Wood fiber extruding injection forming process and device

An injection molding and wood fiber technology, which is used in wood processing appliances, pretreatment of molding materials, and manufacturing tools, etc., can solve problems such as low production efficiency, prolonged manufacturing cycle, and inability to obtain web boards.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

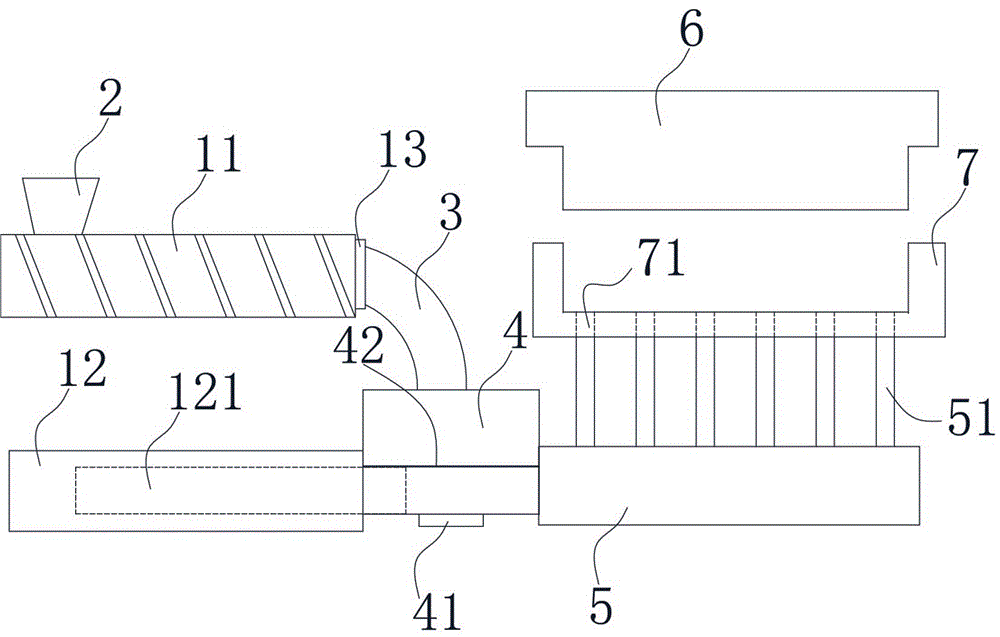

[0011] Embodiment 1: A wood fiber extrusion injection molding process, comprising the following steps: Step A Stirring: The wood fiber passes through the screw conveying mechanism, enters the agitator continuously and falls in a free fall shape, and the adhesive is drawn from the agitator by the glue spraying mechanism Spray on the left and right sides, mix in the mixer and output on the other side, by adjusting the ratio of the screw conveying speed to the glue spraying amount, the wood fiber sizing amount that meets the process requirements is 8, and the glue solid content is 20%; Step B Feeding: The wood fiber and glue mixture output from the mixer enters the feeding port directly below, the side wall of the feeding port is smooth, the upper end is connected with the outlet of the agitator, and the lower end is connected with the screw barrel feeding port of the extruder Connection; Step C Extrusion: The material falling into the screw barrel from the feeding port, through t...

Embodiment 2

[0012] Embodiment 2: A kind of wood fiber extrusion injection molding process, it is characterized in that, comprises the following steps: Step A stirs: Wood fiber enters agitator continuously through screw conveying mechanism and falls in the shape of free fall, and adhesive is produced by The glue spraying mechanism sprays out from the left and right sides, mixes in the mixer and outputs on the other side. By adjusting the ratio of the screw conveying speed to the glue spraying amount, the wood fiber sizing amount is 50% and the glue solid content is 50% according to the process requirements. 35%; Step B feeding: the wood fiber and glue mixture output from the mixer enters the feeding port directly below. The feeding port of the screw barrel is connected; step C extrusion: the material falling into the screw barrel from the feeding port, through the action of the screw inside the barrel, the material is pushed forward and mixed again, so that the combination of wood fiber and...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com