Chromium-molybdenum alloy heat-resistant steel plate and manufacturing method thereof

A chrome-molybdenum alloy and steel plate technology, which is applied in the field of metal material manufacturing, can solve problems such as unqualified ultrasonic inspection, low yield of steel ingots, and slow cooling of steel plates, etc., and achieve excellent cold and hot processing performance, good comprehensive structure performance, and stable structure. performance effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

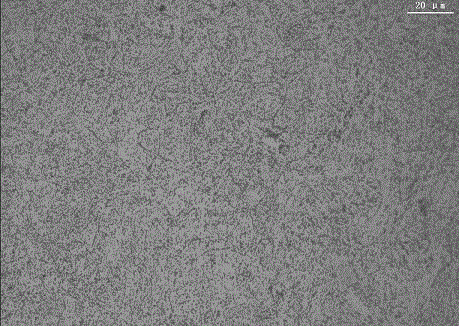

Image

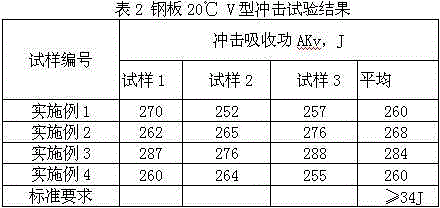

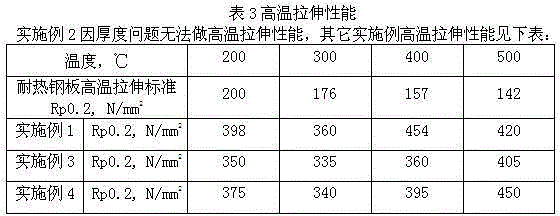

Examples

Embodiment 1

[0045] A chromium-molybdenum alloy heat-resistant steel plate, the weight percentage of the steel plate is composed of: carbon 0.12%, silicon 0.25%, manganese 0.45%, phosphorus 0.010%, sulfur 0.002%, chromium 2.25%, molybdenum 1.00%, and the balance is iron and unavoidable impurities.

[0046] The manufacturing method is:

[0047] (1) Hot metal pretreatment: hot metal pretreatment includes desulfurization to 0.002%, after KR deep desulfurization pretreatment and slag removal, the bright side of hot metal is greater than 90%, hot metal temperature is 1267°C, and arsenic (As) in hot metal is ≤0.002 %.

[0048] (2) Converter smelting and deoxidation alloying: 0.06% carbon, 0.006% phosphorus, and 0.005% sulfur at the end of smelting, ferromolybdenum is added to the converter along with scrap steel, and ferroalloy, lime, and fluorite are added during tapping to make top slag; slag stoppers are used , Double slag blocking bar for tapping; deoxidation alloying, blowing argon in CAS f...

Embodiment 2

[0056] A chromium-molybdenum alloy heat-resistant steel plate, the weight percentage of the steel plate is composed of: carbon 0.08%, silicon 0.40%, manganese 0.55%, phosphorus 0.011%, sulfur 0.008%, chromium 2.50%, molybdenum 0.90%, and the balance is iron and unavoidable impurities.

[0057] The manufacturing method is:

[0058] (1) Hot metal pretreatment: hot metal pretreatment includes desulfurization to 0.002%, after KR deep desulfurization pretreatment and slag removal, the bright side of hot metal is greater than 90%, hot metal temperature is 1335°C, and arsenic (As) in hot metal is ≤0.003 %.

[0059] (2) Converter smelting and deoxidation alloying: 0.08% carbon, 0.007% phosphorus, and 0.003% sulfur at the end of smelting, ferromolybdenum is added to the converter along with scrap steel, and ferroalloy, lime, and fluorite are added to the converter during tapping; slag stoppers are used , Double slag blocking bar for tapping; deoxidation alloying, blowing argon in CAS...

Embodiment 3

[0067] A chromium-molybdenum alloy heat-resistant steel plate, the weight percentage of the steel plate is composed of: carbon 0.16%, silicon 0.35%, manganese 0.60%, phosphorus 0.012%, sulfur 0.006%, chromium 2.00%, molybdenum 0.90%, and the balance is iron and unavoidable impurities.

[0068] The manufacturing method is:

[0069] (1) Hot metal pretreatment: hot metal pretreatment includes desulfurization to 0.005%, after KR deep desulfurization pretreatment and slag removal, the bright side of hot metal is greater than 90%, hot metal temperature is 1250 ° C, arsenic (As) in hot metal ≤ 0.003 %.

[0070] (2) Converter smelting and deoxidation alloying: 0.10% carbon, 0.008% phosphorus, and 0.002% sulfur at the end of smelting, ferromolybdenum is added to the converter along with scrap steel, and ferroalmanganese, lime, and fluorite are added to make top slag during tapping; slag stoppers are used , Double slag blocking bar for tapping; deoxidation alloying, blowing argon in C...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com