Low-alloy heat-resistant steel plate and manufacturing method thereof

A manufacturing method and low-alloy technology, applied in the field of alloy material manufacturing, can solve unrecorded problems and achieve the effects of corrosion resistance to a certain medium, stable structural properties, and good oxidation resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

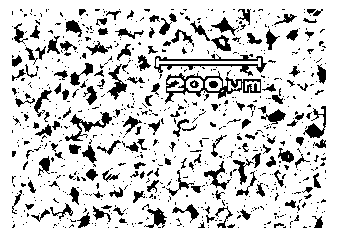

Image

Examples

Embodiment 1

[0031] Embodiment 1: The thickness of the produced steel plate is 80mm.

[0032] A method for manufacturing a low-alloy heat-resistant steel plate, the steps are as follows:

[0033] 1) Hot metal pretreatment step: Desulfurization by KR hot metal pretreatment, the sulfur content after treatment is 0.003%, the hot metal temperature is 1269°C, and the arsenic content is 0.002%.

[0034]2) Converter smelting and deoxidation alloying steps: Converter smelting: target carbon content at the end point is 0.08%, P: 0.006%, S: 0.005%, and the target tapping temperature is 1620°C; double slag blocking with slag blocking plug and slag blocking rod Tapping; ferromolybdenum is added to the converter along with scrap steel, and ferroalmanganese, lime, and fluorite are added to make top slag during the tapping process; ferrochrome, silicon-manganese alloy, ferroalmanganese, and ferro-vanadium are added in turn for alloying, and the time for blowing argon during tapping is 14 minutes.

[00...

Embodiment 2

[0042] Embodiment 2: The thickness of the produced steel plate is 10mm.

[0043] A method for manufacturing a low-alloy heat-resistant steel plate, the steps are as follows:

[0044] 1) Hot metal pretreatment step: Desulfurization by KR hot metal pretreatment, the sulfur content after treatment is 0.002%, the hot metal temperature is 1250°C, and the arsenic content is 0.001%.

[0045] 2) Converter smelting and deoxidation alloying steps: Converter smelting: the final carbon content is 0.08%, P: 0.006%, S: 0.005%, and the tapping temperature is 1620°C; the slag blocking plug and the slag blocking rod are used to tap double slag blocking ; Ferromolybdenum is added to the converter along with scrap steel, and ferroalmanganese, lime, and fluorite are added to make top slag during the tapping process; ferrochrome, silicon-manganese alloy, ferroalmanganese, and ferro-vanadium are added in turn for alloying, and argon blowing time is 15 minutes during the tapping process .

[0046]...

Embodiment 3

[0053] Embodiment 3: The thickness of the steel plate involved in this embodiment is 40 mm.

[0054] A method for manufacturing a low-alloy heat-resistant steel plate, the steps are as follows:

[0055] 1) Hot metal pretreatment step: Desulfurization by KR hot metal pretreatment, the sulfur content after treatment is 0.003%, the hot metal temperature is 1256°C, and the arsenic content is 0.001%.

[0056] 2) Converter smelting and deoxidation alloying steps: Converter smelting: the final carbon content is 0.08%, P: 0.006%, S: 0.005%, and the tapping temperature is 1625°C; the slag blocking plug and the slag blocking rod are used to tap the steel; Ferromolybdenum is added to the converter along with scrap steel, and ferroalmanganese, lime, and fluorite are added to make top slag during the tapping process; ferrochrome, silicon-manganese alloy, ferroalmanganese, and ferro-vanadium are added in turn for alloying, and argon blowing time is 16 minutes during the tapping process.

...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com