Method for preparing anode-catalyzed electrode for electrolyzing slurry coal

A catalytic electrode and anode technology, applied in the direction of electrodes, electrolysis process, electrolysis components, etc., can solve the problems of short service life of electrodes, unsuitable for large-scale application, low catalytic activity, etc., and achieve extended service life, high stability, and improved The effect of catalytic activity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0032] This embodiment is the preparation of Ti / Pt-CO3O4 anode catalytic electrode, and its preparation steps are as follows:

[0033] (1) Pretreatment of the electrode metal titanium substrate: first, polish it with metal phase sandpaper from coarse to fine until it is bright and uniform; rinse it with deionized water, and then ultrasonically clean it in ethanol or acetone to remove oil stains, and then use Rinse with deionized water, then use 4% HF to remove oxide impurities, then rinse with hot double distilled water and place in ethanol for later use;

[0034] (2) Electrodeposition of metal on the metal titanium substrate: in the electrolytic cell, the platinum plate electrode is used as the anode, and the above-mentioned treated metal titanium substrate is used as the working electrode; the catalytic layer electrodeposition is carried out on the metal titanium substrate; the catalytic layer Electrode deposition adopts step-by-step constant current deposition; the steps ar...

Embodiment 2

[0039] This embodiment is the preparation of the anode catalytic electrode of Ti / Pt-NiO, and its preparation steps are as follows:

[0040] (1) The pretreatment of the metal titanium substrate is the same as that of the above-mentioned embodiment 1.

[0041] (2) Electrodeposition of the metal on the metal titanium substrate is exactly the same as that of the above-mentioned embodiment 1. The difference is that in the second step, nickel is redeposited, and the electroplating solution used is a mixed solution of nickel sulfate heptahydrate with a concentration of 200g / L, boric acid of 30g / L and sodium chloride of 15g / L.

[0042](3) The pre-heating treatment and post-heating treatment after metal electrodeposition on the metal titanium substrate are exactly the same as those in the above-mentioned embodiment 1.

[0043] Ti / Pt-NiO was finally prepared as a titanium-based anode catalytic electrode.

Embodiment 3

[0045] This embodiment is Ti / Pt-CO 3 o 4 -The preparation of NiO anode catalytic electrode, its preparation steps are as follows:

[0046] (1) The pretreatment of the metal titanium substrate is the same as that of the above-mentioned embodiment 1.

[0047] (2) Electrodeposition of the metal on the metal titanium substrate is exactly the same as that of the above-mentioned embodiment 1. The difference is: in the second step, two metals, cobalt and nickel, are simultaneously deposited; A mixed solution of boric acid and 15g / L sodium chloride.

[0048] (3) The pre-heating treatment and post-heating treatment after metal electrodeposition on the metal titanium substrate are exactly the same as those in the above-mentioned embodiment 1.

[0049] Ti / Pt-CO 3 o 4 -NiO.

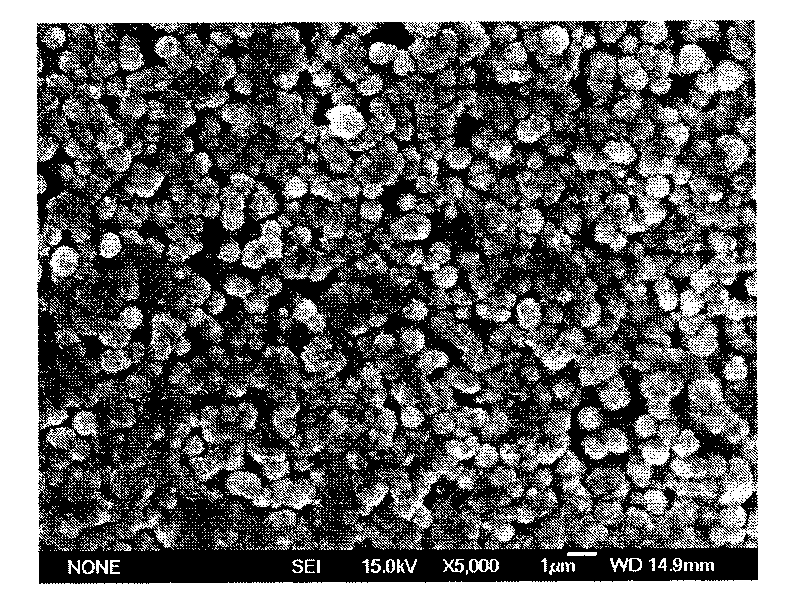

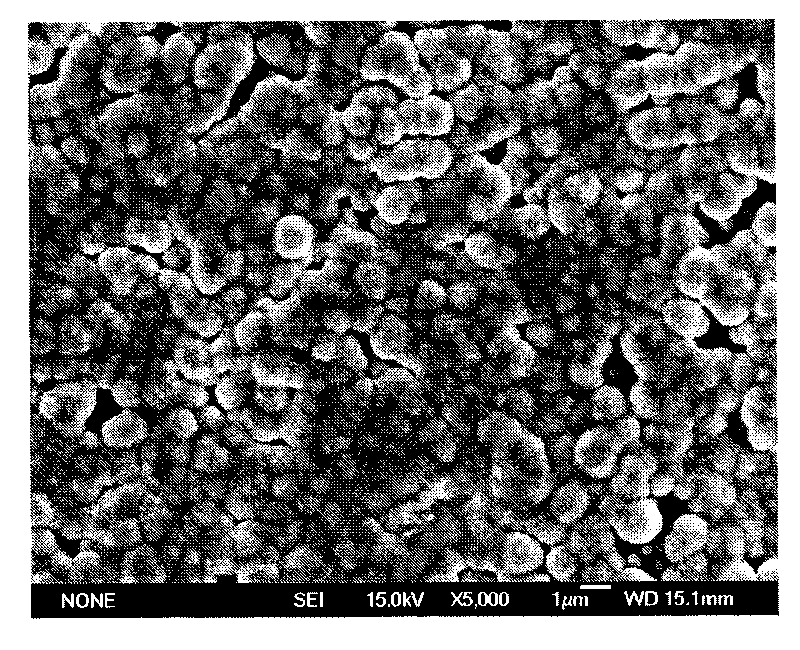

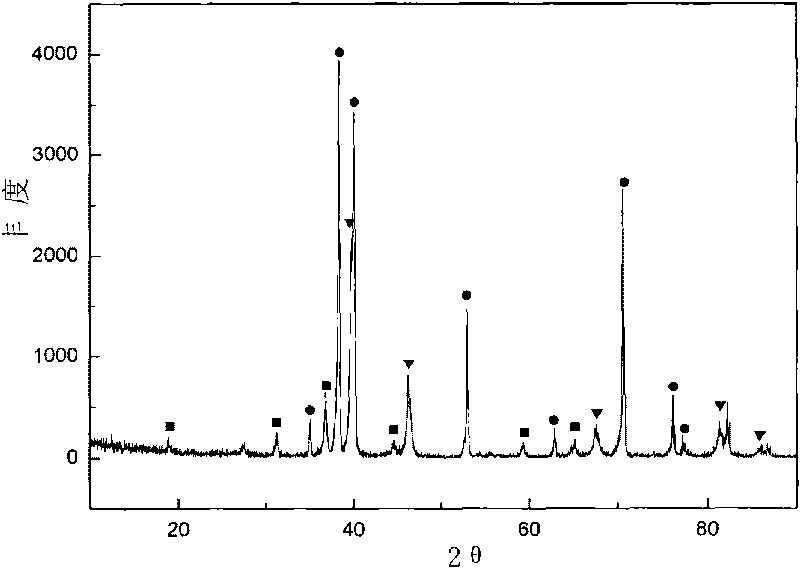

[0050] The instrument detection result that above-mentioned embodiment product is done, has done the detection and the test of I-V change characteristic etc. when SEM, XRD and electrolytic coal slurry are done...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com