Formula and preparation method of petroleum perforating bullet sealing adhesive

A preparation method and technology of perforating bullets, applied in the direction of non-polymer adhesive additives, adhesive additives, etc., can solve the problems of drug-type cover easy to fall off, long curing time, poor bonding effect, etc. Cover phenomenon, good sealing effect, high bonding effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

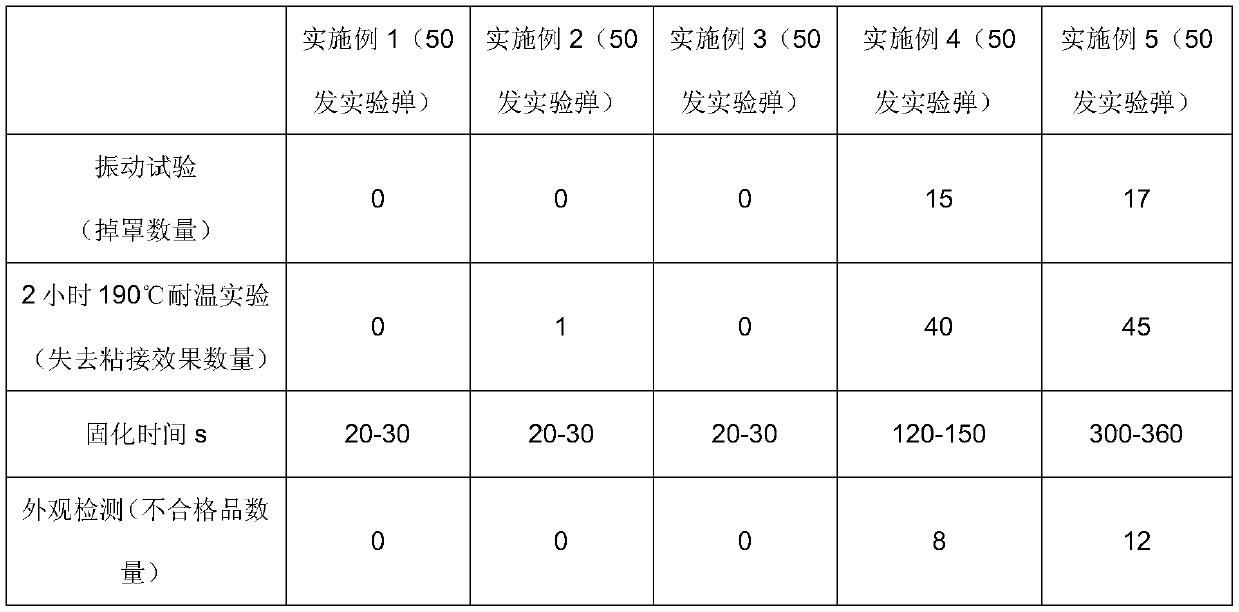

Examples

Embodiment 1

[0013] Mix the weighed adhesive 3M Scotch-Weld CA40H 280 g and silver powder 3 g in proportion. The temperature of the mixing process is 20°C-25°C and the humidity is 40-60%. After mixing and stirring evenly, the shell to be bonded and Smear the joint part of the drug-type cover to form a ring-shaped adhesive tape with a thickness of more than 0.5 mm for bonding.

Embodiment 2

[0015] Mix the weighed adhesive 3M Scotch-Weld CA40H 280 g and silver powder 5 g in proportion. The temperature of the mixing process is 20°C-25°C and the humidity is 40-60%. After mixing and stirring evenly, the shell to be bonded and Smear the joint part of the drug-type cover to form a ring-shaped adhesive tape with a thickness of more than 0.5 mm for bonding.

Embodiment 3

[0017] Mix the weighed adhesive 3M Scotch-Weld CA40H 280 g and silver powder 4 g in proportion. The temperature of the mixing process is 20°C-25°C and the humidity is 40-60%. After mixing and stirring evenly, the shell to be bonded and Smear the joint part of the drug-type cover to form a ring-shaped adhesive tape with a thickness of more than 0.5 mm for bonding.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com