A high-temperature and hydrolysis-resistant epoxy resin matrix for sucker rods

A technology for decomposing epoxy resin and epoxy resin, which is applied in the field of high-temperature-resistant and hydrolysis-resistant epoxy resin matrix and its preparation, can solve the problems of resin decomposition, affecting the long-term reliability of carbon fiber composite sucker rods, etc., and achieve good high pressure resistance High humidity aging performance, non-cracking effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0040] The preparation raw materials of the biphenyl novolac epoxy resin of the present invention include biphenyl novolac and epichlorohydrin.

[0041] In a preferred embodiment, the molar ratio of the biphenyl novolac and epichlorohydrin is 1:(7-9); preferably, the molar ratio of the biphenyl novolac and epichlorohydrin is 1: 8.

[0042] In a preferred embodiment, the raw materials for the preparation of biphenyl novolac include 4,4'-dimethoxymethyl biphenyl and phenol.

[0043] In a more preferred embodiment, the molar ratio of the 4,4'-dimethoxymethyl biphenyl to phenol is 1:(4-6); more preferably, the 4,4'-dimethoxymethyl biphenyl The molar ratio of methoxymethyl biphenyl and phenol was 1:5.

[0044]In a more preferred embodiment, the preparation process of the biphenyl novolac is: in a 250mL four-neck flask, add 4,4'-dimethoxymethyl biphenyl and phenol, add oxalic acid to adjust the pH to 5~ 6. The reaction is stirred and refluxed for 3 to 5 hours under nitrogen atmos...

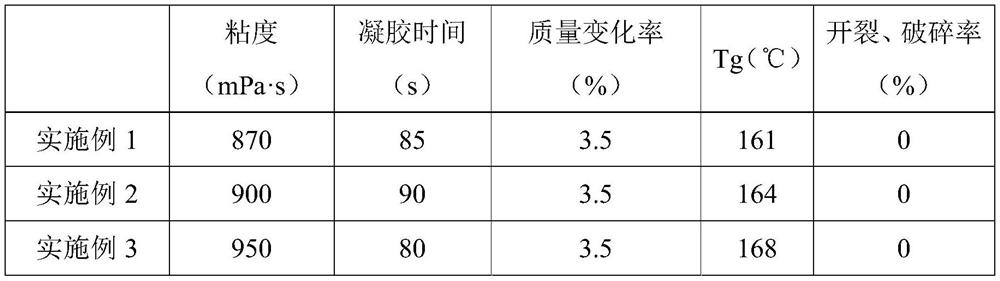

Embodiment 1

[0098] Embodiment 1 of the present invention provides a high temperature-resistant and hydrolysis-resistant epoxy resin matrix for sucker rods. The preparation raw materials include component A and component B; in parts by weight, component A includes 50 parts of bisphenol A-type epoxy resin, 15 parts of novolac novolac epoxy resin, 10 parts of cycloaliphatic epoxy resin, 30 parts of glycidyl amine epoxy resin;

[0099] The B component includes 50 parts of curing agent, 5 parts of toughening agent, 1 part of accelerator, and 1 part of catalyst;

[0100] The epoxy equivalent of the bisphenol A epoxy resin is 170-200 g / mol.

[0101] The bisphenol A epoxy resin was purchased from Shandong Deyuan Epoxy Technology Co., Ltd., and the model is DY-128E.

[0102] The novolac-type novolac epoxy resin includes biphenyl novolac epoxy resin and o-cresol-type novolac epoxy resin; the epoxy equivalent of the o-cresol-type novolac epoxy resin is 200-240 g / mol, which can be purchased from Fr...

Embodiment 2

[0119] Embodiment 2 of the present invention provides a high-temperature and hydrolysis-resistant epoxy resin matrix for sucker rods, the preparation raw materials include A component and B component; in parts by weight, the A component includes 70 parts of bisphenol A-type epoxy resin, 25 parts of novolac novolac epoxy resin, 25 parts of cycloaliphatic epoxy resin, 70 parts of glycidyl amine epoxy resin;

[0120] The B component includes 100 parts of curing agent, 20 parts of toughening agent, 5 parts of accelerator, and 5 parts of catalyst;

[0121] The epoxy equivalent of the bisphenol A epoxy resin is 170-200 g / mol.

[0122] The bisphenol A epoxy resin was purchased from Shandong Deyuan Epoxy Technology Co., Ltd., and the model is DY-128E.

[0123] The novolac-type novolac epoxy resin includes biphenyl novolac epoxy resin and o-cresol-type novolac epoxy resin; the epoxy equivalent of the o-cresol-type novolac epoxy resin is 200-240 g / mol, which can be purchased from From...

PUM

| Property | Measurement | Unit |

|---|---|---|

| glass transition temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com