Hopkinson pressure bar experimental apparatus

A Hopkinson pressure bar and experimental device technology, applied in measurement devices, instruments, scientific instruments, etc., can solve problems such as being oxidized, and achieve the effect of improving repeatability and avoiding complexity and uncertainty

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

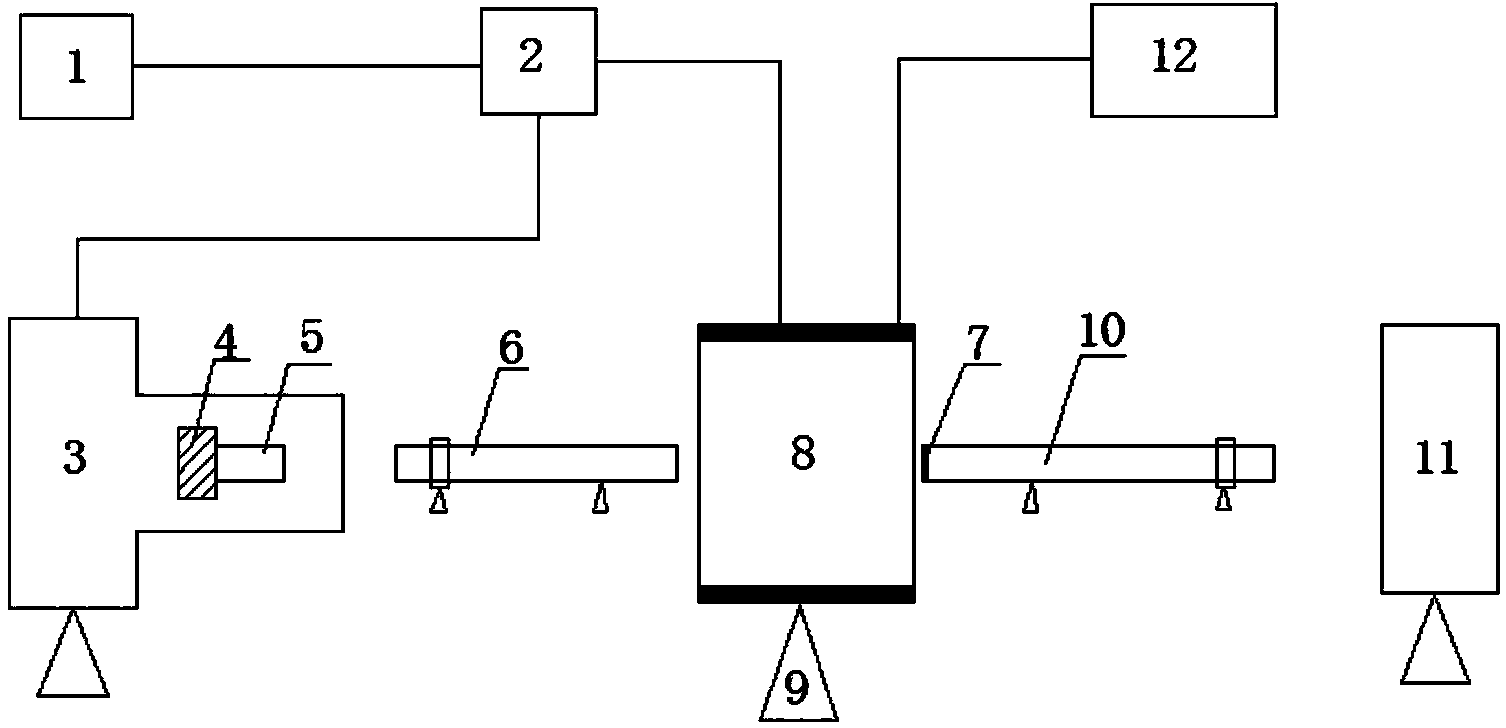

[0037] Attached below Figure 1-5 The present invention will be described in detail.

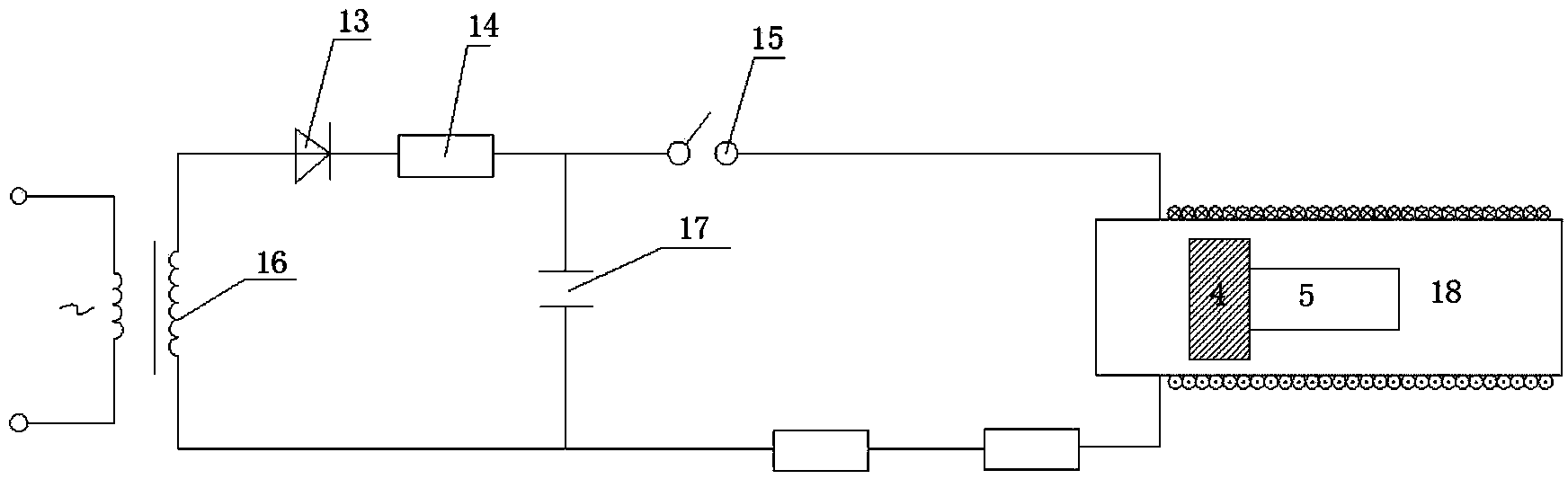

[0038] figure 1 It is the high-precision Hopkinson compression bar experimental device under high temperature described in the present invention, comprising: electromagnetic trigger switch 1, heating furnace door automatic opening switch 2, electromagnetic drive device 3, drive plate 4, bullet 5, incident rod 6, force Sensor 7, heating furnace 8, heating furnace support device 9, transmission rod 10, buffer device 11 and air compression filter device 12.

[0039] Specifically, the electromagnetic trigger switch 1 and the automatic opening switch 2 of the heating furnace door are connected in series, the automatic opening switch 2 of the heating furnace door can work independently, and the electromagnetic drive cannot be activated if the automatic opening switch of the heating furnace door is not closed; The bullets are connected as one, and the electromagnetically driven flat panel also dr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com