Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

60results about How to "Improve high temperature plasticity" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

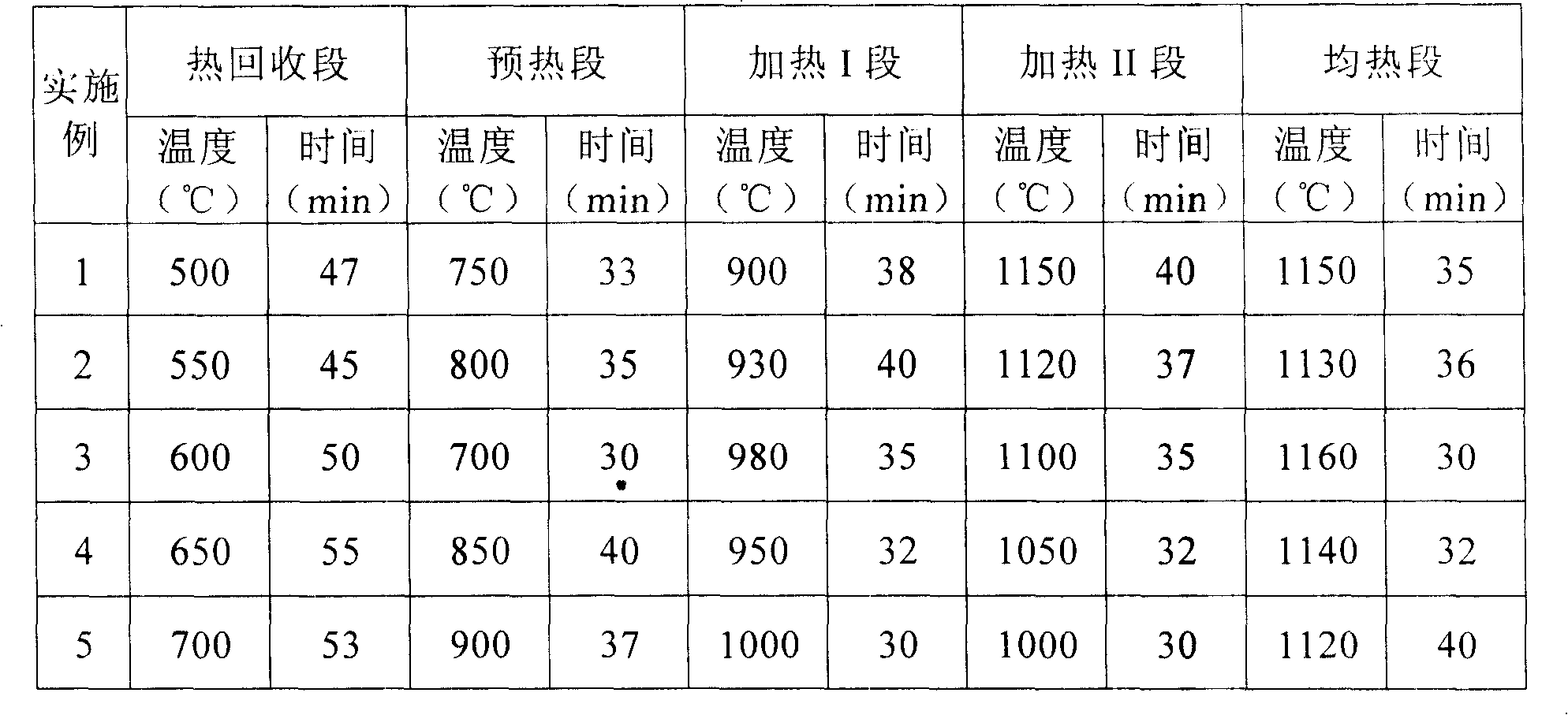

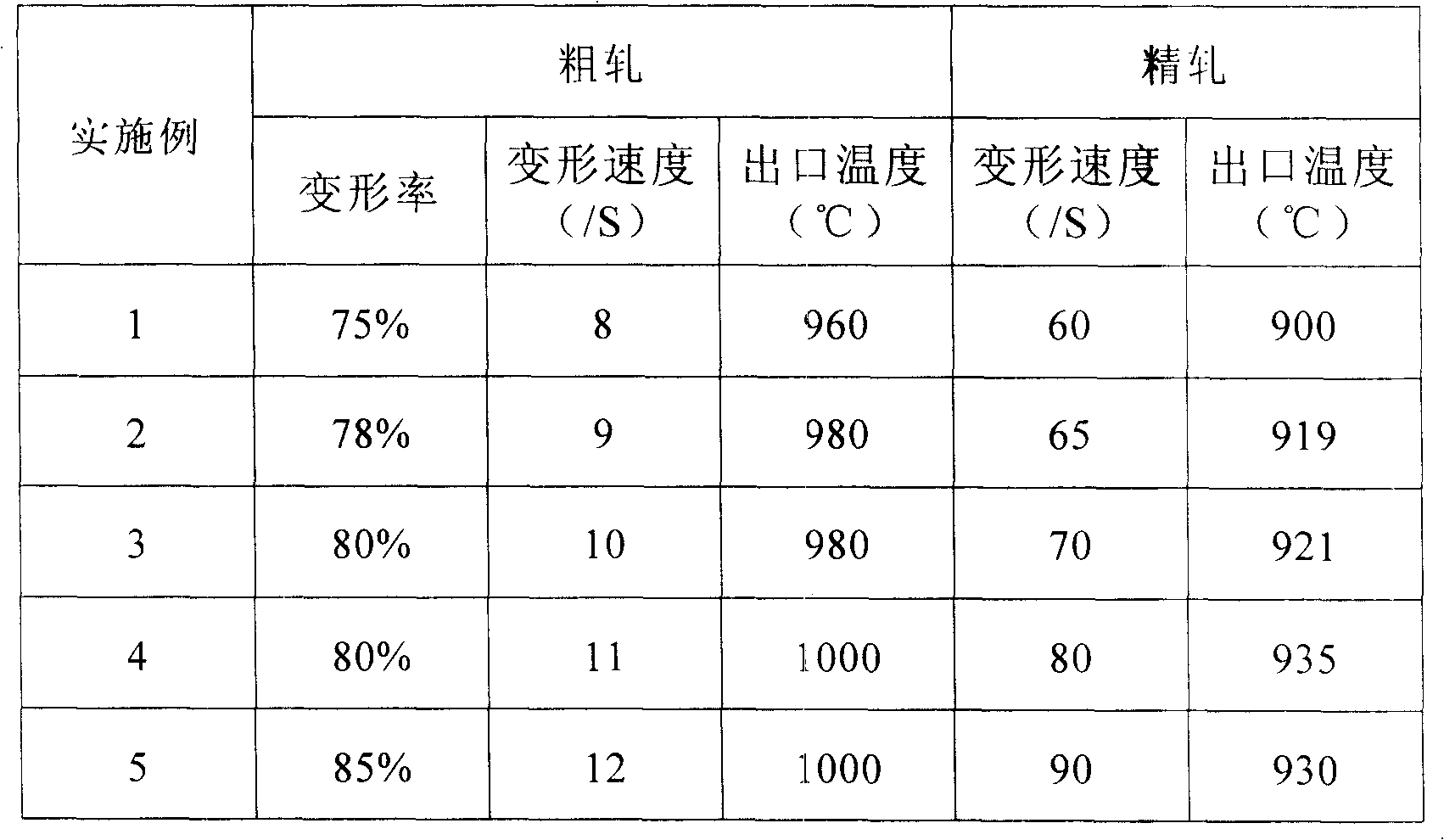

Method for producing hot-rolled ferritic stainless steel strip steel

InactiveCN101245435AFree from common surface defectsNo surface defectsRoll mill control devicesHeat treatment process controlSurface finishChemical composition

The invention discloses a method for producing a hot-rolled ferrite stainless strip steel, which comprises the following steps: 1) the chemical components by weight percentage are: 0.025-0.04 percent of C, less than or equal to 1.00 percent of Si, 0.25-0.4 percent of Mn, less than or equal to 0.030 percent of S, less than or equal to 0.035 of P, 12-12.5 percent of Cr and the rest is Fe; 2) a billet is formed by smelting and casting; 3) heating: the heating temperature zone for heating are divided into a heat recovery section, a preheating section, a I heating section, a II heating section and a holding section; furnace gas is controlled to be neutral atmosphere of non-oxidizing atmosphere; 4) when in heat rolling and rough rolling, the rolling temperature is 1,120 DEG C-1,160 DEG C, and the deforming speed during rolling is 10 / s-12 / s; 5) finish rolling: the deforming speed of the last pass rolling is 60 / s-90 / s, and the outlet temperature of the finish rolling is more than 900 DEG C; 6) cooling is carried out after rolling, and then reeling is carried out. The method of the invention has the advantages that the method guarantees not only the edge quality of the hot-rolled strip steel but also the stamping property of the cold-rolled strip steel, improves the surface finish quality and lowers the production cost, and has high production efficiency and rolling yield, etc.

Owner:BAOSHAN IRON & STEEL CO LTD

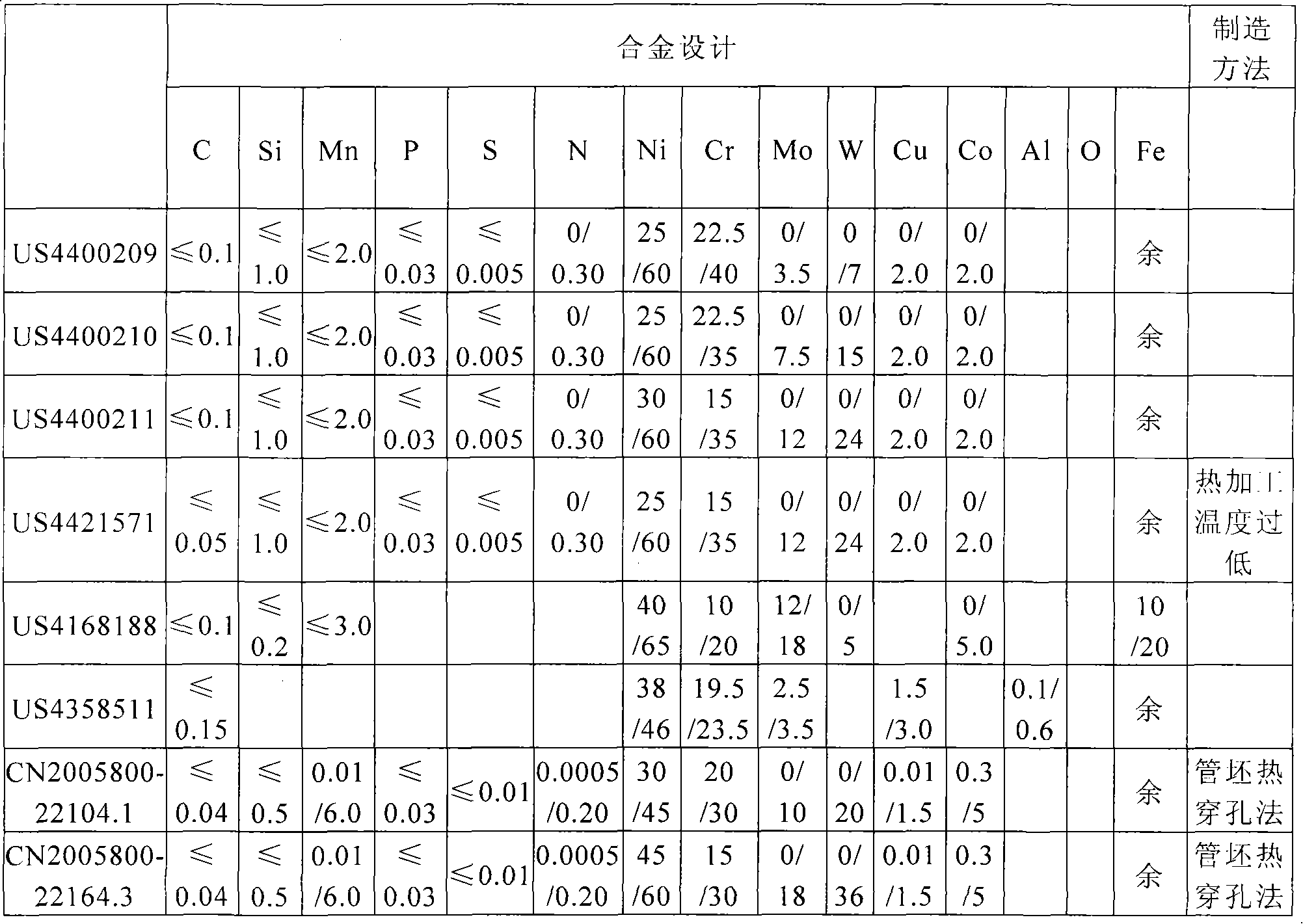

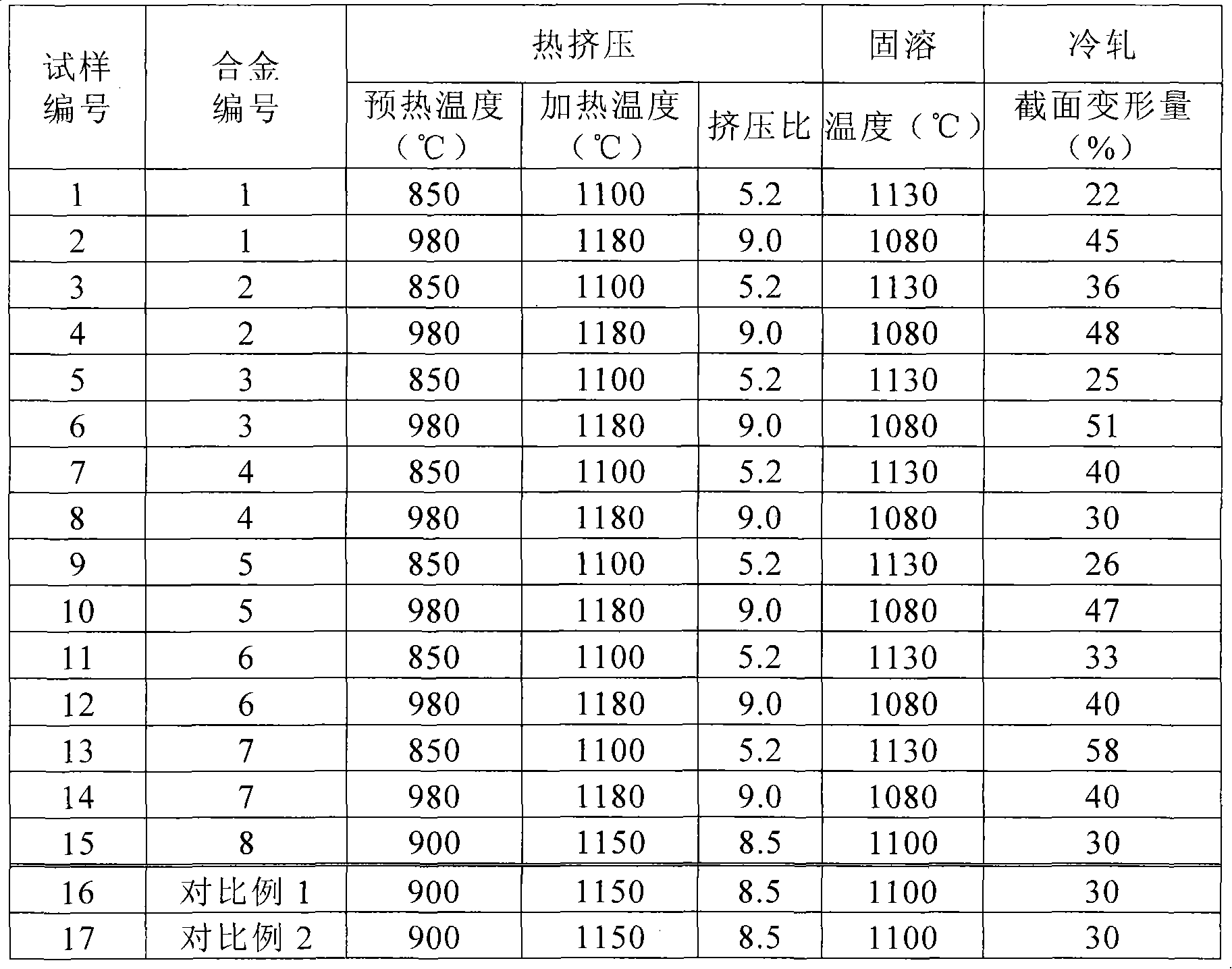

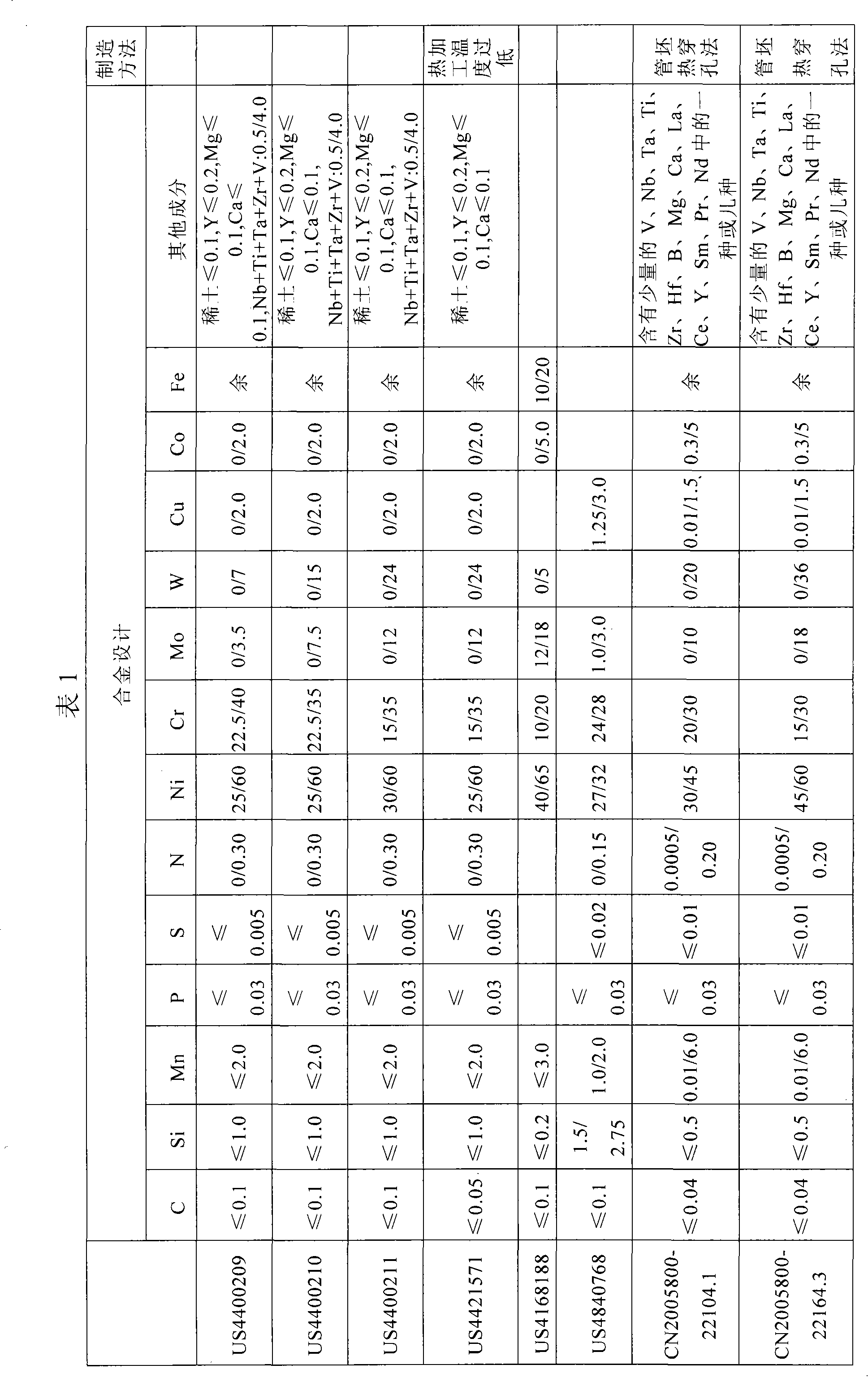

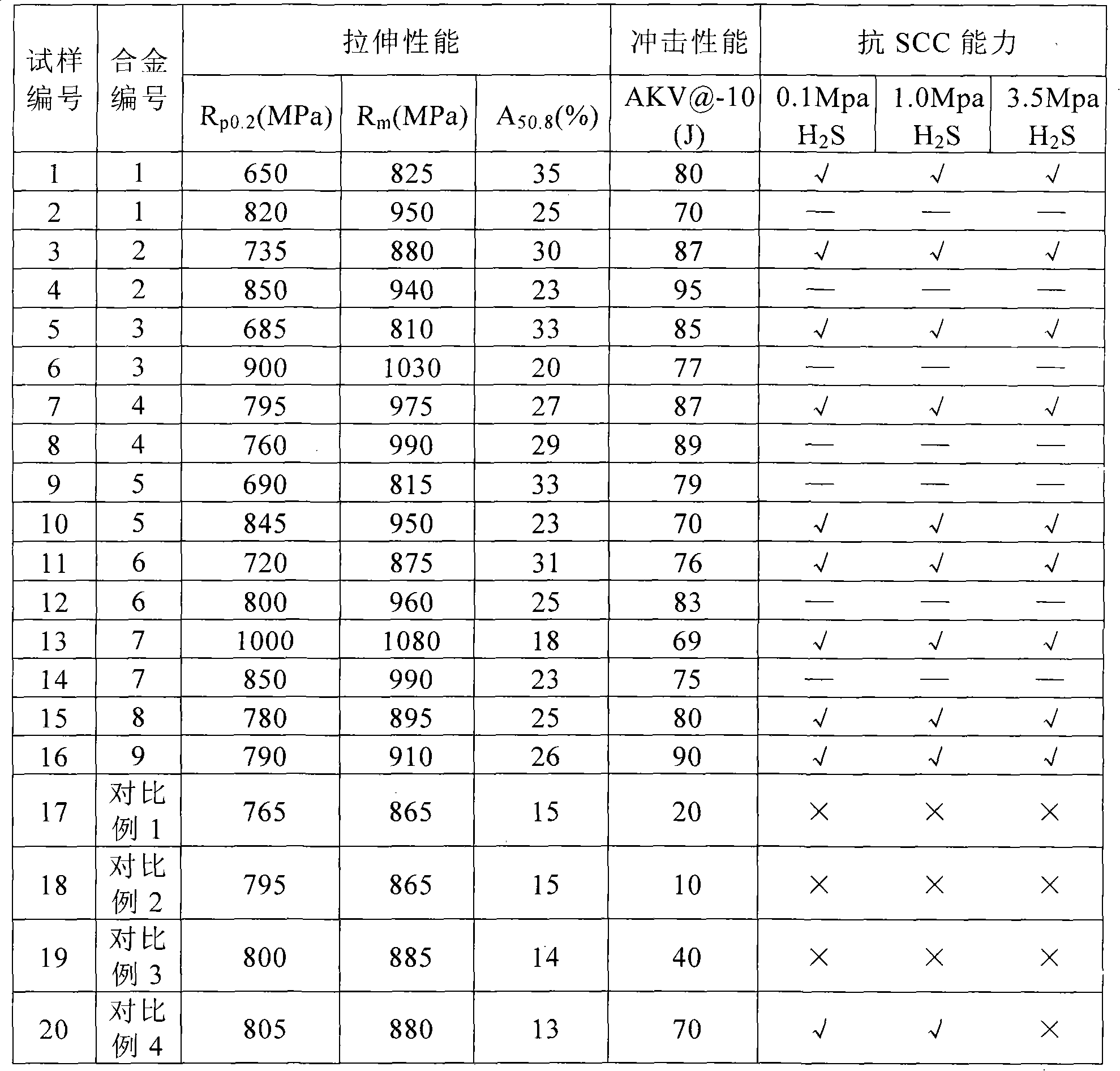

Ni-based alloy oil sleeve and manufacturing method for high-acidity deep well

ActiveCN101613833ALow costImprove high temperature corrosion resistanceDrilling rodsRoll mill control devicesSolution treatmentImpurity

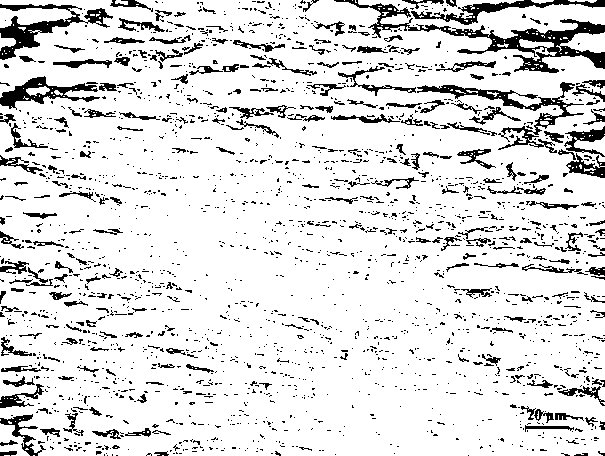

The invention relates to a Ni-based alloy oil sleeve for a high-acidity deep well, which comprises the following components in percentage by mass: less than or equal to 0.02 percent of C, less than or equal to 0.03 percent of P, less than or equal to 0.03 percent of S, less than or equal to 0.5 percent of Si, less than or equal to 1.0 percent of Mn, 40 to 60 percent of Ni, 20 to 30 percent of Cr, 1 to 10 percent of Mo, 1 to 5 percent of W, 0 to 5 percent of Co, 0.1 to 3.0 percent of Cu, 0.01 to 0.5 percent of Al, less than or equal to 0.01 percent of O, less than or equal to 1.5 percent of Ti, and the balance of Fe and inevitable impurities. In the invention, the thermal extrusion processing performance and corrosion resisting performance of the alloy are effectively ensured by controlling the contents of the Al and O. The 90 to 140 ksi steel-grade Ni-based alloy oil sleeve meeting different well depth requirements of high-acidity oil fields and gas fields is manufactured by thermal extrusion, 1,050-1,150 DEG C of solution treatment and cold rolling of the smelted and forged blanks.

Owner:BAOSHAN IRON & STEEL CO LTD

Fe-based austenite alloy oil sleeve and manufacturing method for high-acidity deep well

InactiveCN101613834ALow head lifeIncrease production costDrilling rodsRoll mill control devicesSolution treatmentChemical composition

The invention relates to a Fe-based austenite alloy oil sleeve, which comprises the following components in percentage by mass: less than or equal to 0.03 percent of C, less than or equal to 0.03 percent of P, less than or equal to 0.03 percent of S, 0.01 to 1.0 percent of Si, 0.01 to 3.0 percent of Mn, 25 to 40 percent of Ni, 20 to 35 percent of Cr, 1 to 5 percent of Mo, 0.1 to 1.5 percent of Cu, 0.01 to 0.5 percent of Al, less than or equal to 0.01 percent of O, and the balance of Fe and inevitable impurities. The 90 to 140 ksi steel-grade Fe-based alloy oil sleeve meeting different well depth requirements of high-acidity oil fields and gas fields is manufactured by thermal extrusion, 1,050-1,180 DEG C of solution treatment and cold rolling of the smelted and forged blanks.

Owner:BAOSHAN IRON & STEEL CO LTD

Nickel-saving type double-phase stainless steel and preparation process thereof

ActiveCN103014559AEasy to produceImprove high temperature plasticityHigh carbonIntermediate frequency

The invention relates to a preparation process of nickel-saving type double-phase stainless steel, comprising the following steps of: 1) controlling components of a mother solution in an electric furnace as follows: more than 1.0% of C, less than 1.0% of Si, 12-21% of Cr, 1.5-1.9% of Ni and less than 0.025% of P, controlling a tapping temperature at 1580-1630 DEG C, and mixing the mother solution in the electric furnace with a high-carbon ferro-chrome mother solution in an intermediate-frequency furnace to form a mixed mother solution, wherein the high-carbon ferro-chrome mother solution contains the following components of 6-10% of C, less than 0.5% of Si, less than 0.06% of P, 62-72% of Cr and the balance of iron; and 2) blending the mixed mother solution into an AOD (Argon Oxygen Decarburization) furnace to carry out oxygen blowing and decarburization, nitrogen blowing and component adjustment, refining in a steel ladle refining furnace and adding a micro-alloy into the components, and finally adjusting, wherein the adjusted chrome-nickel equivalence ratio is more than or equal to 2.2. The chrome-nickel equivalence ratio is properly controlled to be good for forming double-phase stainless steel high-temperature ferrite so that heat machining is carried out in a single-phase region to the greatest extent; and furthermore, the preparation process is good for the high-temperature plasticity of the double-phase stainless steel.

Owner:ZHENSHI GROUP EASTERN SPECIAL STEEL

Low-cost X65 pipeline steel based on magnesium treatment, and manufacturing method thereof

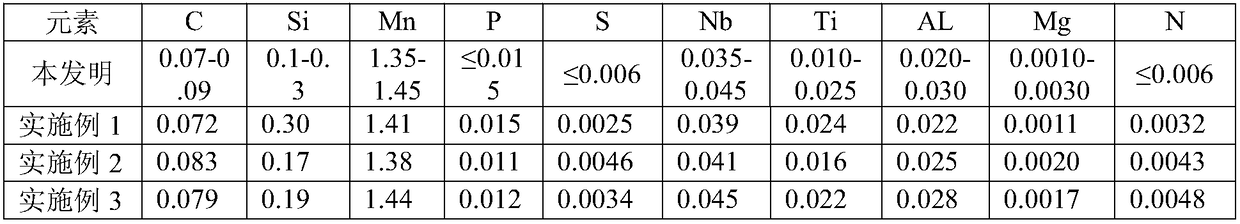

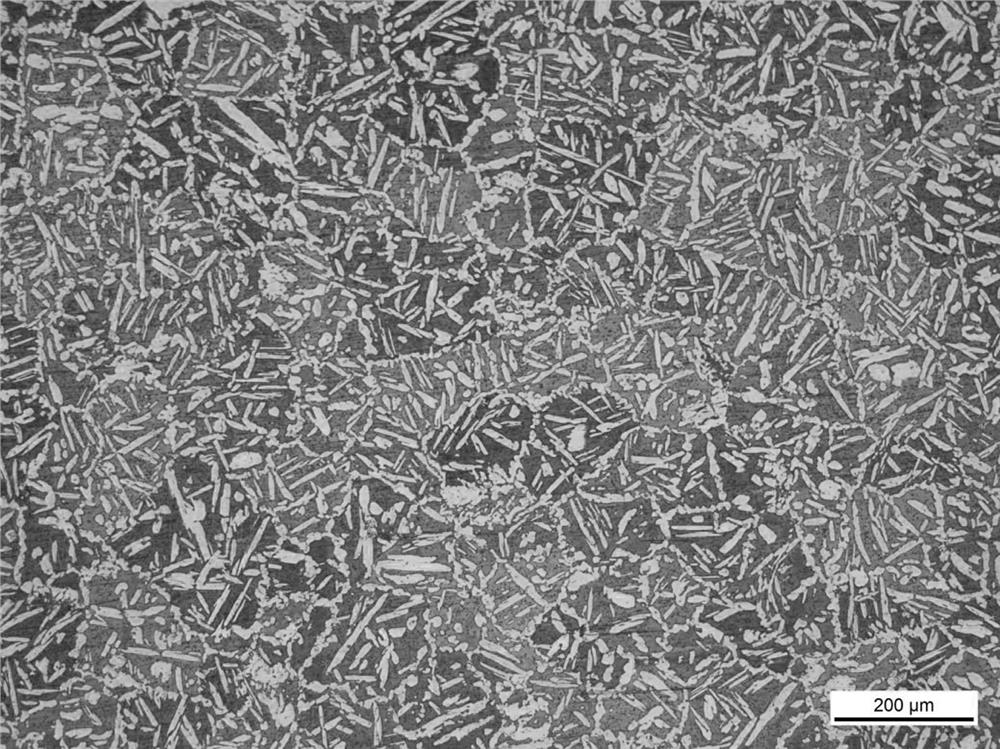

The invention discloses a low-cost X65 pipeline steel based on magnesium treatment, and a manufacturing method thereof. A purpose of the present invention is mainly to solve the technical problem of high manufacturing cost of the existing X65 pipeline steel. According to the present invention, the low-cost X65 pipeline steel comprises the following chemical components by weight: 0.07-0.09% of C, 0.1-0.3% of Si, 1.35-1.45% of Mn, less than or equal to 0.006% of S, less than or equal to 0.015% of P, 0.035-0.045% of Nb, 0.010-0.025% of Ti, 0.0010-0.0030% of Mg, 0.020-0.030% of Al, less than or equal to 0.006% of N, and the balance of Fe and unavoidable impurities. According to the present invention, the metallographic structure of the hot-rolled steel plate comprises fine-grained ferrite, acicular ferrite and pearlite, and the elongation A after break of the hot-rolled steel plate having the thickness of 10.0-15.0 mm is more than or equal to 24%.

Owner:SHANGHAI MEISHAN IRON & STEEL CO LTD

Secondary cooling nozzle arranging method for improving surface plasticity of casting blank and secondary cooling control method

InactiveCN104607609AInhibit precipitation behaviorImprove high temperature plasticityHot TemperatureGrain boundary

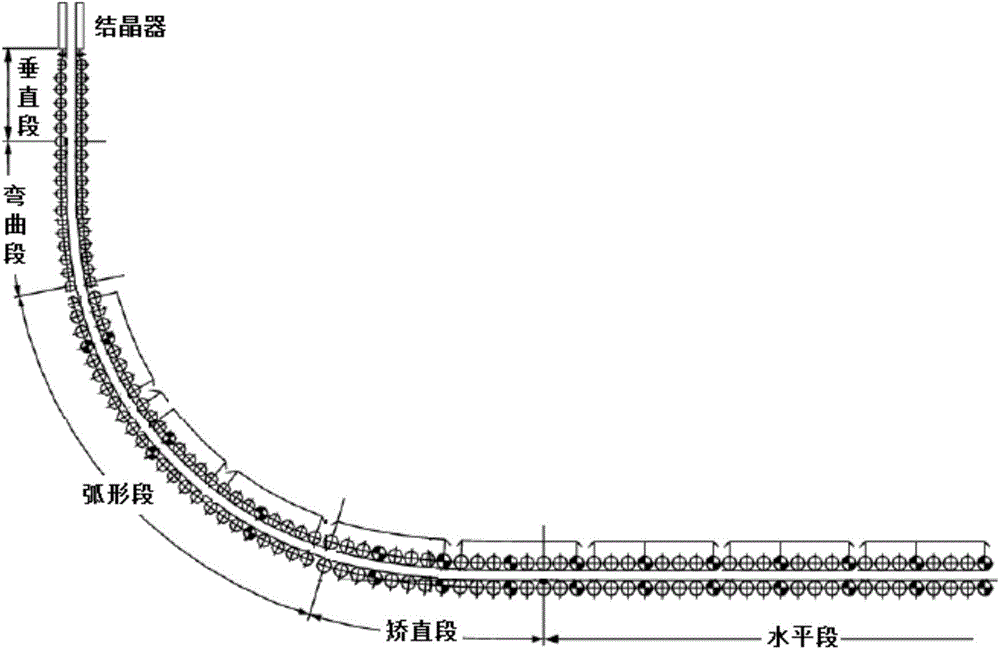

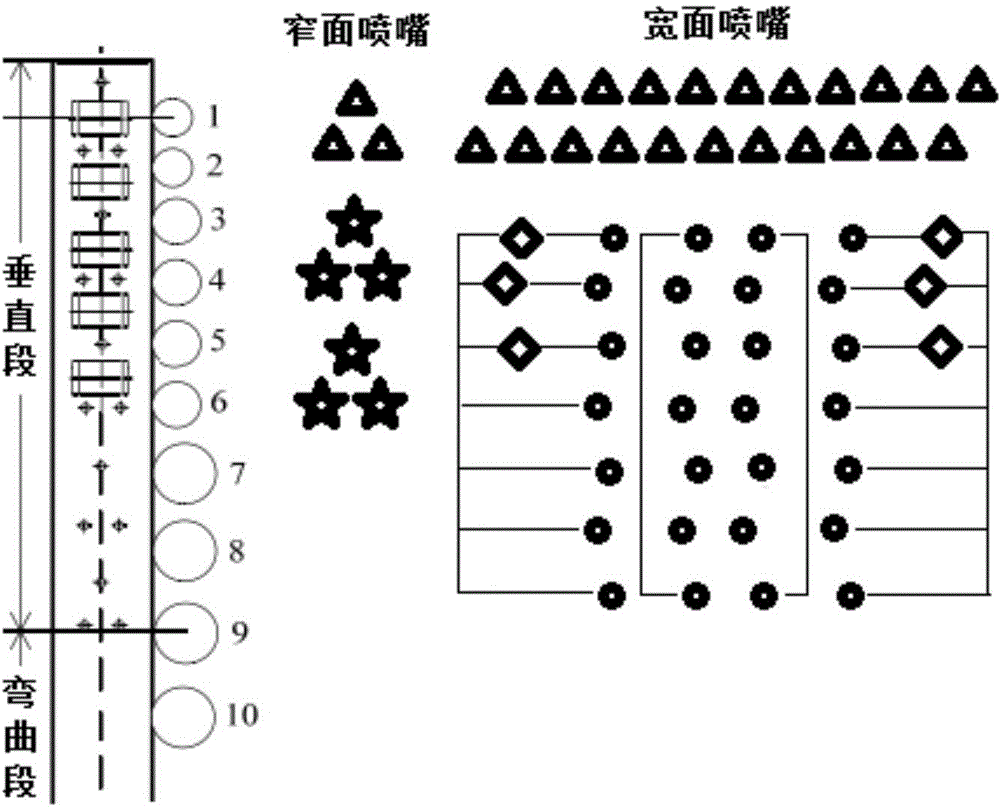

The invention relates to a secondary cooling nozzle arranging method for improving surface plasticity of a casting blank and a secondary cooling control method. In the secondary cooling nozzle arranging method, wide nozzles and narrow nozzles are formed in the vertical section of a continuous casting machine, and the wide nozzles and the narrow nozzles are controlled by independent loops respectively; after a continuous casting blank is discharged from a crystallizer, by the secondary cooling nozzle arranging method, the casting blank is forcibly cooled with the amount of secondary cooling water of 15-40m<3> / h to rapidly reduce the surface temperature of the casting blank to below 750 DEG C; narrow corner nozzles and wide corner nozzles in a lower area of the vertical section are closed to rapidly raise the surface temperature of the casting blank to about 1100 DEG C, and from the bent section to the horizontal section, a conventional cooling mode is adopted with the amount of the secondary cooling water of 2-10m<3> / h. In the secondary cooling nozzle arranging method, the changing course of the surface temperature of the casting blank enables the surface tissue of the casting blank to experience once heat treatment, so that the surface tissue of the casting blank is greatly thinned; after rewarming, a dense austenitic tissue is formed on the surface of the casting blank, the precipitation amount of a grain boundary ferrite film is inhibited at the same time, and the high-temperature plasticity of the surface of the casting blank is radically improved.

Owner:CISDI ENG CO LTD

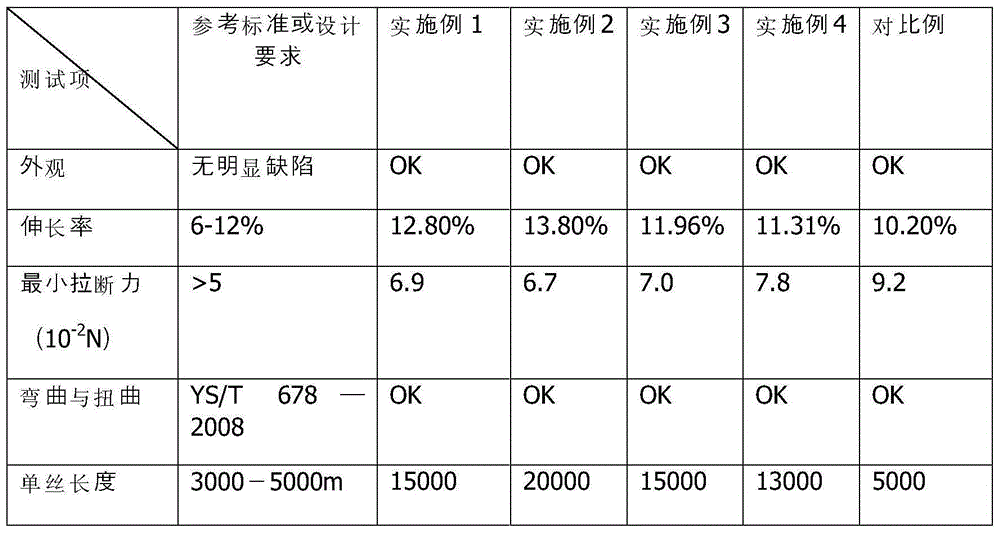

Ultra-thin copper alloy bonding wire for microelectronic packaging and preparing method of ultra-thin copper alloy bonding wire

InactiveCN105132735AImprove performanceImprove grain refinement effectSolid-state devicesSemiconductor devicesRare-earth elementImpurity

An ultra-thin copper alloy bonding wire for microelectronic packaging is characterized by being prepared from 10-50 wt.ppm of Ti, 10-50 wt.ppm of Li, 10-50 wt.ppm of Zr, 10-50 wt.ppm of Fe, 10-50 wt.ppm of Ag, 10-50 wt.ppm of B, 10-50 wt.ppm of a rare earth element and the balance copper and inevitable impurities, wherein the content of O and S in the impurities accounts for 5 wt.ppm or less in the whole copper alloy bonding wire, and the rare earth element is one of Eu, Y and Dy or a combination of Eu, Y and Dy. The invention further provides a preparing method of the ultra-thin copper alloy bonding wire for microelectronic packaging. The copper alloy bonding wire has the good oxidation resistance, good electric and heat conductivity, good weldability, large single wire length and other good performance, and the preparing method of the copper alloy bonding wire is easy and convenient to implement.

Owner:NICHE TECH KAISER SHANTOU

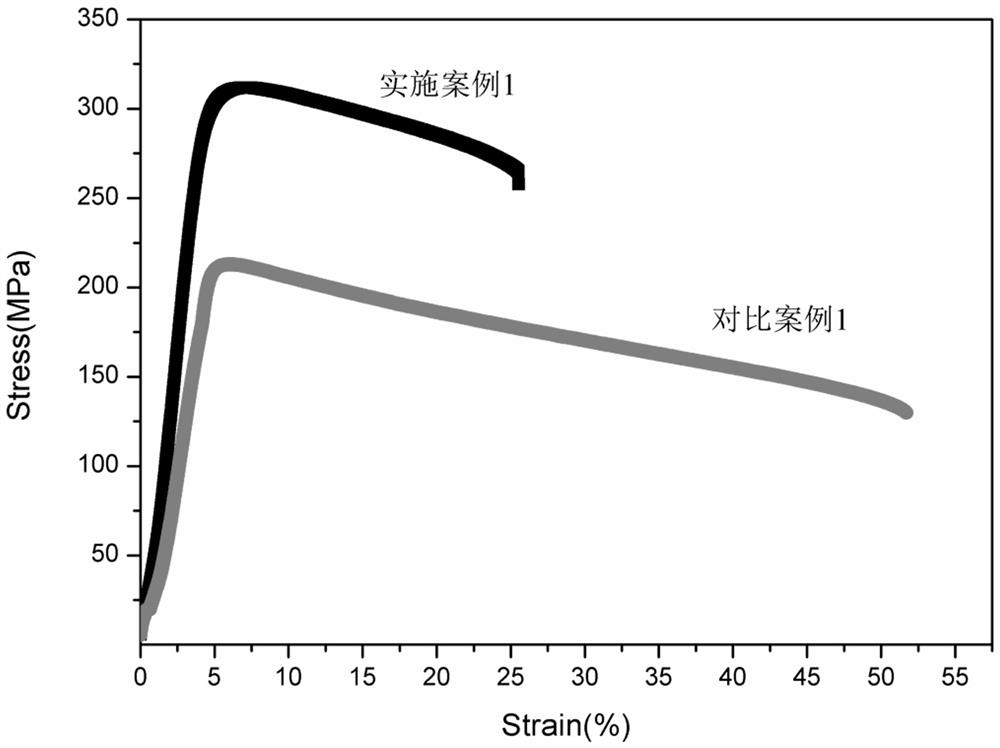

High-strength high-plasticity high-yield-ratio magnesium-lithium alloy and preparation method and application thereof

ActiveCN112593131AGood solid solution strengthening effectMorph coordinationDigital processing power distributionVacuum castingSolution treatment

The invention belongs to the technical field of magnesium-lithium alloy material preparation, and particularly relates to a high-strength high-plasticity high-yield-ratio magnesium-lithium alloy and apreparation method and application thereof. The high-strength high-plasticity high-yield-ratio magnesium-lithium alloy and the preparation method and application thereof are used for solving the problems of low absolute strength, difficult matching of strong plasticity and yield ratio of the magnesium-lithium alloy, the high-strength high-plasticity high-yield-ratio magnesium-lithium alloy material with high yield ratio, good plasticity, stable quality and high purity is obtained by designing the components of the magnesium-lithium alloy, optimizing a vacuum casting process and adopting a novel deformation heat treatment process, and the magnesium-lithium alloy has an industrialized practical application prospect. According to the preparation method of the high-strength, high-plasticity and high-yield-ratio magnesium-lithium alloy, the plastic processing procedure is simple, the maneuverability is high, only medium-high temperature solution treatment and medium-low temperature deformation are needed, intermediate process annealing is not needed, the yield is high, the economical efficiency is high, and the magnesium-lithium alloy product with the tensile strength of 330 MPa, the yield strength of 314 MPa, the elongation of 16% and the yield ratio of up to 95% or above can be obtained through the method.

Owner:郑州轻研合金科技有限公司

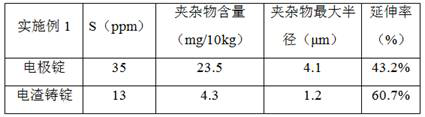

Super-pure smelting method for industrially producing Incone1690 alloy

The invention belongs to the technical field of vacuum induction smelting, and relates to an improvement on a smelting process for industrially producing Incone1690 alloy, in particular to a super-pure smelting process for industrially producing Incone1690 alloy. The process uses a CaO fireproof material with high purity (CaO is more than 98.5 percent) and good thermodynamic stability as a crucible material for the vacuum induction smelting. The specific smelting process comprises charging, smelting period, refining period, condensing, deoxidizing and desulfurizing period and casting, whereinin the refining period, effective deoxidization and desulfurization are carried out on the wall part of a crucible and the surface of molten steel by improving the refining temperature and strengthening the thermodynamic and kinetic conditions of deoxidization and desulfurization; and in the deoxidizing and desulfurizing period, final deoxidization and desulfurization are carried out for the alloyby adding strong deoxidizing and desulfurizing agent so as to further reduce the contents of oxygen and sulfur in the alloy below 10 ppm.wt. The process effectively improves the high-temperature plasticity of the alloy, improves the thermal processing performance of the alloy, and obtains the high-quality alloy.

Owner:INST OF METAL RESEARCH - CHINESE ACAD OF SCI

Low-pollution energy conservation slag system used for manufacturing hollow ingot by remelting electroslag in ingot drawing way

ActiveCN103334015AImprove performanceMeet the production process requirementsProcess efficiency improvementElectricityChemical composition

The invention provides a low-pollution energy conservation slag system used for manufacturing a hollow ingot by remelting electroslag in an ingot drawing way. The low-pollution energy conservation slag system comprises the following components in percentage by weight: 15 to 25% of Al2O3, 30 to 40% of CaO3, 8 to 14% of SiO2, 1 to 3% of MgO, 0 to 3% of Na2O, and the balance of CaF2 and inevitable impurities; and the binary basicity of CaO / SiO is 2.5 to 5.0. According to the slag system, components of the slag system are optimized, therefore, relevant performances of the slag system can be further improved, the requirement of a process for producing the hollow ingot by remelting the electroslag is met, and the stability of chemical components of a steel element in the remelting process, high capability of removing inclusion, low environmental pollution and low electricity consumption can be ensured, and as a result, the energy conservation and emission reduction effects are realized.

Owner:NORTHEASTERN UNIV

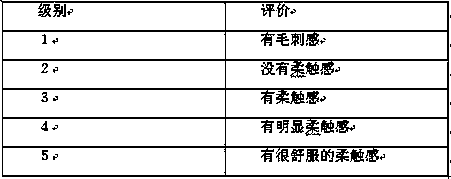

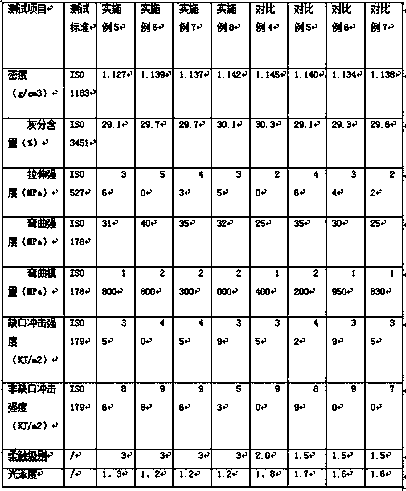

Low-gloss soft-touch modified thermoplastic resin and preparation method thereof

The invention relates to low-gloss soft-touch modified thermoplastic resin and a preparation method thereof, and belongs to the technical field of modified plastics and composite materials, the low-gloss soft-touch modified thermoplastic resin comprises the following substances by weight: 40-80 parts of thermoplastic resin; 10-40 parts of elastomer master batch; 0-20 parts of nylon; 0-30 parts ofinorganic mineral powder; 0-6 parts of a compatilizer; 0-2 parts of a coupling agent; 0.01-2 parts of an antioxidant; 0-2 parts of a colorant; 0.5-2 parts of a flow modifier; 0.2-1 part of lubricant.The modified thermoplastic resin prepared by the method is relatively low in cost; smooth and attractive appearance, the product has low glossiness and high performance, soft touch can be improved, the preparation method is simple, operation is completed in one step, the product can be widely applied to the fields of automobile industry, daily home furnishing, electrical equipment, construction and building materials, safety labor protection and the like, meanwhile, the production process is simple, original production equipment is used, and additional investment for purchasing equipment is not needed; the raw material cost is low and the product added value is high. Therefore, the device can be widely used and popularized.

Owner:SHANDONG DAWN POLYMER CO LTD

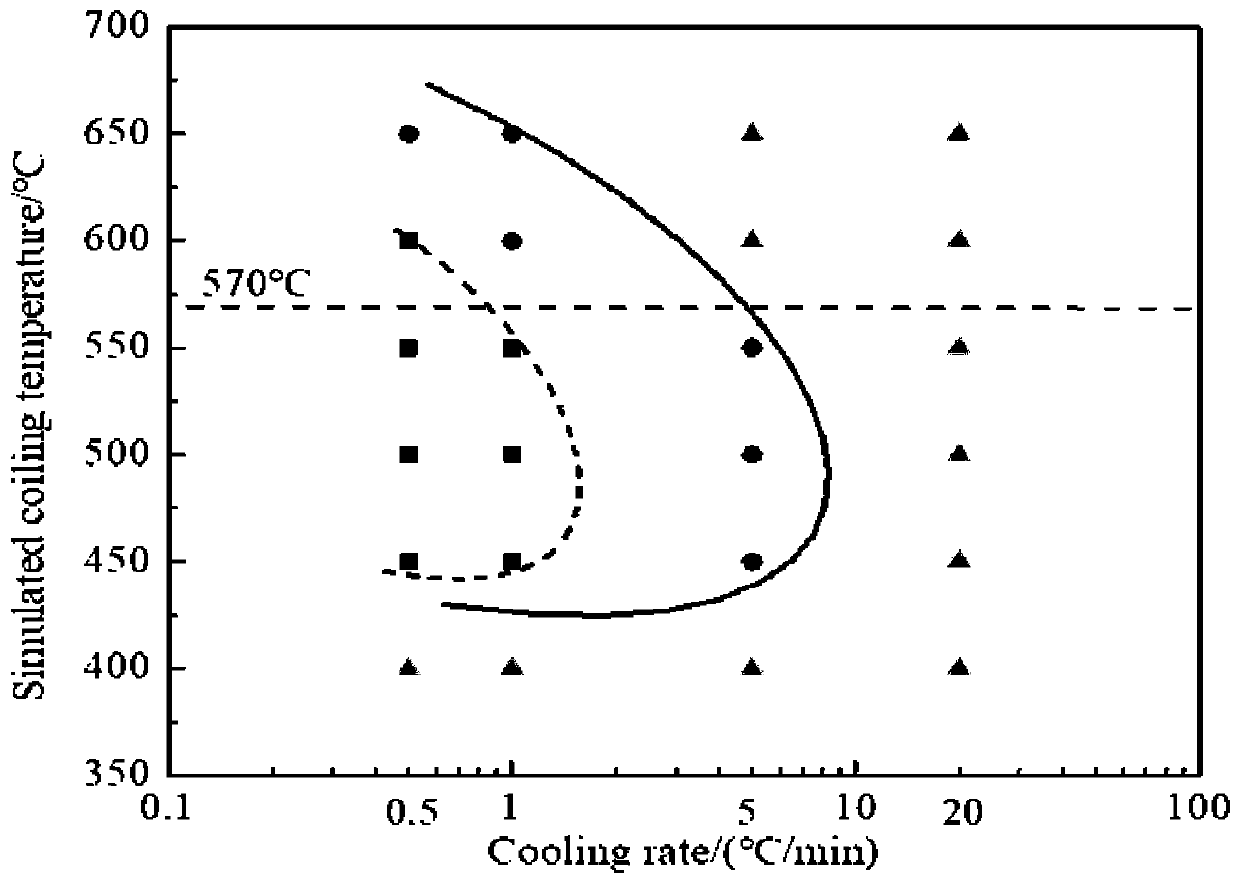

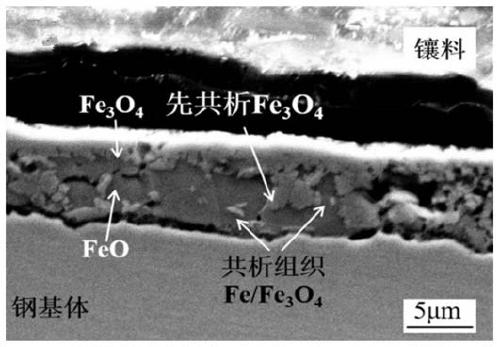

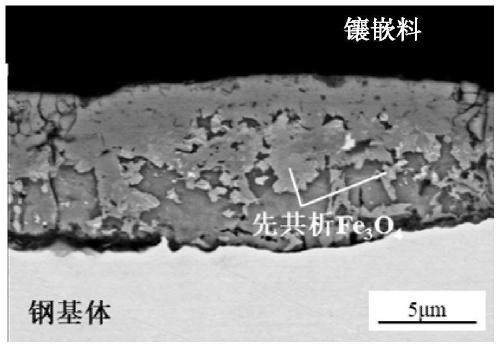

Automobile beam steel plate with tensile strength of 750MPa grade and heavy gauge, and preparation method of automobile beam steel plate

The invention relates to an automobile beam steel plate with tensile strength of 750MPa grade and heavy gauge, and a preparation method of the automobile beam steel plate. The steel plate comprises, by mass, 0.03 to 0.12% of C, 0.05 to 0.60% of Si, 0.2 to 1.0% of Cr, 1.0 to 2.5% of Mn, not greater than 0.015% of S, not greater than 0.025% of P, 0.015 to 0.045% of Als, 0.07 to 0.15% of Ti, 0.02 to0.08% of Nb, and the balance being Fe and impurities that are unavoidable during smelting. During preparation, a steel billet adopting the above chemical composition proportion is subjected to reasonable process design, so as to prevent the pickling preparation process from replacing the original process, reduce the thickness of the scale, and obtain the scale complex structure of Fe3O4, FeO and eutectoid Fe3O4 coexisting with alpha-Fe, so that the surface quality of the steel plate is significantly improved, and the requirements of the use of pickling-free direct stamping or roll forming andeliminate the pickling process can be met, production efficiency is improved, environmental pollution is reduced and production cost is reduced.

Owner:NORTHEASTERN UNIV

Electroslag ignition agent and preparation method thereof

InactiveCN104726721AGood arc starting effectReduce manufacturing costCarrying capacityGraphite electrode

The invention discloses an electroslag ignition agent and a preparation method thereof. The electroslag ignition agent is used for igniting and remelting slag material in an electroslag remelting technology to establish electroslag. The ignition agent comprises the following raw material components in percentage by weight: 25-35% of fluorite powder, 2-12% of silica powder, 30-40% of graphite electrode powder, 1-11% of quicklime powder and 18-28% of water glass. The preparation method comprises the following process steps: preparing mixed dry powder: uniformly mixing the raw materials according to the content in percentage by weight of each raw material and the carrying capacity of a mold to obtain the mixed dry powder; mixing with sludge, loading into the mold, adding the water glass into the mixed dry powder, stirring till no dry powder exists, loading a mixture which is uniformly stirred into the mold, tamping and compacting; blowing gas, demolding, blowing CO2 into the mold, and demolding after stopping gas blowing to obtain an ignition agent block; and drying at low temperature. The ignition agent disclosed by the invention has a good arc starting effect in the using process and can avoid a titanium-increasing effect, and high-temperature smelting is not required in the manufacturing process of the ignition agent.

Owner:SINOSTEEL XINGTAI MACHINERY & MILL ROLL

Production method for preventing straightening and hot delivering cracks of microalloy continuous casting slab

ActiveCN109202029AImprove high temperature plasticityImprove heat transfer efficiencyMicroalloyed steelContinuous casting

The invention discloses a production method for preventing straightening and hot delivering cracks of a microalloy continuous casting slab. The production method comprises the following steps: quicklycooling the continuous casting slab before straightening, wherein the cooling rate is 5-10 DEG C / s and the surface temperature of the continuous casting slab is reduced to be lower than 450 DEG C; controlling the surface temperature of a blank in a straightening stage to be smaller than or equal to 600 DEG C; and carrying out temperature return control on the continuous casting slab which is straightened and is not cut, and controlling the surface temperature of the continuous casting slab after temperature return to be higher than the temperature of a steel type Ar3. The production method has the advantages that the hot filling and hot delivering quality and efficiency are improved while the surface quality of the continuous casting slab is improved.

Owner:ZHANGJIAGANG RONGSHENG SPECIAL STEEL CO LTD +2

Method for controlling blank casting quality of phi-280mm 37Mn circular tube blank

ActiveCN105695659AImprove purityHomogenization of ingredientsManufacturing convertersMolten steelParameter control

The invention discloses a method for controlling the internal quality of a 37Mn circular tube steel casting blank with a phi-280mm production section, and belongs to the field of metallurgy. The method comprises the steps such as smelting in a converter, molten steel refining in an LF furnace, RH vacuum treatment and continuous casting of molten steel. First of all, the purity of the molten steel is improved according to reasonable parameter control in the molten steel smelting stage, and the high-temperature plasticity of the molten steel is improved and the steel grade crack sensitivity is lowered after the molten steel is subjected to titanium microalloying; and then, mold electromagnetic stirring and final electromagnetic stirring are combined in the molten steel pouring stage, so that component and temperature homogenization of the molten steel can be achieved, the shell of the circular tube steel casting blank can grow uniformly, the solidification structure of the circular tube steel casting blank can be effectively improved, the loose level can be raised, the area of an equiaxial crystal region can be enlarged, the compactness of the central region of the circular tube steel casting blank can be effectively improved, the crack defect of the circular tube steel casting blank can be effectively controlled, the surface non-clearing rate can be improved, and the quality of such a rolled product can be controlled well and stably.

Owner:CHENGDU ADVANCED METAL MATERIALS IND TECH RES INST CO LTD

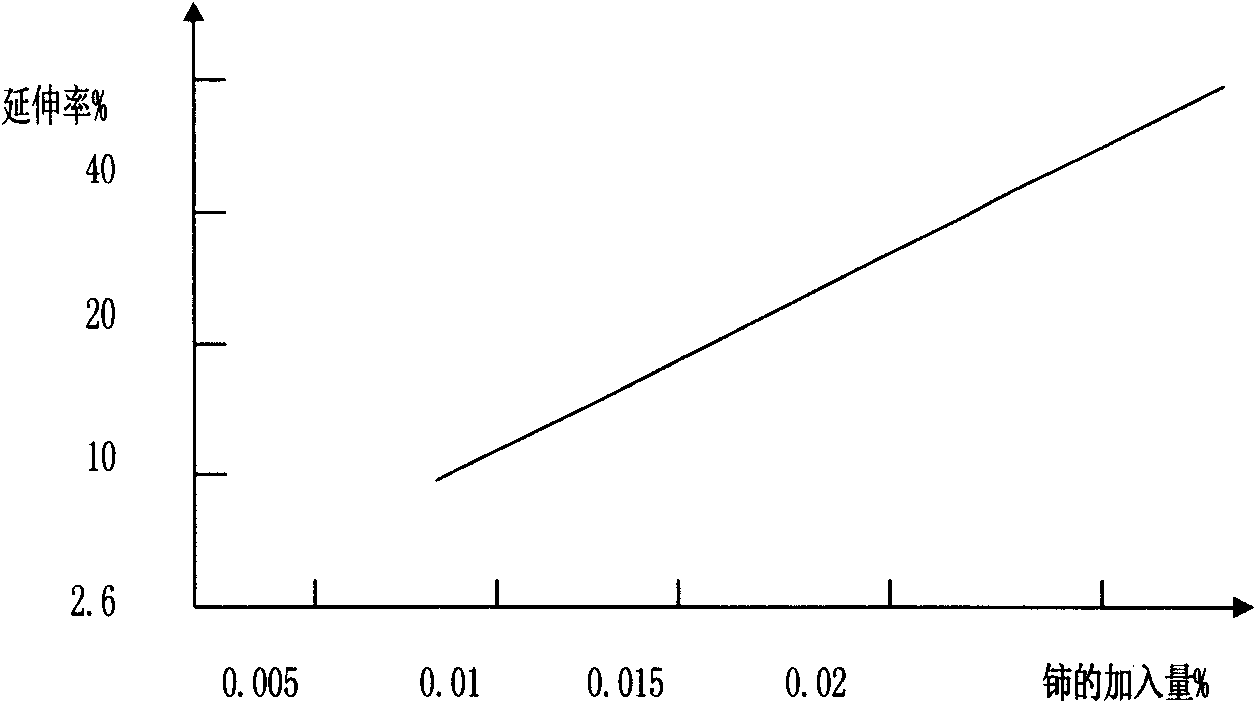

Smelting method for improving copper strip plasticity

The invention relates to a smelting method for producing copper strips with bright surface, no crack and good plasticity. The smelting method for improving copper strip plasticity is characterized in that rare-earth element cerium is added in pure copper by a mode of intermediate alloy, the input amount is 105-120g per ton of copper water, and the casting process flow is as follows: burdening, smelting, warming, adding cerium, entering a holding furnace by subcurrent type copper water, casting, milling face, cold blooming, annealing, pickling, finish rolling, annealing of an air cushion furnace, stretch bending, slitting and packaging. The rare-earth element cerium hardly dissolves in copper by a solid mode, a bit of addition of the cerium is in favor of mechanical property of copper and has no obvious influence on copper conductivity, and the important point is that cerium can form high-melting-point compounds with impurities of lead and bismuth in copper which are distributed in copper water in fine spherical particles, thus being in favor of nucleating, refining crystal particles, improving high-temperature plasticity of copper and enhancing copper elongation by adding cerium.

Owner:CNMC ALBETTER ALBRONZE

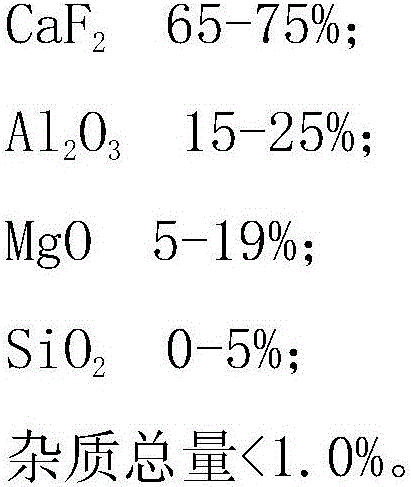

Nickel-based superalloy electroslag remelting slag system

InactiveCN106834729AImprove high temperature plasticityReduce conductivityNon-metallic inclusionsSlag

Provided is a nickel-based superalloy electroslag remelting slag system. The slag system is prepared from, by weight, 65%-75% of CaF2, 15%-25% of Al2O3, 5%-19% of MgO and 0-5% of SiO2. The total quantity of impurities is smaller than 1.0%. When the slag system is used for carrying out electroslag remelting on nickel-based superalloy, a steel ingot obtained through remelting is low in oxygen content and small in non-metal occluded foreign substance quantity, the surface and interior quality of the electroslag remelting steel ingot can be effectively improved, and the subsequent machinable property of electroslag remelting steel ingot can be enhanced.

Owner:CHONGQING MATERIALS RES INST

Flux-cored wire for welding of titanium-steel dissimilar metal sheet and preparation method of flux-cored wire

InactiveCN107378305ALess alloying elementsSimple preparation processWelding/cutting media/materialsWelding/soldering/cutting articlesAlloy elementDissimilar metal

The invention discloses a flux-cored wire for welding of a titanium-steel dissimilar metal sheet. The flux-cored wire comprises a flux core and a metal sheath. The flux core comprises, by mass percentage, 60-80% of V powder and 20-40% of Ni powder, wherein the sum of the mass percentage of the components is 100%. The preparation method comprises the steps that the V powder and Ni powder are sintered after being mixed and then are wrapped with a copper strip, and the flux-cored wire is obtained after drawing. A welding joint obtained by the flux-cored wire has the excellent toughness. The number of the alloy elements of the flux-cored wire is small, the preparation process is simple, and the large-scale mass production is facilitated.

Owner:XIAN UNIV OF TECH

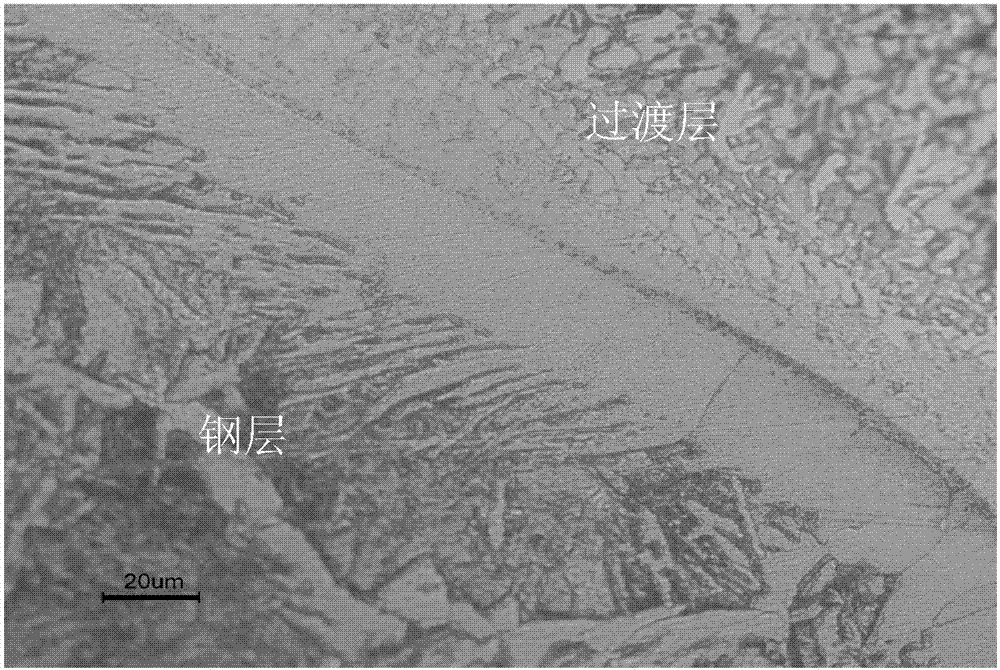

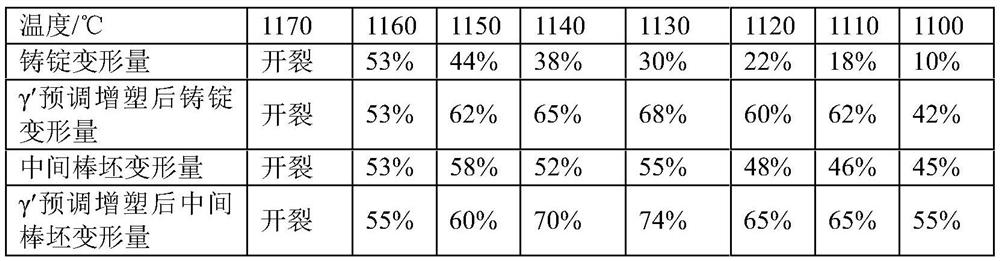

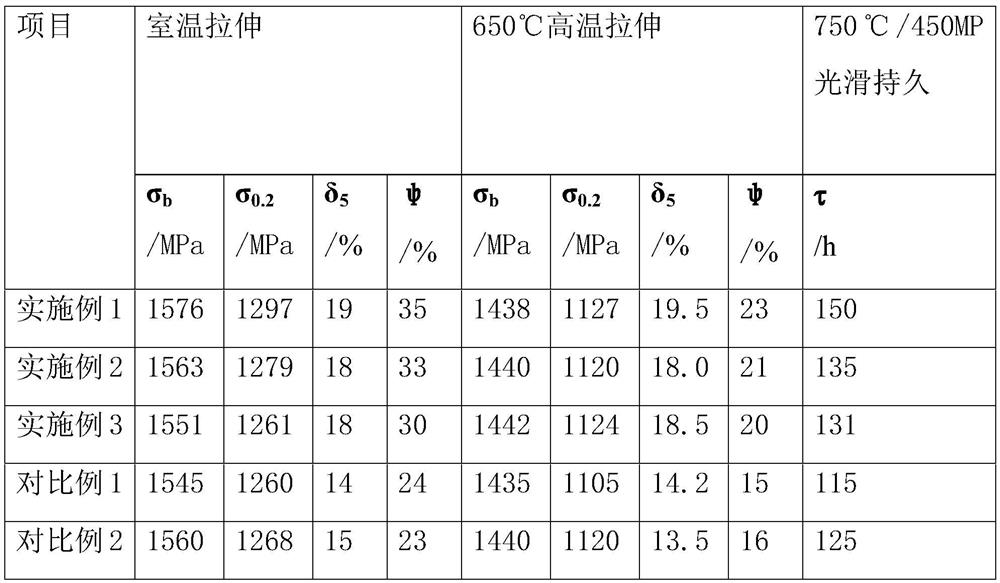

Gamma'phase pre-adjusting plasticizing production process of high-performance high-temperature alloy

ActiveCN112746231AImprove high temperature plasticityReduce deformation resistanceMetal-working apparatusIngotHeat conservation

The invention discloses a gamma'phase pre-adjusting plasticizing production process of a high-performance high-temperature alloy, and belongs to the technical field of material processing. The gamma 'phase pre-adjusting plasticizing production process comprises the following preparation steps: 1, smelting is performed to prepare a cast ingot to form a fine-grain homogeneous bar after multi-heating forging; 2, before the bar is forged in a two-phase region, when the heating number forging deformation is higher than the critical cracking deformation, the bar is treated through the gamma'phase pre-adjusting plasticizing technology so as to improve the critical cracking deformation, gamma 'phase pre-adjusting plasticizing adjusts the temperature of the bar subjected to two-phase region forging to be the forging temperature Td, heat preservation is conducted for 2-12 h, then the temperature is reduced to 800-1000 DEG C at the speed of 5-50 DEG C / min, and heat preservation is conducted for 3-12 hours; and 3, the cast ingot or the bar billet obtained in the second step is heated to the forging temperature Td again, heat preservation is conducted, the cast ingot or the bar billet is taken out of a furnace and forged, and a homogeneous bar billet is obtained after multiple times of forging. The hot working high-temperature plasticity of the high-temperature alloy is improved.

Owner:BEIJING CISRI GAONA TECH +1

Titanium-silicon-carbon metal composite converter slag-stopping sliding plate brick and preparation method thereof

PendingCN112876265AHigh melting pointImprove wear resistanceManufacturing convertersSteelmakingAl powder

The invention discloses a titanium-silicon-carbon metal composite converter slag-stopping sliding plate brick and a preparation method thereof. The titanium-silicon-carbon metal composite converter slag-stopping sliding plate brick comprises fused zirconia corundum, fused zirconia mullite, sintered tabular corundum and fused magnesia-alumina spinel particles, fused magnesia-alumina spinel powder, metal silicon powder, metal aluminum powder, alpha calcined alumina powder, boron carbide, titanium silicon carbon and carbon black, organic silicon resin and thermosetting phenolic resin. The preparation method comprises the following steps: uniformly mixing the raw materials, molding, drying, sintering, hooping, grinding, coating and carrying out finish machining to obtain a finished product. The titanium-silicon-carbon metal composite converter slag-stopping sliding plate brick disclosed by the invention has strong corrosion resistance and oxidation resistance, and is not easy to react with molten steel and steel slag to generate a low melt; and meanwhile, relatively high wear resistance and relatively low wettability can ensure relatively long service life and relatively high use stability of the product, and particularly the titanium-silicon-carbon metal composite converter slag-stopping sliding plate brick has obvious advantages in complex steelmaking processes such as smelting of high-grade steel.

Owner:MAANSHAN LIER KAIYUAN NEW MATERIAL

Ultrahigh-strength and ultrahigh-toughness high-density high-entropy alloy and preparation method thereof

ActiveCN113718154AImprove stabilityHigh melting pointMetal-working apparatusBinary alloyHigh density

The invention provides an ultrahigh-strength and ultrahigh-toughness high-density high-entropy alloy and a preparation method thereof. The ultrahigh-strength and ultrahigh-toughness high-density high-entropy alloy comprises main alloy elements and trace alloy elements; the main alloy elements comprise essential elements and adjustable elements, the essential elements comprise tungsten, molybdenum and nickel, and the adjustable elements comprise cobalt and / or niobium; and the trace alloy elements comprise one or more of palladium, tantalum and hafnium. The preparation method of the ultrahigh-strength and ultrahigh-toughness high-density high-entropy alloy comprises the steps that raw materials are smelted to obtain a cast ingot, and then homogenization treatment, forging and heat treatment are sequentially conducted. According to the ultrahigh-strength and ultrahigh-toughness high-density high-entropy alloy, the adoption of elements such as nickel and cobalt as a binary alloy matrix in the prior art is broken through, a high-density mono-stable face-centered cubic high-entropy alloy phase is constructed by adopting various high-density elements and strengthening elements, the stability and strengthening capacity of a solid solution are greatly improved by utilizing the high-entropy effect and the cocktail effect, and the deformability of the alloy is improved.

Owner:UNIV OF SCI & TECH BEIJING

Electroslag remelting slag system for duplex stainless steel

PendingCN110029229AGood chemical stabilityHigh strengthProcess efficiency improvementSlagSS - Stainless steel

The invention discloses an electroslag remelting slag system for duplex stainless steel. The electroslag remelting slag system is prepared from the following components in percent by weight: 50.0-65.0% of CaF2, 8.0-15.0% of Al2O3, 3.0-10.0% of CeO2, 15.0-20.0% of CaO, 3.0-5.0% of MgO, 1.0-3.0% of SiO2 and the balance impurities which are not more than 1%. According to the slag system, the slag viscosity changes gently as the temperature is reduced, and the high temperature plasticity and the strength of slag can be also improved, so that bleed-out and slag leakage are prevented. The conductivity of the slag can be reduced, the chemical stability of the slag can be improved, and the system has better deoxidizing and desulfurizing effects and inclusion absorption action, thereby playing a role of purifying molten steel deeply. As-cast grains can be refined, and the strength and the toughness of steel are improved. The electroslag remelting slag system is uniform to transfer heat and goodin lubricating effect, and the slag layer is kept stable and is melted uniformly.

Owner:JIANGSU XIHU SPECIAL STEEL

High-formability boron-containing steel with tensile strength higher than or equal to 320 MPa and production method

The invention discloses high-formability boron-containing steel with tensile strength higher than or equal to 320 MPa. The high-formability boron-containing steel is prepared from the following components in percentage by weight (wt%): 0.03-0.07% of C, 0.01-0.3% of Si, 0.4-0.9% of Mn, less than or equal to 0.020% of P, less than or equal to 0.010% of S, less than or equal to 0.006% of N, 0.0005-0.003% of B, and 0.03-0.08% of Ti. A production method comprises the following steps: continuously casting to form blank after smelting; heating in stages; roughly rolling; performing fine rolling; performing laminar cooling; and rolling. The high-formability boron-containing steel has yield strength of 250-350 MPa, tensile strength of 320-460 MPa, and ductility higher than or equal to 32%; moreover, cast blank does not need to cut corner after being unloaded if a secondary cooling water ratio is not reduced and N content is not strictly limited; and hot rolling can be directly performed, so that a product defect rate can be controlled to be lower than 0.5%.

Owner:武汉钢铁有限公司

High-reliability copper alloy bonding wire for microelectronic packaging and manufacturing method thereof

The invention discloses a high-reliability copper alloy bonding wire for microelectronic packaging. The high-reliability copper alloy bonding wire for microelectronic packaging is characterized in that the bonding wire comprises, by weight, 0.001%-0.005% of Ru, 0.001%-0.005% of Nb, 0.001%-0.005% of Zr, 0.001%-0.005% of Mn, 0.001%-0.005% of Mg, 0.001%-0.005% of Li, 0.001%-0.003% of Dy and the balance copper and inevitable impurities, and the content of S and O in the impurities in the whole copper alloy bonding wire is less than or equal to 0.0005%. The invention further provides a manufacturing method of the high-reliability copper alloy bonding wire for microelectronic packaging. The copper alloy bonding wire has the advantages of being high in reliability, low in hardness, good in electrical conductivity and heat conductivity and the like. The manufacturing method is easy to operate.

Owner:NICHE TECH KAISER SHANTOU

Internal quality control method of 30Mn tube bloom steel cast blanks

The invention relates to the field of ferrous metallurgy and particularly relates to an internal quality control method of 30Mn tube bloom steel cast blanks. The technical problem to be solved is to provide an internal quality control method of 30Mn tube bloom steel cast blanks; the method is capable of effectively controlling crack defects of cast blanks, effectively improving solidification structures of the cast blanks and achieving the internal quality control. The method comprises the following steps: a, firstly carrying out a converter smelting process; b, secondly carrying out an LF furnace molten steel refining process; and c, finally carrying out section continuous casting process, wherein electromagnetic stirring parameters of a crystallizer are characterized in that the stirring current is 300-400A, and the frequency is 2-4Hz; electromagnetic stirring parameters of a solidification end are characterized in that the stirring current is 100-200A, and the frequency is 4.0-7.0Hz; the superheat degree is controlled to be 25-35 DEG C; the pulling rate is controlled to be 0.70-1.00m / min; the cooling rate of the crystallizer is controlled to be 2400-2500L / min; the specific special water flow rate of secondary cooling is controlled to be 0.21-0.30 / kg steel. The internal quality control method of the 30Mn tube bloom steel cast blanks is especially applicable to the internal quality control process of large-size 30Mn tube bloom steel cast blanks produced by phi 350mm section.

Owner:PANZHIHUA IRON & STEEL RES INST OF PANGANG GROUP

Nuclear stainless steel electroslag remelting slag used for high-level radioactive waste curing container and method adopting electroslag remelting

InactiveCN111748696AGood for hot and cold processingPromote sustainable developmentIncreasing energy efficiencySlag (welding)Radioactive waste

The invention relates to nuclear stainless steel electroslag remelting slag used for high-level radioactive waste curing container and a method adopting electroslag remelting. The slag comprises, by weight part, 55 to 70 parts of CaF2, 8 to 15 parts of CaO, 8 to 15 parts of Al2O3, 5 to 15 parts of MgO, 1 to 5 parts of SiO2 and 1 to 5 parts of CeO2, a slag remelting method is adopted, rare earth inthe stainless steel can be stably controlled, harmful impurities can be greatly reduced, the structure is uniform and compact, the alloy machining performance can be greatly improved, the yield rateis improved, the good mechanical property, and good properties of high temperature resistance, corrosion resistance, oxidation resistance and the like are achieved, good hot and cold machining performance, welding performance and machining performance are achieved, and the method has the wide application prospect in the nuclear waste treatment field.

Owner:CHONGQING MATERIALS RES INST

Heating technology for avoiding surface defects of steel plate

ActiveCN111809028AAvoid surface defects such as cracks and slag inclusionsImprove energy savingFurnace typesHeat treatment furnacesSteel platesSlag

The invention relates to a heating technology for avoiding surface defects of a steel plate. The heating technology comprises the specific technological process that a continuous casting machine produces a plate blank, the plate blank is cut and sprayed with a number, the plate blank enters a heating furnace to be heated, primary rolling is conducted on the plate blank, finish rolling is conductedon the plate blank, coiling and packing are conducted, and a finished product is divided. Temperature control is conducted on the plate blank before the plate blank enters the heating furnace for heating, and the specific reaction condition comprises that the surface temperature of the plate blank is controlled to be higher than the Ar3 temperature or controlled to be lower than the Ar1 temperature and higher than 200 DEG C. By the adoption of the heating technology for avoiding the surface defects of the steel plate, on the premise of not increasing any equipment and production cost, hot delivery and hot charging of the plate blank are achieved, waste heat of a continuous casting blank is fully utilized, and then a good energy-saving effect is achieved; and oxidized scale on the surfaceof the steel plate is easier to remove, carbonitride is fully dissolved in the heating process, the high-temperature plasticity of steel is improved, and the surface defects such as slag inclusion andcracks of the rolled steel plate are avoided.

Owner:SHANGHAI MEISHAN IRON & STEEL CO LTD

Quality Control Method of 37mn Round Tube Billet with φ280mm

ActiveCN105695659BImprove purityHomogenization of ingredientsManufacturing convertersMolten steelParameter control

The invention discloses a method for controlling the internal quality of a 37Mn circular tube steel casting blank with a phi-280mm production section, and belongs to the field of metallurgy. The method comprises the steps such as smelting in a converter, molten steel refining in an LF furnace, RH vacuum treatment and continuous casting of molten steel. First of all, the purity of the molten steel is improved according to reasonable parameter control in the molten steel smelting stage, and the high-temperature plasticity of the molten steel is improved and the steel grade crack sensitivity is lowered after the molten steel is subjected to titanium microalloying; and then, mold electromagnetic stirring and final electromagnetic stirring are combined in the molten steel pouring stage, so that component and temperature homogenization of the molten steel can be achieved, the shell of the circular tube steel casting blank can grow uniformly, the solidification structure of the circular tube steel casting blank can be effectively improved, the loose level can be raised, the area of an equiaxial crystal region can be enlarged, the compactness of the central region of the circular tube steel casting blank can be effectively improved, the crack defect of the circular tube steel casting blank can be effectively controlled, the surface non-clearing rate can be improved, and the quality of such a rolled product can be controlled well and stably.

Owner:CHENGDU ADVANCED METAL MATERIALS IND TECH RES INST CO LTD

Method for controlling blank casting quality of phi-280mm 30Mn circular tube blank

ActiveCN105695657AImprove purityHomogenization of ingredientsManufacturing convertersMolten steelSteel casting

The invention discloses a method for controlling the internal quality of a 30Mn circular tube steel casting blank with a phi-280mm production section, and belongs to the field of metallurgy. The method comprises the steps such as smelting in a converter, molten steel refining in an LF furnace, continuous casting of molten steel. First of all, the purity of the molten steel is improved according to reasonable parameter control in the molten steel smelting stage, and the high-temperature plasticity of the molten steel is improved and the steel grade crack sensitivity is lowered after the molten steel is subjected to titanium microalloying; and then, mold electromagnetic stirring and final electromagnetic stirring are combined in the molten steel pouring stage, so that component and temperature homogenization of the molten steel can be achieved, the shell of the circular tube steel casting blank can grow uniformly, the solidification structure of the circular tube steel casting blank can be effectively improved, the loose level can be raised, the area of an equiaxial crystal region can be enlarged, the compactness of the central region of the circular tube steel casting blank can be effectively improved, the crack defect of the circular tube steel casting blank can be effectively controlled, the surface non-clearing rate can be improved, and the quality of such a rolled product can be controlled well and stably.

Owner:PANZHIHUA IRON & STEEL RES INST OF PANGANG GROUP

Method for smelting high-tungsten high-cobalt-nickel alloy through electroslag remelting, high-tungsten high-cobalt-nickel alloy and shaped charge liner

ActiveCN112030020AIncrease alkalinityStrong desulfurization abilityIncreasing energy efficiencyCobalt nickel alloyNickel alloy

The invention provides a method for smelting a high-tungsten high-cobalt-nickel alloy through electroslag remelting, the high-tungsten high-cobalt-nickel alloy and a shaped charge liner. The method for smelting the high-tungsten high-cobalt-nickel alloy through electroslag remelting comprises steps that raw materials of an electroslag remelting slag system are subjected to slagging, then an electrode ingot made of the raw materials of the high-tungsten high-cobalt-nickel alloy is smelted, and the high-tungsten high-cobalt-nickel alloy is obtained, wherein the electroslag remelting slag systemcomprises the following raw materials in percentage by mass: 39-44% of CaF2, 24-28% of CaO, 14-18% of Al2O3, 3-5% of MgO and 5-10% of SiO2. The high-tungsten high-cobalt-nickel alloy is prepared by using the method for smelting the high-tungsten high-cobalt-nickel alloy through electroslag remelting. The raw material of the shaped charge liner comprises the high-tungsten high-cobalt-nickel alloy.According to the electroslag remelting slag system provided by the invention, the sulfur content of the alloy can be effectively reduced, the purity of the alloy is improved, and the high-plasticity alloy with good surface quality is obtained.

Owner:UNIV OF SCI & TECH BEIJING

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com