Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

537results about How to "Increase heating power" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

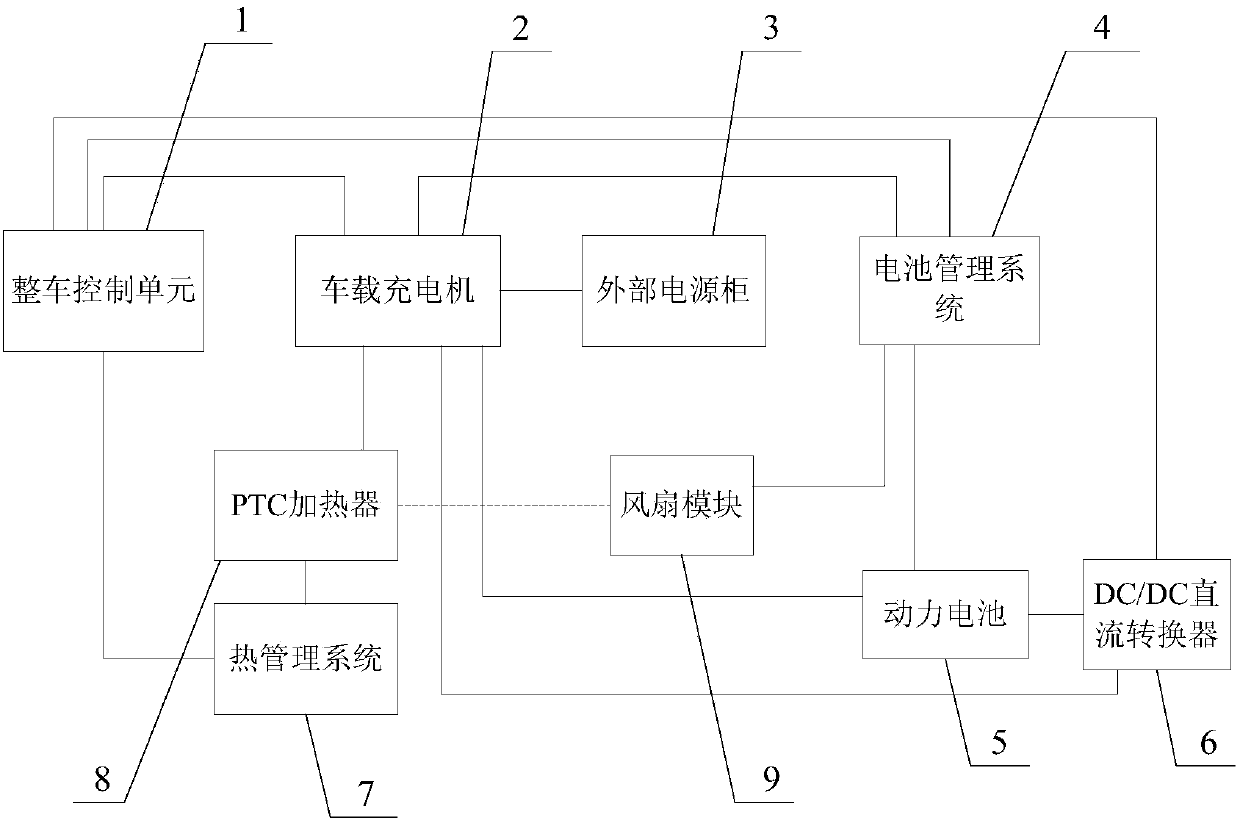

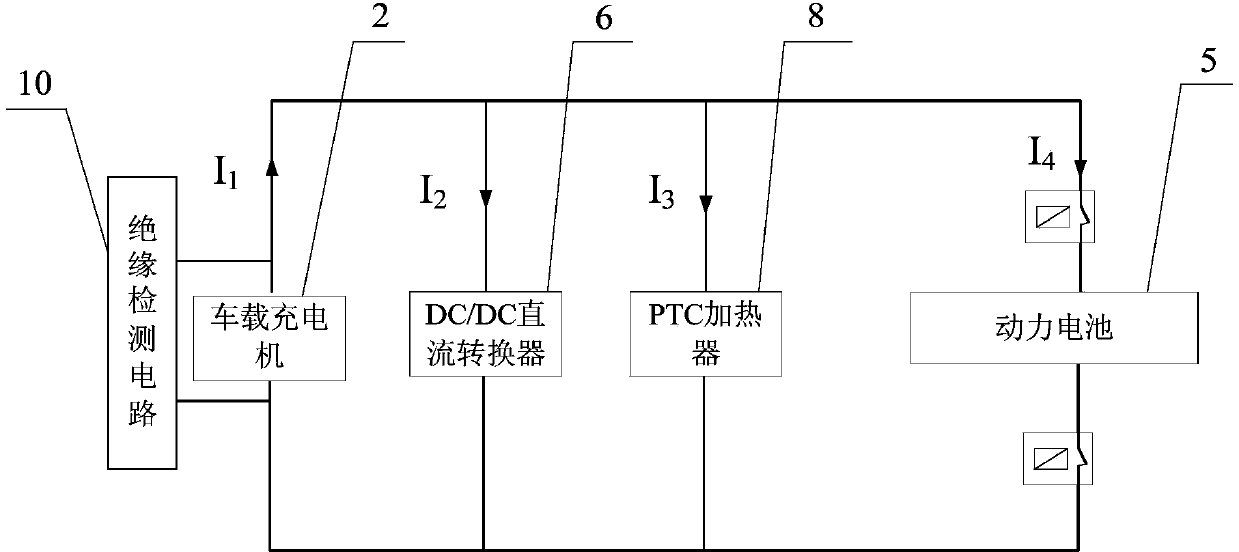

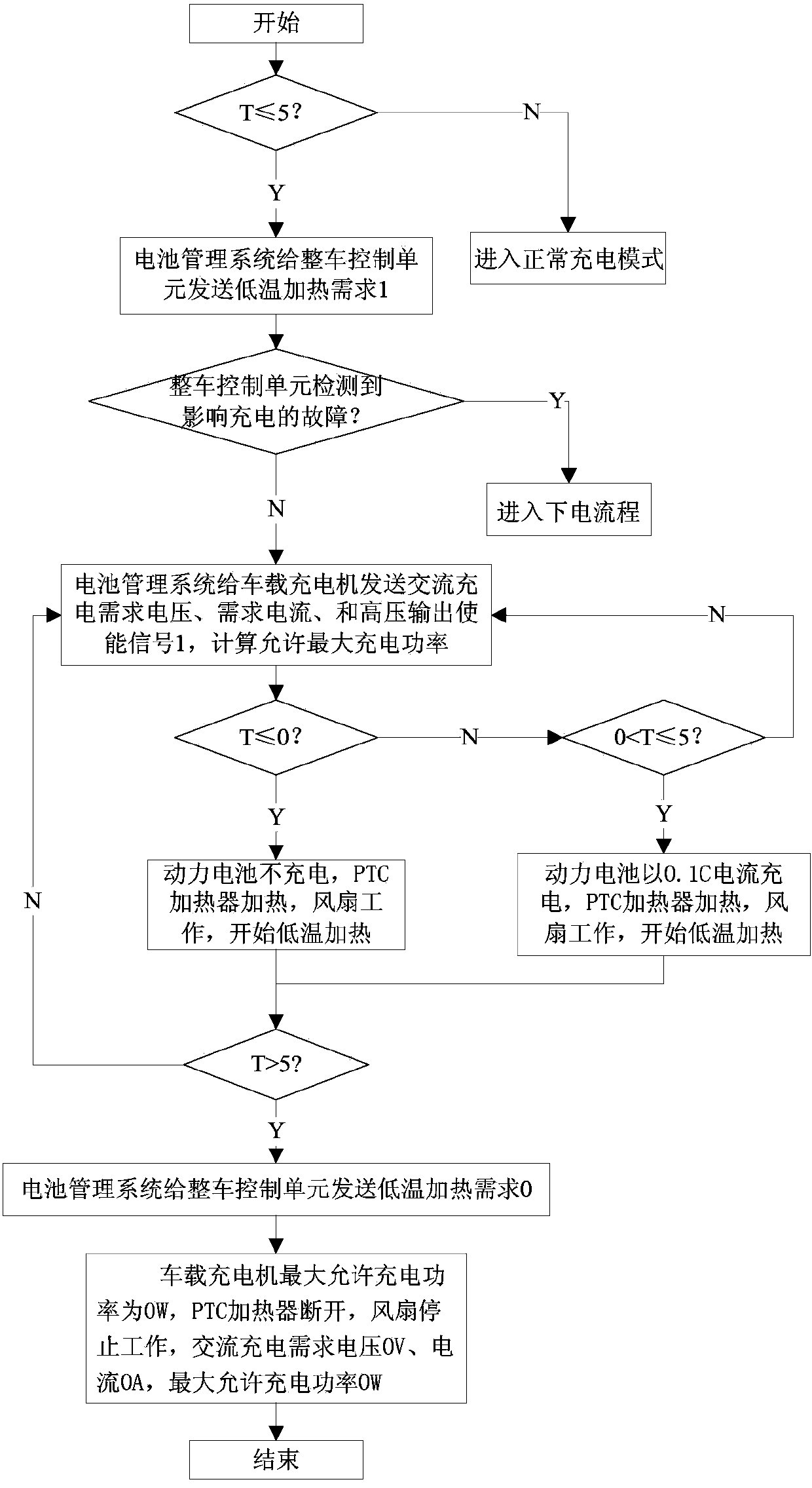

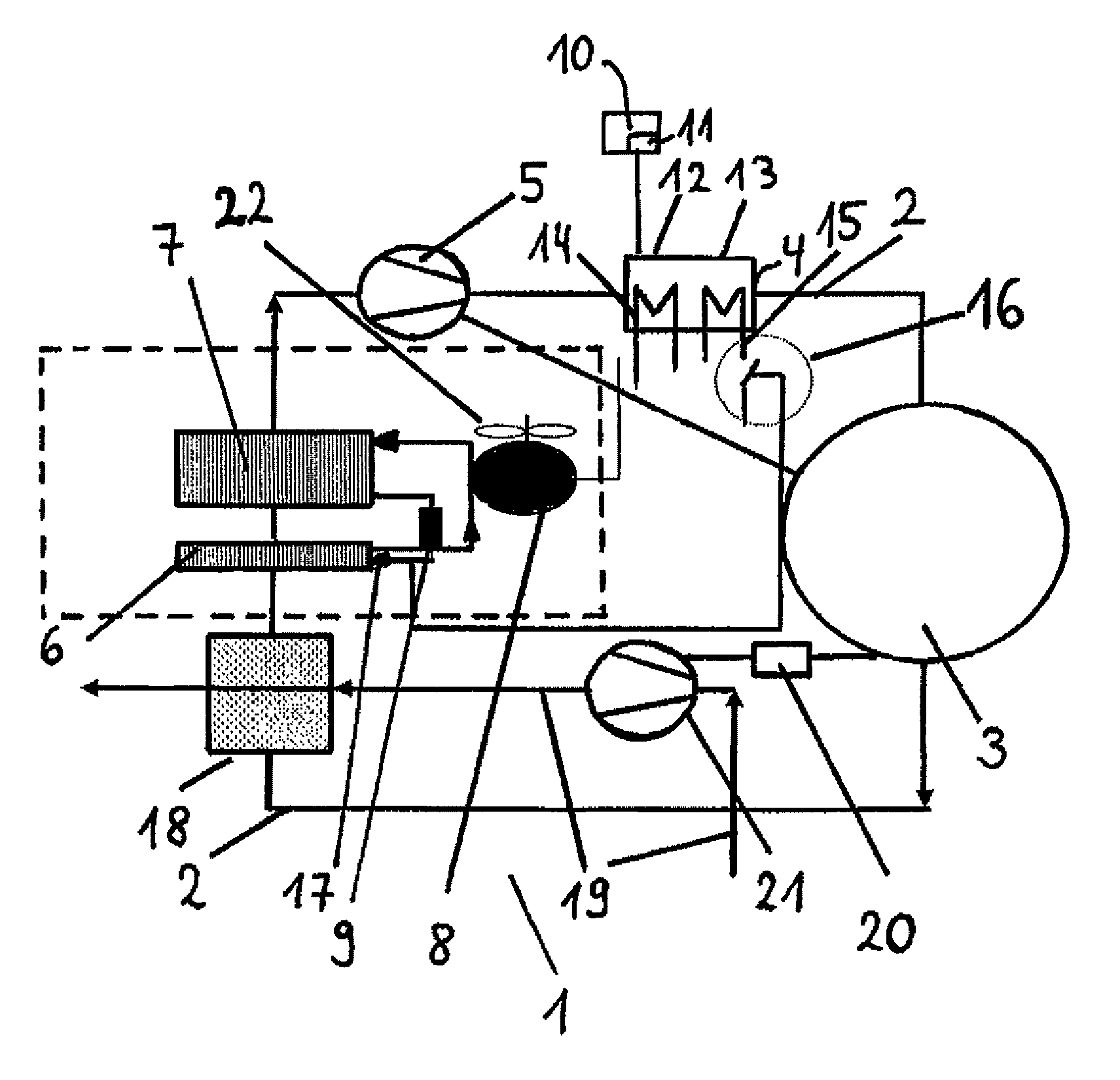

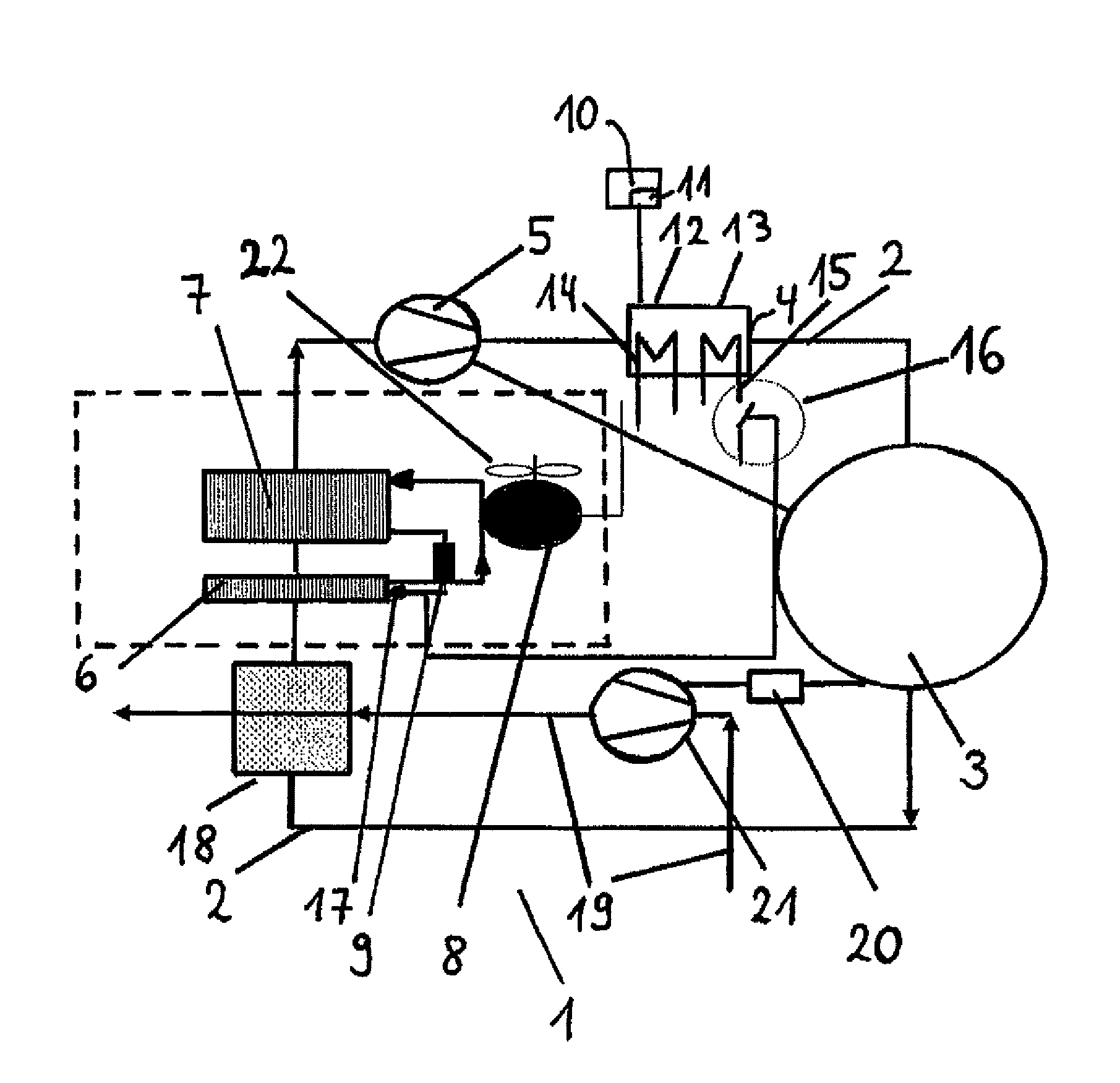

Low-temperature charge and heating system and method for power battery for all-electric vehicles

ActiveCN103427137AShorten heating timeImprove securitySecondary cells charging/dischargingVehicular energy storageElectrical batteryHeating system

The invention discloses a low-temperature charge and heating system and method for a power battery for all-electric vehicles. The system comprises a vehicle control unit, a vehicular charger, a battery management system, the power battery, a DC / DC converter, a heat management system, a PTC heater and a fan module. The method includes: during charging, heating is allowed only when the temperature is very low and the temperature T of the power battery is smaller than or equal to 5 DEG C; when the temperature is very low, heating and charging with low current are performed simultaneously; if the temperature T of the power battery is larger than 5 DEG C, low-temperature heating is aborted and a normal charge mode is allowed. The system and the method have the advantages that low-temperature charge and heating time can be shortened, normal charge of the power battery is guaranteed and the service life of the power battery is unaffected.

Owner:重庆长安新能源汽车科技有限公司

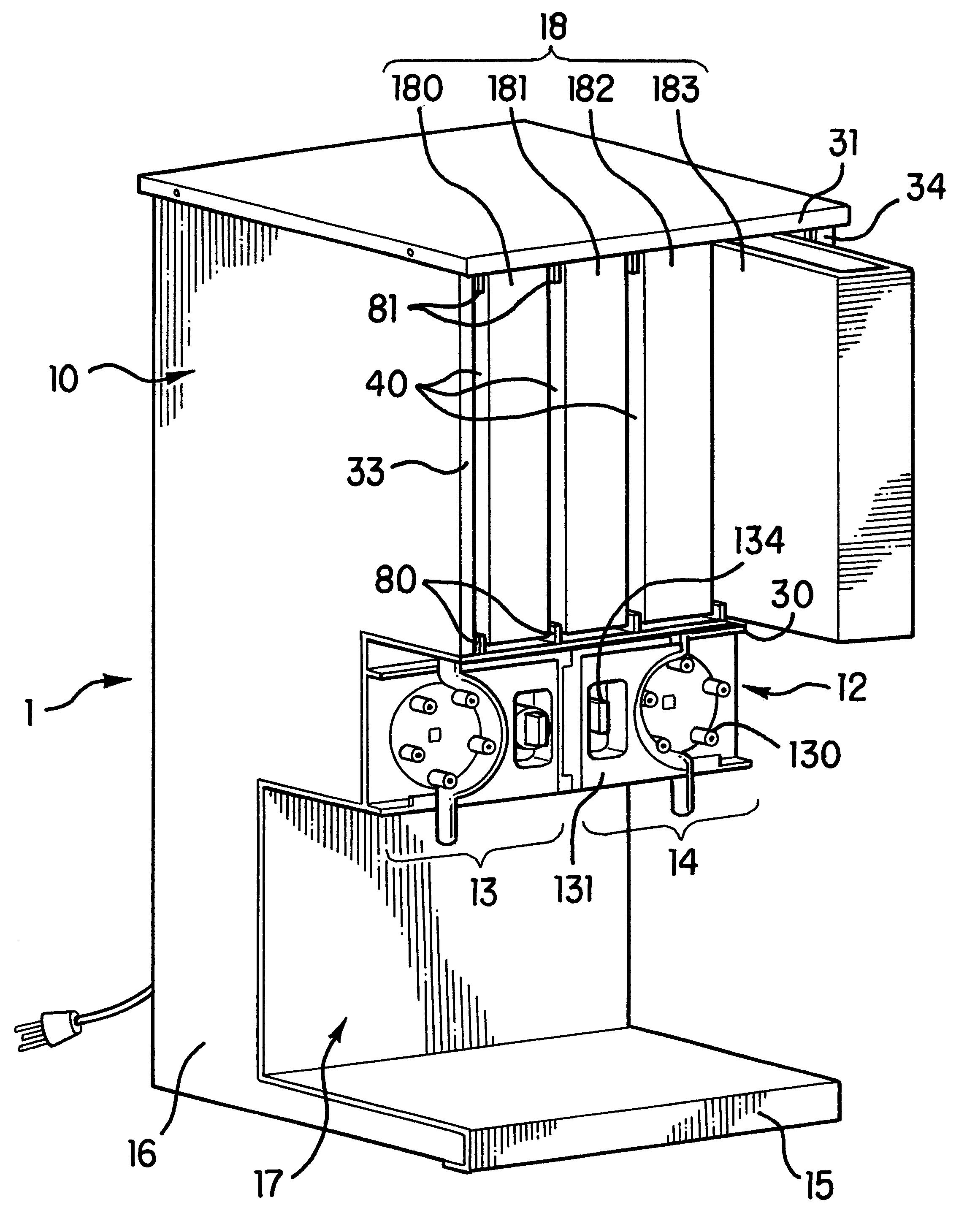

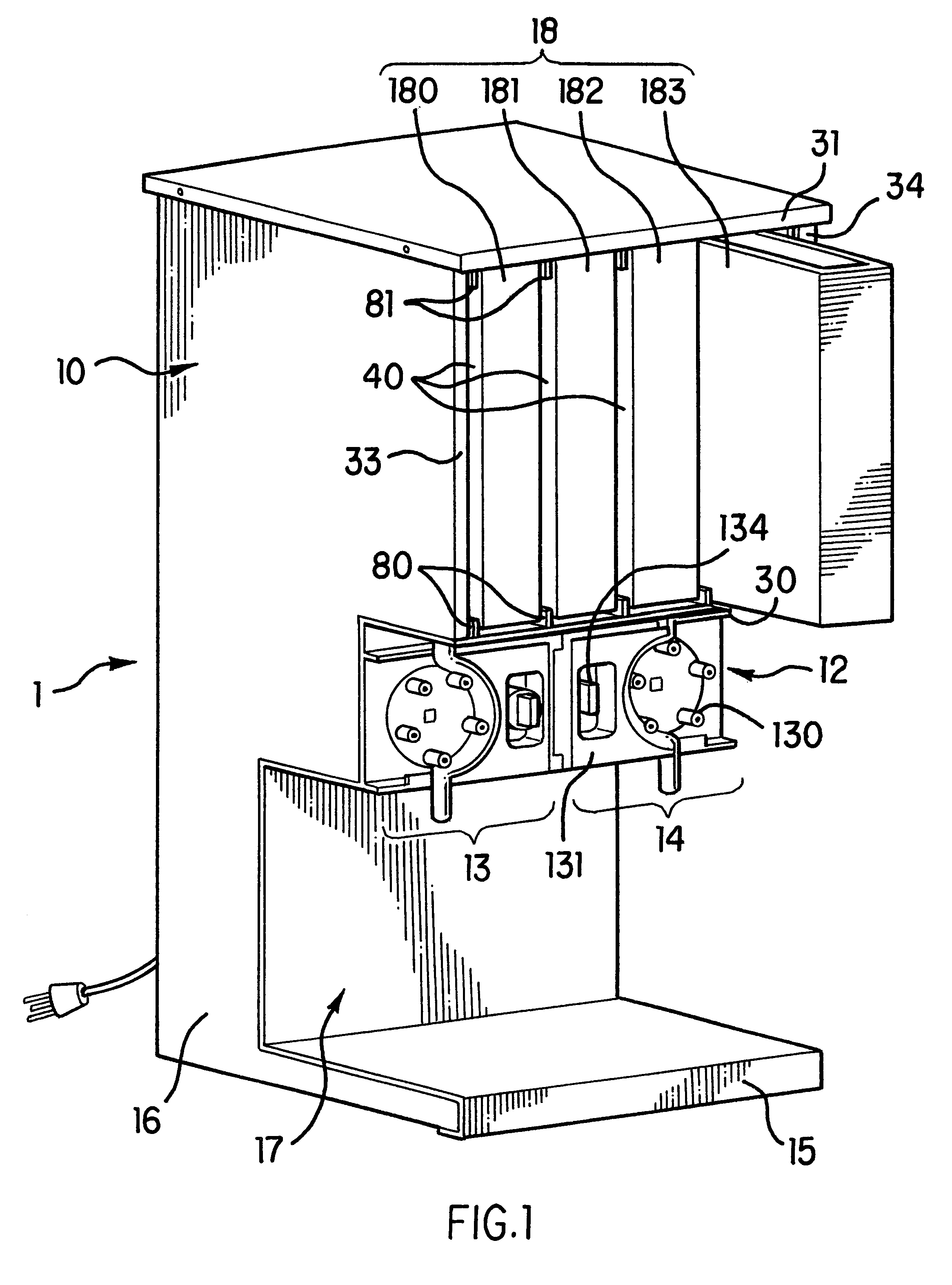

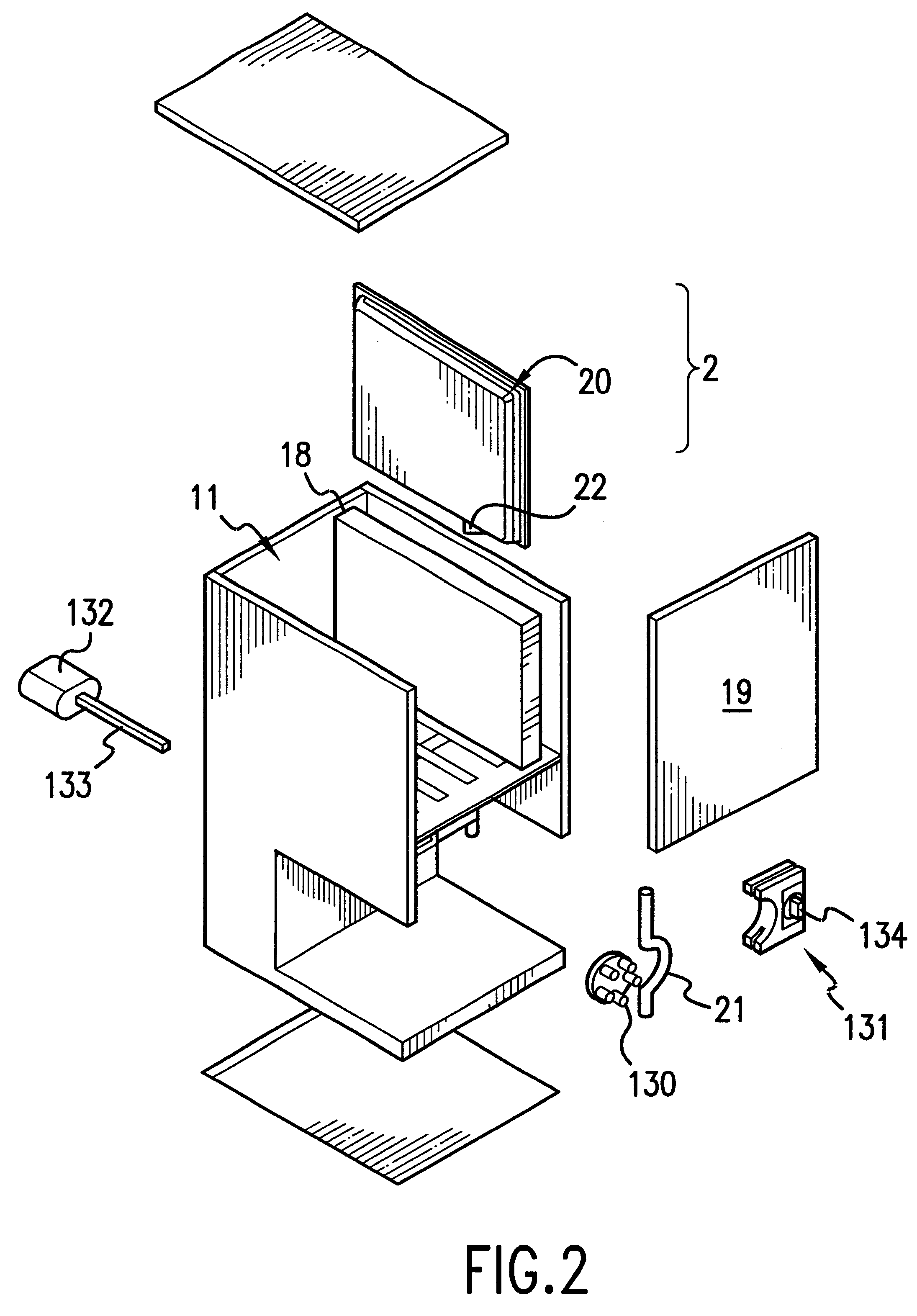

Dispensing device and method for rapidly heating and delivering a flowable product

InactiveUS6419121B1Improved heating/cooling outputShorten the timeLiquid flow controllersLiquid transferring devicesBiomedical engineeringFood products

Owner:NESTEC SA

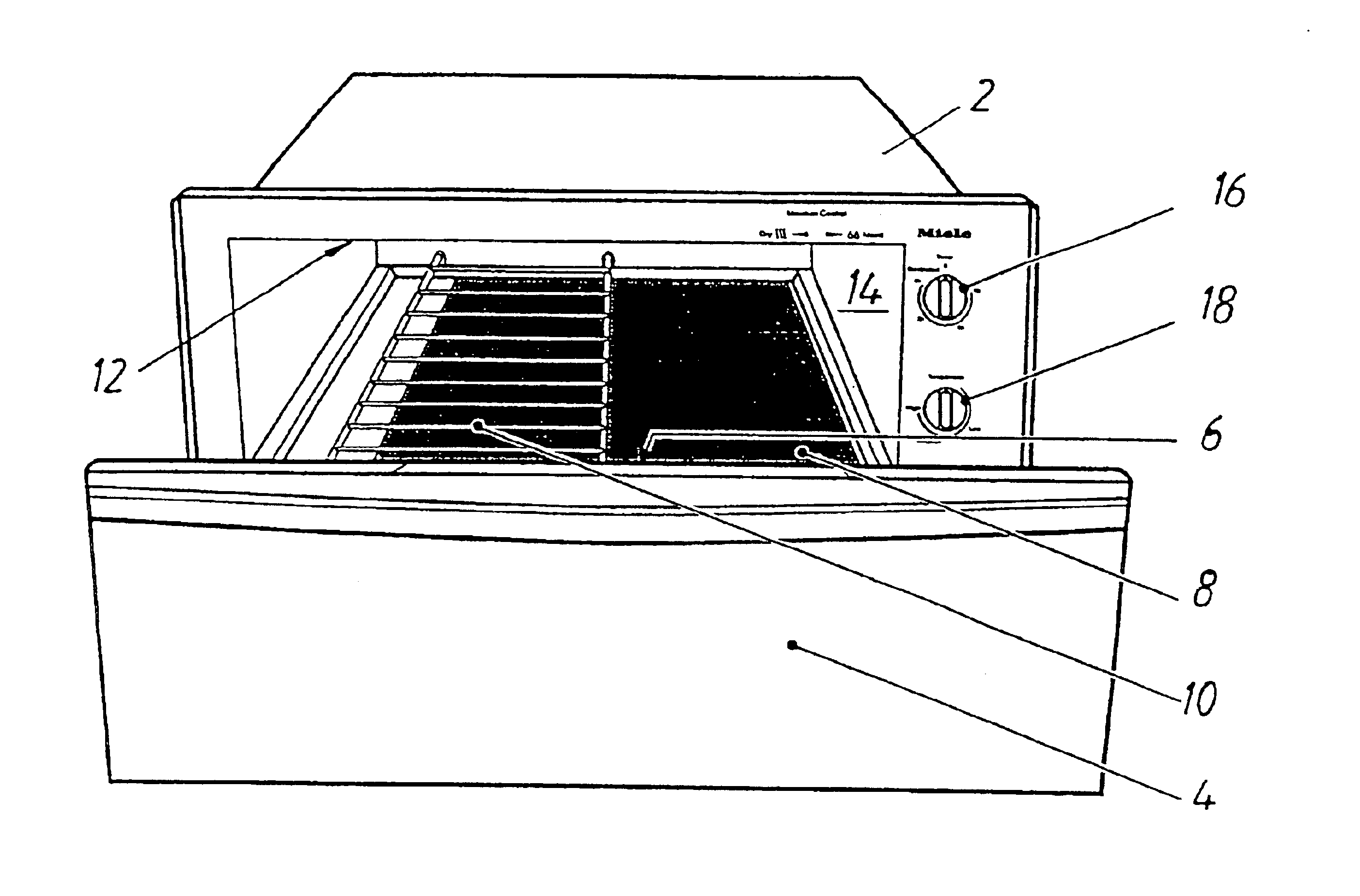

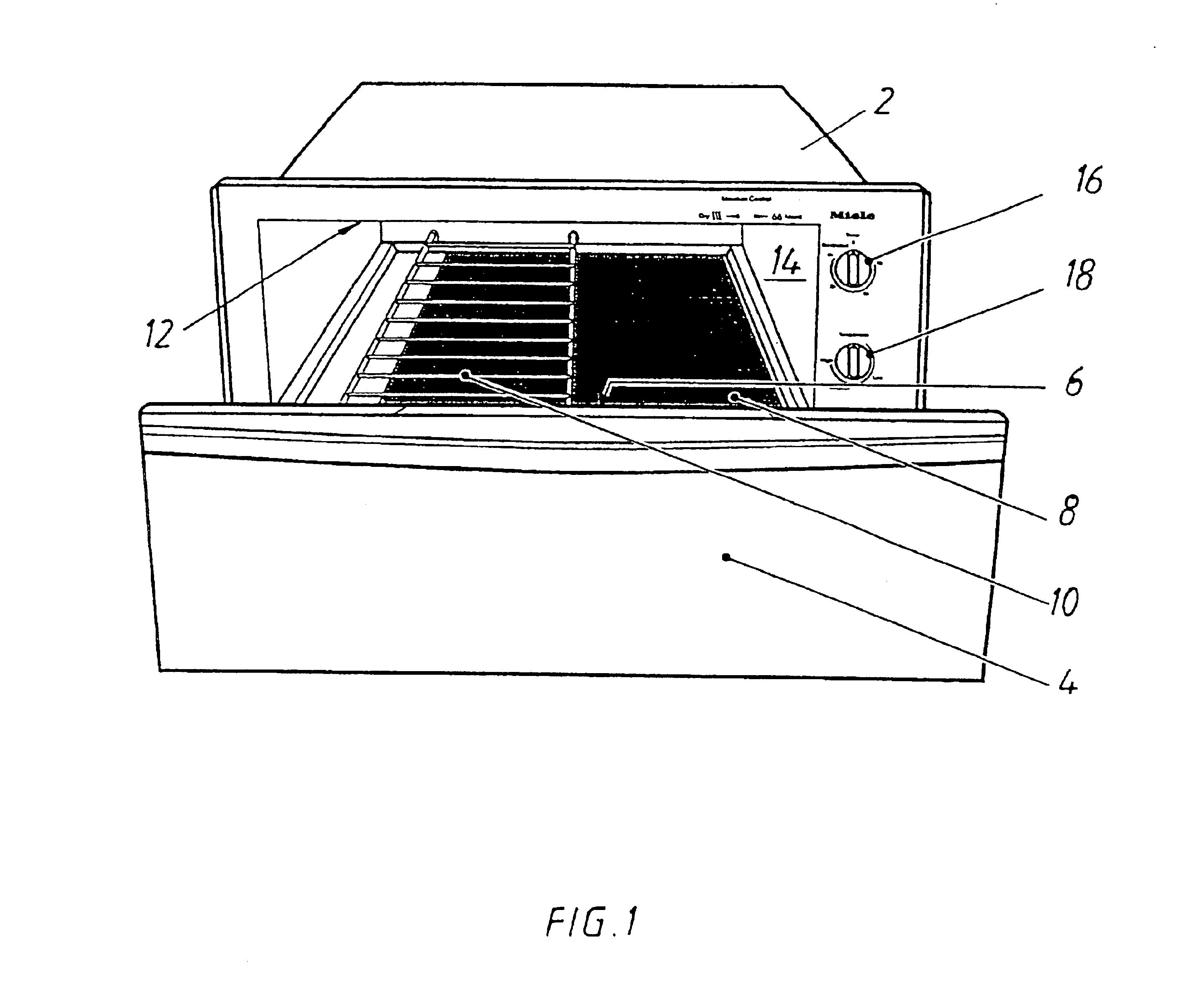

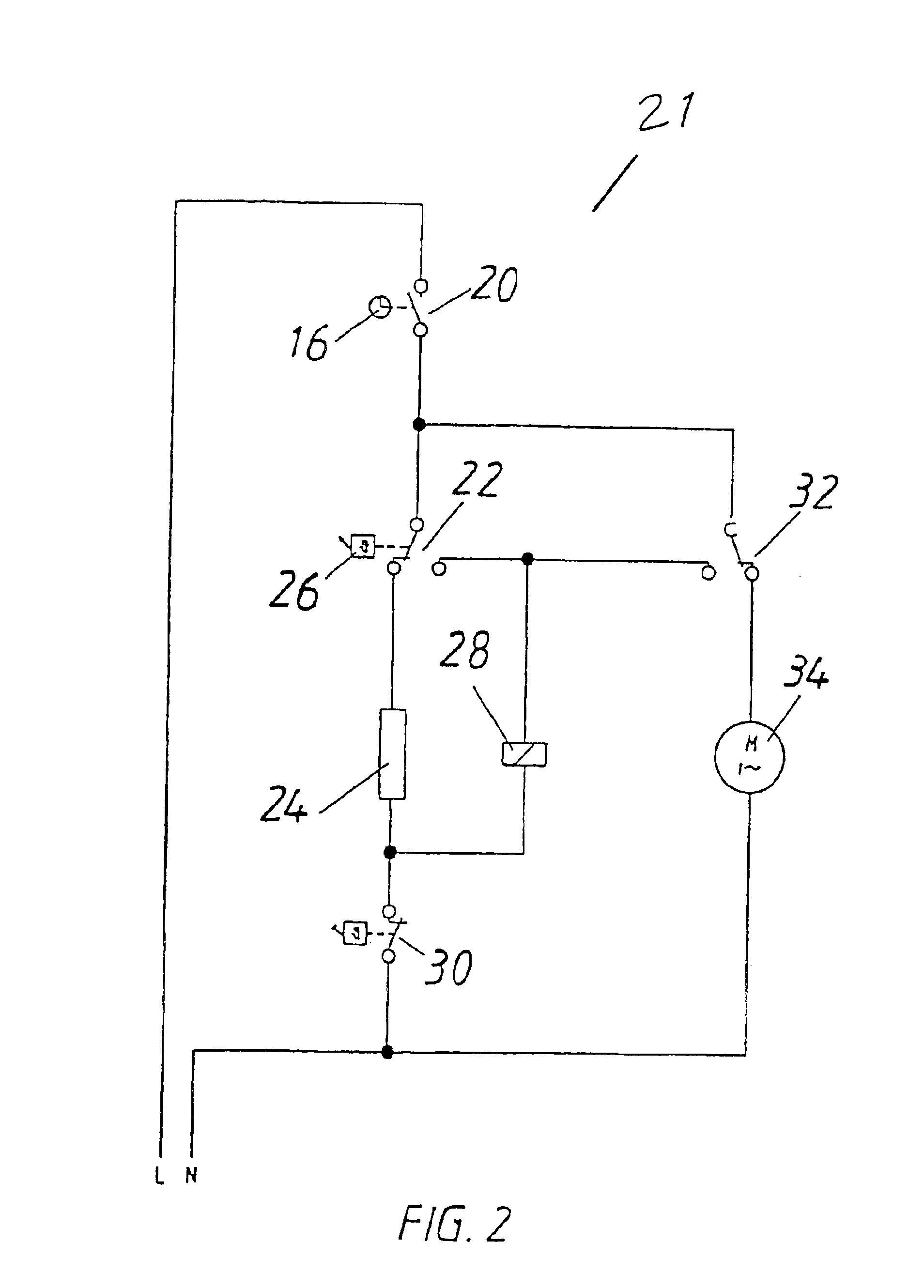

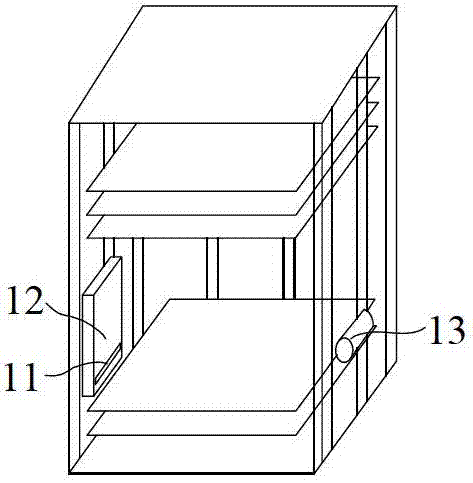

Household food warmer for keeping foods and beverages warm

InactiveUS6849835B2Reduce energy requirementShort heat-up timeDomestic stoves or rangesElectrical heating fuelElectricityHeating element

A household food warmer for keeping foods and beverages warm includes a housing, a drawer which can be inserted into the housing, an interior chamber which is bounded by the housing and the inserted drawer and which is used to accommodate foods placed on plates, a heating element, an electrical circuit in which is arranged a first electrical switch for switching on the heating element, and a temperature sensor for measuring the interior chamber temperature. A convection fan is provided. The convection fan can be switched on via a second electrical switch arranged in the electrical circuit and can be switched off via the second electrical switch upon the occurrence of a switching condition that is dependent on the temperature sensor.

Owner:MIELE & CO KG

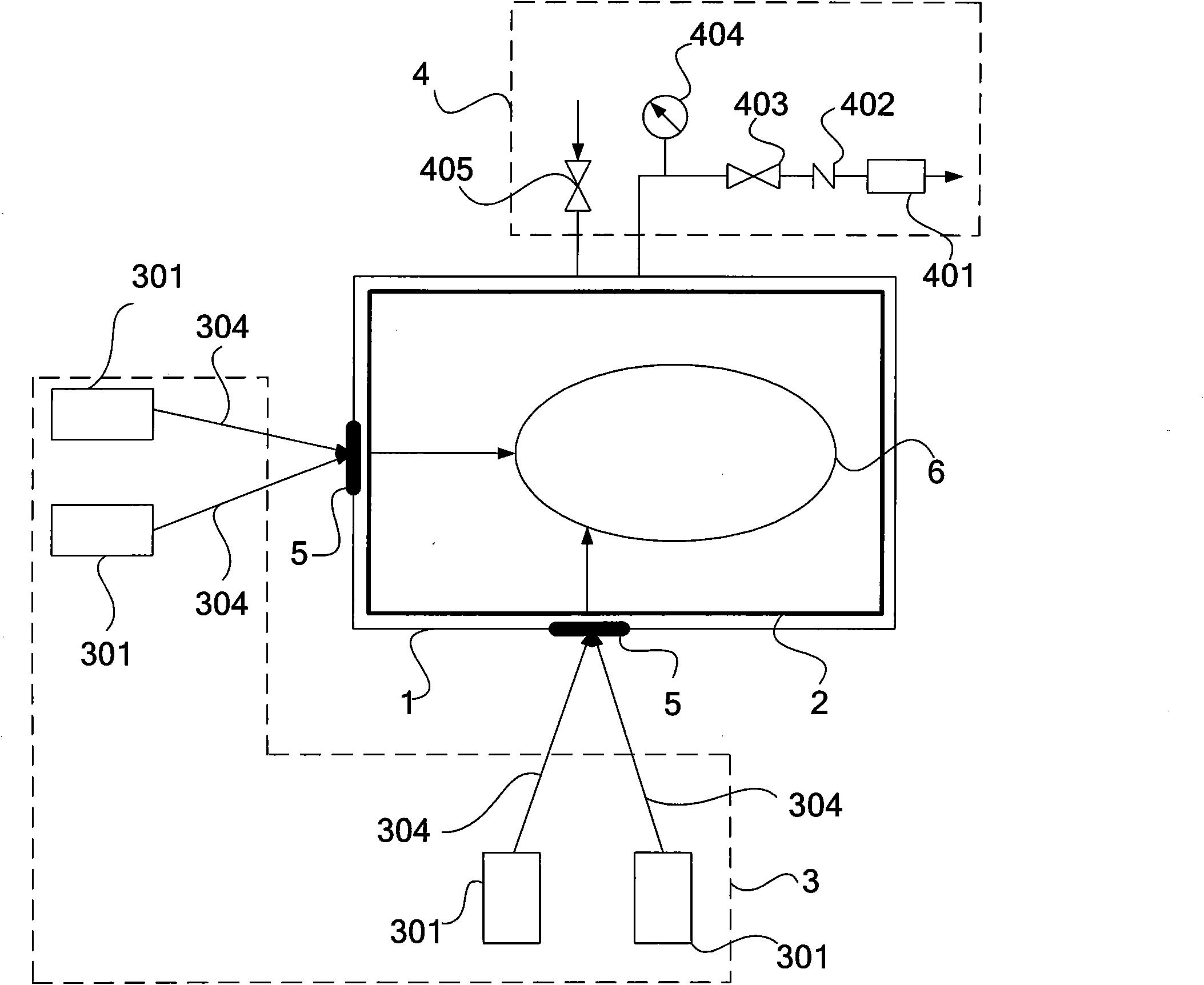

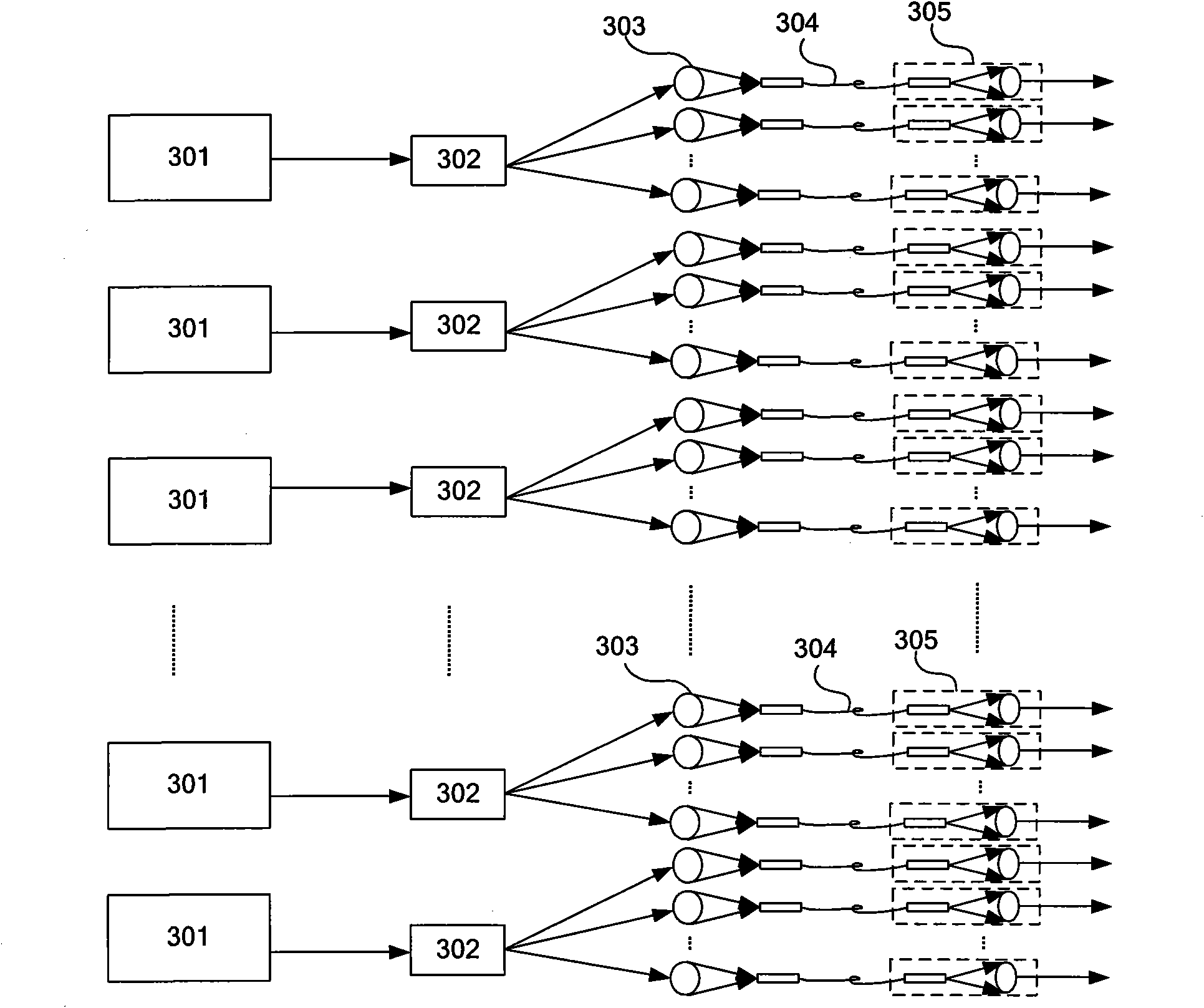

System and method for simulating irradiation heating environment of hypersonic aircraft

InactiveCN101915654AReduce technical difficultyReduce difficultyAerodynamic testingInfrared lampFlight vehicle

The invention disclosed a system and a method for simulating irradiation heating environment of a hypersonic aircraft. The system comprises an environment simulation chamber, an infrared lamp array, a laser heating unit and a vacuumizing unit. The infrared lamp array arranged on the inner wall of the environment simulation chamber is used for carrying out medium-high temperature heating on the whole aircraft or local parts of the aircraft, the environment simulation chamber is externally connected with the vacuumizing unit which is used for increasing and reducing pressure inside the environment simulation chamber, and the laser heating unit is arranged outside the environment simulation chamber and emits a laser beam which can penetrate through the glass which is arranged on the side wall of the environment simulation chamber so as to carry out ultrahigh temperature heating on the whole aircraft or the local parts of the aircraft. The infrared lamp array and a solid-state laser are adopted as heating sources, therefore, the large component of the aircraft even the whole aircraft can be tested, and the technology difficulty of height thermal environment comprehensive simulation is little; and the system has simple structure, and is more flexible.

Owner:BEIHANG UNIV

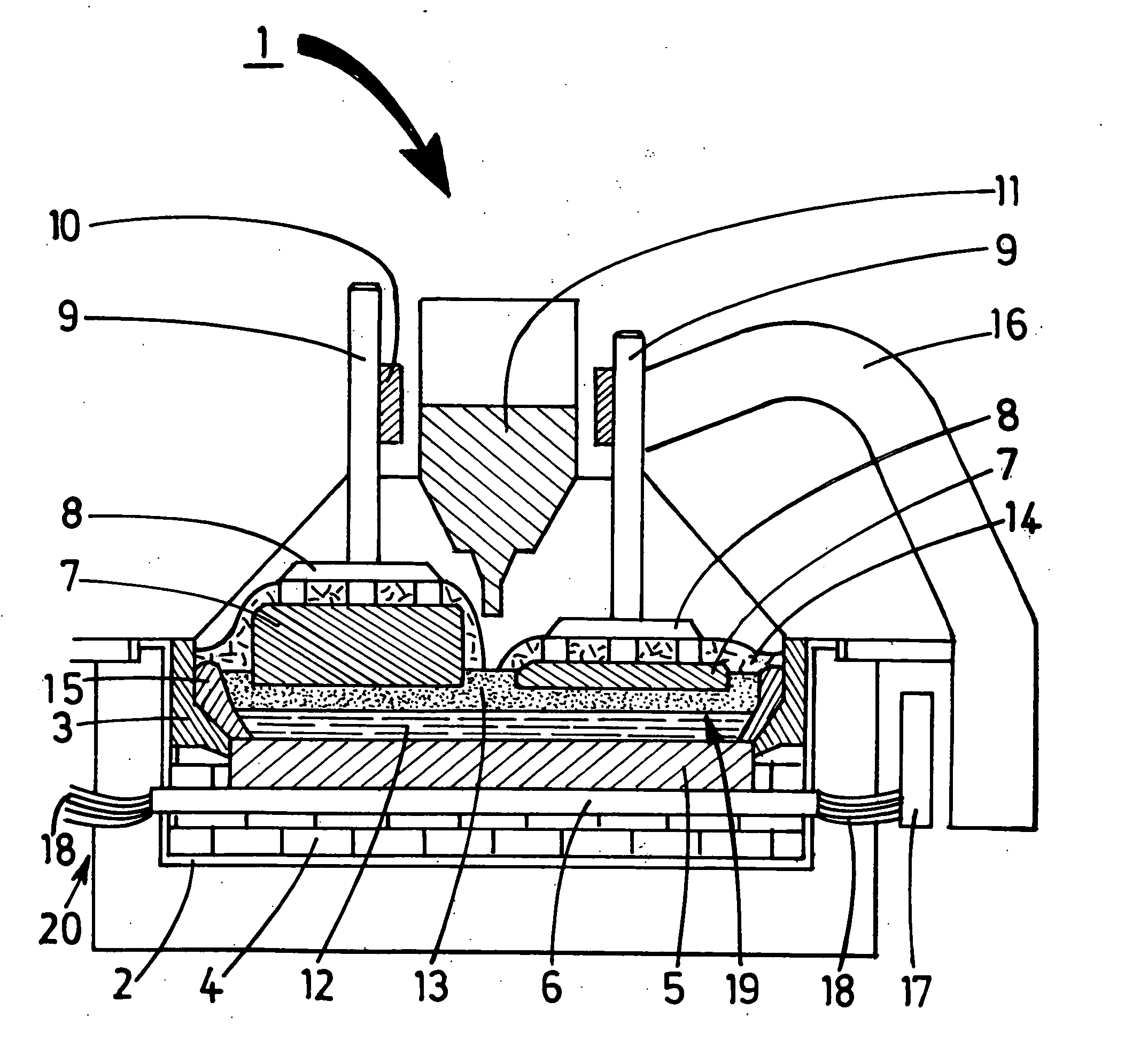

Method and system for cooling an electrolytic cell for aluminum production

InactiveUS20060118410A1Increase heating powerIncrease heating capacityCellsLighting and heating apparatusElectrical batteryHeat transfer fluid

The invention relates to a cooling method of a igneous electrolytic cell for aluminium production wherein heat transfer fluid droplets (or “divided heat transfer fluid”) are produced, preferentially in a confined volume in contact with a specified surface of at least one wall of the shell of the pot of the electrolytic cell, so as to induce the evaporation of all or part of said droplets by contact with said surface and remove the heat from said surface. The invention also relates to a cooling system capable of implementing the cooling method. The invention makes it possible to obtain a high cooling efficiency due to the latent heat of vaporisation of the heat transfer fluid.

Owner:ALUMINUM PECHLNEY

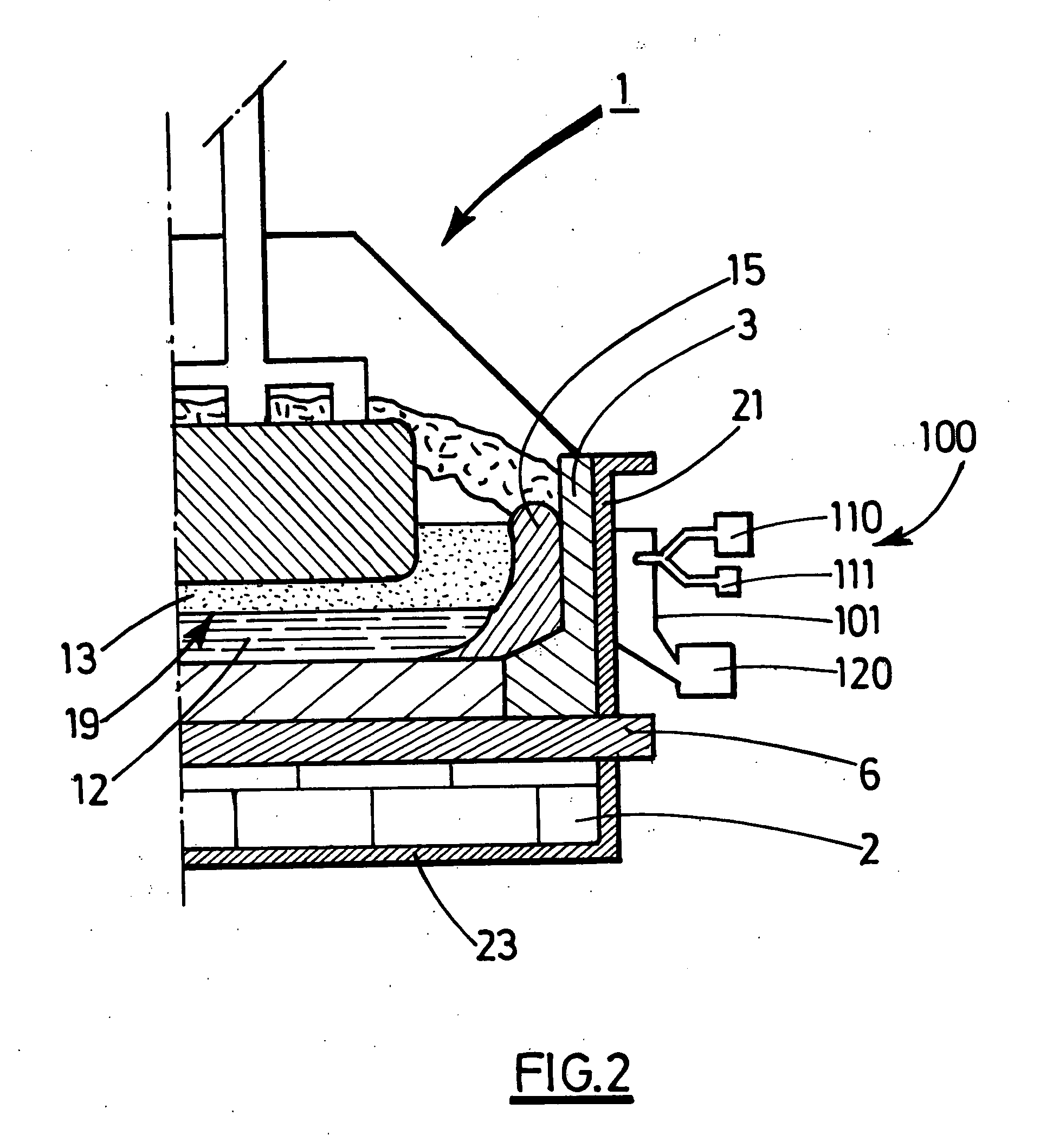

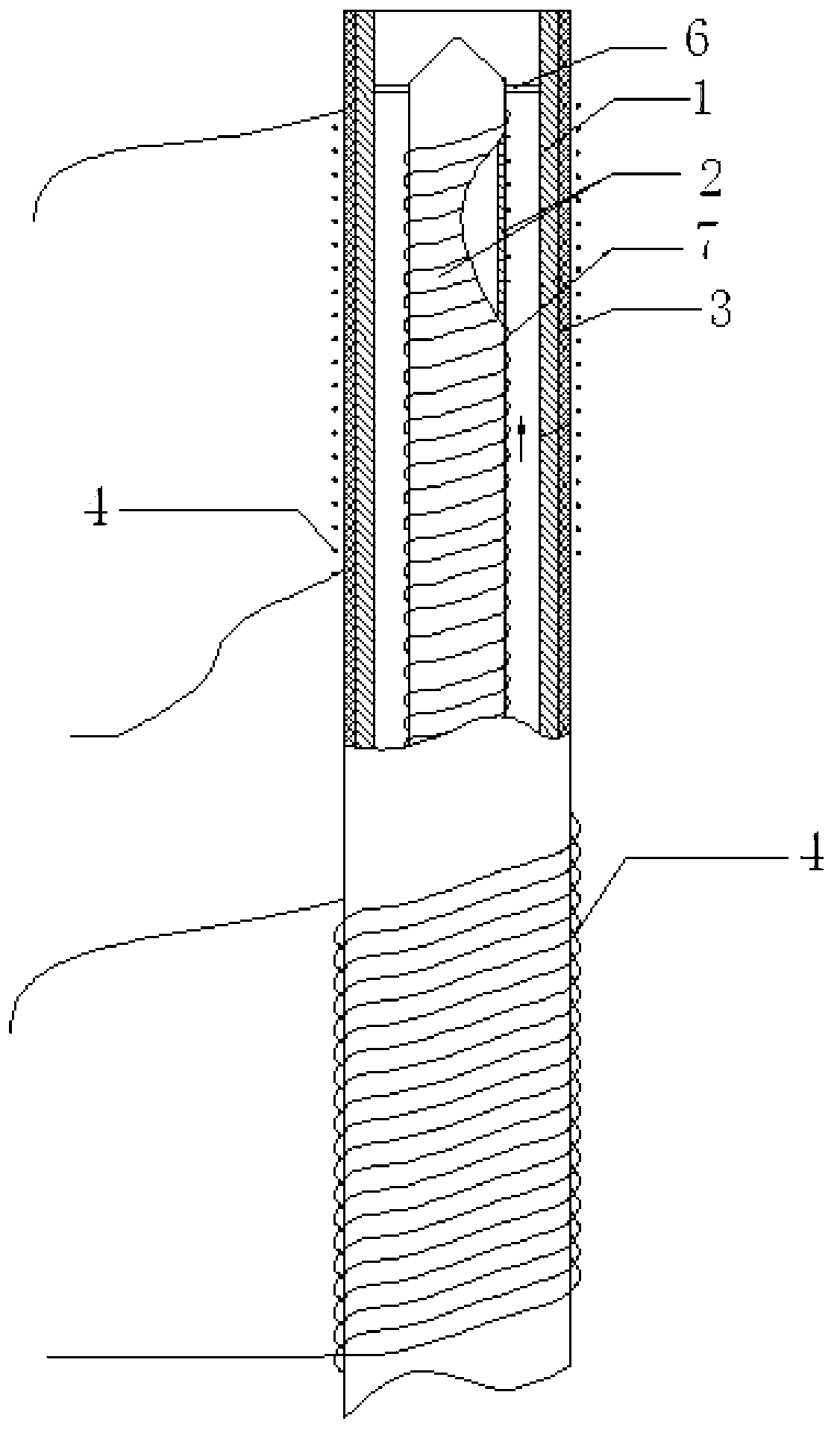

Electrically heatable liquid line

ActiveUS20050063689A1Simple to manufactureEasy to manufactureInternal combustion piston enginesExhaust apparatusLiquid lineElectricity

An electrically heatable liquid line in which a heating wire is arranged on an inner plastic layer and an electrically insulating tape is helically wound around the plastic layer and the heating wire. This object is met in the liquid line of the above-type by providing the insulating tape as an adhesive tape whose adhesive can be glued to the plastic layer.

Owner:NORMA GERMANY GMBH

Heat exchanger and method for converting thermal energy of a fluid into electrical power

InactiveUS20120118344A1Increase surface areaIncrease heating powerInternal combustion piston enginesThermoelectric device with peltier/seeback effectThermal energyThermal expansion

A heat exchanger for converting thermal energy of a fluid, e.g., exhaust gas of an internal combustion engine, into electrical power, has a flow channel for conveying a hot fluid, and at least one thermoelectric module for generating electrical power is thermally connected to the flow channel. The flow channel is manufactured from a ceramic material. Thermal expansion effects of the flow channel is reduced by the ceramic material of the flow channel so that the design complexity for converting thermal energy into electrical power is reduced.

Owner:ROBERT BOSCH GMBH

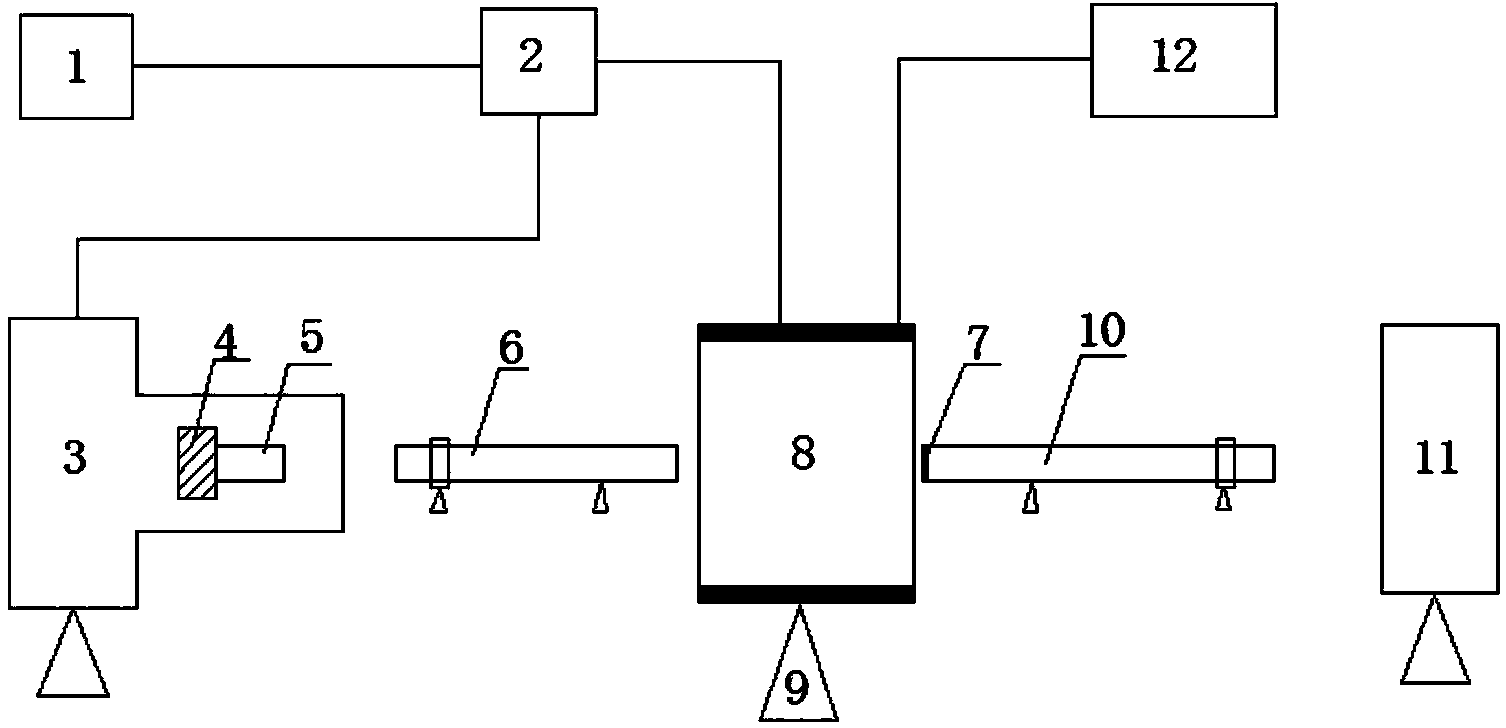

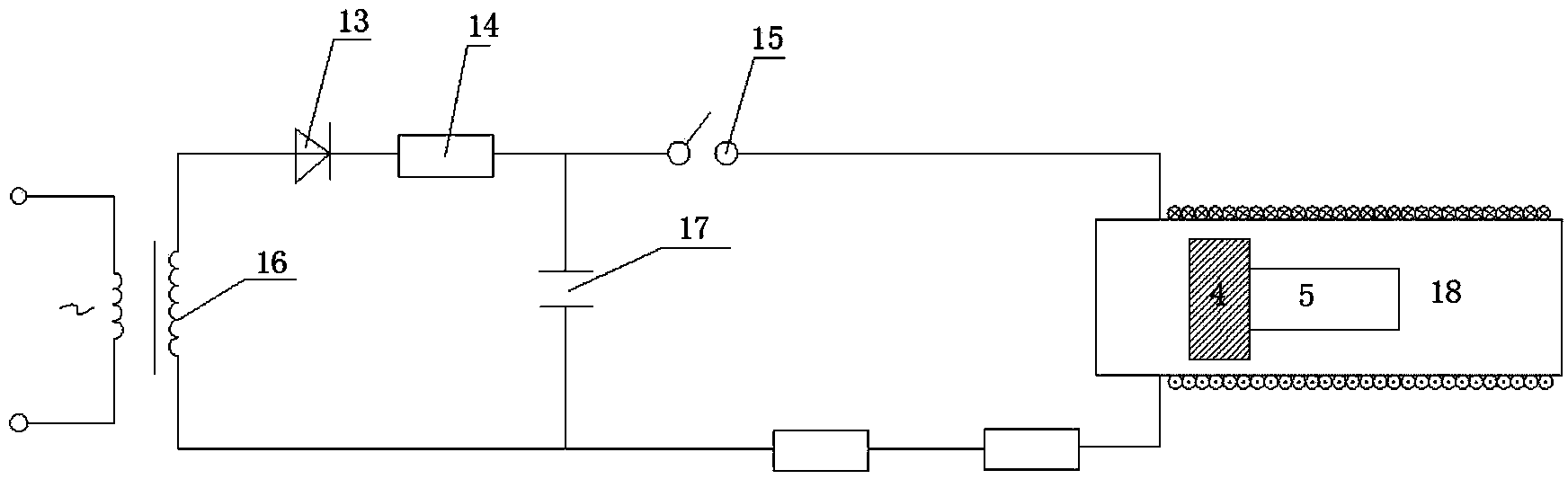

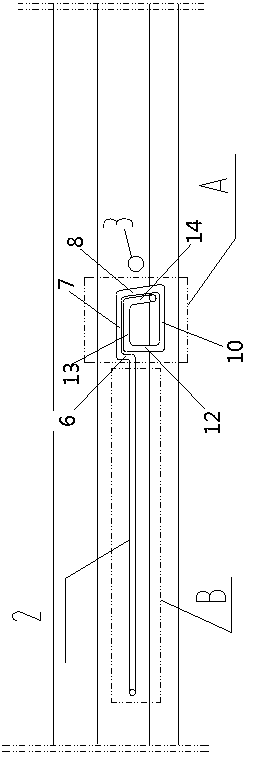

Hopkinson pressure bar experimental apparatus

InactiveCN103868806AAvoid Complexity and UncertaintyHigh repeatabilityStrength propertiesStress waveEngineering

The invention discloses a Hopkinson pressure bar experimental apparatus. The Hopkinson pressure bar experimental apparatus is characterized by comprising an electromagnetic trigger switch (1), a heating furnace door automatic opening switch (2), an electromagnetic driving device (3), a driving panel (4), a bullet (5), an incident pole (6), a force sensor (7), a heating furnace (8), a heating furnace supporting device (9), a transmitting pole (10), a buffer device (11) and an air compressing and filtering device (12); and the heating furnace is designed for preventing a test piece from being oxidized at a high temperature while heating the test piece and keeping the temperature of the test piece; as high temperature can influence the conduction of stress wave, the digital image correlation (DIC) technology is used for obtaining the change images of the test piece and analyzing the strain, the force sensor is used for analyzing stress, so as to obtain a stress strain curve. The Hopkinson pressure bar is combined with the electromagnetic driving technology and the DIC technology, and therefore the application range of the Hopkinson pressure bar experiment is expanded and a new method for acquiring dynamic parameters of high temperature materials is provided.

Owner:HUNAN UNIV

Electronic cigarette device

ActiveCN105011379ANo leakageNo more problems with changing coilsTobacco devicesSpray nozzleEngineering

The invention discloses an electronic cigarette device. The electronic cigarette device comprises a cigarette liquid supplying device, a cigarette liquid atomizing device and an atomized cigarette mist sucking-out device. The cigarette liquid supplying device is a cigarette liquid pressurizing supplying device. The cigarette liquid atomizing device further comprises a cigarette liquid spraying atomization device body and a cigarette liquid heating atomization device body. The cigarette liquid pressurizing supplying device is communicated with the cigarette liquid spraying atomization device body. The cigarette liquid spraying atomization device body is provided with a spraying nozzle, and the spraying nozzle is arranged to face and be close to the cigarette liquid heating atomization device body. The cigarette liquid heating atomization device body is an electric heating plate. The atomized cigarette mist sucking-out device comprises a sucking-out channel and a sucking-out nozzle. According to the electronic cigarette device, due to the assisting effect of spraying atomization, the heating atomization temperature can be reduced in cooperation with the heating atomization effect, and the stability of an electronic cigarette can be kept to the maximum degree; meanwhile, liquid leakage can be prevented, and no atomization core is needed. The electronic cigarette device is an electronic cigarette product of a brand new structure.

Owner:INNOKIN TECH

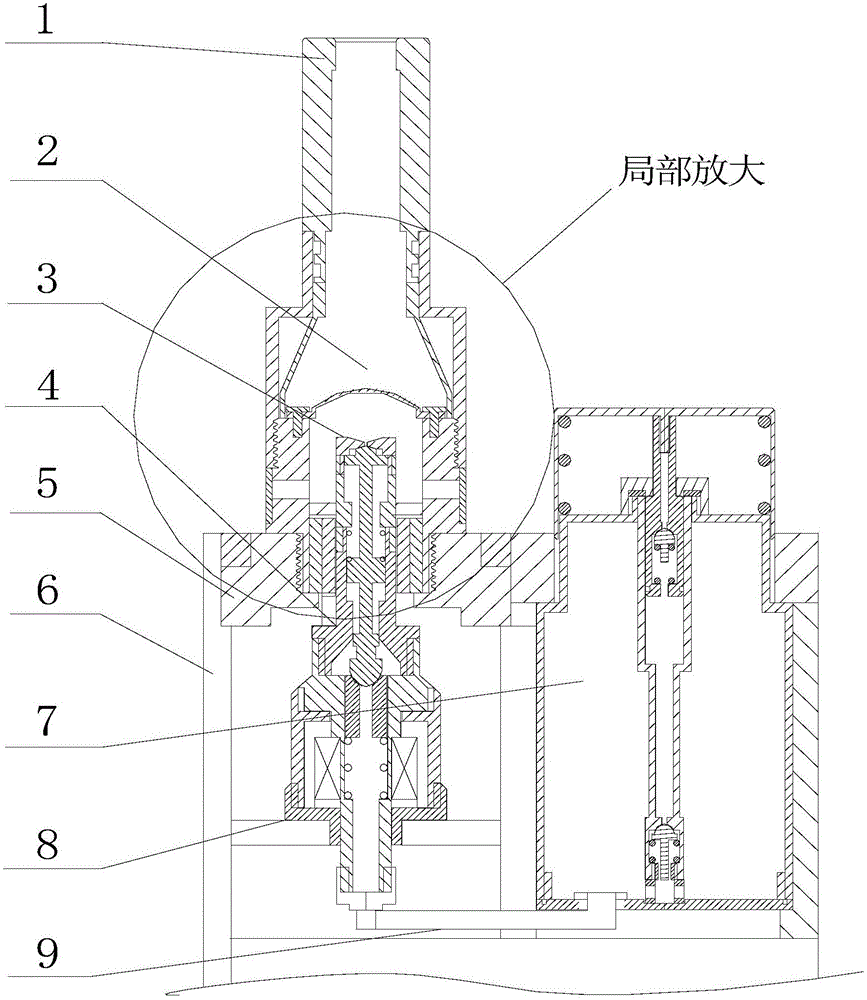

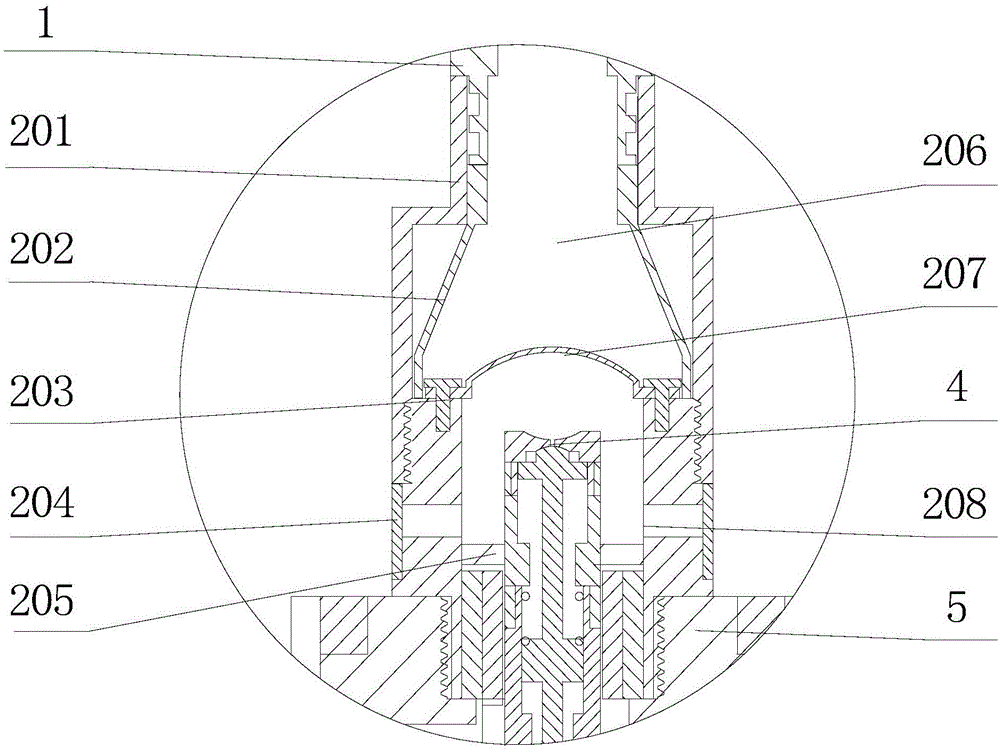

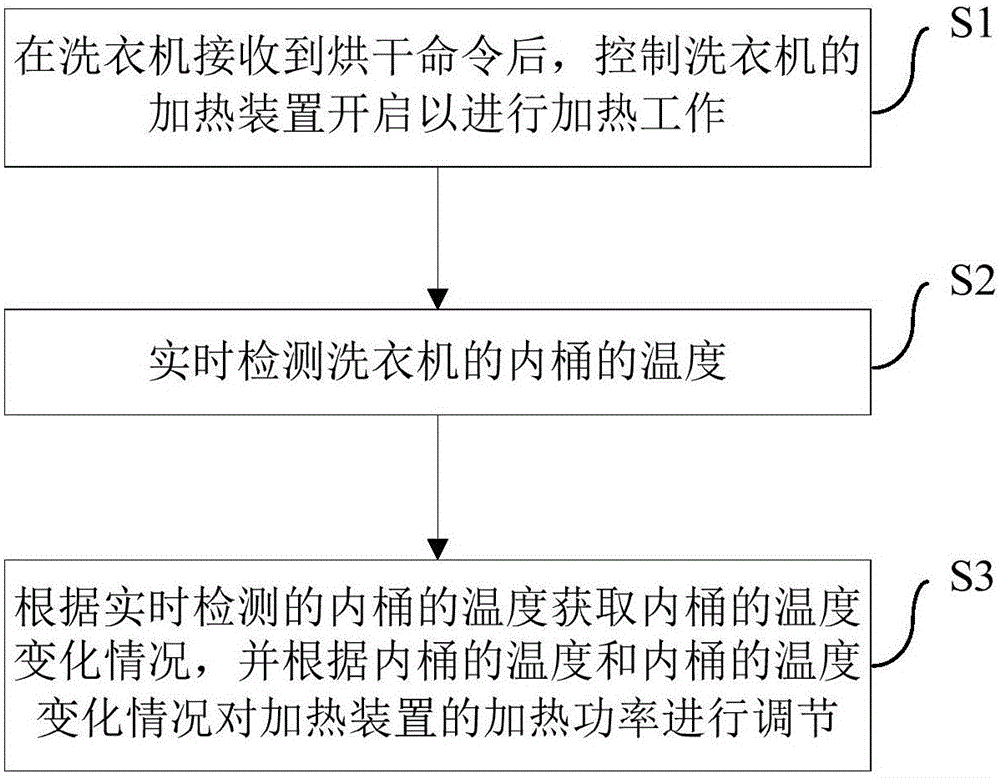

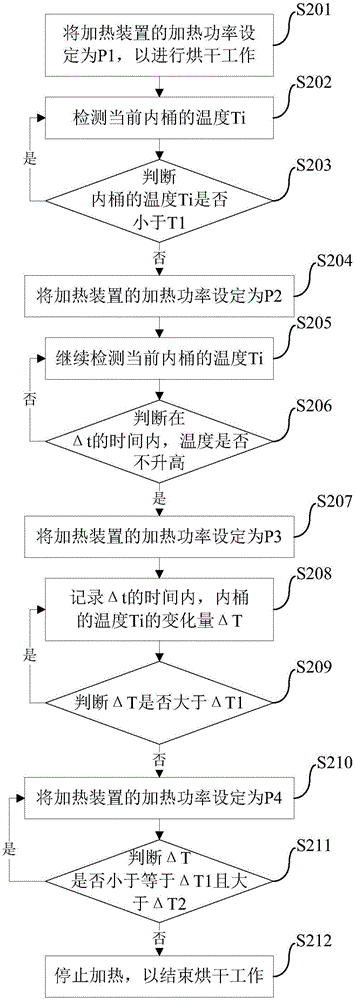

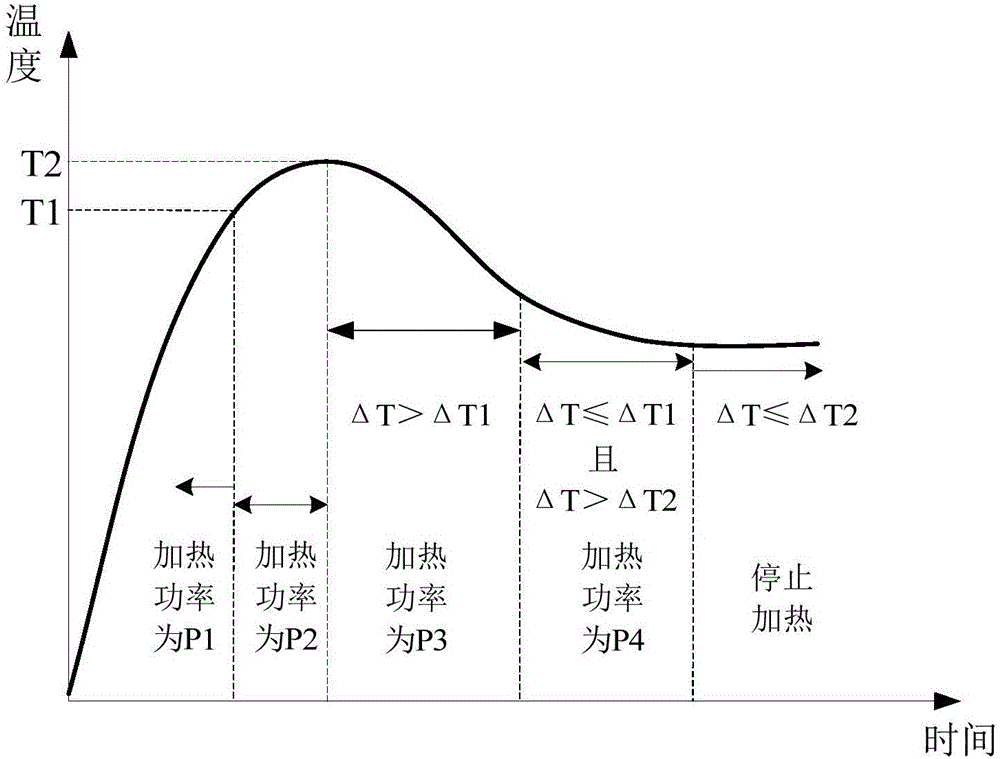

Drying control method of washing machine and washing machine

ActiveCN106012411AImprove drying efficiencyHeating power regulationOther washing machinesWashing machine with receptaclesProcess engineeringHeating power

The invention discloses a drying control method of a washing machine and the washing machine. The drying control method comprises the following steps: controlling a heating device of the washing machine to start so as to carry out heating work after a drying command is received by the washing machine; detecting the temperature of an inner barrel of the washing machine in real time; obtaining the temperature variation situation of the inner barrel according to the temperature, which is detected in real time, of the inner barrel, and regulating the heating power of the heating device according to the temperature of the inner barrel and the temperature variation situation of the inner barrel. According to the method disclosed by the invention, not only can the drying efficiency of the washing machine be increased, but also the consumption of electric energy can be reduced, and energy conservation and environment protection are realized.

Owner:WUXI LITTLE SWAN ELECTRIC CO LTD

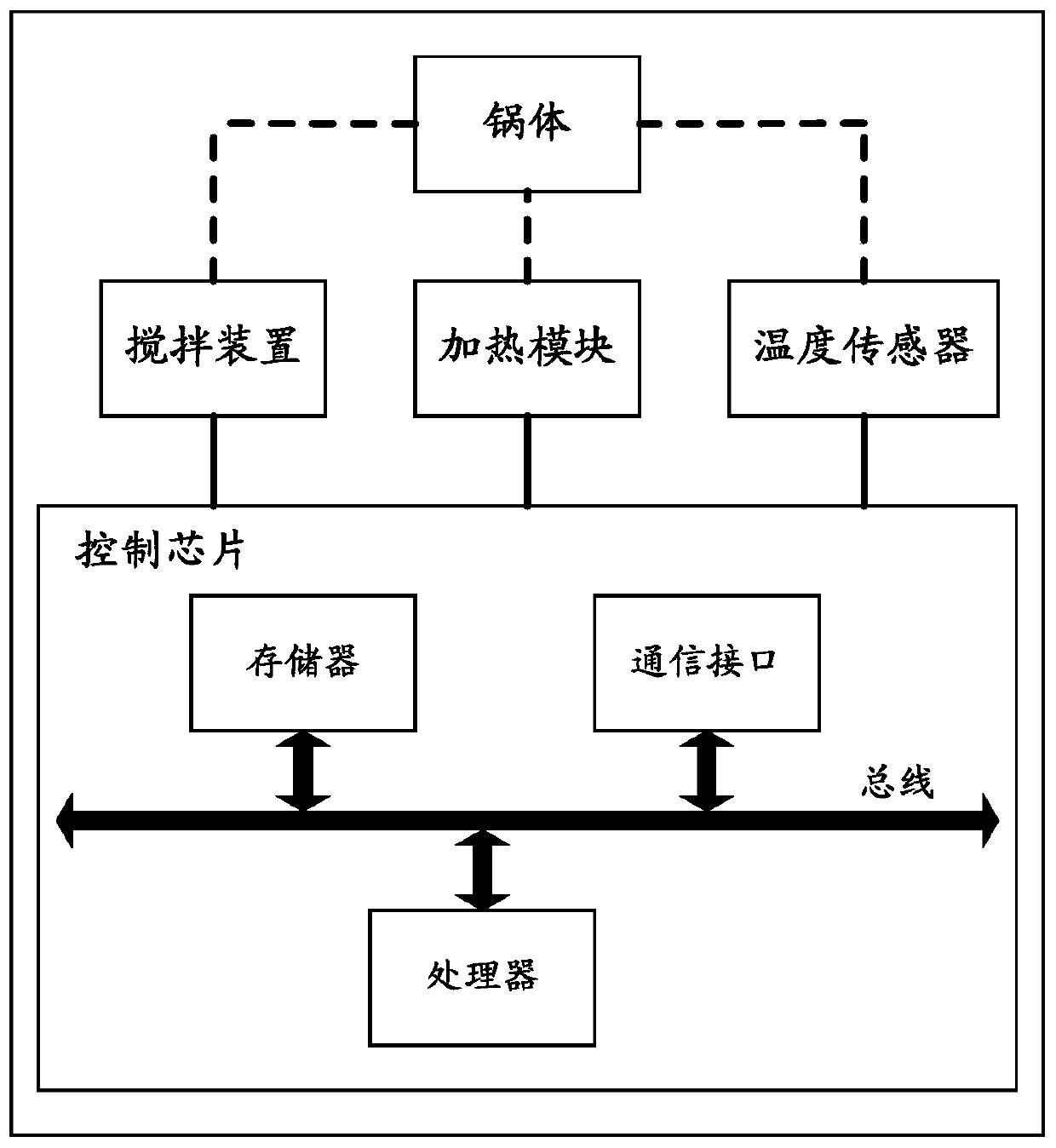

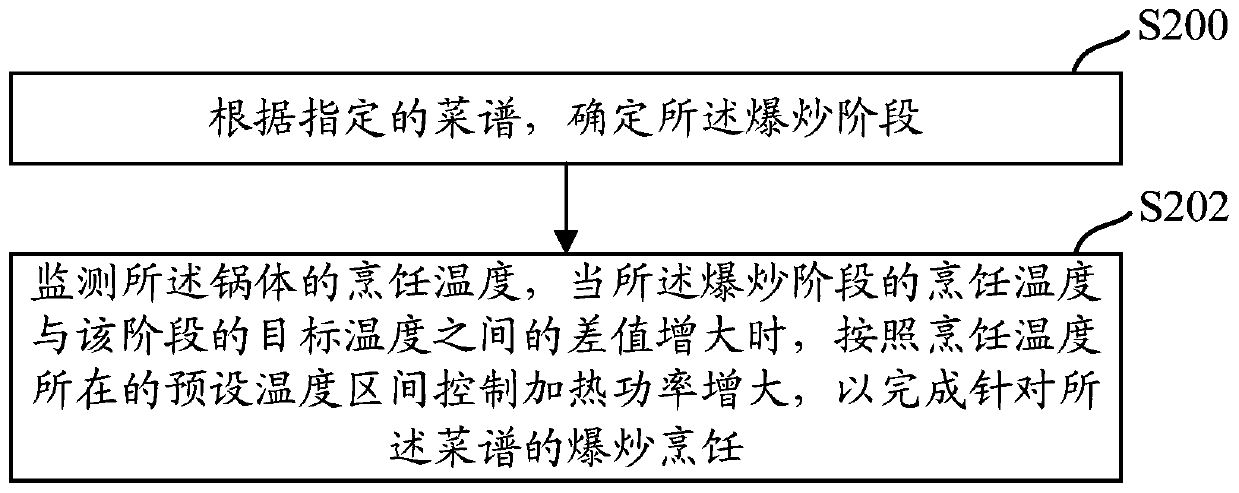

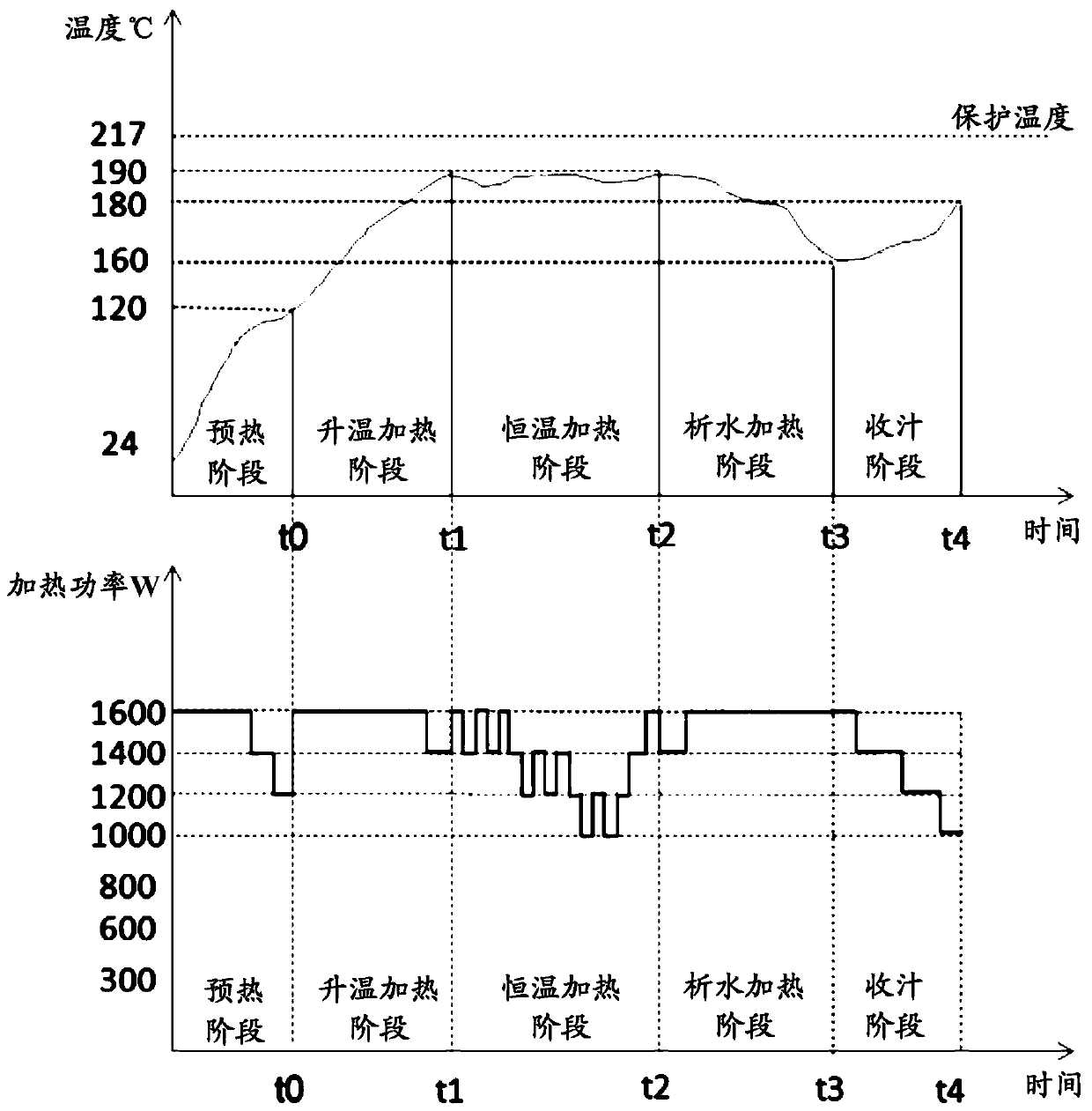

Cooking control method of frying machine and frying machine

InactiveCN110537827AIncrease heating powerCompensate for cooking temperature lossTemperatue controlCooking vessel constructionsComing outProcess engineering

The invention discloses a cooking control method of a frying machine and the frying machine. The frying machine comprises a control chip, a pot body, a heating module, a stirring device, and a temperature sensor. The cooking process of the frying machine comprises a preheating stage and a quick frying stage. The method comprises steps of determining the quick frying stage according to a designatedmenu; monitoring cooking temperature of the pot body, when a difference between cooking temperature of the quick frying stage and target temperature of the stage increases, controlling heating powerto increase according to a preset temperature range in which the cooking temperature is, so as to complete quick frying according to the menu. In the quick frying stage, the preset temperature range in which the cooking temperature is can be dynamically detected, and heating power can be adjusted dynamically, particularly, when water comes out from food due to quick frying and temperature drops suddenly, heating power is increased timely so as to compensate cooking temperature loss, therefore, quick frying effect is ensured.

Owner:JOYOUNG CO LTD

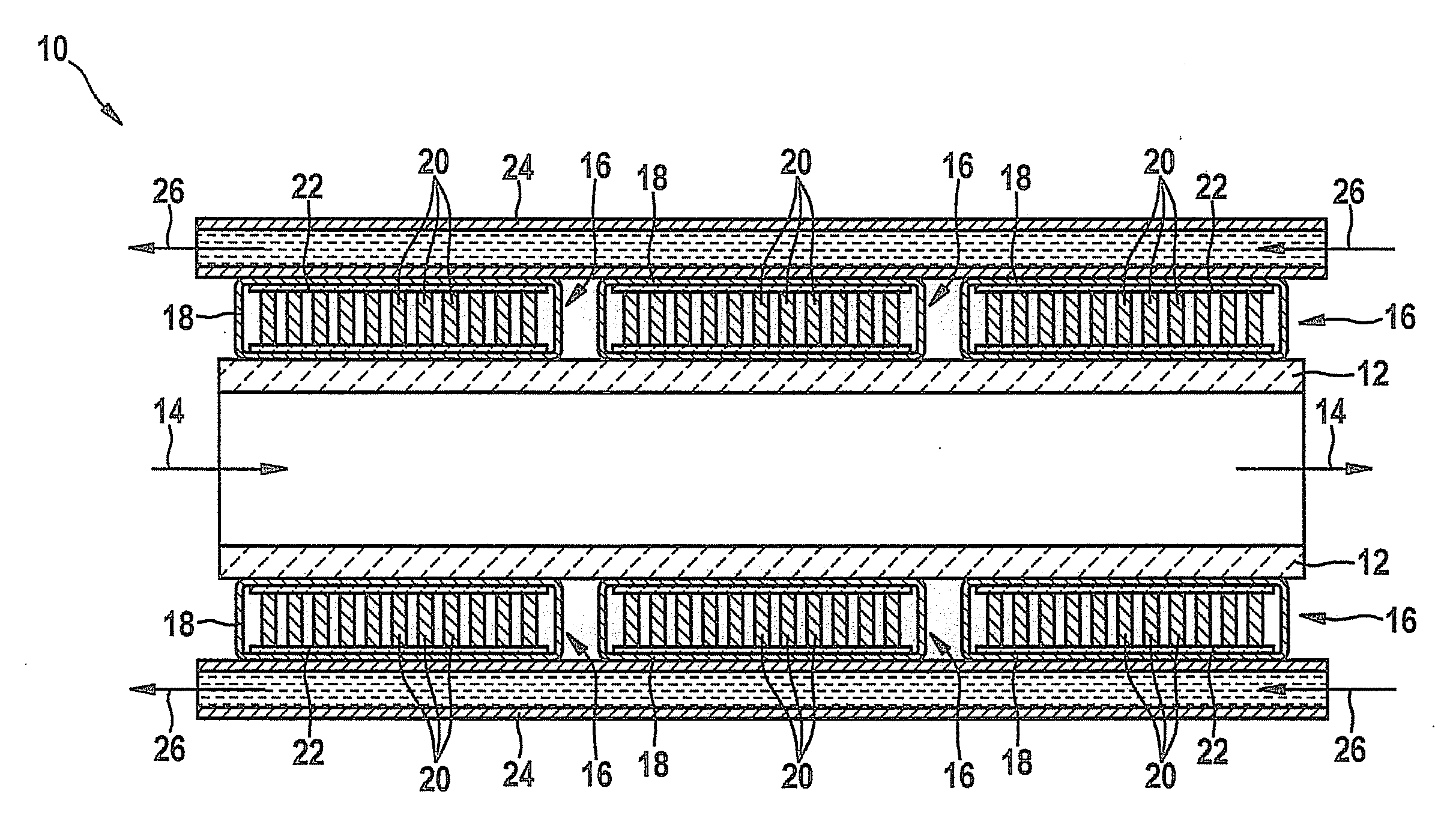

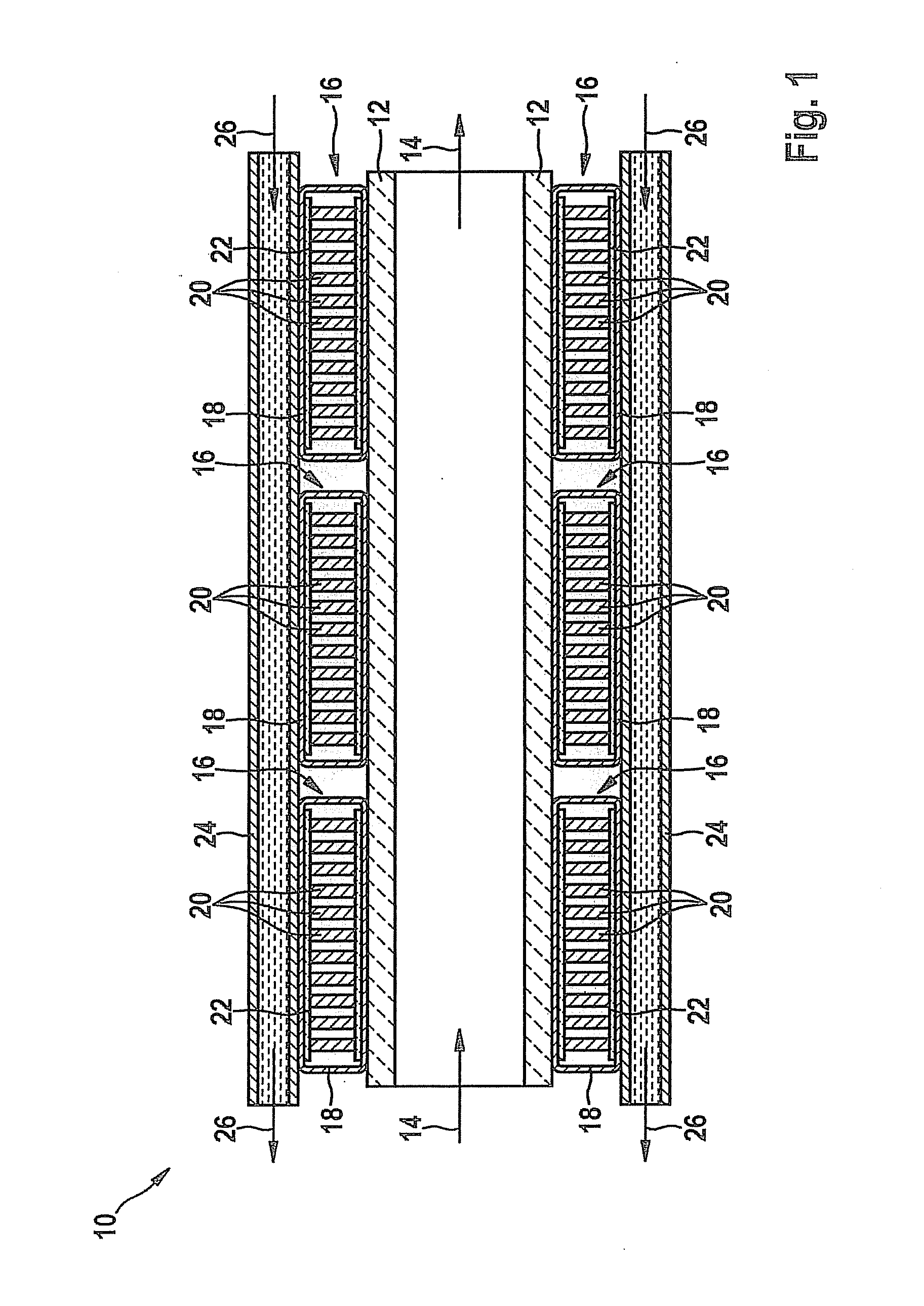

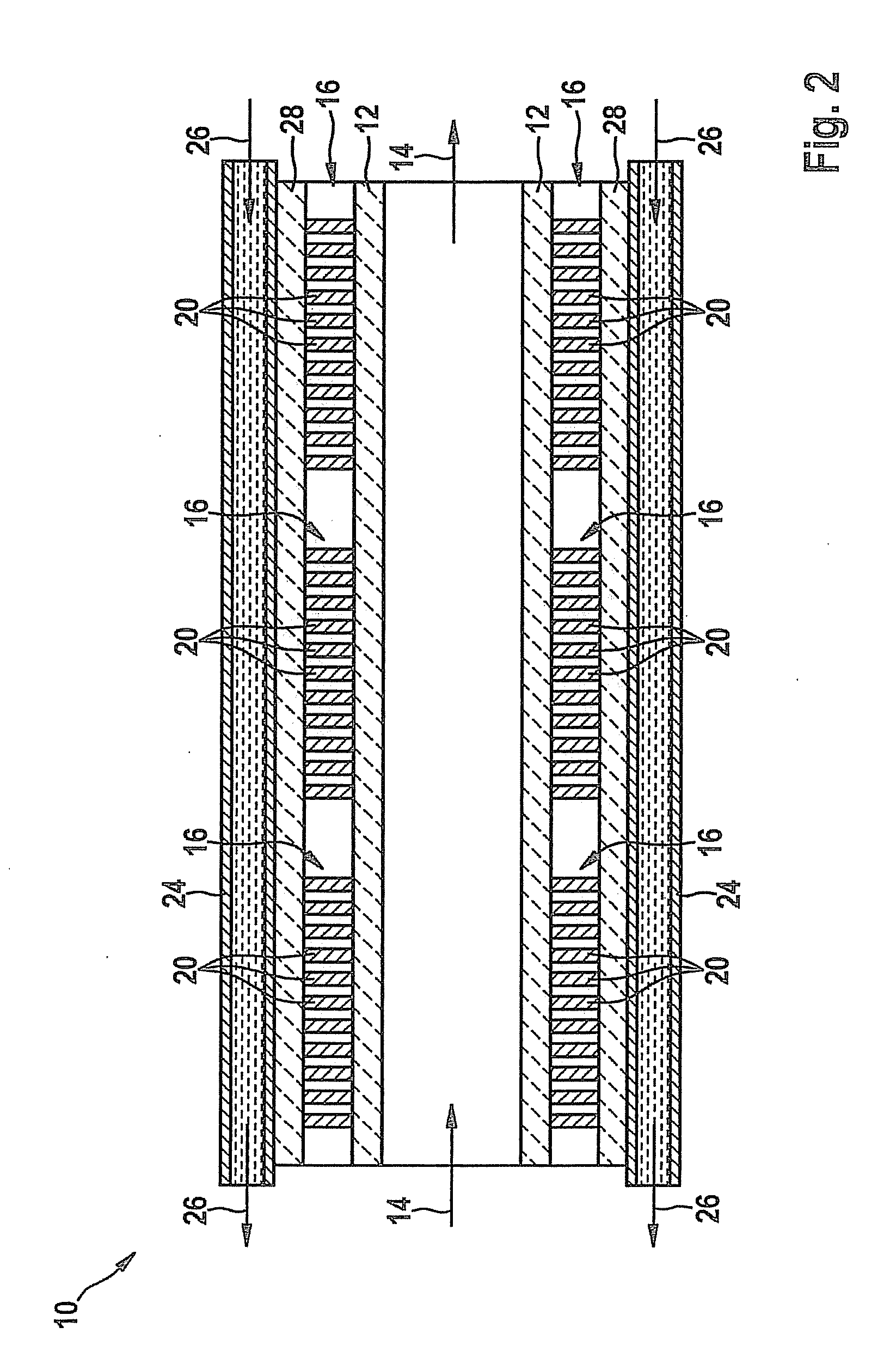

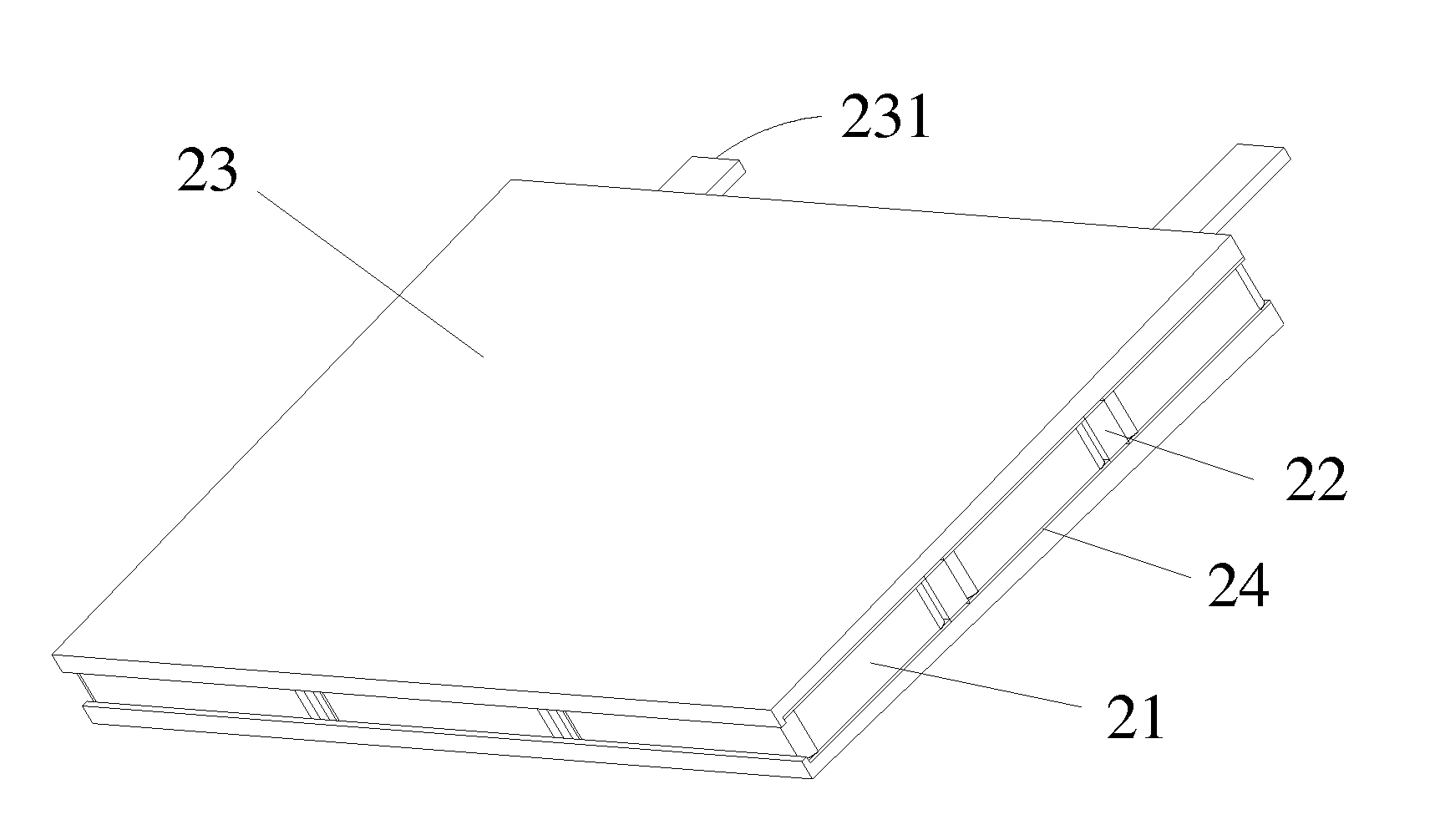

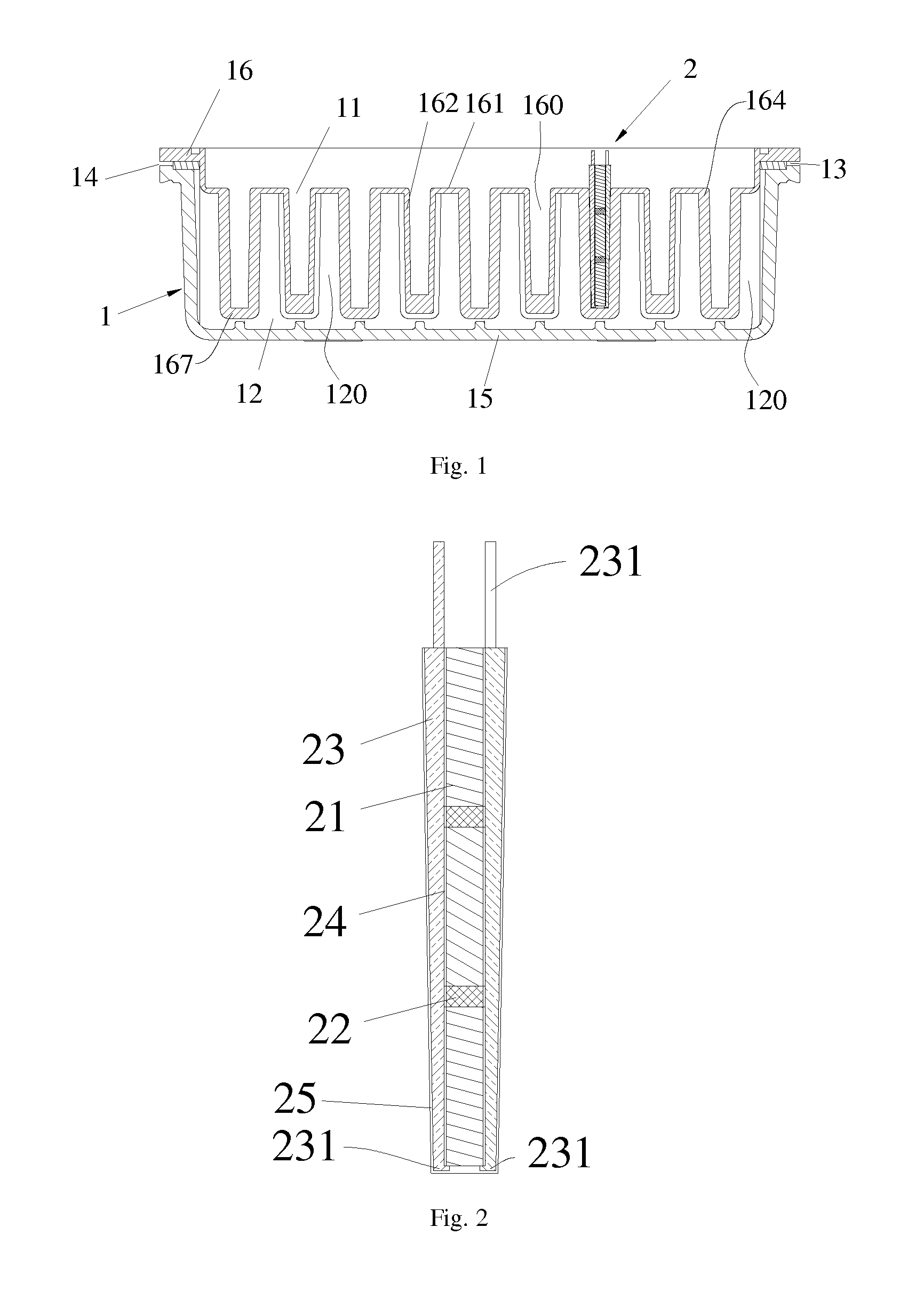

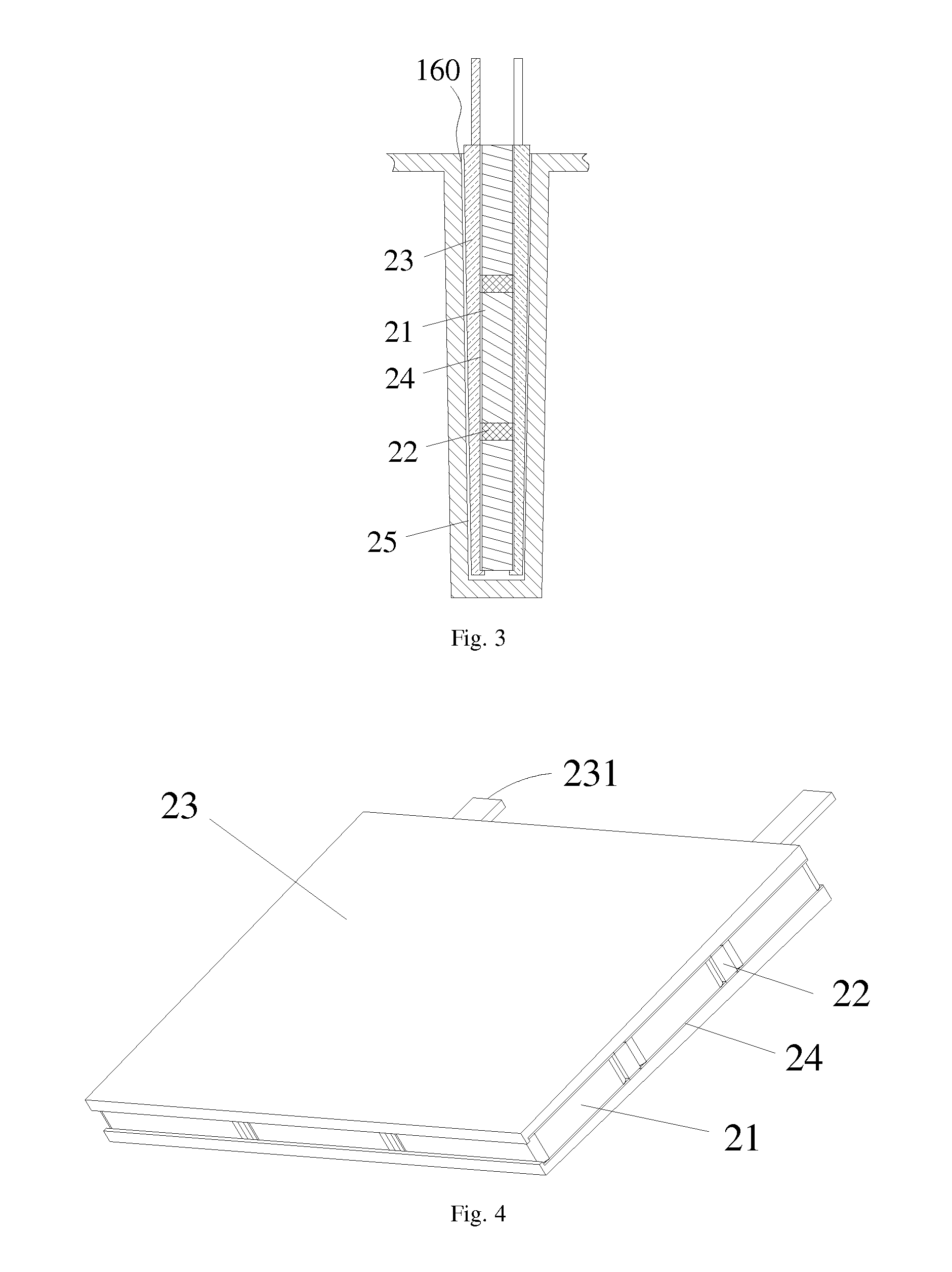

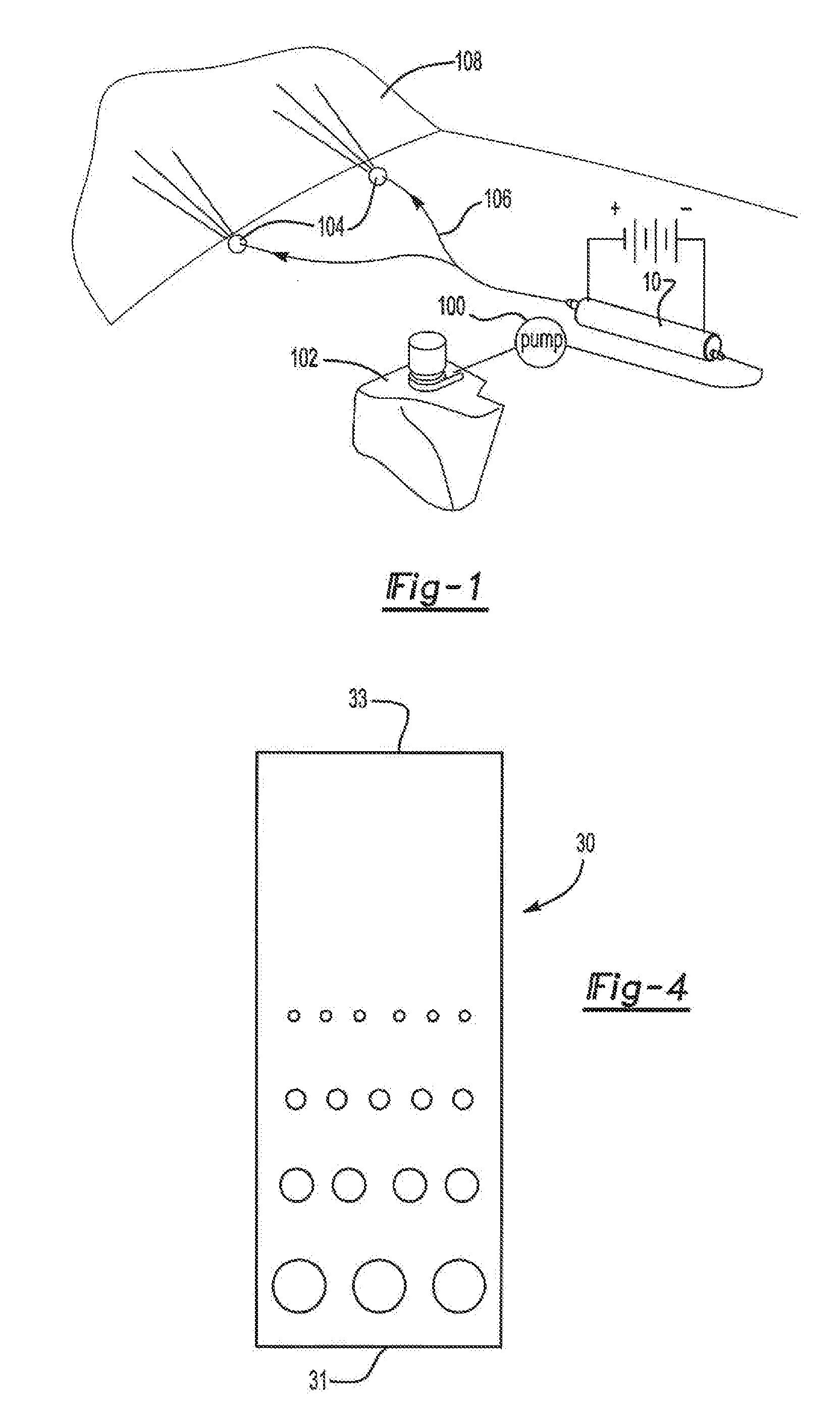

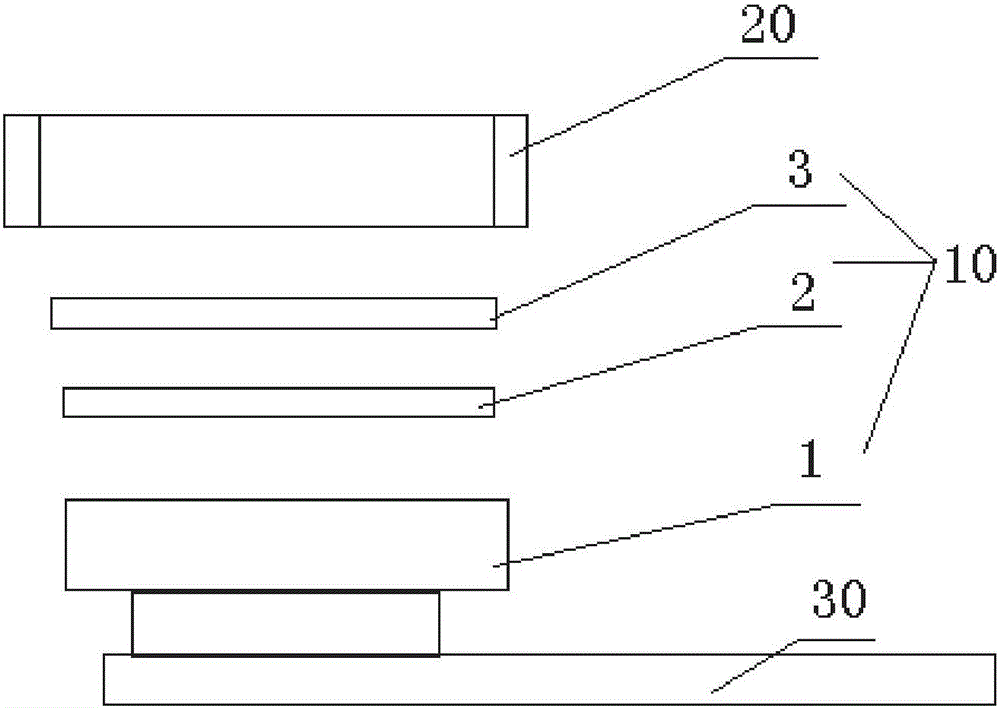

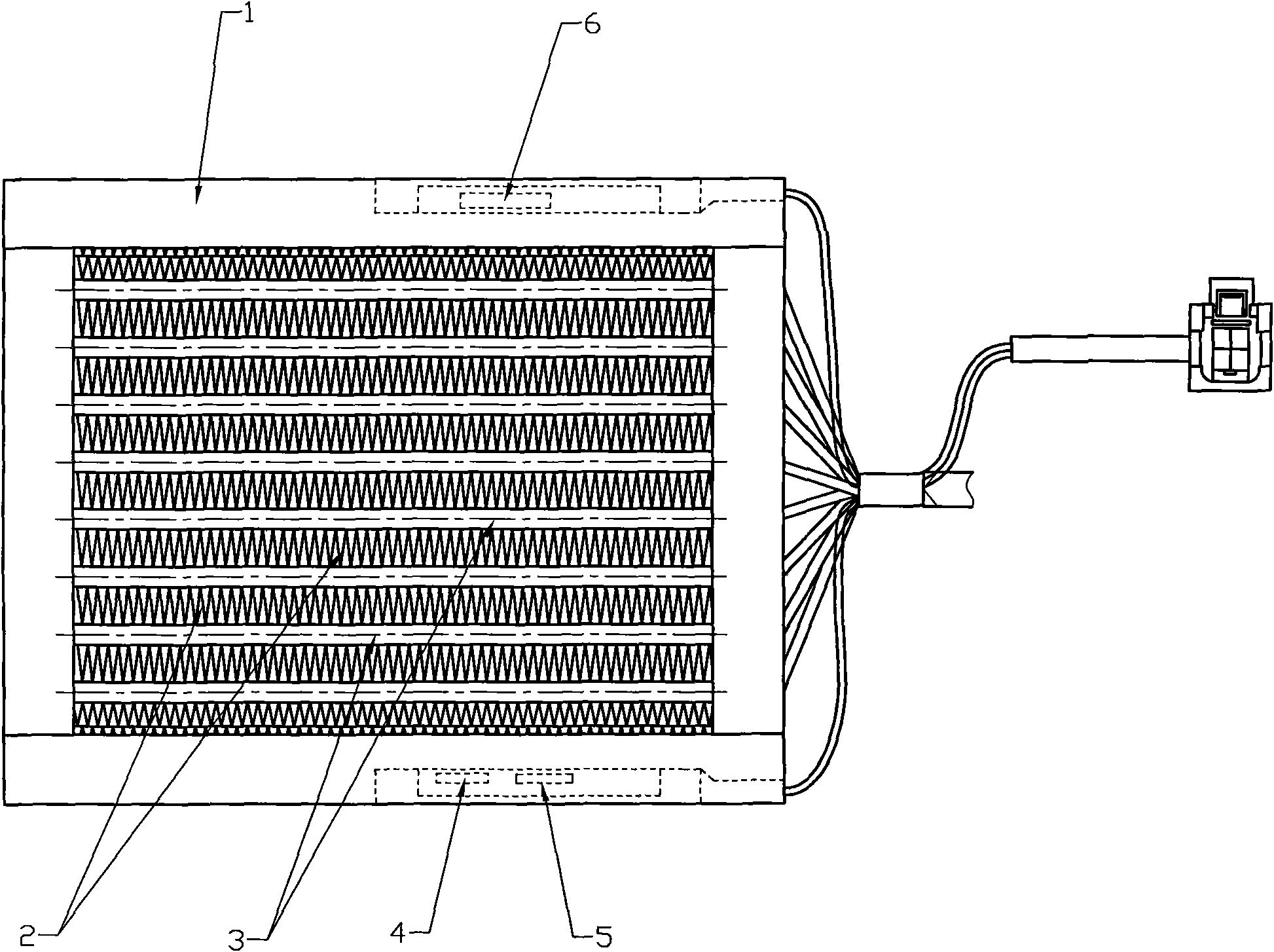

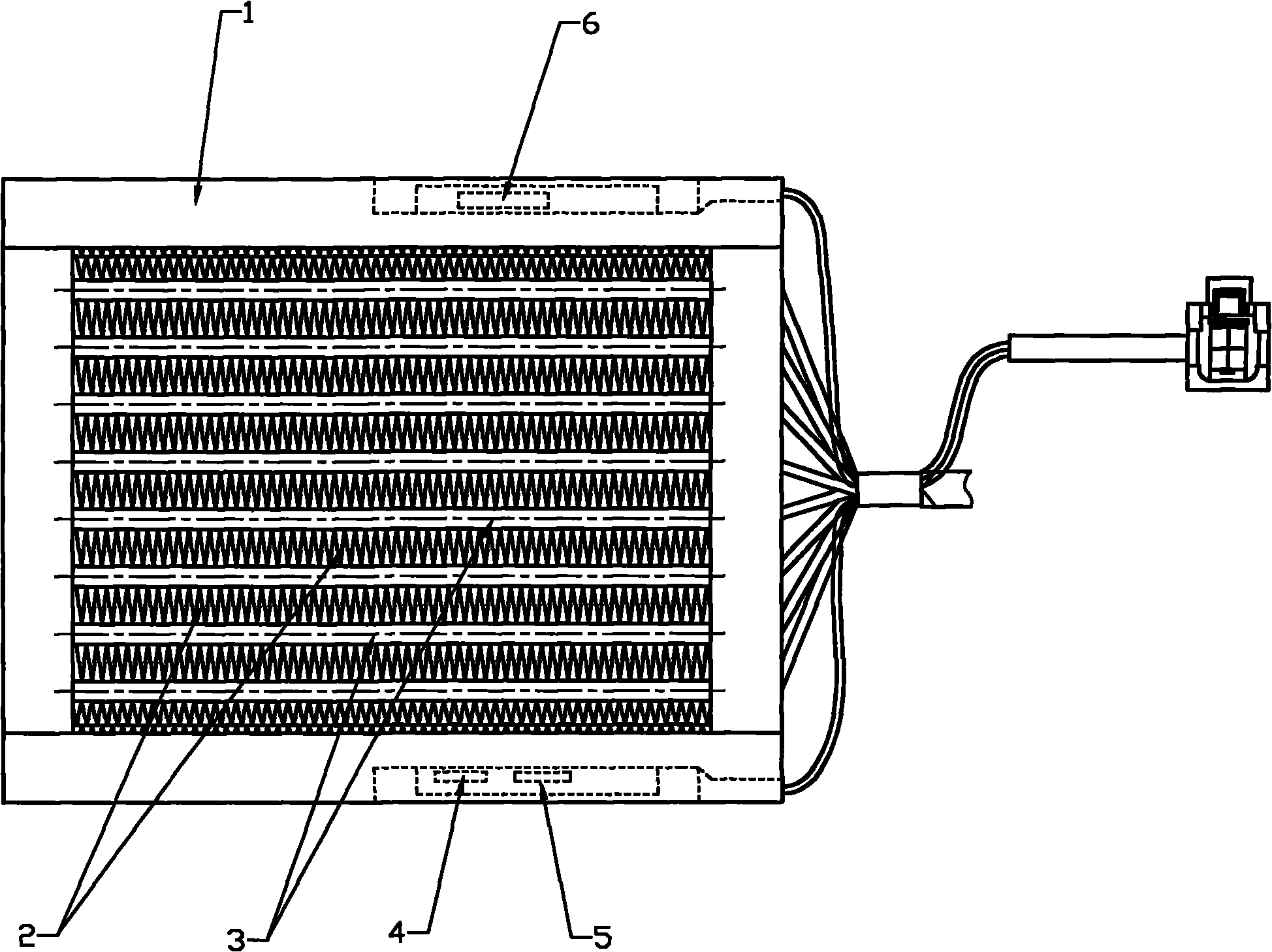

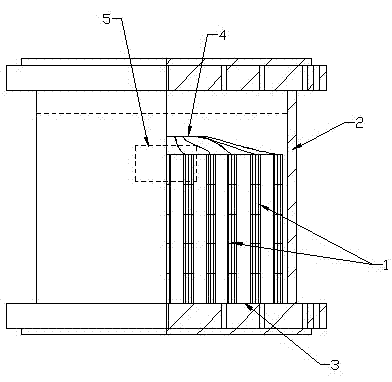

PTC electric heating assembly, electric heating device and electric vehicle

ActiveUS20150168014A1Reduce distractionsIncrease heating powerAir heatersOhmic-resistance heating detailsFixed frameEngineering

A PTC electric heating assembly, an electric heating device and an electric vehicle are provided. The PTC electric heating assembly (2) comprises two electrode plates (23) and a PTC heating module (20) disposed between the two electrode plates (23), and comprising an insulation fixing frame (22) and a plurality of PTC heating elements (21), the insulation fixing frame (22) defining a plurality of fixing units (220) and the PTC heating elements (21) being disposed into the fixing units (220) respectively.

Owner:BYD CO LTD

Experiment device for testing softening and dropping point of sinter

ActiveCN103713007AEasy to operateMeet testing needsInvestigating phase/state changeFurnace temperatureGas cylinder

The invention relates to an experiment device for testing a softening and dropping point of a sinter. The device is composed of a large current transformer, a furnace body fixing column, a tray, a furnace body adjusting frame, a rotary column, a pressurized gas cylinder, a displacement sensor, a furnace top sealing furnace cover, a pressurized graphite compression strut, an anti-radiation graphite cover, a molybdenum disilicide heater, a graphite crucible, a high pure graphite sleeve, a sealed alundum tube, a pinhole camera, an air inlet channel fixing sleeve, a dropping crucible weighing device, a dropping crucible device, a furnace body chassis, furnace body castors, a heating furnace body, a cantilever beam, a sample temperature thermocouple, a alumina hollow ball member, a furnace temperature control thermocouple, a rotary column circular sleeve, a pressurized gas cylinder pipeline and a pressure transmitter. The large current transformer is adopted to supply power for the molybdenum disilicide heater; the pinhole camera is used to observe a dropping process of high temperature liquid slag iron; the dropping crucible weighing device is arranged; the crucible is assembled and disassembled in a manner of laterally opening the door; and the position of the heating furnace body is adjusted by the furnace body adjusting frame, so that the device is flexible, accurate and convenient for operations.

Owner:NORTHEASTERN UNIV

Method for reducing temperature of high-temperature metal piece of gas turbine by ammonia decomposition catalysis reaction

InactiveCN102562310AIncrease heating powerTurbine/propulsion fuel supply systemsTurbine/propulsion engine coolingLiquid ammoniaCombustion chamber

The invention provides a method for reducing temperature of a high-temperature metal piece of a gas turbine by absorbing heat through ammonia decomposition catalysis reaction. The technology comprises the following steps of: (1) providing heat to gasifying liquid ammonia into ammonia gas, and allowing the ammonia gas to enter a fixed or rotary high-temperature metal piece of the gas turbine; and (2) absorbing heat on the surface of a nickel metal catalyst by ammonia and decomposing into hydrogen and nitrogen on the high-temperature metal piece, and taking away heat. The hydrogen and nitrogen flow into a combustion chamber and are used as auxiliary fuels, or are directly sprayed to be combusted on the surface of the turbine so as to increase energy of gas.

Owner:YUNNAN UNIV

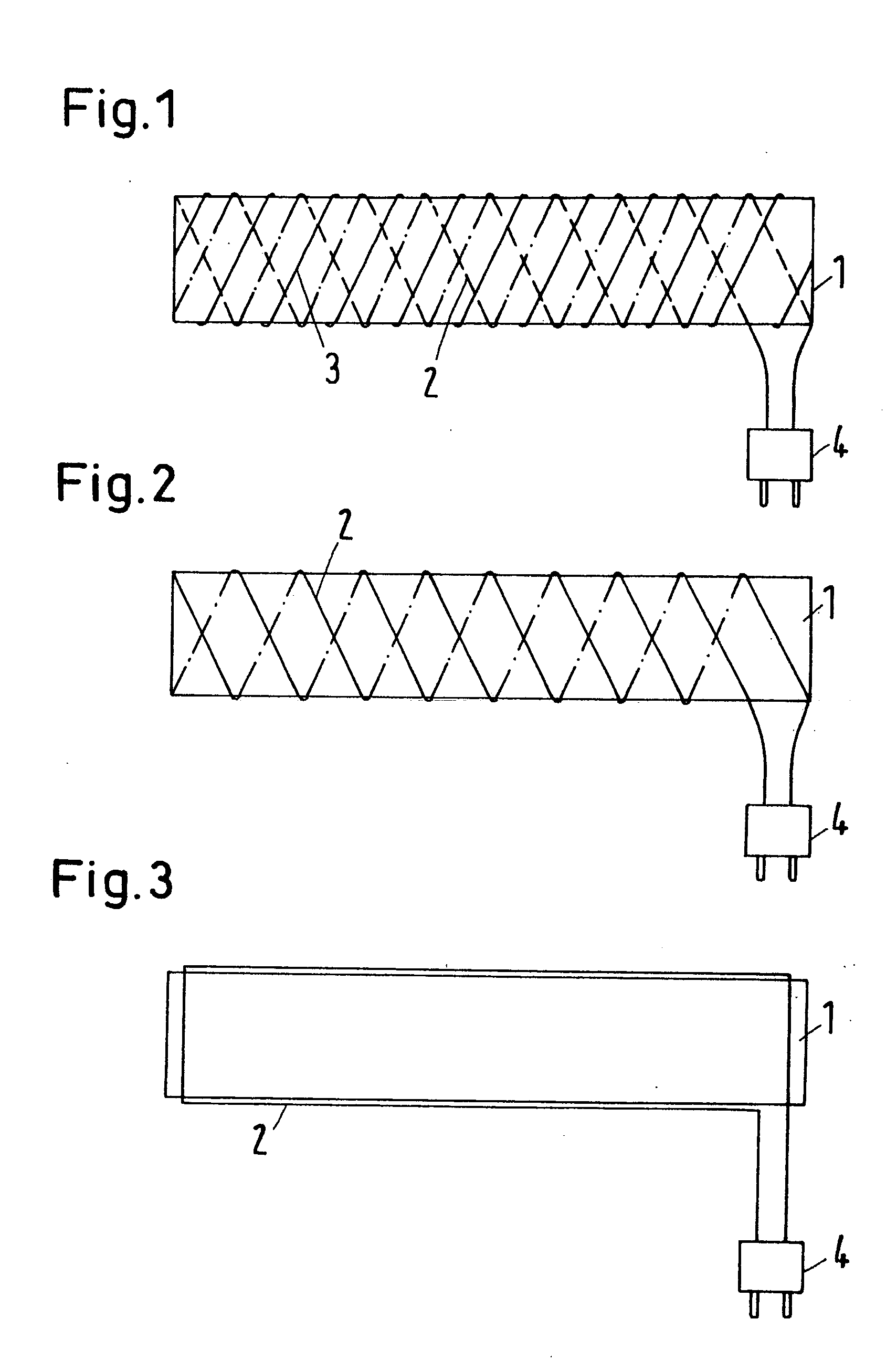

Heatable fluid line with a heating power which can be set

InactiveUS20090238547A1Wide range of variationIncrease heating powerPipe heating/coolingBeverage vesselsElectrical resistance and conductanceElectrical conductor

The present invention relates to a fluid line for conducting and heating a medium, having a heating line comprising a conduit and an electrical heating element which is assigned to the conduit. In this case, a particular heating power per unit length can be set, the heating element comprising at least three heating conductors which run along the conduit. The ends of the heating conductors are connected to one another and can be connected to a supply voltage in such a manner that a plurality of heating conductors are connected in series and / or in parallel such that, for a particular supply voltage, the heating power of the fluid line is determined by the total resistance of the heating conductors.

Owner:VOSS AUTOMOTIVE

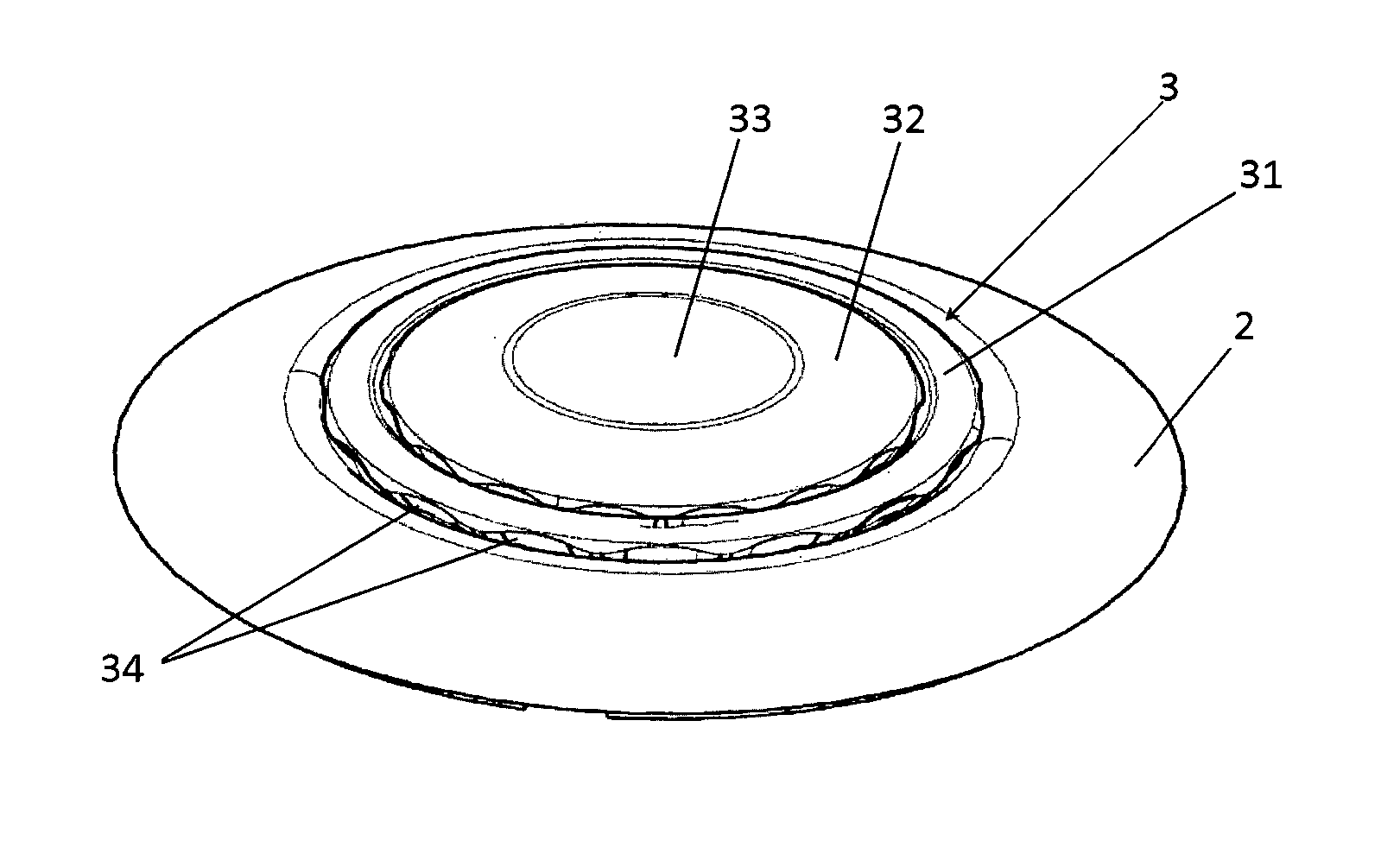

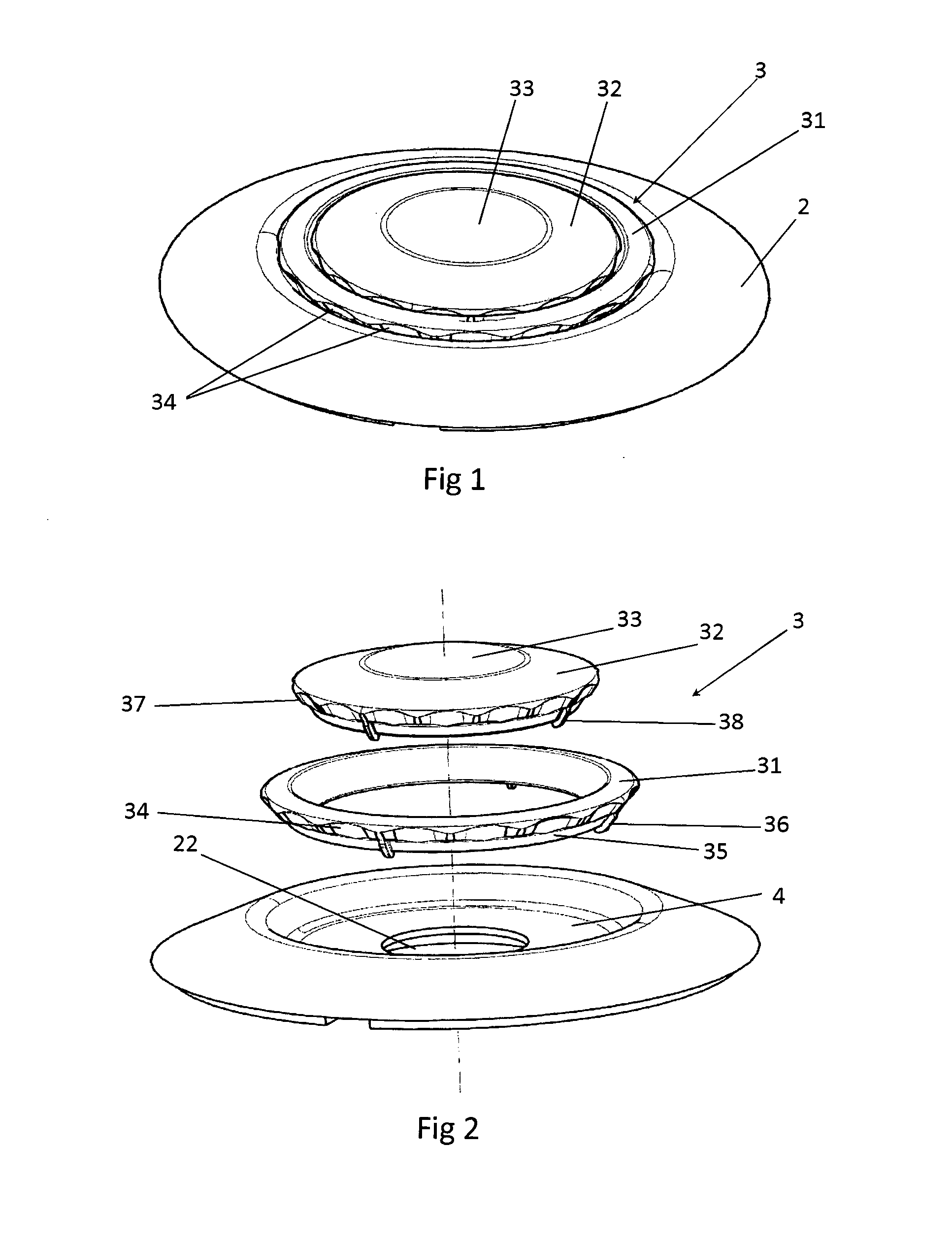

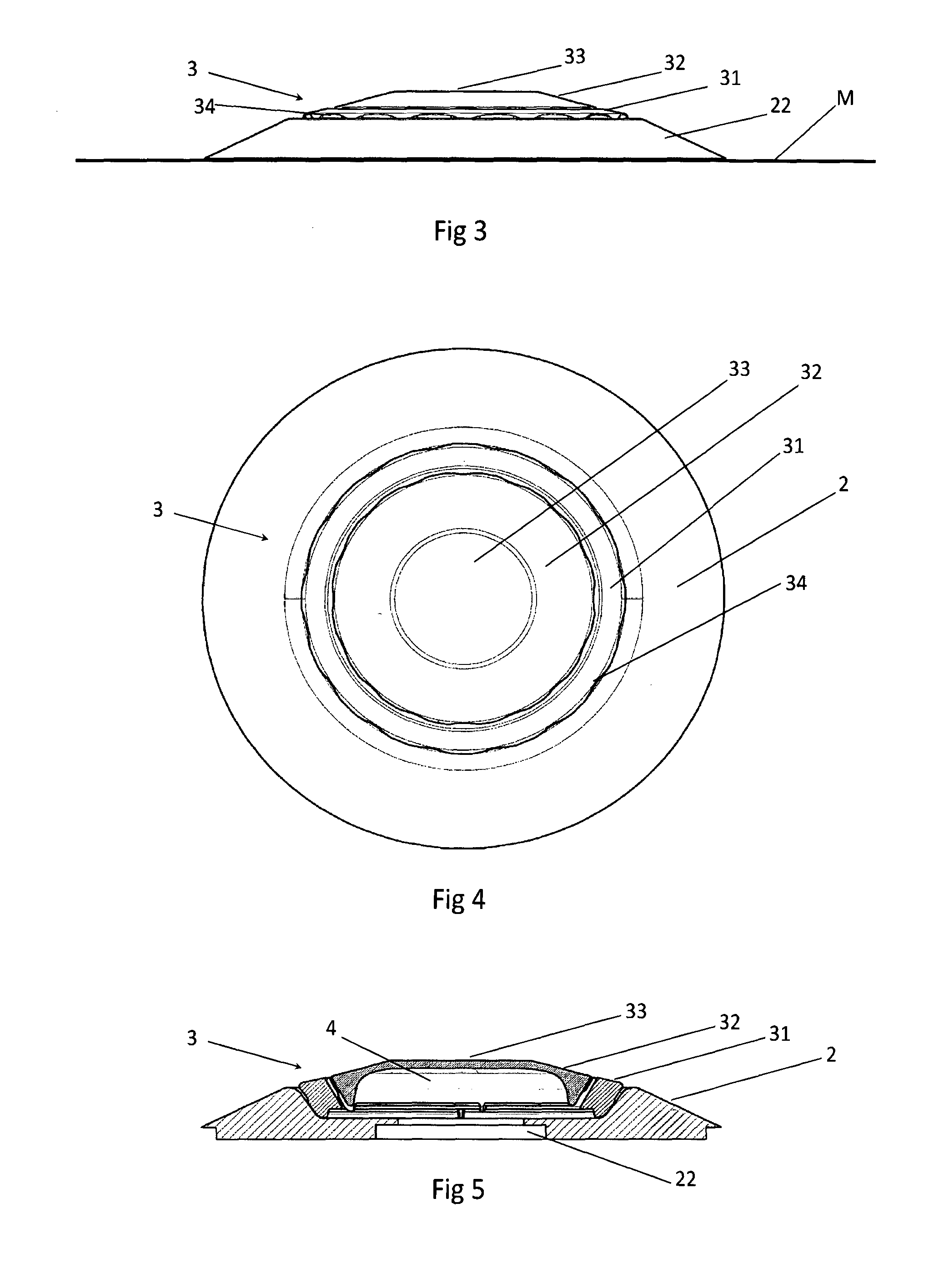

Burner assembly for cooking equipments

InactiveUS20140318527A1Good distribution of flameHigh thermal efficiencyDomestic stoves or rangesGaseous fuel burnerEngineeringThermal efficiency

The present invention relates to a burner assembly for cooking equipments that has been designed to provide significant improvement in thermal efficiency of the burner and making easier the cleaning process by the user. The burner assembly comprises a base (2) upon which a spreading cover (3) rests, and wherein the coupling of the spreading cover (3) on the base (2) originates one internal chamber of expansion (4) of air-fuel mixture which is released through porticos existing under the perimeter edge of the spreading cover (3), and wherein the base (2) comprises in its internal region at least one feeding orifice (22); the spreading cover (3) comprises at least one perimeter ring (31) cooperating with the base (2) and at least one disc (32) cooperating with the perimeter ring (31) and the burner assembly (1) comprises at least one internal chamber of mixture (4) cooperating with the porticos of the spreading cover (3).

Owner:WHIRPOOL SA

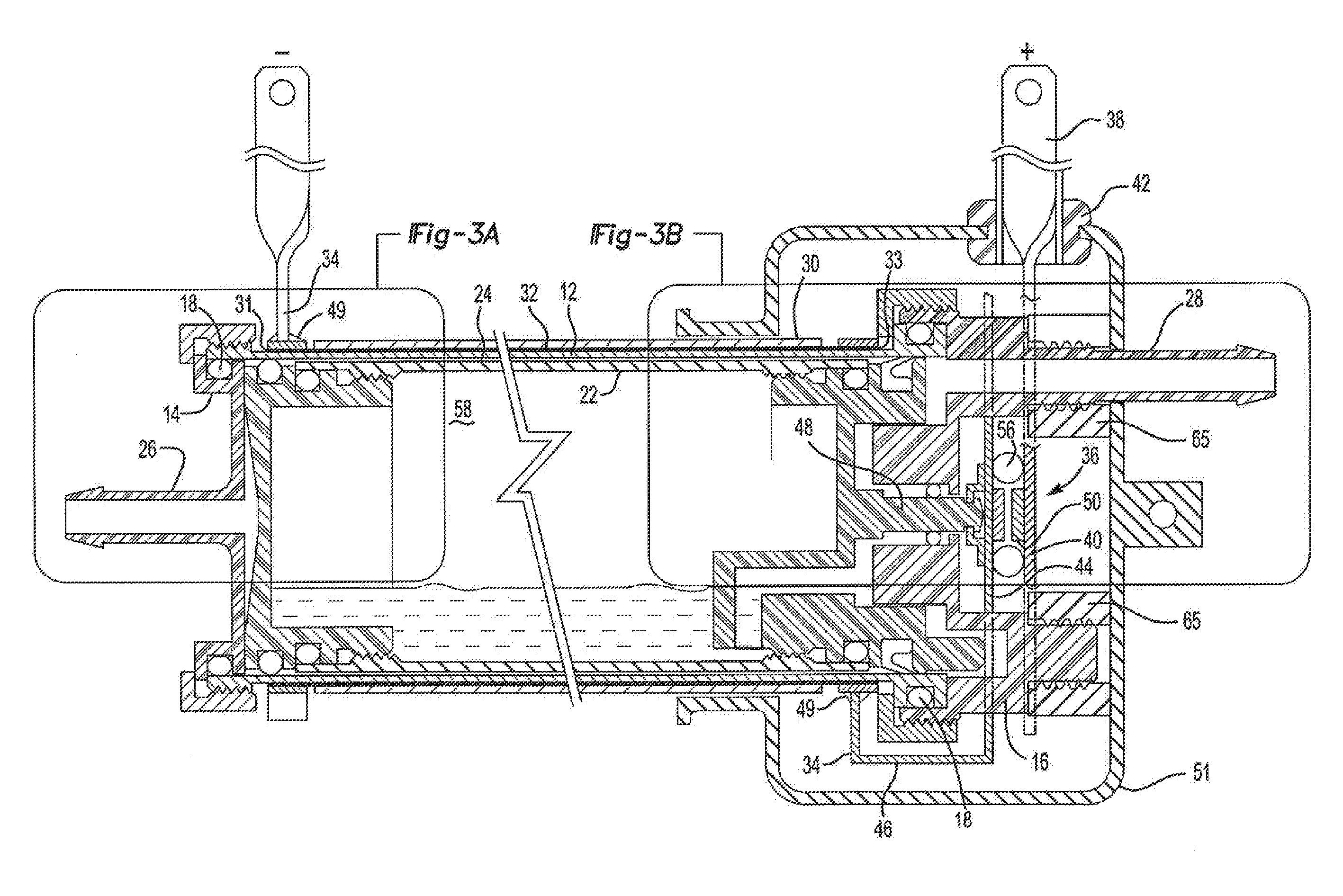

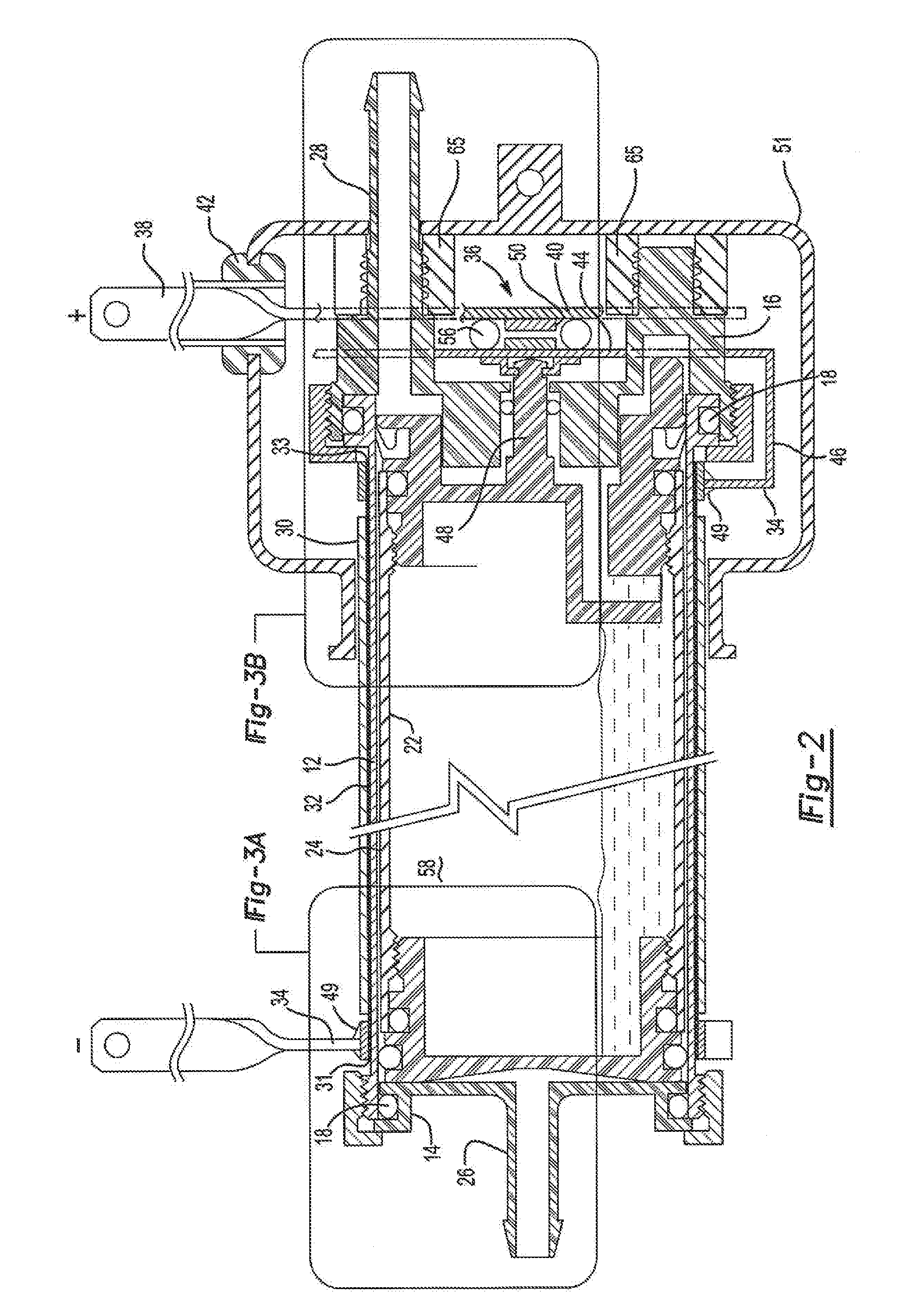

Electrically heating windshield washer fluid system

InactiveUS20160167624A1Low heating rateShort packaging lengthVehicle cleaningWater heatersDifferential pressureEngineering

An electrically powered windshield wiper fluid heater having a housing with an inlet and an outlet. A piston is movably mounted in the housing between a retracted and an extended position and the piston forms a thin annular passageway between the housing and the piston. During fluid flow from the inlet, through the annular chamber and to the outlet, the differential pressure moves the piston to its extended position thus closing a switch which powers a heating element disposed around the housing.

Owner:SEEVA TECH INC

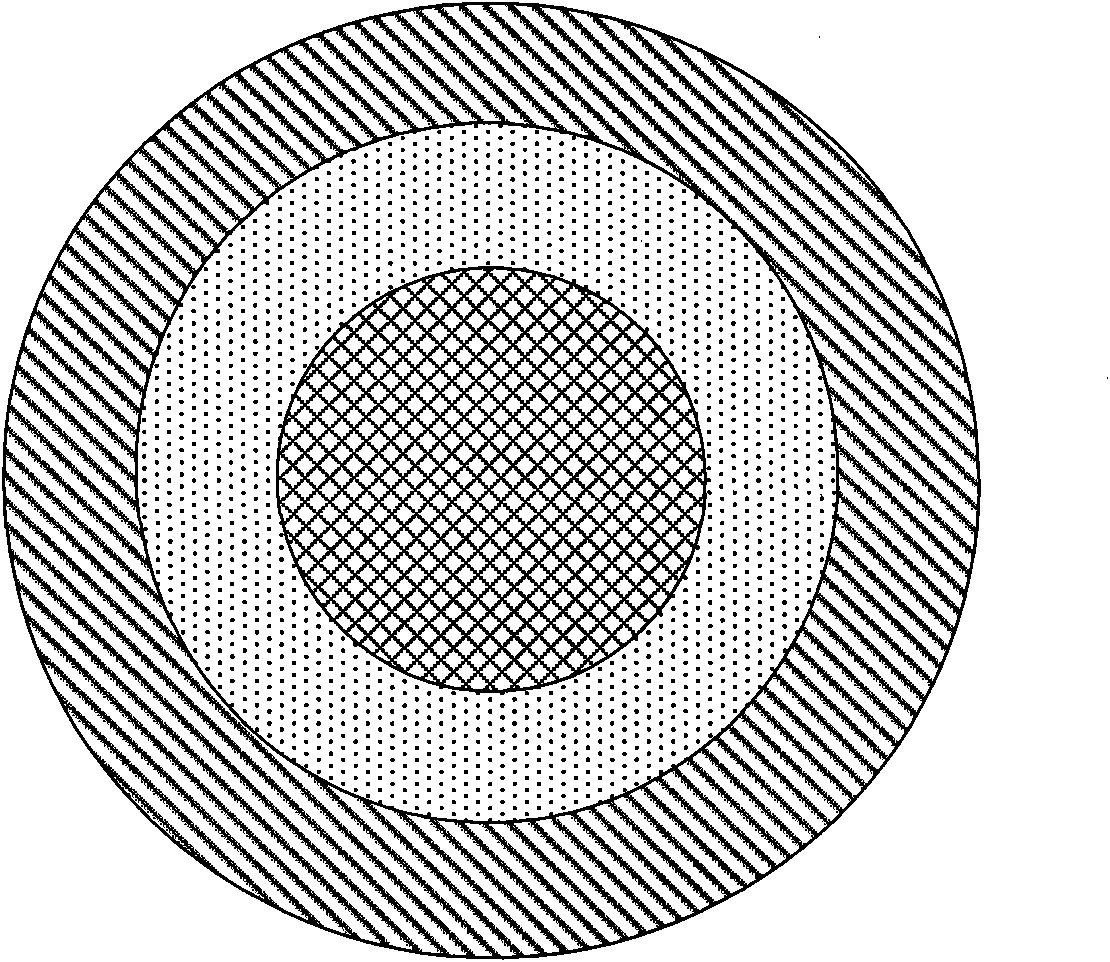

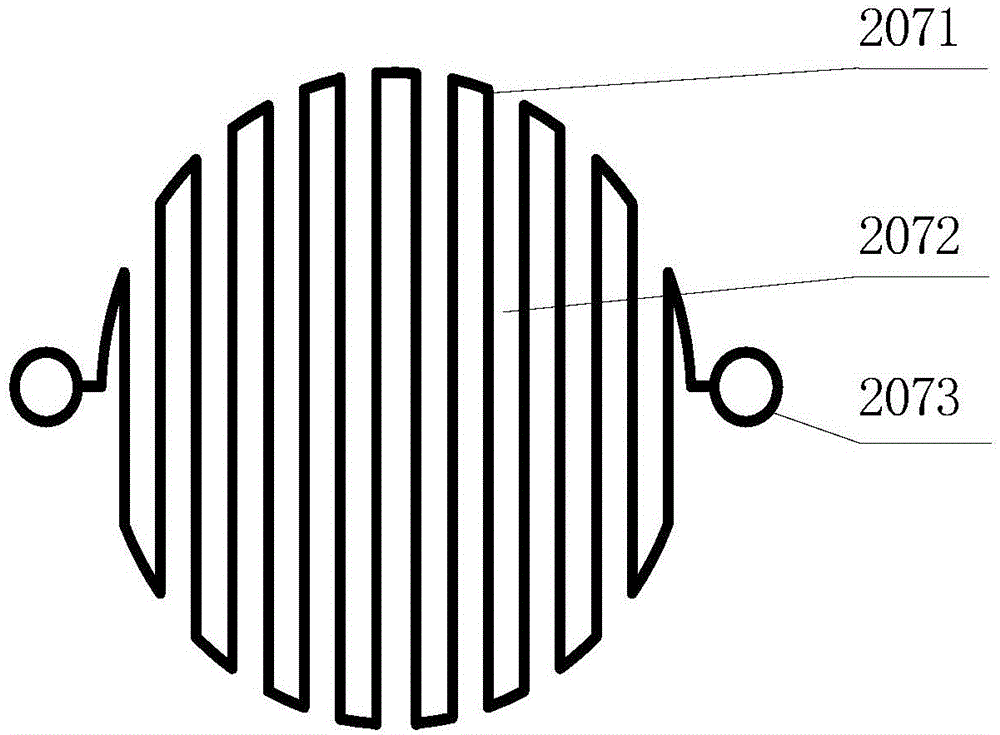

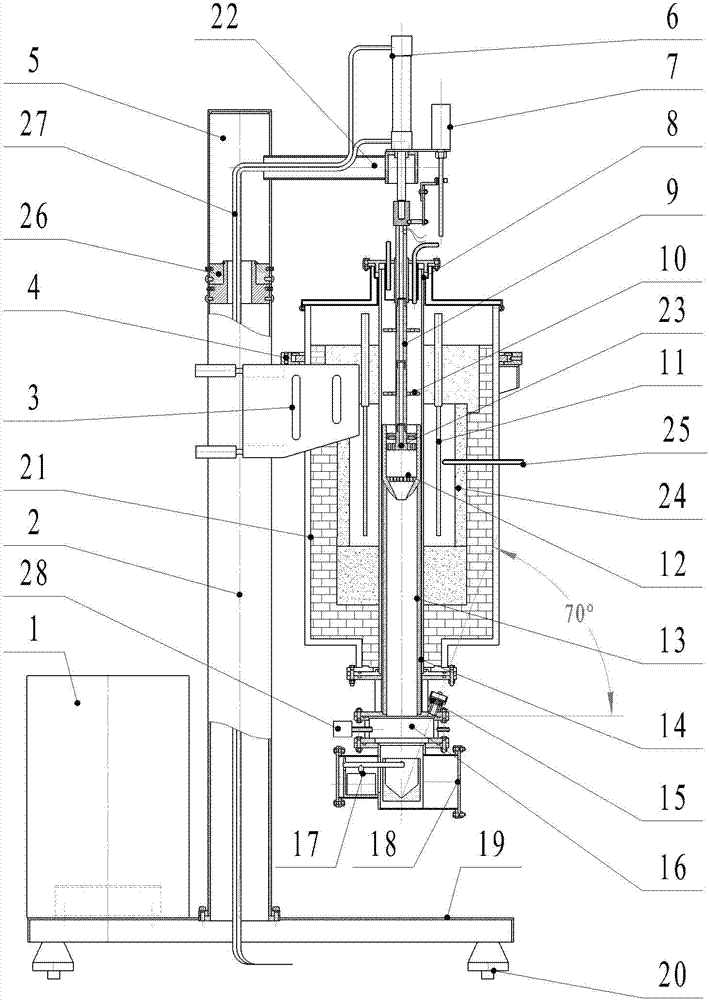

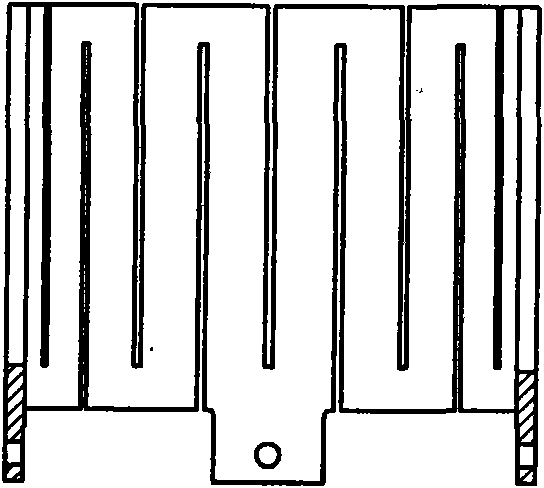

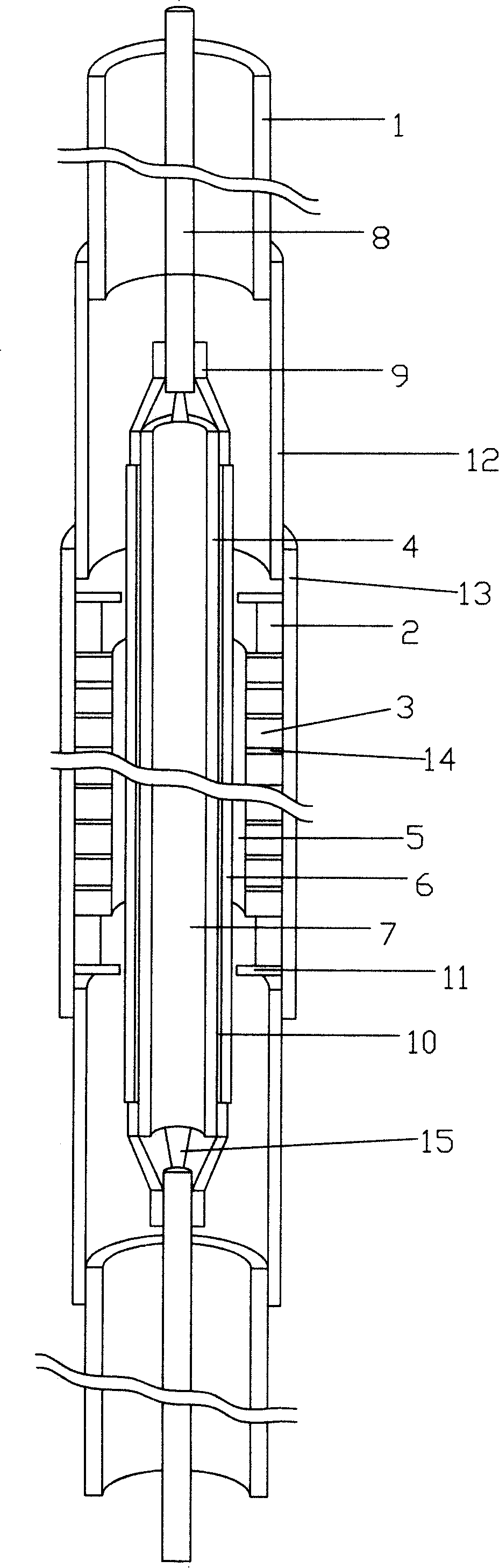

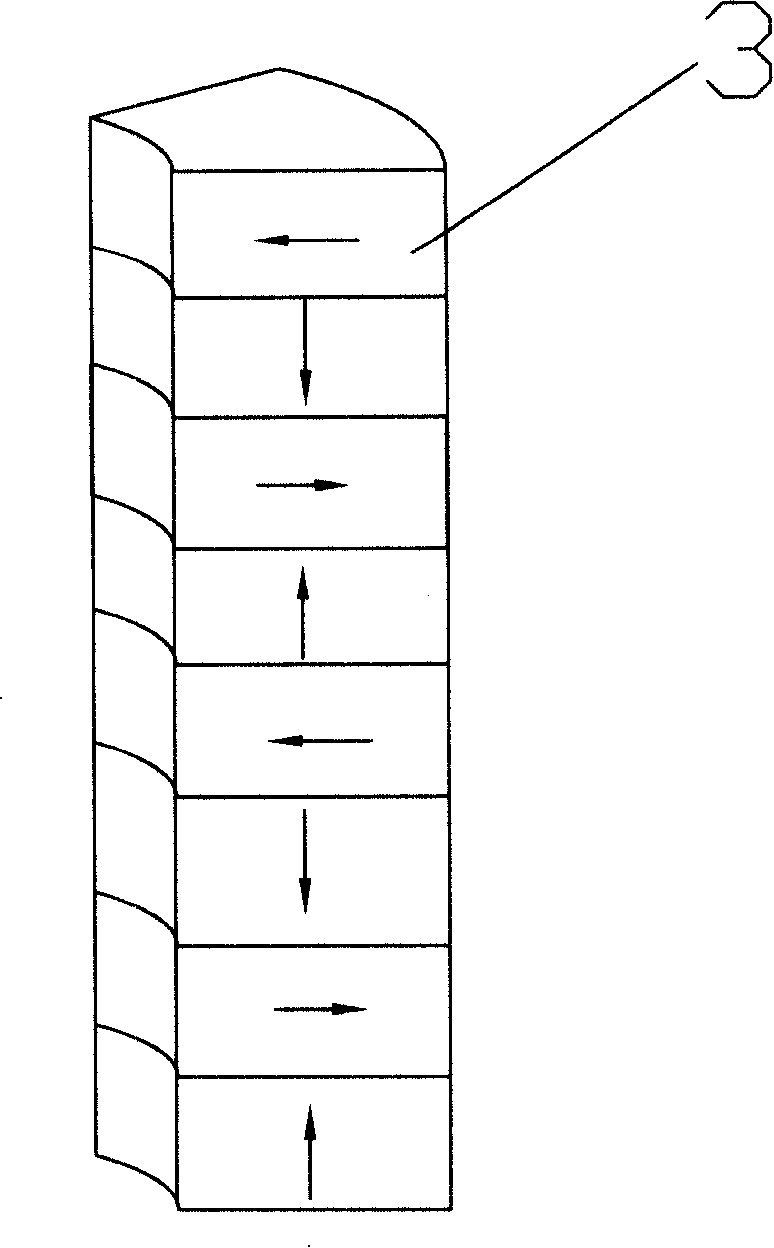

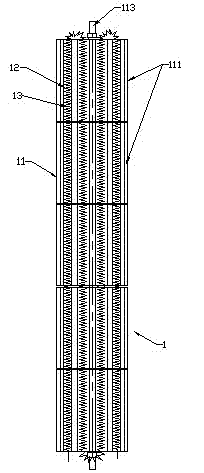

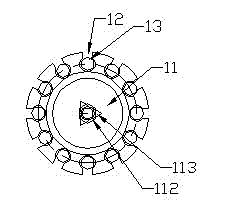

Improved structure of heater of czochralski crystal growing furnace

InactiveCN101580962AReduce manufacturing costIncrease heating powerBy pulling from meltAxial distributionEngineering

The invention relates to a heater device, aiming at providing an improved structure of a graphite heater of a czochralski crystal growing furnace. The heater comprises the ring-shaped graphite heater evenly provided with slots in a crossing way along the axis direction and a thinning heating section arranged on the ring-shaped graphite heater; wherein, the radial cross-sectional area of the thinning heating section is 2 / 3-3 / 4 of that of the rest parts of the heater; the thinning heating section is the part from the bottom of the heater to the height of 1 / 5-1 / 4 of the total height. The invention leads the heating power to be increased at the thinning part of the heater and changes the axial distribution, so as to indirectly form additional bottom heater function at the bottom of the ring-shaped heater, thus achieving the effect of two heaters which are the ring-shaped bottom heater and the bottom heater in the prior art by the structural design of the single graphite heater. Therefore, the invention not only reduces the equipment investment, but also lowers the manufacturing cost of the graphite heater and simplifies the operating procedures.

Owner:ZHEJIANG JINGSHENG MECHANICAL & ELECTRICAL

Biomass fuel and production method thereof

The invention relates to the technical field of biomass fuels, in particular to biomass fuel and a production method thereof. According to the production method, the materials, such as biogas residue, crop stalks, marshal sludge and sawdust, are mixed prior to being treated via a fermentation process; thus, organics are biologically react microscopically, the materials act with one another, the structure of biomass is enhanced, crushing and compressing treatment of the materials is easier, the difficulty and energy consumption of the biomass fuel is lowered, and the cost of biomass fuel production is lowered. In addition, pulverized coal is subjected to crushing treatment and added with illegal cooking oil and gasoline; thus, the waste, the illegal cooking oil and the gasoline are made full use, the ignition point of the biomass fuel is lowered, and the ignition cost of the biomass fuel in applications is lowered.

Owner:玉林市新滔环保科技有限公司

Tumble dryer comprising a heat pump and heating system and method for operating the same

InactiveUS8910394B2Easy to set upEasy to cleanDrying solid materials with heatDrying machines with non-progressive movementsProcess engineeringEngineering

A tumble dryer having a drying chamber for articles to be dried; a process-air duct; a heater arranged to heat process air, wherein the heater is a two-stage heater having a first heating stage in a first circuit and a second heating stage in a second circuit that is parallel to the first circuit; a first fan to direct heated process air over the articles to be dried in the drying chamber; a heat pump having a heat sink, a heat source and a heat transfer device; a controller; and a thermostatic switch arranged in the first circuit or the second circuit, wherein the thermostatic switch is thermally coupled to the heat pump.

Owner:BSH BOSCH & SIEMENS HAUSGERAETE GMBH

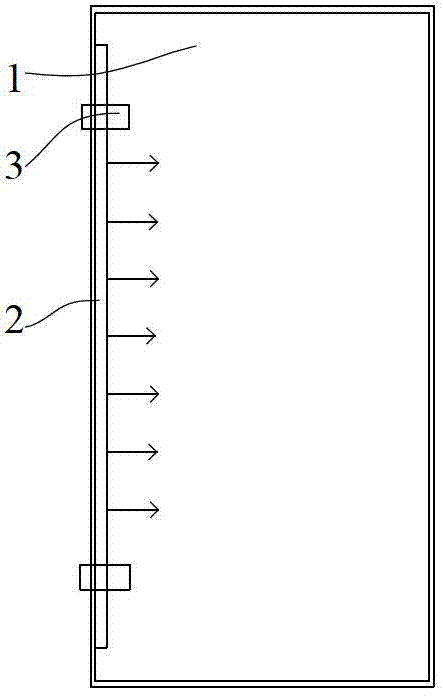

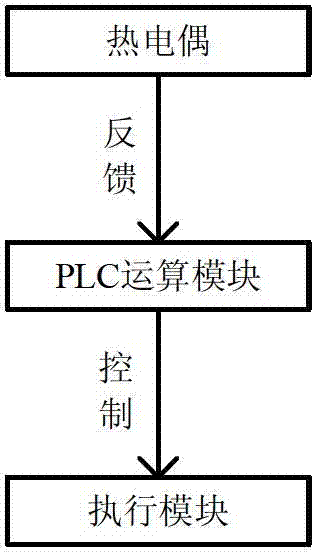

High-temperature solidifying furnace

InactiveCN102784747ATemperature monitoringImprove monitoring accuracyThermometer detailsMuffle furnacesMonitoring temperatureTemperature monitoring

The invention discloses a high-temperature solidifying furnace. The high-temperature solidifying furnace comprises a heating cavity, a heater and a temperature monitoring system, wherein the heater comprises a plurality of heating modules which can be controlled independently; and the temperature monitoring system comprises a thermocouple for monitoring the internal ambient temperature information of the heating cavity, an infrared monitoring device for monitoring temperature information on the surface of each layer of substrate inside the heating cavity and generating a temperature signal, a signal processing module for performing signal connection of the thermocouple and the infrared monitoring device and generating a corresponding execution command when a substrate with temperature abnormality is judged according to the temperature information fed back by the thermocouple and the temperature signal fed back by the infrared monitoring device, and an executing module in signal connection with the signal processing module and regulating the heating power of a heating module corresponding to the substrate with the temperature abnormality according to the execution command generated by the signal processing module. The high-temperature solidifying furnace monitors the ambient temperature of the heating cavity and the temperature on the surface of the substrate through the thermocouple and the infrared monitoring device, so that the solidifying temperature monitoring precision is improved.

Owner:BOE TECH GRP CO LTD +1

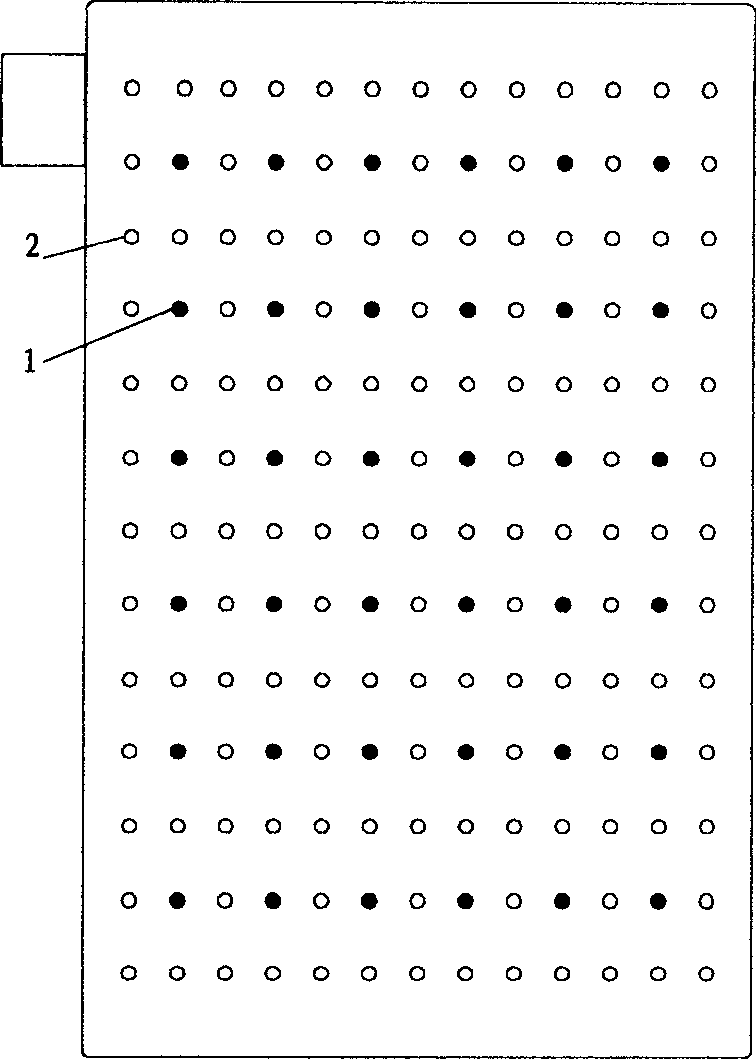

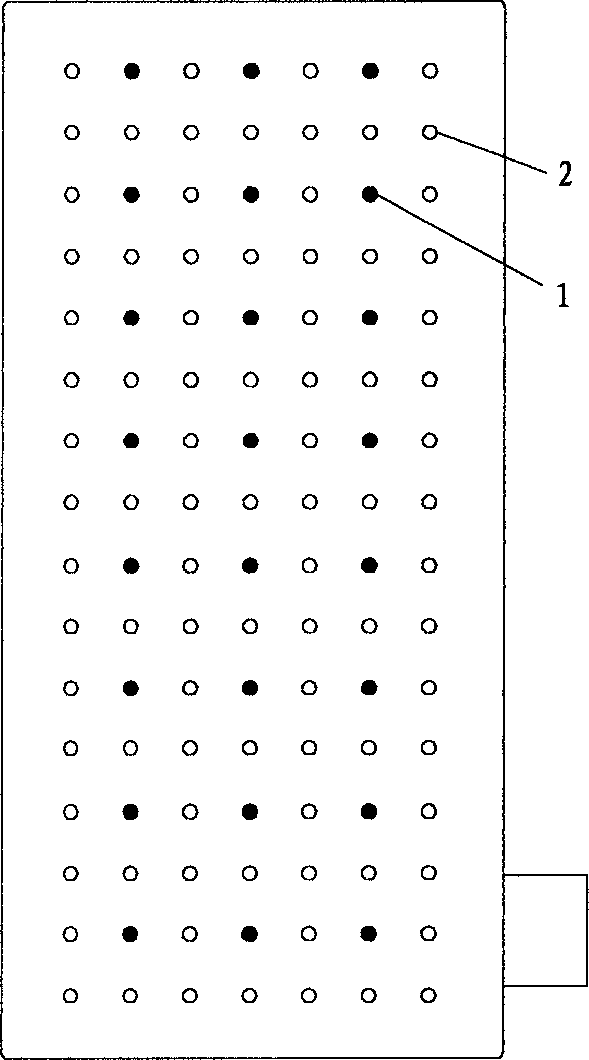

Warm air cushion

ActiveCN1600198AEasy to useAvoid radiationStuffed mattressesSpring mattressesTemperature differenceEngineering

A warm air pad for heat dissipation in a quick drying device for quilts. After a large number of experiments on different perforation parameter combinations on the warm air pad, the present invention finds that the area and number of air holes and the number of adjacent riveted holes on the same layer The spacing is the most important factor in determining the performance of the heater pad. According to the present invention, through the control of the related parameters of the later punching of the pad body, the warm air pad manufactured has smooth air exhaust and uniform heat dissipation. The warm air pad is used to heat the bedding, with fast temperature rise, large temperature rise, and small temperature difference between the front and the rear. It can be used for bedding preheating and heat preservation, dehumidification, moisture-proof, disinfection and sterilization.

Owner:丛德奎

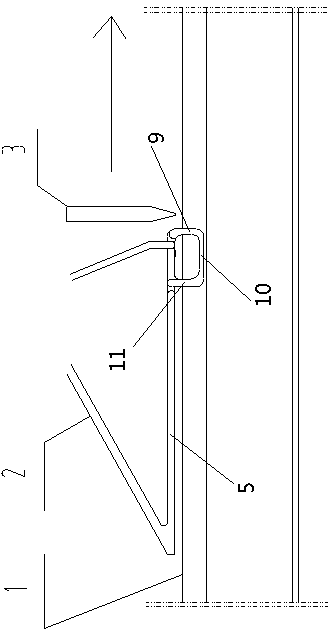

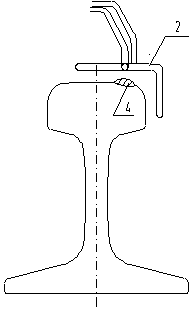

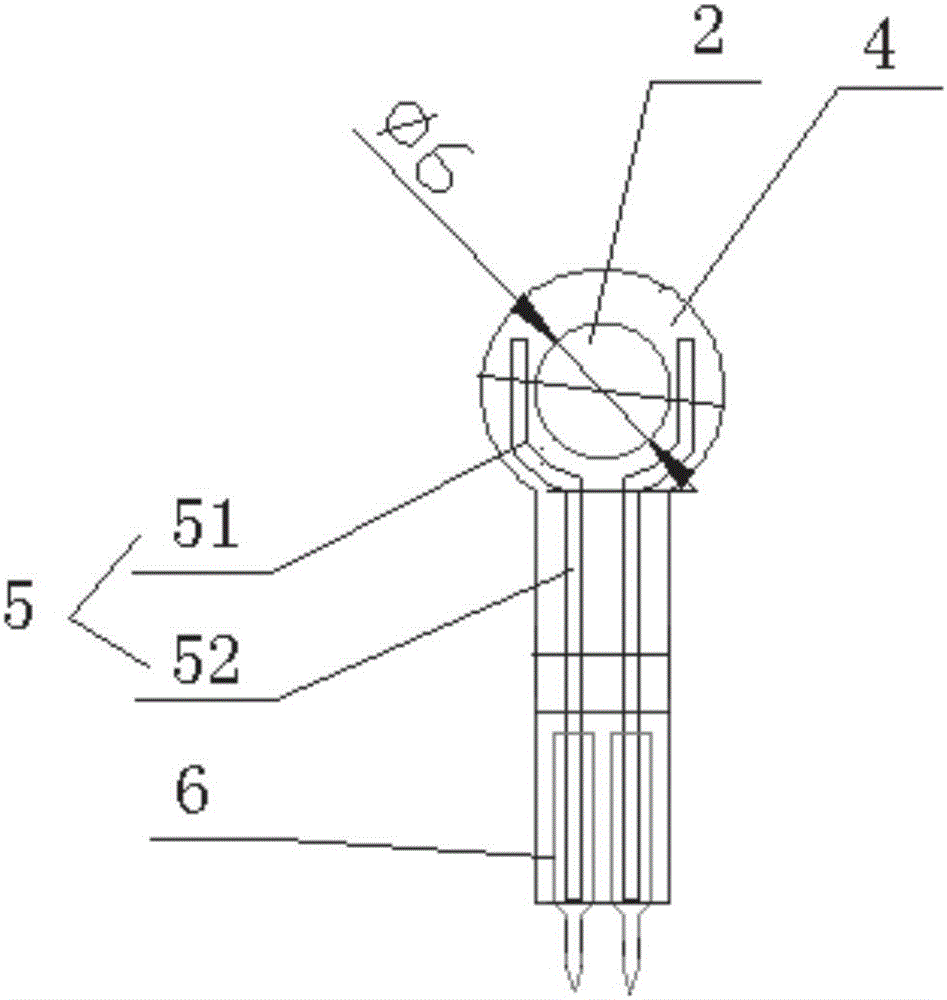

Induction heater and method for realizing non-preheating cladding of alloy on steel rail by using same

InactiveCN103132008ASave energyExtended heating rangeMolten spray coatingHeat transmissionMiniaturization

The invention discloses an induction heater which comprises a heating zone 1 and a heating zone 2, wherein the heating zone 1 is divided into two heating surfaces; a first heating surface is shaped like a trapezoid without the bottom; a second heating surface is a U-shaped one; the two lateral sides of the trapezoid-shaped heating surface are connected with the U-shaped heating surface; and an included angle is formed between the first heating surface and the second heating surface. When the induction heater is used to perform alloy cladding on a steel rail, preheating does not need to be performed in advance, so that on the premise of the same steel rail cladding speed, heat energy required by the method is only one third or less of the prior art; and meanwhile, the method lays a foundation for miniaturization of a generator or even construction without the aid of a rail car. By performing detailed analysis on structure phase change and heat transmission of a steel rail in the cladding process, the invention breaks through the theory that the steel rail must be preheated prior to welding for the first time, and presents that the steel rail can be directly subjected to alloy cladding without being preheated while generation of martensite can be avoided. The technology disclosed by the invention is put forward for the first time at home and abroad.

Owner:CHENGDU ZHONGGUI TECH CO LTD

Industrial electromagnetic heating process, apparatus and use

InactiveCN1867211AImprove thermal efficiencyReduce distractionsCoil arrangementsElectromagnetic shieldingElectromagnetic heating

The invention relates to an industrial electromagnetic heating method and relative device. Wherein, said method comprises: coating multilayer electromagnetic induction heating coil plane or arc on the frame of heated metal container or tube; or using electromagnetic induction to directly heat the metal container or tube; it mounts the multilayer electromagnetic induction heating coil formed by at least two layer of electromagnetic coils outside the heated metal container or tube; the magnetic lines of layered by electromagnetic heating coils functions the heated metal container or tube; the whole compound multilayer electromagnetic induction heating coil heating method comprises: the rectification circuit transforms the external alternative voltage into direct-current voltage, the control circuit transforms the direct-current voltage into high-frequency voltage, then functions the high-frequency voltage on the compound multilayer electromagnetic induction heating coil, to use electromagnetic induction to heat the material inside the metal container or tube.

Owner:黄克

Magnetic-heat wax preventing device for oil production

InactiveCN101205804AChange distributionImprove heating efficiencyDrilling rodsCleaning apparatusForce linesWax

The invention discloses an oil extraction magnetocaloric paraffin prevention device which comprises a heating pipe which is sleeved and fixed on a pumping rod and magnets which are closely fixed on the inner wall of an oil pipe, wherein, a metal pipe with high magnetic permeability is embedded on the inner wall of the heating pipe; the pumping rod provided with a heating pipe part is a hollow structure. The invention makes distribution of magnetic force lines generate qualitative changes through arranging the magnets by adoption of an Halbach array, namely magnetic flux of areas which need heating vortexes on sides of the heating pipe and the metal pipe is obviously increased, and magnetic flux on the side of the oil pipe is relatively sparse, thereby heating efficiency of the heating pipe is improved. The structure of the invention can change distribution of the magnetic force lines, thereby the heating efficiency is improved as much as possible.

Owner:张国成

Lens and camera equipped with lens

InactiveCN106125464ANot easy to ageReduce energy consumptionCamera body detailsCamera lensElectrical resistance and conductance

The invention discloses a lens and a camera equipped with the lens. The lens comprises an eyeglass set, a lens cover which is arranged outside the eyeglass set and is used for fixing the eyeglass set, and an assembled printed circuit board which is arranged at one side of the eyeglass set and is connected with the eyeglass set, wherein the eyeglass set comprises eyeglasses, waterproof glass arranged at outer sides of the eyeglasses and electrical heating sheets arranged between the eyeglasses and the waterproof glass, the electrical heating sheets are used for conducting heat to the waterproof glass to realize anti-mist anti-frost functions, and the electrical heating sheets comprise one type of graphene film heating sheets and tin-doped indium oxide film heating sheets. Resistance of the electrical heating sheets employed by the lens is 300-350 ohm, when the external temperature is 10-25 DEG C, the arrival heating temperature of the electrical heating sheets is 35-45 DEG C, the heating temperature can be realized through 3-second heating; when the external temperature is 0-5 DEG C, the arrival heating temperature of the electrical heating sheets is 25-30 DEG C, the heating temperature can be realized through 5-second heating. According to the lens, the heating temperature is relatively mild, a heating speed is relatively fast, not only can aging of the eyeglasses be not easy, but also energy loss is low, and the heat conduction effect is relatively good.

Owner:苏州国创电子科技有限公司

Electric automobile PTC (Positive Temperature Coefficient) electric heater

InactiveCN101902845AImprove operational reliabilityMeet the use requirementsHeater elementsElectricityAutomobile air conditioning

The invention relates to an electric automobile PTC (Positive Temperature Coefficient) electric heater for an automobile air conditioner system, comprising a square-shaped frame, a plurality of aluminum heat radiating strips and a plurality of PTC electric heating pipes, wherein the square-shaped frame is adapted to an air outlet of the automobile air conditioner system; the aluminum heat radiating strips are parallelly arrayed in the square-shaped frame; and the PTC electric heating pipes are provided with flat shells and clamped among the aluminum heat radiating strips. The invention has the advantages that the densely-arranged aluminum heat radiating strips and the PTC electric heating pipes can obtain higher heating power in the narrow and small space of an automobile, the aluminum heat radiating strips and the PTC electric heating pipes are closely fixedly connected through soldering so as to be enhanced in the integral strength and be adapted to the bumping and shaking running environment of the automobile, and running temperature can be monitored at real time on the basis of overheat self-protection, therefore the running reliability of electrical heater can be further enhanced by utilizing an automobile running computer system.

Owner:ZHENJIANG DONGFANG ELECTRIC HEATING TECH

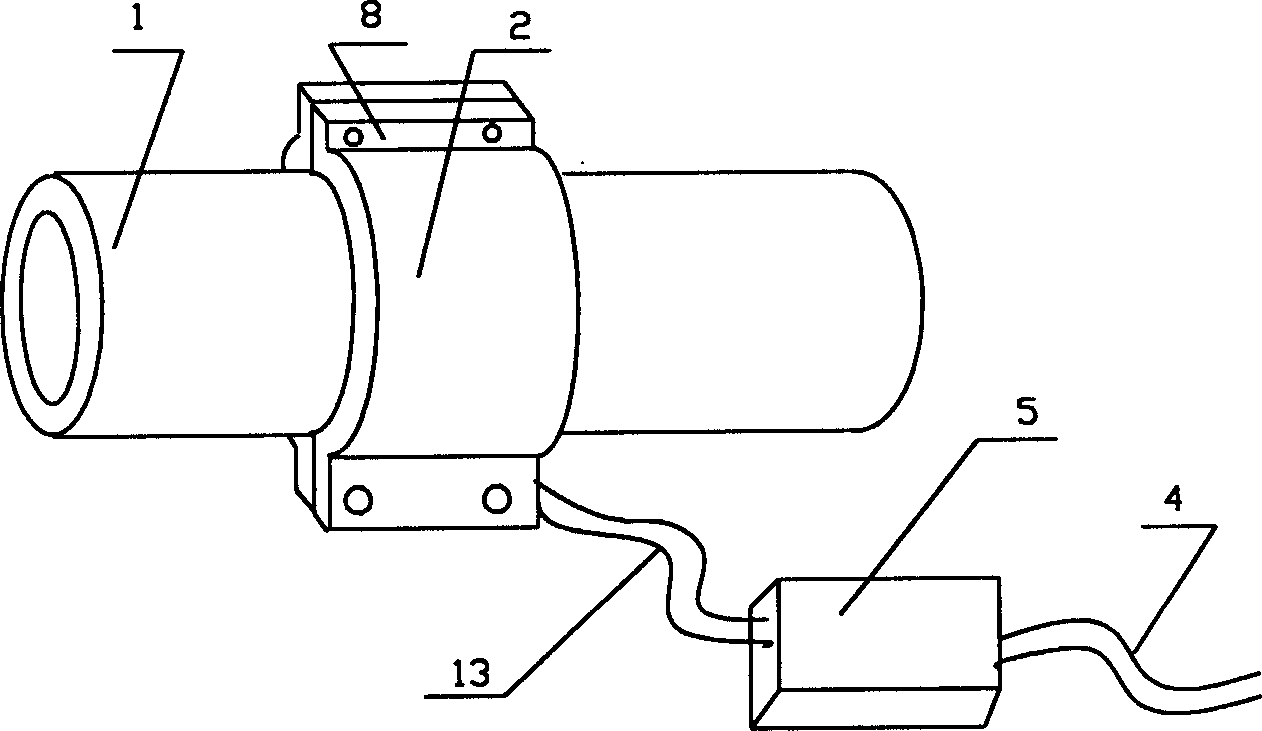

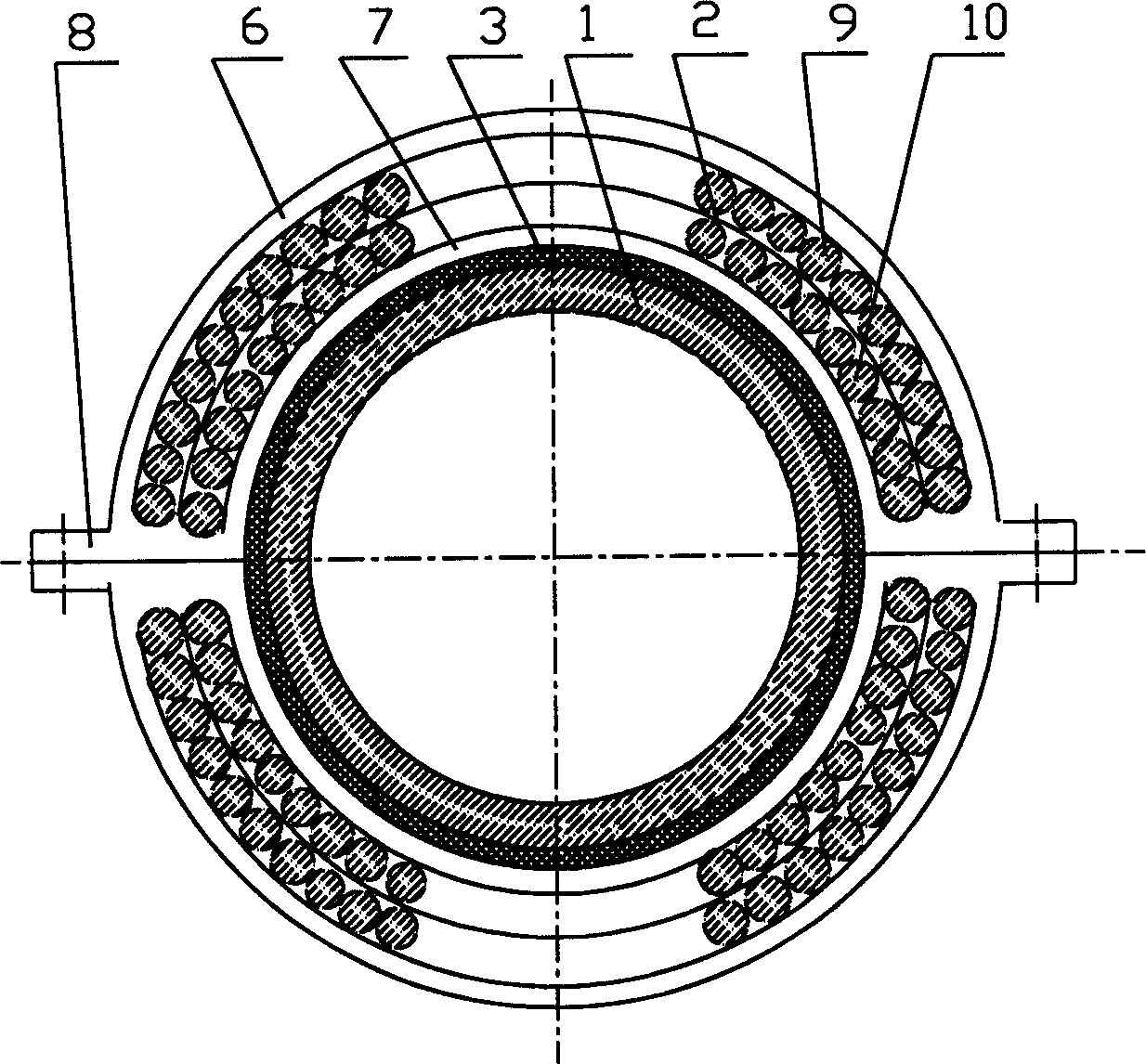

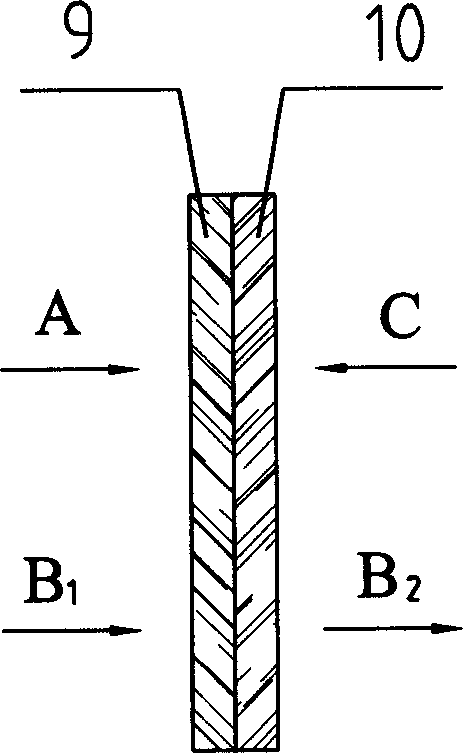

Pipe electromagnetism heating device and electromagnetism heating method

InactiveCN102711300ALarge heating areaIncrease heating powerPipe heating/coolingInduction heating apparatusPipingHeat flow

The invention relates to a pipe electromagnetism heating device and an electromagnetism heating method. The pipe electromagnetism heating device is characterized in that a main heating tube and a center heating tube which are made of magnetic materials are adopted; and a plurality of groups of heating coils are wound at the periphery of the main heating tube at certain intervals, each group of heating coil is respectively connected with an electromagnetic controller used for providing high-frequency current, the two ends of the centre heating tube are sealed and fixedly arranged in the main heating tube, the central axis of the centre heating tube coincides with that of the main heating tube, and a layer of a metal flow-obstructing wire is wound at the periphery of the centre heating tube. Materials to be heated flow into a space between the main heating tube and the centre heating tube, the groups of heater coils are energized, the main heating tube and the central heating tube heat up simultaneously, and the materials to be heated flow between the main heating tube and the centre heating tube and are heated quickly and thoroughly. The pipe electromagnetism heating device can rapidly heat up the material flowing between the main heating pipe and the centre heating pipe based on the principle of electromagnetism heating and by being combined with a reasonable piping, and is simple in structure, easy to manufacture, install and replace, and applicable to the heating of liquid and solid-liquid mixtures.

Owner:北京绿创生态科技有限公司

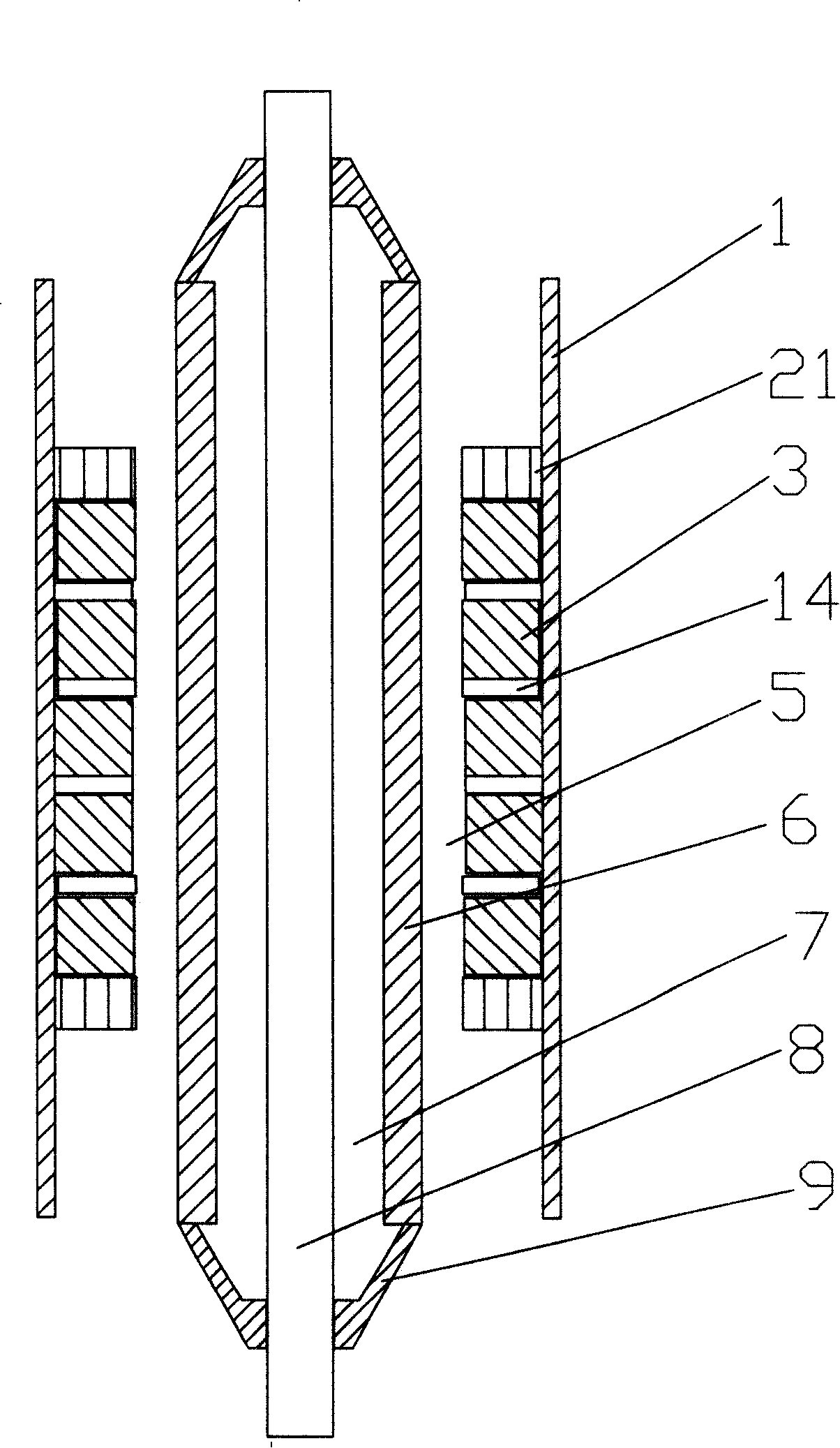

Electric heating element and pipeline electric heater

InactiveCN102811514AHigh densityIncrease heating powerPipe heating/coolingHeating element shapesElectrical resistance and conductanceHigh density

The invention relates to an electric heating device and particularly relates to an electric heating element for heating gas flowing in a pipeline and a pipeline electric heater adopting the electric heating element. The electric heating element comprises a cylindrical base body which is manufactured by a fireproof material; vertical mounting grooves are uniformly distributed on the outer cylindrical face of the base body; a spiral resistance wire is placed in each mounting groove in a reciprocated manner; and extraction electrodes are arranged at the two ends of each resistance wire. According to the electric heating element disclosed by the invention, the resistance wires are highly-densely distributed on the vertical mounting grooves on the outer cylindrical face of the base body; the structure is compact and the occupied space is small; and the effective density and the heating power of the heating elements of the pipeline electric heater are effectively improved.

Owner:ZHENJIANG WSK ELECTRICAL APPLIANCES

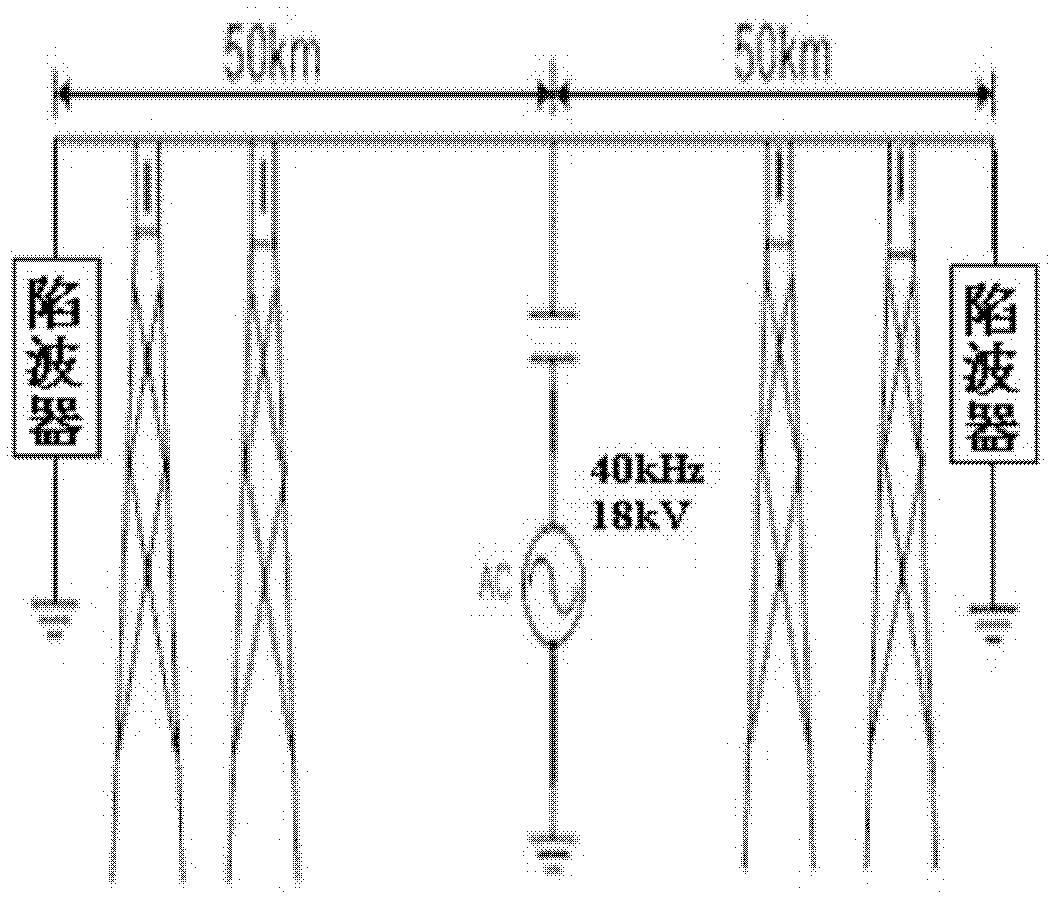

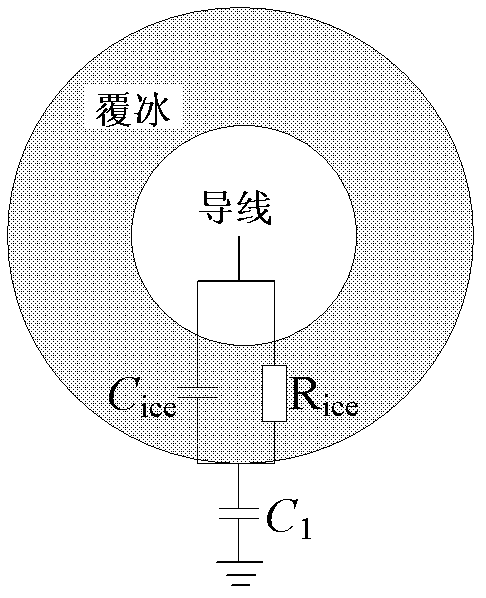

18kV and 40kHz high-frequency de-icing device and de-icing method thereof

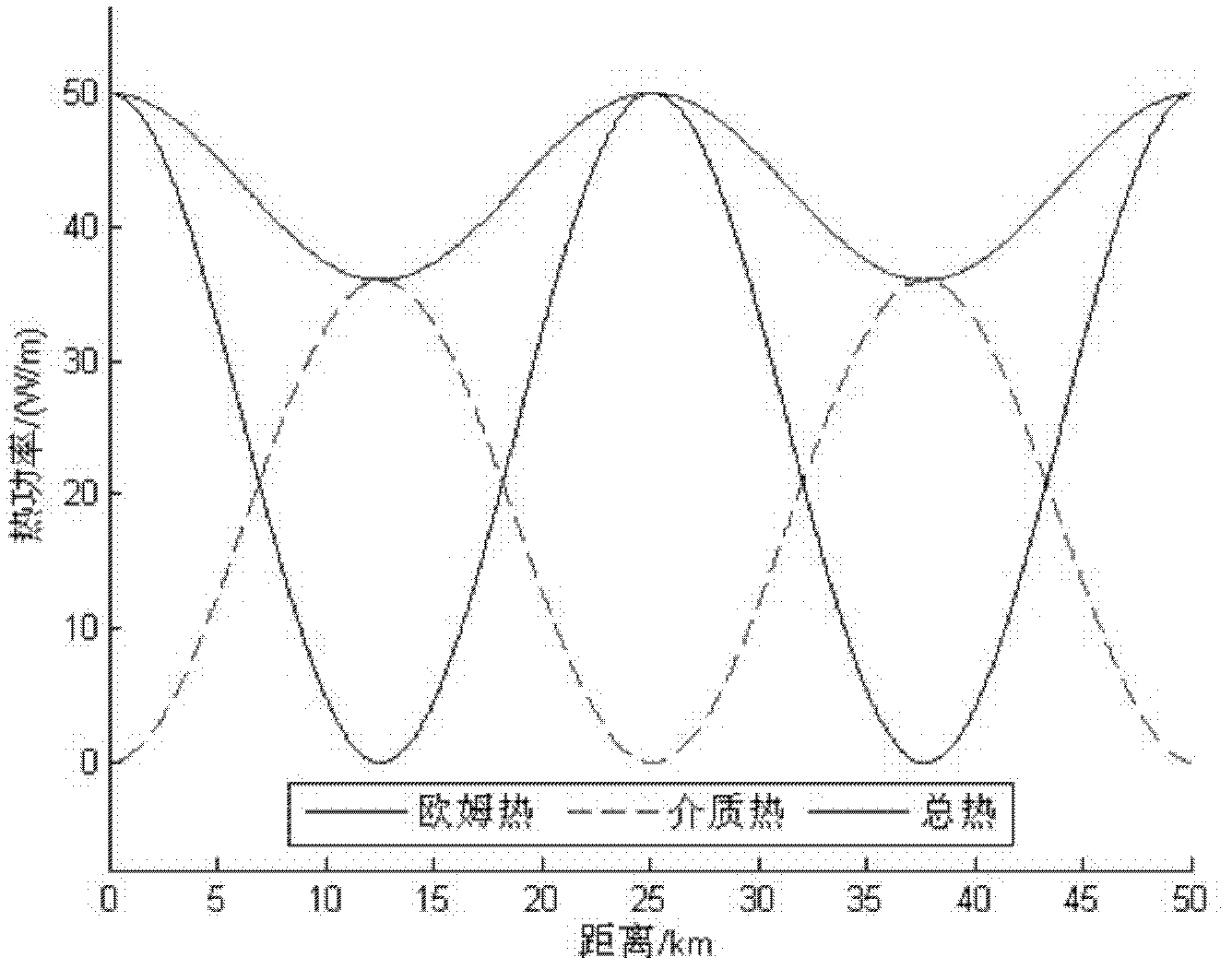

InactiveCN102195261AReduce transmission currentReduce the impactOverhead installationHeating powerVoltage

The invention discloses an 18kV and 40kHz high-frequency de-icing device and an de-icing method thereof. The 18kV and 40kHz high-frequency de-icing device comprises an excitation source and notch filters, wherein the excitation source is connected in parallel with two parallel-connected notch filters and grounded respectively. By the device and the method, transmission current of a circuit can be reduced and the heating power can be increased; under the condition of no power failure, an effect of de-icing within a short time can be achieved; compared with the frequency 100kHz and the voltage 33kV in the high-frequency de-icing technology provided in the foreign country, the level of the frequency and the voltage of the excitation source in the 18kV and 40kHz high-frequency de-icing technology is reduced greatly, so the influence of high frequency on communication is lowered greatly; meanwhile, the implementation of the device is facilitated.

Owner:CHANGSHA UNIVERSITY OF SCIENCE AND TECHNOLOGY

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com