Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

65results about How to "Meet the hardness" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

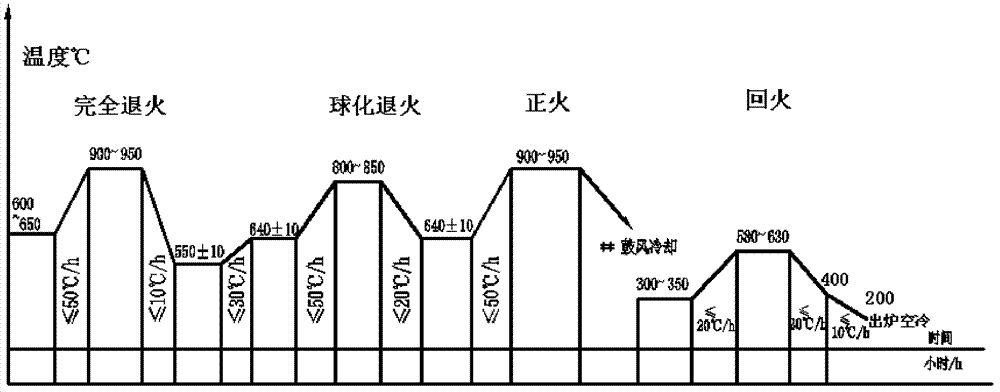

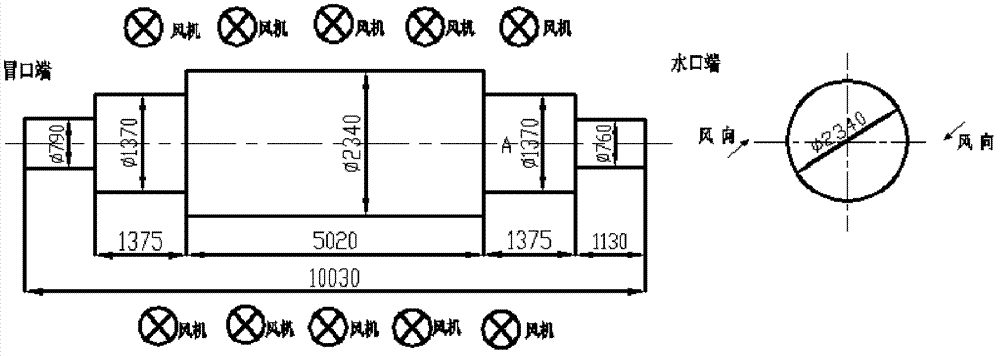

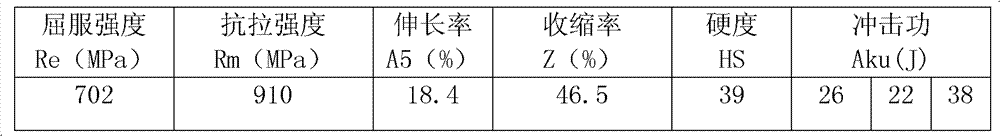

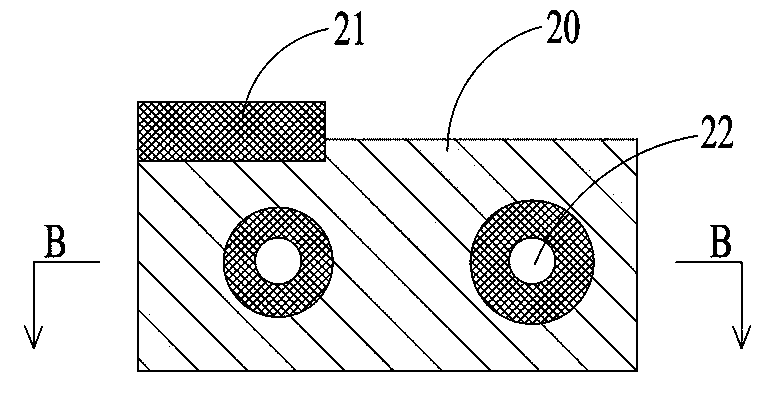

Heat treatment method after forging for forged steel bearing roller used for large heavy plate mill

ActiveCN103088199AEasy to shapeMeet the hardnessFurnace typesHeat treatment furnacesStrip millHardness

The present invention discloses a heat treatment method after forging for forged steel bearing roller used for large heavy plate mill, which is used for heat treatment after forging of supporting rollers used for a rolling mill with a plate width of above 2500 mm. The method comprises the following steps of: first, fully annealing; second, spheroidizing annealing; third, normalizing; and fourth, tempering. The operation method of once heat treatment after forging is used for supporting rollers used for the rolling mill with the plate width of above 2500 mm, so that the roll neck stiffness and other mechanical properties of the workpiece meet technical requirements through a manner of normalizing blast cooling. A preheat treatment process is reduced, the production cycle is shortened, and the production cost is reduced. The large plate supporting roller after heat treatment after forging can acquire pearlitic structure and sorbite structure with good mechanical properties, so that the hardness of the roll neck is up to 30-40 HS. The mechanical properties meet the technical requirements. The structure preparation for subsequent heat treatment is made.

Owner:SHANGHAI ELECTRIC SHMP CASTING & FORGING CO LTD +1

Cobalt-base alloy welding wire, hook claw using welding wire, connection rod and surfacing method

InactiveCN103921013AEffective control of hardnessMeet the hardnessConnecting rod bearingsConnecting rodsChemical compositionHardness

The invention discloses a cobalt-base alloy welding wire, a hook claw using the welding wire, a connection rod and a surfacing method. The cobalt-base alloy welding wire comprises chemical components including, by mass, 0.9-1.05% of C, 26.0-32.0% of Cr, 3.0-6.0% of W, less than or equal to 3.0% of Ni, less than or equal to 1.0% of Mo, less than or equal to 1.0% of Mn, less than or equal to 2.0% of Si, less than or equal to 3.0% of Fe, and the balance Co. By controlling the content of C, deposited metal meets the requirements of hardness and nondestructive testing.

Owner:SICHUAN HUADU NUCLEAR EQUIP MFR

Polylactic acid self-curled and self-bonded composite cigarette tow and preparation method thereof

InactiveCN108642601AAvoid mechanical propertiesAvoid heat damageTobacco smoke filtersArtificial filament heat treatmentPlasticizerSingle fiber

The invention discloses a polylactic acid self-curled and self-bonded composite cigarette tow and a preparation method thereof. The preparation method comprises the following steps: drying polylacticresin; adding a spinning assistant for the polylactic resin into conventional polylactic resin, adding the spinning assistant to polylactic resin containing a plasticizer, and performing melting plasticization to obtain a polylactic resin melt; spraying the melt from a spinneret hole to form single composite fibers; cooling a polylactic acid two-component cigarette tow; oiling the two-component tow, and carrying out drafting and tension heat setting to obtain the polylactic acid self-curled and self-bonded composite cigarette tow. The single fibers in the tow is one of a side-by-side, orange-slice, sheath-core and sea-island composite structures, one of the components of the side-by-side type or the orange-slice type structure is the polylactic resin containing the plasticizer, and the remaining component is the conventional polylactic resin and a composition thereof. The preparation method has the advantages of simplification of the production process, avoiding of mechanical and thermal damages, increase of the rod yield of the polylactic fiber tow, and reduction of the production cost; and the polylactic acid self-curled and self-bonded composite cigarette tow has a good biodegradability.

Owner:CHANGSHU GOLD SPRING CHEM FIBERS & KNITTINGS

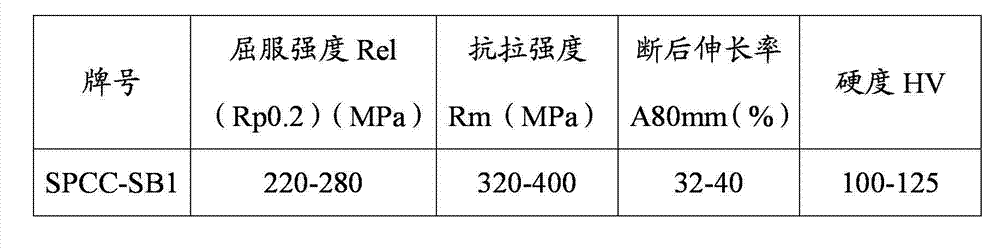

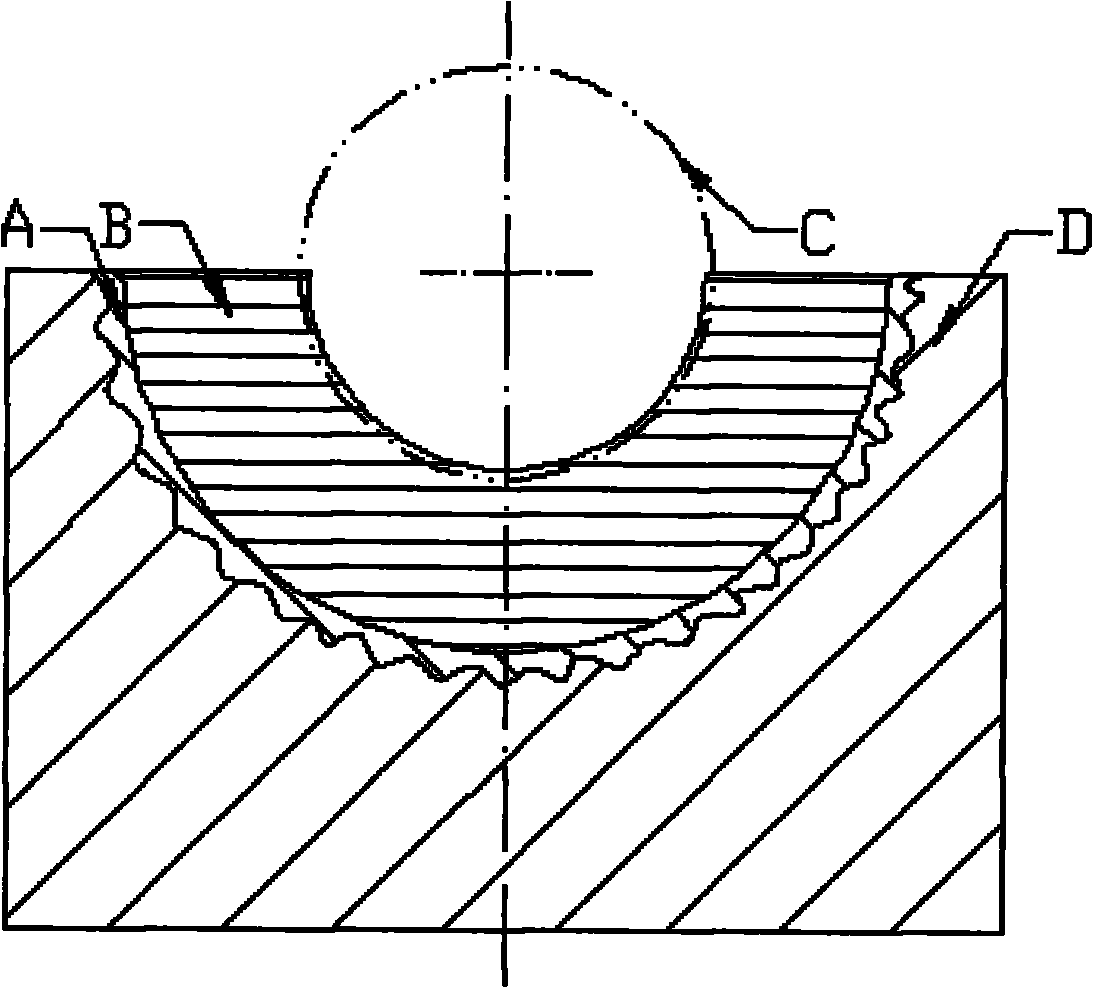

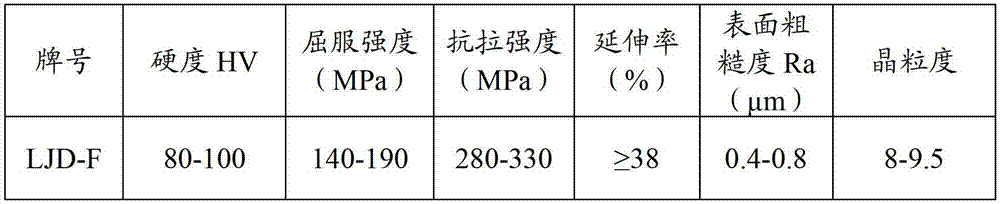

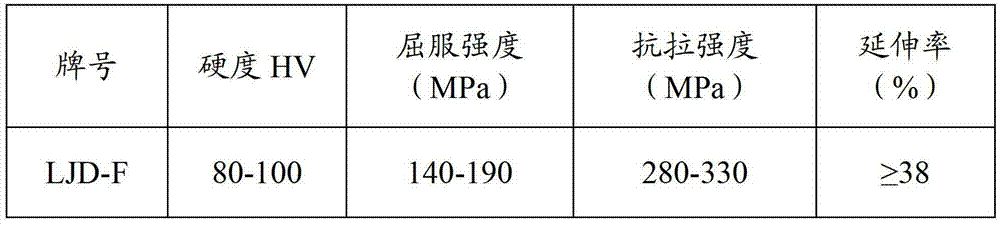

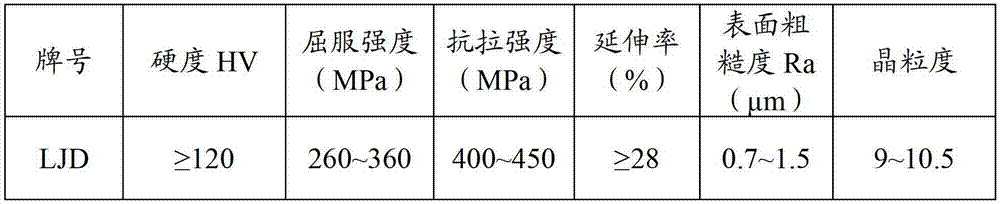

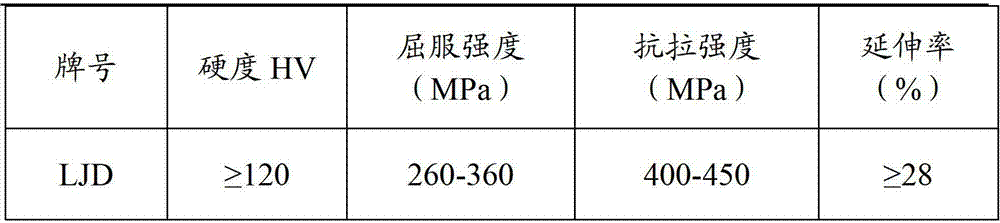

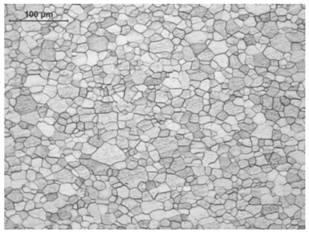

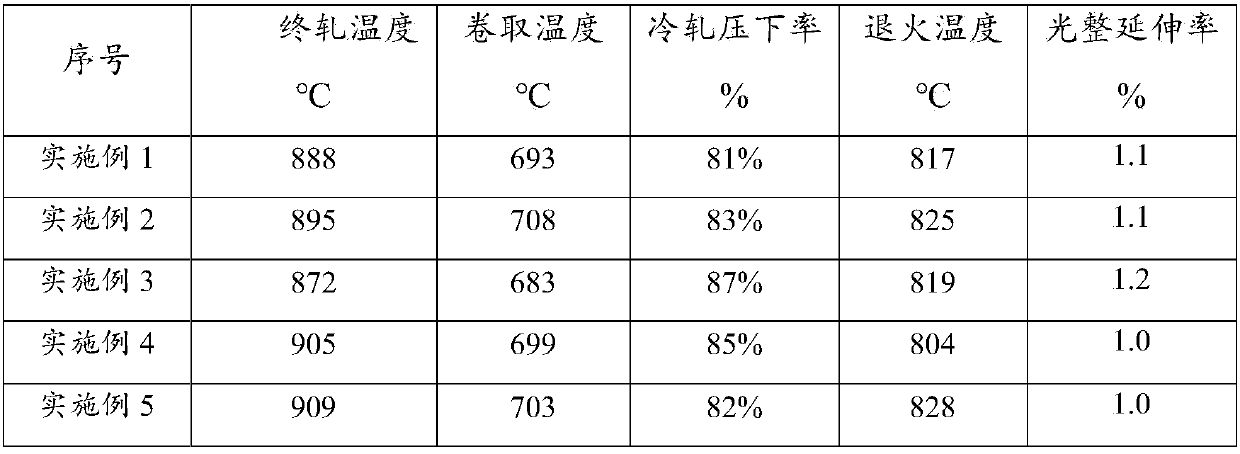

Steel strip for LED bracket and manufacturing method thereof

The invention provides a steel strip for an LED bracket and a manufacturing method thereof. The steel strip comprises the following chemical compositions by mass percent: 0.03%<=C<=0.07%, 0.01%<=Si<=0.03%, 0.2%<=Mn<=0.3%, 0%<P<0.02%, 0%<S<0.02%, 0.01%<=Al<=0.035% and the balance of Fe, as well as a trace of inevitable impurities. Repeated tests and trials show that the LED steel strip completely satisfies the quality requirements on the strength, the rigidity and the extensibility, which ensure that the LED bracket is free from cracks after being punched and bent for 6 times, and at present, the LED steel strip gains popularity of customers; and as the LED new material cold-rolled strip has a very wide development prospect, the popularization and application values are extremely high and the prospect is very wide.

Owner:浙江龙盛薄板有限公司

Aqueous blackboard paint

The invention discloses an aqueous blackboard paint which solves the problem of solvent release of existing solvent type blackboard paints. The aqueous blackboard paint comprises the following components in parts by mass: 260 parts of water, 1 part of dispersant, 1.5 parts of a wetting agent, 200 parts of emulsion, 1 part of a defoamer, 200 parts of pigment, 120 parts of filler, 15 parts of coalescing agents and 3 parts of thickener. The preparation method comprises the following steps of: during preparation, adding water into a reaction kettle, adding the wetting agent, the dispersant and the defoamer at 100-300 r / m, and stirring for 30-40 minutes; adding the pigment and filler under stirring, and dispersing for 1-1.5 hours at 500-800 r / m; then, adding the emulsion, and stirring for 30 minutes at 800-1000 r / min; pumping the materials to a grinding miller, and grinding the materials till the fineness is below 45 microns; and pumping the grinded materials to a proportioning kettle, adding the coalescing agents, the defoamer and the thickener, and adjusting the viscosity to discharge and package so as to obtain a finished product. According to the paint provided by the invention, various film forming matters in different performances are adopted to compound and modify, so that demands of the blackboard paint such as high hardness, scrubbing resistance, wear resistance and color residual prevention are satisfied.

Owner:SHANXI HUABAO NEW MATERIALS CO LTD

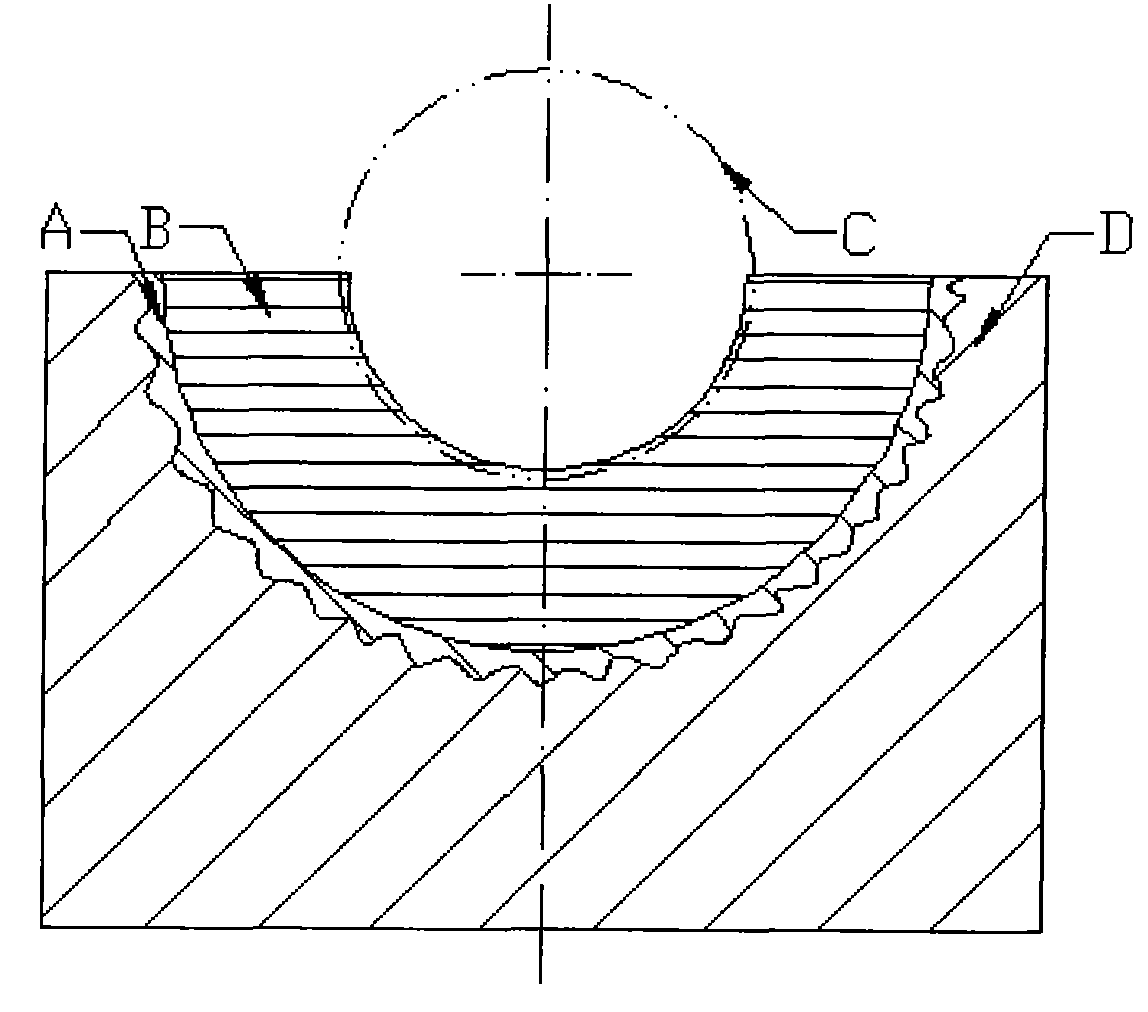

Reproducing method of forging mold by using composite build-up welding and spray welding method

ActiveCN101767262AMaintain maximum qualityReduces the possibility of crackingMolten spray coatingArc welding apparatusSurface layerThermal fatigue

The invention discloses a reproducing method of forging mold by using composite build-up welding and spray welding method. The method comprises the following steps of: a. integrally shaving a cavity part of an ineffective mold until the defect of the cavity is removed; b. spray-welding a uniform spray welding layer on the inner surface of the mold cavity by using a one-step spray welding method; c. build-up welding a surface reinforcement layer on the spray welding surface of a mold transition layer by using an automatic gas shield build-up welding technique; d. finishing the build-up welding, carrying out the remelting and warming at once by using a tempering and slow cooling technique and ensuring that the mold is thoroughly heated during the warming time; and e. fine finishing, and putting the size of each part of the cavity in place. In the invention, the combination of the build-up welding and the spray welding is innovatively provided, compared with the prior art, the production cost is reduced, the condemnation factor of a product is decreased, meanwhile, the joint strength of the mold substrate and a welding layer is enhanced, the strength and the impact toughness of the mold are improved, the wear-resisting and the thermal fatigue resistance properties of a surface layer are optimized, and the property of the mold in a reinforcement region surpasses that of the new-made integral molds of 5CrNiMo and 5CrMnMo.

Owner:CHONGQING JIEPIN TECH

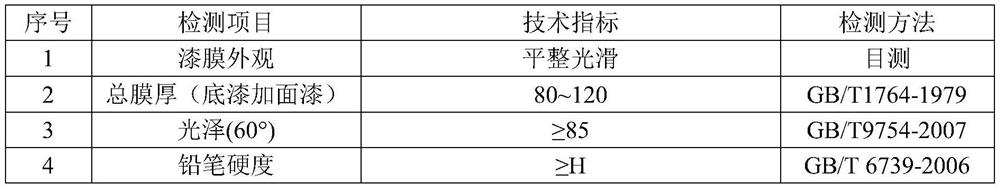

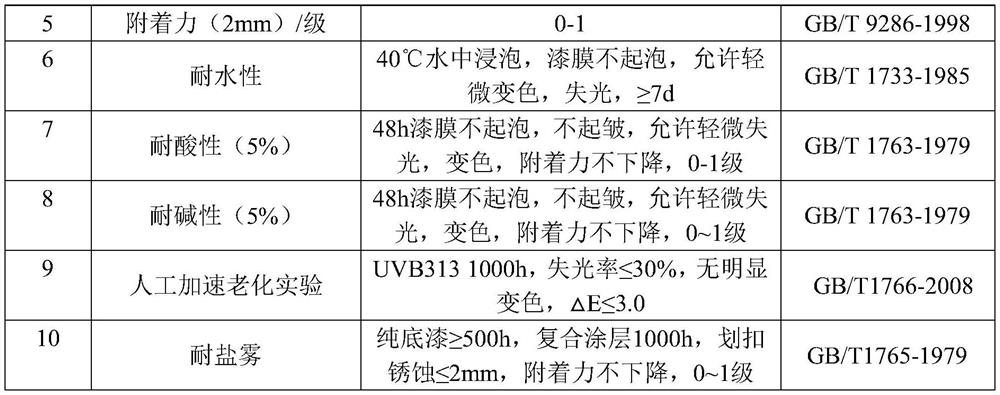

Waterborne epoxy wet-on-wet polyurethane matched paint applied to engineering machinery and preparation method of waterborne epoxy wet-on-wet polyurethane matched paint

ActiveCN112876962ARealize "wet-on-wet" processSatisfy fullnessAnti-corrosive paintsPolyurea/polyurethane coatingsEpoxyProcess engineering

The invention discloses a water-based epoxy wet-on-wet polyurethane matching paint applied to engineering machinery and a preparation method of the water-based epoxy wet-on-wet polyurethane matching paint. According to the invention, a water-based two-component epoxy anticorrosive primer is matched with a water-based two-component polyurethane finish paint, so while meeting the performance requirements of paint film appearance, fullness, gloss, hardness, flexibility, salt mist resistance, 40-DEG C water resistance, acid and alkali resistance and the like in the field of engineering machinery coating, a wet-to-wet process in engineering machinery can be realized on the premise of not changing a current production line and using a crude oil paint coating line; and thus, production efficiency is improved, production energy consumption is reduced, and the process of converting oil into water in various industries in China is promoted.

Owner:WANHUA CHEM GRP CO LTD

Steel strip for household electric appliance panel and production method thereof

ActiveCN103194670AGuaranteed plasticityGuaranteed thickness accuracyFurnace typesHeat treatment furnacesChemical compositionHardness

The invention provides a steel strip for deep drawing of a household electric appliance panel film. The steel strip comprises the following chemical components by mass percent: 0.01 percent<=C<=0.03 percent; zero percent<Si<=0.02 percent; 0.1 percent<=Mn<=0.25 percent; zero percent<P<=0.02 percent; zero percent<S<=0.025 percent; 0.02 percent<=Al<=0.05 percent; and the balance of Fe. The high-hardness steel strip for a household electric appliance panel totally meets the quality requirements for strength, hardness and elongation of refrigerator panel steel based on many tests and trial use, is popular among clients, and has popularization application value and broad prospect as the cold rolled strips for household appliances have a very broad development prospect.

Owner:浙江龙盛薄板有限公司

Preparation method of forging mold by using composite build-up welding and spray welding method

ActiveCN101767268AReduces the possibility of crackingExtend your lifeMolten spray coatingArc welding apparatusManufacturing technologyThermal fatigue

The invention initially provides a preparation method of a forging mold by using a composite build-up welding and spray welding method, combined with the characteristics of the build-up welding and the spray welding, and aiming at the status quo of the traditional forging mold manufacturing technology in China at present. The method comprises the following steps of: a. forging a forging mold substrate and carrying out thermal refining, wherein an allowance is reserved at a substrate cavity; b. build-up welding uniformly distributed build-up welding transition layers on a specific cavity surface by using an automatic gas shield build-up welding technique; c. forming a surface reinforcement layer on the surface of the transition layer by using a one-step spray welding method; d. finishing the spray welding and carrying out the remelting and warming at once by using a tempering and slow cooling technique; and e. fine finishing, and putting the size of each part of the cavity in place. Compared with the traditional preparation method of the forging molds, the production cost is reduced, the condemnation factor of a product is decreased, meanwhile, the joint strength of the mold substrate and a welding layer is enhanced, the strength and the impact toughness of the mold are improved, the wear-resisting and the thermal fatigue resistance properties of a surface layer are optimized, and the property of the mold surpasses that of the new-made integral molds of 5CrNiMo and 5CrMnMo.

Owner:CHONGQING JIEPIN TECH

Polyamide acid resin having unsaturated group, photosensitive resin composition using same, and cured product thereof

InactiveCN1898299AMeet the hardnessMeet solvent resistancePhotomechanical apparatusPrinted circuit manufactureHeat resistancePolyamide

The present invention provides a novel unsaturated group-containing polyamic acid resin (A) suitable for photosensitive resin compositions, and a photosensitive resin composition with excellent photosensitivity using the resin. The cured product obtained from the photosensitive resin composition has excellent Flexible, but also has excellent adhesion, pencil hardness, solvent resistance, acid resistance, heat resistance, gold plating resistance, etc. The unsaturated group-containing polyamic acid resin (A) is obtained by reacting an unsaturated group-containing polyester resin (a) with an anhydride group at the end and a compound (b) having 2 amino groups in the molecule. The resin composition is obtained by making it into the resin composition containing this unsaturated group containing polyamic-acid resin (A), a crosslinking agent (B), and a photoinitiator (C).

Owner:NIPPON KAYAKU CO LTD

Glass fiber reinforced polystyrene micro-foam double-layer co-extrusion section and its making method

ActiveCN103213366AWon't breakEvenly dispersedSynthetic resin layered productsGlass fiberSurface layer

The invention aims to provide a glass fiber reinforced polystyrene micro-foam double-layer co-extrusion section. The core layer of the section contains 3-8% of a uniform-distribution glass fiber (by polystyrene) having a length-diameter ratio of 10-20. The surface of the core layer is coated with a layer of high-impact-resistance polystyrene, and the mass fraction ratio of the material of the core layer to the material of the surface layer is 100:5-25. The density of the section reaches 0.40g / cm<3>, so the tensile strength and the charpy impact strength of the section can reach 12MPa and 4.5kJ / m<2> respectively, and are 31% and 23% higher than that of a same micro-foam material not added with the glass fiber respectively. In the invention, a polystyrene raw material is substantially saved, and the production cost is reduced.

Owner:SHANGHAI INTCO INDUSTRIES CO LTD +1

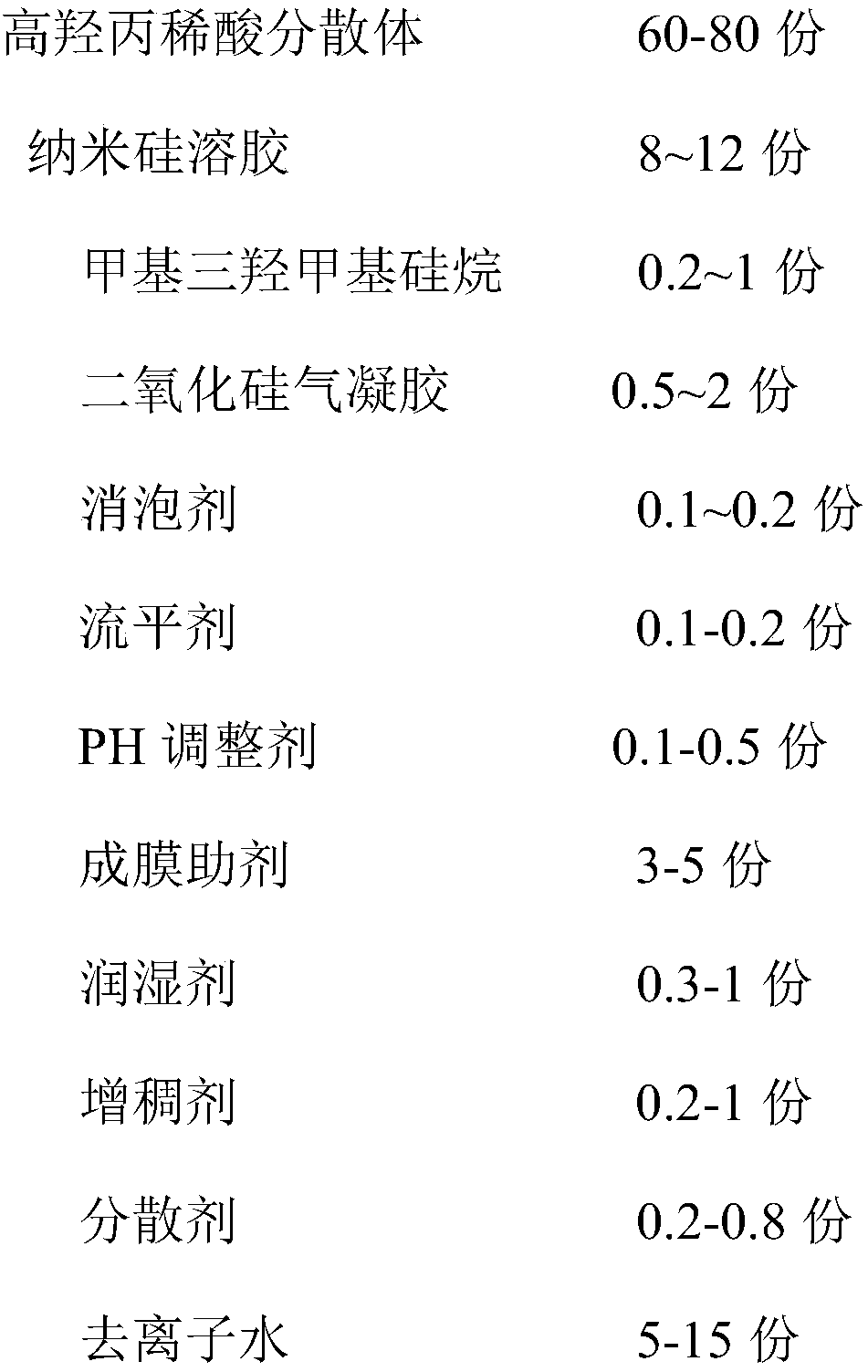

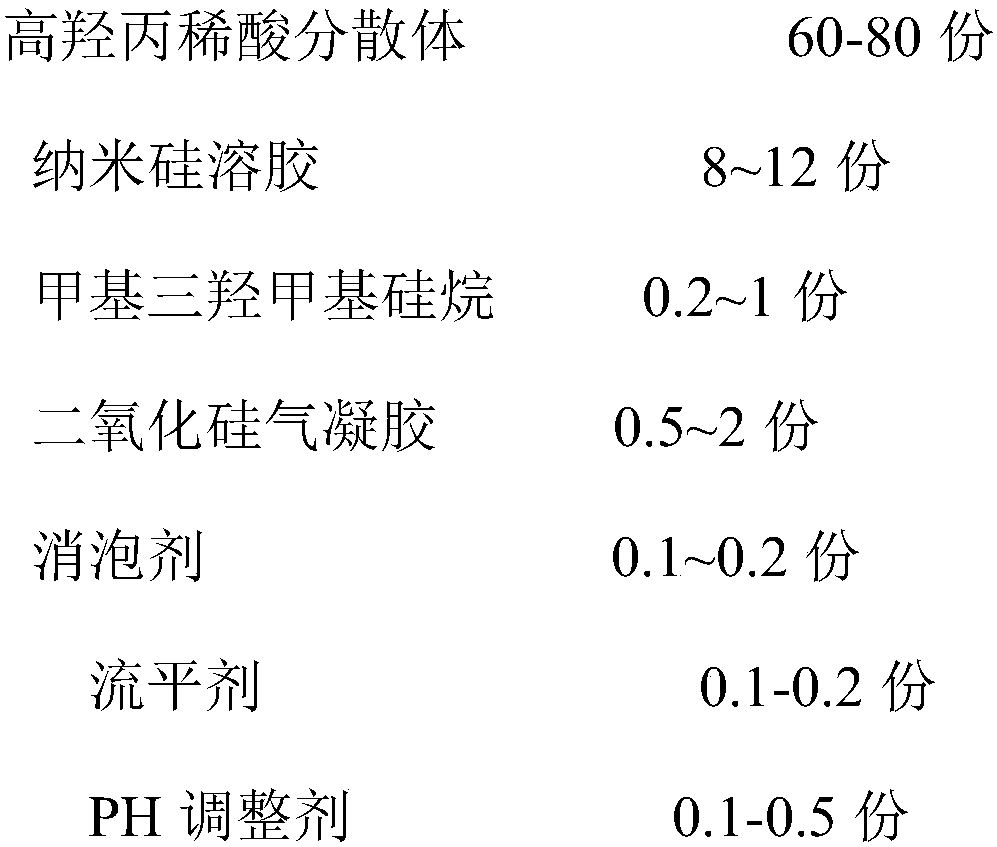

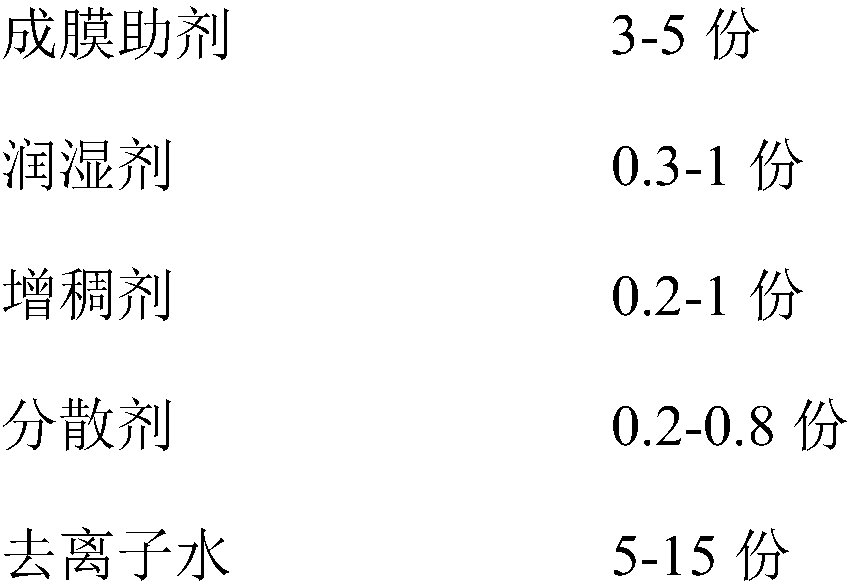

Water-borne bicomponent inorganic modified heat-resistant wood paint and preparation method and use method thereof

ActiveCN108264832AImprove heat resistanceImprove performanceFireproof paintsLiquid surface applicatorsEnvironmental resistanceSilicon dioxide

The invention discloses a water-borne bicomponent inorganic modified heat-resistant wood paint and a preparation method and a use method thereof. The wood paint is prepared by mixing the following components in parts by weight: a component A comprising 60-80 parts of a high hydroxypropionic acid dispersion body, 8-12 parts of nano silica sol, 0.2-1 part of methyl trimethylsilane, 0.5-2 parts of silicon dioxide aerogel, 0.1-0.2 part of a defoaming agent, 0.1-0.2 part of a leveling agent, 0.1-0.5 part of a pH regulator, 3-5 parts of a film formation auxiliary agent, 0.3-1 part of a wetting agent, 0.2-1 part of a thickener, 0.2-0.8 part of a dispersant, and 5-15 parts of deionized water; and a component B comprising 65-70 parts of a hydrophilic isocyanate curing agent and 30-35 parts of dimethoxy dipropylene glycol; the components are mixed evenly according to the ratio of the component A to the component B to water of 100 to 15 to (10-20). The wood paint is environmentally friendly and safe, and an obtained paint film has good heat resistance and scalding resistance.

Owner:深圳广田高科新材料有限公司

High-hardness steel belt for home appliances and manufacturing method

InactiveCN103205629AGuaranteed thickness accuracyGuaranteed cleanlinessFurnace typesHeat treatment furnacesChemical compositionHome appliance

The invention provides a high-hardness steel belt for home appliances. The chemical component of the high-hardness steel belt includes, by mass, 0.06%<=C<=0.13%, 0.03%<=Si<=0.25%, 0.2%<=Mn<=0.4%, 0%<P<0.025%, 0%<S<0.025%, 0.01%<=Al<=0.05%, and the balance of Fe. After many tests and tries, the high-hardness steel belt completely meets quality requirements for strength, hardness and elongation of high-hardness steel for side plates of refrigerators, is quite popular with customers, and has high popularization and application values and wide prospect since cold-rolled steel belts for home appliances are quite wide in development prospect.

Owner:浙江龙盛薄板有限公司

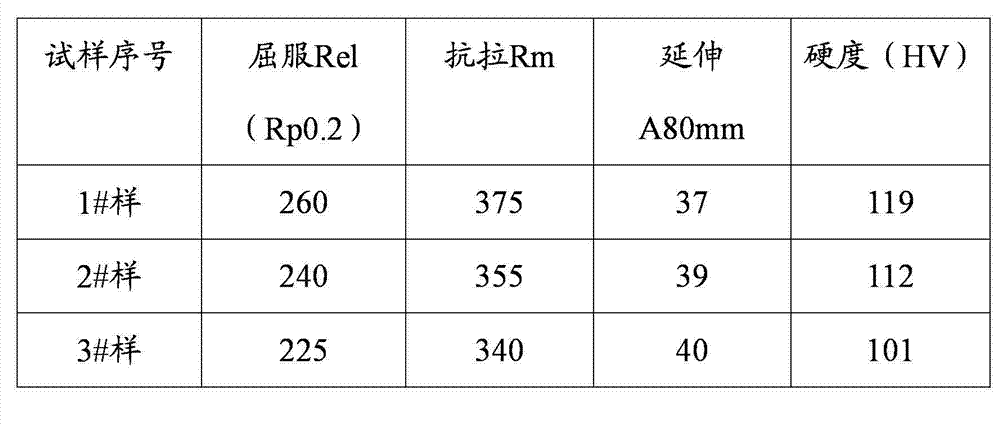

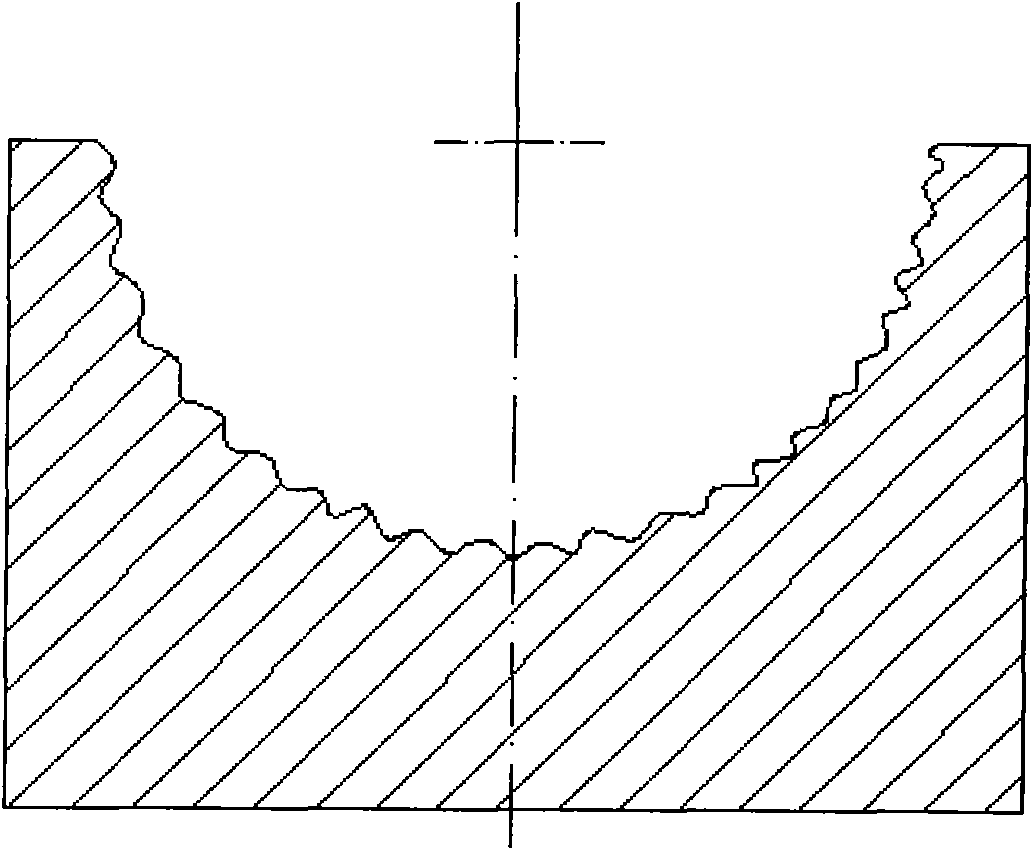

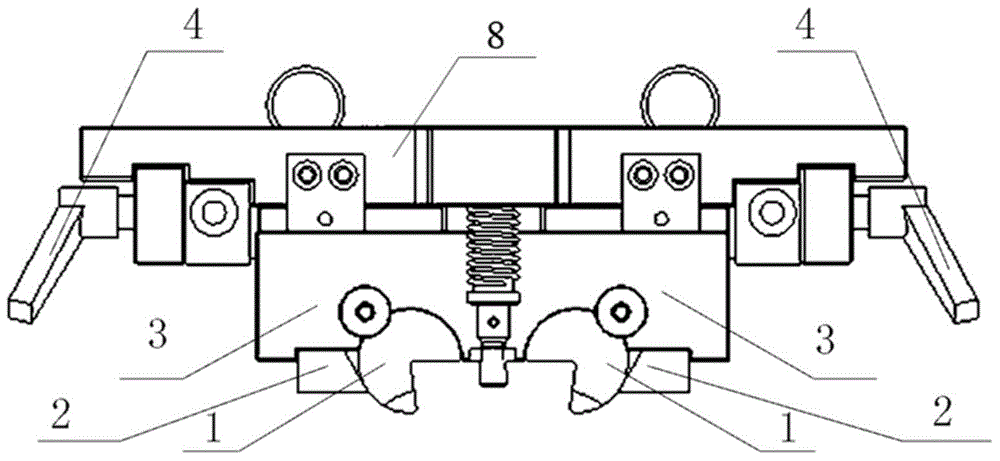

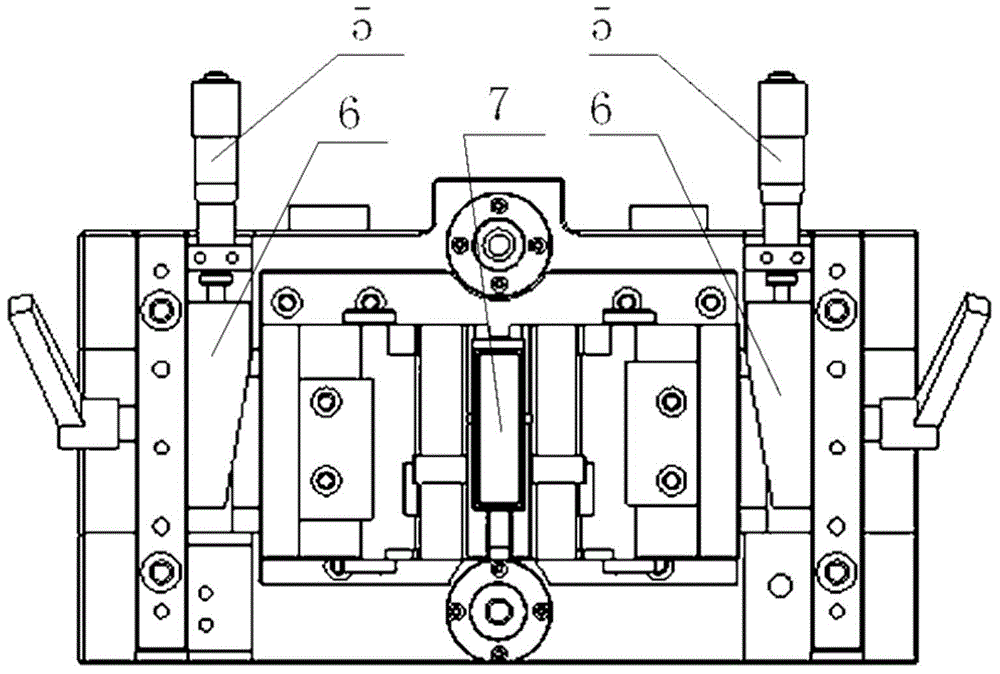

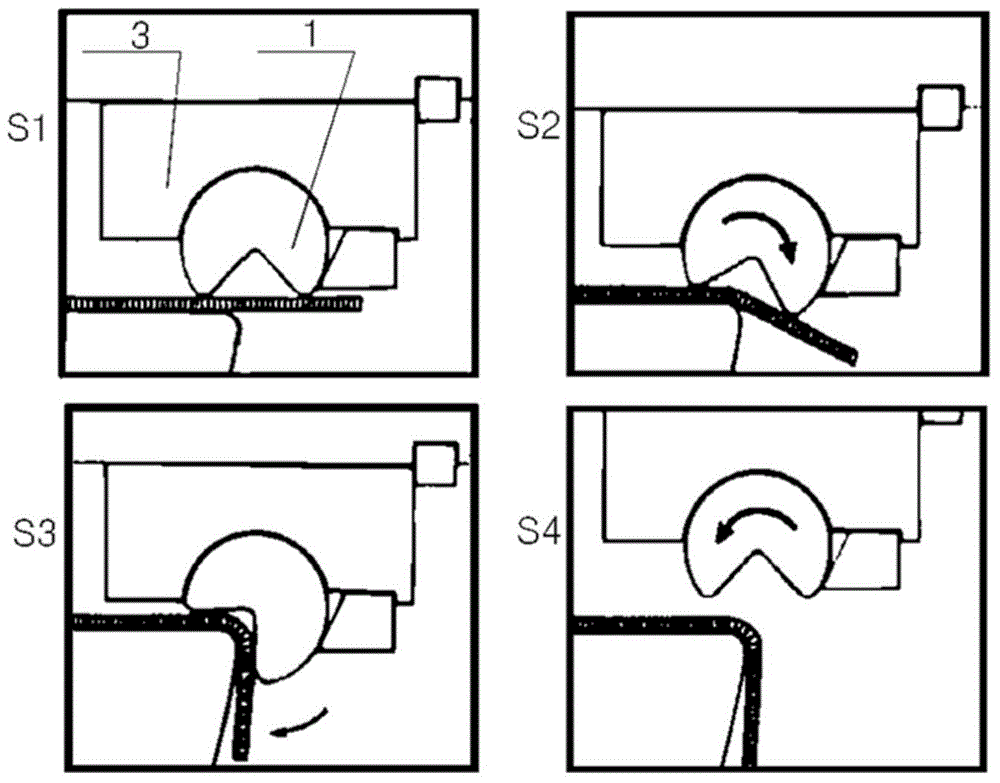

Device for bending metal plate by any angle

The invention relates to a device for bending a metal plate by any angle. The device comprises a rack and a bending mechanism arranged on the rack and further comprises a bending angle adjusting mechanism. The bending mechanism comprises two symmetrically-arranged tool aprons. Each tool apron is provided with a hob. The bending angle adjusting mechanism is connected with the tool aprons and the hobs. After the tool aprons are fixed by the bending angle adjusting mechanism, the hobs are driven to move vertically to conduct metal plate bending, and the bending angle and width can be adjusted. Compared with the prior art, the device has the beneficial effects of being convenient to operate, high in production efficiency, low in cost and the like.

Owner:SHANGHAI XINYU ZHENCHENG ELECTRIC CONTROL TECH

Wide steel strip for paper cutting blade and manufacturing method thereof

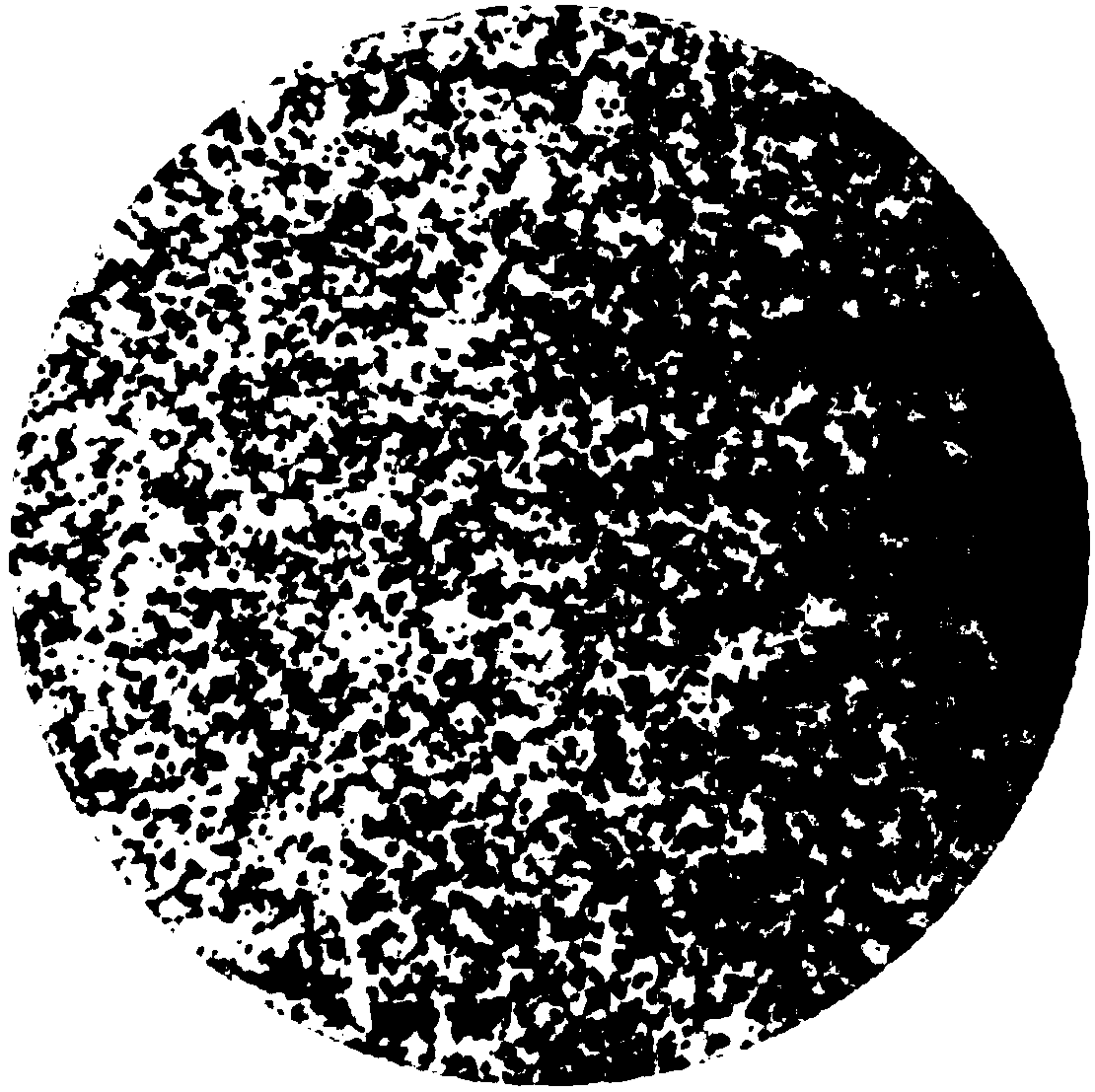

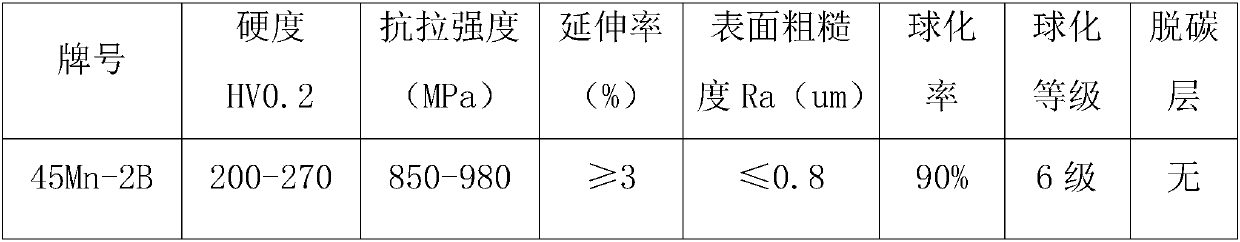

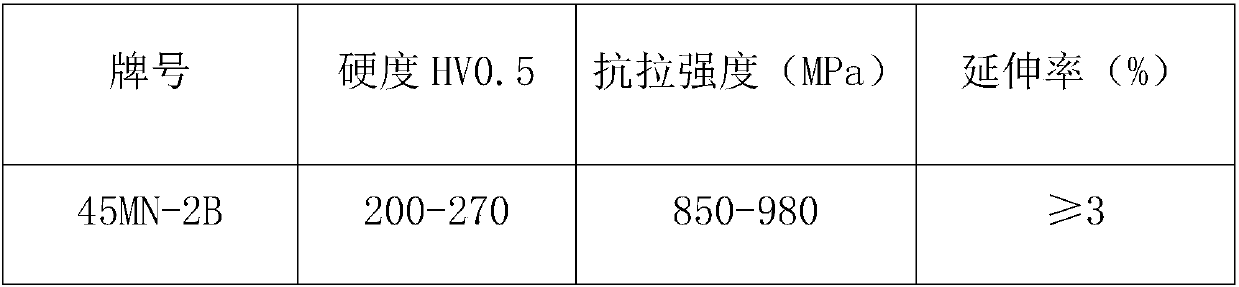

The invention provides a wide steel strip for a paper cutting blade. The wide steel strip is characterized in that the content of the chemical components of the steel comprises, by weight, 0.43%-0.47%of C, 0.17%-0.28% of Si, 0.7%-1.0% of Mn, 0-0.035% of P, 0-0.035% of S, 0.15%-0.3% of Cr, and the balance Fe; and the thickness of the wide steel strip 0.45-1.42mm, the width is 23-35 mm. According to the wide steel strip for the paper cutting blade, through repeated testing and trial, requirements of the steel for the paper cutting blade for the strength, the hardness, the size precision, the straightness and the quality requirement of the spheroidized structure can be completely met, and the wide steel strip has been favored by customers at present; and due to the fact that the developmentprospect of the cold-rolled wide steel strip for the paper cutting blade is very wide, the wide steel strip has great popularization and application values and is quite wide in prospect.

Owner:浙江龙盛薄板有限公司

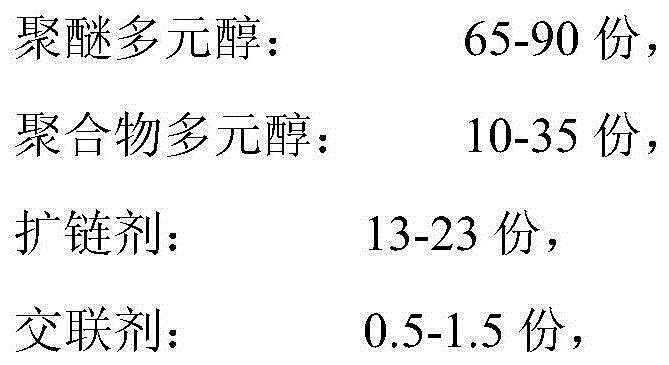

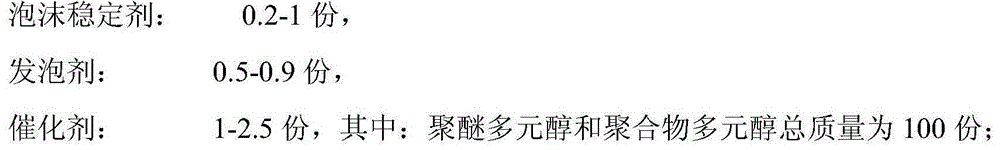

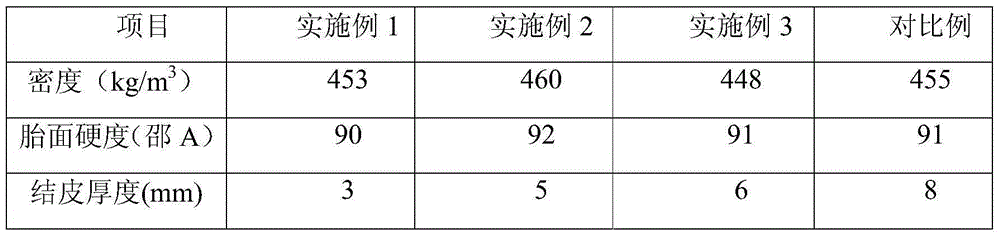

Environment-friendly polyurethane foaming mixed material for tyre and preparation method thereof

The invention specifically relates to an environment-friendly polyurethane foaming mixed material for a tyre and a preparation method thereof, belonging to the technical field of polyurethane. The mixed material is prepared by mixing a component A and a component B according to a mass ratio of 100: 85-105. The component A is prepared from polyether polyol, polymer polyol, a chain extender, a cross-linking agent, a bubble stabilizing agent, a foaming agent and a catalyst; and the component B is a polyester polyol modified isocyanate component and is prepared from polyester polyol, isocyanate and a storage stabilizing agent. Compared with the prior art, the invention has the following advantages: the foaming agent is water, so environmental protection is realized, cost for a physical foaming agent is saved, and preparation cost is greatly reduced. The environment-friendly polyurethane foamed tyre prepared in the invention has good skinning performance and a shiny surface while meeting the requirement of hardness. The mixed material can be used for production of normally foamed tyres and is an ideal substitute material for tyre production. The invention also provides a preparation method for the mixed material. The preparation method is reasonable in process.

Owner:SHANDONG INOV POLYURETHANE

Synthesis method of peelable water-based polyurethane resin for car cover

The invention discloses a synthesis method of peelable water-based polyurethane resin for a car cover. The synthesis method comprises the following steps: firstly, adding polytetramethylene ether glycol and polyether-modified organosilicone into a reaction container, performing vacuum dewatering, introducing nitrogen, dropwise adding diisocyanate into the reaction container, and reacting to obtain a prepolymer I; cooling the prepolymer I to 60 DEG C or below, adding dried polyhydroxycarboxylic acid into the reaction container, then dropwise adding dihydric alcohol into the reaction container, and reacting to obtain a hydrophilic group-containing prepolymer II; cooling the prepolymer II to 45 DEG C, dropwise adding diamine into the reaction container, and reacting to obtain a prepolymer III; and adding organic amine into the prepolymer III, neutralizing to form salt, and then adding diamine diluted with deionized water, stirring for 30-60 min, and emulsifying to obtain the peelable water-based polyurethane resin for the car cover, having the solid content of 30-45%. The peelable water-based polyurethane resin for the car cover, prepared by the synthesis method provided by the invention, improves the water resistance and the aging resistance of the car cover on the premise of easy peeling.

Owner:TONGGUANG JIANGSU INFORMATION TECH CO LTD

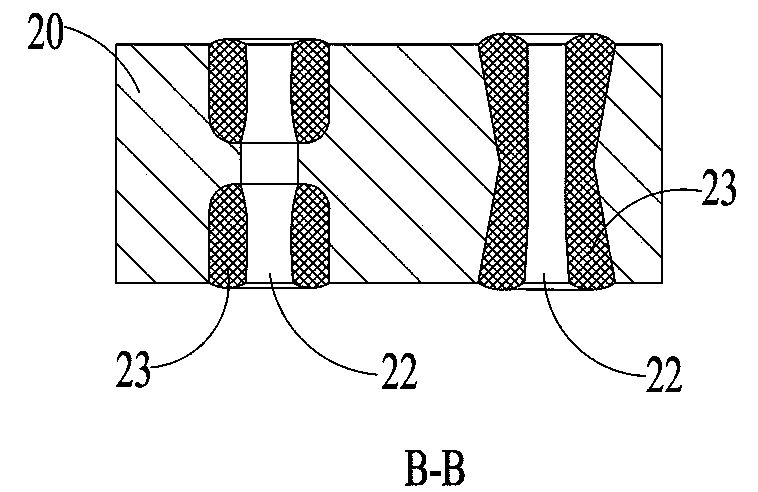

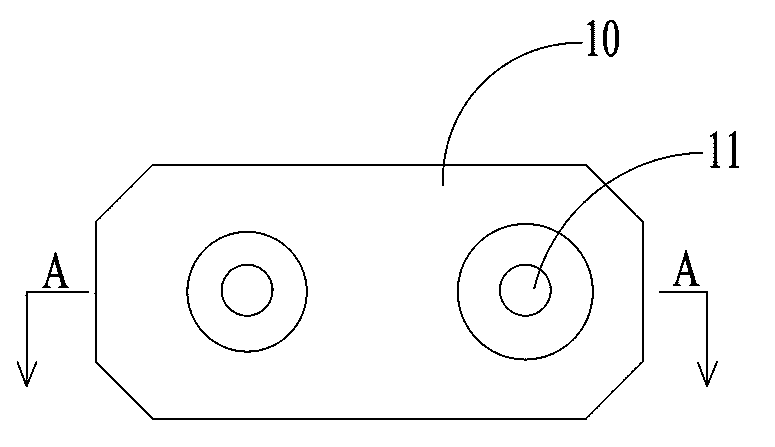

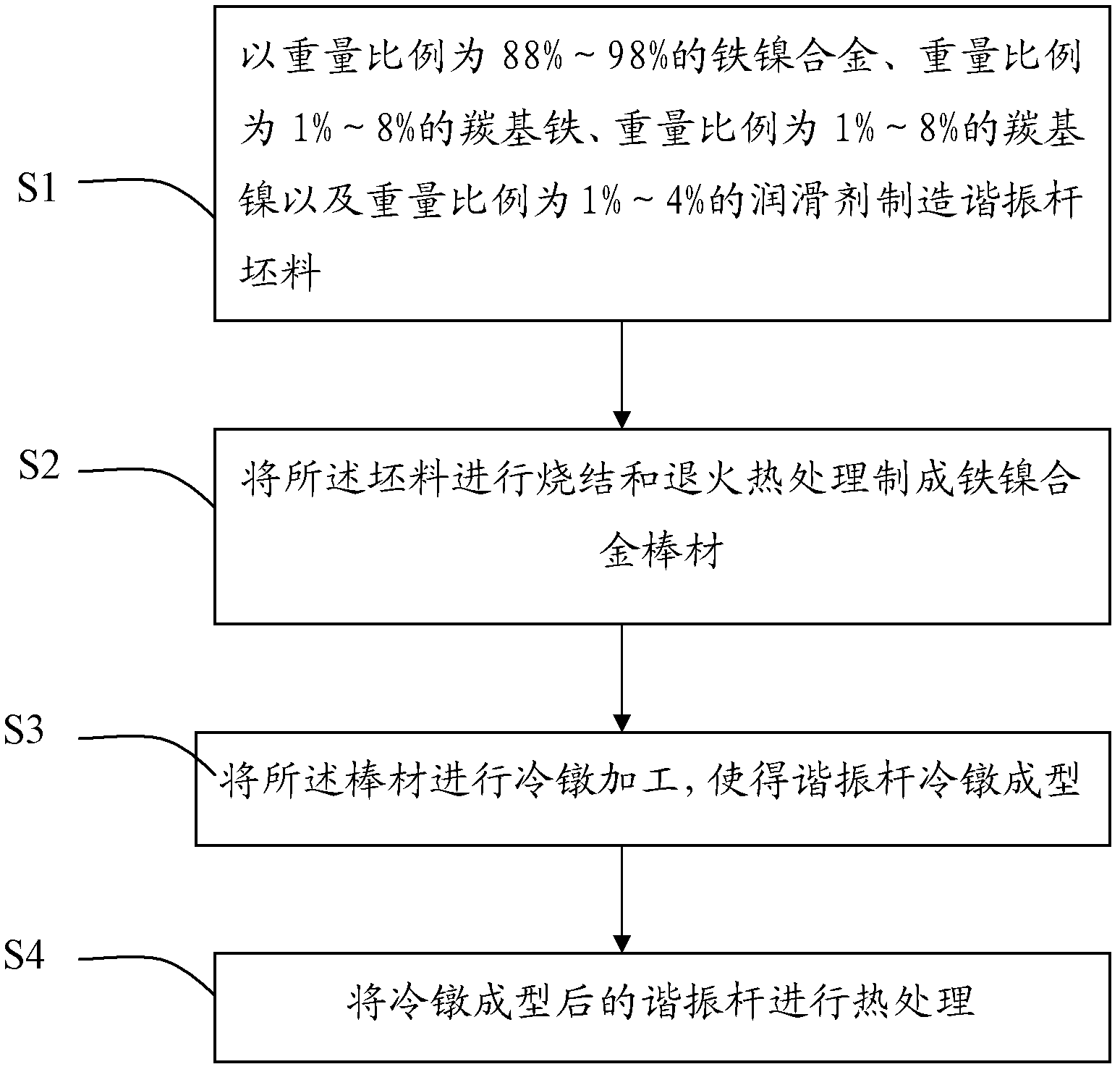

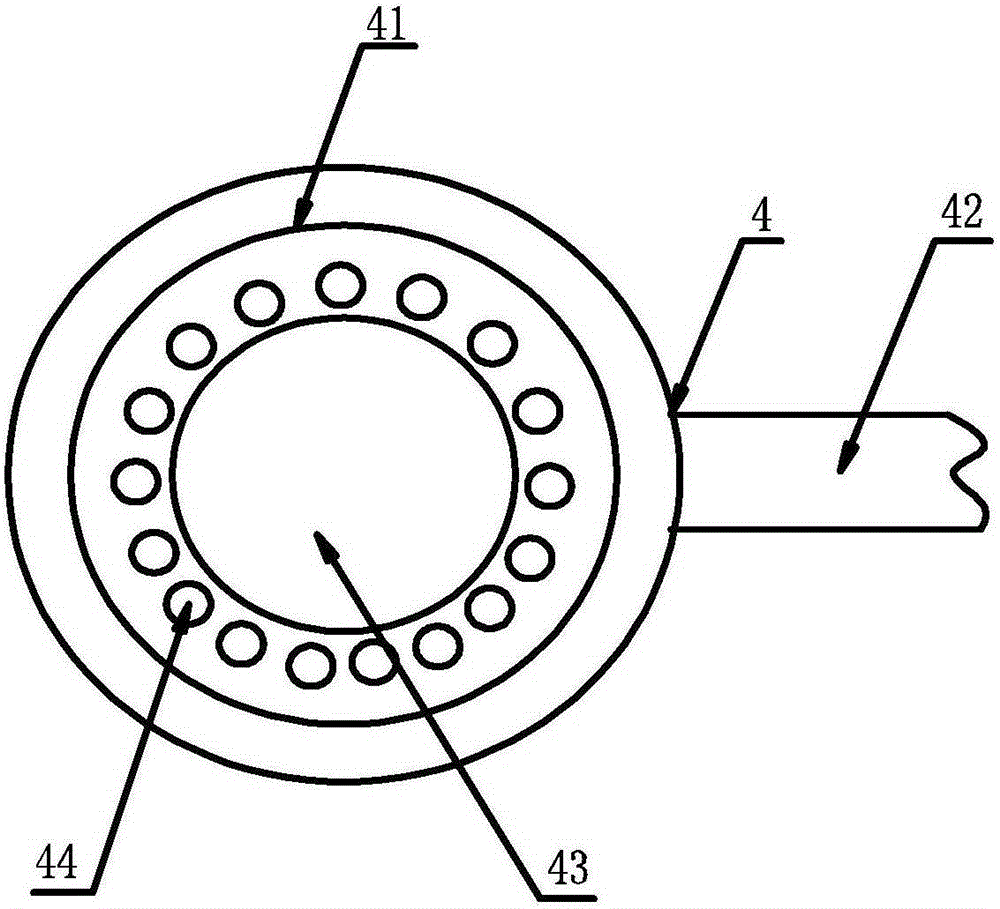

Resonance rod, cavity filter and method for manufacturing resonance rod

InactiveCN102810715AMeet the hardnessFulfil requirementsResonatorsHigh volume manufacturingIron powder

The invention provides a method for manufacturing a resonance rod. The method comprises the steps of: manufacturing a resonance rod blank by using the following accessories in percentage by weight: 88%-98% of water atomization iron-nickel alloy powder, 1%-8% of iron carbonyl powder, 1%-8% of nickel carbonyl powder and lubricant in an amount which is 1%-4% of the total weight of iron-nickel alloy, carbonyl iron and nickel carbonyl; performing continuous sintering and follow-up heat treatment for a blank so as to manufacture an iron-nickel alloy bar by the blank; performing cold heading processing for the bar; and performing heat treatment for the resonance rod after cold heading forming. The resonance rod manufactured by the method has high expansion coefficients and drawing coefficients, and is suitable to be arranged in a cavity filter widely. The method solves the problems that the resonance rod in the prior art is low in processing efficiency and wastes a great quantity of materials, so that the resonance rod can be produced and processed in batches.

Owner:ANHUI TATFOOK TECH CO LTD

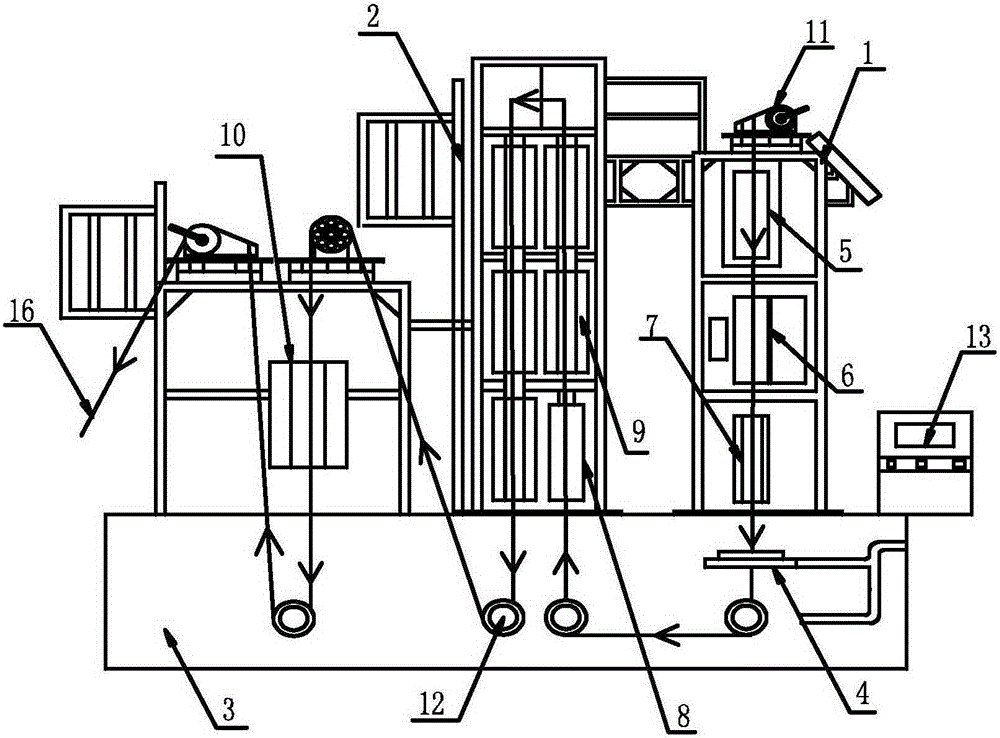

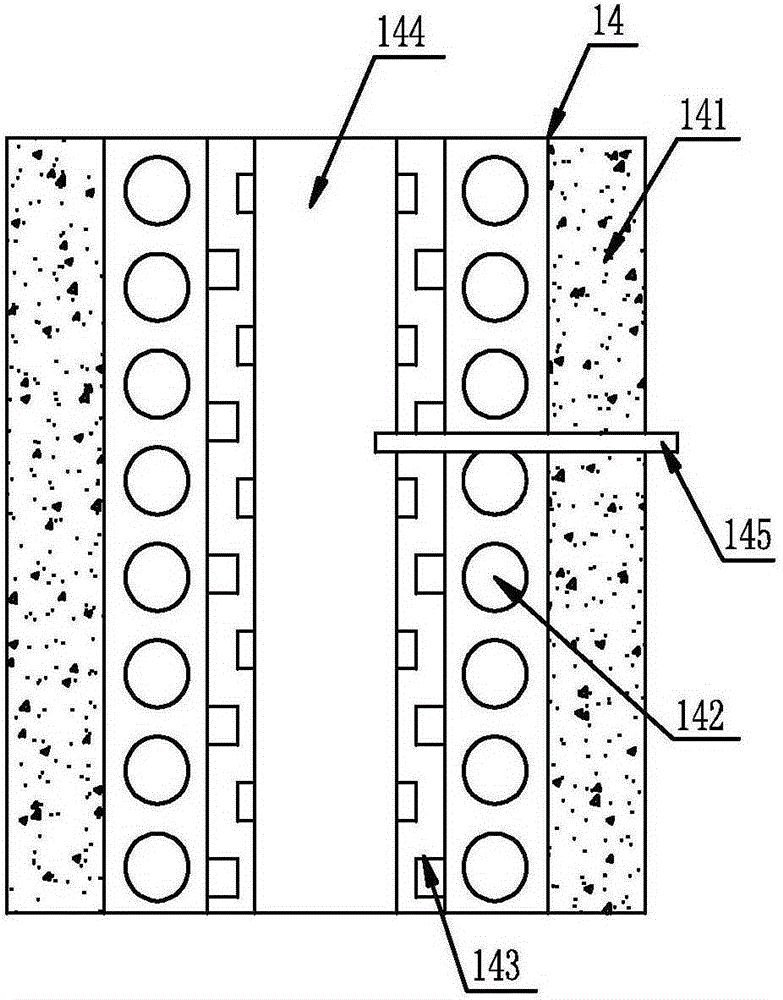

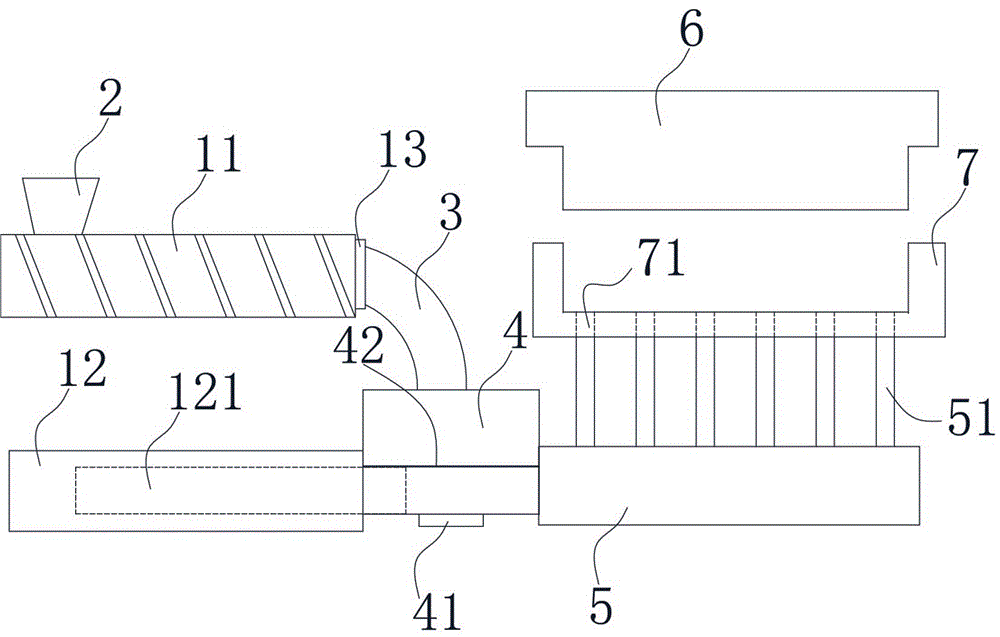

Heat treatment device for round-link chain and application method thereof

ActiveCN105349757AHigh degree of integrationImprove work efficiencyFurnace typesHeat treatment furnacesHardnessLath

The invention discloses a heat treatment device for a round-link chain and an application method thereof. The device comprises a quenching part and a tempering part which are sequentially arranged, wherein first cooling parts are arranged at the quenching part and the tempering part; the quenching part is provided with a quenching temperature regulating box; the tempering part is sequentially provided with an uniform-temperature tempering heating box, at least one tempering temperature regulating box and a differential-temperature tempering heating box; the quenching temperature regulating box is provided with a second cooling part. The device has the characteristics of being high in integration degree and high in working efficiency; after the round-link chain is quenched, an uniform and small low-carbon lath martensite structure can be obtained; the quenching quality is high; the second cooling part and the first cooling parts are correspondingly connected to a cooling source, so that the cooling quality can be improved, and the requirements of each part of the round-link chain on hardness and toughness can be met.

Owner:SHANDONG LUNAN GRP ENERGY EQUIP MFG

High-strength impact-resistance type steel used for shelf beam and welding technology thereof

InactiveCN104762558ALow wear resistanceGuaranteed flexibilitySuperimposed coating processElectroplatingImpurity

The invention discloses a high-strength impact-resistance type steel used for shelf beam, which comprises the following chemical components by weight percentage: 0.13-0.28% of C, 0.20-0.30% of Si, 0.20-0.46% of Mn, 0.85-0.95% of Cr, 0.28-0.32% of Ti, 0.16-0.22% of Mo, 0.24-0.36% of Nb, 0.05-0.07% of Cu, 0.18-0.36% of V, 0.59-0.79% of Al, 0.25-0.32% of rare earth trace element and the balance of Fe and impurity; the rare earth trace element comprises the following chemical components by mass percentage: 2-4% of Nd, 4-8% of Ce, 3-5% of Er, 2-6% of Pr, 1-4% of Pm, 0-5% of Dy, and the balance of La; the total content of impurity is less than or equal to 0.2, wherein, P is less than or equal to 0.005%, S is less than or equal to 0.007%, H is less than or equal to 0.004%, N is less than or equal to 0.006%, and O is less than or equal to 45ppm. The steel processing technology comprises the following steps: feeding, electroplating, drawing, annealing, insulating, pickling, drying and warehousing. The invention also designs a processing technology of the high-strength impact-resistance type steel used for shelf beam. The high-strength impact-resistance type steel used for shelf beam can obviously increase the wear-resistant compact-resistant capability of the steel, and has the advantages of simple operation technology, energy saving and environmental protection.

Owner:SUZHOU KESHENG STORAGE & LOGISTICS EQUIP

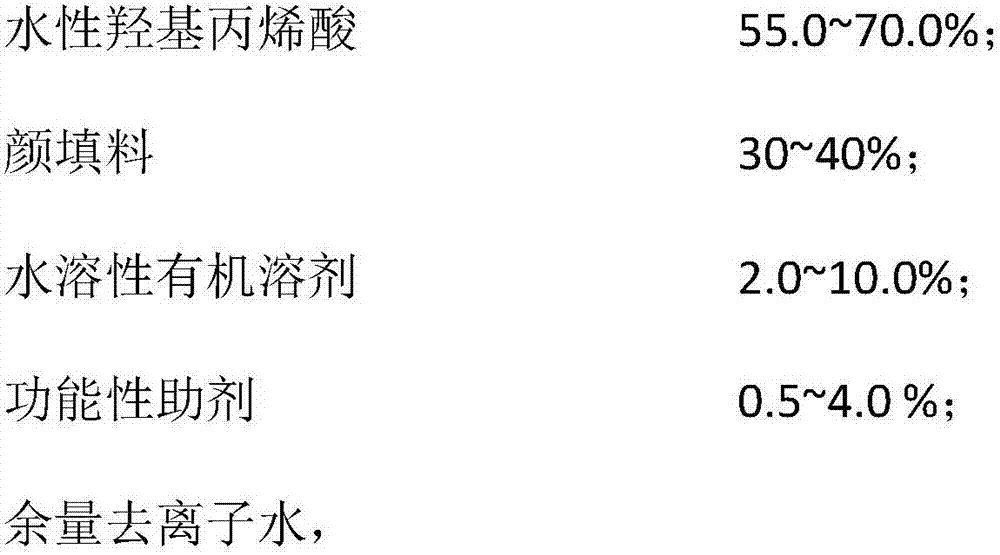

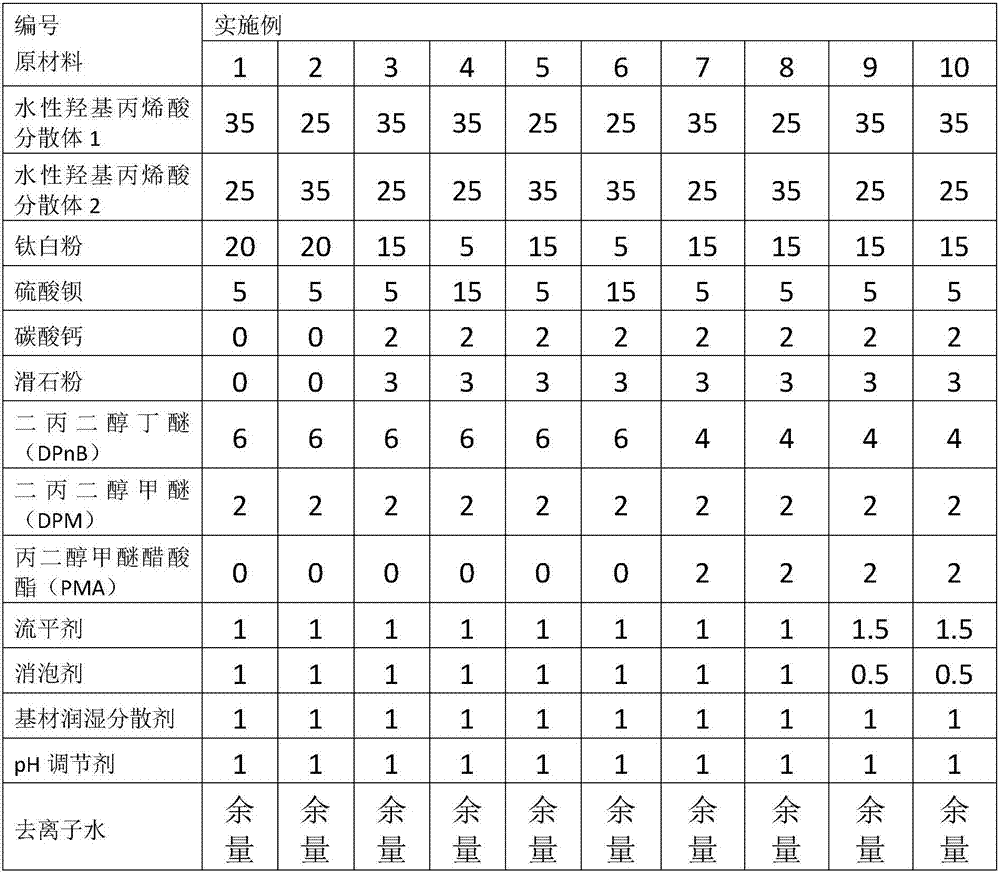

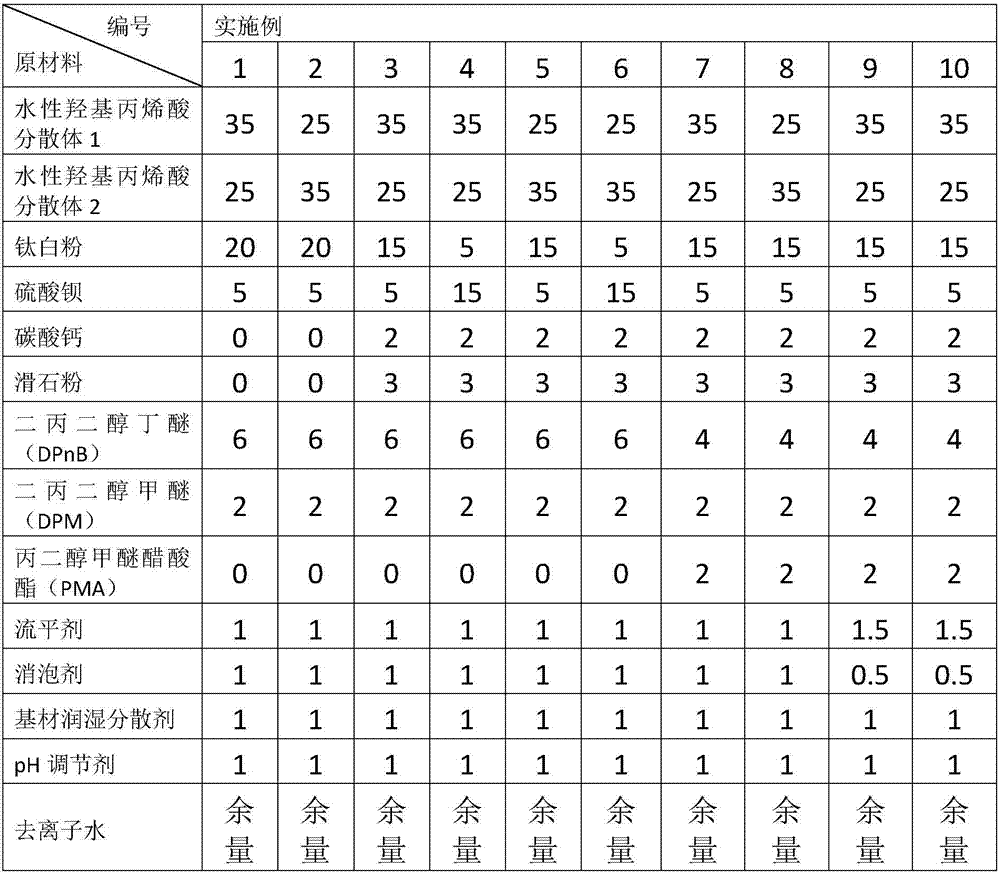

High appearance effect waterborne topcoat paint composition for bus body and preparation method thereof

InactiveCN107142000AMeet the colorful appearance requirementsGood lookingPolyurea/polyurethane coatingsOrganic solventWeather resistance

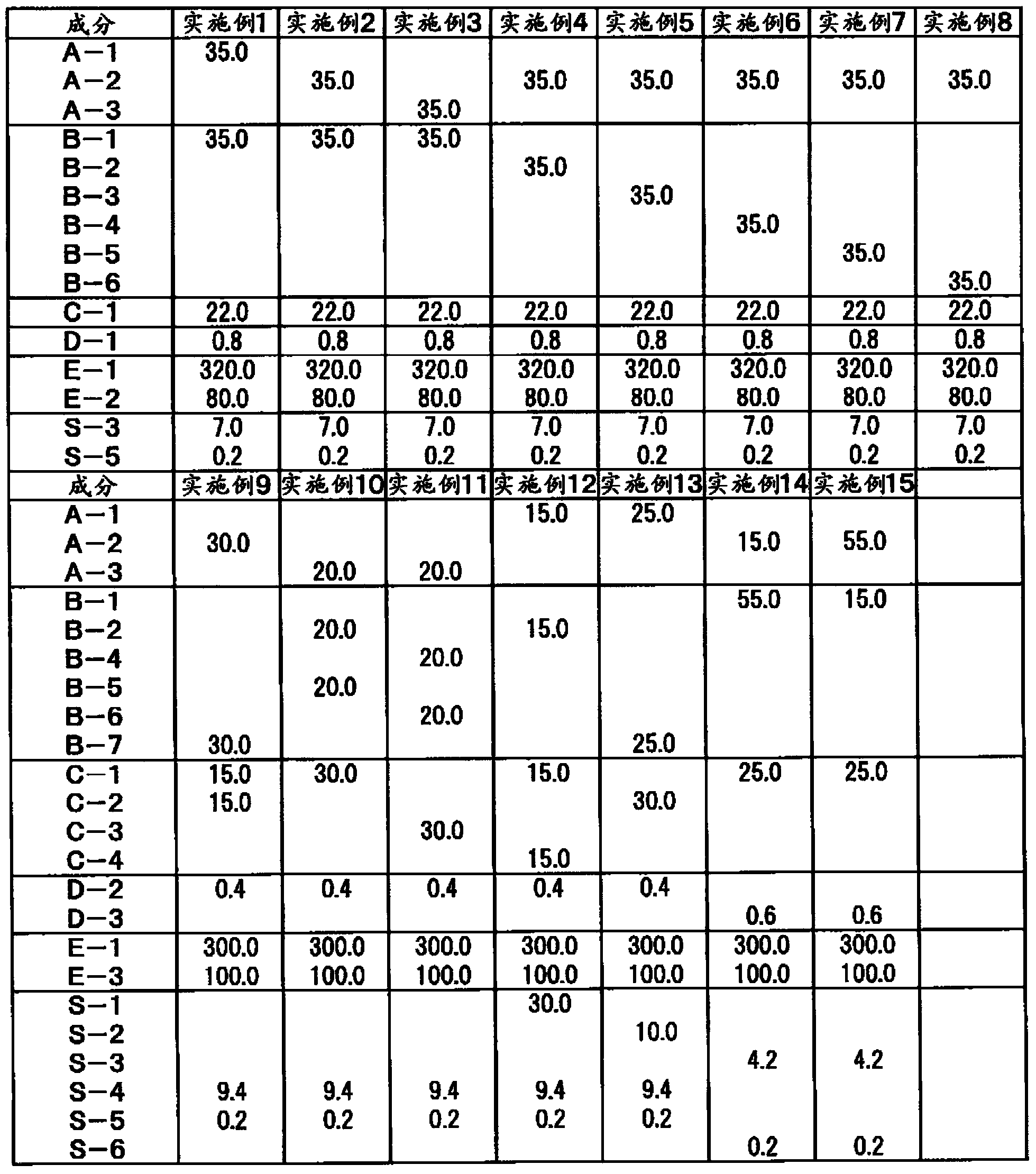

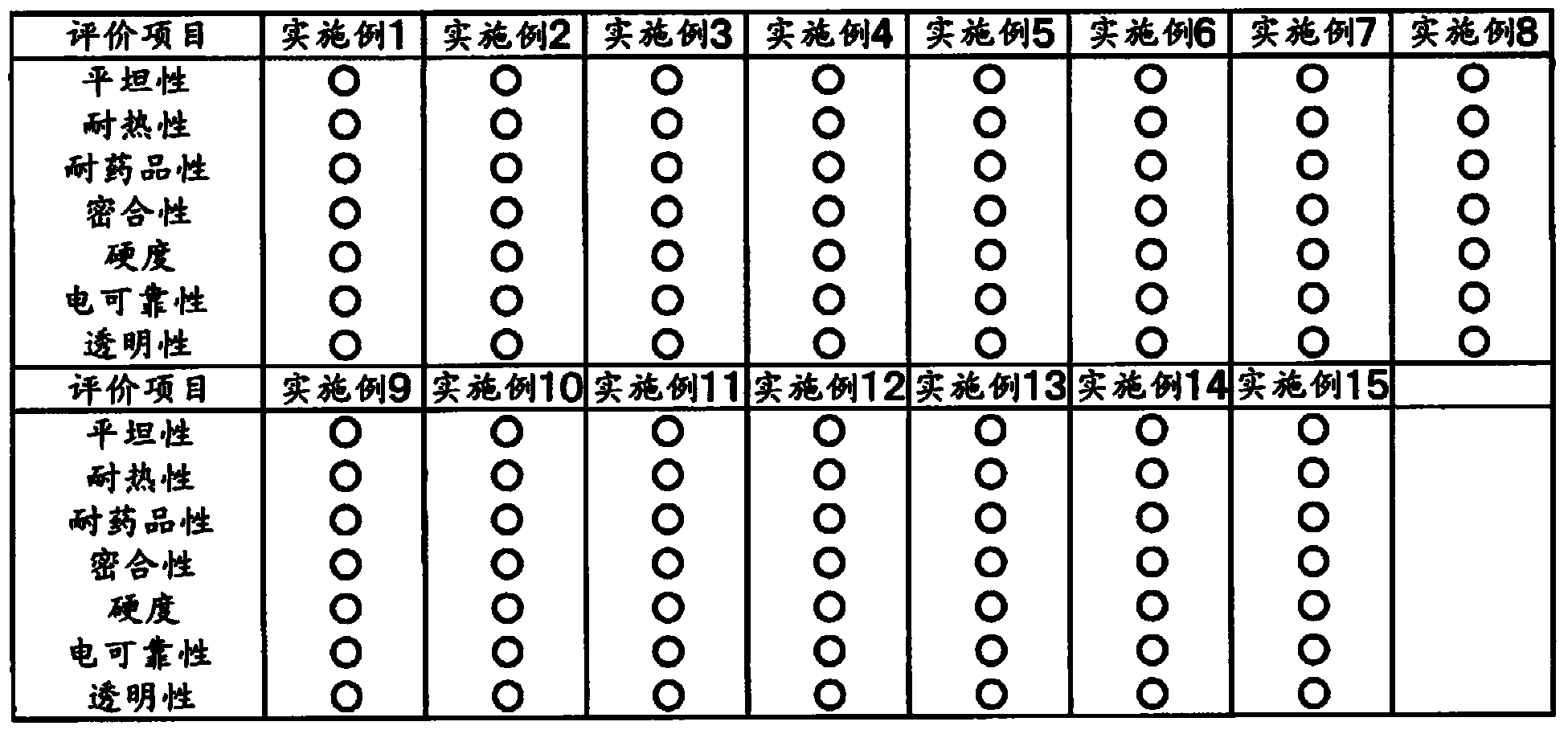

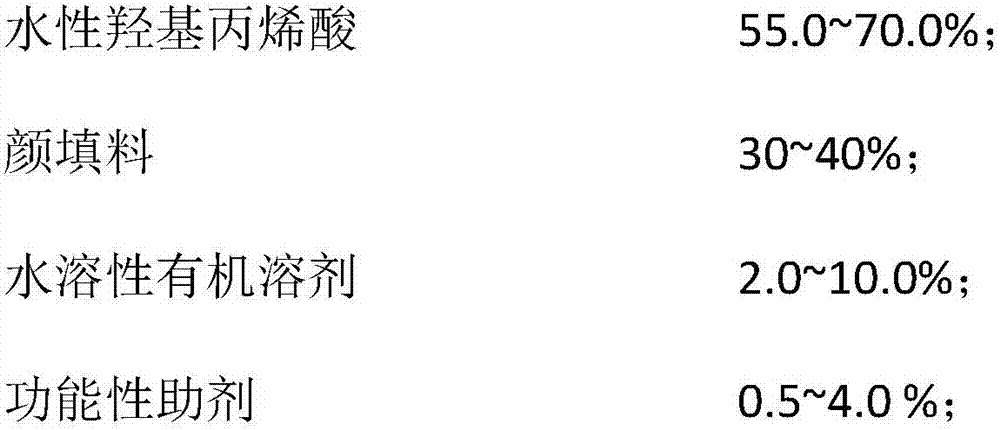

The invention relates to a high appearance effect waterborne topcoat paint composition for a bus body. The waterborne topcoat paint composition comprises a component A and a component B, wherein the component A includes the following ingredients by weight percentage: 55.0-70.0% of waterborne hydroxy acrylic acid; 30-40% of pigment and filler; 2.0-10.0% of a water-soluble organic solvent; 0.5-4.0% of functional additives; and the balance deionized water, and the component B includes the following ingredients by weight percentage: 60.0-80.0% of a waterborne isocyanate curing agent; and 20.0-40.0% of a water-soluble organic solvent. The weight percent of the component A is 75-90.0%, and the weight percent of the component B is 25%-10.0%. The paint composition provided by the invention has very good appearance effect and high gloss, and also meets the hardness, impact, weather resistance and other performance requirements and quick and defect-free construction requirements.

Owner:HAOLISEN COATING SHANGHAI

Hot-dip galvanized steel for automobile wheel cover and production method thereof

InactiveCN109252093AMeet the hardnessFulfil requirementsHot-dipping/immersion processesSteelmakingChemical composition

Owner:BEIJING SHOUGANG COLD ROLLED SHEET

Wood fiber extruding injection forming process and device

InactiveCN106827158AAchieve productionAvoid soft surfaceDomestic articlesFlat articlesWood fibreHardness

The invention discloses a wood fiber extruding injection forming process and device. The process comprises the steps of stirring, feeding, extruding, buffer stock bin operation, plunger feeding, die pressing and die stripping. In the process, the related wood fiber extruding injection forming device comprises a stirring unit, a feeding and extruding unit and a forming unit. The feeding and extruding unit comprises an extruder and a plunger type cylinder. The forming unit comprises a distribution unit, an upper die and a lower die, wherein the upper die and the lower die can be separated. By adopting the method and cooperatively using the extruding injection forming device, the quality defects such as surface softness and insufficient density due to the fact that local corners of products are not filled densely because of the low random stacking density and poor liquidity of wood fibers are effectively avoided, so that the hardness is reached while the density is uniform, and production of large plates can be achieved.

Owner:NINGBO JIANGBEI RUICHEN HANDICRAFT DESIGN

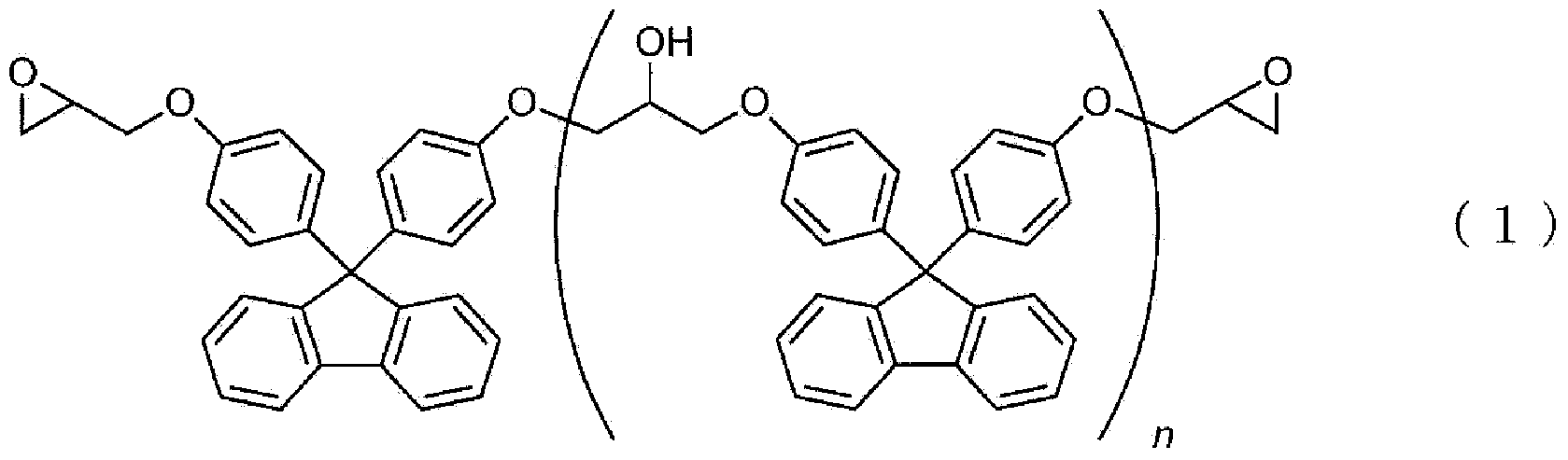

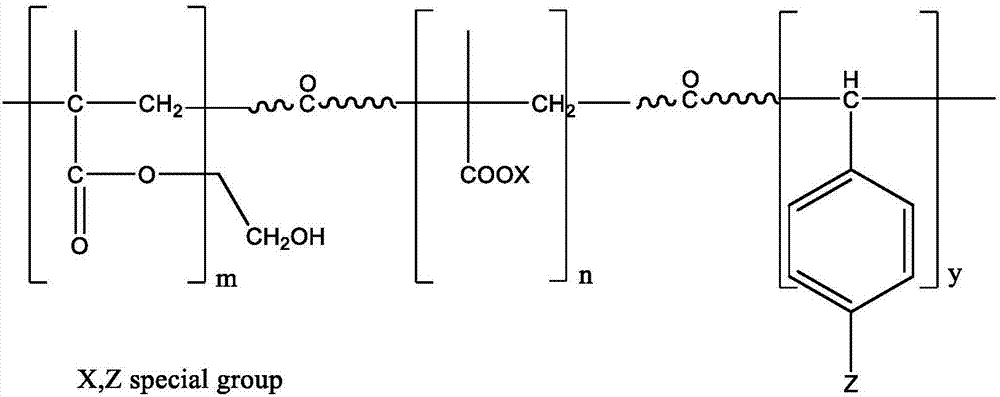

Thermosetting composition, curing film and filter

The invention relates to a kind of thermosetting composition, a curing film and a filter. The invention provides a kind of thermosetting composition and the curing film thereof that can be used as filter protection film with flatness, heat resistance, chemical resistance, adhesiveness, hardness, electrical reliability and transparency. A kind of thermosetting composition is characterized in containing epoxy compound (A), epoxy compound (B) and a curing agent (C), wherein the epoxy compound (A) is expressed by formula (1), and the avenue value of n is 0.2-1.0; the epoxy compound (B) is obtained through polymerizing or copolymerizing more than 1 polymerizable unsaturated compound that takes glycidyl methacrylate as an essential ingredient. When epoxy equivalent is smaller than 200g / eq and number-average molecular weight less than 10 thousand, the curing agent (C) is selected from polycarboxylic acid, anhydride of polycarboxylic acid and thermal decomposition ester of polycarboxylic acid. The above thermosetting composition is cured to obtain the curing film.

Owner:NIPPON STEEL CHEMICALL &MATERIAL CO LTD

Water-soluble quenching medium

The invention provides a water-soluble quenching medium. The water-soluble quenching medium comprises the following components by mass percent: 6-8 percent of sodium hydroxide, 3-4 percent of alum, 1-2 percent of starch, 1-2 percent of potassium chloride, 1-2 percent of a foaming agent, 1-2 percent of a foam booster, and the balance of water. The water-soluble quenching medium is low in cost, good in environment-friendly performance, and convenient to operate. The water-soluble quenching medium is used for quenching hot die steels, and the obtained hot die steels can meet the performance requirements in rigidity, metallographic structure, tensile strength, yield strength, deflection, thermal cracking resistance, wear resistance and the like.

Owner:WUXI YANGGONG MACHINERY MFG

Steel tube and production technique thereof

InactiveCN102071364AHigh strengthAccelerated corrosionProcess efficiency improvementElectric furnaceManganeseNitrogen

The invention relates to a steel tube which is characterized by comprising Fe, C, Mn, P, S, Si, Ni, Cr, N and Ti, wherein in terms of the percentage by mass of Fe, the contents of C, Mn, P, S, Si, Ni, Cr, N and Ti are as follows: 0.03%<=C<=0.12%, 0.5%<=Mn<=1.6%, 0.01%<=P<=0.05%, 0.005%<=S<=0.04%, 0.4%<=Si<=1.2%, 0.2%<=Ni<=0.6%, 22%<=Cr<=26%, 0.05%<=N<=0.25% and 0.02%<=Ti<=0.06%. In the steel tube, manganese and nitrogen are used instead of part of nickel to lower the production cost, and the steel tube has the advantages of high strength and favorable corrosion resistance; the contents of the chromium and carbon in the steel tube are properly increased at the same time, thereby not only meeting the requirements for hardness and wearability, but also giving consideration to certain corrosion resistance; and since the titanium is added to the steel tube, intercrystalline corrosion can be properly prevented. Based on the advantages, the steel tube can be widely used as a high-temperature component, a fastener or the like.

Owner:苏州奕欣特钢管业有限公司

Transfer film for decoration

ActiveCN104995028AMeet the hardnessSatisfy tightnessDecorative surface effectsSynthetic resin layered productsPolytetrafluoroethyleneAcrylic acid

Provided is a transfer film for decoration, which exhibits satisfactory molding performance during injection molding, while having excellent surface protection performance. A transfer film for decoration according to the present invention is obtained by sequentially laminating, on the surface of a supporting film, a mold release layer (2), a hard coat layer (3), a primer layer (4), a decorative layer (5) and a bonding layer (6). The hard coat layer (3) is formed of a tack-free ultraviolet curable composition which contains at least an acrylic acrylate resin that contains a hydroxyl group and has a weight average molecular weight of from 40,000 to 100,000 (inclusive), an ultraviolet initiator, silica particles having an average particle diameter of from 10 nm to 100 nm (inclusive), and a polytetrafluoroethylene powder having an average particle diameter of from 1 μm to 10 μm (inclusive). The primer layer (4) is formed of a two-package curable resin which contains at least an acrylic polyol resin, a polyisocyanate compound and a vinyl chloride-vinyl acetate copolymer resin containing a hydroxyl group.

Owner:TOPPAN PRINTING CO LTD

Water-based finish coating composition for appearance effect of bus body and its preparation method

InactiveCN107418414AMeet the colorful appearance requirementsGood lookingPolyurea/polyurethane coatingsEmulsion paintsWater basedOrganic solvent

The invention relates to a water-based finish coating composition for appearance effect of bus body, which comprises the A component and the B component, wherein the A component is prepared from, by weight percent, 55.0-70.0% of water-based hydroxy acrylic acid, 30-40% of pigment filler, 2.0-10.0% of water-soluble organic solvent, 0.5-4.0% of functional assistant, and allowance of deionized water. The B component is prepared from, by weight percent, 60.0-80.0% of water-based isocyanate curing agent, 20.0-40.0% of water-soluble organic solvent; according to the weight percent, the A component is 75-90.0%, and the B component is 25-10.0%. The coating composition is featured by very good appearance effect and high gloss; the water-based finish coating composition can meet performance requirements such as hardness, impact and weather fastness, and the construction requirement of rapid and no-mistake.

Owner:HAOLISEN COATING SHANGHAI

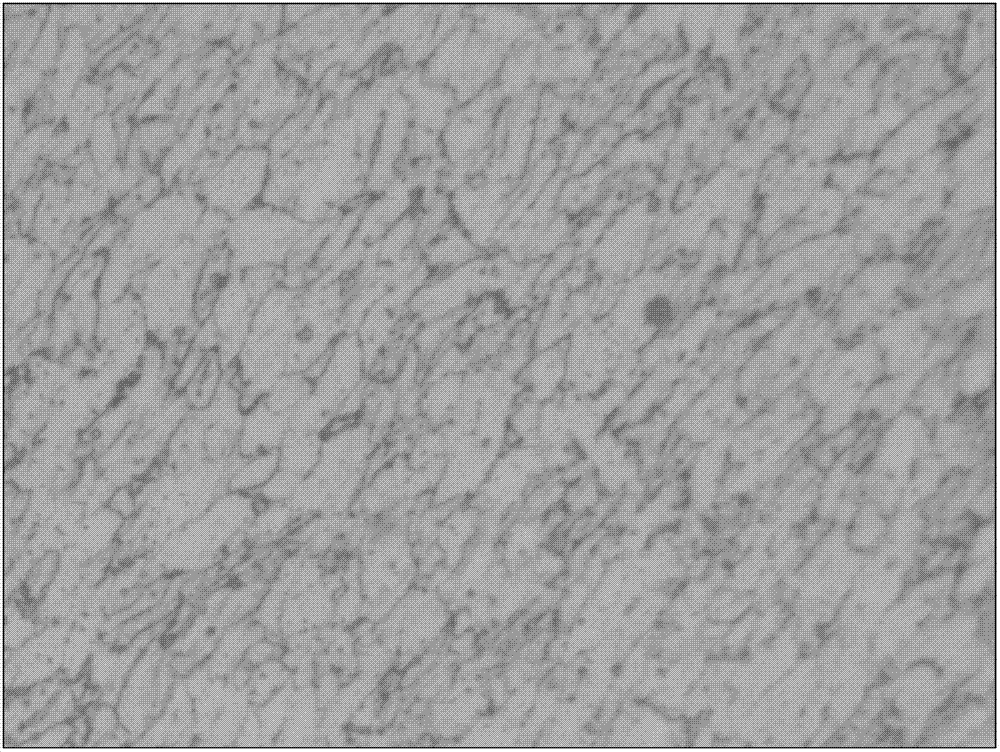

Carburizing and quenching heat treatment method

InactiveCN112593183AGuaranteed technical requirementsEnsure carburizing efficiencySolid state diffusion coatingHeat treatment process controlTemperingCarbon potential

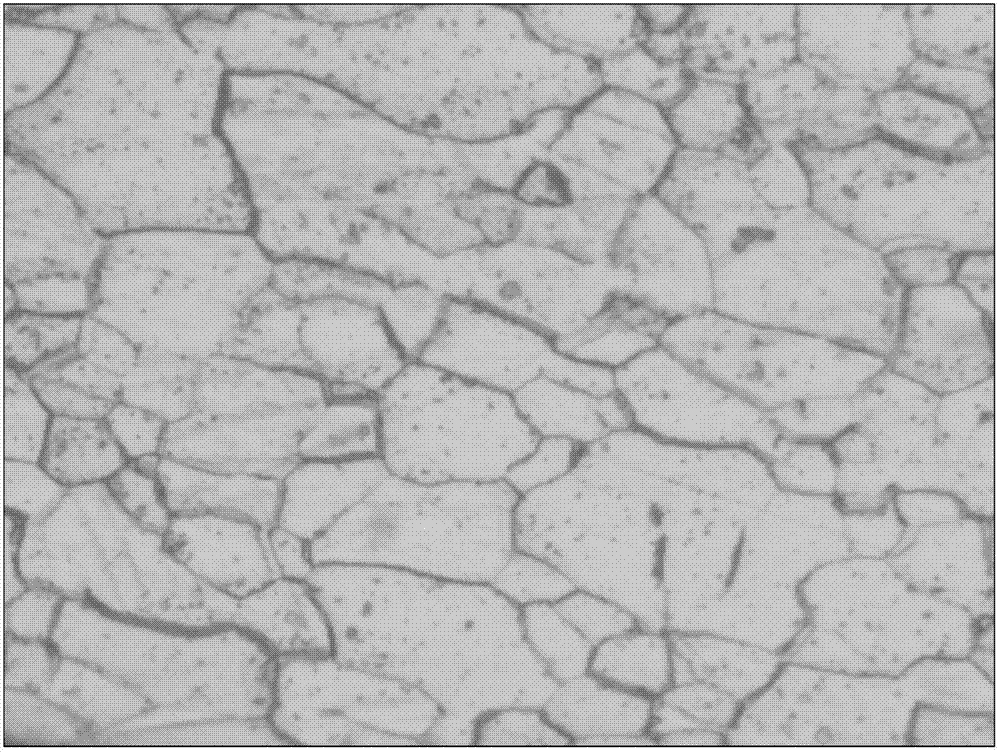

The invention discloses a carburizing and quenching heat treatment method which is applied to gas carburizing and quenching production normally required by common low-carbon steel and low-carbon alloysteel workpieces. The carburizing and quenching heat treatment method specifically comprises the following steps of S1, firstly, putting the workpieces into a carburizing furnace, and strong carburizing section treatment and diffusion section treatment are performed on the workpieces in the carburizing furnace, wherein the carburizing temperature of the strong carburizing section treatment is 915DEG C-925 DEG C, the carbon potential of the strong carburizing section treatment is 1.1%-1.2%, the carburization temperature of the diffusion section treatment is 905 DEG C-915 DEG C, the carbon potential of the diffusion section treatment is 0.8%-0.9%, and the carburizing heat preservation time ratio of the strong carburizing section treatment to the diffusion section treatment is 11: 9; S2, performing cooling and quenching along with the carburizing furnace; S3, performing quenching oil cooling; and S4, performing tempering. By means of the method, the hardness and the hardened layer depthof the low-carbon alloy steel workpieces are guaranteed, meanwhile, it is guaranteed that the refined metallographic structure meets the national standard, and the carburizing and quenching quality is stably improved.

Owner:JIANGSU JUYUAN ELECTRICAL

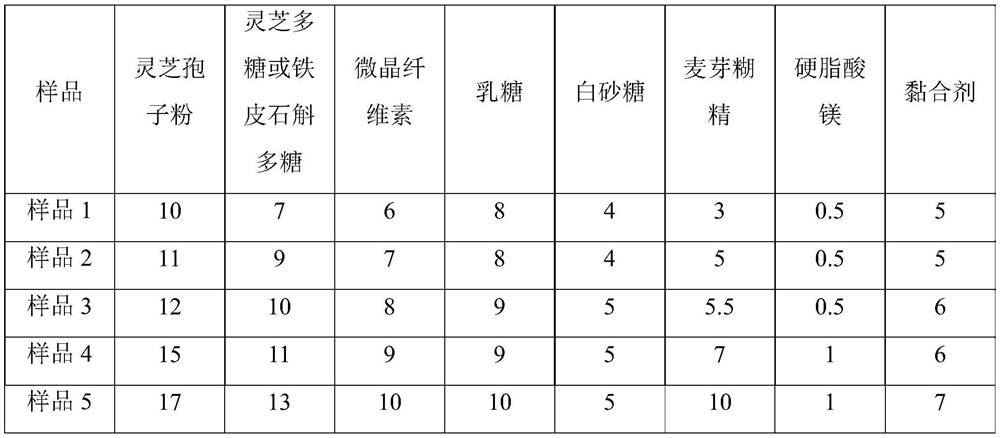

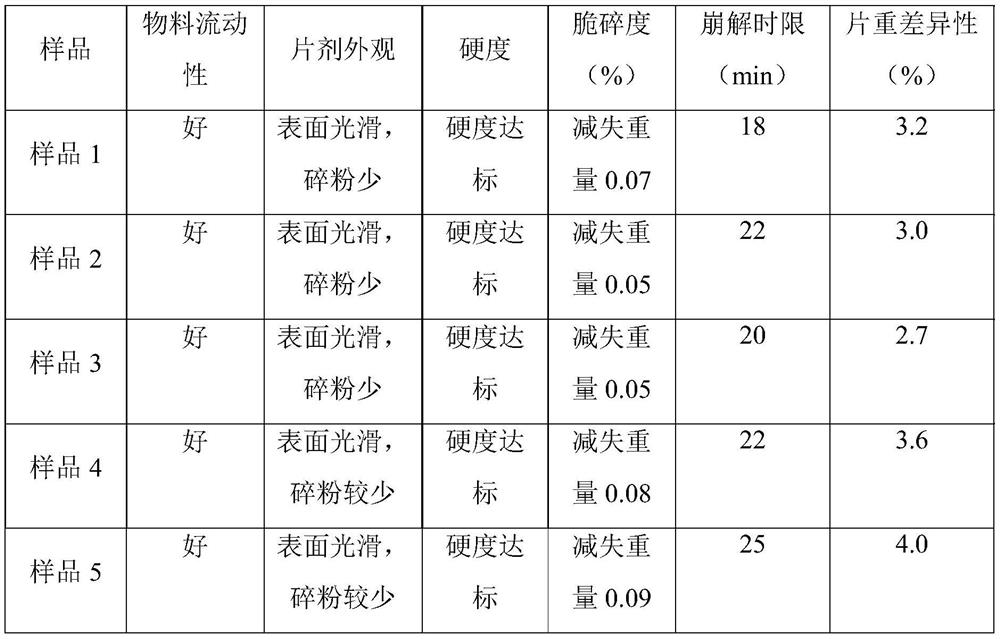

Ganoderma lucidum spore powder tablet and preparation method thereof

PendingCN113017081AImprove liquidityGood compressibilityFood ingredient as viscosity modification agentFood ingredient as anti-caking agentBiotechnologyMagnesium stearate

The invention discloses a ganoderma lucidum spore powder tablet and a preparation method thereof. The tablet comprises 10-17 parts of ganoderma lucidum spore powder, 7-13 parts of ganoderma lucidum polysaccharide or dendrobium officinale polysaccharide, 6-10 parts of microcrystalline cellulose, 8-10 parts of lactose, 4-5 parts of white granulated sugar, 3-10 parts of maltodextrin, 0.5-1 part of magnesium stearate and 5-7 parts of 50-60% ethanol solution or 15-20% glutinous rice flour slurry. The preparation method comprises the following steps: mixing part of the raw materials according to an equivalent incremental mixing principle, adding maltodextrin and an adhesive to prepare a soft material, performing granulating, performing drying, finishing granules, adding magnesium stearate, performing mixing, and performing tabletting. Through formula optimization and process optimization, the prepared ganoderma lucidum spore powder tablets are uniform in color, smooth and complete in surface, and good in hardness and friability, the obtained tablet products are good in quality consistency, the content of ganoderma lucidum spore powder in the products is high, and the sensory property and palatability of the tablets are improved.

Owner:CHONGQING CITY BIOLOGICAL TECH INST

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com