] (2) Heat the stamping die processed in step (1) to 600°C, keep it warm for 8 minutes, then cool it down to room temperature naturally, immerse it in absolute ethanol for 10 minutes at a temperature of 80°C, take it out, and clean it with deionized water. Then dry to constant weight, get final product;

[0075] (3) soak the stamping die after step (2) processing in the phosphating solution, soak for 8min, then take out, the surface adopts deionized water to clean to neutrality, then dry, and described phosphating solution comprises following r...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com