A kind of cerium phosphate modified silicon carbide fiber reinforced silicon carbide composite material and preparation method thereof

A silicon carbide fiber and composite material technology, which is applied in the field of aerospace material preparation, can solve the problems of limiting material use temperature and service life, performance loss of BN interface layer, performance degradation of composite materials, etc., achieves excellent chemical stability, and realizes cracks Deflection, performance-enhancing effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

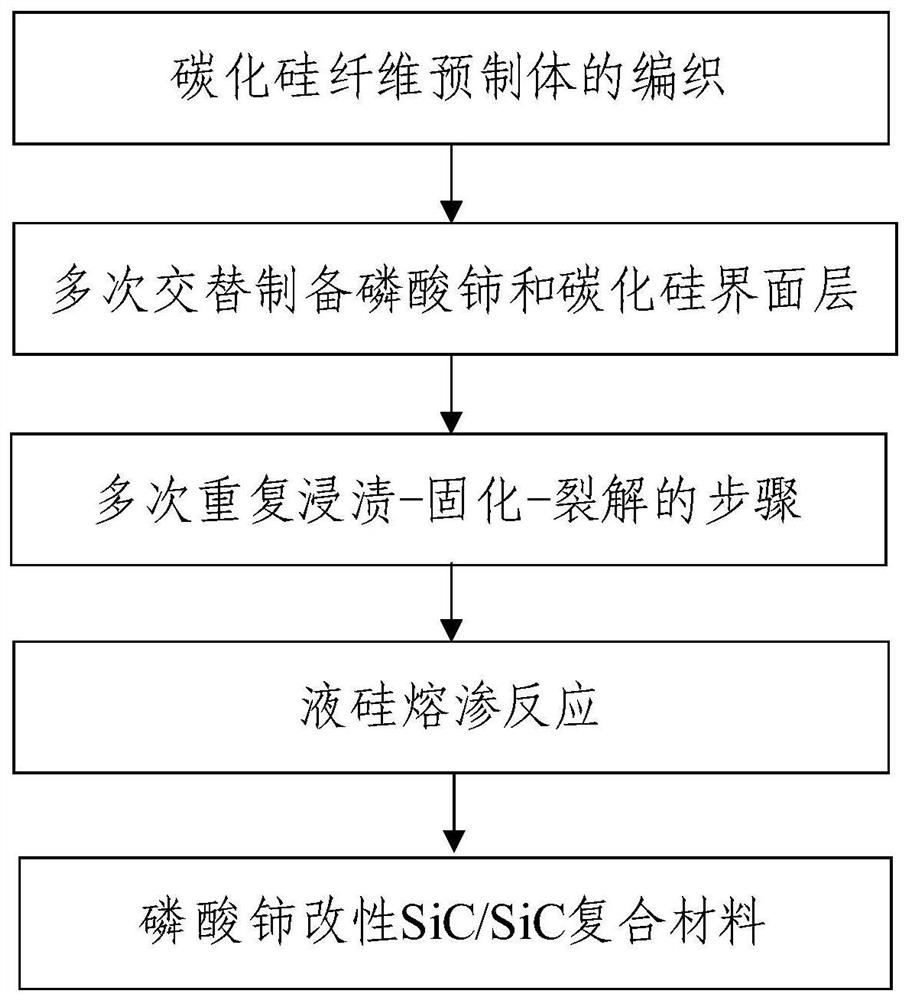

[0028] The preparation method of the cerium phosphate modified silicon carbide fiber reinforced silicon carbide composite material of the present invention comprises the following steps:

[0029] (1) Alternately prepare cerium phosphate interface layer and silicon carbide interface layer on the surface of silicon carbide fiber preform (SiC fiber preform) until it reaches a predetermined thickness or predetermined number of layers, and the cerium phosphate interface layer and silicon carbide interface layer prepared by alternating A modified silicon carbide fiber preform modified by a composite interface layer (cerium phosphate / silicon carbide composite interface layer) composed of an interface layer;

[0030] (2) impregnating the modified silicon carbide fiber preform obtained in step (1) with a carbon precursor solution, and then subjecting the impregnated modified silicon carbide fiber preform to a curing step and a cracking step in sequence;

[0031] (3) Repeat step (2) at ...

Embodiment 1

[0065] ① Weave the second-generation SiC fiber (Hi-Nicalon) into a 2.5D silicon carbide fiber preform to obtain a silicon carbide fiber preform with a fiber volume fraction of 35%, with a warp density of 8 fibers / cm and a weft density of 3.5 fibers / cm.

[0066] ②Choose cerium nitrate hexahydrate to form a 0.1mol / L aqueous solution, then add an appropriate amount of sodium phosphate to make the molar ratio of cerium and phosphate radicals 1:1; then add an appropriate amount of polyvinyl alcohol surfactant to make the concentration of polyvinyl alcohol 0.5g / L; then add hydrochloric acid to adjust the pH of the solution to 1, stir evenly to obtain a cerium phosphate precursor solution; put the silicon carbide fiber prefabricated body in ① into the cerium phosphate precursor solution for 15 minutes, take it out and put it in an oven at 140°C to keep the temperature React for 24 hours; finally take out the silicon carbide fiber preform and treat it in an oven at 60° C. for 10 hours...

Embodiment 2

[0074] ① Weave the second-generation SiC fiber (Hi-Nicalon) into a 2.5D silicon carbide fiber preform to obtain a silicon carbide fiber preform with a fiber volume fraction of 35%, with a warp density of 8 fibers / cm and a weft density of 3.5 fibers / cm.

[0075] ②Choose CeCl 3 ·7H 2 O is dissolved in deionized water at a concentration of 0.2mol / L, and H is added in a stoichiometric 1:1 ratio 3 PO 4 solution, mixed evenly to obtain a cerium phosphate precursor solution; put the silicon carbide fiber preform in ① into the cerium phosphate precursor solution and soak for 15 minutes, take it out and put it in an oven at 80°C for 16 hours; finally take out the dried silicon carbide The fiber preform was heat-treated at 1350° C. for 2 hours, and then taken out, so that a cerium phosphate interface layer with a thickness of 150 nm was obtained on the surface of the silicon carbide fiber preform.

[0076] ③Move the silicon carbide fiber prefabricated body prepared with the cerium ph...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com