Low-dielectric liquid crystal polyester composition and preparation method thereof

A technology of liquid crystal polyester and composition, which is applied in the field of low dielectric liquid crystal polyester composition and preparation, and can solve problems such as poor mechanical properties, high temperature resistance, high fluidity, low dielectric and high strength performance, foaming deformation, etc. , to achieve the effect of simple steps and non-strict process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0108] Preparation of LCP(A1)

[0109] In a reactor equipped with a stainless steel C-type stirrer, torque gauge, nitrogen conduit, thermometer, pressure gauge and reflux condenser, 1027.5 g of 4-hydroxybenzoic acid (HBA), 470 g of 6-hydroxy-2-naphthoic acid ( HNA), 1122 g of acetic anhydride, 200.0 g of acetic acid. The reactor was purged by evacuating and flushing with dry nitrogen, and 0.3 g of 1-methylimidazole was added. Under nitrogen, with stirring at 150 rpm, the temperature was raised to 150°C over 60 minutes and refluxed by maintaining at this temperature for 60 minutes. After 13.0 g of phenol was added to the reactor, the temperature was raised to 340°C in 120 min. During this time, the by-product acetic acid was removed by distillation. After constant temperature at 340°C for 30min, the pressure was gradually reduced to about 100pa within 20min to maintain a vacuum until the torque increased by more than 30%, the reaction was terminated, and the prepolymer was t...

Embodiment 1

[0119] This example provides a preparation method of a low-dielectric liquid crystal polyester composition, and the steps include:

[0120] S1: 70 parts by weight of LCP (A1) is plasticized and melted through a twin extruder to obtain a first melt, and the plasticizing temperature is 320°C;

[0121] S2: Input the first melt into the grooved roll contact type dipping roll system die (4 dipping rolls, the diameter of the dipping rolls is 25 mm, and the distance between the dipping rolls is 30 mm), and 30 parts by weight of LCP (B1) fibers are also input into the dipping die head, the dipping time was 3 min, and the temperature of the dipping tank was 325 ° C to obtain the second melt;

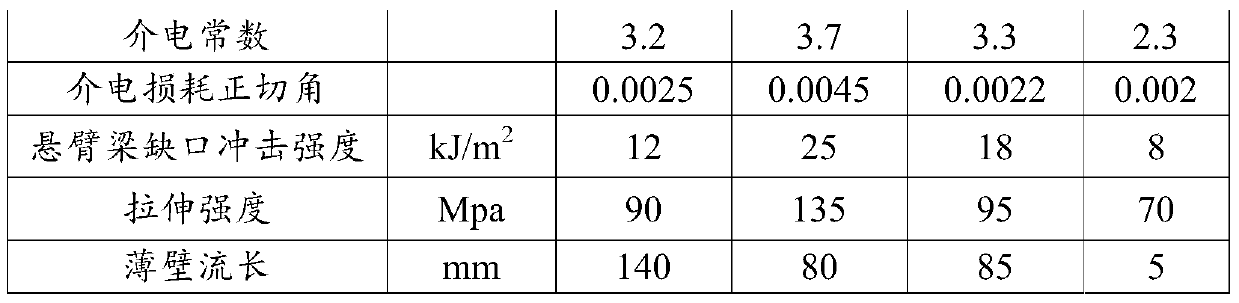

[0122] S3: pulling the second melt out of the dipping head at a speed of 300 mm / s, cooling and dicing to obtain the low-dielectric liquid crystal polyester composition. The test results are recorded in Table 1.

Embodiment 2

[0124] This example provides a preparation method of a low-dielectric liquid crystal polyester composition, and the steps include:

[0125] S1: mixing 60 parts by weight of LCP (A1) and 10 parts by weight of hollow glass microspheres, adding them to a double extruder for plasticization and melting to obtain a first melt, and the plasticizing temperature is 315°C;

[0126] S2: Input the first melt into the grooved roll contact type dipping roll system die (4 dipping rolls, the diameter of the dipping rolls is 25 mm, and the distance between the dipping rolls is 30 mm), and 30 parts by weight of LCP (B1) fibers are also input into the dipping die head, the dipping time was 3 min, and the temperature of the dipping tank was 325 ° C to obtain the second melt;

[0127] S3: pulling the second melt out of the dipping head at a speed of 200 mm / s, cooling and dicing to obtain the low-dielectric liquid crystal polyester composition. The test results are recorded in Table 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Melting point | aaaaa | aaaaa |

| Melting point | aaaaa | aaaaa |

| Intrinsic viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com