Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

160 results about "Cobalt nickel alloy" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Nickel / Cobalt Alloys. Nickel / Cobalt superalloys are high performance materials for demanding applications that require high tensile and yield strength, and ductility, over a wide temperature range. Chrome, nickel, and cobalt are predominant elements, though many others (including aluminum, tungsten, and molybdenum) are frequently used.

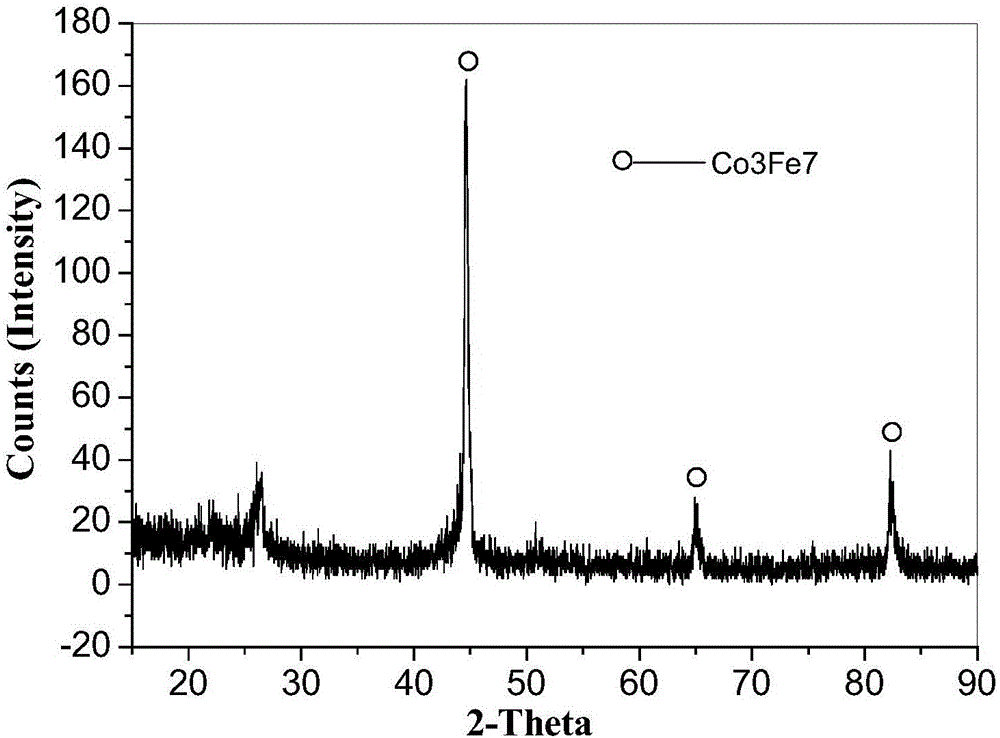

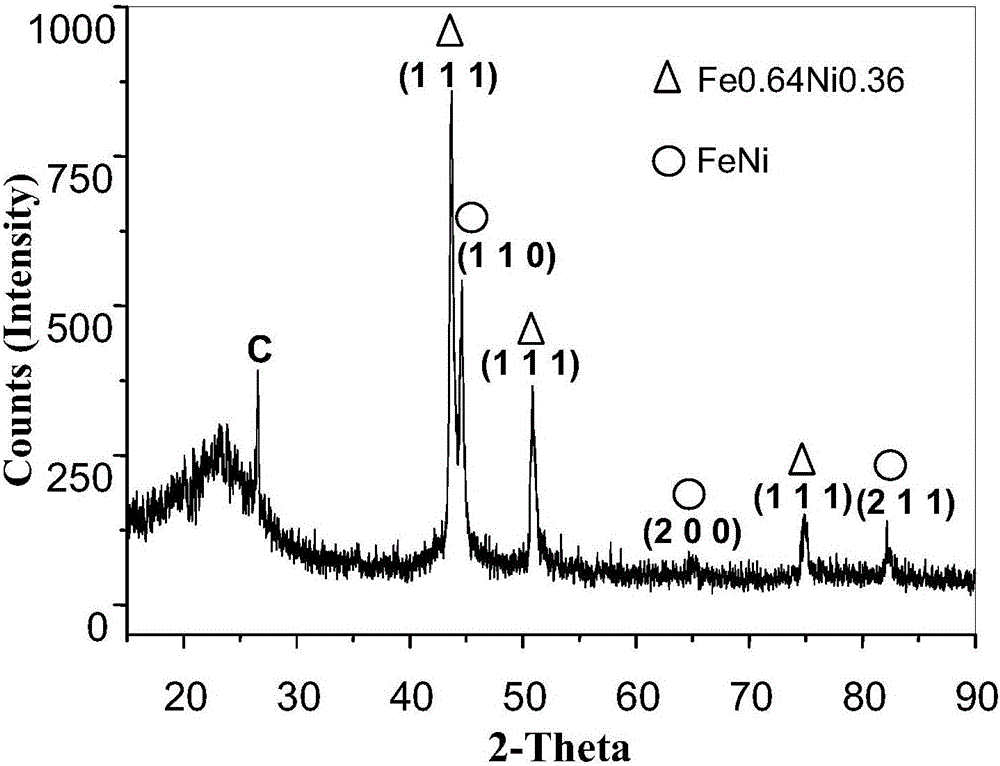

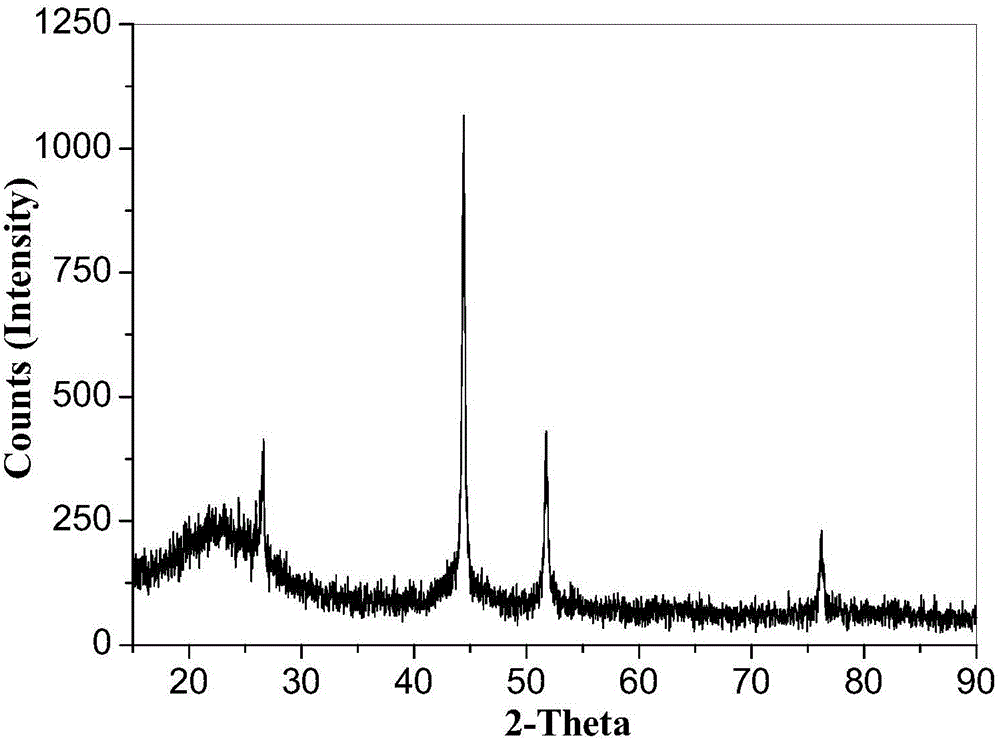

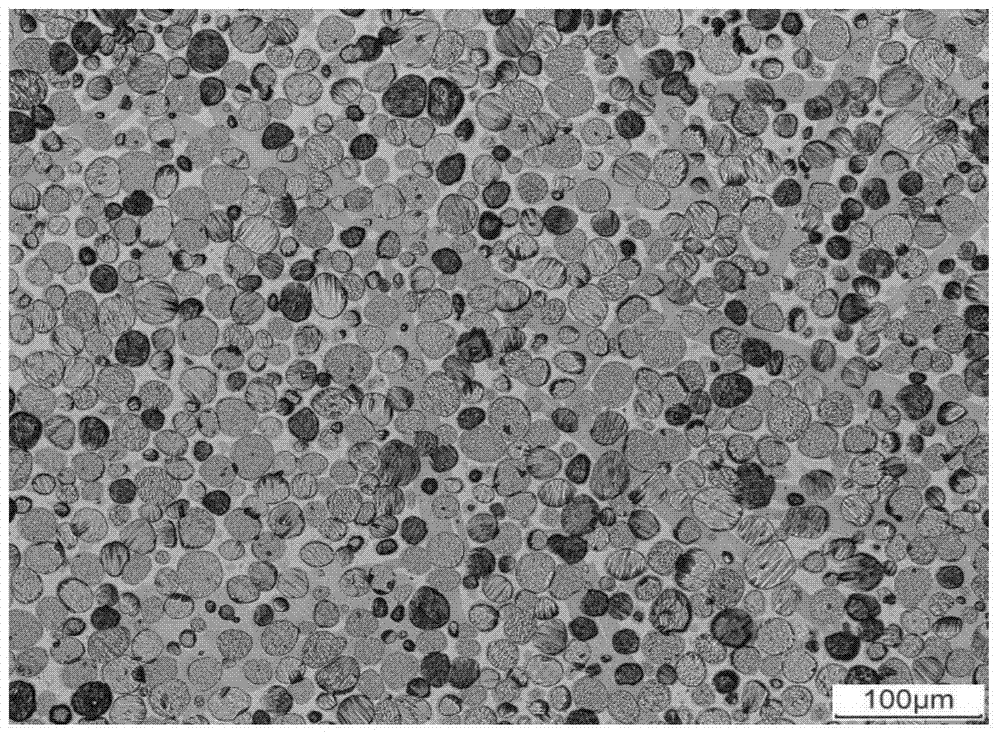

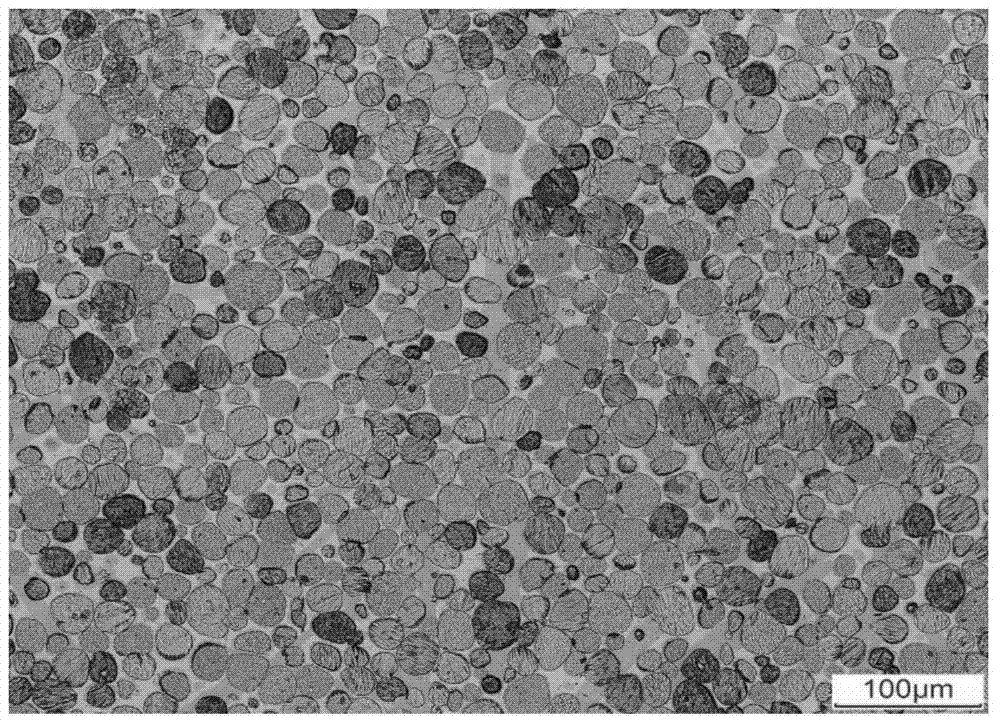

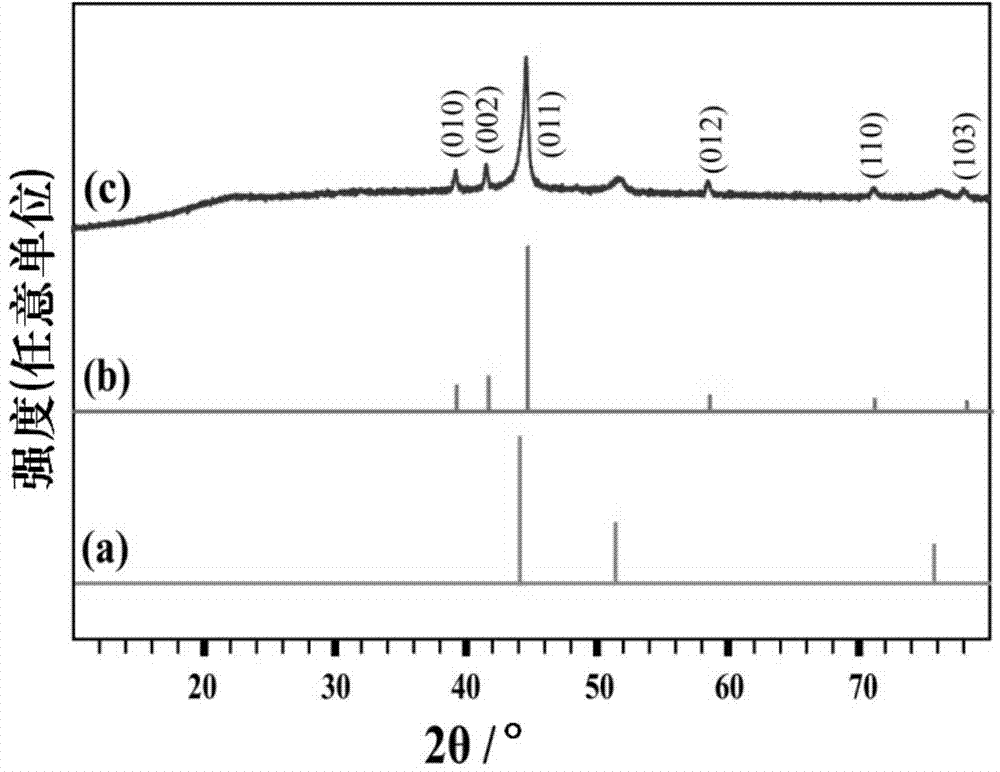

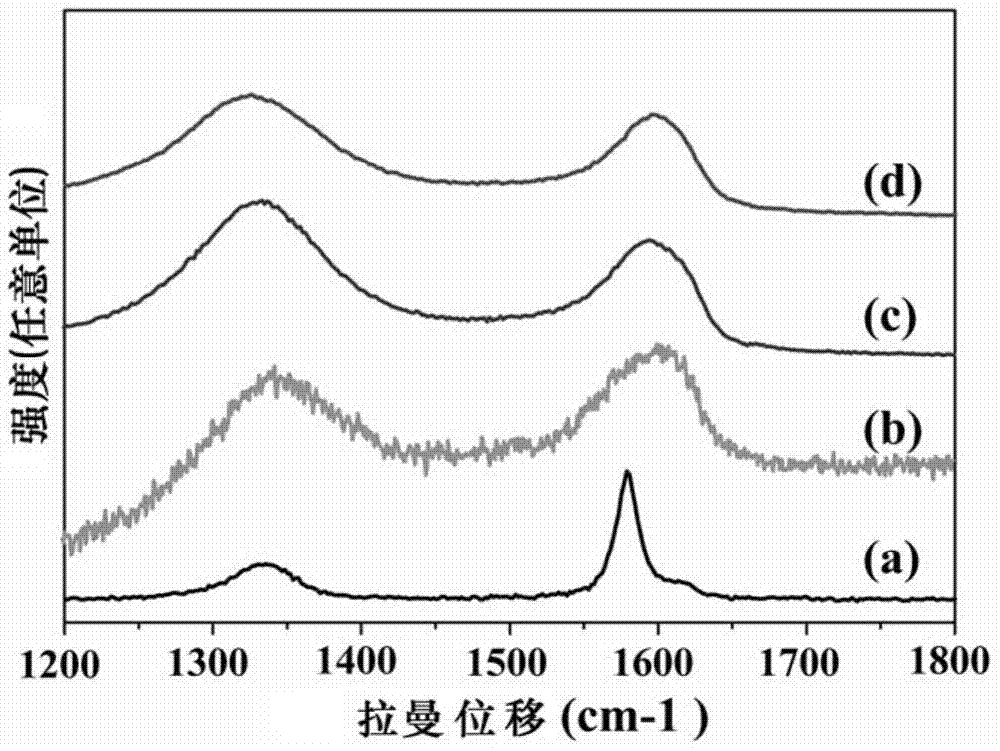

Preparation method of magnetic-alloy-loaded porous carbon sphere composite wave-absorbing material

The invention relates to a preparation method of a magnetic-alloy-loaded porous carbon sphere composite wave-absorbing material. The method comprises the following steps: 1) preparing a precursor solution containing two or more magnetic metal ion salts; 2) stirring the porous carbon spheres in the precursor solution for impregnation; 3) filtering out the porous carbon spheres, washing and drying; 4) calcining the dried porous carbon spheres in an inert atmosphere; and 5) cooling to room temperature in an inert atmosphere to obtain the magnetic-alloy-loaded porous carbon sphere composite wave-absorbing material. The iron salt / cobalt salt, iron salt / nickel salt and cobalt salt / nickel salt mixed precursor solution are introduced to the inside of the ducts of the carbon spheres by using the high specific area and strong adsorptivity of the porous carbon spheres through the capillary actions and are combined with the hydrophilic oxygen-containing functional group; and finally, the drying and sintering treatment in the inert atmosphere are performed to obtain the iron-cobalt / iron-nickel / cobalt-nickel-alloy-loaded porous carbon sphere composite material. The whole preparation process is simple in technique and convenient to operate, and has low requirements for the production equipment.

Owner:XI'AN INST OF OPTICS & FINE MECHANICS - CHINESE ACAD OF SCI

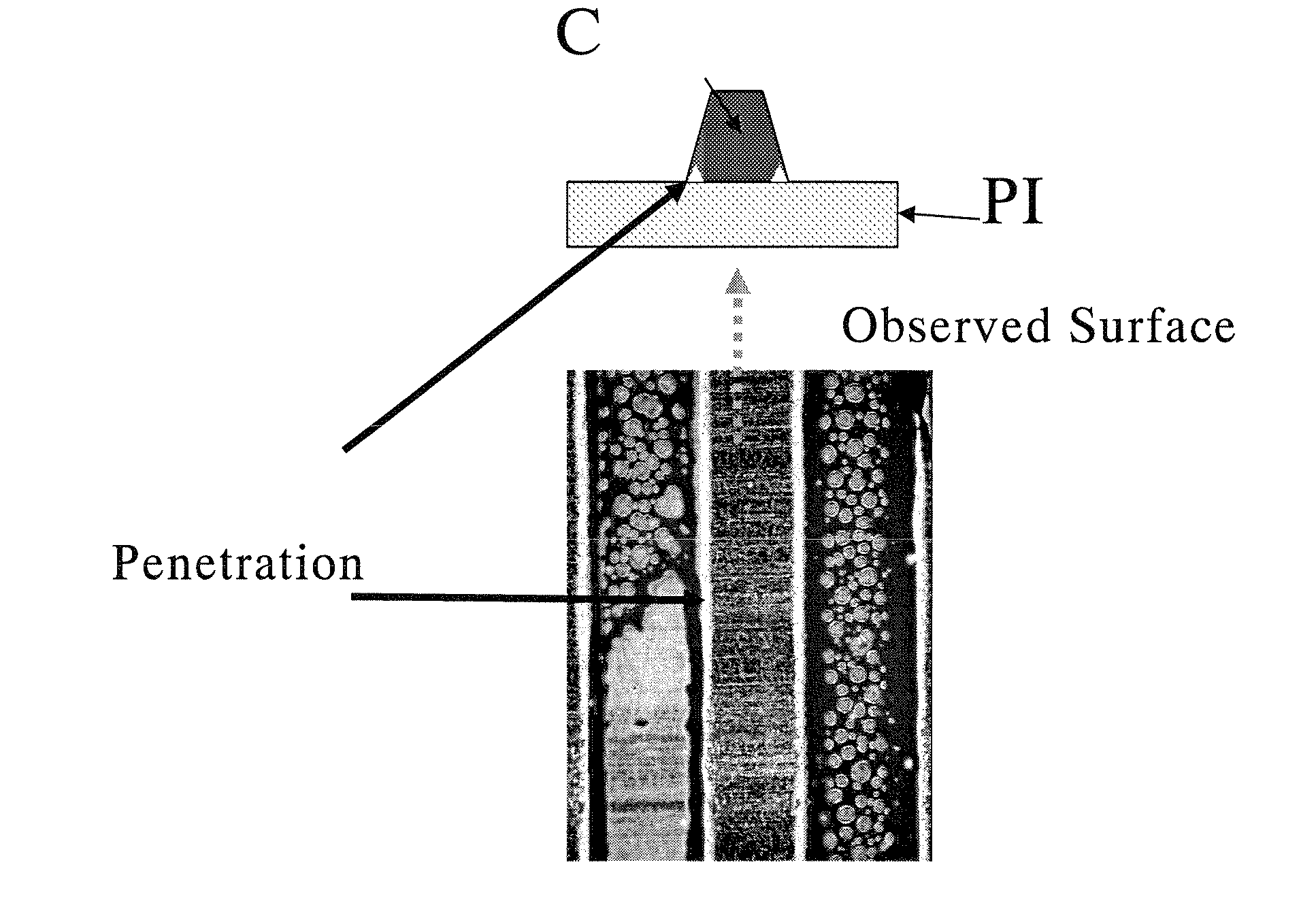

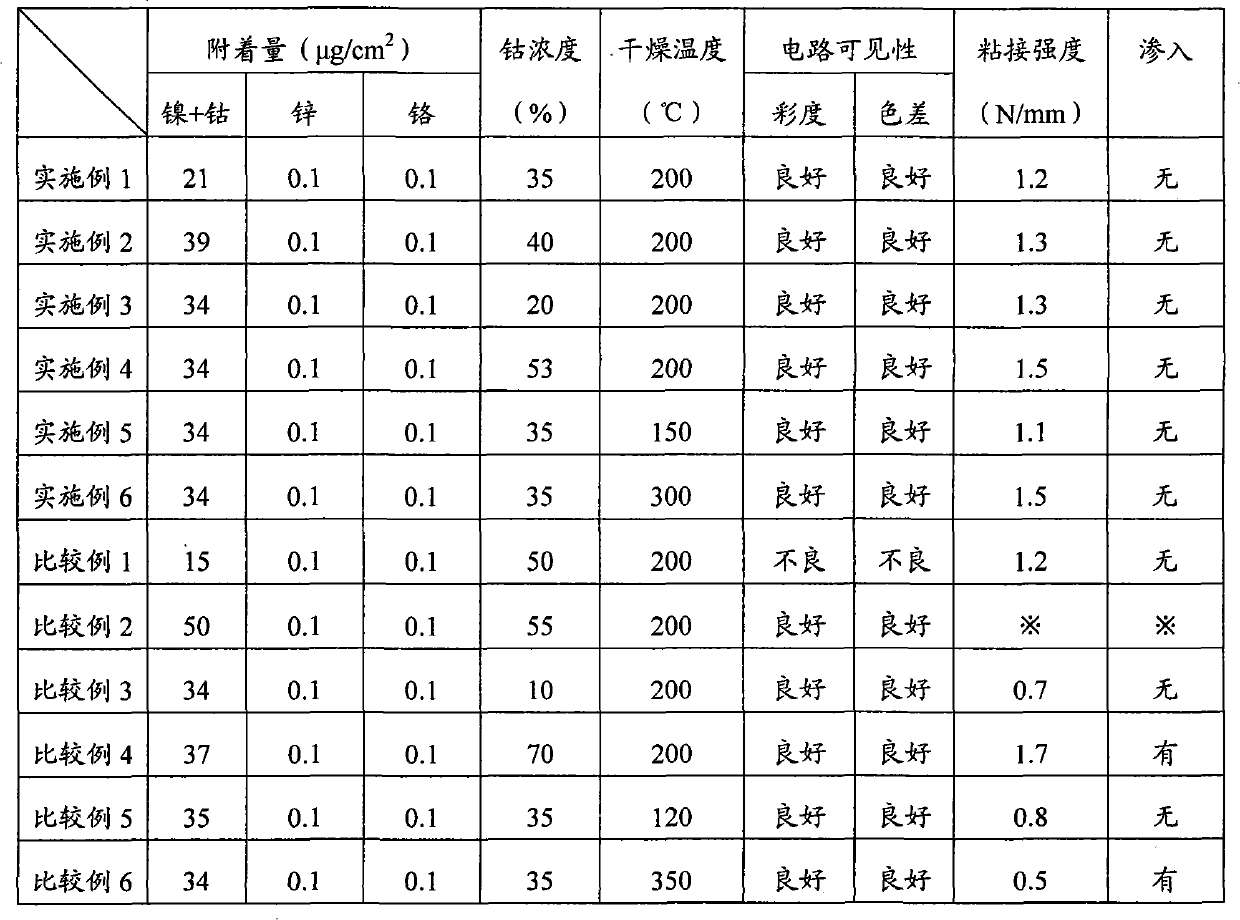

Copper Foil for Printed Circuit and Copper-Clad Laminate

ActiveUS20100212941A1Easy to integrateIncrease temperatureNon-insulated conductorsElectrolytic inorganic material coatingEtchingCopper foil

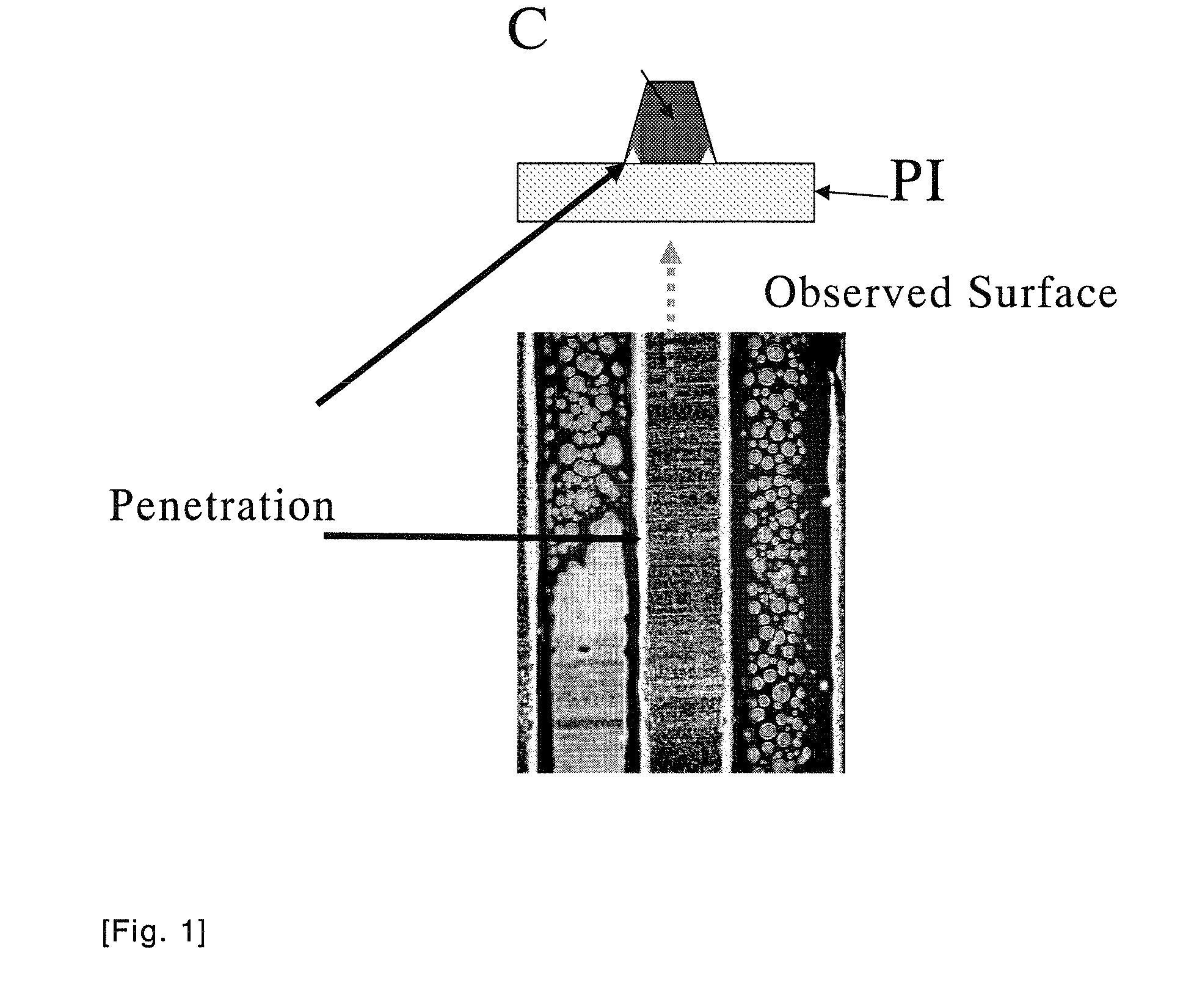

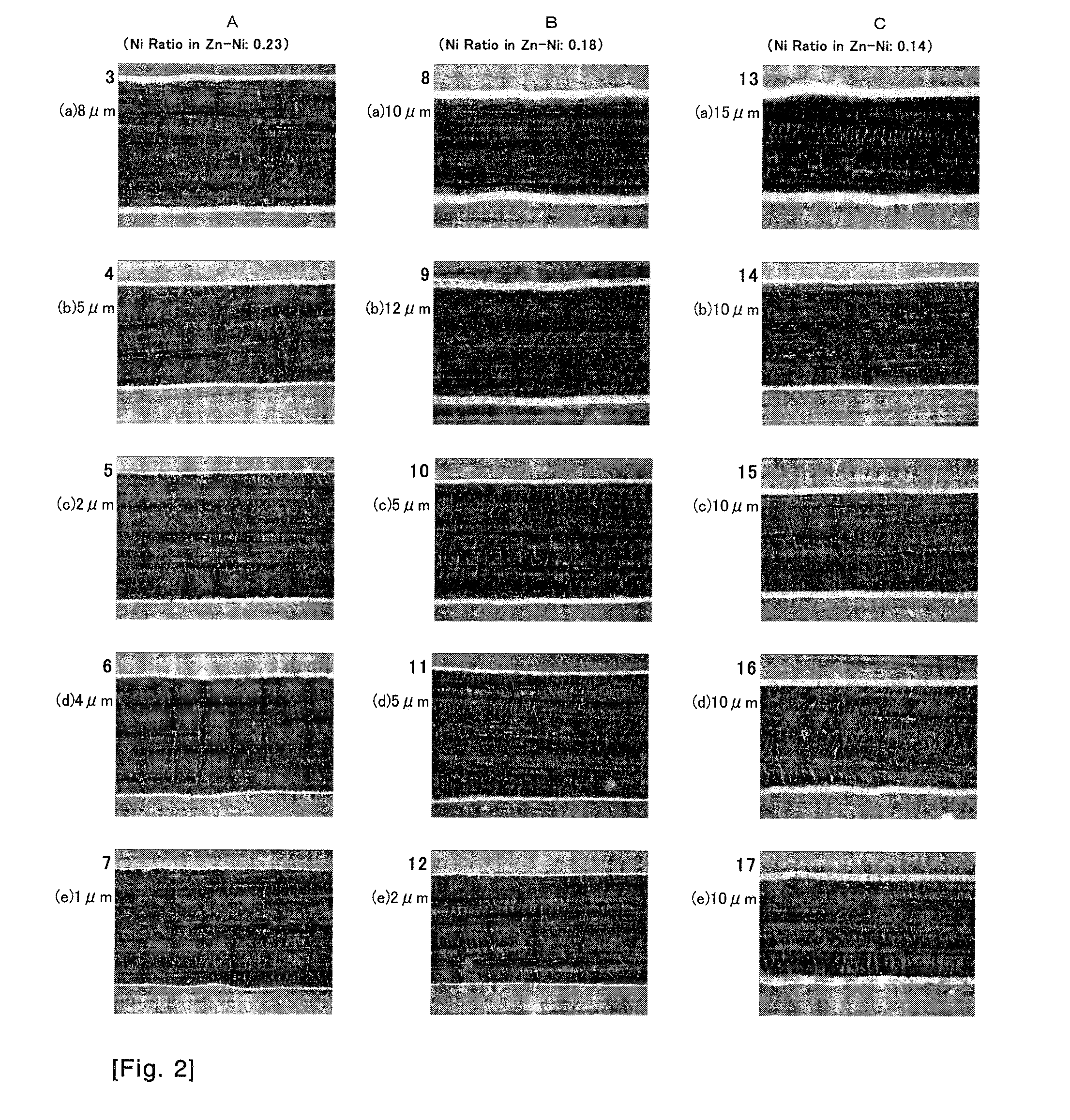

Provided is a copper foil for printed circuit comprising a roughened layer on a surface of a copper foil by way of copper-cobalt-nickel alloy plating, a cobalt-nickel alloy plated layer formed on the roughened layer, and a zinc-nickel alloy plated layer formed on the cobalt-nickel alloy plated layer, wherein the total amount of the zinc-nickel alloy plated layer is 150 to 500 μg / dm2, the lower limit of the nickel ratio in the alloy layer is 0.16, the upper limit thereof is 0.40, and the nickel content is 50 μg / dm2 or more.With the development of electronic equipment, the miniaturization and high integration of semiconductor devices have advanced further. This tendency has led to a demand for the adoption of a higher temperature in treatment in a production process of printed circuits and has led to heat generation during the use of electronic equipment after the productization. The present invention provides a technique that, even under these circumstances, the adhesive strength between a copper foil and a resin base material does not decrease and the penetration into a circuit edge part can be effectively prevented when performing the soft etching of a copper foil circuit.

Owner:JX NIPPON MINING& METALS CORP

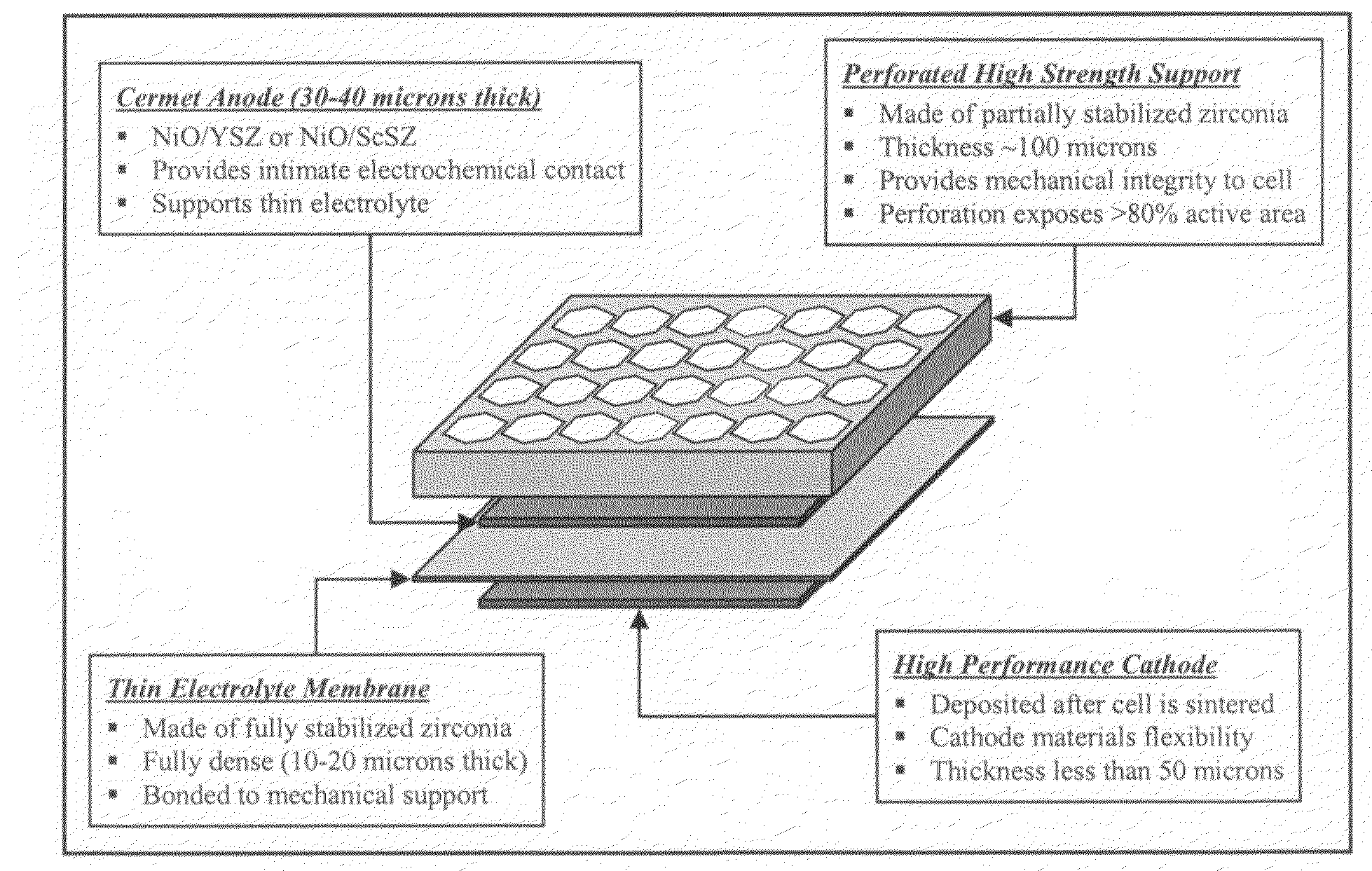

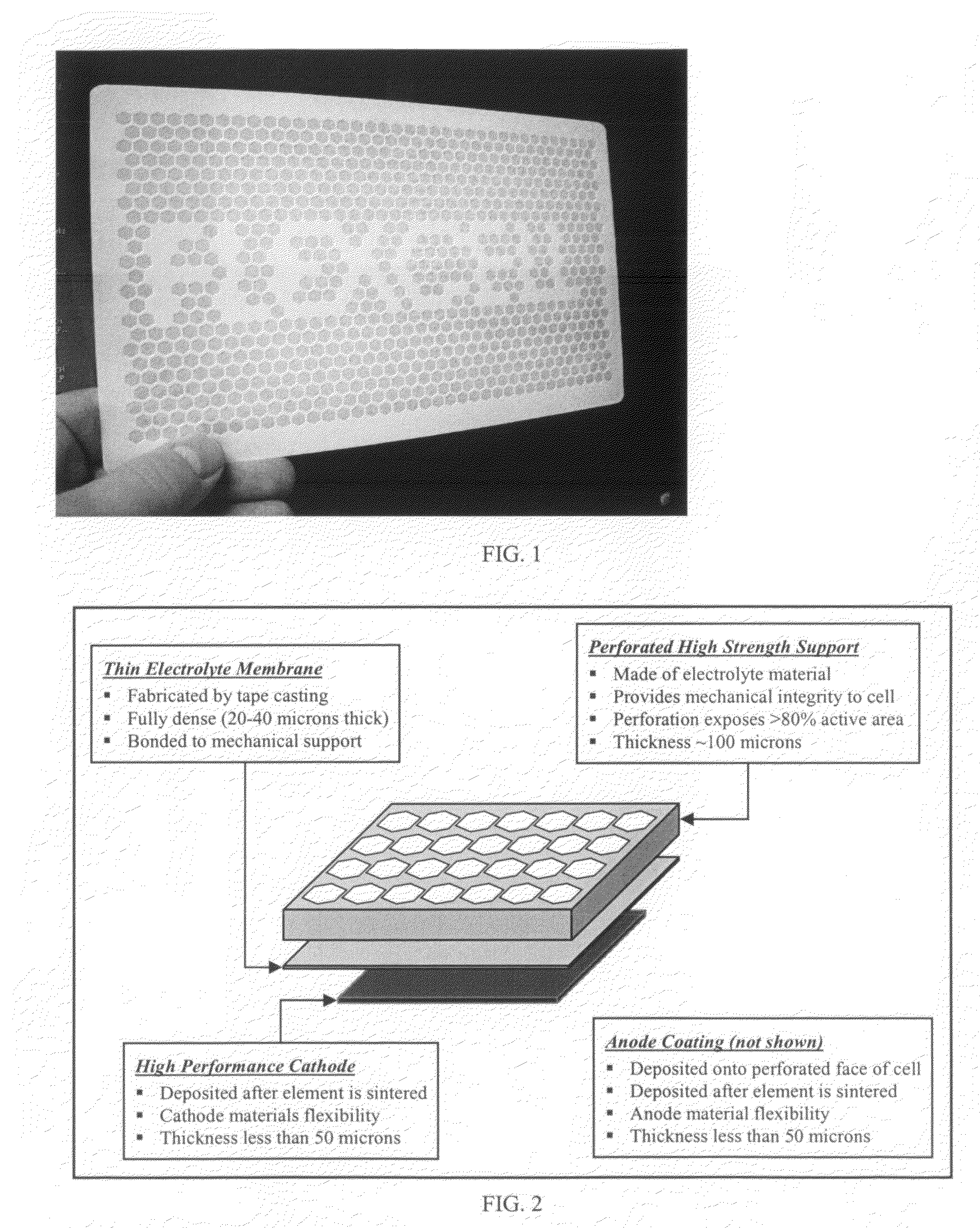

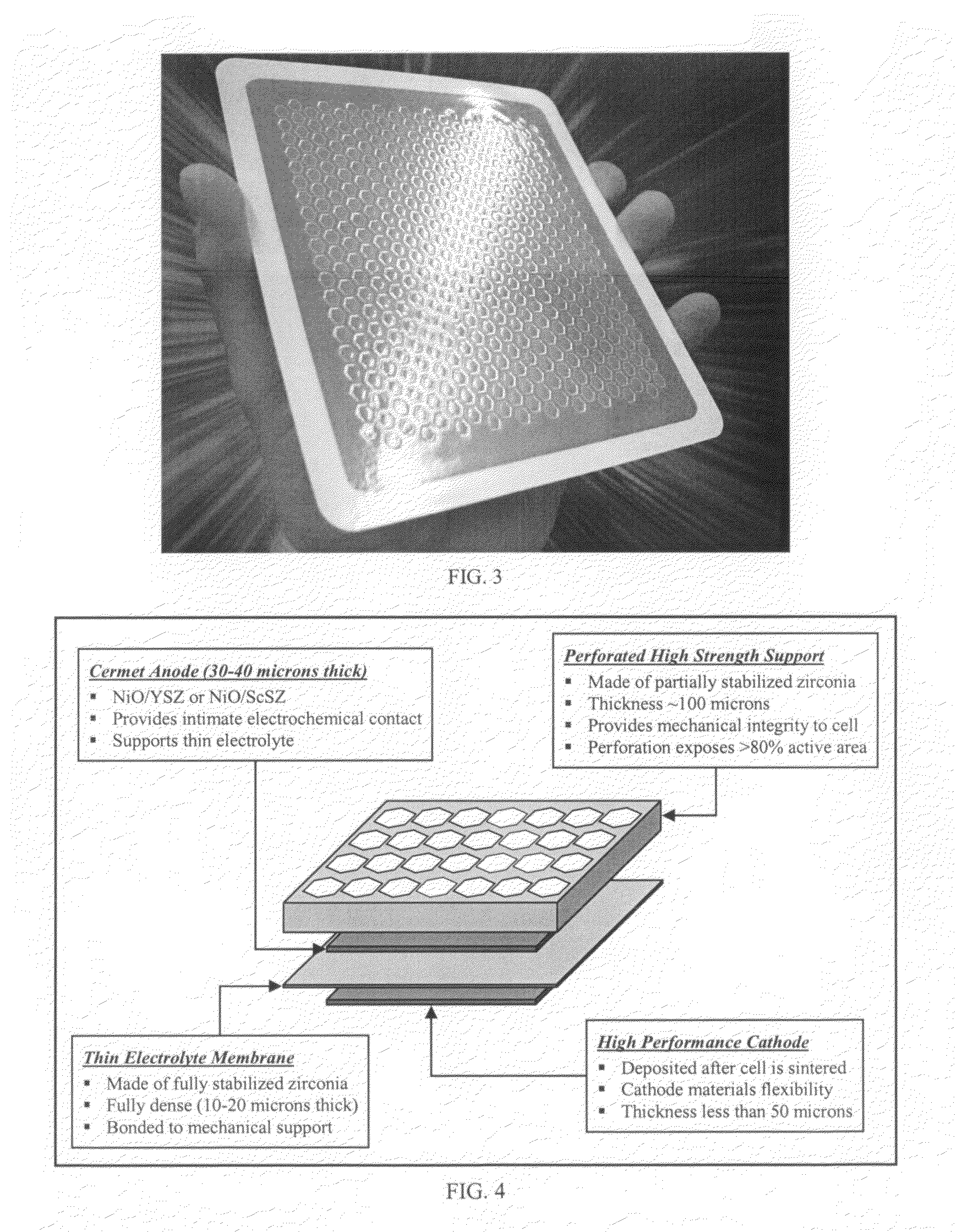

High performance multilayer electrodes for use in reducing gases

Electrode materials systems for planar solid oxide fuel cells with high electrochemical performance including anode materials that provide exceptional long-term durability when used in reducing gases and cathode materials that provide exceptional long-term durability when used in oxygen-containing gases. The anode materials may comprise a cermet in which the metal component is a cobalt-nickel alloy. These anode materials provide exceptional long-term durability when used in reducing gases, e.g., in SOFCs with sulfur contaminated fuels. The cermet also may comprise a mixed-conducting ceria-based electrolyte material. The anode may have a bi-layer structure. A cerium oxide-based interfacial layer with mixed electronic and ionic conduction may be provided at the electrolyte / anode interface.

Owner:NEXCERIS INNOVATION HLDG LLC

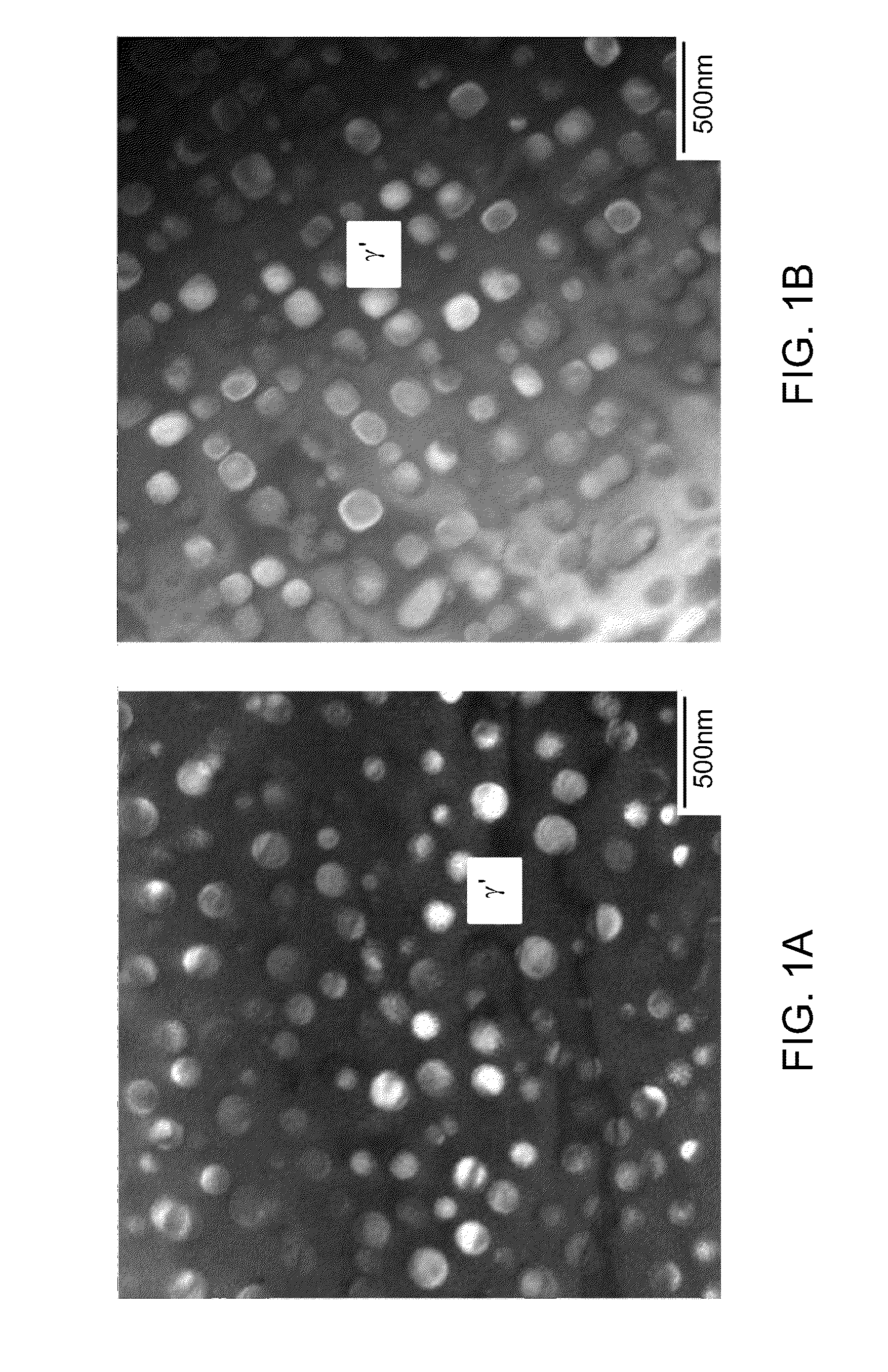

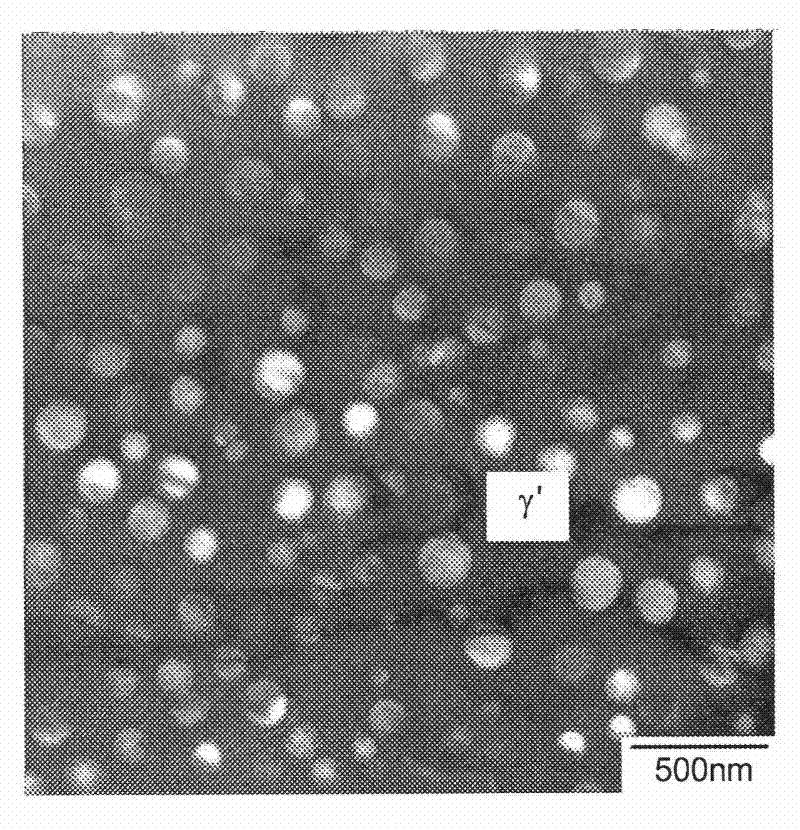

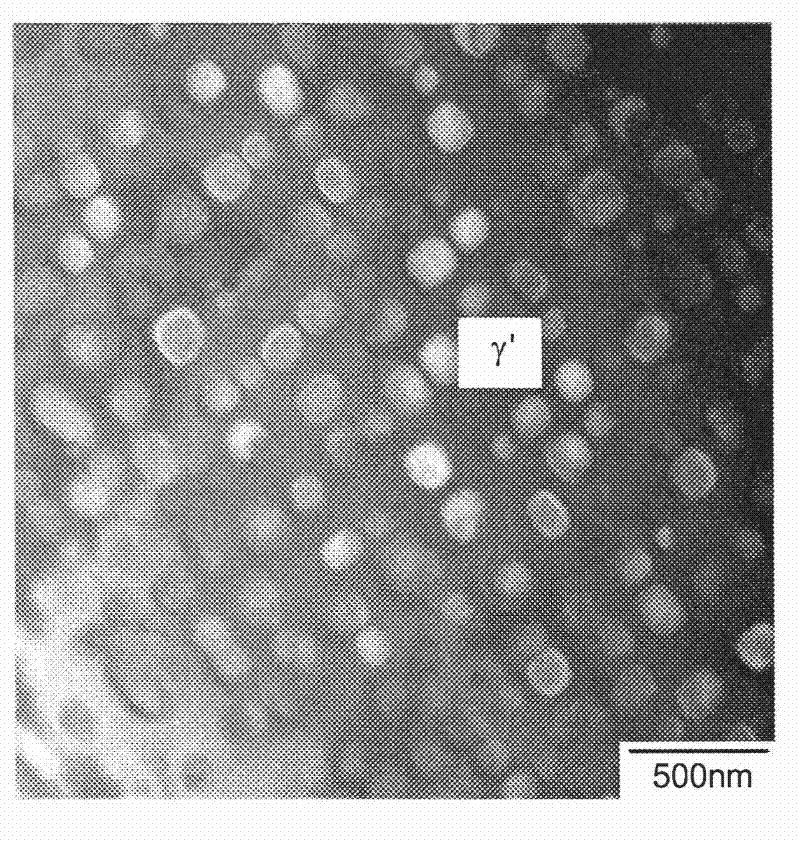

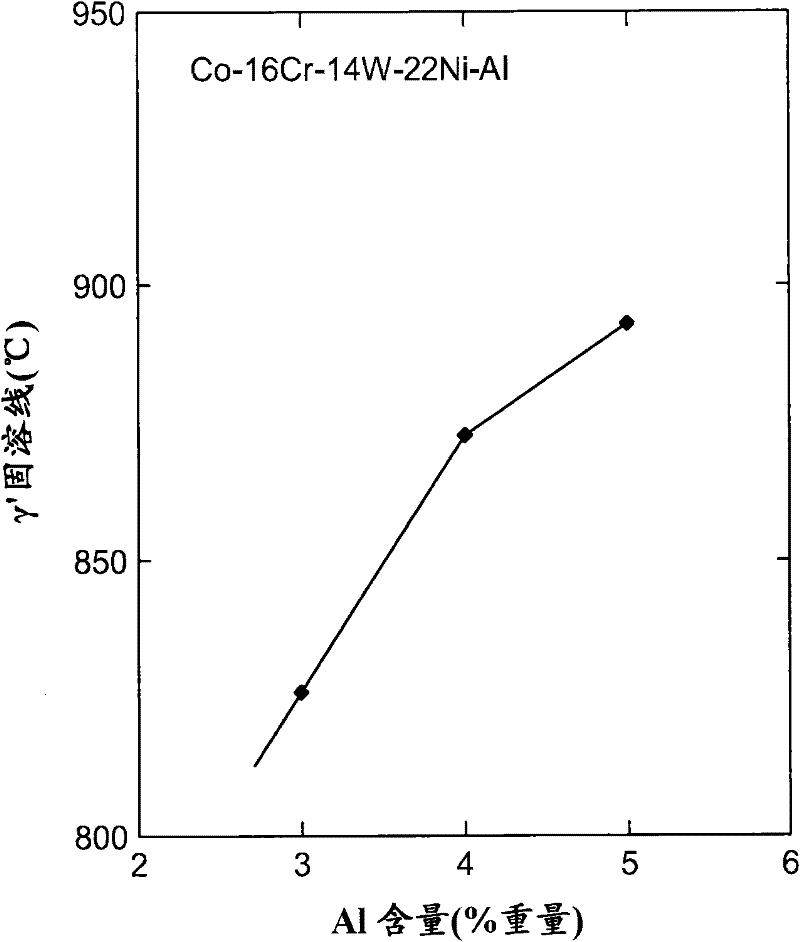

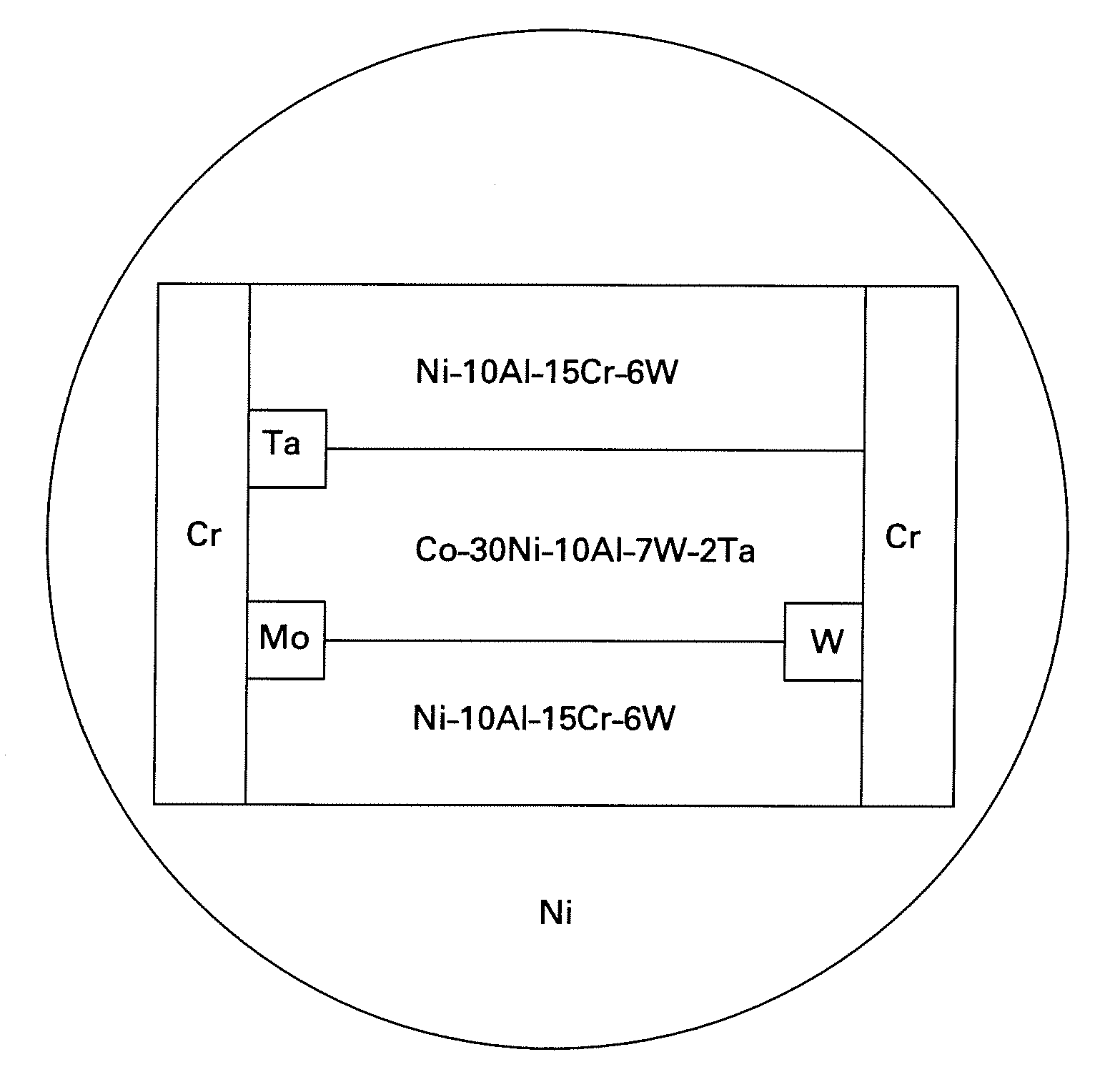

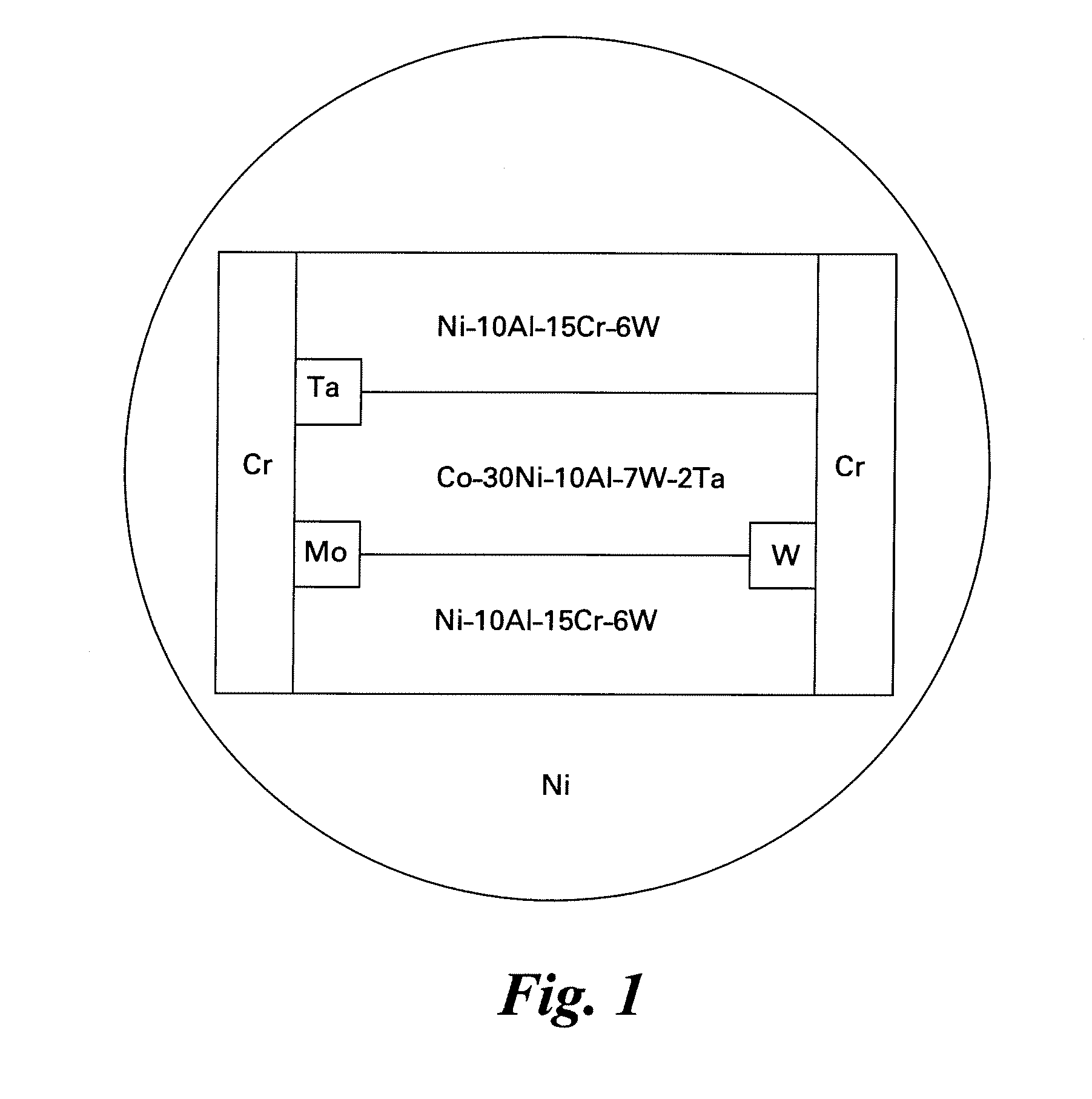

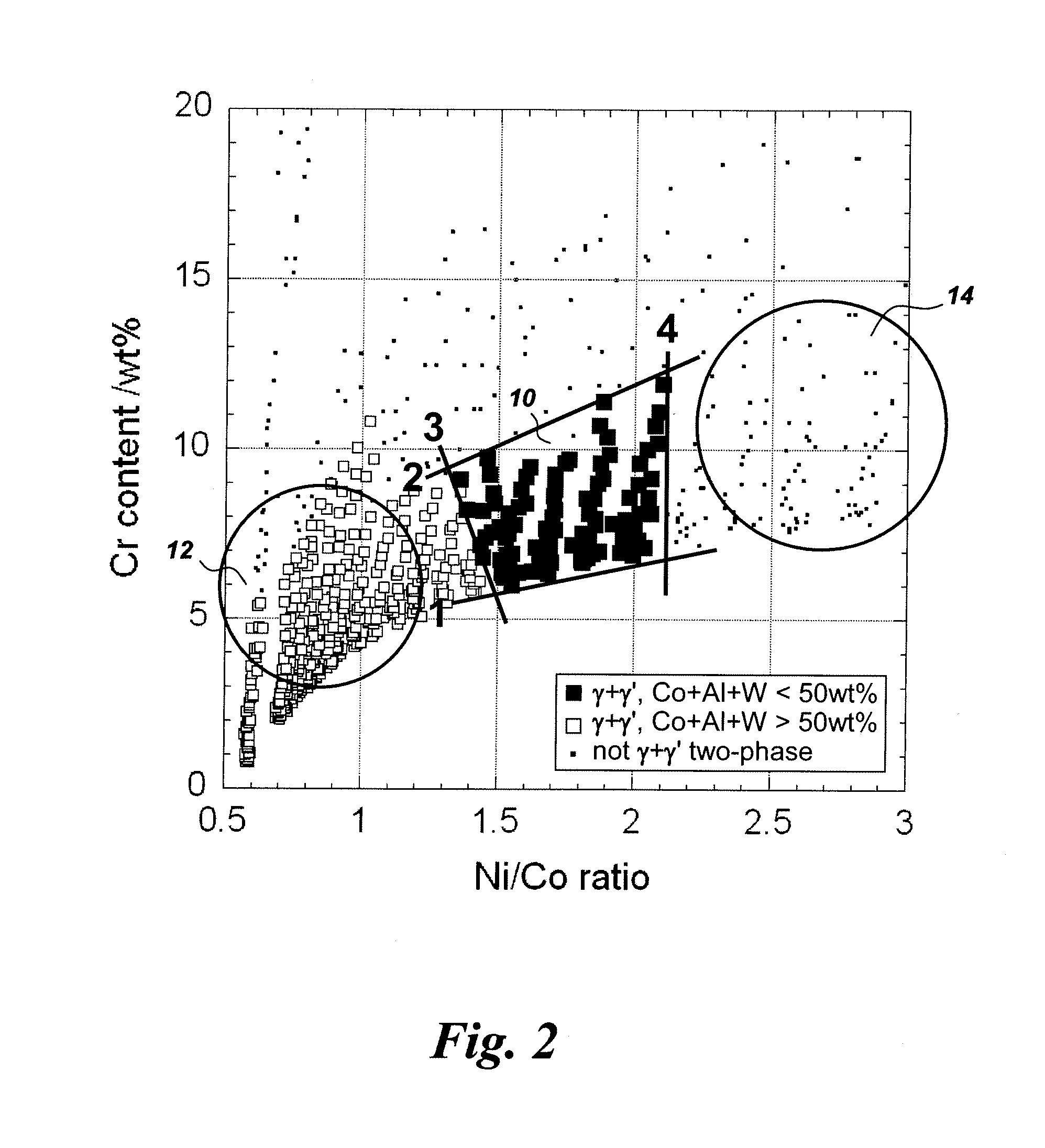

Cobalt-nickel superalloys, and related articles

A cobalt-nickel alloy composition is disclosed comprising, by weight about 30% to about 50% cobalt, about 20% to about 40% nickel, at least about 10% chromium, aluminum; and at least one refractory metal. Moreover, the alloy composition comprises an L12-structured γ′ phase having the formula (Co, Ni)3(Al,Z), wherein Z is at least one refractory metal. Various components made from, or cladded with, the cobalt-nickel alloy compositions are also described.

Owner:GENERAL ELECTRIC CO

Composite electromagnetic screen film material and mfg. method thereof

InactiveCN1787114AMeet the needs of normal workLow costMagnetic/electric field screeningScreening apparatusComposite filmElectromagnetic shielding

The invention belongs to the field of magnetic material, relating to an electromagnetic shielding material and the making method thereof. The invention is a composite metallic film formed on a conductive substrate by multiple deposition in the water solution, and the obtained composite metallic film is 1-100 mum thick, and each layer of the composite metallic film is 1.1-99.9 mum thick, and the combination between the layers of the composite film is by chemical bond, and each layer is layered. The substrate can be stainless steel, copper plate, Ti plate, Al plate or one of the corrosion-resistant alloy plates, and also made of conductive glass, conductive plastics, polymer high molecular material, or other material; the composite metallic film comprises two or above different metallic film layers; each metallic film layer can be of copper, iron, iron-nickel alloy, nickel-cobalt alloy, iron-cobalt alloy or iron-cobalt-nickel alloy. The invention can shield the frequencies between 50Hz and 100 Hz and the shielding efficacy reaches above 70dB.

Owner:ADVANCED TECHNOLOGY & MATERIALS CO LTD

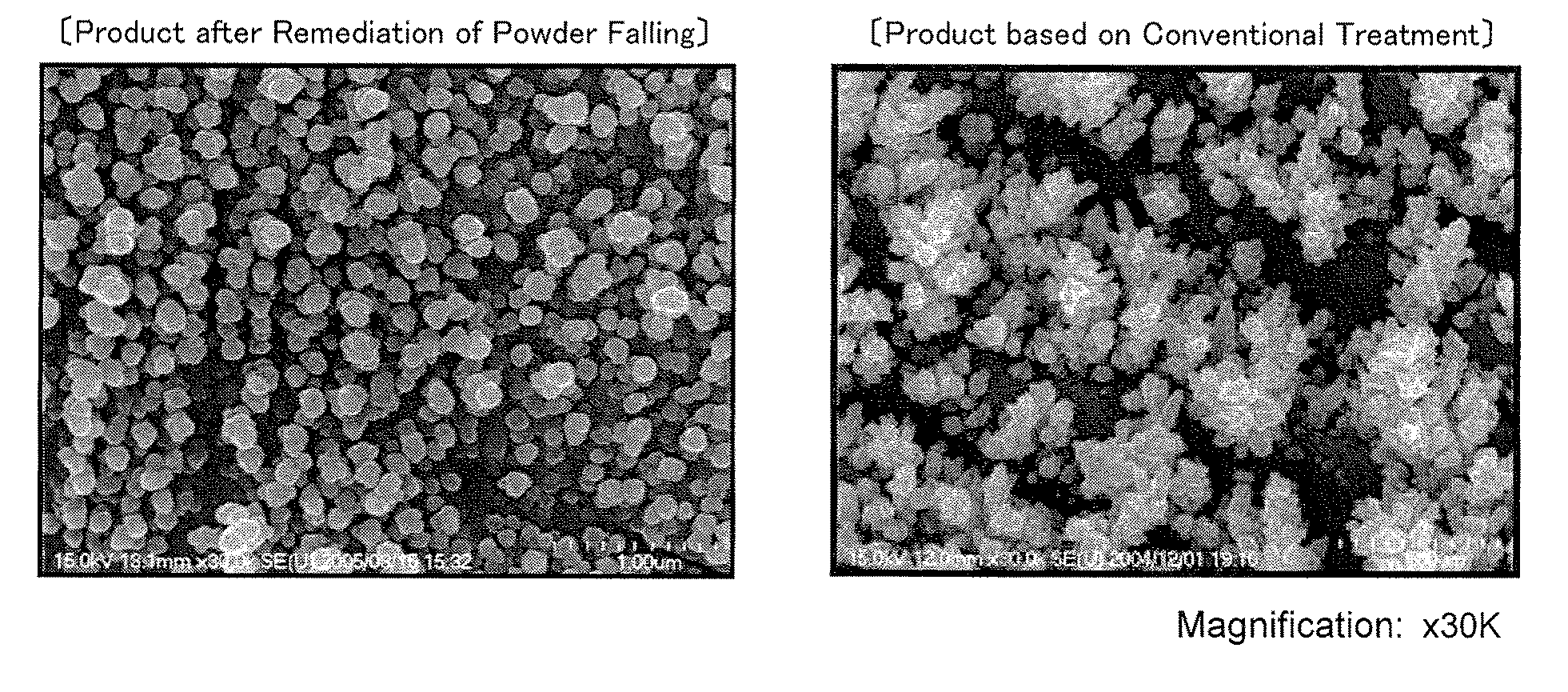

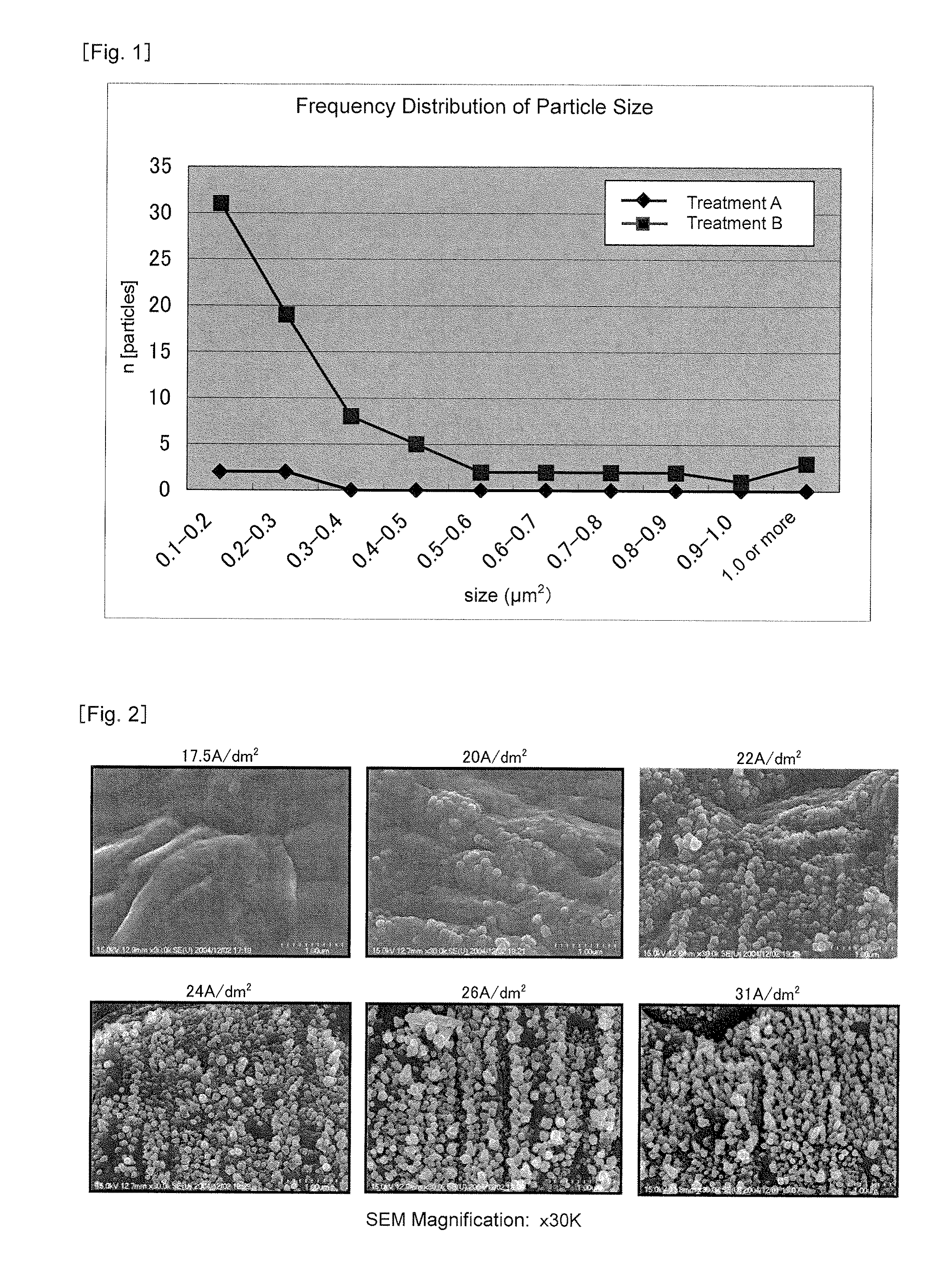

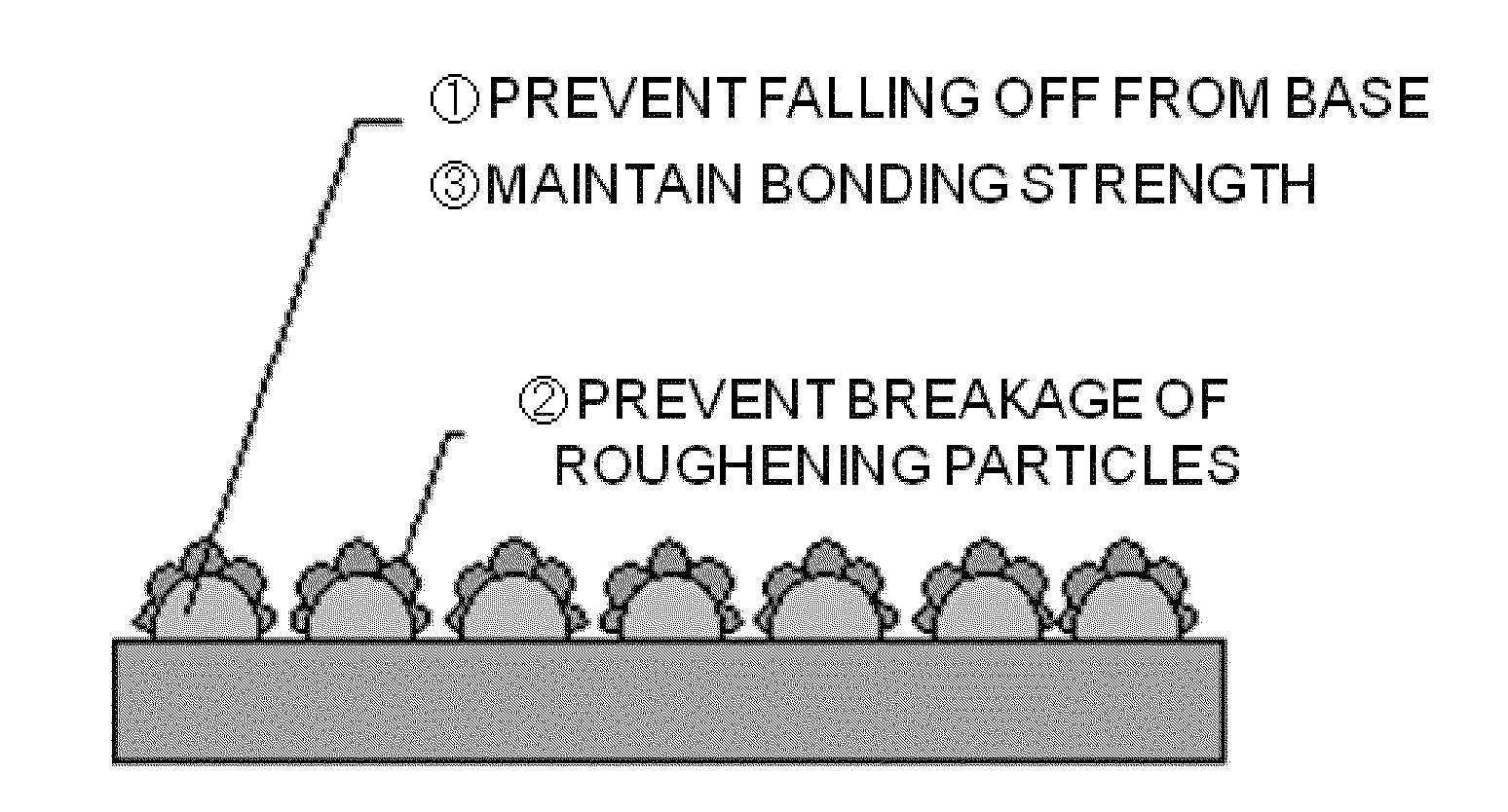

Copper Foil for Printed Circuit

ActiveUS20110262764A1Small sizeEasy to integrateThermometers using material expansion/contactionPrinted circuit aspectsCobalt nickel alloyCopper foil

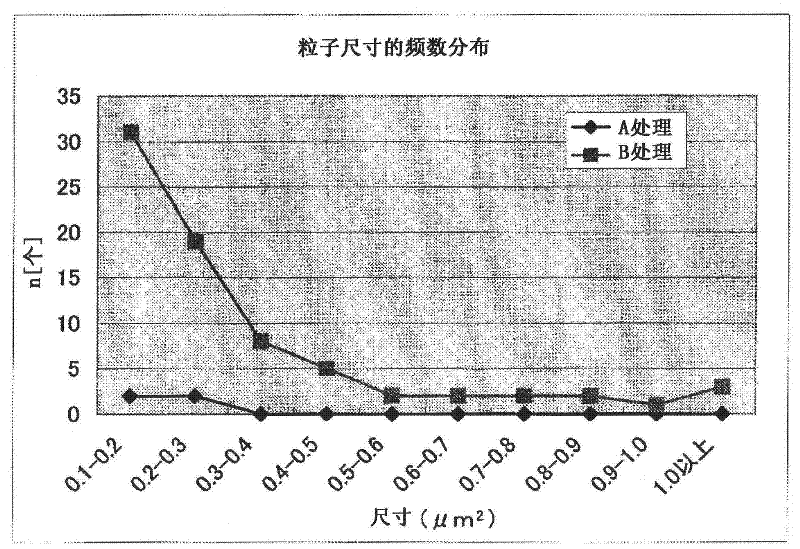

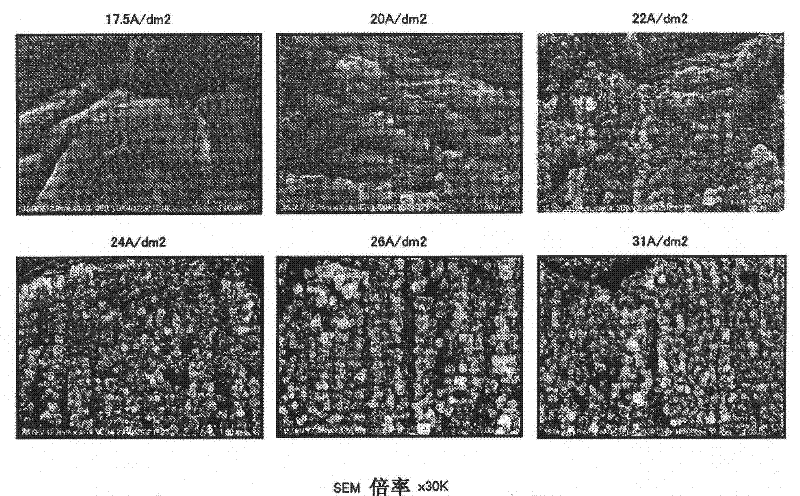

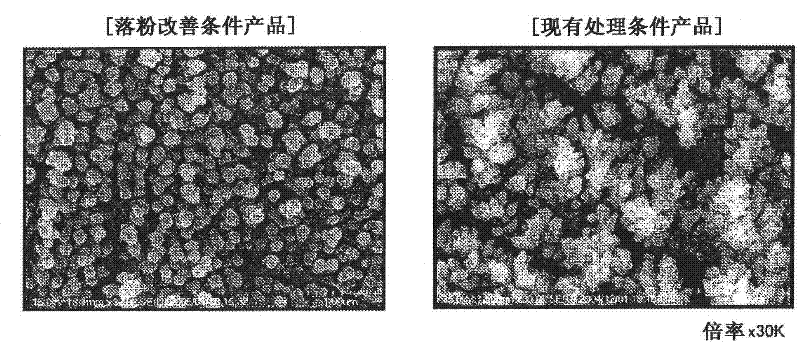

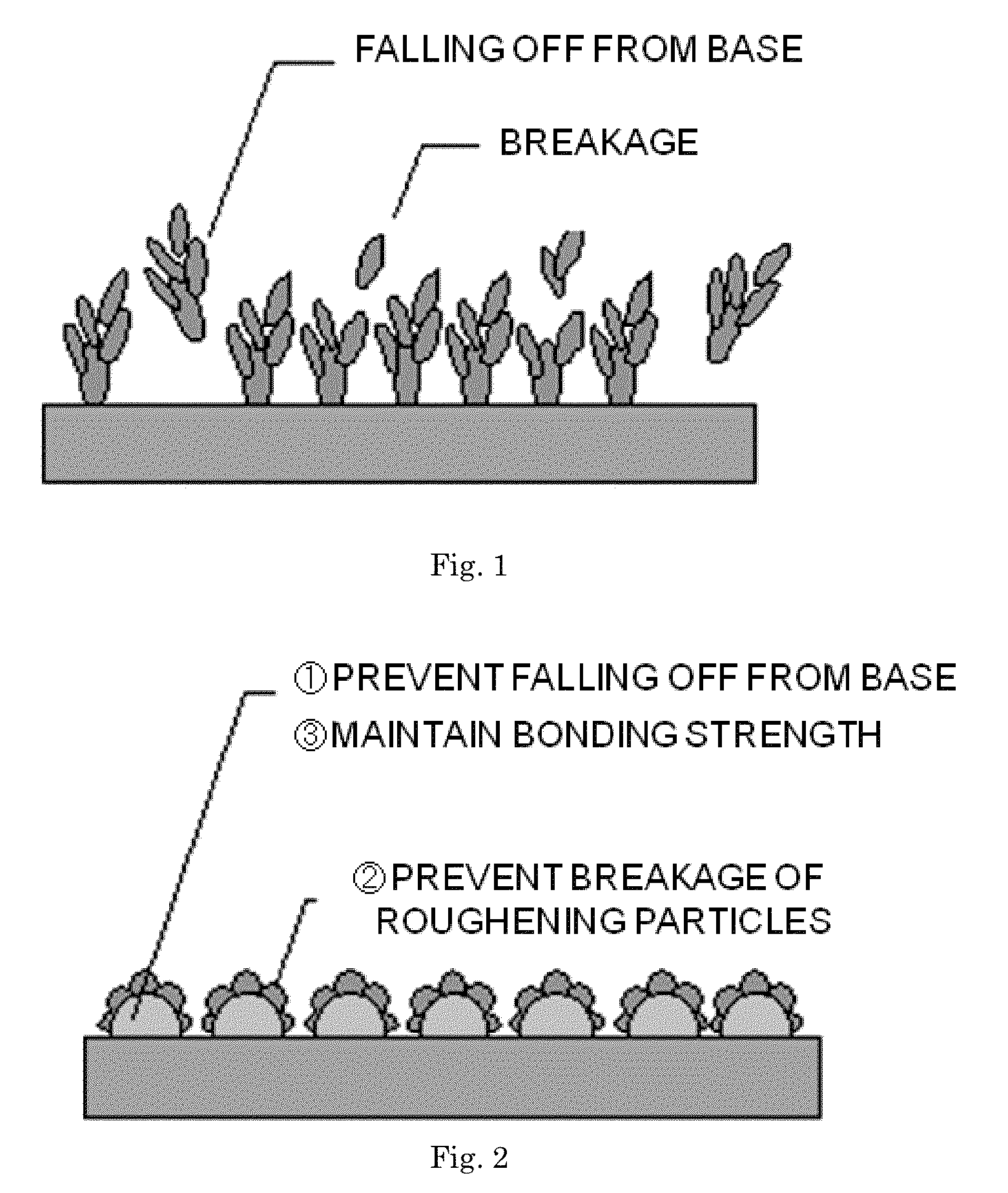

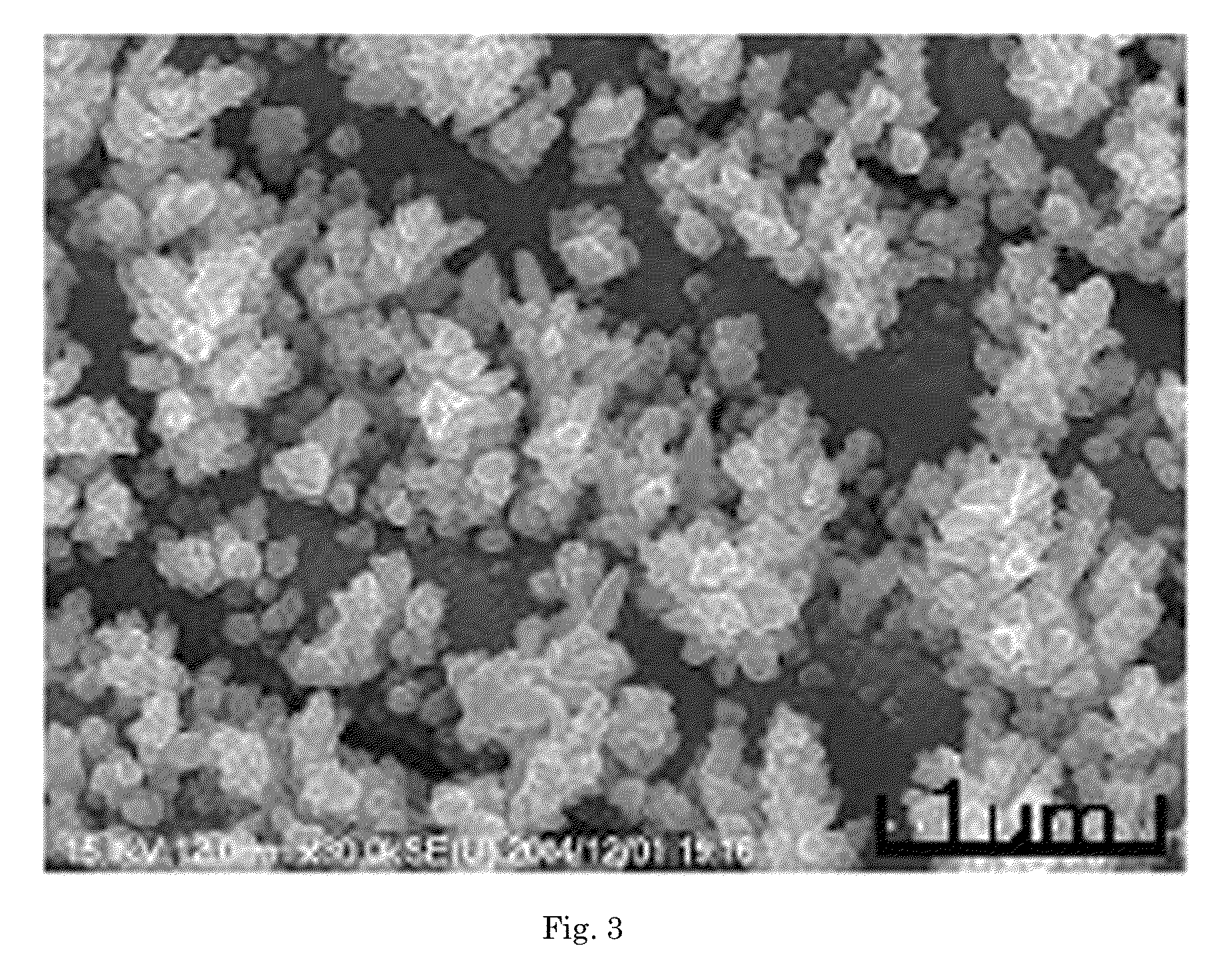

Provided is a copper foil for a printed circuit with an electrodeposited ternary-alloy layer composed of copper, cobalt and nickel formed on a surface of the copper foil, wherein the electrodeposited layer comprises dendritic particles grown on the copper foil surface, and the entire surface of the copper foil is covered with particles having an area as seen from above the copper foil surface of 0.1 to 0.5 μm2 at a density of 1000 particles / 10000 μm2 or less, particles exceeding 0.5 μm2 at a density of 100 particles / 10000 μm2 or less, and particles less than 0.1 μm2 as the remainder. Roughening particles formed dendritically in a roughening treatment based on copper-cobalt-nickel alloy plating are inhibited from shedding from the copper foil surface, and the phenomenon known as powder falling and uneven treatment are thereby inhibited.

Owner:JX NIPPON MINING & METALS CORP

Copper foil for printed circuit

ActiveCN102224281AMiniaturizationHigh integration improvesPrinted circuit aspectsPrinted circuit manufactureCobalt nickel alloyCopper foil

A copper foil for printed circuits which comprises a copper foil and, formed on the surfaces thereof, an electrodeposited ternary-alloy layer comprising copper, cobalt, and nickel. The copper foil for printed circuits is characterized in that the electrodeposited layer is constituted of dendritic particles grown on the copper foil surfaces and that the copper foil has been entirely coated with the particles, which comprise particles having a size of 0.1-0.5 [mu]m2, in terms of the area of each particle viewed from over the copper foil surfaces, at a density of 1,000 particles / 10,000 [mu]m2 or lower, particles larger than 0.5 [mu]m2 at a density of 100 particles / 10,000 [mu]m2 or lower, and particles smaller than 0.1 [mu]m2 as the remainder. In a roughening treatment comprising plating with a copper-cobalt-nickel alloy, roughening particles which are being dendritically formed are inhibited from shedding from the surfaces of the copper foil and thereby causing the phenomenon generally called powder falling and resulting in treatment unevenness.

Owner:JX NIPPON MINING & METALS CORP

Cobalt-nickel superalloys, and related articles

A cobalt-nickel alloy composition is disclosed comprising, by weight about 30% to about 50% cobalt, about 20% to about 40% nickel, at least about 10% chromium, aluminum; and at least one refractory metal. Moreover, the alloy composition comprises an L12-structured [gamma]' phase having the formula (Co, Ni)3(Al,Z), wherein Z is at least one refractory metal. Various components made from, or cladded with, the cobalt-nickel alloy compositions are also described.

Owner:GENERAL ELECTRIC CO

Composite-coating continuous casting crystallizer copper plate with long service life and manufacturing technology thereof

InactiveCN104759596AExtended service lifeImprove efficiencyMolten spray coatingSuperimposed coating processManufacturing technologyWear resistant

The invention provides a composite-coating continuous casting crystallizer copper plate with a long service life and a manufacturing technology thereof and belongs to the technical field of electroplating. The composite-coating continuous casting crystallizer copper plate with the long service life comprises a copper plate substrate and a coating on the surface of the copper plate substrate. The coating comprises an upper electroplating layer and a lower coating layer. The upper electroplated layer is a pure nickel layer or a low-cobalt nickel alloy layer resistant to high temperature and corrosion. The mass percent of cobalt in the low-cobalt nickel alloy layer is not higher than 3%. The lower coating layer is a wear-resistant coating layer or a ceramic coating layer. According to the composite-coating continuous casting crystallizer copper plate with the long service life and the manufacturing technology thereof, the electroplating technology and the supersonic thermal coating technology are combined, the upper portion and the lower portion of the crystallizer copper plate are different alloy coating layers, the different requirements for the upper portion and the lower portion of the crystallizer copper plate in continuous casting are effectively met, the upper electroplating layer is not prone to thermally cracking and falling at a high temperature, the lower coating layer has the excellent wear-resistant performance, in this way, the service life of the continuous casting crystallizer copper plate is greatly prolonged, and the product quality is greatly improved.

Owner:XIXIA LONGCHENG SPECIAL MATERIALS CO LTD

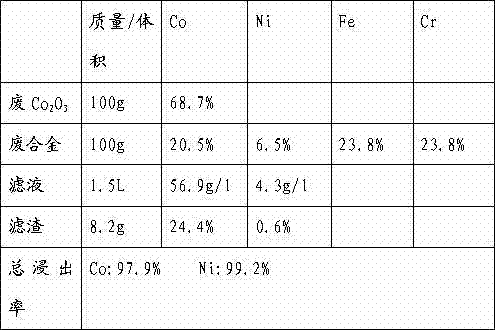

Processing method of trivalent cobalt nickel oxide waste material and waste cobalt nickel alloy

ActiveCN102952954AEasy dischargeShort leaching timeProcess efficiency improvementCobalt nickel alloyHydrogen-Ion Concentrations

The invention provides a processing method of trivalent cobalt nickel oxide waste materials and waste cobalt nickel alloy, which comprises the following steps: firstly pulpifing trivalent cobalt nickel oxide waste materials by adding an acid solution with a hydrogen ion concentration of 1-2 mol / l, adding the cobalt nickel alloy waste materials under stirring, wherein the mass ratio of the alloy waste materials to the trivalent cobalt nickel oxide waste materials is 1:0.5-4, reacting at a temperature maintained at 80-99 DEG C, filtering, returning the filter residues to the above mentioned steps for leaching, performing chemical preliminary impurity removal and extraction deep purification impurity removal of the filtrate to obtain a high-concentration, pure cobalt nickel solution. The processing method can greatly reduce consumption of auxiliary materials, improve the leaching rate, shorten the reaction time, reduce the generation of toxic and harmful gas, and has great economic benefits and environment benefits.

Owner:GEM CO LTD

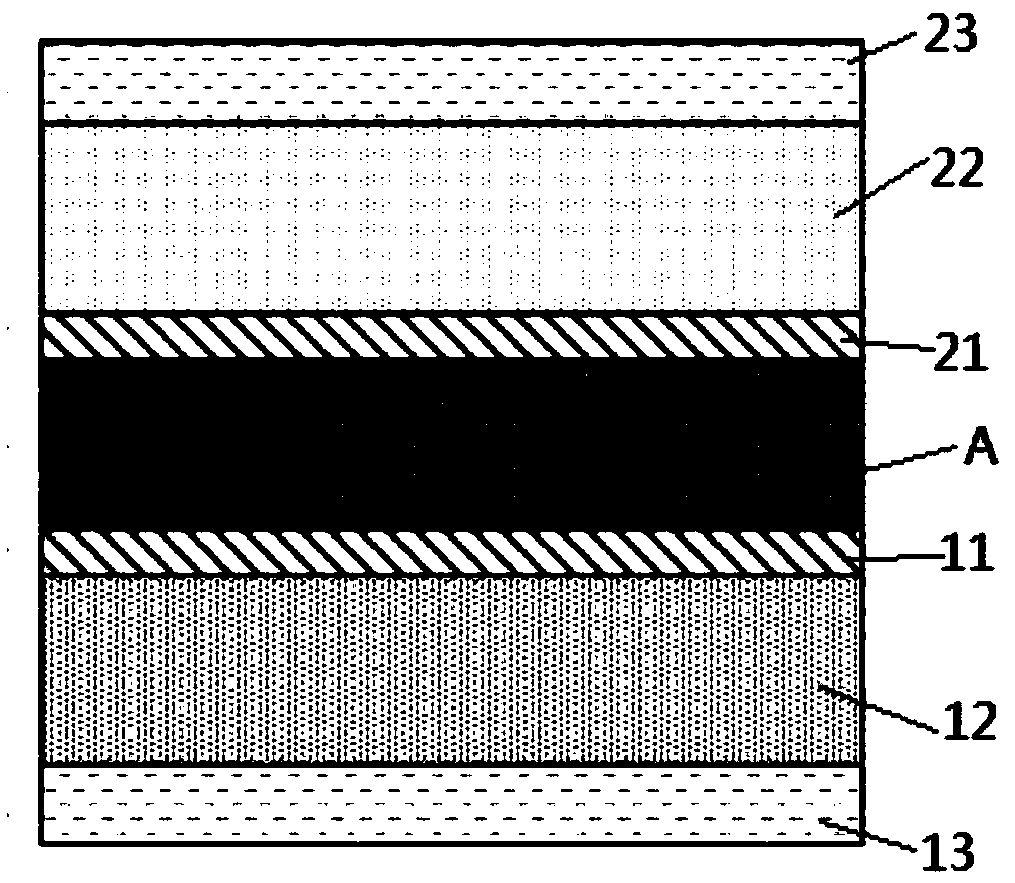

Multi-layered magnetic thin film pigment chip and preparation method thereof

InactiveCN108922776AImprove compactnessFast formingConductive/insulating/magnetic material on magnetic film applicationMagnetic film to substrate applicationNickel chromium alloyCobalt nickel alloy

The invention relates to a multi-layered magnetic thin film and pigment chips thereof, in particular to a multi-layered magnetic thin film pigment chip. The multi-layered magnetic thin film pigment chip comprises a magnetic reflection layer, one side of the magnetic reflection layer sequentially comprises a first adhesion layer, a first medium layer and a first absorption layer; the other side ofthe magnetic reflection layer sequentially comprises a second adhesion layer, a second medium layer and a second absorption layer; the first adhesion layer and the second adhesion layer are located onthe end faces of the two sides of the magnetic reflection layer respectively; the thin film pigment chip is of a symmetrical structure; and the first adhesion layer and the second adhesion layer areboth made of an elemental chromium metal material. The invention further provides a method used for preparing the multi-layered magnetic thin film pigment chip. The multi-layered magnetic thin film pigment chip adopts nickel monomer as the magnetic reflection layer, the reflection rate is higher than nickel-chromium alloys and cobalt-nickel alloys, the film layer stability is improved greatly, andthe optical effect is not affected.

Owner:广东晟铂纳新材料科技有限公司

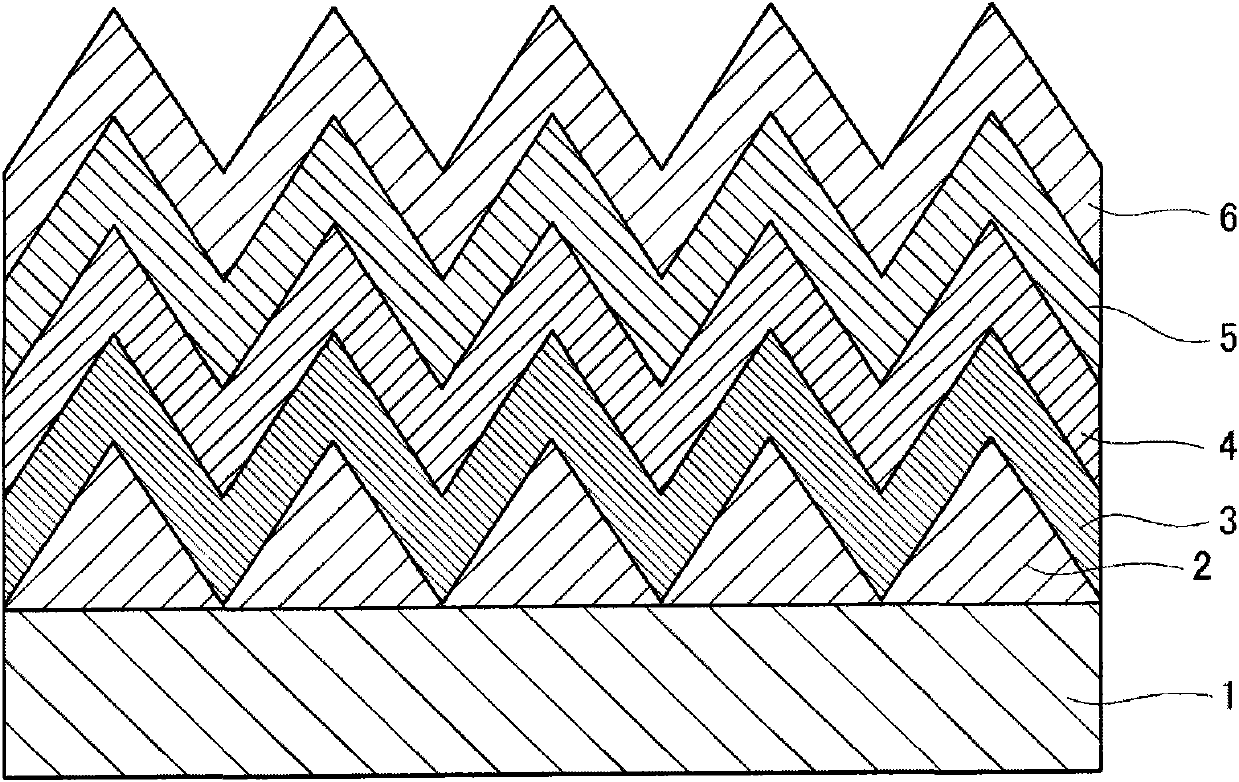

Copper foil for printed circuit boards and method for manufacturing the same

ActiveCN101998776AImprove visibilityInsulating substrate metal adhesion improvementPrinted circuit aspectsCobalt nickel alloyCopper coil

The present invention provides a copper foil for printed circuit boards and a method for manufacturing the same, the copper foil has high visibility of penetrating an insulating base material, and it is possible to avoid inleakage and peeling in a process of manufacturing the printed circuit board. The copper coil for the printed circuit board is characterized in that the copper coil is used for forming a conductor distribution picture of the printed circuit board and is pasted to the surface of the insulating base material, and has a cobalt-nickel alloy plating layer in which a chroma (based on Japanese Industrial Standard JIS Z 8729) c *= (a*2 + b*2) 1 / 2 of the surface of the copper coil is less than 6 optically detected by spacing the insulating base material.

Owner:CHANG CHUN PETROCHEMICAL CO LTD

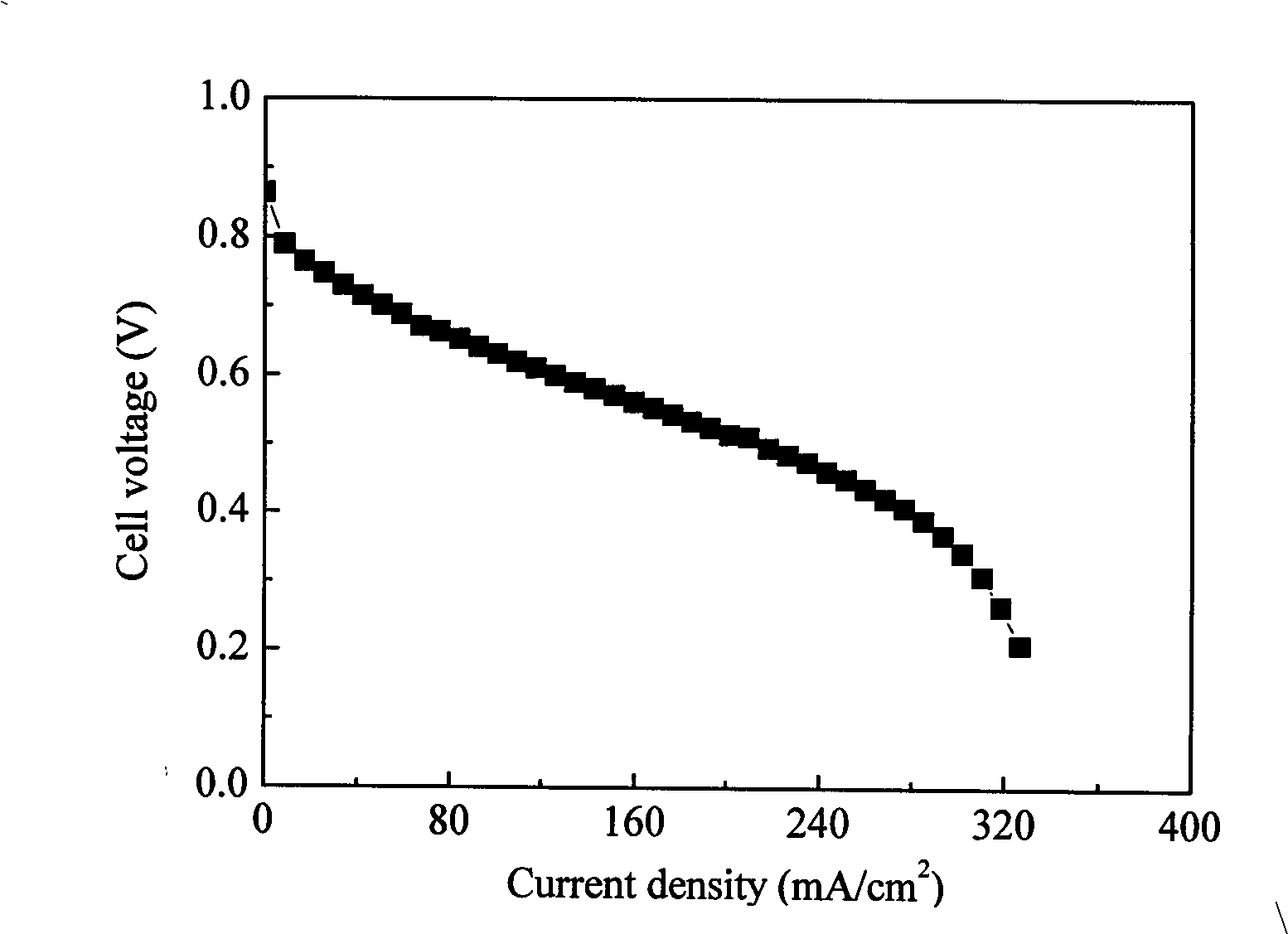

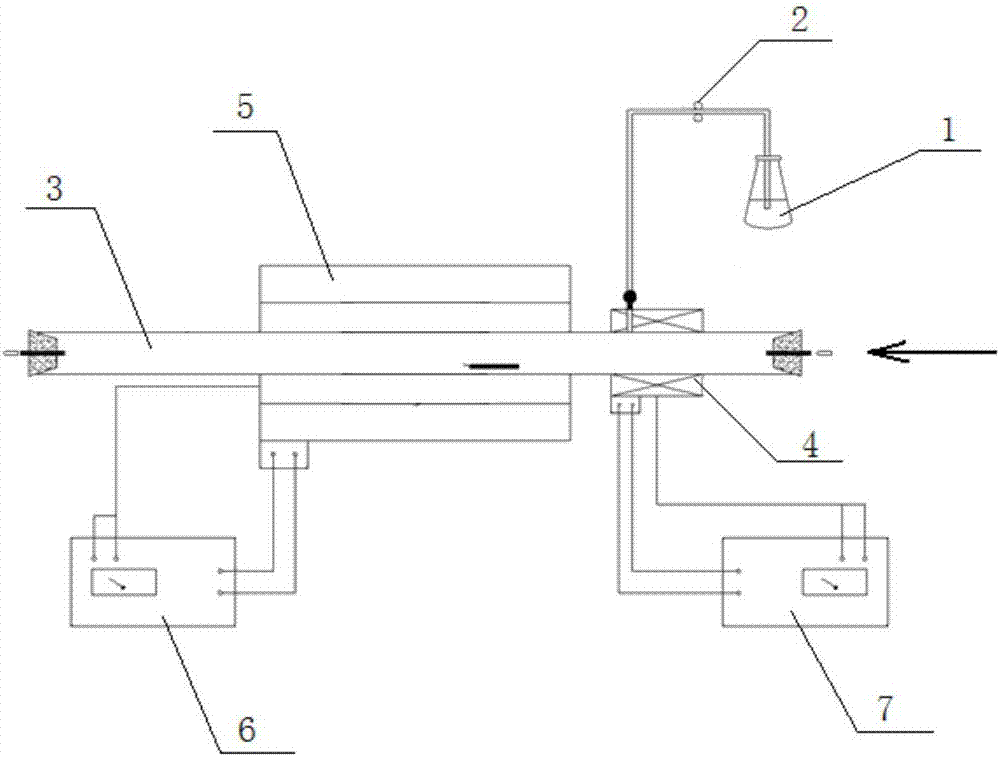

Gaseous diffusion layer for polymer electrolyte film fuel cell and preparation method thereof

InactiveCN101350412AEnhanced interactionAvoid accumulationCell electrodesFinal product manufactureConcentration polarizationSlurry

The invention relates to a gaseous diffusion layer for a polymer electrolyte membrane fuel battery and a preparation method thereof, relating to a gaseous diffusion layer for a fuel battery and a preparation method thereof. The invention is capable of settling the problem of uneven distribution of carbon paper or hydrophobic material in the existing gaseous diffusion layer which degrades the performance of the fuel battery due to relatively big concentration polarization and ohm polarization of the gaseous diffusion layer. The porous-material layer in the gaseous diffusion layer comprises a porous fiber layer and carbon nano-palp growing on the fibers of the porous fiber layer. The preparation method of the invention includes the procedures that the porous fiber layer is rinsed and dried; nano-particles of cobalt, nickel or cobalt-nickel alloy are loaded onto the fiber surface; hydrophobic treatment is conducted; and the slurry is coated on the surface of the supporting layer and sintered. The hydrophobic materials of the gaseous diffusion layer are distributed evenly, as a result, the concentration polarization and the ohm polarization of the gaseous diffusion layer are lowered and the performance of the fuel battery is improved. Besides, the equipments needed by the method are simple and are easy to realize.

Owner:HARBIN INST OF TECH

Cobalt-nickel superalloys, and related articles

A cobalt-nickel alloy composition is described, containing about 20% to about 28% cobalt; about 37% to about 46% nickel; at least about 6% chromium; aluminum; and at least one refractory metal. The total weight of cobalt, aluminum, and refractory metal in the composition is less than about 50% of the total weight of the composition. Moreover, the alloy composition comprises both a (Co, Ni)-gamma phase and an L12-structured (gamma prime) phase. Various components made from the cobalt-nickel alloy composition are also described. Examples include high-temperature machinery and devices, e.g., components of gas turbine engines.

Owner:GENERAL ELECTRIC CO

Carbon-nano-tube composite microwave absorbing material and preparation method thereof

ActiveCN107032325AStrong environmental corrosion resistanceLight in massCarbon compoundsMagnetic/electric field screeningCarbon nanotubeRare earth

The invention belongs to the technical field of microwave absorbing materials, and relates to a carbon-nano-tube composite microwave absorbing material and a preparation method thereof. According to the material, a catalyst is dissolved in a liquid carbon source containing an additive to prepare a precursor solution, then, a pressureless sintering method is adopted to prepare the composite microwave absorbing material of which matrixes are carbon nano tubes, iron particles and cobalt-nickel alloy particles are added in the inner walls of the carbon nano tubes, and rare-earth compounds are attached to the outer walls of the carbon nano tubes; the liquid carbon source is a 1,2-dichloroethane solution, the additive is lanthanum nitrate, and ethyl alcohol which promotes the dissolution of lanthanum nitrate is further added in the liquid carbon source; the volume ratio of the 1,2-dichloroethane solution to ethyl alcohol is 9:1, and the catalyst contains 33.93 wt.% of ferrocene, 33.19 wt.% of cobaltocene and 32.88 wt.% of nickelocene. The carbon-nano-tube composite microwave absorbing material has the advantages of being light in weight, wide in absorption frequency band, extremely improved in microwave absorbing performance, high in environmental corrosion resistance and wide in application range; carbon-nano-tube filler prepared by the preparation method is high in purity and few in impurity.

Owner:EAGLES MEN AERONAUTIC SCI & TECH GRP

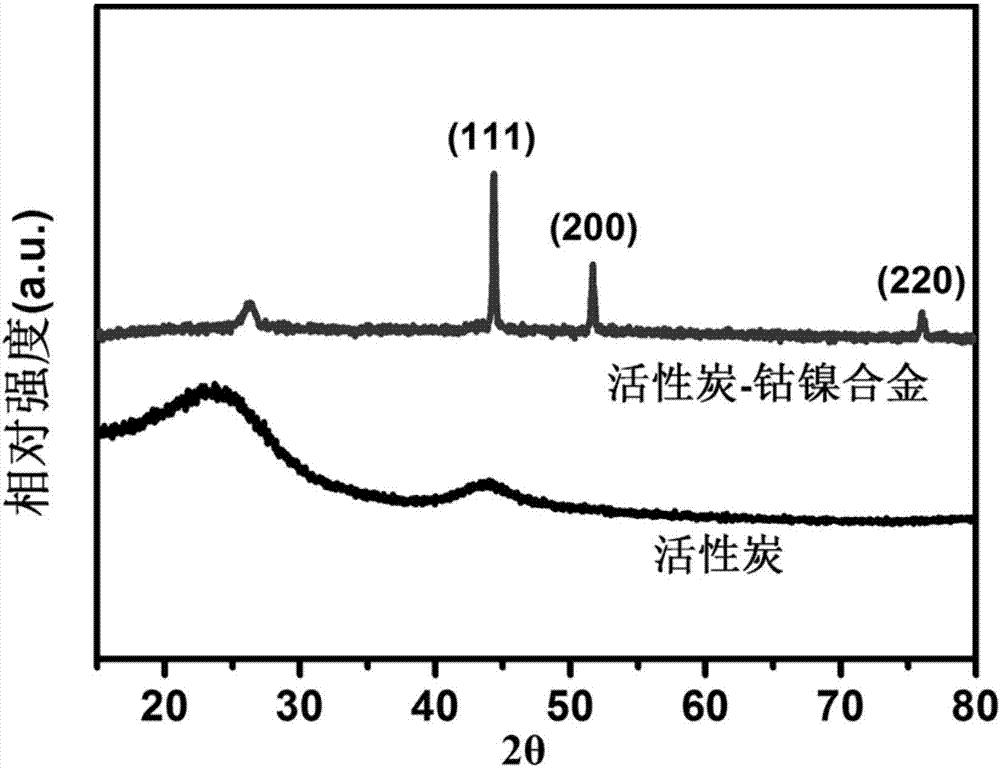

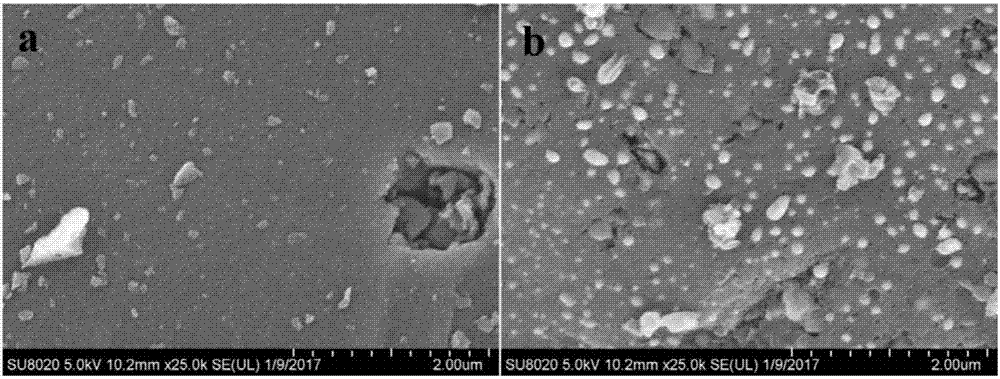

Preparation method of activated carbon-supported cobalt-nickel alloy material and electrochemical application of preparation method

The invention discloses a preparation method of an activated carbon-supported cobalt-nickel alloy material and electrochemical application of the preparation method. The preparation method comprises the following steps: dissolving a cobalt source and a nickel source with a molar ratio of 1:0.1-10 into distilled water, so as to obtain clear mixed solution; adding activated carbon into the clear mixed solution, forming slurry after adsorption is saturated and performing heat treatment on the slurry, so as to obtain the activated carbon-supported cobalt-nickel alloy material. The activated carbon-supported cobalt-nickel alloy material can be applied in the field of electro-catalytic water decomposition or the field of electro-catalytic oxidation of low molecular weight organic matters. The activated carbon-supported cobalt-nickel alloy material prepared by the invention has excellent performances of hydrogen and oxygen evolution through electro-catalytic water decomposition, and the efficiency of producing hydrogen through electro-catalytic water decomposition is further improved when the organic matters are synthesized through efficient electro-catalytic oxidation, therefore, the preparation method has potential application prospect in the fields of electro-catalytic organic synthesis and hydrogen energy sources.

Owner:HEFEI INSTITUTES OF PHYSICAL SCIENCE - CHINESE ACAD OF SCI

alloy

A cobalt-nickel alloy composition comprising by weight (wt %): about 31 to 42 percent cobalt (Co); about 26 to 31 percent nickel (Ni); about 10 to 16 percent chromium (Cr); about 4 to 6 percent aluminium (Al); about 6 to 15 percent tungsten (W); the Co and Ni being present in an atomic ratio of about 1.3:1

Owner:ROLLS ROYCE PLC

Electrolyte media for the deposition of tin alloys and methods for depositing tin alloys

An electroplating bath medium for electroplating articles with a tin-cobalt, tin-nickel, or tin-cobalt-nickel alloy comprises: at least one tin salt; an alloying metal salt comprising a cobalt salt and / or a nickel salt; a complexant comprising a hydroxycarboxylic acid or alkali metal salt thereof such as a sodium or potassium gluconate or heptonate complexant; boric acid; and a bath soluble substituted phenolic compound. The current regime applied to the plating bath can include time intervals of direct current and of pulsed current in order to selectively control the deposition of tin by activation or diffusion control.

Owner:MACDERMID ACUMEN INC

Method for preparing anode-catalyzed electrode for electrolyzing slurry coal

The invention relates to a method for preparing an anode-catalyzed electrode for electrolyzing slurry coal, i.e. a method for preparing an alloy electrode of which the metallic titanium base material is coated with cobalt and nickel oxides and platinum, belonging to the technical field of chemical material preparation process. The method comprises the following steps of: (1) pretreating a metallic titanium substrate; (2) generating a platinum-cobalt-nickel alloy catalyst layer on the titanium substrate by a constant-current and stepped electrolytic deposition method; and (3) after the electrolytic deposition of the metal on the titanium substrate, heat-pretreating in an oven and heat-posttreating in a muffle furnace with a treating temperature of 400-600 DEG C. The main electrolytic deposition process is carried out in an electrolytic bath, and main salts for depositing platinum, cobalt and nickel are respectively H2PtCl6.6H2O, CoSO4.6H2O and NiSO4.7H2O. Ti / Pt-CO3O4, Ti / Pt-NiO and Ti / Pt-CO3O4-NiO catalyzed electrodes prepared by the method can provide the current density and the current efficiency in the electrolytic process and have higher catalytic activity.

Owner:SHANGHAI UNIV

High-magnetic micro-particle-size nano magnetic beads and preparation method thereof

ActiveCN110038533ACapable of strong magnetic responseSmall and uniform particle sizeIon-exchange process apparatusOther chemical processesSodium acetateCarbon layer

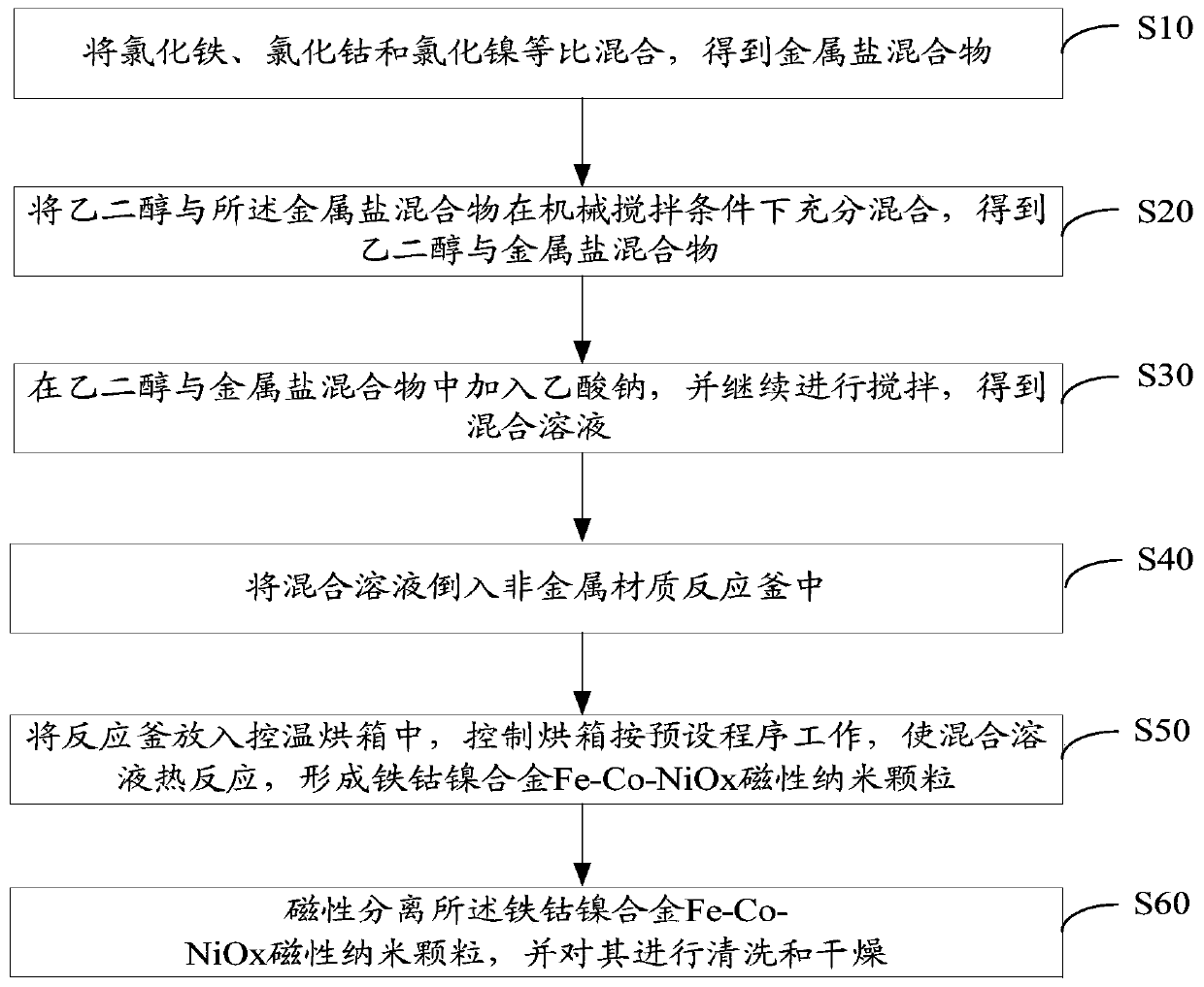

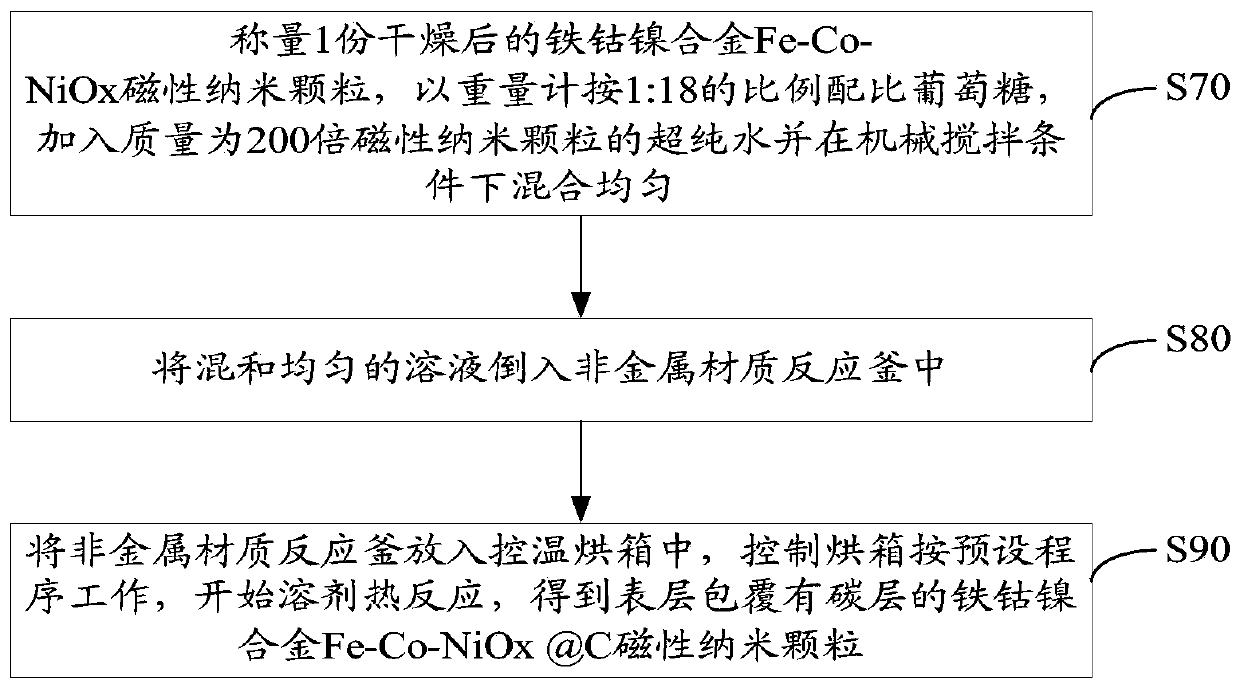

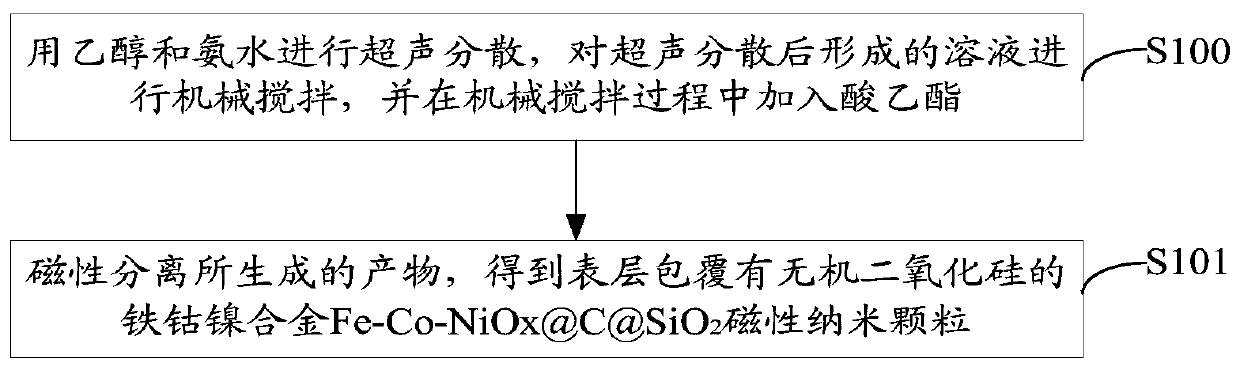

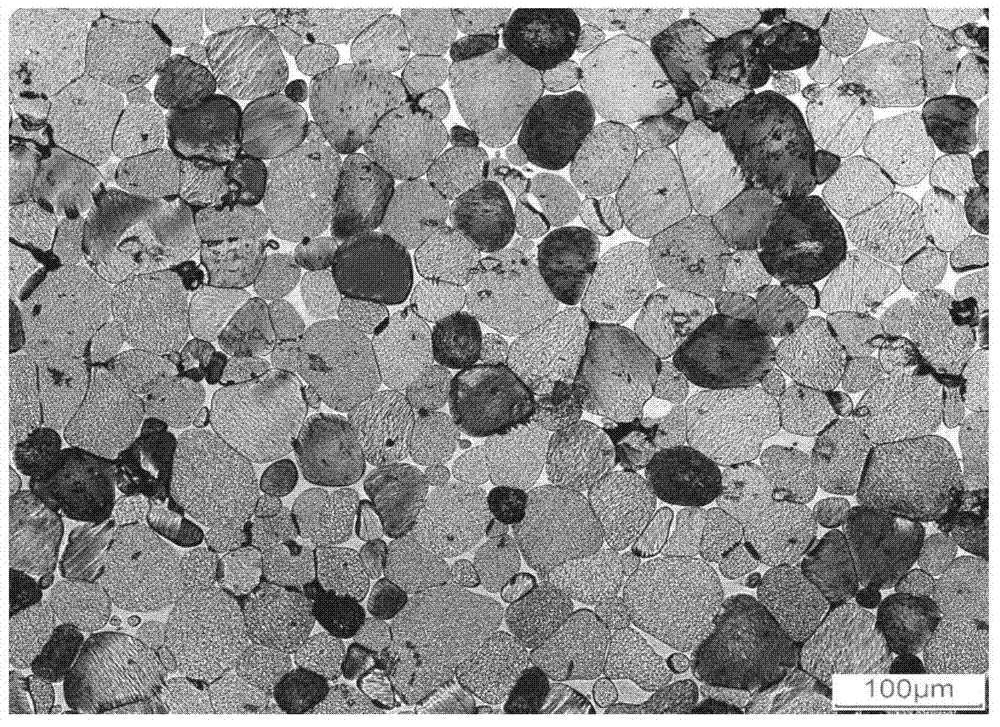

The invention discloses a preparation method of high-magnetic micro-particle-size nano magnetic beads. The preparation method comprises the following steps: mixing iron chloride, cobalt chloride and nickel chloride in an equal ratio to obtain a metal salt mixture; mixing ethylene glycol with the metal salt mixture sufficiently under the condition of mechanical stirring to obtain a mixture of the ethylene glycol and metal salt; adding sodium acetate into the mixture of the ethylene glycol and the metal salt, and continuing to stir to obtain a mixed solution; pouring the mixed solution into a non-metallic reaction kettle; placing the reaction kettle in a temperature-controlled oven, and controlling the oven to operate according to a preset procedure to make the mixed solution be subjected toa thermal reaction to form iron-cobalt-nickel alloy Fe-Co-NiOx magnetic nanoparticles; magnetically separating the iron-cobalt-nickel alloy Fe-Co-NiOx magnetic nanoparticles, and washing and drying;coating the surface layers of the iron-cobalt-nickel alloy Fe-Co-NiOx magnetic nanoparticles with a carbon layer and a silicon dioxide layer sequentially, and covalently grafting polyethylene glycol onto an outermost layer. The preparation method disclosed by the invention solves the technical problems of relatively large particle size, wide distribution range, small specific surface area and lowmagnetic response of magnetic beads in the prior art.

Owner:艾铂图生物(江苏)有限公司

Cobalt-nickel-free based alloy for strengthening coating of sealing surface of nuclear power valve

InactiveCN101717881ASmall and dense tissueImprove mechanical propertiesMetallic material coating processesNuclear powerNickel free

The invention discloses a cobalt-nickel-free based alloy for a strengthening coating of a sealing surface of a nuclear power valve. The alloy contains the following components by weight percentage: 37.5%-38.5% of chromium, 5.0-6.0 % of carbon, 2.0%-2.5% of silicon, 1.0%-1.5% of boron, 0.5%-1.5% of yttrium oxide and the balance of nickel. The mixing alloy powder is compounded, and the strengthening coating is prepared by a laser cladding technology. The obtained cobalt-nickel-free based alloy strengthening coating of the sealing surface of the nuclear power valve has the relative parameters as follows: the average hardness HRC is 45-50, and is 39-43 higher than the traditional cobalt-nickel alloy coating; the grain size is 11-12, and is finer than the traditional plasma spray-welding coating of 9-10 and the flame surfacing welding layer of 8-9, which is favorable for the comprehensive mechanical property correspondingly; the combined bandwidth of the coating and the base body is 25-40 mum, and is compacter than the traditional plasma spray-welding combined band with the width of 80-120 mum and the flame surfacing welding combined band with the width of 20-300 mum. The invention has the advantages of saving of noble metal, i.e. cobalt, cost reduction, simple preparation technology, conformance to special requirement of nuclear environment, and the like.

Owner:SUZHOU UNIV +1

Manufacturing method of fine-grain high-hardness tungsten cobalt nickel alloy

The invention provides a manufacturing method of fine-grain high-hardness tungsten cobalt nickel alloy. The manufacturing method comprises the following steps of 1 respectively weighing tungsten powder, cobalt power and nickel powder, 2 adding the tungsten powder, cobalt power and nickel powder into a mixing machine for mixing to obtain mixed powder, 3 pressing the mixed powder to form a press blank, 4 sintering the press blank to obtain a sintered blank and then performing vacuum annealing on the sintered blank to obtain the fine-grain high-hardness tungsten cobalt nickel alloy. The size of the manufactured fine-grain high-hardness tungsten cobalt nickel alloy prepared by means of the manufacturing method is not larger than 20 microns, the hardness is not smaller than 35, and the fine-grain high-hardness tungsten cobalt nickel alloy is small in grain and high in densification degree.

Owner:XIAN HUASHAN TUNGSTEN PROD CO LTD

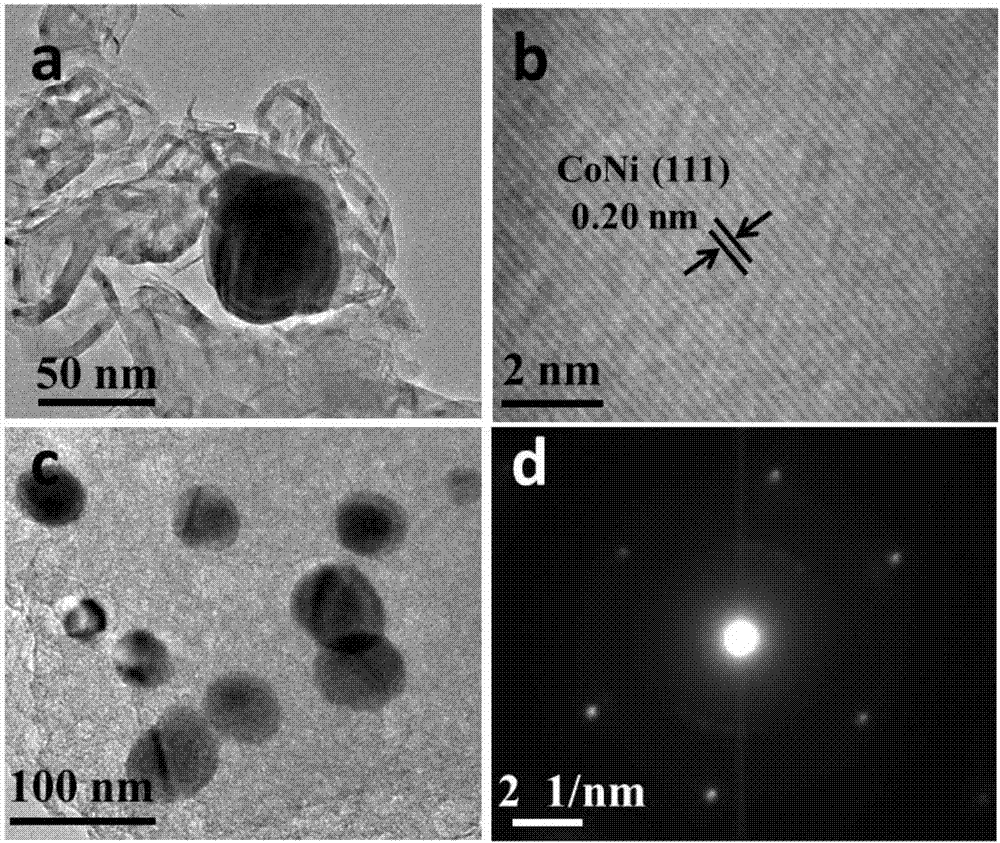

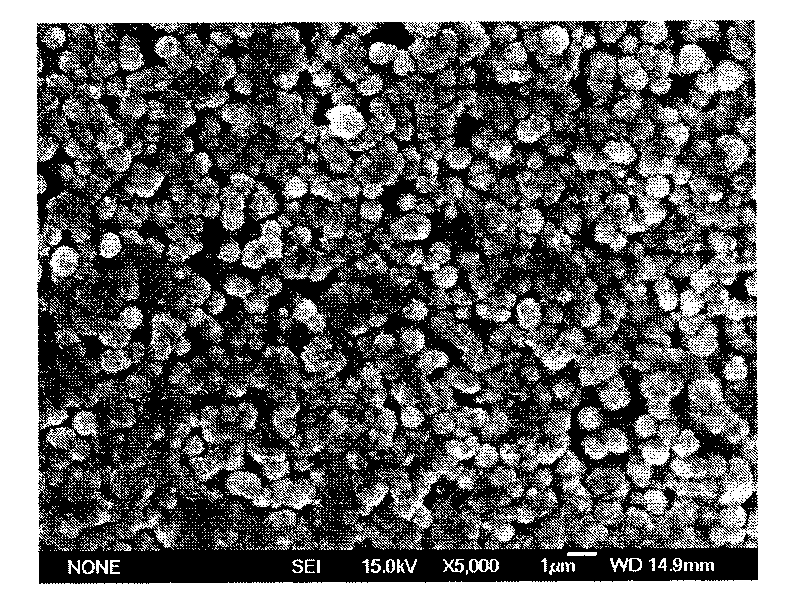

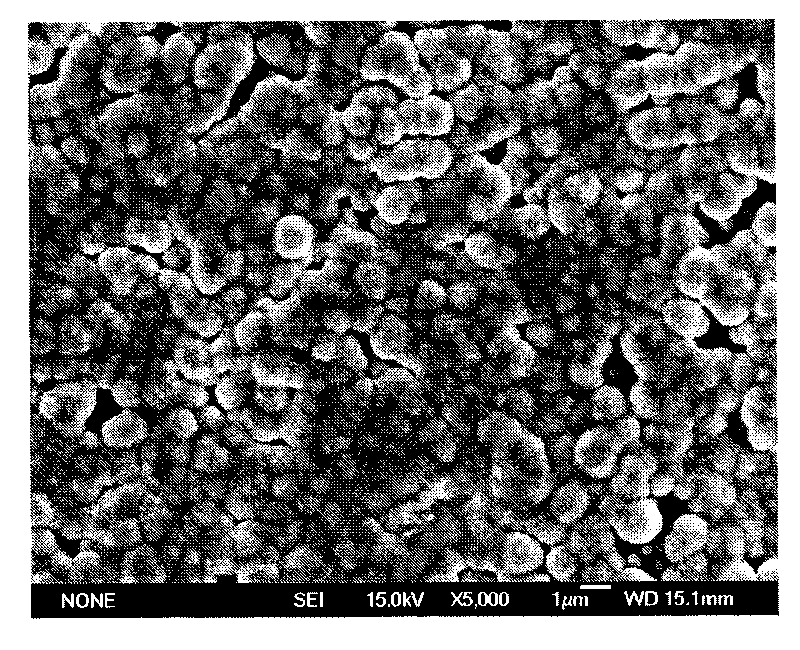

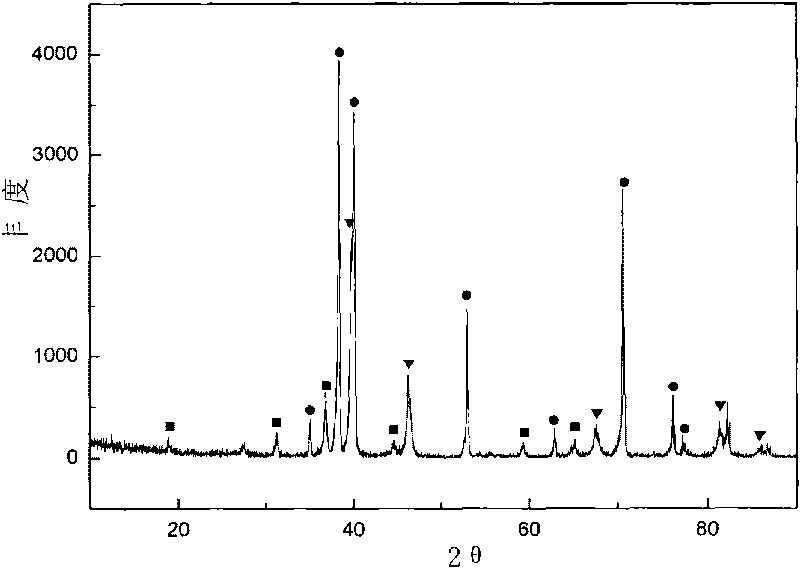

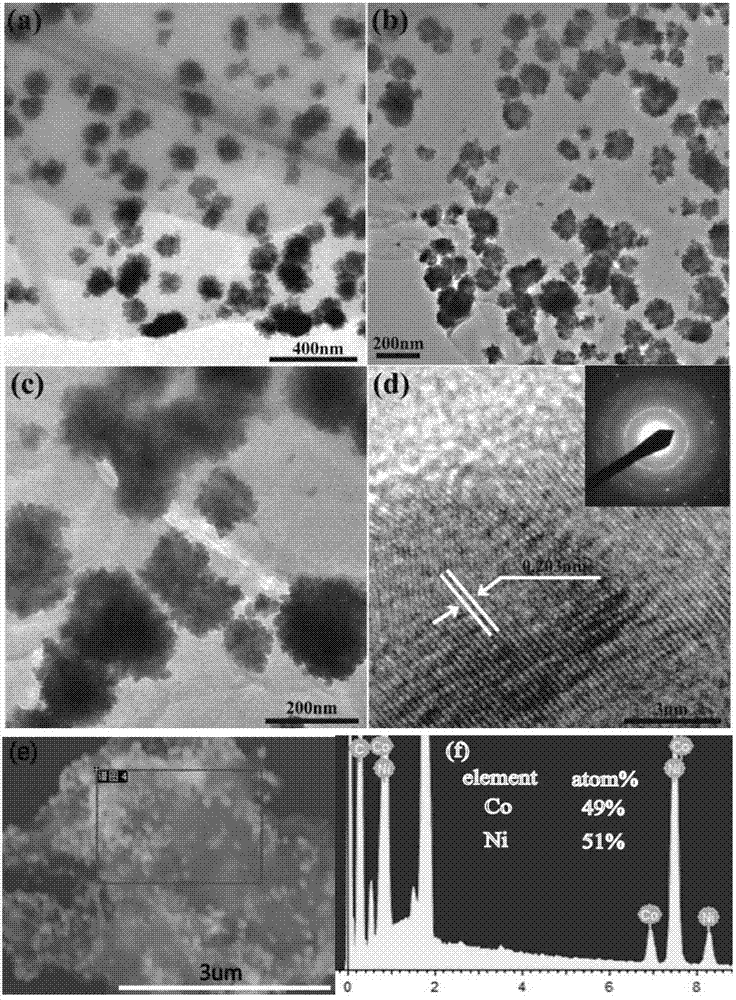

Hexagonal phase nickel-cobalt alloy nanocluster-graphene composite material and preparation method and application thereof

InactiveCN104117683AMaterial nanotechnologyMagnetic/electric field screeningGraphite oxideHexagonal phase

The invention relates to a hexagonal phase nickel-cobalt alloy nanocluster-graphene composite material and a preparation method and application thereof, and belongs to the field of electromagnetic wave absorption materials. The hexagonal phase nickel-cobalt alloy nanocluster-graphene composite material with good wave absorption performance is prepared at a low cost according to the thermal decomposition method which is easy, convenient and fast to implement and good in reduction effect. The preparation method comprises the steps of (a) adding graphite oxide into 2-pyrrolidone and dispersing the graphite oxide; (b) adding cobalt acetylacetonate, nickel acetylacetonate and octadecylamine, heating the mixture to 110-140 DEG C in the atmosphere of inert protective gas, maintaining the temperature for 20-40 minutes, then heating the mixture to 230-245 DEG C, and maintaining the temperature for 1.5-2.5 hours; (c) adding an organic solvent to stop the reaction suddenly; (d) isolating a reaction product; (e) optionally washing and drying the reaction product.

Owner:BEIJING NORMAL UNIVERSITY +1

Method for preparing graphene through chemical vapor deposition

InactiveCN103409728AImprove mobilityChemical vapor deposition coatingGas phaseCharge carrier mobility

The invention relates to a method for preparing graphene through chemical vapor deposition. The method comprises the following steps: cleaning a substrate cobalt-nickel alloy three times by using an ethanol solution with a mass fraction of 75%, and drying at a temperature of 50-80 DEG C; placing the cobalt-nickel alloy substrate into a quartz furnace, heating to achieve a temperature of 880-890 DEG C, and introducing helium gas, wherein a helium gas flow rate is 50 sccm; maintaining the temperature at 880-890 DEG C, and uniformly adding ethylbenzene to the quartz furnace; cooling the quartz furnace to a room temperature, and taking the sample; and carrying out an ultrasound treatment on the sample to obtain the graphene, wherein an ultrasound treatment power is 800 w, and a time is 60-90 min. The prepared graphene has high carrier mobility.

Owner:SUZHOU AITESI FURTHER MATERIALS CO LTD

Preparation method of high-tungsten and high-cobalt nickel alloy high- purity fine-grained bar material

ActiveCN110760718ALower performance requirementsIncrease productivityCobalt nickel alloyNickel alloy

The invention discloses a preparation method of a high-tungsten and high-cobalt nickel alloy high- purity fine-grained bar material. The alloy composition is of 25 wt.% - 45wt.% of tungsten, 15 wt.% -30 wt.% of cobalt and the balance nickel. A vacuum induction melting mode is adopted, a high-tungsten high-cobalt nickel alloy ingot is heated to 1150 - 1250 DEG C after casting, and forging is carried out after heat preservation; the forging adopts a repeated deformation route alternating radial drawing-out with axial upsetting, the deformation amount of each firing is 15% - 35%, blanks after different firing forging in the middle is subjected to furnace returning heat preservation, and the time of furnace returning heat preservation is 30 - 120 min; and the final forging temperature is greater than or equal to 1000 DEG C, and the deformation amount of the last firing forging is more than or equal to 25%. According to the preparation method of a high-tungsten and high-cobalt nickel alloyhigh- purity fine-grained bar material, the oxygen content of a prepared high-tungsten high-cobalt nickel alloy bar material is less than or equal to 30 ppm, the sulfur content is less than or equalto 20 ppm, and the sound speed can reach 5015 m / s; and according to the preparation method, the requirement on equipment capacity can be reduced by adopting a hot forging mode, the obtained bar material is uniform in deformation, free of defects such as surface cracks, has internal structure with fine and uniform grains, has ideal microstructure and excellent mechanical property, the grain size can exceed 5 grade, the grade difference does not exceed 2 grade, ultrasonic flaw detection can reach class A, the elongation reaches 68%, and the tensile strength reaches 980 MPa.

Owner:UNIV OF SCI & TECH BEIJING

Plating solution for electroplating tungsten-cobalt-nickel alloy on surface of structural steel

The invention discloses a plating solution for electroplating a tungsten-cobalt-nickel alloy on a surface of structural steel. The plating solution is composed of 12-18 g / L of cobalt sulfate, 80-84 g / L of sodium tungstate, 14-18 g / L of nickel sulfate, 34-38 g / L of boric acid, 30-36 g / L of sodium sulfate, 20-24 g / L of ammonium sulfate, 30-34 g / L of tartaric acid, 11-15 g / L of potassium pyrophosphate, 10-14 g / L of ascorbic acid, 1-3 ml / L of formaldehyde, 2-4 ml / L of dimethyl hexynol, and the balance being water.

Owner:无锡市锡山区鹅湖镇荡口青荡金属制品厂

Electrolyte media for the deposition of tin alloys and methods for depositing tin alloys

An electroplating bath medium for electroplating articles with a tin-cobalt, tin-nickel, or tin-cobalt-nickel alloy comprises: at least one tin salt; an alloying metal salt comprising a cobalt salt and / or a nickel salt; a complexant comprising a hydroxycarboxylic acid or alkali metal salt thereof such as a sodium or potassium gluconate or heptonate complexant; boric acid; and a bath soluble substituted phenolic compound. The current regime applied to the plating bath can include time intervals of direct current and of pulsed current in order to selectively control the deposition of tin by activation or diffusion control.

Owner:MACDERMID INC

Graphene oxide/cobalt-based composite plating as well as preparation method and application thereof

The invention discloses a graphene oxide / cobalt-based composite plating as well as a preparation method and application thereof. The preparation method comprises the following steps: soaking cobalt, nickel or a cobalt-nickel alloy serving as a positive electrode and a workpiece to be plated serving as a negative electrode in a composite electroplating solution for ultrasonic oscillation; performing electro-deposition on the workpiece to be plated by adopting pulse current to obtain the graphene oxide / cobalt-based composite plating, wherein the composite electroplating solution is prepared from30 to 200 g / L of cobalt salt, 30 to 200 g / L of nickel salt, 5 to 80 g / L of phosphate, 10 to 60 g / L of boric acid, 10 to 50 g / L of a complexing agent, and 0.1 to 5 g / L of graphene oxide and the balance of deionized water. The preparation method is simple, efficient and environmentally friendly. The composite plating has the advantages of high hardness, superior wear resistance and corrosion resistance, and can be widely applied to various mechanical parts which have high requirements on hardness, wear resistance, low friction coefficient and high corrosion resistance as a functional protectionlayer.

Owner:GUANGDONG UNIV OF TECH

Technology for electroplating tungsten-cobalt-nickel alloy on surface of structural steel

The invention discloses a technology for electroplating a tungsten-cobalt-nickel alloy on a surface of structural steel. A plating solution adopted in the technology is composed of 12-18 g / L of cobalt sulfate, 80-84 g / L of sodium tungstate, 14-18 g / L of nickel sulfate, 34-38 g / L of boric acid, 30-36 g / L of sodium sulfate, 20-24 g / L of ammonium sulfate, 30-34 g / L of tartaric acid, 11-15 g / L of potassium pyrophosphate, 10-14 g / L of ascorbic acid, 1-3 ml / L of formaldehyde, 2-4 ml / L of dimethyl hexynol, and the balance being water. The technology comprises the steps of washing and activating the structural steel; then putting the structural steel in the above plating solution; taking stainless steel as an anode; adjusting a pH value to 7.5-8.5 with ammonia water; heating to a temperature of 50-60 DEG C; controlling a current density at 12-16 A / dm<2> and electroplating for 20-30 minutes.

Owner:无锡市锡山区鹅湖镇荡口青荡金属制品厂

Liquid crystal polymer copper-clad laminate and copper foil used for said laminate

ActiveUS9060431B2High peel strengthImprove accuracyInsulating substrate metal adhesion improvementChromatisationPolymer resinCobalt nickel alloy

Provided is a copper-clad laminate obtainable by bonding a copper foil on which roughening treatment including copper-cobalt-nickel alloy plating is performed and a liquid crystal polymer to each other, wherein the copper-clad laminate is free from a roughening particle residue on a surface of the liquid crystal polymer resin after copper foil circuit etching. The copper-clad laminate obtainable by bonding a copper foil and a liquid crystal polymer to each other, wherein the copper foil includes a copper primary particle layer formed on a surface bonded to the liquid crystal polymer and a secondary particle layer formed on the primary particle layer and made from a ternary alloy including copper, cobalt, and nickel; the primary particle layer has an average particle size of 0.25 to 0.45 μm; and the secondary particle layer has an average particle size of 0.05 to 0.25 μm.

Owner:JX NIPPON MINING & METALS CORP

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com