Processing method of trivalent cobalt nickel oxide waste material and waste cobalt nickel alloy

A cobalt-nickel oxide and treatment method technology, which is applied in the direction of improving process efficiency, can solve the problems of long leaching time and low leaching rate, and achieve the effects of short leaching time, avoiding toxic and harmful gases, and high leaching rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

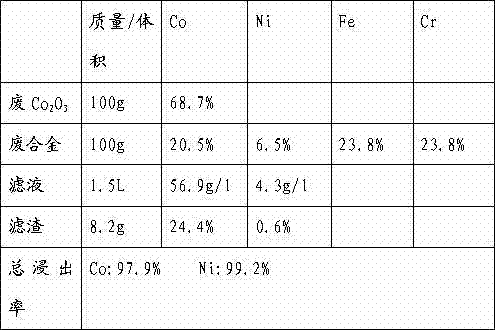

Embodiment 1

[0021] Adopt following method to process trivalent cobalt-nickel oxide waste material and waste cobalt, nickel alloy, comprise the steps:

[0022] 1. Slurry the nickel trioxide waste with a sulfuric acid solution with a hydrogen ion concentration of 1mol / l, the solid-to-liquid ratio is 1:5, and the reaction temperature is 80°C;

[0023] 2. Add waste alloys containing cobalt and nickel under stirring, the stirring speed is 100-800r / min, the mass ratio of alloy waste to trivalent cobalt-nickel oxide waste is 1:0.5, and the reaction time is 4 hours. The temperature is maintained at 80°C, during which acid needs to be supplemented to maintain the concentration of hydrogen ions. Among them, the particle size of nickel oxide waste is 0.1mm, and the particle size of waste cobalt and nickel-containing alloys is 0.1mm;

[0024] 3. After filtering, the filter residue returns to step 1 for leaching;

[0025] 4. Impurity removal: Add an alkali solution with a concentration of 6mol / l to t...

Embodiment 2

[0027] Adopt following method to process trivalent cobalt-nickel oxide waste material and waste cobalt, nickel alloy, comprise the steps:

[0028] 1. Slurry the trivalent cobalt-nickel oxide waste—lithium cobaltate, with a hydrogen ion concentration of 2mol / l sulfuric acid solution, the solid-to-liquid ratio is 1:20, and the reaction temperature is 99°C;

[0029] 2. Add the alloy scrap containing cobalt and nickel - nickel-iron alloy under stirring, the stirring speed is 100-800r / min, the mass ratio of the alloy scrap to the trivalent cobalt-nickel oxide scrap is 1: 4, and the reaction time is 10 Hours, the reaction temperature is maintained at 99 ° C, during which acid needs to be added to maintain the concentration of hydrogen ions, wherein the particle size of lithium cobaltate is 1.0mm, and the particle size of nickel-iron alloy is 5.0mm;

[0030] 3. After filtering, the filter residue is returned to step 1 for leaching. In addition to cobalt and nickel ions, the filtrate ...

Embodiment 3

[0033] Adopt following method to process trivalent cobalt-nickel oxide waste material and waste cobalt, nickel alloy, comprise the steps:

[0034] 1. Add lithium nickelate waste to a nitric acid solution with a hydrogen ion concentration of 1.5mol / l to make slurry, the solid-to-liquid ratio is 1:10, and the reaction temperature is 90°C;

[0035] 2. Add cobalt-copper alloy waste under stirring, the stirring speed is 100-800r / min, the mass ratio of cobalt-copper alloy waste to lithium nickelate waste is 1:3, the reaction time is 7 hours, and the reaction temperature is maintained at 90°C. It is necessary to add acid to maintain the concentration of hydrogen ions. Among them, the particle size of lithium nickelate waste is 0.5mm, and the particle size of cobalt-copper alloy waste is 2.0mm;

[0036]3. After filtering, the filter residue is returned to step 1 for leaching. In addition to cobalt and nickel ions, the filtrate also contains impurities such as iron, chromium, copper, t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com