Environmentally-friendly white halogen-free reinforced flame-retardant high-temperature nylon and preparation process thereof

A preparation process and environment-friendly technology, which is applied in the field of environment-friendly natural white halogen-free reinforced flame-retardant high-temperature nylon and its preparation process, can solve the problem that cannot meet the continuous miniaturization trend of integrated circuit boards and surface mount technology, which affects appearance and environment. Pollution and other issues, to meet the requirements of heat resistance and fire prevention, improve production efficiency, and broad market prospects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

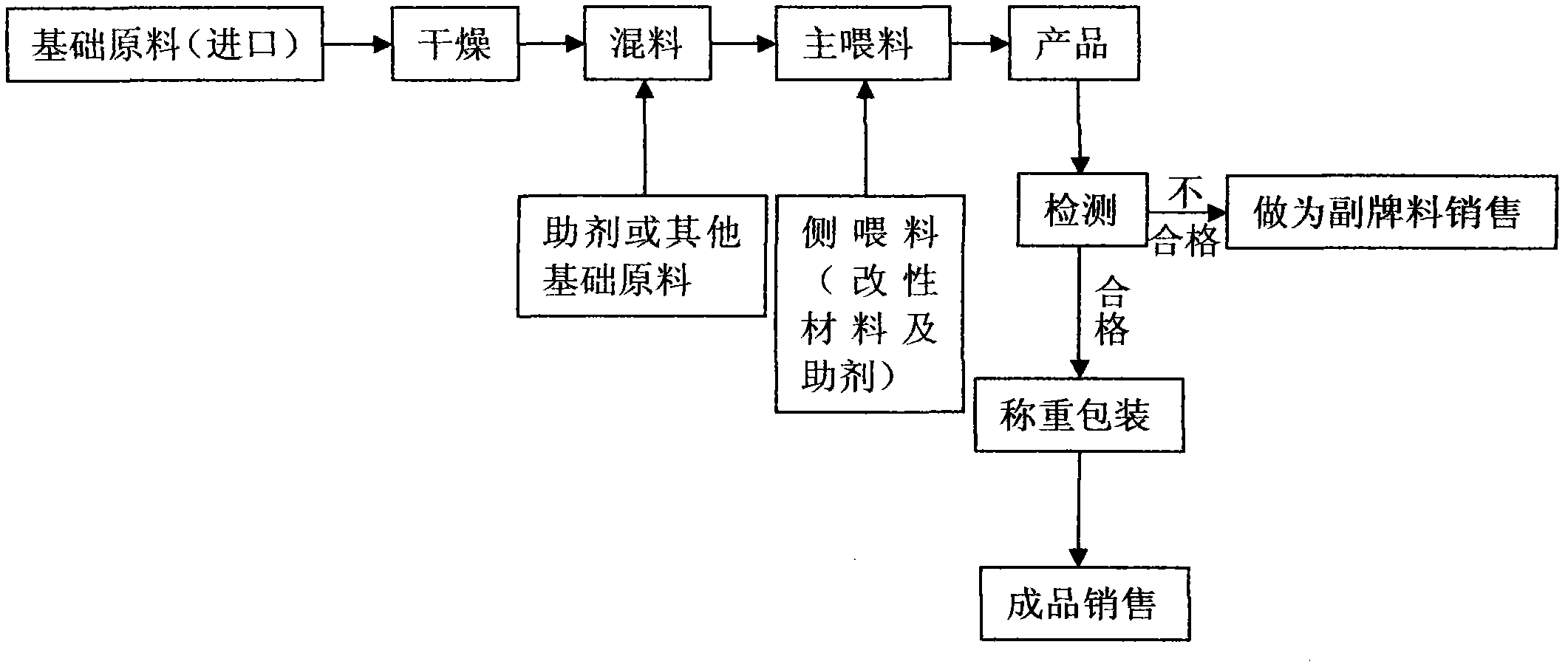

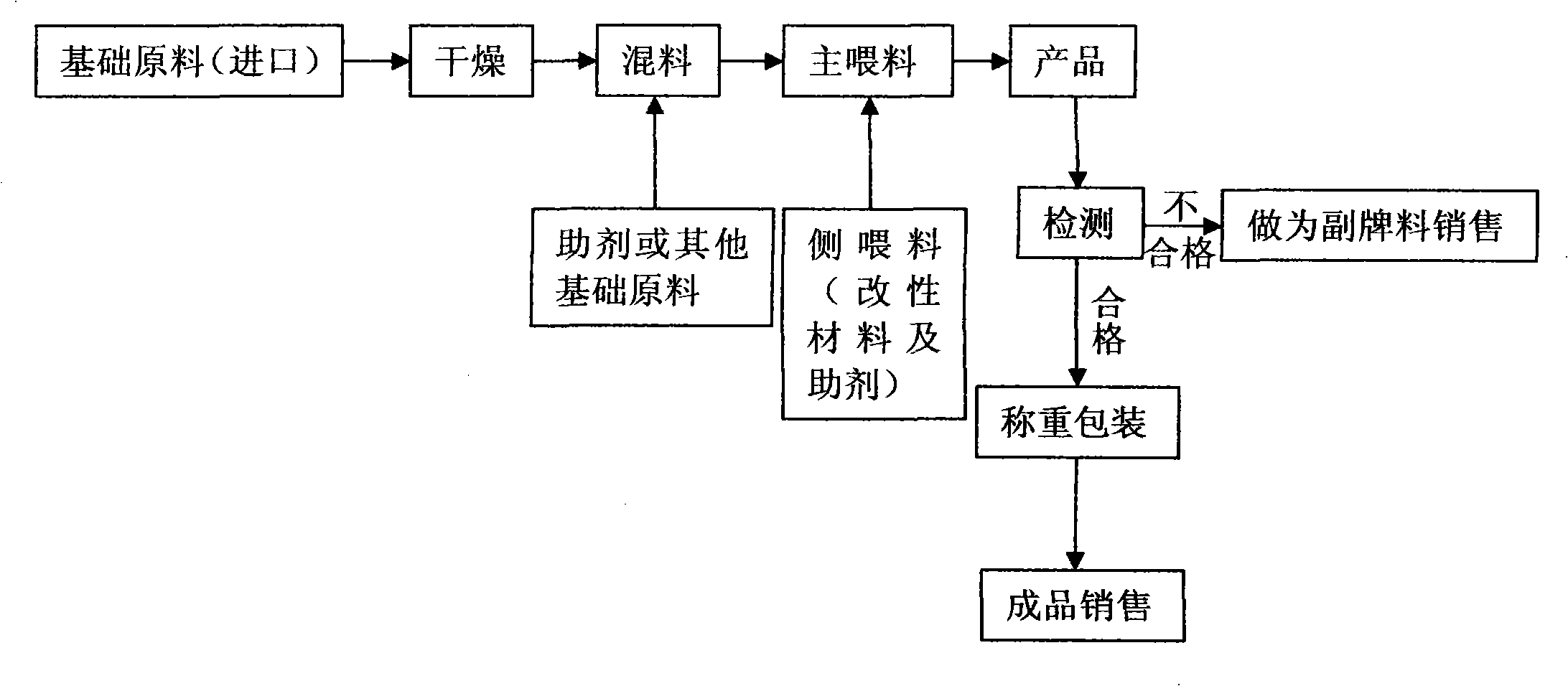

Method used

Image

Examples

specific Embodiment 1

[0026] Specific embodiment one: 35kg high-temperature nylon resin is dried in the blast dryer, and the set temperature in the blast dryer is 105°C, and the drying time is 6 hours, so that the final water content is 0.2%; High-temperature nylon resin, 6kg halogen-free environmentally friendly flame retardant, 0.08kg antioxidant, 0.03kg nucleating agent and 0.07kg lubricant were mixed in a high-speed mixer for 5 minutes while keeping the temperature at 40°C; Extruded by a twin-screw extruder, 10kg of long glass fibers are added through side feeding, the temperature is set at 320°C, and the screw speed of the co-rotating twin-screw extruder is 280 rpm; finally, after water-cooled pelletizing and vibration screening , sealed waterproof packaging, made of environmentally friendly off-white halogen-free reinforced flame-retardant high-temperature nylon.

specific Embodiment 2

[0027] Specific embodiment two: 50kg high-temperature nylon resin is dried in the blast dryer, and the set temperature in the blast dryer is 112°C, and the drying time is 10 hours, so that the final water content is 0.1%; High-temperature nylon resin, 18kg halogen-free environmentally friendly flame retardant, 0.13kg antioxidant, 0.08kg nucleating agent and 0.15kg lubricant were mixed in a high-speed mixer for 5 minutes while keeping the temperature at 75°C; Extruded by a twin-screw extruder, 30kg of long glass fibers are added through side feeding, the temperature is set at 318°C, and the screw speed of the co-rotating twin-screw extruder is 330 rpm; finally, after water-cooled pelletizing and vibration screening , sealed waterproof packaging, made of environmentally friendly off-white halogen-free reinforced flame-retardant high-temperature nylon.

specific Embodiment 3

[0028] Specific embodiment three: 75kg high-temperature nylon resin is carried out drying treatment in blast drier, and setting temperature in blast drier is 120 ℃, and drying time is 8 hours, makes final water content at 0.16%; High-temperature nylon resin, 25kg halogen-free environmentally friendly flame retardant, 0.11kg antioxidant, 0.12kg nucleating agent and 0.2kg lubricant were mixed in a high-speed mixer for 5 minutes while keeping the temperature at 55°C; Extruded by a twin-screw extruder, 50kg of long glass fibers are added through side feeding, the temperature is set at 315°C, and the screw speed of the co-rotating twin-screw extruder is 300 rpm; finally, after water-cooled pelletizing and vibration screening , sealed waterproof packaging, made of environmentally friendly off-white halogen-free reinforced flame-retardant high-temperature nylon.

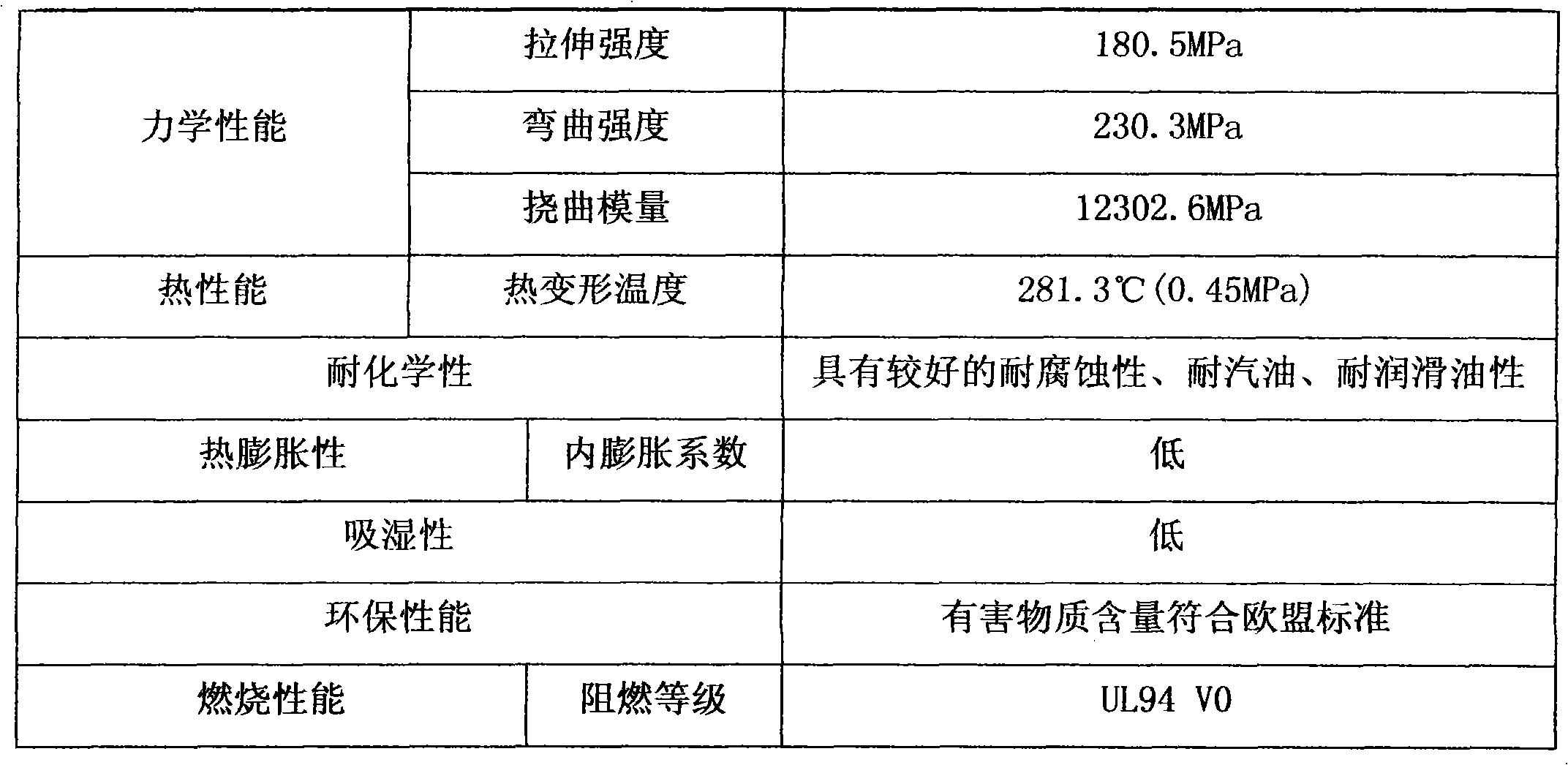

[0029] Product performance test report:

[0030] Test items

[0031]

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

| heat deflection temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com