Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

109results about How to "Meet heat resistance" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

High-temperature resisting methyl vinyl silicone rubber

The invention discloses high-temperature resisting methyl vinyl silicone rubber as well as a prescription and a preparation process thereof. The high-temperature resisting modified silicon rubber material which has more than 300 DEG C of application temperature and can not crack when according with requirements of 550 DEG C, 4mm distance and high-temperature radiation for more than 12 minutes is prepared by adopting the following steps of: adding cerium oxide and polymide into the prescription in which methyl vinyl silicon crude rubber is taken as a rubber raw material to improve the heat-resisting temperature, adding hydroxy silicone oil, dimethyl silicon oil and a silane coupling agent to improve the oil-resisting performance, adding precipitation method white carbon black and gas-phase method white carbon black to improve the tearing-resistance strength, adding quartz power and kieselguhr to improve the tensile strength and matching technical schemes of the preparation process. The high-temperature resisting methyl vinyl silicone rubber overcomes the problems and the defects of poor high-temperature and aging resistance performance and short service life of the common silicone rubber in the prior art, satisfies the special requirements for the heat-resisting performance, the electrical strength and the mechanical strength of automotive rubber products, and ensures that the silicone rubber products achieve the aims of improving the high-temperature resistance performance and prolonging the service life.

Owner:NINGBO GUANGMING RUBBER & PLASTIC

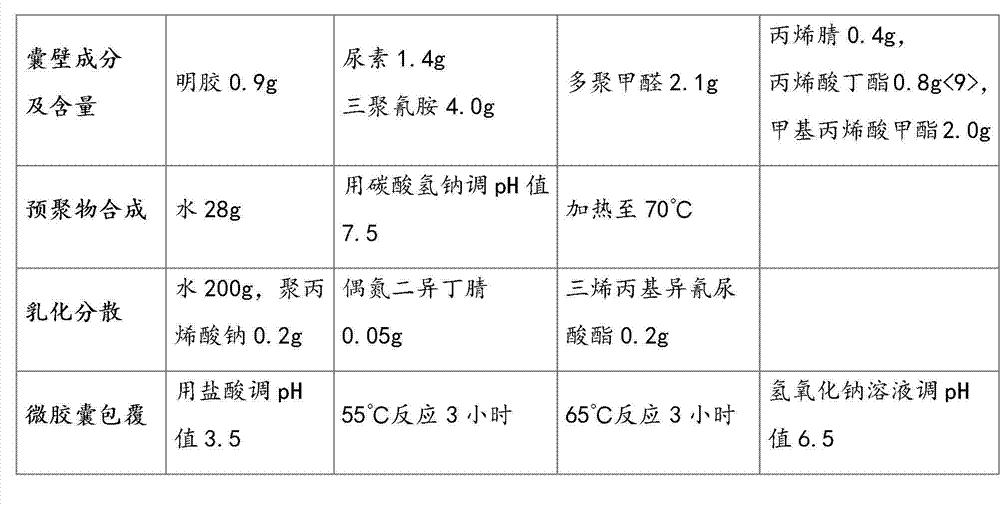

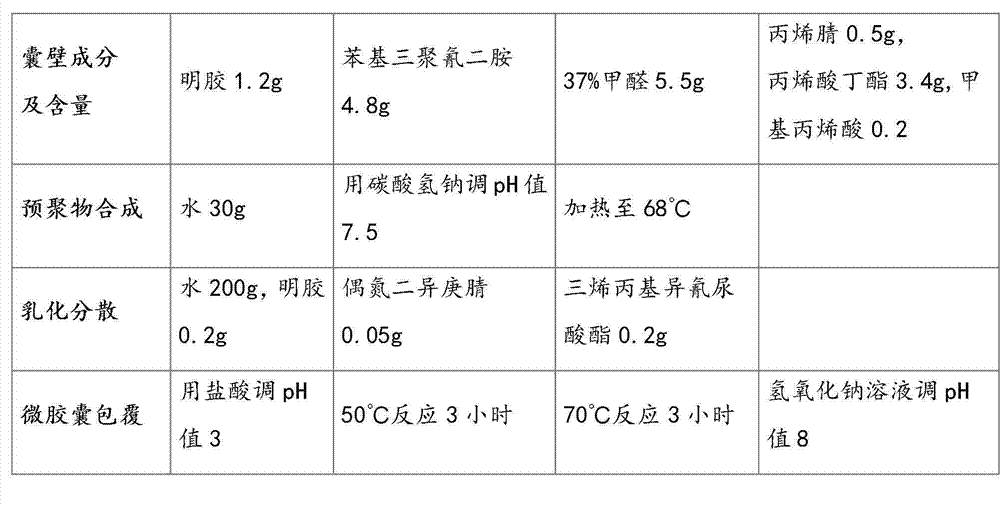

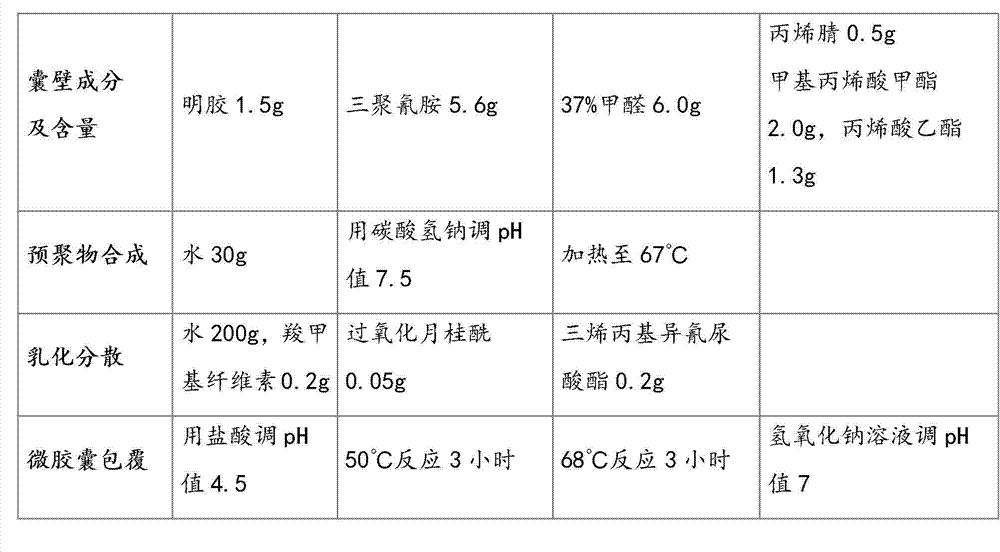

Double-layer coated essence microcapsule and preparation method thereof

ActiveCN102899168AMeet heat resistanceFulfil requirementsEssential-oils/perfumesMicroballoon preparationAcrylate polymerMechanical property

The invention discloses a double-layer coated essence microcapsule and a preparation method thereof. The essence microcapsule takes an oil soluble liquid essence as a capsule core, a gelatin modified amino resin composite material as a first-layer capsule wall and an acrylate polymer as a second-layer capsule wall, wherein a grafting transition area is formed by graft copolymerization of gelatin and acrylate between the first-layer capsule wall and the second-layer capsule wall. The preparation method comprises a step of prepolymer compounding, emulsification dispersion, microcapsule continuous double-layer coating and post-treatment. Compared with a single-layer coated microcaposule, the essence microcapsule has the advantages that the slow release performance, the heat resistance performance and the capsule wall material mechanical property are greatly improved, and the essence microcapsule can be used for most of microencapsulated essence products processed by heat extrusion molding of high molecular materials.

Owner:湖南方税达科技有限公司 +1

High-dispersity acidic copper plating additive as well as preparation method and application thereof

InactiveCN105734623AImprove ductilityImprove current efficiencyPrinted element electric connection formationDispersityCopper plating

The invention relates to the field of highly dispersive all-bright acidic copper plating of printed circuit boards, in particular to a highly dispersive acidic copper plating additive and its preparation method and application. A highly dispersed acidic copper plating additive: at least one divalent sulfide main brightener, at least one polyethylene glycol or polypropylene glycol or both block copolymer polymer inhibitors, at least one alkyl quaternary ammonium salt Type cationic surfactant, 5‑50ml / L sulfuric acid, 0.1‑4ml / L formaldehyde. Its preparation method is to slowly add a specified amount of concentrated sulfuric acid into water, stir evenly and cool to room temperature, then sequentially add the inhibitor, surfactant, main brightener and formaldehyde into the sulfuric acid aqueous solution, stir until completely dissolved Concentrate to the final volume to obtain the highly dispersed acidic copper plating additive of the present invention. The high-dispersion acidic copper plating additive of the invention is especially suitable for electroplating through-holes with high thickness-to-diameter ratio of printed circuit boards, and can obviously improve the dispersion ability of the plating solution.

Owner:GUANGDONG LEAR ELECTROCHEM LTD

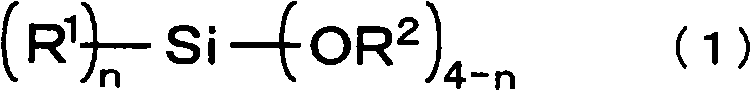

Positive type radiation-sensitive composition, cured film, interlayer insulating film, method for forming method interlayer insulating film, display element and siloxane polymer

ActiveCN101937172AExcellent mechanical propertiesExcellent electrical propertiesSemiconductor/solid-state device detailsSolid-state devicesSilane compoundsQuinone

The present invention relates to a positive-type radiation-sensitive composition, a cured film, an interlayer insulating film, a method for forming the interlayer insulating film, a display element and a siloxane polymer. The invention provides a polysiloxane series positive-type radiation-sensitive composition having high compatibility with a quinone diazide compound and capable of forming the interlayer insulating film having excellent corrosion inhibitor stripping liquid resistance in an ITO film etching step. The composition contains (A) a siloxane polymer, and (B) a quinone diazide compound, in which the content of aryl groups relative to Si atoms in the siloxane polymer (A) is greater than 60% by mole and no greater than 95% by mole. The (A) siloxane polymer is a hydrolytic condensation containing a hydrolytic silane compound represented by formula (1).

Owner:JSR CORPORATIOON

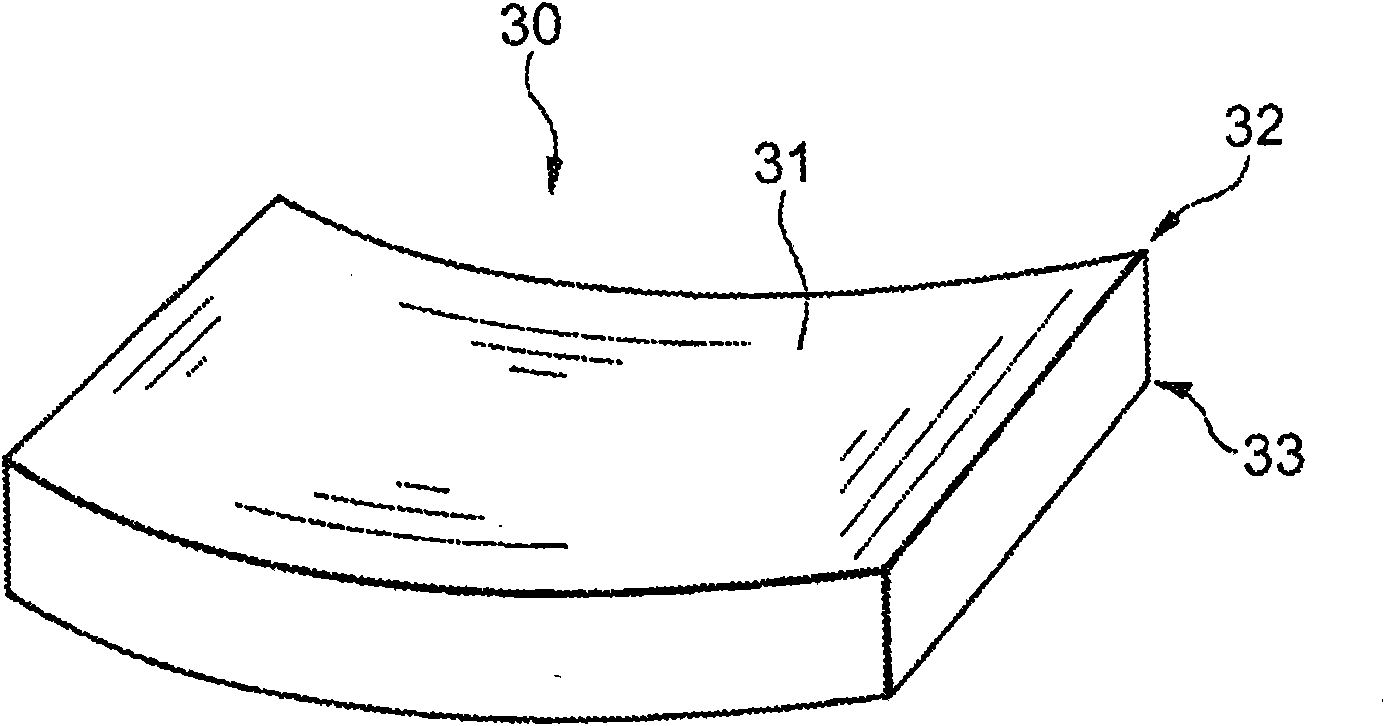

Metallic material having chromate-free-treated surface excellent in corrosion resistance, heat resistance, anti-fingerprint property, conductivity, coating property and black deposit resistance during

ActiveCN101228294AMeet the corrosion resistanceMeet heat resistanceMetallic material coating processesThin material handlingAdditive ingredientMetallic materials

The present invention provides a metal material with a non-chromate surface treatment, which can satisfy the corrosion resistance, heat resistance, fingerprint resistance, electrical conductivity, paintability and processing requirements that were difficult to achieve with the conventional non-chromate technology. Anti-blackening and other properties. The non-chromate surface-treated metal material of the present invention forms a composite film containing various components by applying and drying a water-based metal surface treatment agent on the surface of the metal material. The water-based metal surface treatment agent contains one The organic silane coupling agent (A) of amino group and the silane coupling agent (B) containing 1 glycidyl group in the molecule are mixed according to the ratio of solid content mass ratio [(A) / (B)] of 0.5 to 1.7. A silicon compound (W), at least one fluorine compound (X) selected from titanium hydrofluoride or zirconium hydrofluoride, phosphoric acid (Y) and a vanadium compound (Z).

Owner:NIPPON STEEL CORP

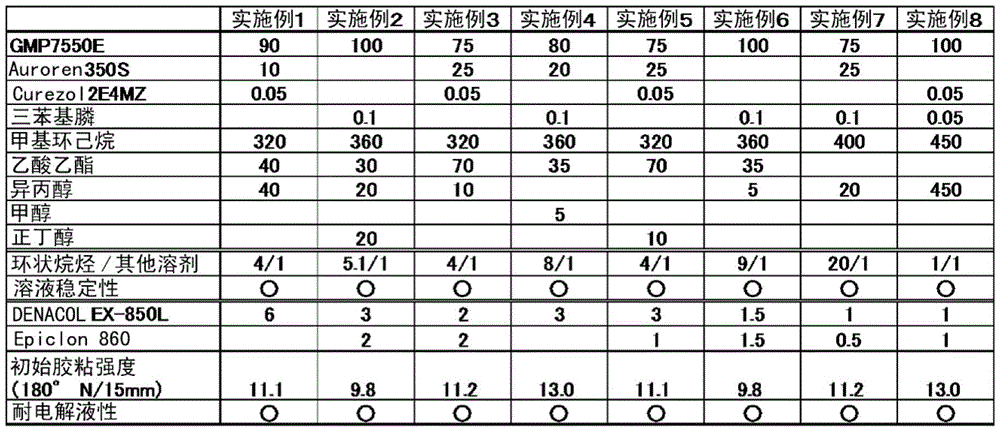

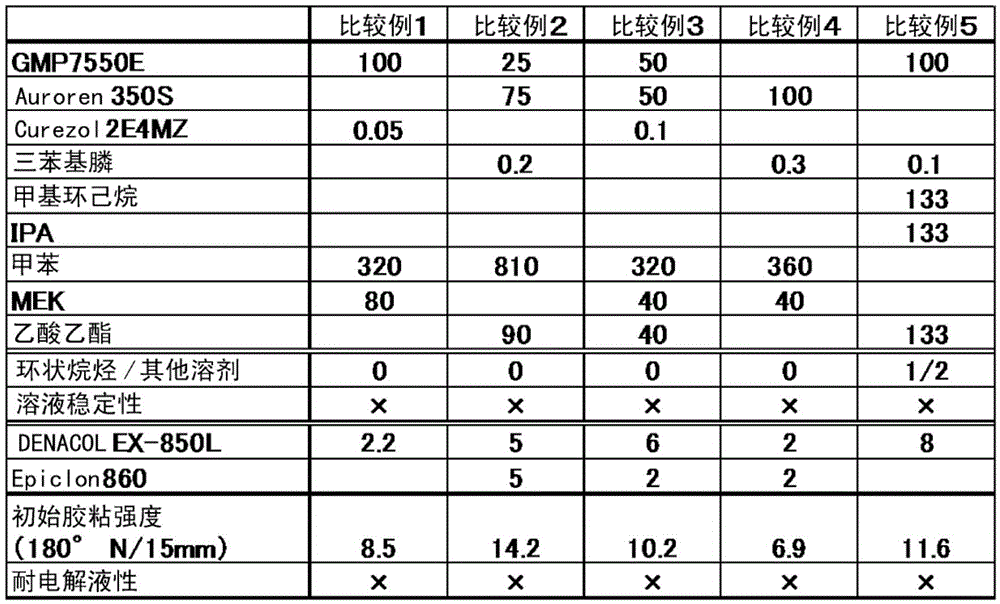

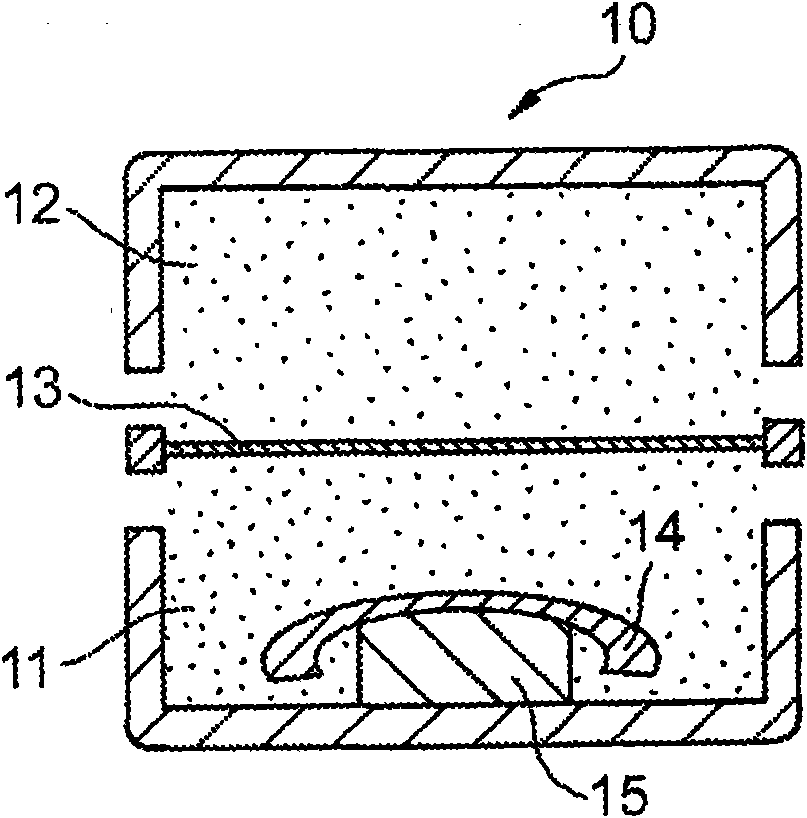

Laminate adhesive, stack using the same, and secondary battery

ActiveCN105658753AGood adhesivenessMeet moisture resistanceNon-macromolecular adhesive additivesCell electrodesPolyolefinAdhesive

By providing a heretofore unknown laminate adhesive, the present invention addresses the problem of providing an adhesive composition for laminate stacks, which provides excellent adhesion between a metal layer and a plastic layer and satisfies moisture resistance, heat resistance, insulation performance, durability, etc., further combined with electrolyte resistance in low-temperature curing, without causing delamination over time. The present invention also addresses the problem of providing a stack using the adhesive composition, and a secondary battery. The above problems are solved with a laminate adhesive containing a non-chlorine polyolefin resin (A), an epoxy compound (B), and an organic solvent (C) essentially containing a cyclic alkane compound and containing an ester solvent or an alcohol solvent, wherein the organic solvent (C) is constituted such that the ratio of the mass parts of the cyclic alkane compound to the mass parts of other solvents is in the range of 1 / 1 to 20 / 1, inclusive.

Owner:DIC CORP

Low-temperature curing color coiled material paint and method for preparing same

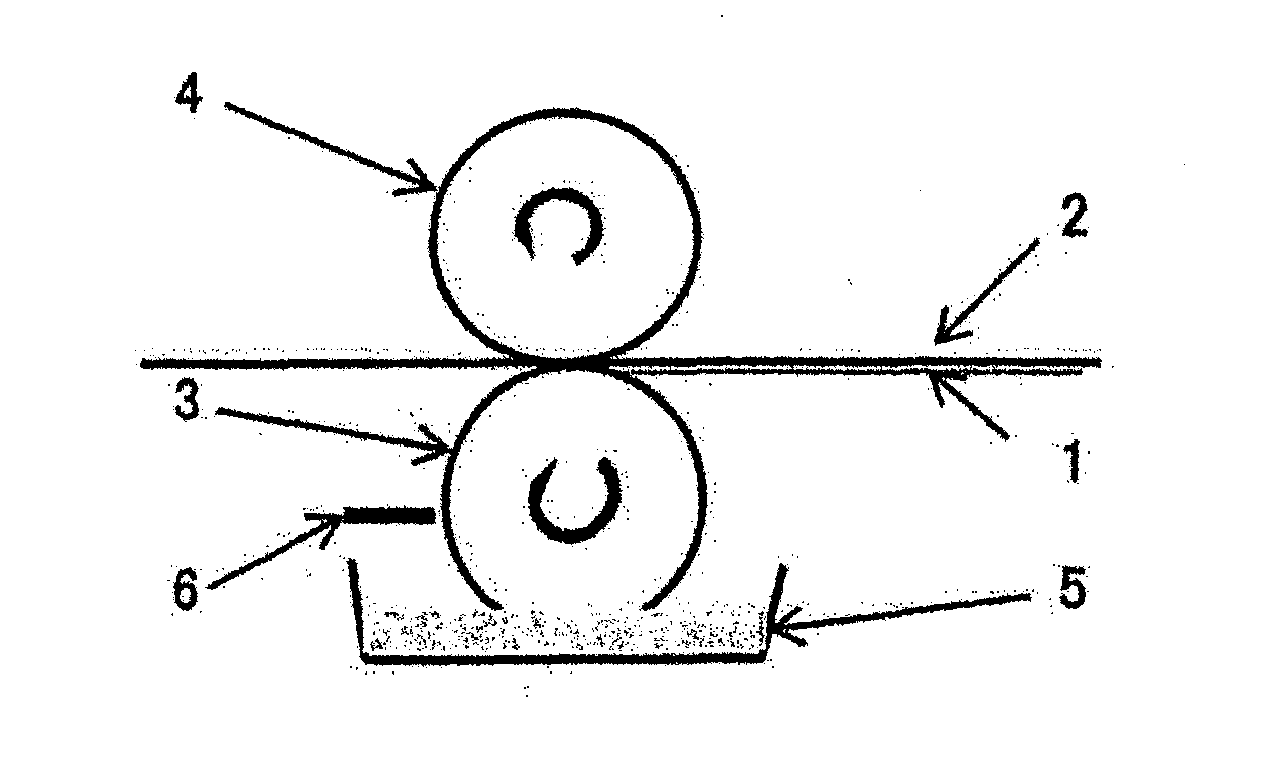

ActiveCN101531860ASuitable for continuous roller coatingMeet the hardness and toughnessPolyester coatingsLow temperature curingSolvent

The invention relates to a paint composition, in particular to a low-temperature curing paint used for manufacturing color steel plates and a method for preparing the same. The method comprises the following steps: adding 45 to 60 weight percent of saturated polyester resin, 3 to 5 weight percent of fully-methylated amino resin and 3 to 5 weight percent of partially-methylated amino resin into a reaction kettle; while stirring, adding 3 to 5 weight percent of propylene glycol ether acetate, 2 to 5 weight percent of binary acid dimethyl ester, 2 to 0.5 weight percent of closed cooling catalyst, 0.2 to 0.5 weight percent of open cooling catalyst, 5 to 10 weight percent of trimethyl benzene solvent to the mixture; after stirring the mixture evenly, adding 0.3 to 0.8 weight percent of dispersant to the mixture, and then adding 20 to 40 weight percent of filling pigment and 0.3 to 0.8 weight percent of wax powder while stirring; and after the mixture is dispersed evenly, performing sanding in a sand mill, and then performing paint and color mixing process to obtain the finished product, namely the low-temperature curing color coiled material paint. The method can solve the problems that the prior high-temperature baking curing paint has high curing temperature to cause energy sources waste.

Owner:JIANGSU LANLING POLYMER MATERIAL CO LTD

Fingerprint-resistant paint and preparation method thereof

The invention discloses a fingerprint-resistant paint and a preparation method thereof. The fingerprint-resistant paint comprises the following components in parts by weight: 50-60 parts of acrylic resin emulsion (solid content is 45%), 5-8 parts of silicasol, 4-7 parts of mixed wax slurry, 0.2-1 part of defoaming and leveling agent, 4-6 parts of film-forming cosolvent and 30-40 parts of deionized water. The fingerprint-resistant paint takes water as the main solution, and is added with aqueous high-molecular organic substances which have superior properties and are harmless to human bodies. A low surface tension structure is formed on surface of the added filler and the paint film, thereby greatly enhancing the fingerprint resistance of the steel sheet. The fingerprint-resistant paint can be coated on the surface of a hot galvanized steel sheet or electrogalvanized steel sheet in a mode of dip coating, curtain coating, roller coating, gasket coating or the like, so that fingerprints can not be attached to the surface. In addition, the paint is environment-friendly.

Owner:WUXI JINJIAN PAINTING

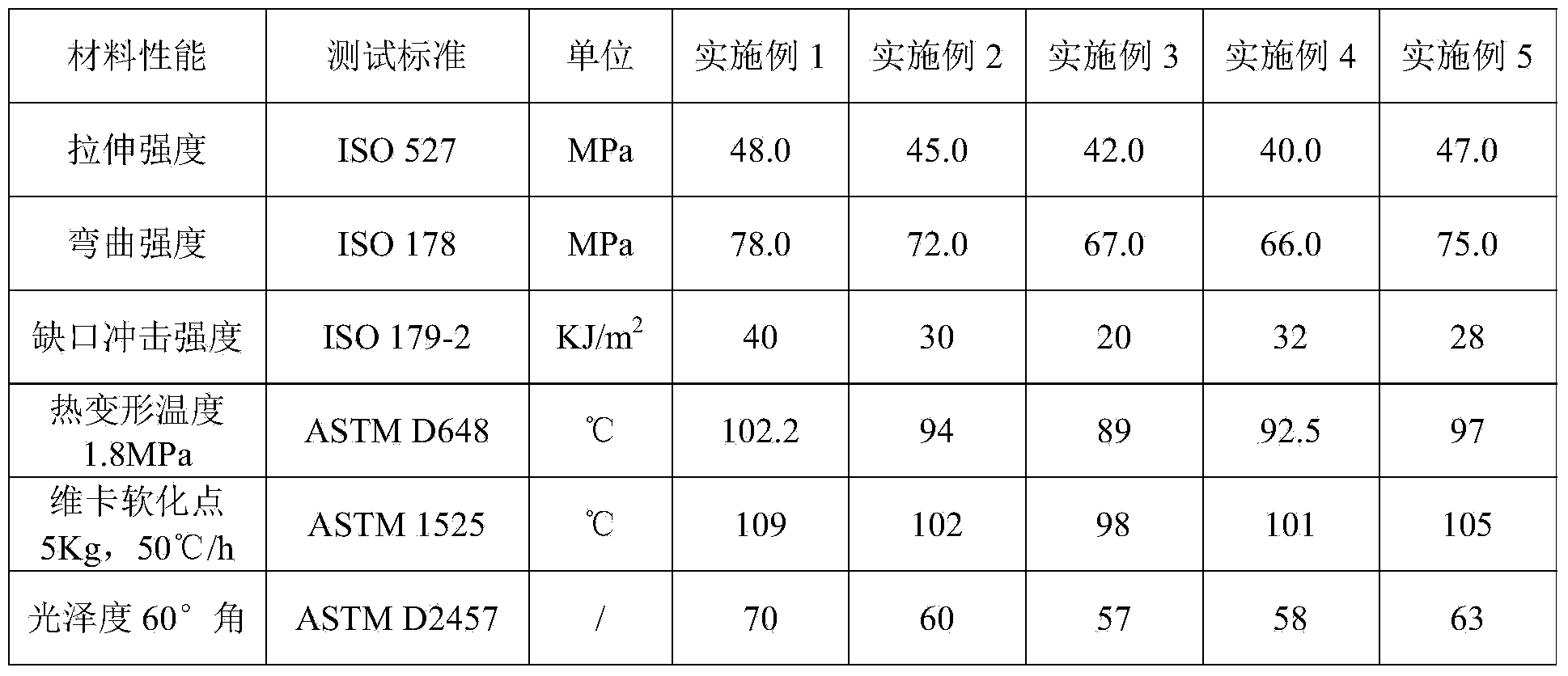

Extinctive PC/ABS (Poly Carbonate/Acrylonitrile Butadiene Styrene) plastic alloy and manufacturing method thereof

The invention provides an extinctive PC / ABS (Poly Carbonate / Acrylonitrile Butadiene Styrene) plastic alloy which is prepared from the following components in percentage by weight: 30-50% of PC, 40-65% of ABS, 1-10% of compatilizer, 1-5% of flatting agent, 0.2-1% of lubricant and 0.2-1% of antioxidant. The extinctive PC / ABS plastic alloy provided by the invention has the advantages of low surface glossiness, good toughness and flowability, low cost and the like. The manufacturing method is simple in processing step and low in comprehensive cost and is especially suitable for the fields of electronics, home appliances, automotive trims and the like.

Owner:青岛中新华美塑料有限公司

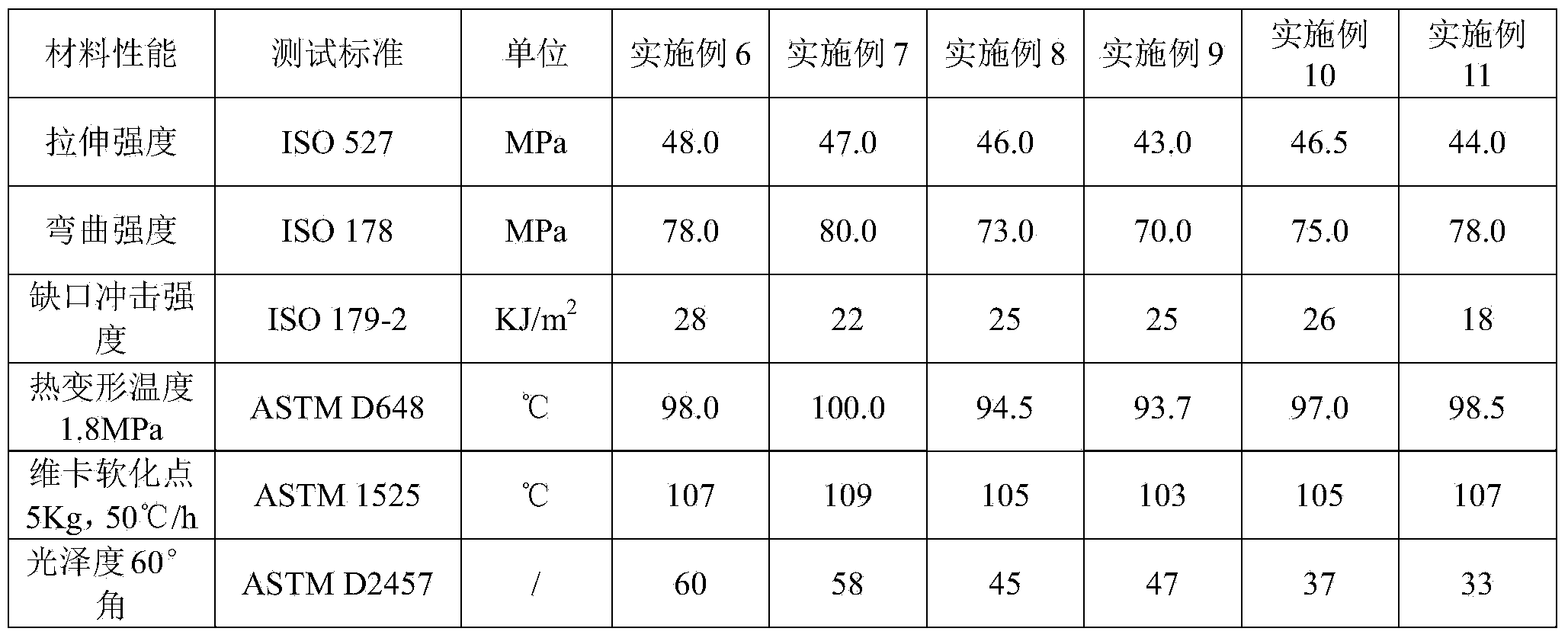

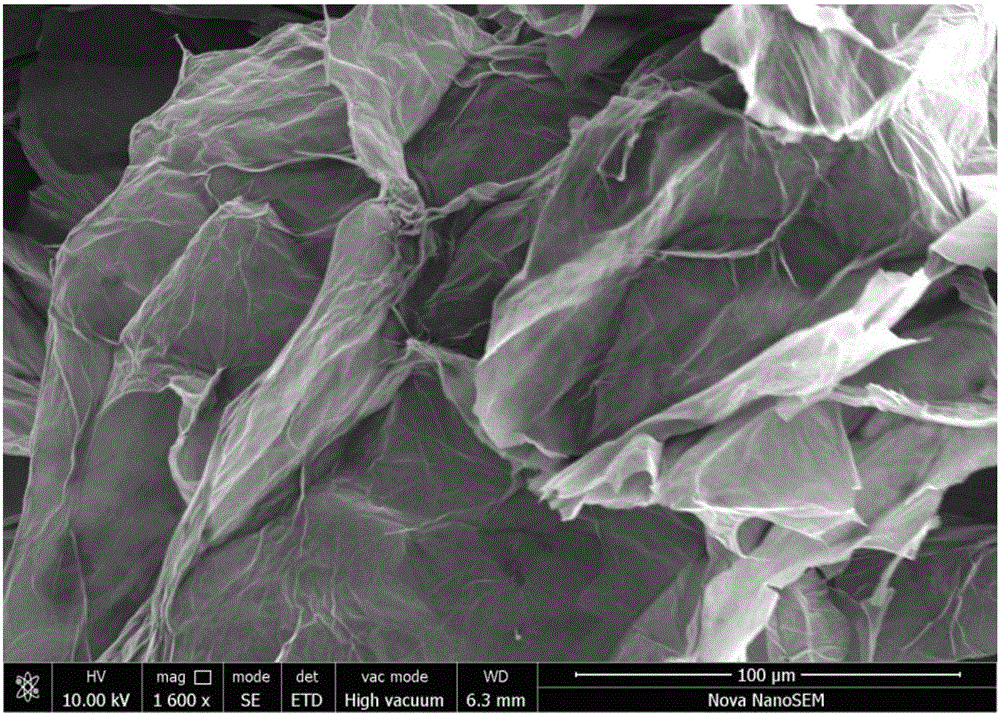

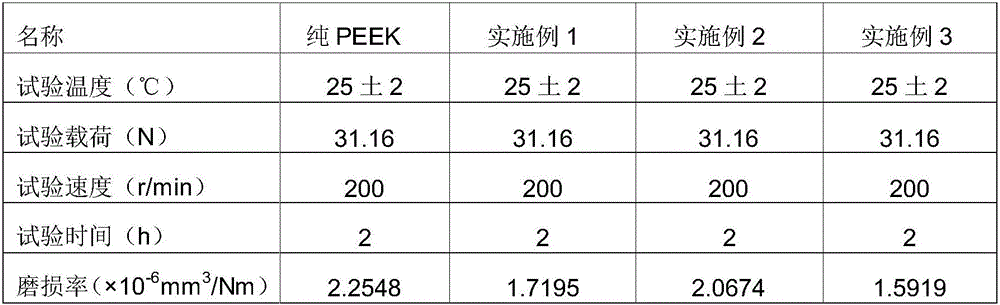

Polyether-ether-ketone wear resistant composite material, preparation method and application thereof in mechanical polishing retaining rings

InactiveCN105754288AGood compatibilityEnhance the interface forceWear resistantPolyether ether ketone

Belonging to the technical field of polymer composite materials, the invention relates to a polyether-ether-ketone wear resistant composite material, a preparation method and application thereof in mechanical polishing retaining rings. The polyether-ether-ketone wear resistant composite material is composed of, by mass percentage, 90-99.99% of polyether-ether-ketone resin and the balance coupling agent modified graphene oxide, and is prepared by a melt blending process. In order to improve the dispersibility of graphene oxide, the coupling agent is employed to perform surface treatment on graphene oxide. The polyether-ether-ketone wear resistant composite material prepared by the method provided by the invention has the characteristics of good wear resistance, high strength, high temperature resistance and the like, the processing technology is simple, the processing cost is low, and the polyether-ether-ketone wear resistant composite material meets the material requirement of mechanical polishing retaining rings. The material greatly reduces the processing cost of mechanical polishing retaining rings, and prolongs the service life of mechanical polishing retaining rings.

Owner:JILIN UNIV

Light solidifying/heat solidifying one-part welding resistant agent composition and printing circuit plate

ActiveCN101105629AImprove reliabilityHas storage stabilityPrinted circuit manufacturePhotosensitive materials for photomechanical apparatusOrganic acidElectrolysis

The present invention provides an alkali-developable photo curable and heat curable one-liquid solder mask composition and the printed circuit board using the composition, and the composition has the advantages of excellent coating film characters such as heat resisting property, closing property, non-electrolysis gold plating resisting property and the electrical characteristic, etc., and little fog. The invention provides a photo curable and heat curable one-liquid solder mask composition and the printed circuit board using the composition, and the composition includes the following components: (A) a carboxylated photo sensitive resin which is provided with more than two ethylenically unsaturated groups in one molecule and more than one carboxyl, and the acid strength pKa of the carboxyl is below 5.0; (B) a diluent; (C) a a photopolymerization evocating agent; (D) a cyanuramide or the organic acid salt; and (E) an inorganic filler.

Owner:TAIYO INK MFG

Laminating adhesive, laminate using the same, and secondary battery

InactiveUS20170088753A1Improve adhesionSatisfactory durabilityNon-macromolecular adhesive additivesCell electrodesPolyolefinAdditive ingredient

It is an object to provide a novel laminating adhesive to thereby allow provision of a laminating adhesive composition for a laminate that provides good adhesion between a metal layer and a plastic layer, has satisfactory moisture barrier properties, heat resistance, insulation properties, durability, etc., also exhibits electrolyte resistance even after low-temperature curing, and does not undergo delamination over time. A laminate that uses the laminating adhesive composition and a secondary battery are also provided. The object is achieved by a laminating adhesive containing a non-chlorine-based polyolefin resin (A), an epoxy compound (B), and an organic solvent (C) including a cyclic alkane compound as an essential ingredient and further including an ester-based solvent or an alcohol-based solvent. In the organic solvent (C), the ratio, in parts by mass, of the cyclic alkane compound to the solvent other than the cyclic alkane compound is within the range of 1 / 1 to 20 / 1.

Owner:DAINIPPON INK & CHEM INC

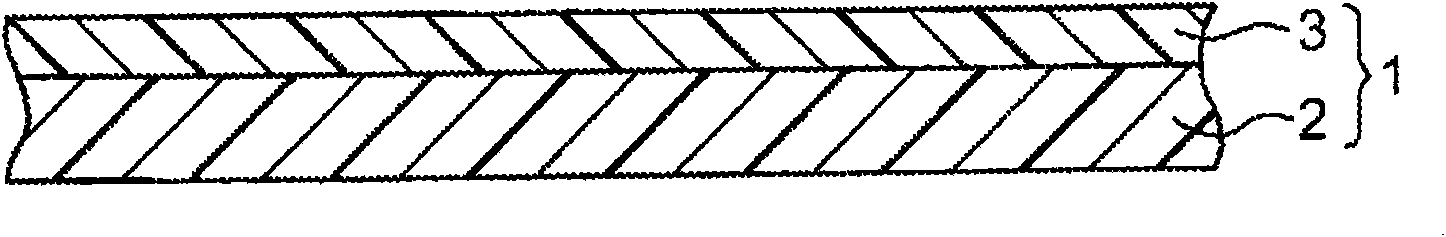

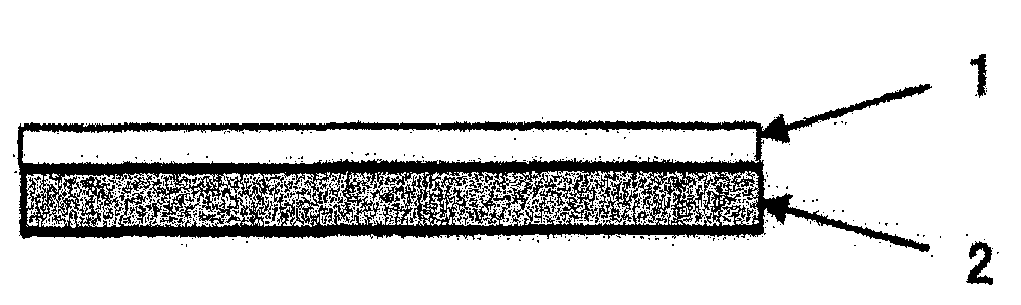

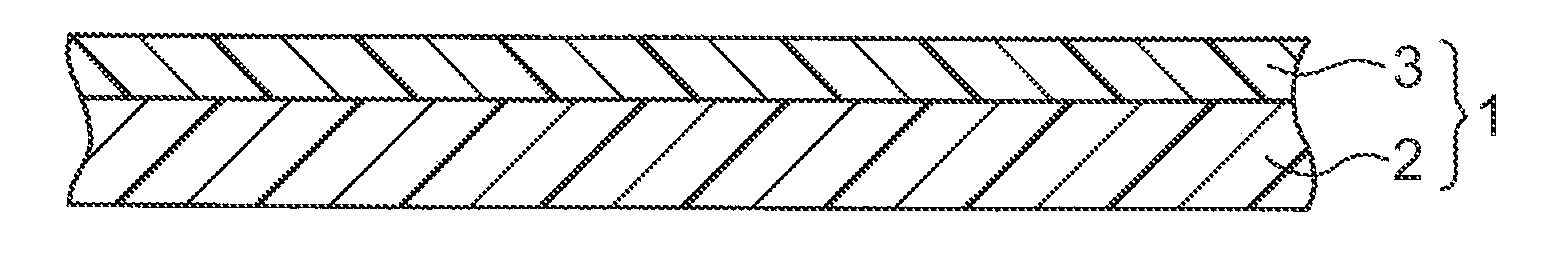

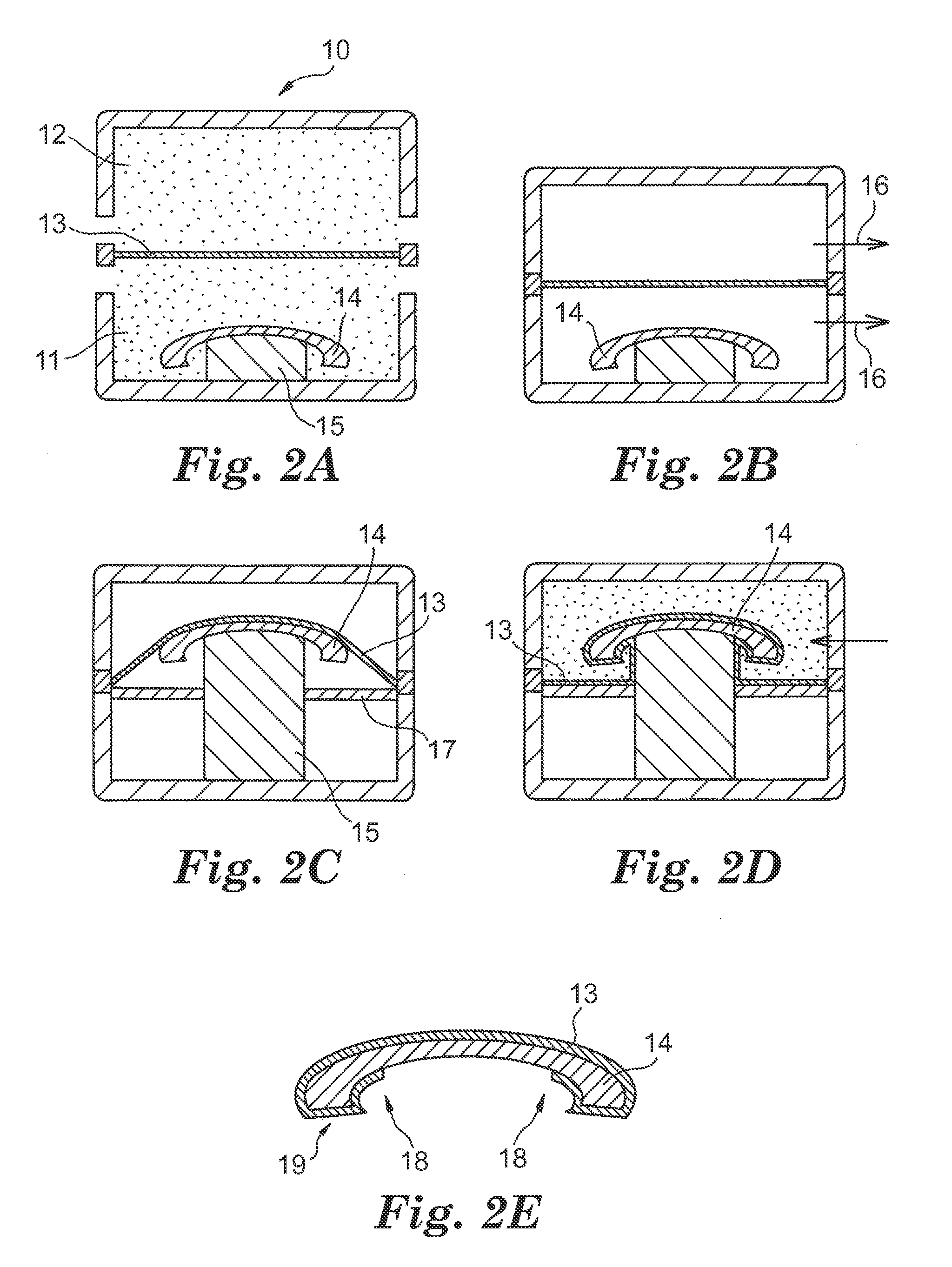

Adhesive film, production method of shaped body

ActiveCN101778915APrevent slidingMeet heat resistanceAdhesive processes with adhesive heatingEster polymer adhesivesMeth-Polymer science

An adhesive film comprising a substrate and an adhesive layer on said substrate, said adhesive layer comprising: (A) a carboxyl group-containing (meth)acrylate polymer having a glass transition temperature (Tg) of 25 C or lower, said carboxyl group-containing (meth)acrylate polymer having a percent number of repeating units of 4.0 to 25% based on the total number of repeating units of the (meth)acrylate polymer; and (B) an amino group-containing (meth)acrylate polymer having a glass transition temperature (Tg) of 75 C or higher, said amino group-containing (meth)acrylate polymer having a percent number of amino group-containing repeating units of 3.5 to 15% based on the total number of repeating units of the (meth)acrylate polymer, wherein the ratio by weight of said component (A) to said component (B) is from 62:38 to 75:25.

Owner:3M INNOVATIVE PROPERTIES CO

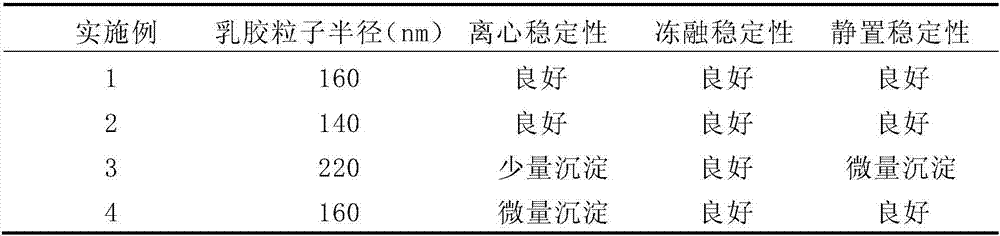

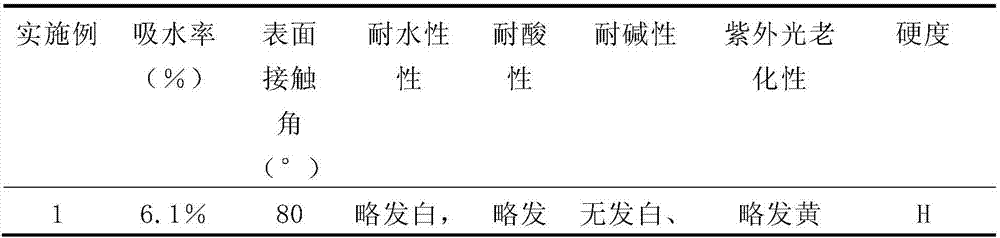

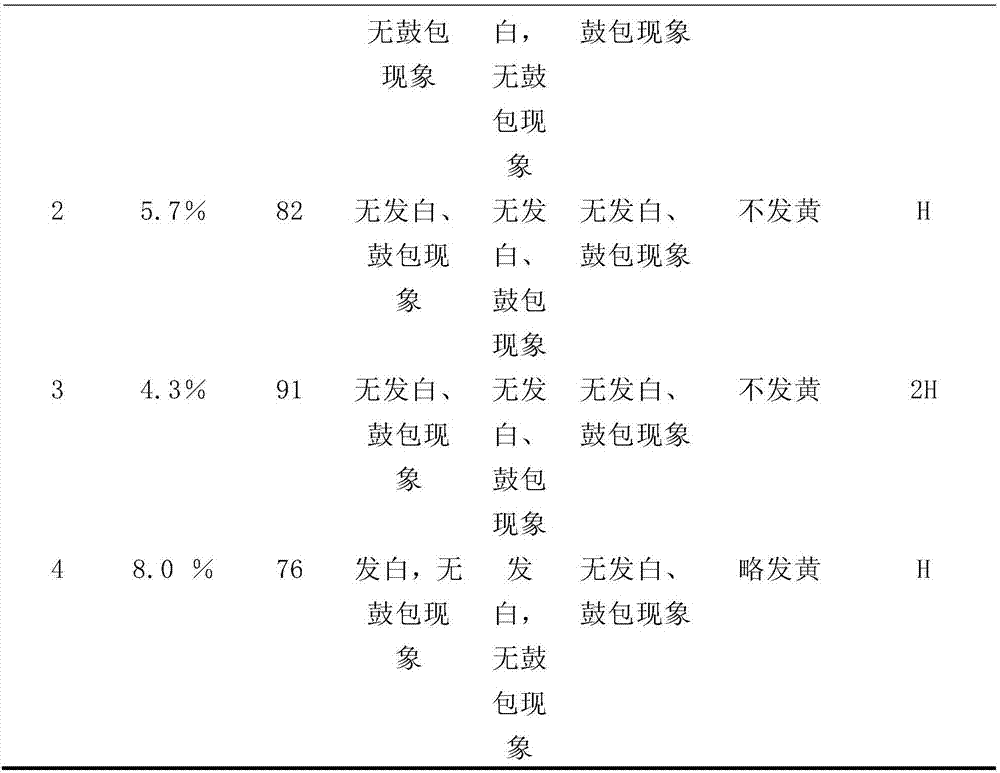

Organic silicone modified polyurethane/epoxy/acrylate composite emulsion and preparation method thereof

The invention relates to an organic silicone modified polyurethane / epoxy / acrylate composite emulsion and a preparation method thereof. The preparation method comprises three steps: a first step, synthesizing a low-molecular-weight epoxy prepolymer; a second step, preparing an organic silicone modified polyurethane, introducing the epoxy prepolymer into a polyurethane system, and terminating with hydroxyl, to prepare a polyurethane / epoxy composite prepolymer; and a third step, adding the prepolymer into an acrylate reaction system under a condition without addition of an emulsifier, carrying out a reaction with acrylic acid monomers under the action of an initiator, and thus preparing the organic silicone modified polyurethane / epoxy / acrylate composite emulsion. The prepared composite emulsion has excellent centrifugal stability, freeze-thaw stability and static stability; after film coating, the appearance is bright, clean and smooth, no bubbles and cracks exist, the tensile strength reaches 7-15 MPa, the elongation at break reaches 400-600%, a coating film has excellent weather resistance, the lowest decomposition temperature is 180 DEG C or more, and the surface contact angle is 70-95 DEG.

Owner:山东新而奇新材料有限公司

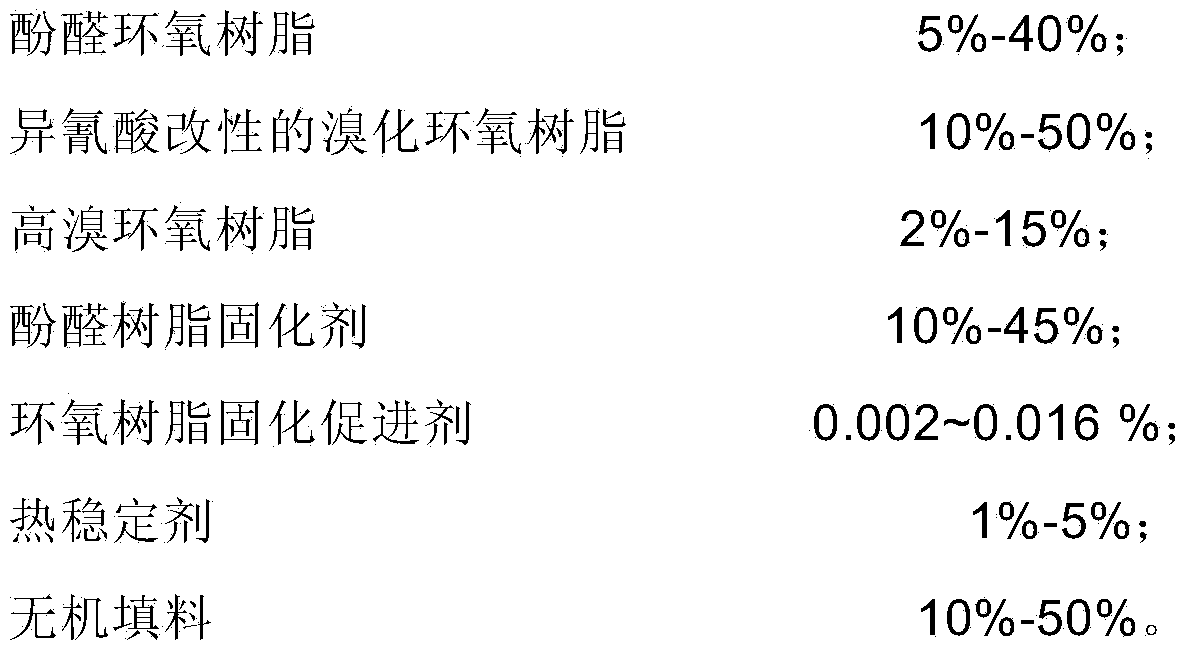

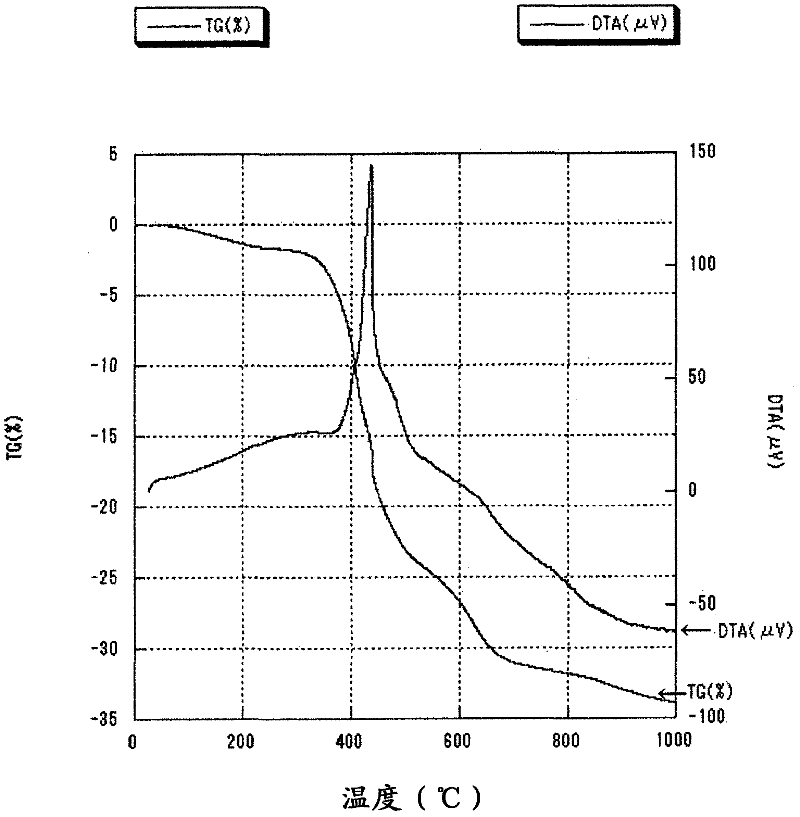

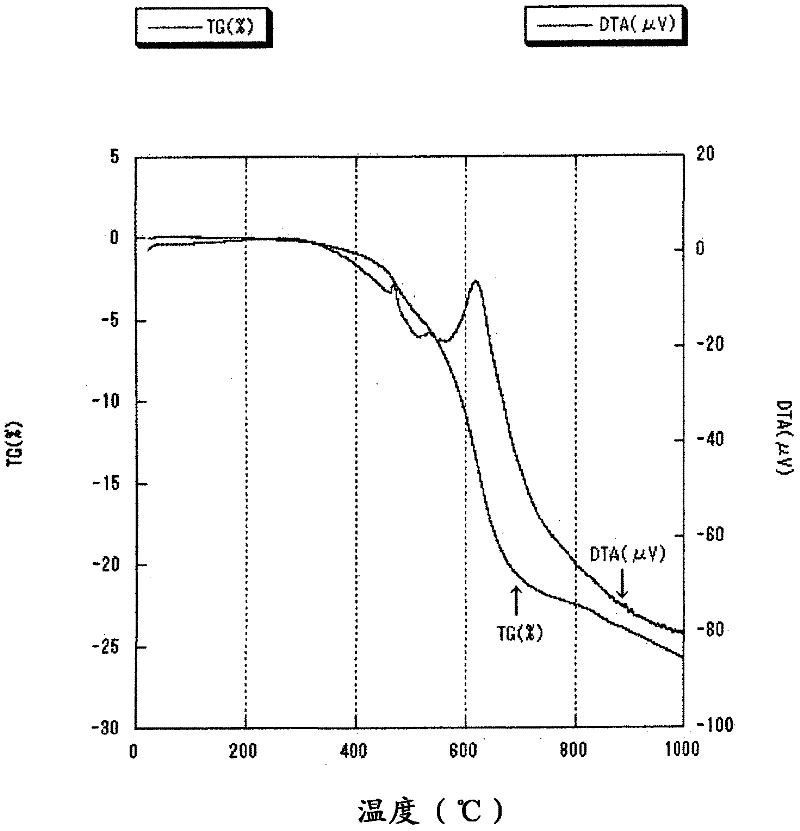

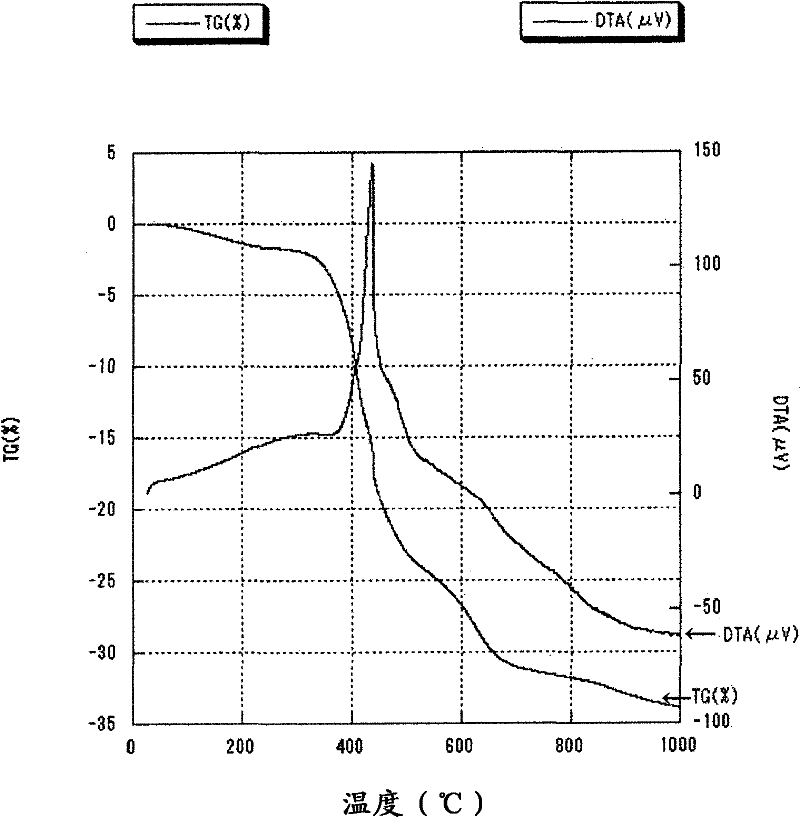

Epoxy resin composition and preparation method thereof

ActiveCN103788576AHigh glass transition temperatureImprove heat resistanceSynthetic resin layered productsMetal layered productsEpoxyGlass transition

The invention discloses an epoxy resin composition which is prepared from novolac epoxy resin, isocyanic acid modified brominated epoxy resin, high-bromine epoxy resin, a phenolic resin curing agent, an epoxy resin curing accelerator, a heat stabilizer, inorganic filler and an organic solvent. A copper-clad laminate prepared by use of the epoxy resin composition disclosed by the invention has the characteristics of high glass transition temperature (higher or equal to 170 DEG C), good heat resistance and peel strength, good machinability and the like, and can meet the requirements for the heat resistance and processability of materials in a PCB (printed circuit board) processing process.

Owner:NANYA NEW MATERIAL TECH CO LTD

Moisture-proof film for electronic devices

InactiveCN102448884AGood weather resistanceSatisfy the gas barrier propertyMaterial nanotechnologySilicon compoundsWater vaporPolyamide

Disclosed is a moisture-proof film for electronic devices, in which modified clay crystals are oriented and densely laminated, and the mechanical strength thereof is at a satisfactory level for use as a self-supporting film. The moisture-proof film comprises a modified clay and an additive, has a water vapor barrier property, and a water vapor permeability of less than 0.2 g / m2 / day (at 40 DEG C and a relative humidity of 90%), wherein the modified clay is produced by a silylation reaction of a clay, the additive is a polyamide or a polyimide, and lithium ions make up at least 90 mol% of exchangeable ions in the modified clay. The moisture-proof film is a novel material that fulfils all of the requirement of weather resistance, gas barrier performance, water vapor barrier performance, flexibility, heat resistance, electrical insulation performance, and water resistance.

Owner:NAT INST OF ADVANCED IND SCI & TECH

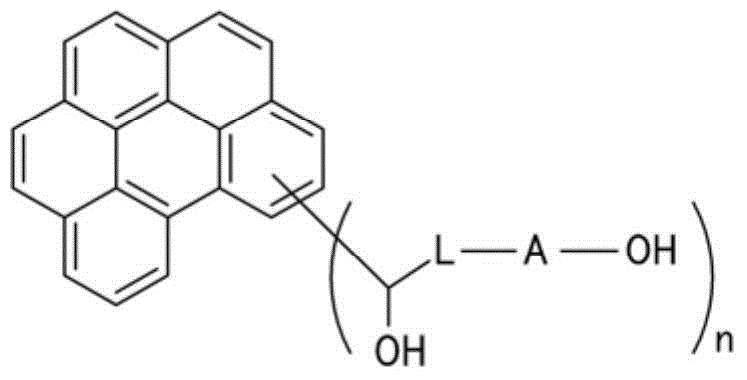

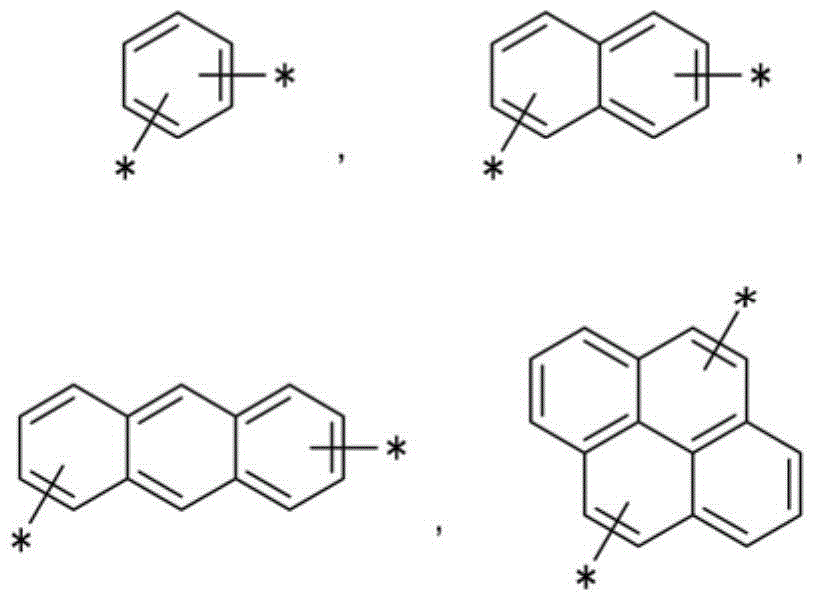

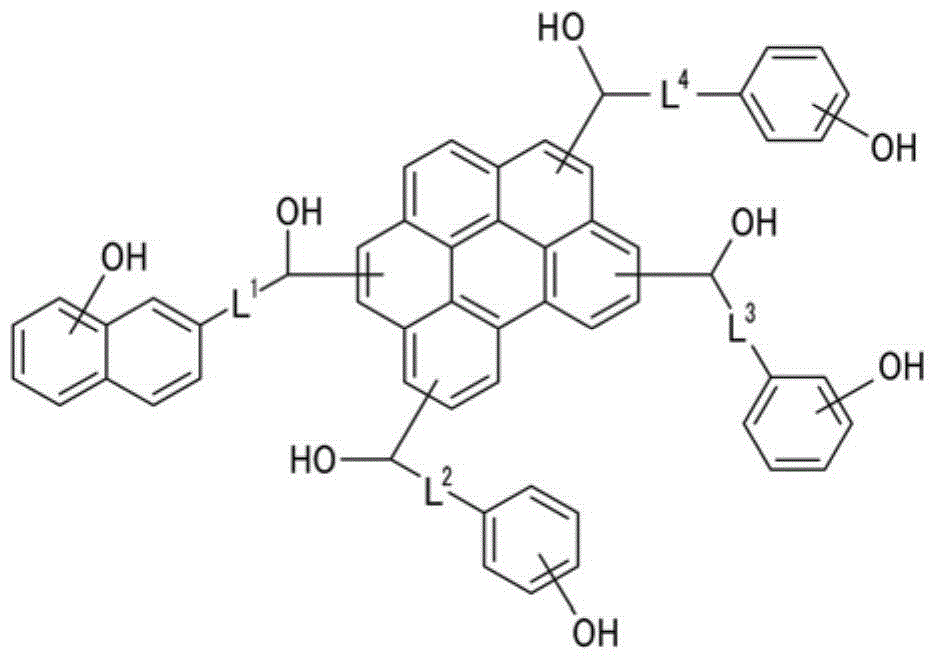

Monomer for hardmask composition, hardmask composition including monomer, and pattern forming method using hardmask composition

ActiveCN103959170AMeet chemical resistanceMeet heat resistanceOrganic chemistryPretreated surfacesPolymer scienceHard mask

The present invention relates to a monomer for a hardmask composition expressed by chemical formula 1, a hardmask composition including the monomer, and a pattern forming method using the same.

Owner:CHEIL IND INC

Polyamide acid resin having unsaturated group, photosensitive resin composition using same, and cured product thereof

InactiveCN1898299AMeet the hardnessMeet solvent resistancePhotomechanical apparatusPrinted circuit manufactureHeat resistancePolyamide

The present invention provides a novel unsaturated group-containing polyamic acid resin (A) suitable for photosensitive resin compositions, and a photosensitive resin composition with excellent photosensitivity using the resin. The cured product obtained from the photosensitive resin composition has excellent Flexible, but also has excellent adhesion, pencil hardness, solvent resistance, acid resistance, heat resistance, gold plating resistance, etc. The unsaturated group-containing polyamic acid resin (A) is obtained by reacting an unsaturated group-containing polyester resin (a) with an anhydride group at the end and a compound (b) having 2 amino groups in the molecule. The resin composition is obtained by making it into the resin composition containing this unsaturated group containing polyamic-acid resin (A), a crosslinking agent (B), and a photoinitiator (C).

Owner:NIPPON KAYAKU CO LTD

Chinese medicine slag filling non woven composite material and preparation thereof

InactiveCN101220562ASimple production processShort processLayered productsNon-woven fabricsSlagFilling materials

The invention relates to a traditional Chinese herb residue filling non-weaving composite material and a preparation method which comprise a non-weaving base cloth material, the filling material traditional Chinese herb residues, thermal melting powders and curing agent, and the preparation method comprises: (1) the powders made from 3 percent to 80 percent of the traditional Chinese herb residues and 2 percent to 40 percent of the thermal melting powders is dispersed evenly on the non-weaving base cloth material; (2) the mixture obtained by the step (1) is put on a plate vulcanization machine so as to perform, and the thermal melting powders are melted, binded and cured with the pressure of 1 to and put on the plate vulcanization machine for curing and molding. The invention has the advantages of simple technique, short process, high efficiency and low cost. Meanwhile, the material has the antibacterial effect.

Owner:DONGHUA UNIV

High-dispersity acidic copper plating additive and preparation method and application thereof

InactiveCN108118372AImprove ductilityImprove current efficiencyPrinted element electric connection formationDispersityCopper plating

The invention relates to the field of high-dispersity full-bright acidic copper plating of printed wiring boards, and particularly relates to a high-dispersity acidic copper plating additive and a preparation method and application thereof. The high-dispersity acidic copper plating additive comprises at least one main divalent sulfide brightening agent, at least one polyethylene glycol or polypropylene glycol or polyethylene glycol and polypropylene glycol segmented copolymer inhibitors, at least one alkyl quaternary ammonium salt cationic surface active agent, 550ml / L of sulfuric acid, and 0.14ml / L of formaldehyde. The preparation method comprises the following steps: slowly adding concentrated sulphuric acid with specified volume to water; uniformly stirring; cooling to reach room temperature; then sequentially adding the inhibitor, the surfactant, the main brightening agent and formaldehyde to a sulphuric acid water solution; stirring until the materials are completely dissolved; and then metering the volume until the final volume is reached, thus obtaining the high-dispersity acidic copper plating additive. The high-dispersity acidic copper plating additive is particularly suitable for through hole electroplating with high thickness to diameter ratio of the printed wiring boards; and the dispersing capacity of the plating liquid can be obviously improved.

Owner:MEIDISI NEW MATERIAL GUANGZHOU

Preparation method of halogen-free CEM-1 copper-clad plate with high peeling strength

ActiveCN106739376AIncrease crosslink densityReduce dosagePaper coatingLaminationBisphenol AChemistry

The invention belongs to the technical field of copper-clad plate production, and especially relates to a preparation method of a halogen-free CEM-1 copper-clad plate with a high peeling strength. Phosphor containing epoxy resin and bisphenol A type epoxy resin are taken as the main resin; phosphor containing linear phenolic resin is taken as the curing agent, polyfunctional epoxy resin is used to enhance the heatproof performance; a certain ratio of aluminum hydroxide is added to increase the electric tracking resistant index of the copper-clad plate; a nitrogen and phosphor containing fire retardant is added, and through the synergistic effect between nitrogen and phosphor, the fireproof performance of the copper-clad plate is enhanced and can reach the FV0 grade. By processing the surface of used filling material and controlling the particle size, the filling material can be evenly dispersed into resin glue to obtain uniform glue dipped sheets, the toughness of sheets is improved, the obtained copper-clad plate can reach the environment protection requirements and does not contain any halogen, the contents of chlorine and bromine are low, the peeling strength is high, the characteristic of resisting tracking caused by electric leakage is excellent, and CTI>=600V.

Owner:SHANDONG JINBAO ELECTRONICS

Overhead heat-resistance aluminum alloy conductor material and preparation method thereof

InactiveCN106893899ARaise the recrystallization temperatureAdd lessConductive materialMetal/alloy conductorsCeriumTemperature resistance

The invention discloses an overhead heat-resistance aluminum alloy conductor material and a preparation method thereof, and relates to the technical field of aluminum alloy conductor materials. The overhead heat-resistance aluminum alloy conductor material comprises the following elements in percentage by mass: 0.10-0.45% of zirconium, 0.01-0.10% of yttrium, 0.01-0.10% of scandium, 0.3-1.0% of lanthanum and cerium, 0.05-0.18% of iron, silicon not more than 0.05%, nickel not more than 0.05, magnesium not more than 0.02, zinc not more than 0.04, boron not more than 0.01, and the balance of aluminum and inevitable impurities. The preparation method comprises the following steps: foundry returns, aluminum ingots and Al-Fe intermediate alloy blanks are put in a smelting furnace, are heated for melting, and are transferred into an insulation furnace; then, Al-Zr, Al-Sc, Al-Y and Al-RE intermediate alloys are added for refining and deslagging to prepare fine alloy melts; a continuous casting and continuous rolling process is adopted to firstly pour the fine alloy melts as aluminum alloy castings; and the aluminum alloy castings are leaded into a rolling mill to roll aluminum alloy rods with needed specifications. The aluminum alloy conductor material is high in electric conductivity and excellent in high-temperature resistance; and the preparation method needs no heat treatment, saves the energy consumption, and reduces the production cost.

Owner:河北欣意电缆有限公司

Heat-proof magnetic conveyor belt cover rubber and preparation method thereof

The invention provides heat-proof magnetic conveyor belt cover rubber. The cover rubber comprises the following components in parts by weight: 100 parts of ethylene propylene diene monomer rubber, 2-5 parts of anti-aging agent, 5-10 parts of zinc oxide, 2-8 parts of magnesium oxide, 1-3 parts of stearic acid, 25-50 parts of carbon black, 4-6 parts of dicumyl peroxide, 30-50 parts of asbestos fiber, 150-300 parts of magnetic powder, and 5-20 parts of paraffin oil. In addition, the invention further provides a preparation method of the heat-proof magnetic conveyor belt cover rubber. The heat-proof magnetic conveyor belt cover rubber meets the heat-proof property of high-temperature parts conveyed on an iron making and steel making production line, the heated aging damage rate of the conveyor belt can be reduced, and the service life of the conveyor belt can be prolonged; furthermore, metal parts falling on the conveyor belt can be effectively adsorbed, the slippage of the metal parts can be prevented, unnecessary damage can be reduced, the production of next procedure can be favorably carried out, and the working efficiency can be improved.

Owner:江苏凯嘉橡胶科技股份有限公司

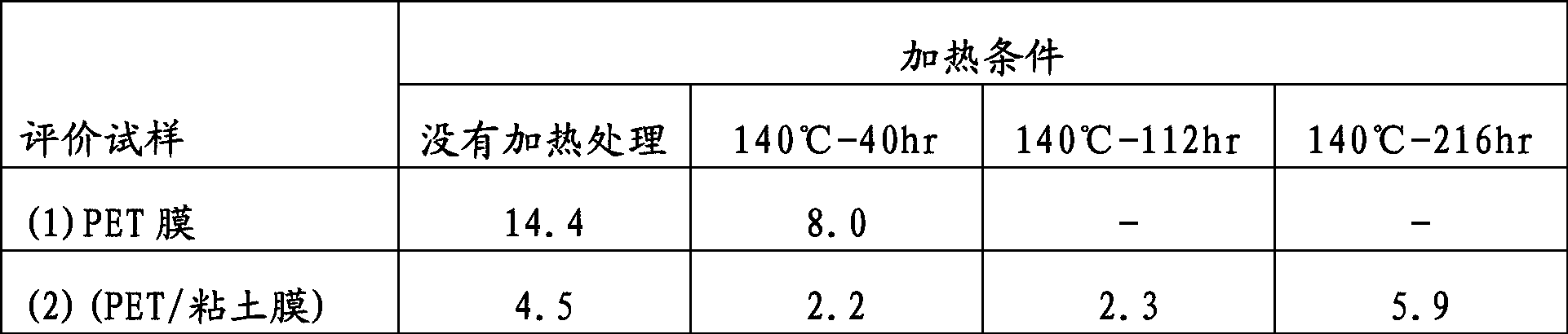

Water vapor barrier film and method for producing same

ActiveCN102939199AGood weather resistanceSatisfy the gas barrier propertyLayered productsPretreated surfacesLithiumWater vapor

Disclosed are: a film for a solar cell back sheet, which has excellent water vapor barrier properties, water resistance and gas barrier properties, while having adequate flexibility, adequate mechanical strength and excellent thermal stability; and a method for producing the film for a solar cell back sheet. Specifically disclosed is a water vapor barrier film which is obtained by coating a PET base with a clay film. The water vapor barrier film is characterized in that: the clay film is configured of clay and an additive; the weight ratio of the clay relative to the total solid is 60-90% by weight in the clay film; the production procedure thereof comprises a water resistance-imparting heat treatment that is carried out at 100-200 DEG C after coating and drying steps; the water vapor barrier film has a water vapor transmission rate of less than 3 g / m2 / day; the additive of the modified clay is a polyimide; and 90% by mole or more of the exchangeable ions are lithium ions. Also specifically disclosed is a method for producing the water vapor barrier film. The film has water vapor barrier properties and is useful as a back sheet for a solar cell or the like.

Owner:NAT INST OF ADVANCED IND SCI & TECH

Adhesive film, production methods of shaped body

ActiveUS20100316872A1Meet heat resistanceAdhesive processes with adhesive heatingLaminationMeth-Polymer science

An adhesive film comprising a substrate and an adhesive layer on said substrate, said adhesive layer comprising: (A) a carboxyl group-containing (meth)acrylate polymer having a glass transition temperature (Tg) of 25 C or lower, said carboxyl group-containing (meth)acrylate polymer having a percent number of repeating units of 4.0 to 25% based on the total number of repeating units of the (meth)acrylate polymer; and (B) an amino group-containing (meth)acrylate polymer having a glass transition temperature (Tg) of 75 C or higher, said amino group-containing (meth)acrylate polymer having a percent number of amino group-containing repeating units of 3.5 to 15% based on the total number of repeating units of the (meth)acrylate polymer, wherein the ratio by weight of said component (A) to said component (B) is from 62:38 to 75:25.

Owner:3M INNOVATIVE PROPERTIES CO

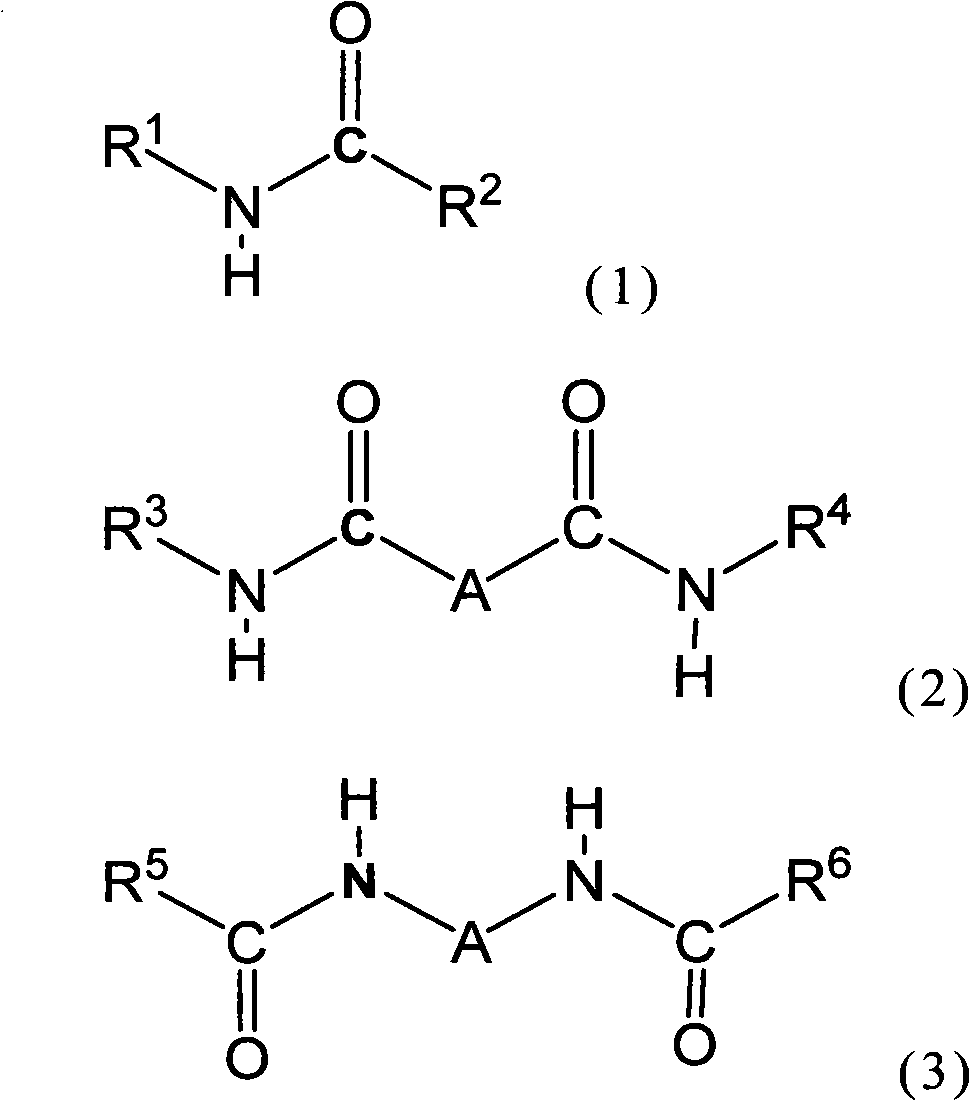

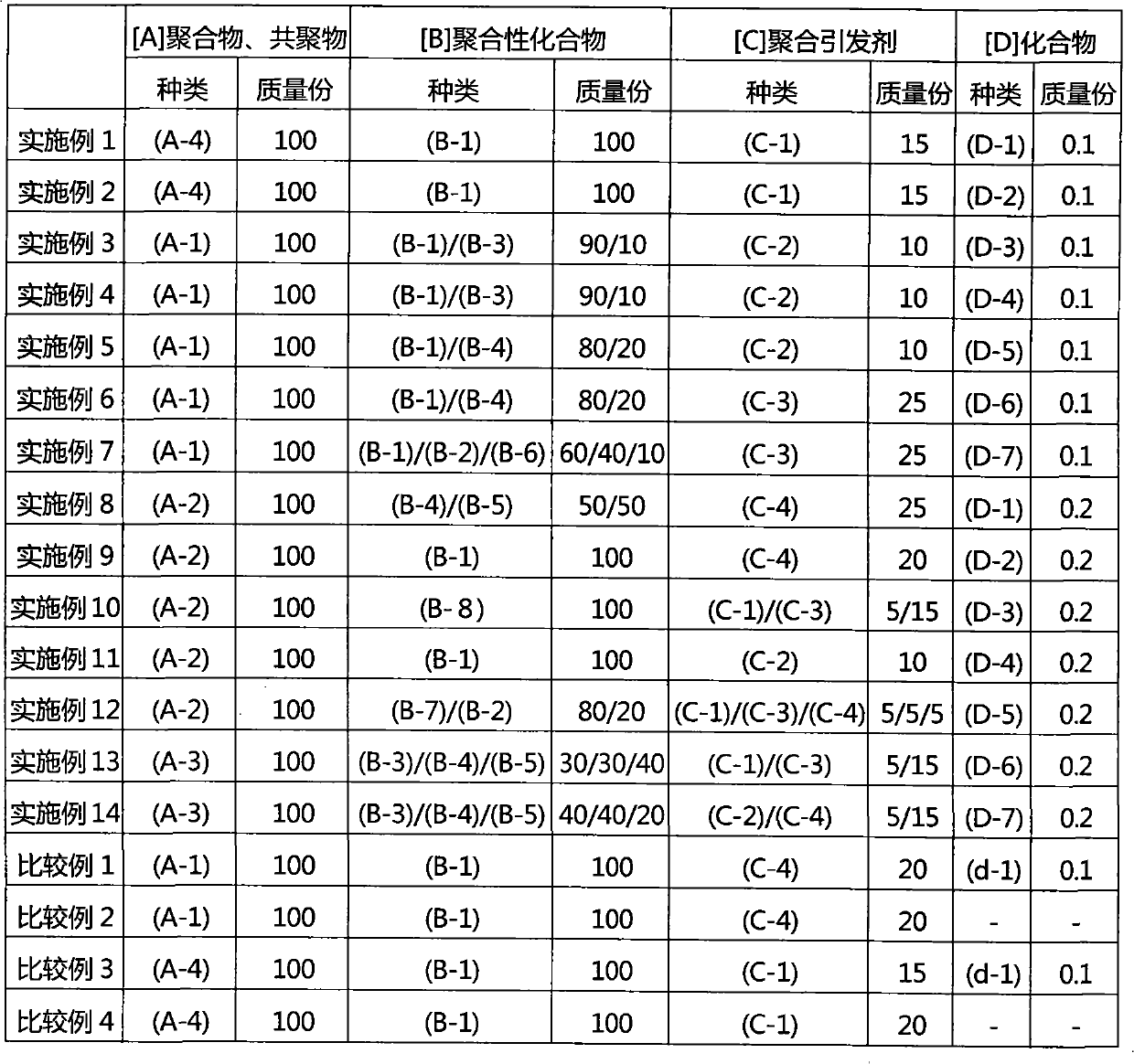

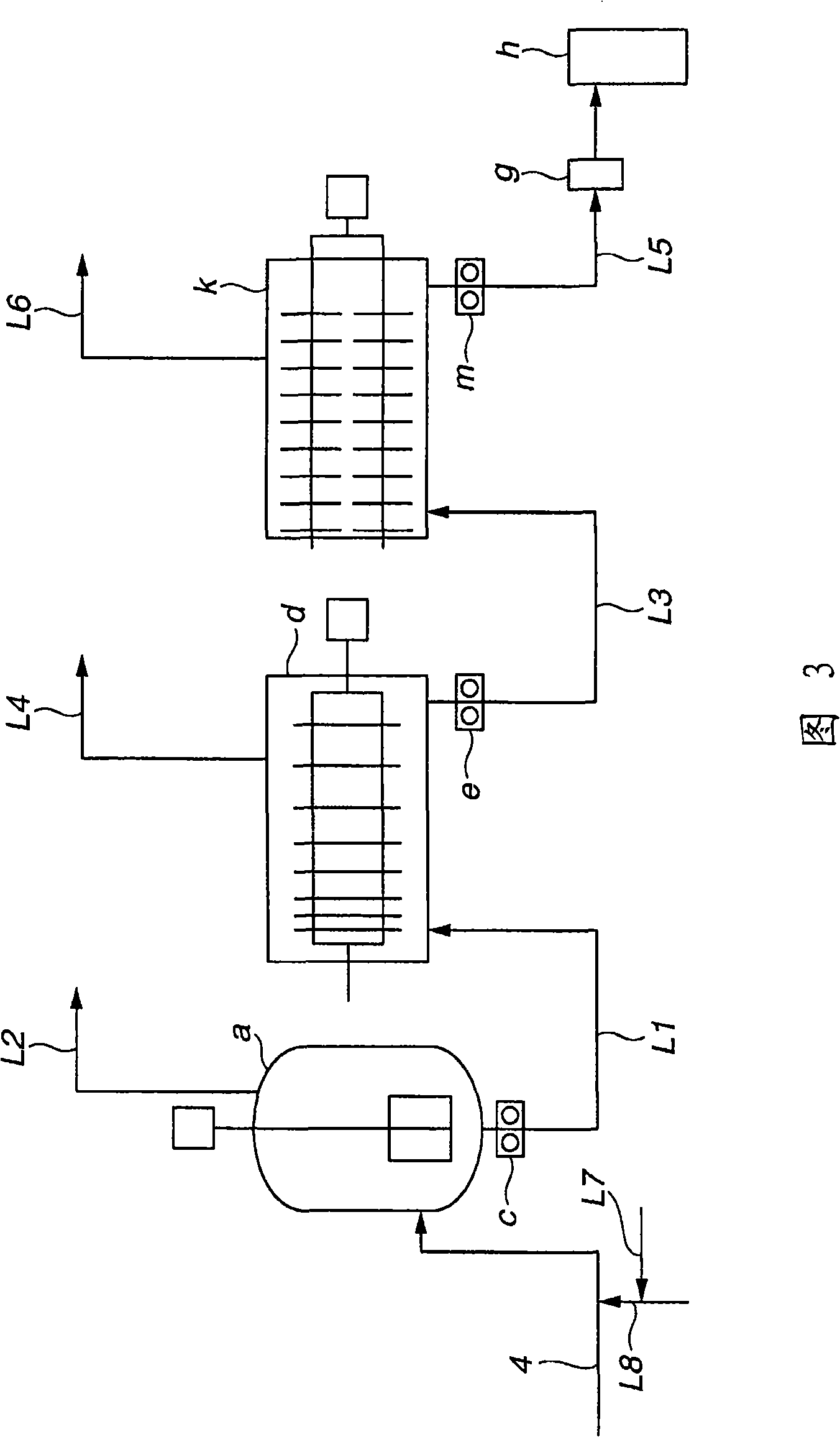

Radiation-sensitive resin composition, cured film, method for forming cured film, and display element

ActiveCN102269932AMeet heat resistanceSatisfies chemical corrosion resistanceSemiconductor/solid-state device manufacturingPhotosensitive materials for photomechanical apparatusHeat resistanceRadiation sensitivity

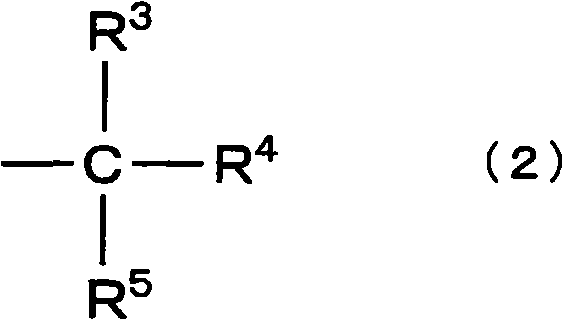

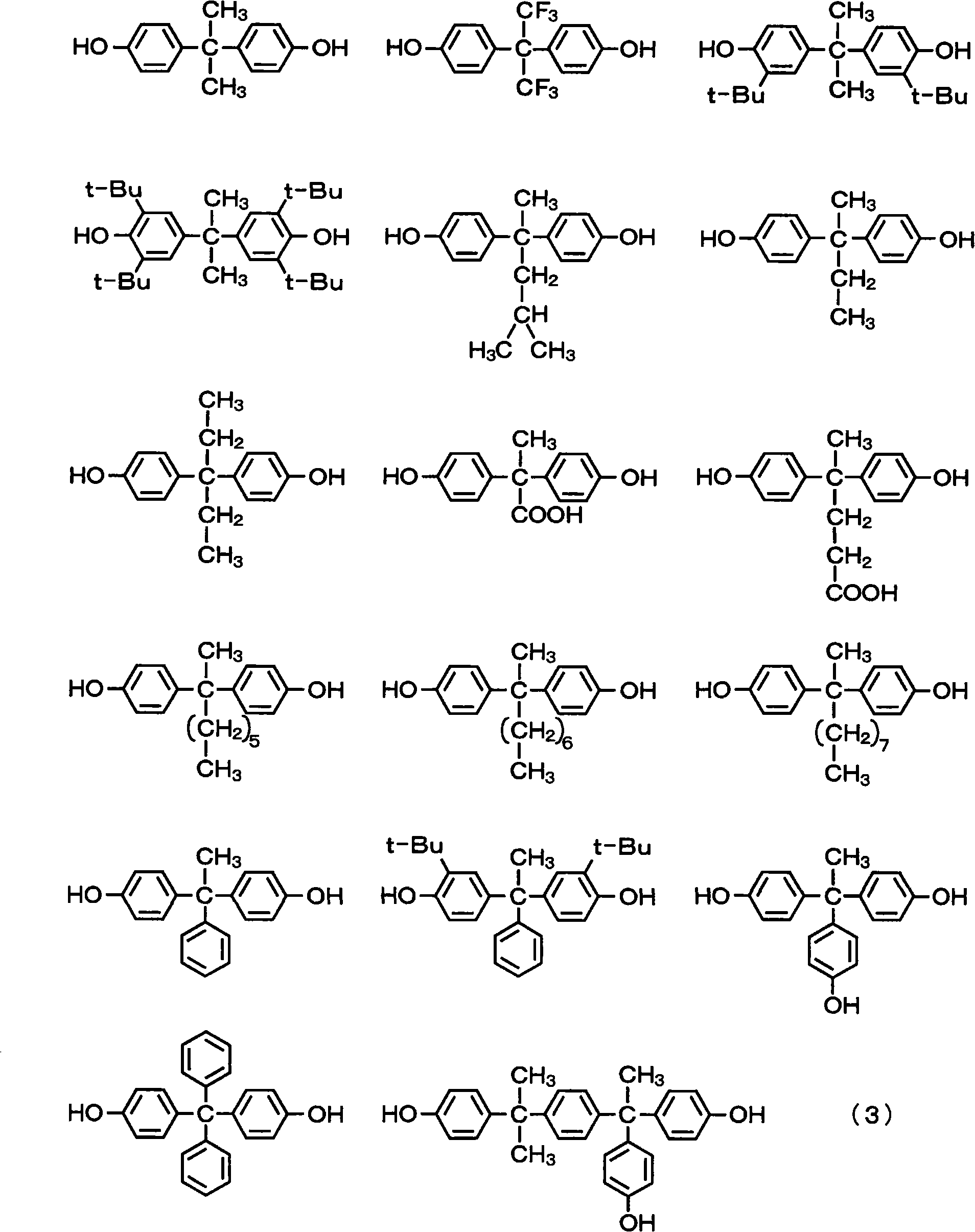

The invention provides a radiation-sensitive resin composition, a cured film and a forming method thereof and a display element. The radiation-sensitive resin composition is excellent in both storage stability and low-temperature firing performance. Meanwhile, the radiation-sensitive resin composition is sufficient in radiation sensitivity. The curved film is excellent in heat resistance, chemical-corrosion resistance, transmittance, smoothness, voltage holding ratio and heat resistant linear expansion property. The radiation-sensitive resin composition is characterized by comprising [A] a polymer having epoxy groups, [B] a polymerizable compound having an ethylenic unsaturated bond, [C] a radiation-sensitive polymerization initiator, and [D] at least one compound selected from the following formula (1)-(3).

Owner:JSR CORPORATIOON

Solder resist composition of light-curing single liquid style and printing circuit board use same

ActiveCN1800979AIncrease production capacityImprove reliabilityForging/hammering/pressing machinesPrinted circuit manufactureEpoxyResist

To provide a photosetting / thermosetting one-liquid type solder resist composite which has excellent storage stability and workability and is superior in heat resistance, adhesiveness, electroless gold plating resistnace, electroless tin plating resistance, and electric characteristic, and which can be developed by alkali, and to provide a printed wiring board using the same. The photosetting / thermosetting one-liquid type solder resist composite contains a copolymer-based resin (A) having a carboxyl group which is made by adding a copolymer comprised of an unsaturated monobasic acid (a), and a compound (b) having one unsaturated group in one or more kinds of molecules, with a compound (c) which has an alicyclic epoxy group and an unsaturated group together within one molecular; a diluent (B); a photopolymerization initiator (C); a melamine (D) or its organic acid salt; and an inorganic filler (E).

Owner:TAIYO INK MFG

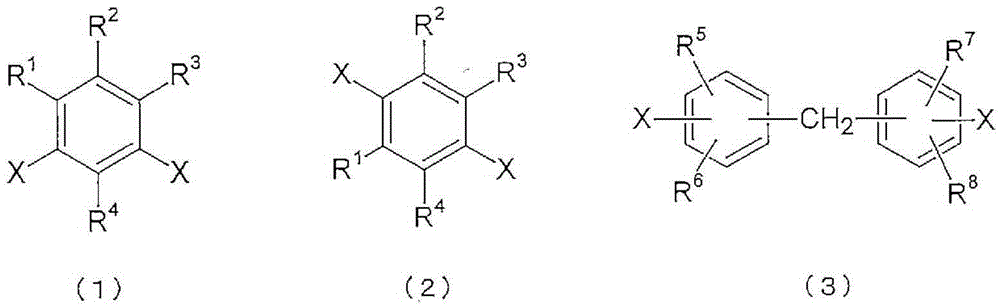

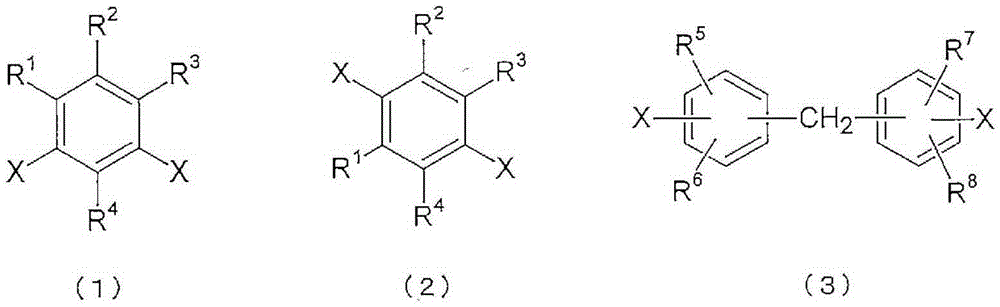

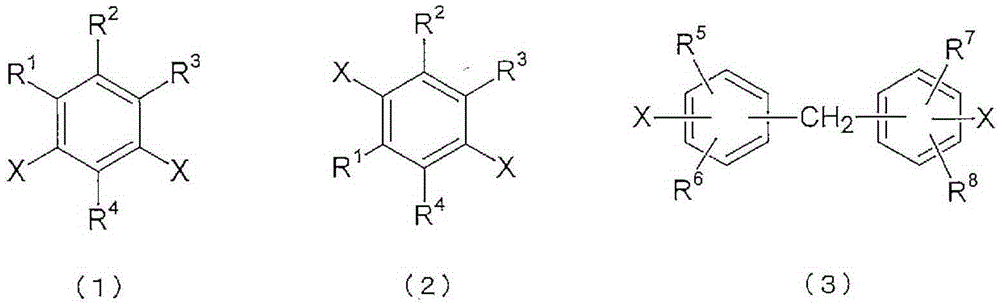

Polyimide copolymer oligomer, polyimide copolymer, and method for producing each of same

Provided are: a polyimide copolymer oligomer that satisfies a high level of solvent solubility, storage stability, and heat resistance, and that is the precursor material for a polyimide copolymer having superior utility; a polyimide copolymer obtained therefrom; and a method for producing each of same. The present invention results from the co-polymerization of (A) 3,3',4,4'-biphenyltetracarboxylic acid dianhydride and / or 3,3',4,4'-diphenylsulfonetetracarboxylic acid dianhydride and (B) at least one diamine and / or diisocyanate represented by general formulae (1) to (3) (in the formulae: X is an amino group or an isocyanate group; R<1>-R<8> each independently represent a hydrogen atom, an alkyl group having 1-4 carbon atoms, an alkenyl group having 2-4 carbon atoms, or an alkoxy group having 1-4 carbon atoms; and at least one of R<1>-R<8> is not a hydrogen atom).

Owner:SOMAR CORP

Aromatic polycarbonate resin composition and molded resin

ActiveCN101346430ASatisfy mobilityMeet the rigidityProductsReagentsPolytetramethylene terephthalatePolybutylene terephthalate

An aromatic polycarbonate resin composition which comprises an aromatic polycarbonate resin (ingredient (A)) and a polybutylene terephthalate resin (ingredient (B)) and optionally further contains a rubbery polymer and / or an inorganic filler, characterized in that the amounts of the aromatic polycarbonate resin (ingredient (A)) and the polybutylene terephthalate resin (ingredient (B)) are 51-99 parts by weight and 1-49 parts by weight, respectively, per 100 parts by weight of the sum of the aromatic polycarbonate resin (ingredient (A)) and the polybutylene terephthalate resin (ingredient (B)) and that the polybutylene terephthalate resin (ingredient (B)) has a titanium compound content of 1-75 ppm, excluding 1 ppm, in terms of titanium atom amount and a terminal carboxy group content of 39 [mu]eq / g or lower. This aromatic polycarbonate resin composition has an excellent balance among various properties, i.e., is satisfactory in all of flowability, rigidity, impact resistance, chemical resistance, fatigue characteristics, heat resistance, thermal stability in residence, and suitability for recycling.

Owner:MITSUBISHI ENG PLASTICS CORP

Environmentally-friendly white halogen-free reinforced flame-retardant high-temperature nylon and preparation process thereof

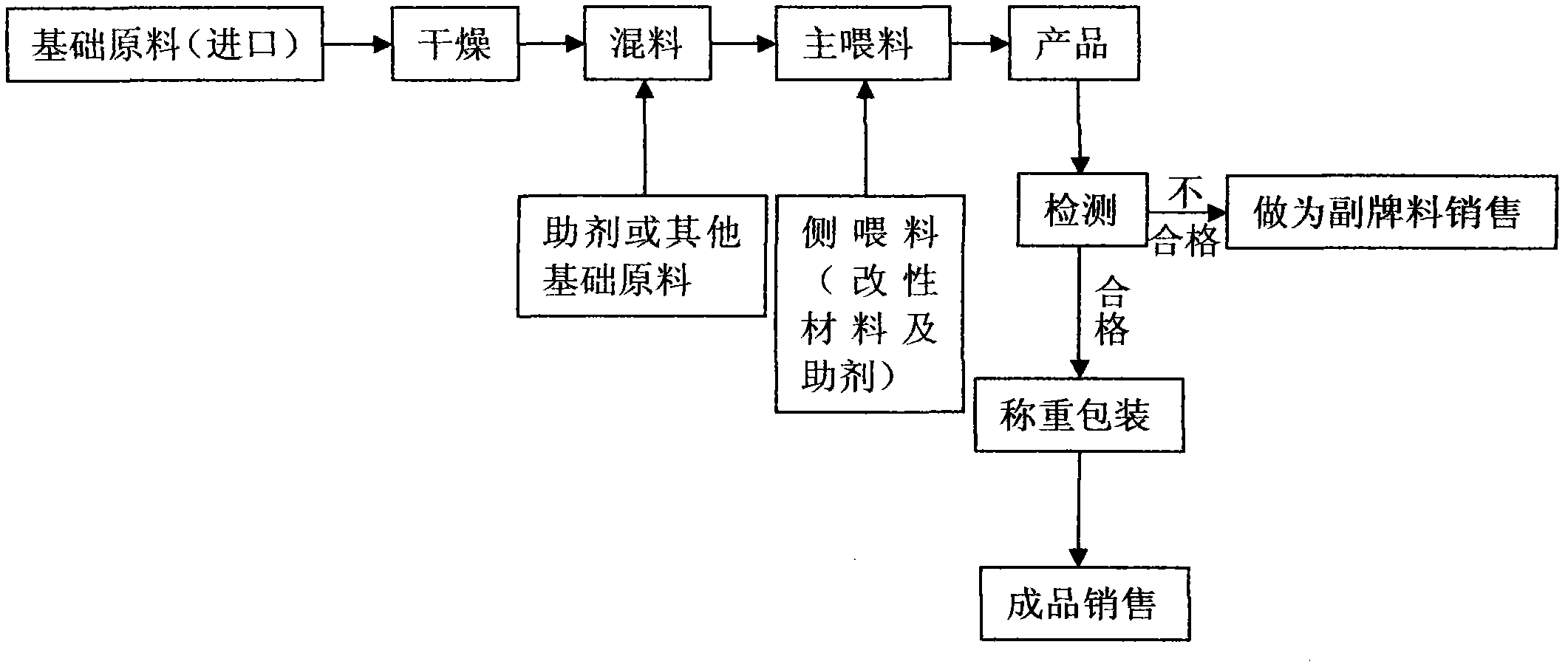

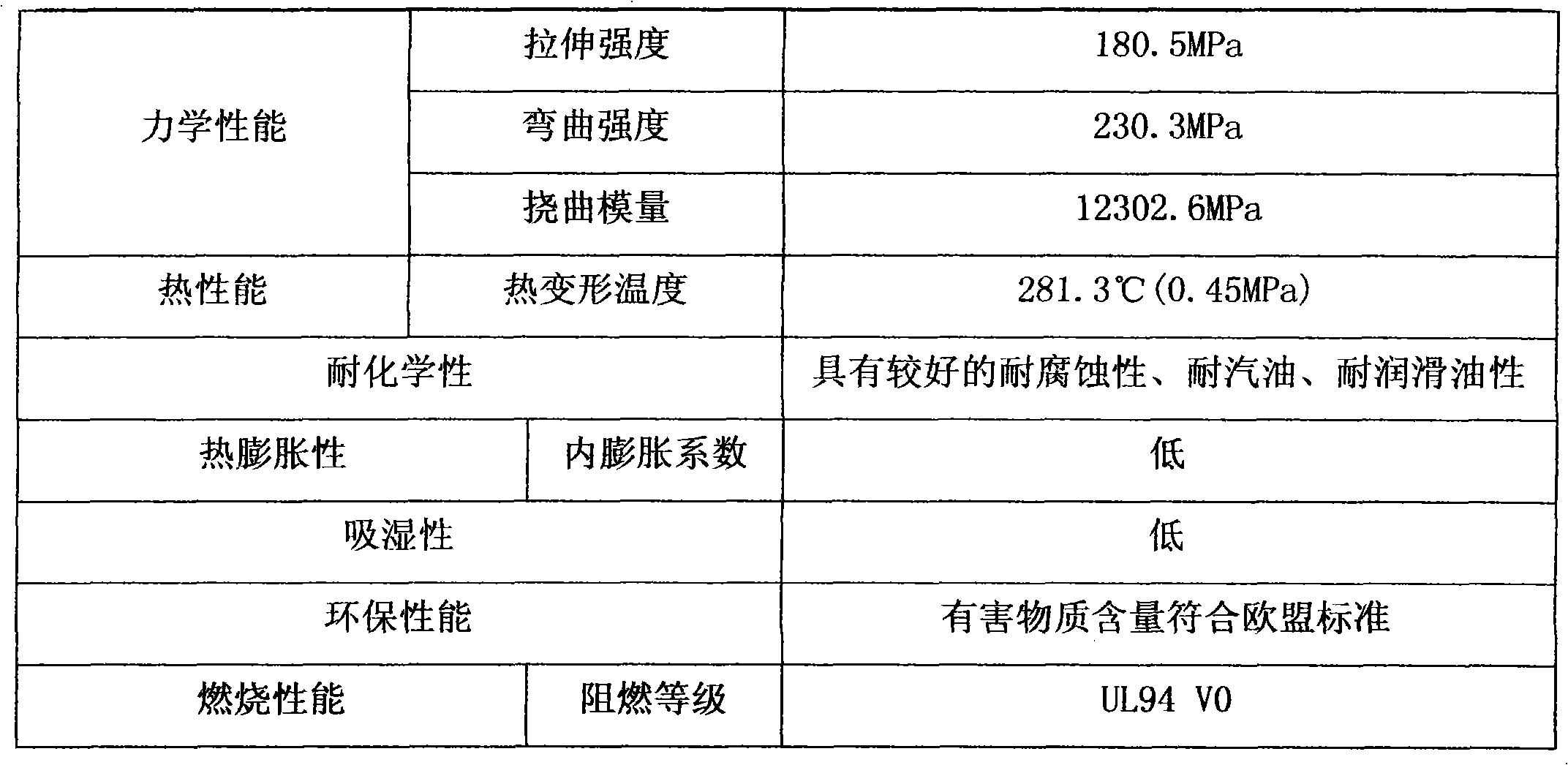

The invention relates to environmentally-friendly white halogen-free reinforced flame-retardant high-temperature nylon. The nylon comprises the following components in part by weight: 35 to 75 parts of high-temperature nylon resin, 4 to 25 parts of flame retardant, 0.1 to 0.5 part of auxiliary agent and 10 to 50 parts of reinforced material. The preparation method for the nylon comprises the following steps of: 1) drying; 2) mixing; 3) extruding; and 4) molding and pelletizing. The product has the advantages of high strength, high flame resistance, high size stability, high temperature resistance, environment friendliness and the like. An antioxidant can play a role in anti-oxidizing protecting, maintains the stability of materials of the product in production, and protects the flame retardant and the high-temperature nylon resin from oxidative discoloration and decomposition; and a nucleating agent and a lubricating agent can improve the fluidity of the product, speed up the cooling and the forming of the product, improve the production efficiency of the product in injection machining, and contribute to demoulding the products in the injection molding. The environmentally-friendly white halogen-free reinforced flame-retardant high-temperature nylon can be used in circuit breakers, socket connectors such as power connectors, storage card connectors and sockets, motor components, computers and auxiliary equipment thereof, electric products, household electric appliance and the like.

Owner:QINGDAO COMPOLY HIGH PERFORMANCE POLYMERS

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com