Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

31results about How to "Meet temperature resistance requirements" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Yttrium silicate modified silicon carbide fiber reinforced silicon carbide composite material and preparation method thereof

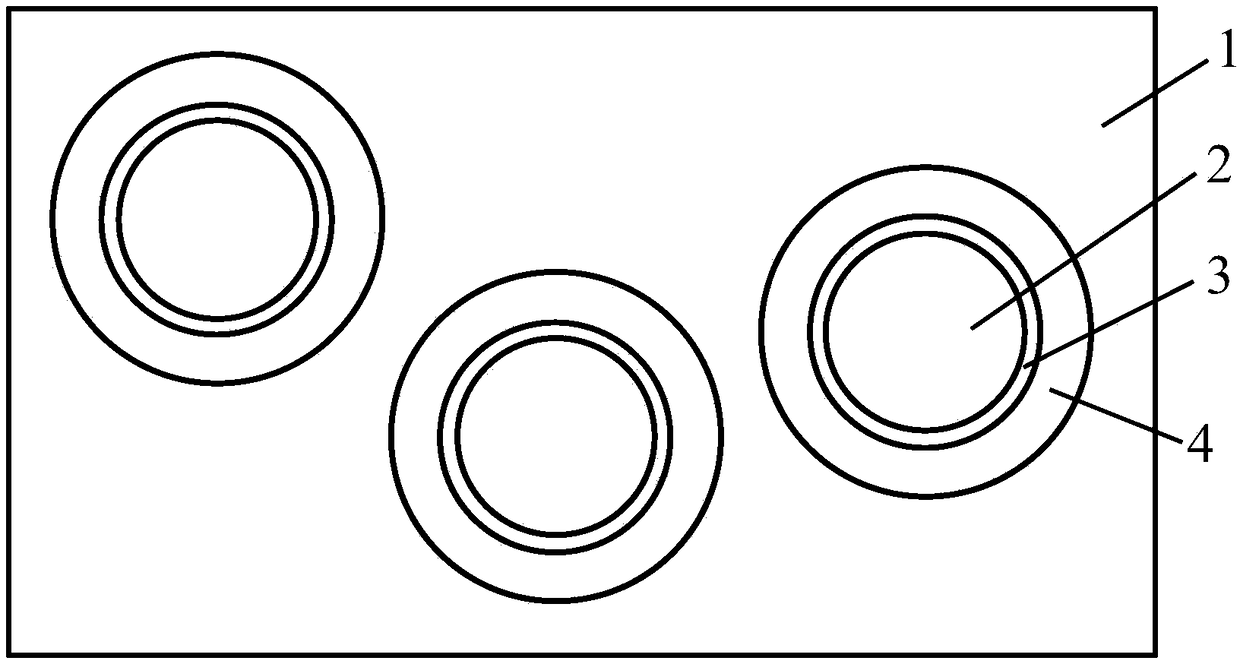

ActiveCN109053207AGood chemical stabilityImprove high temperature resistanceWater vaporInterface layer

The invention relates to a yttrium silicate modified silicon carbide fiber reinforced silicon carbide composite material and a preparation method thereof. The preparation method comprises the following steps: (1) sequentially preparing a yttrium silicate interface layer and a silicon carbide interface layer on the surface of a silicon carbide fiber prefabricated body so as to obtain a yttrium silicate modified silicon carbide fiber prefabricated body; (2) soaking the yttrium silicate modified silicon carbide fiber prefabricated body prepared in the step (1) into a carbon precursor solution, and sequentially carrying out a curing step and a cracking step on the soaked yttrium silicate modified silicon carbide fiber prefabricated body; (3) at least repeating the step (2) once so as to obtaina porous silicon carbide fiber prefabricated body; (4) carrying out a liquid silicon infiltration reaction on the porous silicon carbide fiber prefabricated body prepared in the step (3), thereby obtaining a yttrium silicate modified SiC / SiC composite material. The yttrium silicate modified SiC / SiC composite material provided by the invention has excellent oxidation resistance, temperature resistance, vapor corrosion resistance, and the like, and is excellent in comprehensive property.

Owner:AEROSPACE INST OF ADVANCED MATERIALS & PROCESSING TECH

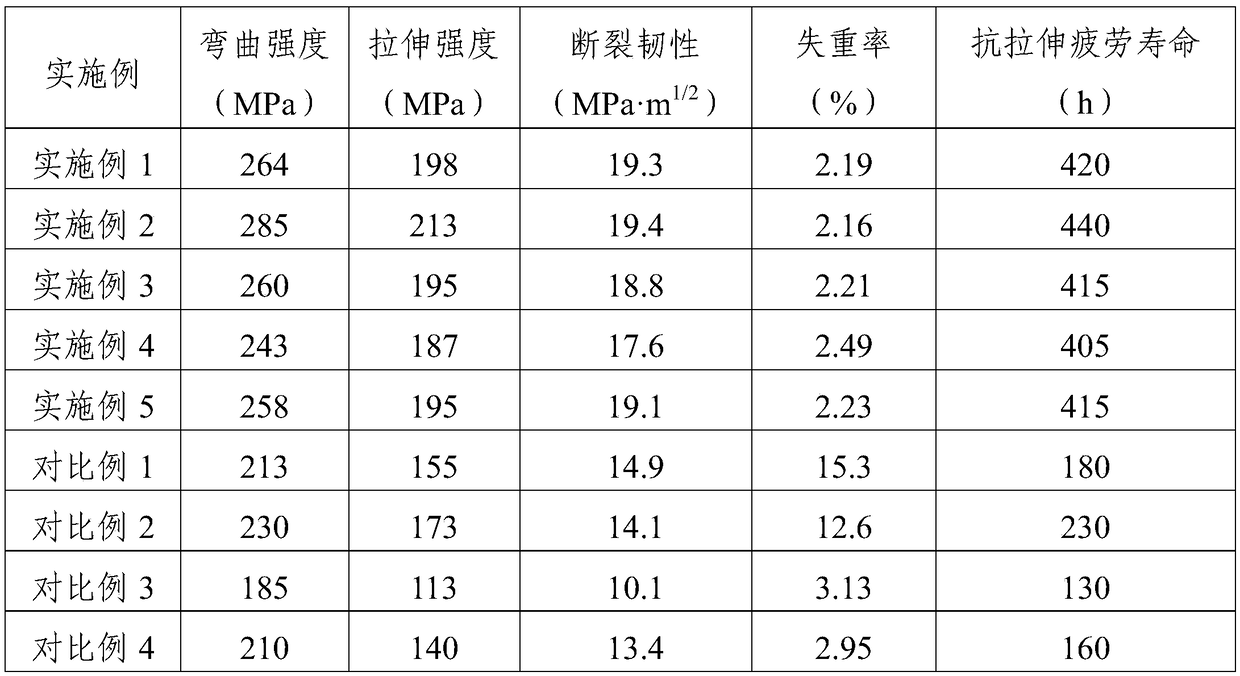

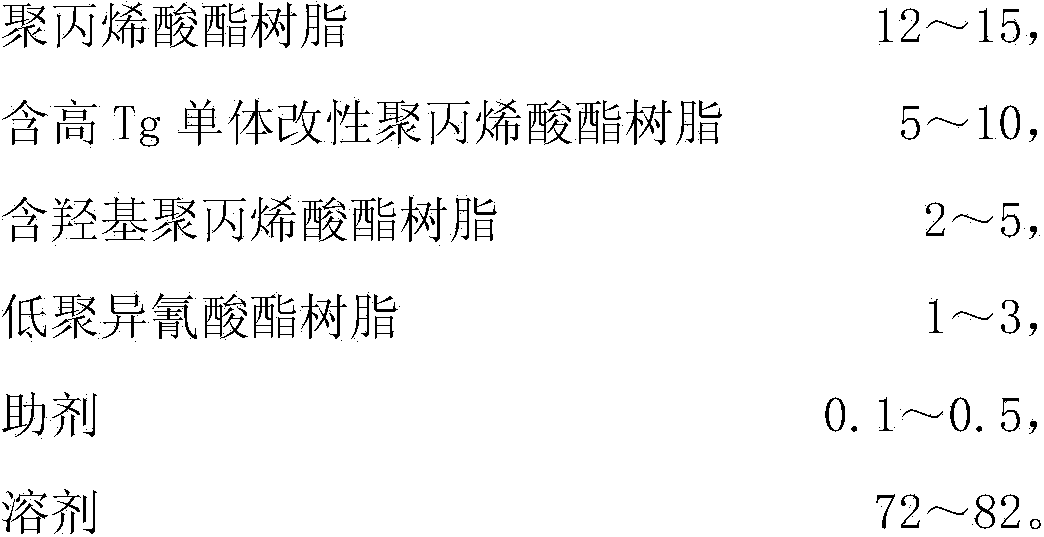

Coating composition for transferable laser anti-counterfeiting plate and method for preparing transferable laser anti-counterfeiting plate

ActiveCN103555113AHigh hardnessMeet high temperature resistance requirementsAnti-corrosive paintsPolyurea/polyurethane coatingsAdhesivePolyethylene glycol

The invention discloses a coating composition for a transferable laser anti-counterfeiting plate and a method for preparing the transferable laser anti-counterfeiting plate. The coating composition comprises the following components in parts by weight: 2-15 parts of polyacrylate resin, 5-10 parts of high-Tg-monomer-containing modified polyacrylate resin, 2-5 parts of hydroxyl-containing polyacrylate resin, 1-3 parts of low polyisocyanate resin, 0.1-0.5 part of aid and 72-82 parts of solvent. The method for preparing the transferable laser anti-counterfeiting plate comprises the following steps: coating the coating composition on a polyethylene glycol terephthalate (PET)-based film, performing die pressing, plating aluminum, coating and transferring a heat-seal adhesive, and preparing a transferable film; stripping the PET-based film on the transferable film, compounding the coating composition to a coil base material, and preparing the transferable laser anti-counterfeiting plate. The coating composition can meet high solvent-resistant and temperature-resistant temperatures in the production process of laser anti-counterfeiting plates. Moreover, the PET-based film used by transferable color steel can be repeatedly used, environment friendliness is promoted, and the production cost is reduced.

Owner:SHANGHAI WEIKAI CHEM +1

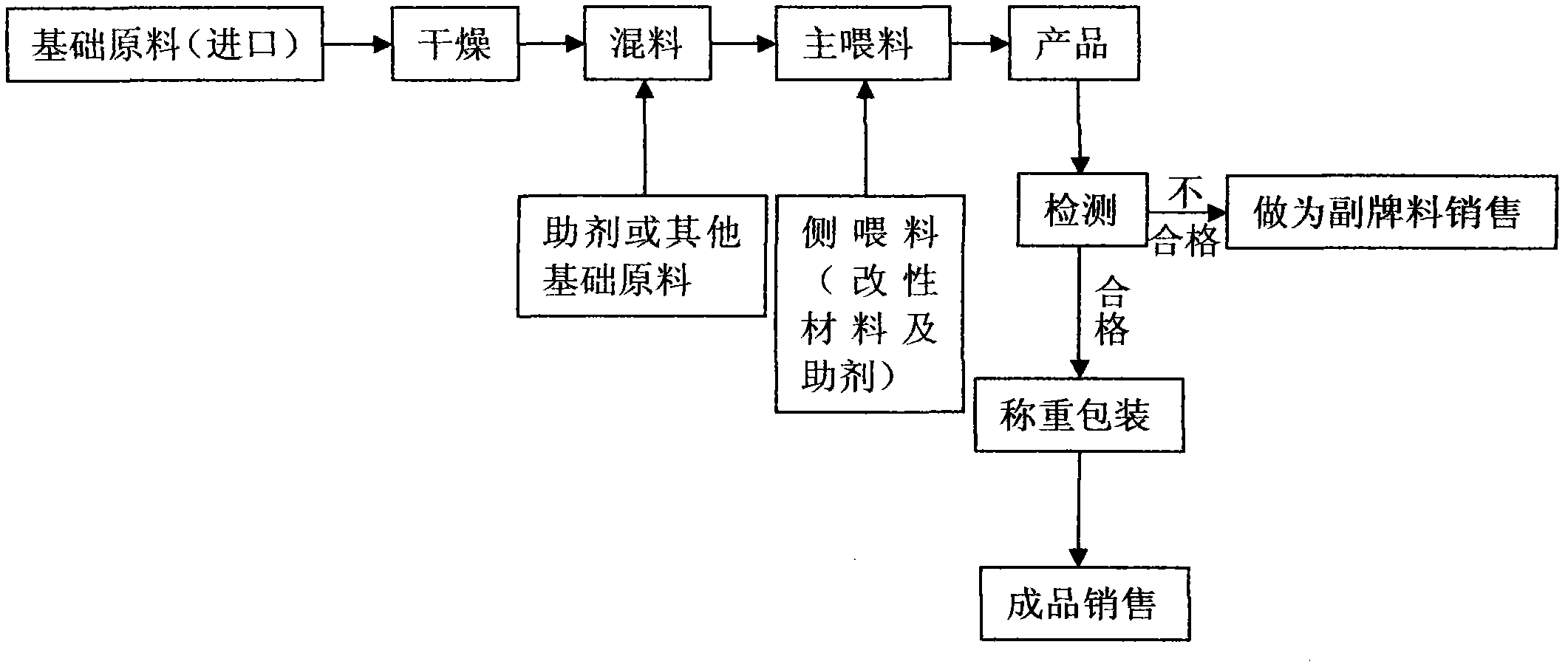

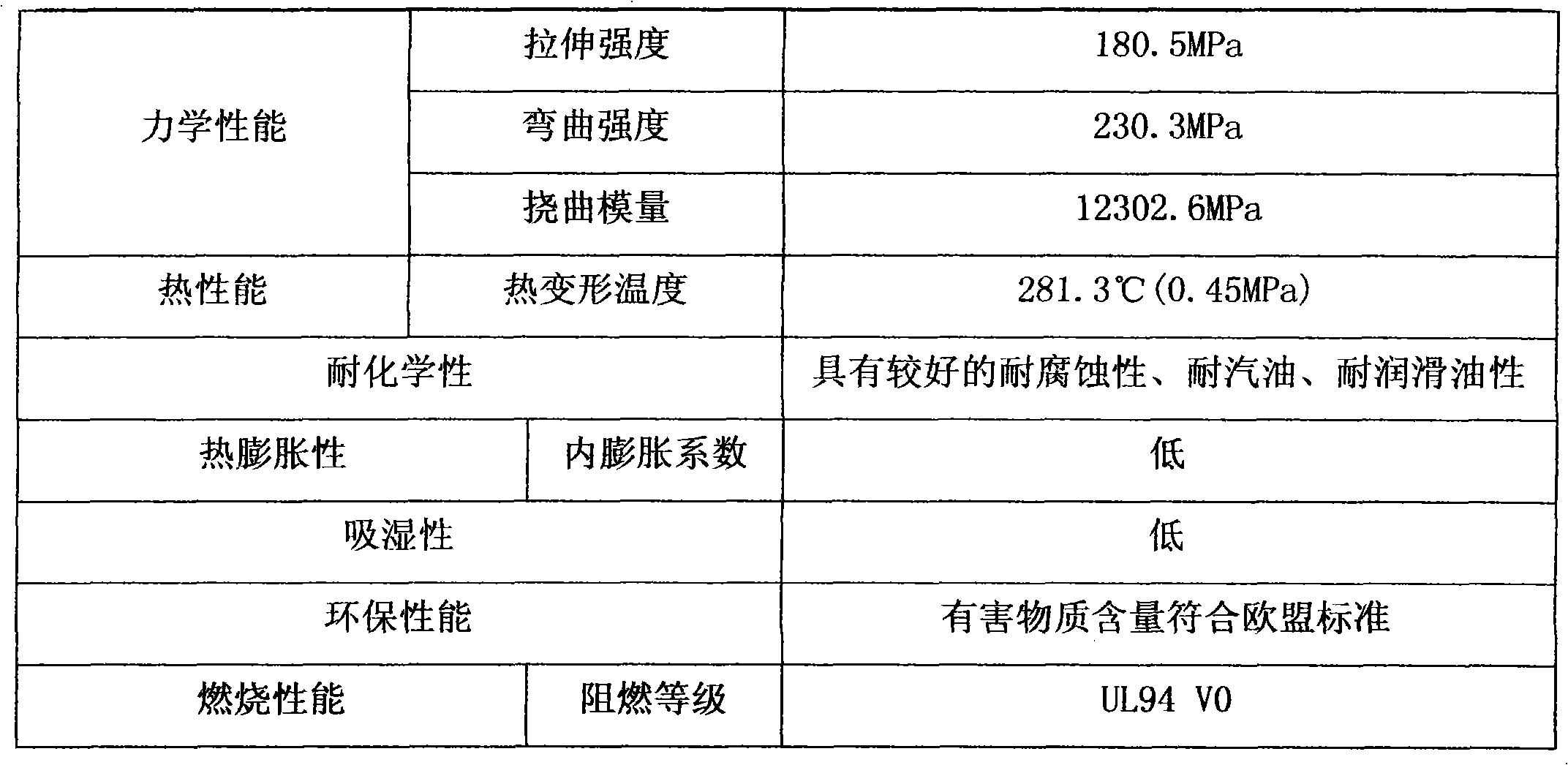

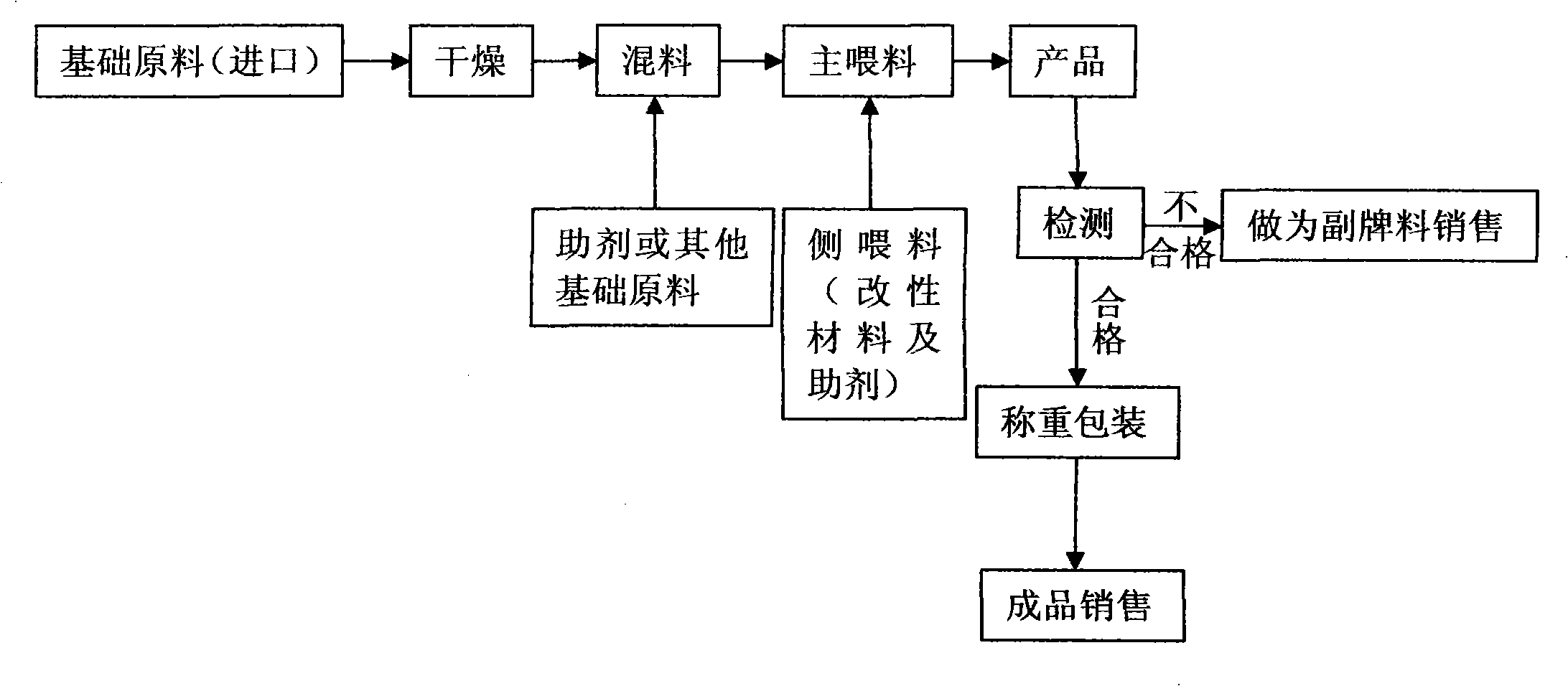

Environmentally-friendly white halogen-free reinforced flame-retardant high-temperature nylon and preparation process thereof

The invention relates to environmentally-friendly white halogen-free reinforced flame-retardant high-temperature nylon. The nylon comprises the following components in part by weight: 35 to 75 parts of high-temperature nylon resin, 4 to 25 parts of flame retardant, 0.1 to 0.5 part of auxiliary agent and 10 to 50 parts of reinforced material. The preparation method for the nylon comprises the following steps of: 1) drying; 2) mixing; 3) extruding; and 4) molding and pelletizing. The product has the advantages of high strength, high flame resistance, high size stability, high temperature resistance, environment friendliness and the like. An antioxidant can play a role in anti-oxidizing protecting, maintains the stability of materials of the product in production, and protects the flame retardant and the high-temperature nylon resin from oxidative discoloration and decomposition; and a nucleating agent and a lubricating agent can improve the fluidity of the product, speed up the cooling and the forming of the product, improve the production efficiency of the product in injection machining, and contribute to demoulding the products in the injection molding. The environmentally-friendly white halogen-free reinforced flame-retardant high-temperature nylon can be used in circuit breakers, socket connectors such as power connectors, storage card connectors and sockets, motor components, computers and auxiliary equipment thereof, electric products, household electric appliance and the like.

Owner:QINGDAO COMPOLY HIGH PERFORMANCE POLYMERS

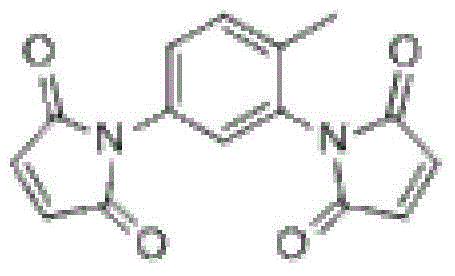

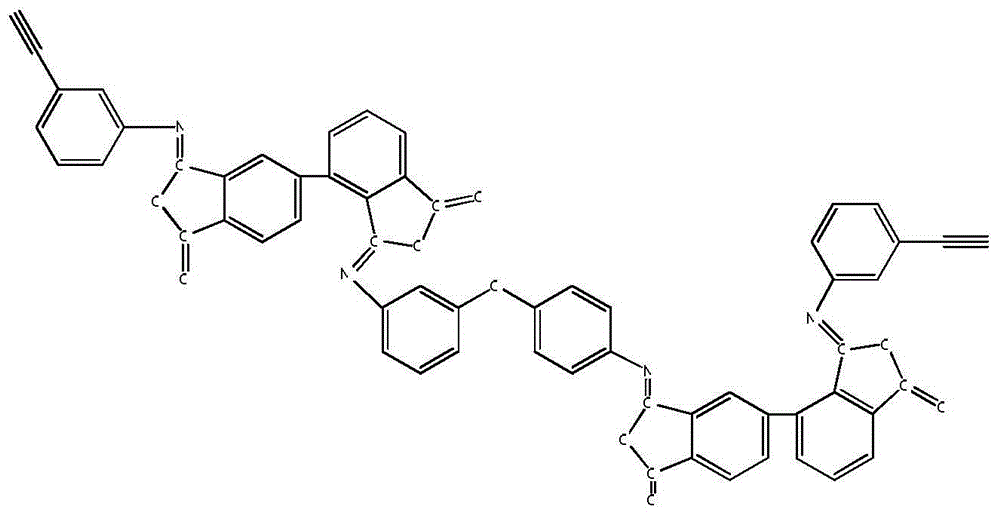

High-temperature-resistant honeycomb node adhesive and preparation method thereof

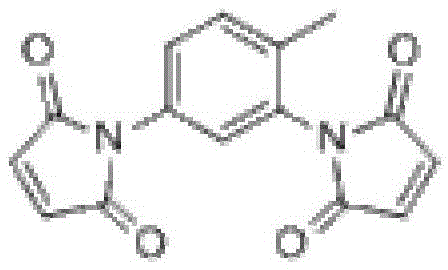

InactiveCN104479620AGood solubilityGood heat resistanceNon-macromolecular adhesive additivesMacromolecular adhesive additivesSolventCyanate ester

The invention discloses a high-temperature-resistant honeycomb node adhesive and a preparation method thereof and relates to an adhesive and a preparation method thereof. The high-temperature-resistant honeycomb node adhesive is used for solving the problem that the existing honeycomb node adhesive cannot meet the requirements on the manufacturing of polyimide paper honeycomb due to low temperature-resistant level and poor bonding compatibility. The adhesive is prepared from matrix resin, BMT type bismaleimide resin, phenolic cyanate ester, a co-polymerization modifier, a rubber elastomer toughening agent, inorganic nanometer filler and a solvent. The preparation method comprises the following steps: firstly, weighing; secondly, preparing toughening modified resin; thirdly, mechanically blending to obtain mixed rubber sheets; and fourthly, preparing uniform rubber liquid under stirring. The high-temperature-resistant honeycomb node adhesive is mainly applied in manufacturing aerospace polyimide paper honeycomb and has the characteristics of high temperature resistance and good process performance. The high-temperature-resistant honeycomb node adhesive prepared by the preparation method is used for the manufacturing of aerospace polyimide paper honeycomb and has the characteristics of high temperature resistance and good process performance.

Owner:INST OF PETROCHEM HEILONGJIANG ACADEMY OF SCI

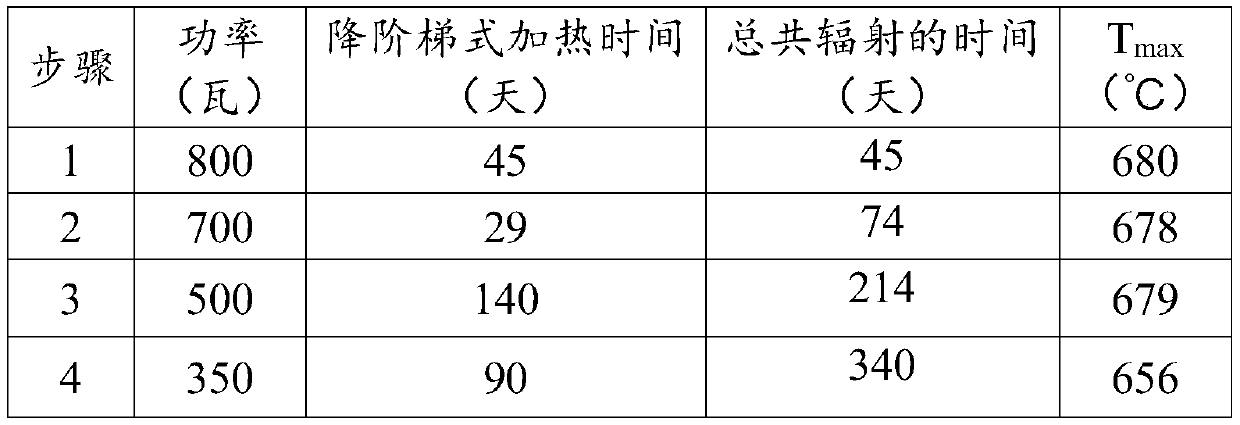

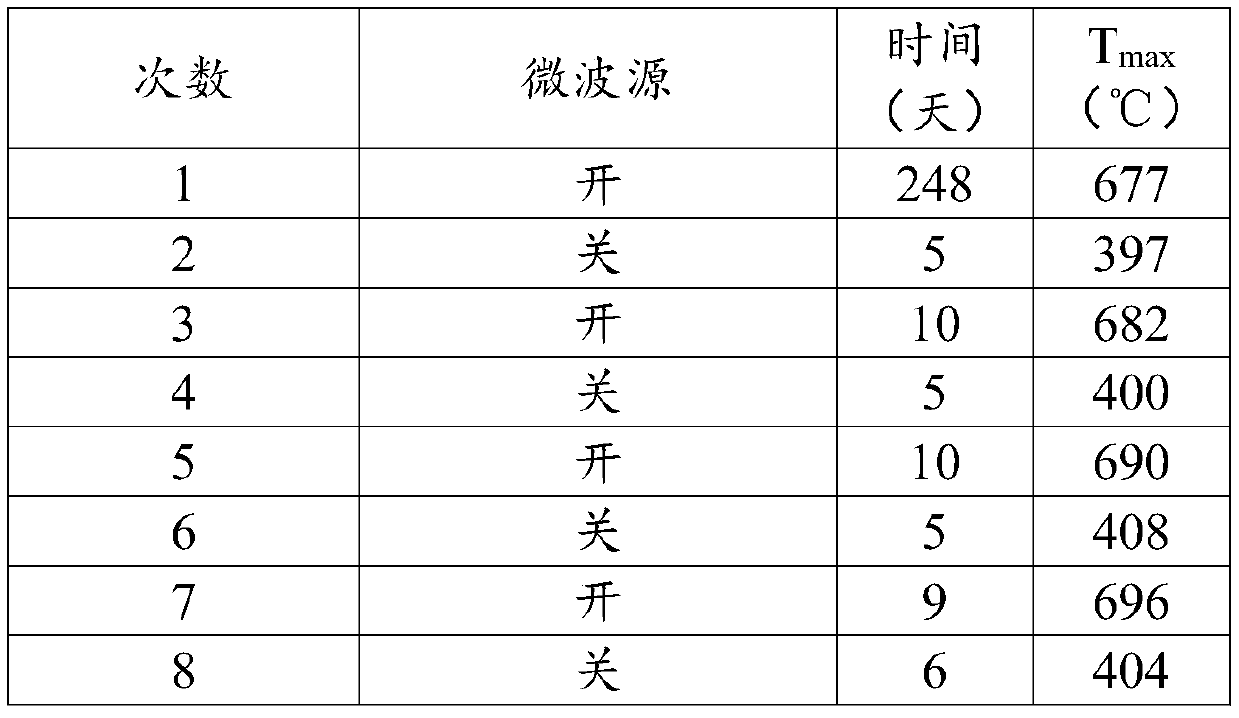

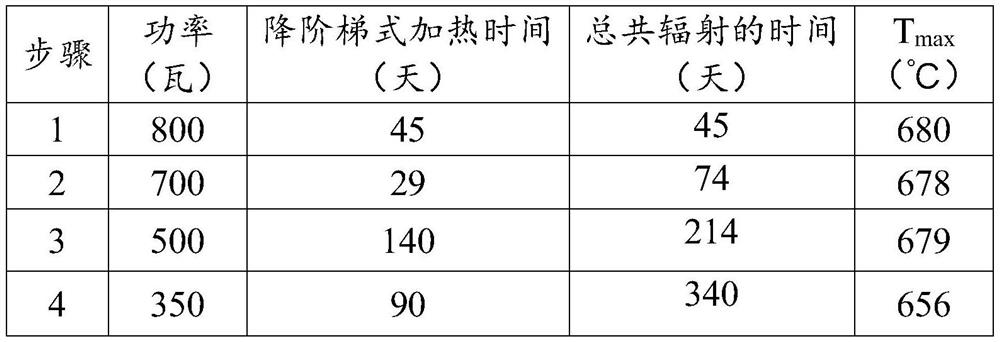

Microwave step-down in-situ heating method for mining oil shale

A microwave step-down in-situ heating method for mining oil shale includes the following steps: (1) setting a microwave heating well on an oil shale ore layer, wherein the microwave heating well is located at the center of an oil and gas export crack; and (2) after a temperature sensor monitors that the temperature of the microwave heating well reaches the upper limit, reducing the microwave powerin a stepwise manner so as to radiately heat the oil shale ore layer, so that the generated oil and gas are exported through the oil and gas export crack. The method adopts the heating mode of step-down type microwave heating for oil shale, not only takes advantage of the easy control of microwave power, but also is a high-efficiency heating method with higher efficiency than an intermittent microwave heating mode.

Owner:SOUTHWEST PETROLEUM UNIV

Temperature-resistant thickening light-cured epoxy vinyl ester resin and preparation method thereof

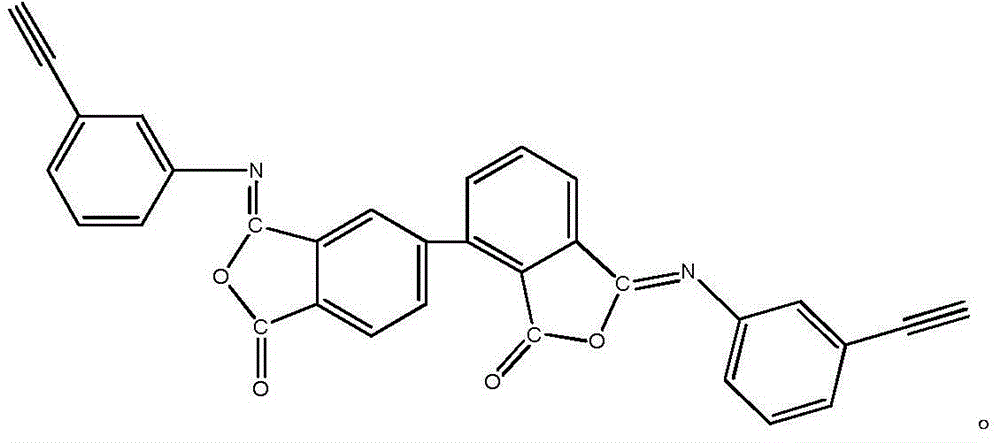

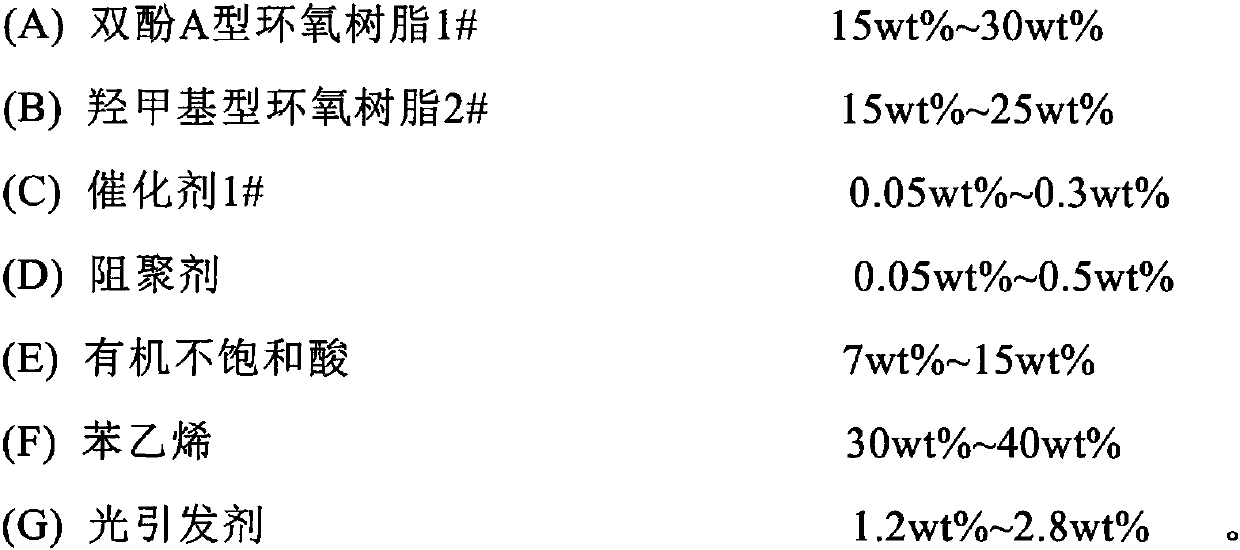

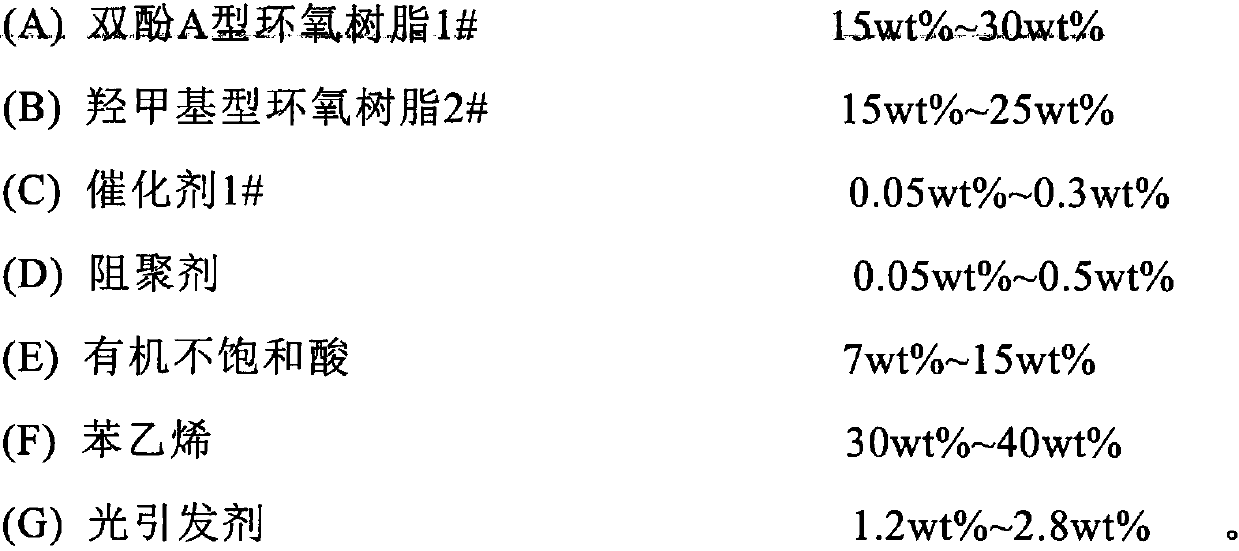

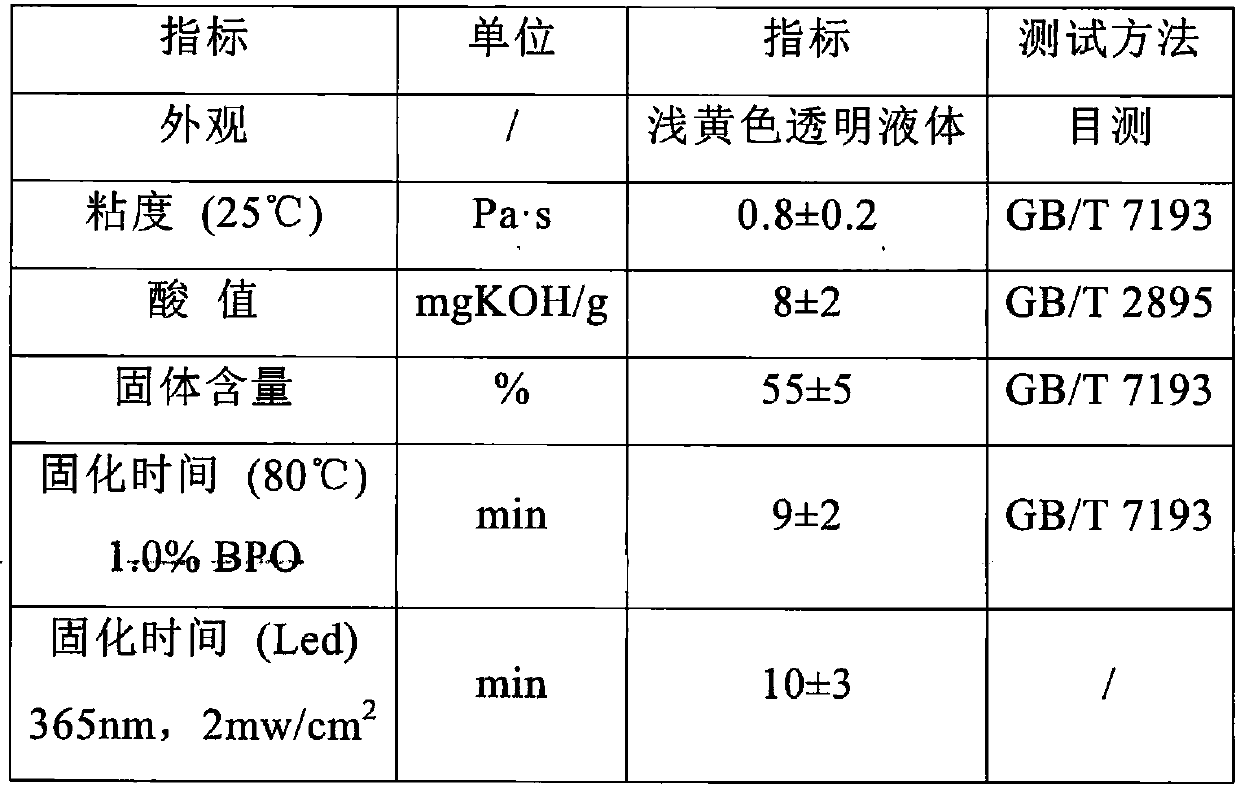

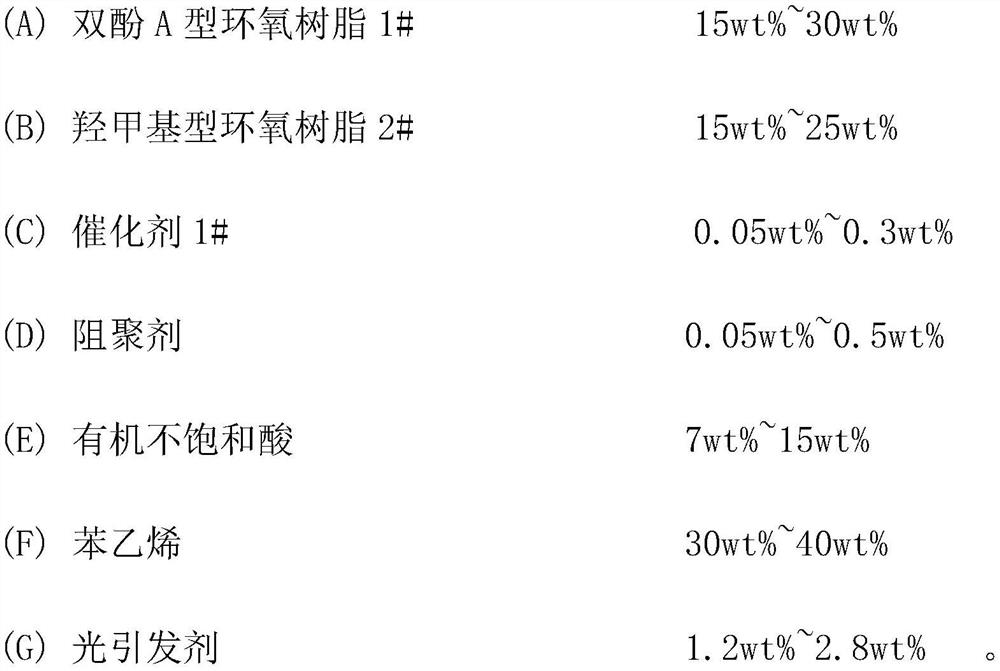

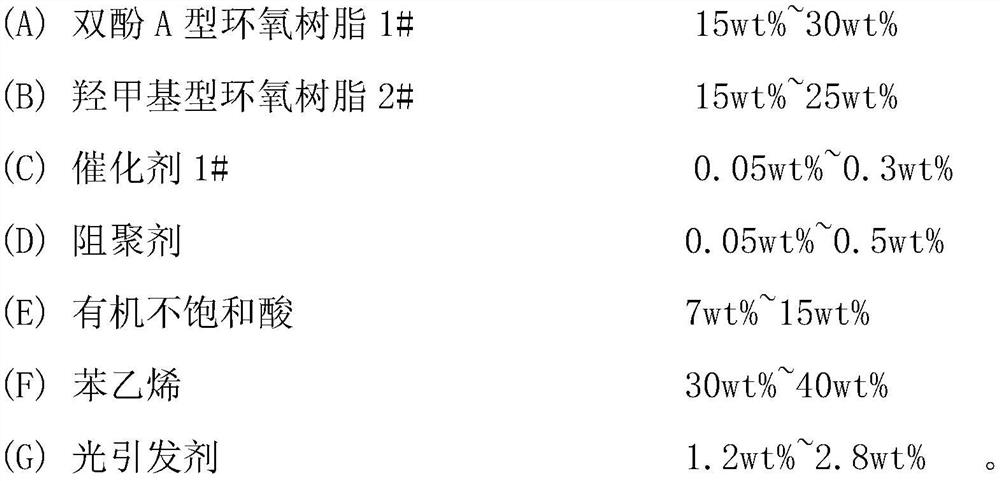

The invention relates to a temperature-resistant thickening light-cured epoxy vinyl ester resin and a preparation method thereof, and specifically discloses an epoxy vinyl ester resin composition. Thecomposition comprises components (A) to (G). The invention also discloses a method for preparing the resin composition, and a resin product comprising the resin composition.

Owner:HUACHANG POLYMER EAST CHINA UNIV OFSCI & TECH

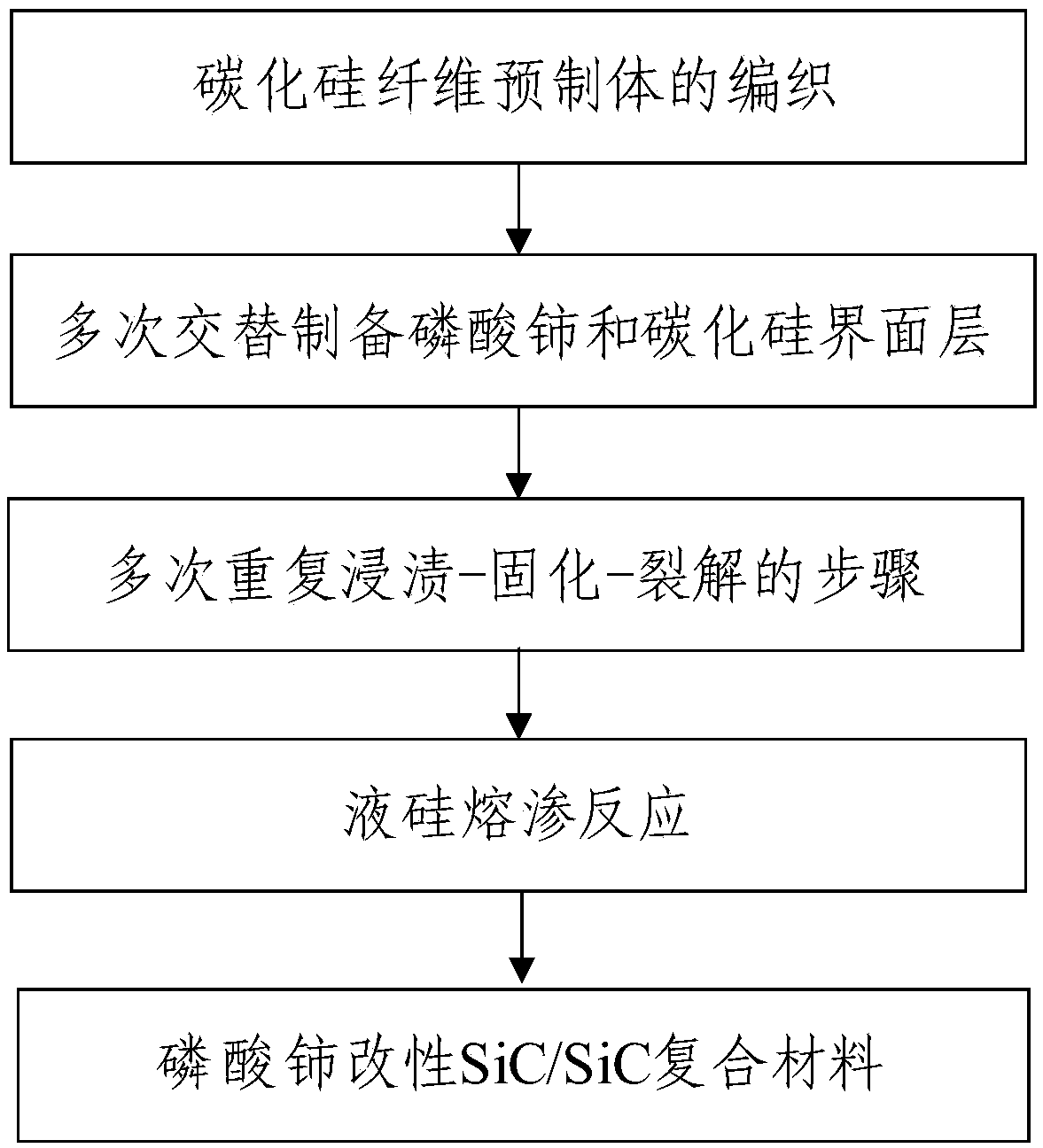

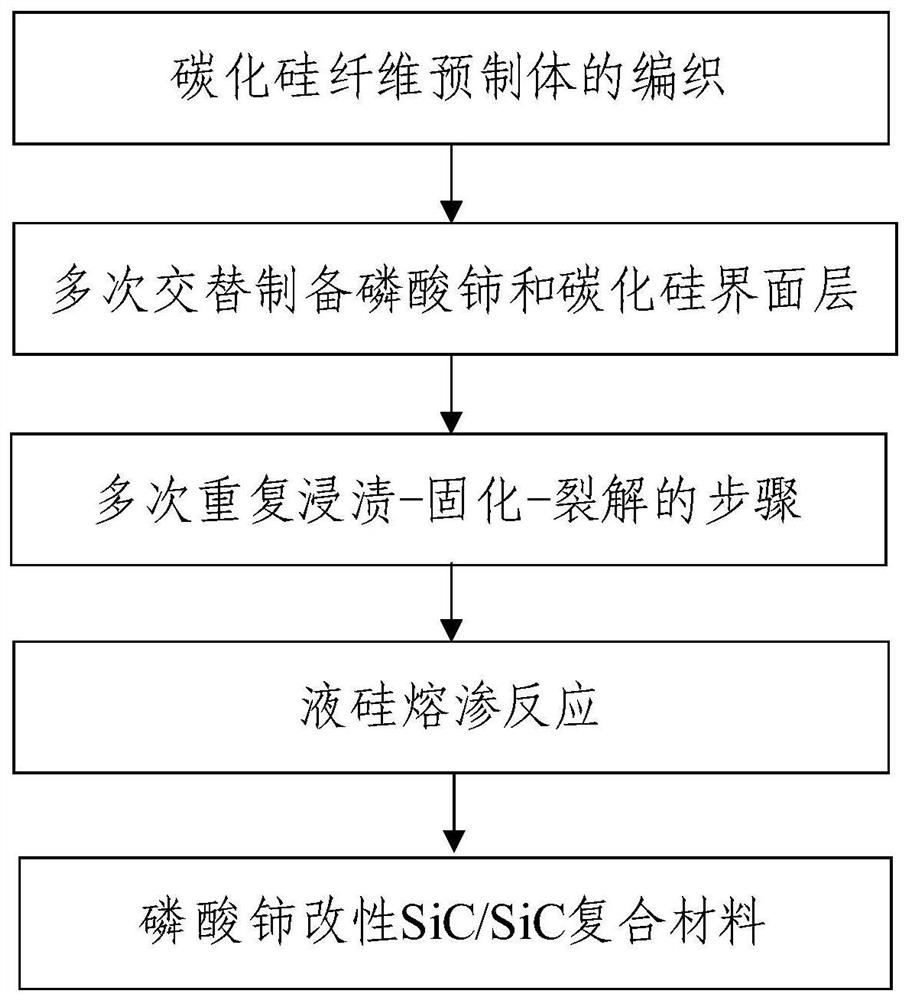

Cerium phosphate modified silicon carbide fiber reinforced silicon carbide composite material and preparation method thereof

ActiveCN109293367AHigh melting pointHigh temperature resistance and oxidation resistanceCeramicwareCerium phosphateInterface layer

The invention relates to a cerium phosphate modified silicon carbide fiber reinforced silicon carbide composite material and a preparation method thereof. The method comprises the steps: (1) alternatively preparing a cerium phosphate interface layer and a silicon carbide interface layer on the surface of silicon carbide fiber preforms until the predetermined thickness or the predetermined number of layers is reached, and thus preparing modified silicon carbide fiber preforms; (2) impregnating the modified silicon carbide fiber preforms with a carbon precursor solution, and then solidifying andsplitting the impregnated modified silicon carbide fiber preforms in turn; (3) repeating the step (2) at least once, and thus preparing porous silicon carbide fiber preforms; and (4) carrying out liquid silicon melt-infiltration reaction of the prepared porous silicon carbide fiber preforms, and thus preparing the cerium phosphate modified silicon carbide fiber reinforced silicon carbide composite material. The prepared cerium phosphate modified silicon carbide fiber reinforced silicon carbide composite material has the advantages of excellent oxidation resistance, temperature resistance andthermal shock resistance, excellent comprehensive performance at high temperature and long service life.

Owner:AEROSPACE INST OF ADVANCED MATERIALS & PROCESSING TECH

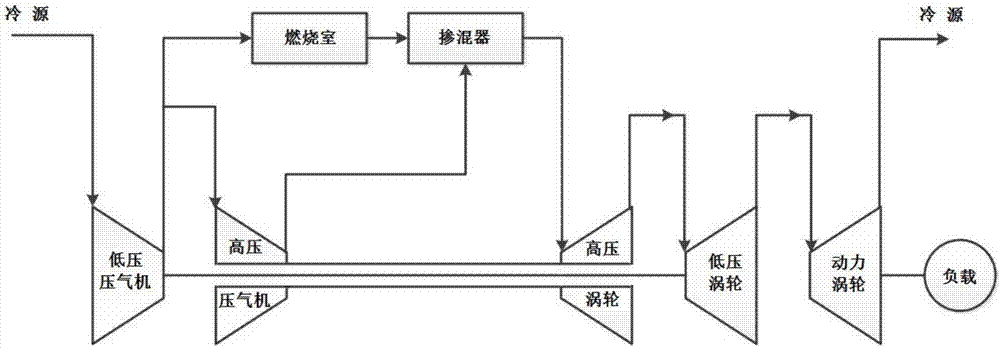

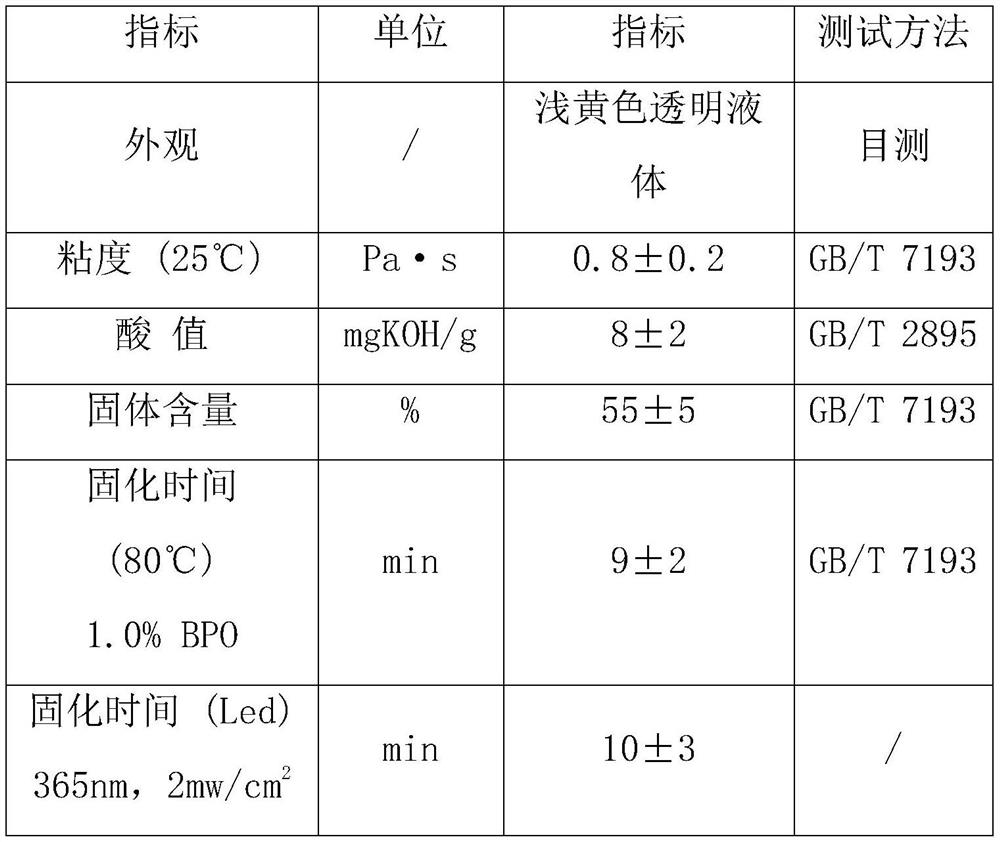

Ship three-shaft gas turbine based on rotary detonation combustion

ActiveCN107084049AImprove cycle thermal efficiencyMeet temperature resistance requirementsTurbine/propulsion engine coolingGas turbine plantsDetonationCombustion chamber

The invention provides a ship three-shaft gas turbine based on rotary detonation combustion. The ship three-shaft gas turbine comprises a low-pressure compressor, a high-pressure compressor, a rotary detonation combustion chamber, a thermojet detonation tube, a mixer, a low-pressure turbine body, a high-pressure turbine body, a power turbine body, a load and a cold source. The rotary detonation combustion chamber is applied to the ship gas turbine. The mode that air of the low-pressure compressor participates in combustion and air of the high-pressure compressor participates in mixing and cooling is adopted, the effect that a working medium at an inlet of the turbine does not exceed the temperature is ensured, and the working medium subjected to detonation combustion has higher working capacity. The supercharging performance of the rotary detonation combustion chamber is used, and the cycle thermal efficiency of the gas turbine is improved by 3% to 5% under the same turbine inlet temperature, part efficiency and compressor pressure ratio.

Owner:HARBIN ENG UNIV

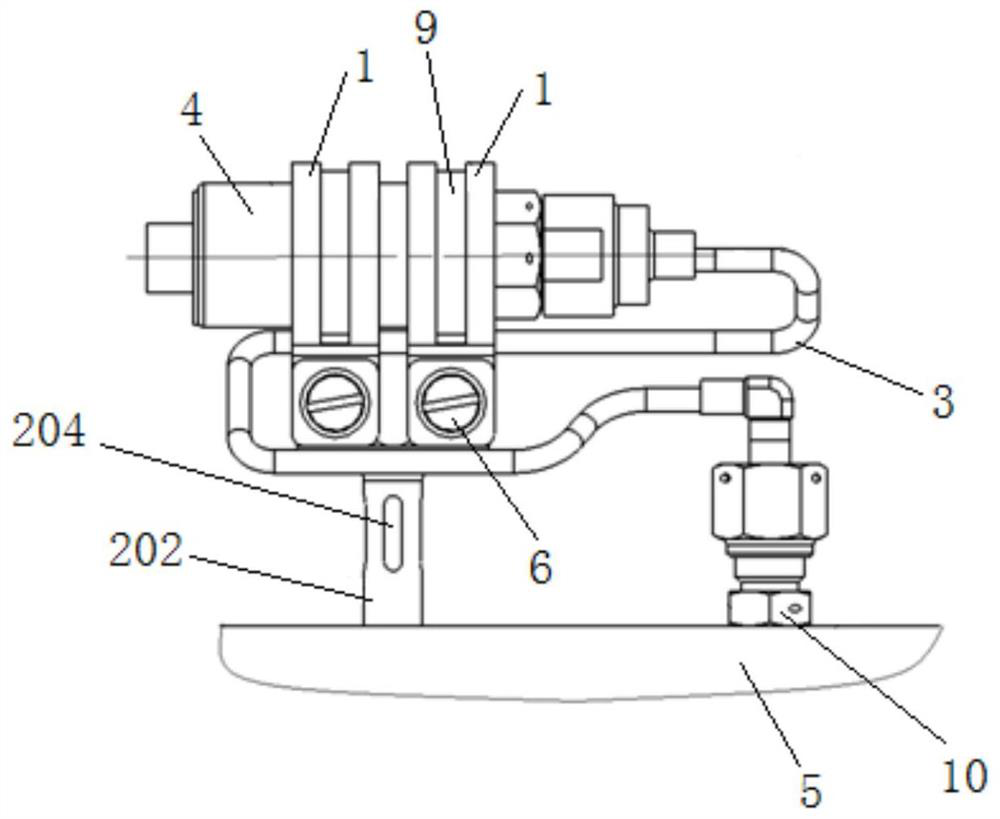

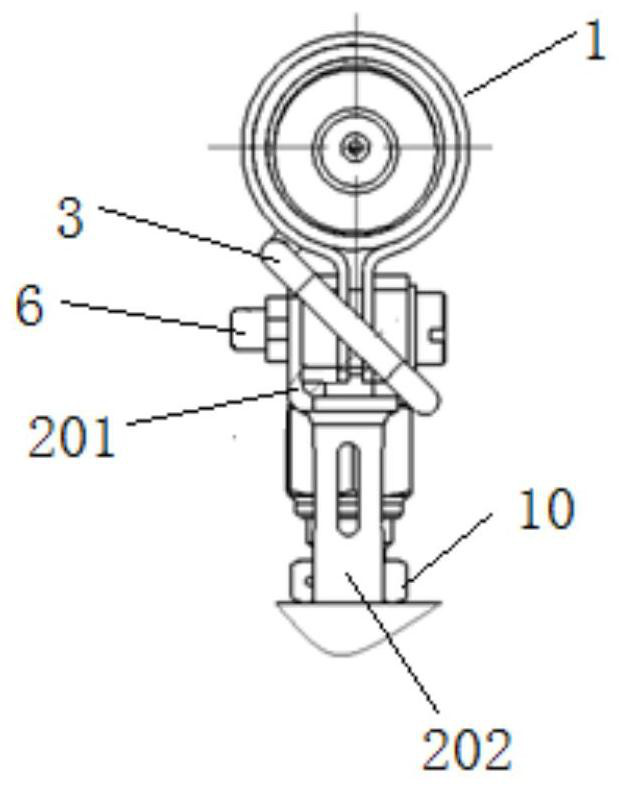

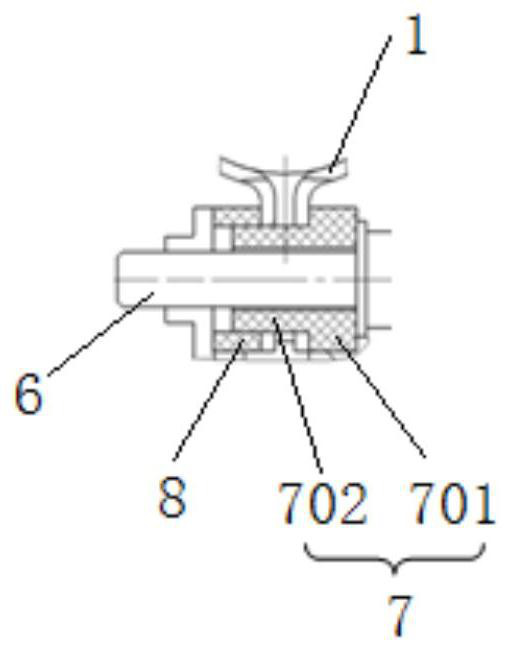

Thermal protection mounting structure for pressure measuring sensor in narrow space

ActiveCN111103143AEasy to fixImprove thermal protection performanceEngine testingStands/trestlesCombustion chamberEngineering

The invention belongs to a mounting structure of a high-temperature gas pressure measuring sensor, aims to solve the technical problems in the prior art that when a pressure measuring sensor is used for measuring the pressure of a combustion chamber, the pressure measuring sensor is prone to inaccurate measurement and even measurement failure due to the fact that the installation space is limitedand the measuring environment is severe, and provides a thermal protection mounting structure for a pressure measuring sensor in narrow space. The thermal protection mounting structure comprises a supporting base, a pressure measuring guide pipe and a hoop. The upper part of the supporting base is an L-shaped fixing plate, and the lower part is a supporting base; one end of the supporting base isconnected to the bottom of the fixing plate, and the other end is fixed to the wall of the combustion chamber. The hoop is arranged on the outer side of the pressure measuring sensor in a sleeving mode, and the hoop connector is installed on the side wall of the fixing plate; one end of the pressure measuring guide pipe is connected with the detection end of the pressure measuring sensor, the other end is communicated with the interior of the combustion chamber, and the middle of the pressure measuring guide pipe is coiled and the pressure measuring guide pipe bypasses the supporting base.

Owner:XIAN AEROSPACE PROPULSION INST

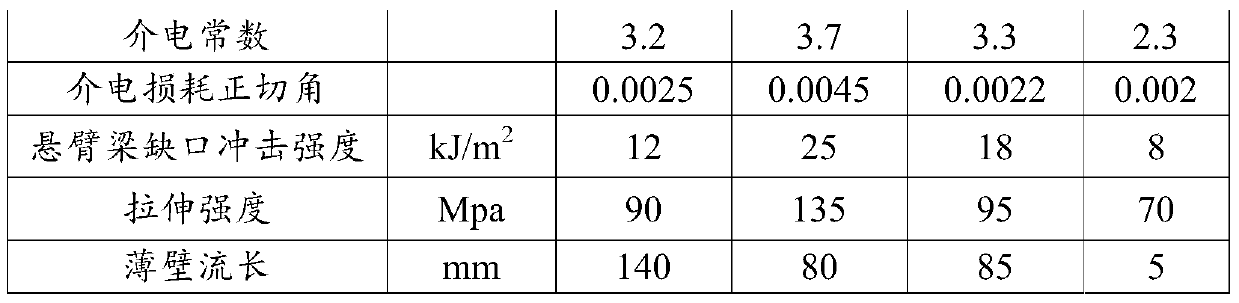

Low-dielectric liquid crystal polyester composition and preparation method thereof

The embodiment of the invention provides a low-dielectric liquid crystal polyester composition and a preparation method thereof. The low-dielectric liquid crystal polyester composition comprises 40-90% LCP (A) and 10-60% LCP (B) fibers, the melting point of the LCP is larger than or equal to 280 DEG C, the dielectric constant is lower than 3.5, the dielectric loss tangent angle is lower than 0.002, and the melting point of the LCP (B) fibers is higher than the melting point of the LCP (A) by 30 DEG C or above. The low-dielectric liquid crystal polyester composition has good flowing performance, the dielectric constant is lower than 3.5, the dielectric loss tangent angle is lower than 0.002, meanwhile, the tensile strength is larger than 150 MPa, and the temperature resistance requirement of the SMT manufacturing procedure is met.

Owner:JIANGMEN DENGZHONGTAI ENG PLASTICS CO LTD

Manufacture method for natural fiber net cover

InactiveCN106003752AIn line with the concept of sustainable developmentEquivalent mechanical strengthGrinding devicesGlass fiberLow temperature curing

The invention relates to a manufacture method for a natural fiber net cover. The manufacture method comprises the following steps: 1, a natural fiber raw materials is subjected to alkali treatment or coupling reagent treatment for modification; 2, the modified natural fiber raw material is continuously stacked to be laminated material through resin liquid coating, or the modified natural fiber raw material is cut into short cut natural fiber; the short cut natural fiber is jointly mixed and dispersively dipped in the resin liquid to form resin paste, and the resin paste is made into a laminated material through roll pressing; 3, the laminated material is cut to obtain a circular natural fiber net cover blank and leftover materials; and 4, the natural fiber net cover blank is subjected to low-temperature curing to form the natural fiber net cover. The natural fiber adopted by the manufacture method is a biological renewable resource, so that a sustainable development idea is met. Compared with a fiber net cover manufactured from glass fiber in the prior art, at the same state, the fiber net cover manufactured from the natural fiber has the advantages that the fiber net cover can naturally degrade, so that no harm is caused to a human body and the environment; the mechanical strength is equivalent; and the production energy consumption is lower.

Owner:高昊

High-temperature-resistant TPE plastic

The invention discloses high-temperature-resistant TPE plastic. The high-temperature-resistant TPE plastic is prepared from, by weight, 10-11 parts of SEBS, 5-7 parts of white mineral oil, 3-5 parts of polypropylene (PP), 2-3 parts of polyethylene, 1-2 parts of polyphenyl ether, 2-3 parts of calcium carbonate and 0.005-0.01 part of stabilizer.

Owner:安徽爱信自动化机械有限公司

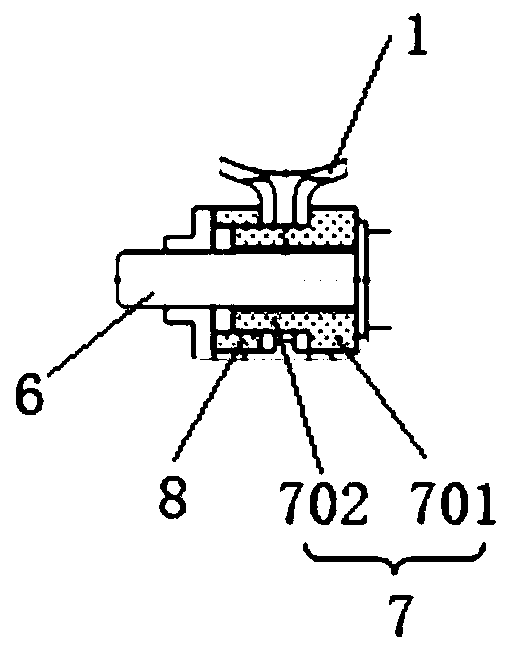

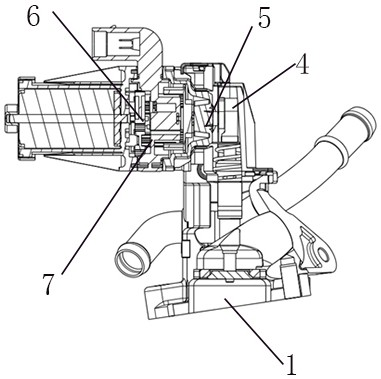

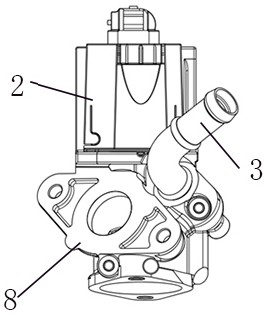

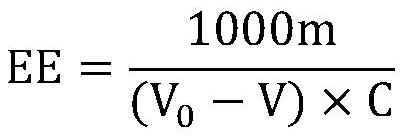

EGR valve temperature field test method

ActiveCN113639989AMeet temperature resistance requirementsMachine valve testingThermometers using electric/magnetic elementsField testsProcess engineering

The invention discloses an EGR valve temperature field test method, which comprises the following steps: S1, carrying out preparation before test, wherein whether the use environment of an EGR valve is worse than that of batch-produced EGR valves is evaluated, wherein the evaluation method comprises the following steps: collecting the inlet temperature of the EGR valve, the EGR valve environment temperature and the EGR rate, and a step S2 is performed when one evaluation index is higher than a factory set index value of the valve; S2, arranging eight thermocouples in the temperature field of the EGR valve to serve as measuring points; S3, fully heating the engine; S4, operating four working conditions; and S5, carrying out modeling and result analysis: S51, modeling by using CFD analysis software, and setting the ambient temperature as the highest temperature around the EGR valve measured by TASE, S52, setting the highest temperature resistance requirement of each sub-part as an alarm red point, and S53, inputting the highest temperature working condition of each measuring point of the EGR valve into the CFD grid model, and calculating whether each temperature of each sub-part of the EGR valve is overheated or not. According to the invention, the temperature of each sub-part is analyzed through actual CAE according to the temperature field data of the eight points, and the temperature resistance requirement of each sub-part is met.

Owner:JIANGLING MOTORS

A kind of high temperature resistant honeycomb node adhesive and preparation method thereof

InactiveCN104479620BGood compatibilityImprove matchNon-macromolecular adhesive additivesMacromolecular adhesive additivesElastomerPolymer science

The invention discloses a high-temperature-resistant honeycomb node adhesive and a preparation method thereof and relates to an adhesive and a preparation method thereof. The high-temperature-resistant honeycomb node adhesive is used for solving the problem that the existing honeycomb node adhesive cannot meet the requirements on the manufacturing of polyimide paper honeycomb due to low temperature-resistant level and poor bonding compatibility. The adhesive is prepared from matrix resin, BMT type bismaleimide resin, phenolic cyanate ester, a co-polymerization modifier, a rubber elastomer toughening agent, inorganic nanometer filler and a solvent. The preparation method comprises the following steps: firstly, weighing; secondly, preparing toughening modified resin; thirdly, mechanically blending to obtain mixed rubber sheets; and fourthly, preparing uniform rubber liquid under stirring. The high-temperature-resistant honeycomb node adhesive is mainly applied in manufacturing aerospace polyimide paper honeycomb and has the characteristics of high temperature resistance and good process performance. The high-temperature-resistant honeycomb node adhesive prepared by the preparation method is used for the manufacturing of aerospace polyimide paper honeycomb and has the characteristics of high temperature resistance and good process performance.

Owner:INST OF PETROCHEM HEILONGJIANG ACADEMY OF SCI

A kind of cerium phosphate modified silicon carbide fiber reinforced silicon carbide composite material and preparation method thereof

ActiveCN109293367BHigh melting pointHigh temperature resistance and oxidation resistanceCeramicwareCerium phosphateCarbide silicon

The invention relates to a cerium phosphate modified silicon carbide fiber reinforced silicon carbide composite material and a preparation method thereof. The method: (1) alternately prepare cerium phosphate interface layers and silicon carbide interface layers on the surface of the silicon carbide fiber preform until reaching a predetermined thickness or predetermined number of layers to obtain a modified silicon carbide fiber preform; (2) use carbon The precursor solution is impregnated with the modified silicon carbide fiber preform, and then the impregnated modified silicon carbide fiber preform is sequentially subjected to a curing step and a cracking step; (3) repeating step (2) at least once to prepare a porous silicon carbide fiber preform and (4) subjecting the prepared porous silicon carbide fiber preform to liquid silicon infiltration reaction to obtain a cerium phosphate modified silicon carbide fiber reinforced silicon carbide composite material. The cerium phosphate modified silicon carbide fiber-reinforced silicon carbide composite material prepared by the invention has excellent oxidation resistance, temperature resistance, thermal shock resistance, etc., excellent comprehensive performance at high temperature, and long service life.

Owner:AEROSPACE INST OF ADVANCED MATERIALS & PROCESSING TECH

A kind of temperature-resistant thickening light-curable epoxy vinyl ester resin and preparation method thereof

The invention relates to a temperature-resistant thickening light-curable epoxy vinyl ester resin and a preparation method thereof. Specifically, the present invention discloses an epoxy vinyl ester resin composition comprising components (A) to (G). Also disclosed are a preparation method of the resin composition and a resin product comprising the resin composition.

Owner:HUACHANG POLYMER EAST CHINA UNIV OFSCI & TECH

A marine three-shaft gas turbine based on rotating detonation combustion

ActiveCN107084049BImprove cycle thermal efficiencyMeet temperature resistance requirementsTurbine/propulsion engine coolingGas turbine plantsDetonationCombustion chamber

Owner:HARBIN ENG UNIV

A thermal protection installation structure of a pressure sensor in a narrow space

ActiveCN111103143BEasy to fixImprove thermal protection performanceEngine testingStands/trestlesCombustion chamberPressure measurement

Owner:XIAN AEROSPACE PROPULSION INST

Glassware coated with non-sticky coating layer, and preparation technology thereof

ActiveCN110330233AComply with health requirementsImprove bindingEpoxy resin coatingsSurface layerSpray coating

The invention discloses a glassware coated with a non-sticky coating layer. The glassware coated with a non-sticky coating layer comprises a glass base body; the glass base body possesses an internalsurface; the internal surface is coated with the non-sticky coating layer; the non-sticky coating layer and the internal surface of the glass base body are connected through a binding layer; the non-sticky coating layer comprises a bottom layer and a surface layer; and preferably, the glass base body is prepared from high borosilicate glass. The invention also discloses preparation technology of the glassware. The preparation technology comprises steps of glassware internal surface pre-treatment, binding layer spraying coating, bottom layer spraying coating, surface layer spraying coating, andsintering, so that a finished product is obtained at last. According to the preparation technology, glass surface sand-blast treatment is avoided, and coating of the binding layer is adopted, the entire effect is improved, the non-sticky coating layer possesses excellent combination force with the glass base body, the glassware surface is not sticky, is convenient to clean, possesses corrosion resistance and high temperature resistance, and is long in service life.

Owner:NINGBO RE COOK IMP & EXP CO LTD

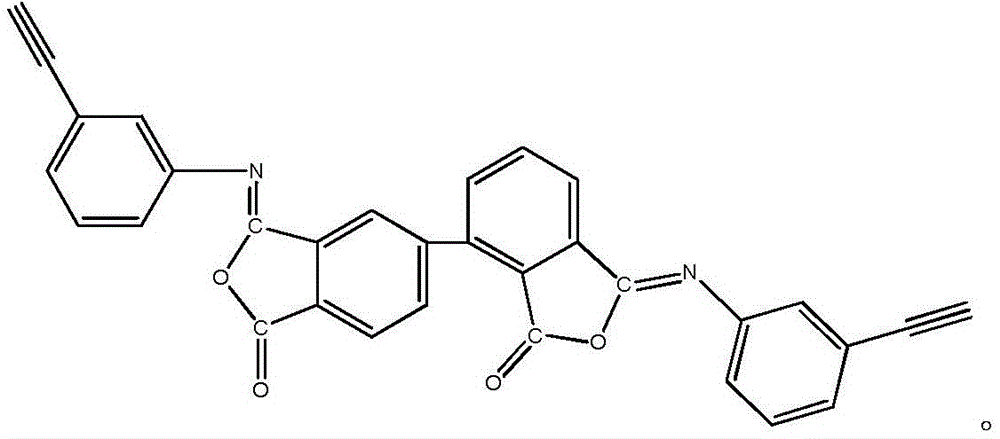

A high-temperature and hydrolysis-resistant epoxy resin matrix for sucker rods

ActiveCN111117157BMeet temperature resistance requirementsHigh pressure and high humidity aging resistanceChemical industryPolymer science

The invention relates to the field of polymer chemical industry, and more specifically, the invention provides a high-temperature-resistant and hydrolysis-resistant epoxy resin matrix for sucker rods and a preparation method thereof. The first aspect of the present invention provides a high-temperature-resistant and hydrolysis-resistant epoxy resin matrix for sucker rods, the preparation raw materials include A component and B component; the A component includes bisphenol A type epoxy resin, phenolic type Novolac epoxy resin, alicyclic epoxy resin, glycidylamine epoxy resin; the B component includes curing agent, toughening agent, accelerator, catalyst; the bisphenol A type epoxy resin The epoxy equivalent is 130-300 g / mol.

Owner:TECHSTORM MATERIAL TECH SHANGHAI CO LTD

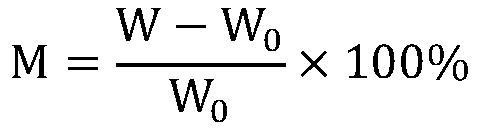

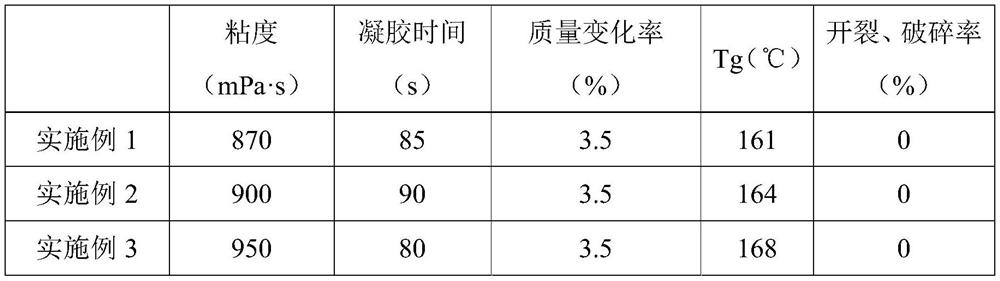

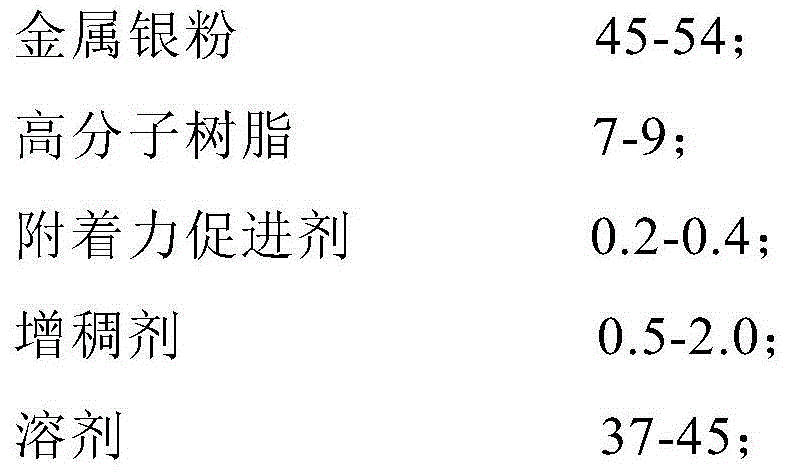

A kind of silver paste for mobile phone shielding and preparation method thereof

ActiveCN103165215BMeet temperature resistance requirementsMeet resistance requirementsNon-conductive material with dispersed conductive materialCable/conductor manufactureSilver pasteSolvent

The invention relates to silver paste for mobile phone shielding and a preparation method of the silver paste for the mobile phone shielding. The conductive silver paste comprises the following components, by weight, 45%-54% of metal silver powder, 7%-9% of high polymer resin, 0.2%-0.4% of adhesive force accelerant, 0.5%-2.0% of thickener, and 37%-45% of solvent. The production and preparation of the silver paste is completed through carrier preparation, silver paste preparation and production. Compared with the prior art, the preparation method can enable silver paste products to be solidified at 80 DECG in 30 minutes, and a resistance value after solidification is less than 1 ohm, and therefore not only are temperature-resistance requirements of shielding materials satisfied, but also resistance requirements needed by shielding are satisfied.

Owner:SHANGHAI BAOYIN ELECTRONICS MATERIALS CO LTD

A kind of yttrium silicate modified silicon carbide fiber reinforced silicon carbide composite material and preparation method thereof

ActiveCN109053207BGood chemical stabilityImprove high temperature resistanceCarbide siliconSic fiber

The invention relates to a yttrium silicate modified silicon carbide fiber reinforced silicon carbide composite material and a preparation method thereof. The preparation method comprises the following steps: (1) sequentially preparing a yttrium silicate interface layer and a silicon carbide interface layer on the surface of a silicon carbide fiber prefabricated body so as to obtain a yttrium silicate modified silicon carbide fiber prefabricated body; (2) soaking the yttrium silicate modified silicon carbide fiber prefabricated body prepared in the step (1) into a carbon precursor solution, and sequentially carrying out a curing step and a cracking step on the soaked yttrium silicate modified silicon carbide fiber prefabricated body; (3) at least repeating the step (2) once so as to obtaina porous silicon carbide fiber prefabricated body; (4) carrying out a liquid silicon infiltration reaction on the porous silicon carbide fiber prefabricated body prepared in the step (3), thereby obtaining a yttrium silicate modified SiC / SiC composite material. The yttrium silicate modified SiC / SiC composite material provided by the invention has excellent oxidation resistance, temperature resistance, vapor corrosion resistance, and the like, and is excellent in comprehensive property.

Owner:AEROSPACE INST OF ADVANCED MATERIALS & PROCESSING TECH

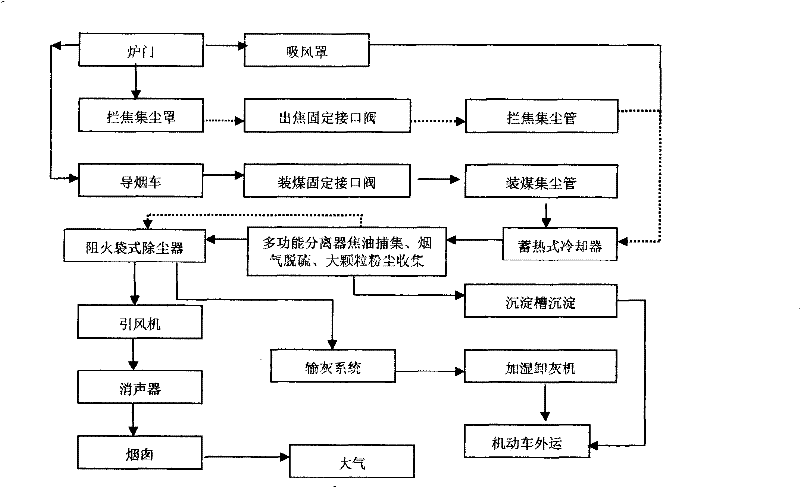

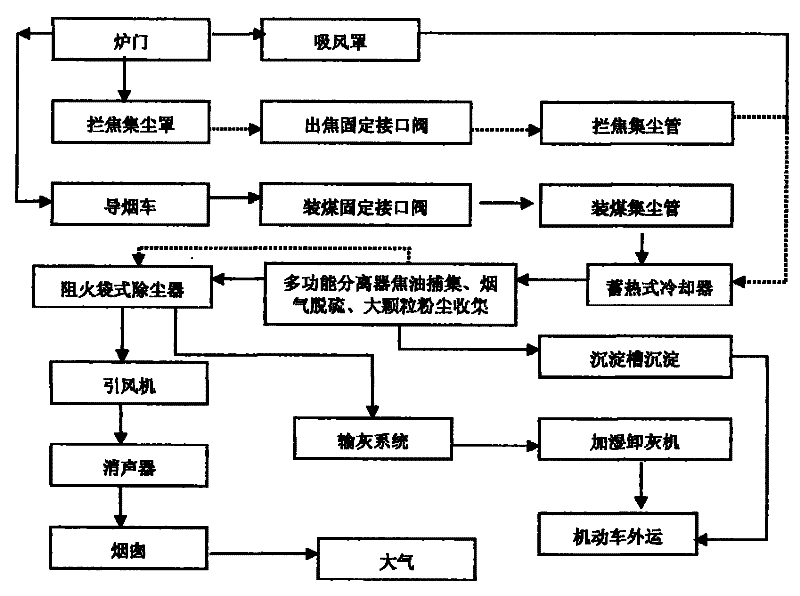

Novel high-efficiency dedusting and desulphurization integrated system process for coke-tamping, coaling and coke-discharging ground station

InactiveCN101862580BLong-term normal operationMeet temperature resistance requirementsHuman health protectionDispersed particle filtrationFiltrationGround station

The invention relates to a novel high-efficiency dedusting and desulphurization integrated system process for a coke-tamping, coaling and coke-discharging ground station, comprising the following steps: smoke gas enters a heat accumulating type cooler to be cooled to below 120 DEG C during coal feeding or coke discharging; the cooled smoke gas enters a multifunctional separator and separated tar and a part of large-particle sparkle dust enter a tar settling tank; the smoke gas processed by the multifunctional separator enters a fire resistance bag type dust remover to be filtered; and clean gas is discharged into the atmosphere after filtration. The novel high-efficiency dedusting and desulphurization integrated system process for the coke-tamping, coaling and coke-discharging ground station thoroughly solves the core problems of flammability, explosion proof, hard elimination of toxic gas and high-sulphur coal desulfurization of hard fire cloth bags, tar paste cloth bags and bag-typedust removers, which plague coking enterprises and dust removal enterprises for many years. Proved by practical tests, the dust removal efficiency is more than 99.7 percent, the discharged dust concentration is less than 40mg / m<3>, dust recycled by the ground station is 1400t / a, and smoke and dust are not generated in the production process of a coke oven, thereby completely meeting environmentalrequirements.

Owner:XIAN YINHE ENVIRONMENTAL PROTECTION EQUIP ENG +1

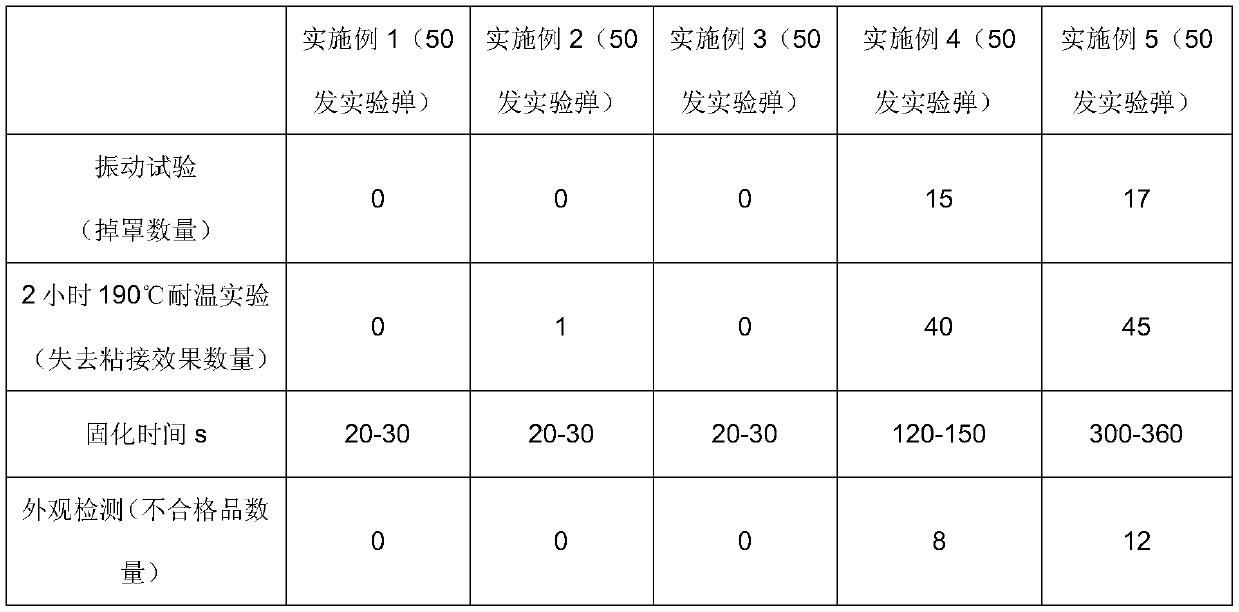

Formula and preparation method of petroleum perforating bullet sealing adhesive

InactiveCN110527457ANot easy to flow glueDry fasterNon-macromolecular adhesive additivesTerra firmaAdhesive

The invention relates to a formula of a petroleum perforating bullet sealing adhesive. The formula is mainly used for solving problems in the prior art that the curing time of an existing sealing adhesive is long, bonding effect is poor, and falling of charge liners is easily caused. The petroleum perforating bullet sealing adhesive comprises, by weight, an adhesive and silver powder at a ratio of280:3-5. A preparation method of the petroleum perforating bullet sealing adhesive comprises following steps: proportionally and uniformly mixing and stirring the weighed adhesive CA40H and silver powder, and smearing the bonding part of a shell to be bonded with a charge liner to form an annular adhesive tape with the thickness of more than 0.5 mm for bonding. According to the petroleum perforating bullet sealing adhesive formula, the curing time can be shortened, the bonding effect is good, the falling problem of charge liners is solved, and a solid foundation is laid for subsequent production.

Owner:DAQING PETROLEUM ADMINISTRATION +1

A method of in-situ heating and mining oil shale with microwave step-down

A method for in-situ heating and exploitation of oil shale by microwave step-down heating, comprising the following steps: (1) setting a microwave heating well on the oil shale ore layer, and the microwave heating well is located at the center of the oil-gas outlet fracture; (2) When the temperature sensor monitors that the temperature of the microwave heating well reaches the upper limit, the microwave power is reduced stepwise, so that the oil shale deposit is radiated and heated, so that the generated oil and gas are exported through the oil and gas outlet fractures. The method adopts the heating mode of step-down microwave heating oil shale, which not only utilizes the advantage of easy control of microwave power, but also is a high-efficiency heating method with higher efficiency than the intermittent microwave heating mode.

Owner:SOUTHWEST PETROLEUM UNIV

Glassware coated with non-stick coating and its preparation process

ActiveCN110330233BImprove bindingSimplify processing stepsEpoxy resin coatingsGlass vesselBorosilicate glass

The invention discloses a glass vessel coated with a non-stick coating, which comprises a glass substrate, the glass substrate has an inner surface, the inner surface is coated with a non-stick coating, and the gap between the non-stick coating and the inner surface of the glass substrate is The transition is connected by an adhesive layer, wherein the non-stick coating includes a bottom layer and a surface layer; preferably, the glass substrate is made of high borosilicate glass. The invention also discloses a preparation process of the glassware coated with the non-stick coating, which includes pretreatment of the inner surface of the glassware, spraying of the adhesive layer, spraying of the bottom layer, spraying of the surface layer, and sintering to finally obtain the product. The glassware of the present invention avoids the sandblasting treatment on the glass surface but adopts the method of spraying a layer of bonding layer, the overall effect is improved, the non-stick coating has good bonding force with the substrate, and the surface of the vessel is non-stick, easy to clean, corrosion-resistant, High temperature resistance, long service life.

Owner:NINGBO RE COOK IMP & EXP CO LTD

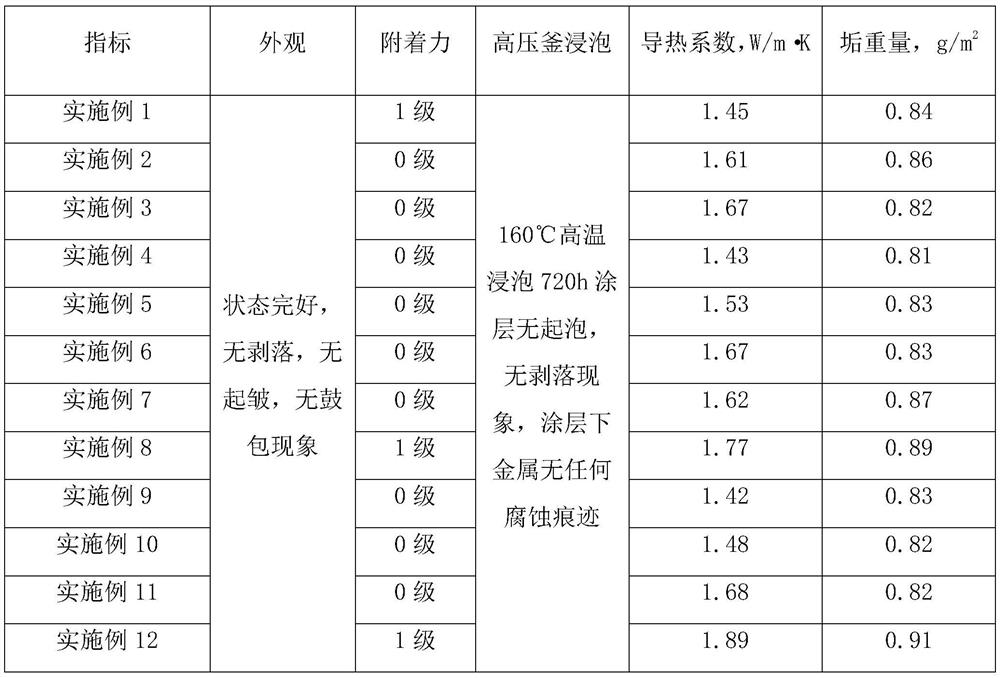

High-thermal-conductivity anticorrosive paint for heat exchanger tube bundle as well as preparation and use methods of high-thermal-conductivity anticorrosive paint

PendingCN114574098AEasy to operateEasy to implementFireproof paintsChemical industryEpoxyCross linker

The invention discloses a high-thermal-conductivity anticorrosive coating for a heat exchanger tube bundle. The high-thermal-conductivity anticorrosive coating comprises the following components: 40-60 parts of high-temperature curable epoxy modified organic silicon resin, 10-30 parts of a thermal conductive filler, 1-2 parts of a cross-linking agent, 0.2-1 part of a defoaming leveling agent and 15-30 parts of a solvent. The prepared anticorrosive paint has the characteristics of high temperature resistance, high heat conductivity, corrosion resistance and good scale inhibition performance, can prevent the heat exchanger from generating the problems of corrosion perforation, scaling blockage and the like in the high-temperature service process on the premise of ensuring the heat exchange efficiency of the heat exchanger, and provides a good protection effect for the heat exchanger.

Owner:CHINA PETROLEUM & CHEM CORP +1

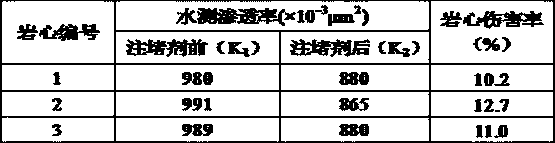

Temperature controlled plugging agent for heavy oil steam stimulation

InactiveCN109181665APhase reversibilityMeet temperature resistance requirementsFluid removalDrilling compositionCelluloseTemperature control

The invention relates to the technical field of oil production engineering and in particular relates to a temperature controlled plugging agent for heavy oil steam stimulation. The problem that the conventional plugging agent is poor in temperature resistance and easily contaminates the reservoir is solved. The plugging agent disclosed by the invention is composed of the following components in percentage by weight: 3-6.9% of cellulose ether, 3-5% of a temperature control agent, 0.9-3.2% of a stabilizer, 1-2.8% of a cosolvent and the balance of water. The plugging agent disclosed by the invention has the characteristic of phase reversibility, is liquid under the normal temperature condition, is changed from liquid to gel while meeting high-temperature steam, then changed from the gel to liquid when the temperature is lower than a gelling temperature of the gel, and can be produced along with crude oil. The plugging agent has excellent temperature resistance and low pollution to the reservoir, and the development effect of steam stimulation is greatly improved.

Owner:PETROCHINA CO LTD +1

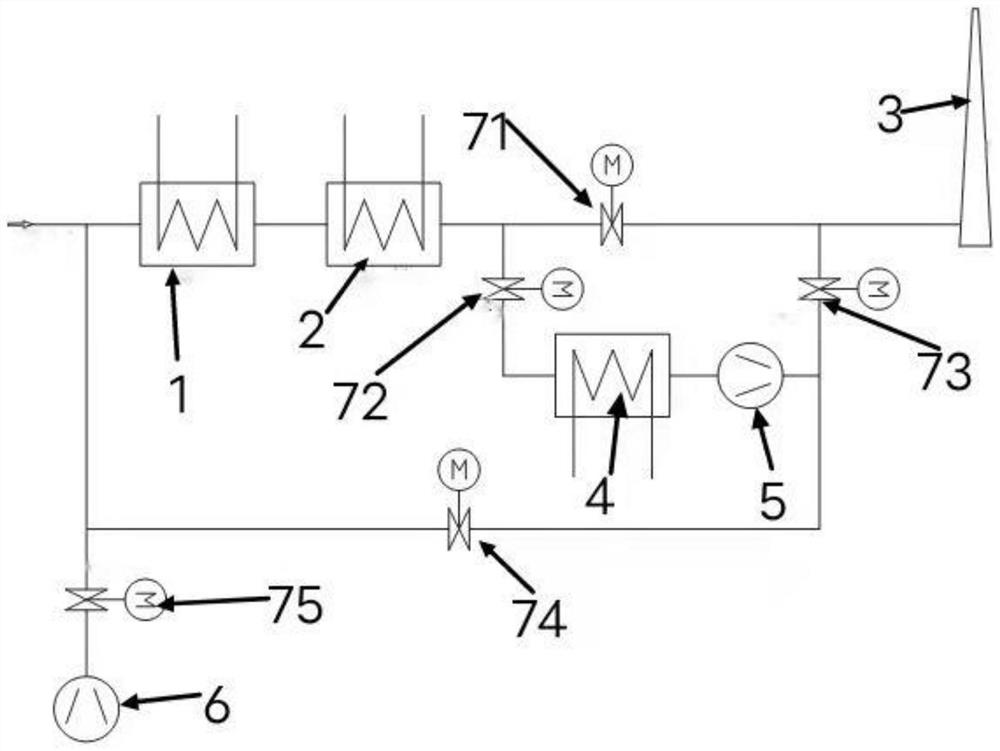

CSP heating furnace flue gas recirculation waste heat recovery system

PendingCN114526612AOxygen controlMeet temperature resistance requirementsIncreasing energy efficiencyControl devices for furnacesAir preheaterSmoke exhaust ductwork

The invention discloses a CSP heating furnace flue gas recirculation waste heat recovery system which comprises an air preheater and a coal gas preheater, the air preheater and the coal gas preheater are in through connection through a smoke exhaust main pipeline, the coal gas preheater is connected with a chimney through a smoke exhaust pipeline, a first adjusting valve is arranged on the smoke exhaust pipeline of the coal gas preheater and the chimney, and a second adjusting valve is arranged on the smoke exhaust pipeline of the coal gas preheater. The second adjusting valve and the third adjusting valve are both arranged on a bypass flue, the bypass flue is provided with a waste heat recovery system and an induced draft fan, the cold air pipeline is provided with a fourth adjusting valve, the other end of the cold air pipeline is connected with a cold air mixing fan through a three-way structure, and the other end of the three-way structure is communicated with a smoke exhaust main pipeline. And a regulating valve V is arranged between the cold air mixing fan and the adjacent three-way structure. The cooled flue gas is circulated to the front of the double preheaters to replace the existing mixed cold air to cool the discharged high-temperature flue gas, so that the oxygen control of the flue gas is realized, and the flue gas emission reaches the environmental protection standard; and a waste heat recovery device is additionally arranged for factory production and living, so that energy is saved.

Owner:江苏道和环保科技有限公司 +1

Silver paste for mobile phone shielding and preparation method thereof

ActiveCN103165215AMeet temperature resistance requirementsMeet resistance requirementsNon-conductive material with dispersed conductive materialCable/conductor manufactureSilver pasteSolvent

The invention relates to silver paste for mobile phone shielding and a preparation method of the silver paste for the mobile phone shielding. The conductive silver paste comprises the following components, by weight, 45%-54% of metal silver powder, 7%-9% of high polymer resin, 0.2%-0.4% of adhesive force accelerant, 0.5%-2.0% of thickener, and 37%-45% of solvent. The production and preparation of the silver paste is completed through carrier preparation, silver paste preparation and production. Compared with the prior art, the preparation method can enable silver paste products to be solidified at 80 DECG in 30 minutes, and a resistance value after solidification is less than 1 ohm, and therefore not only are temperature-resistance requirements of shielding materials satisfied, but also resistance requirements needed by shielding are satisfied.

Owner:SHANGHAI BAOYIN ELECTRONICS MATERIALS CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com