Magnetic-heat wax preventing device for oil production

An anti-wax and magnetothermal technology, which is used in earth-moving drilling, cleaning equipment, drilling equipment, etc., to achieve the effect of improving heating power, long service life, and improving heating efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

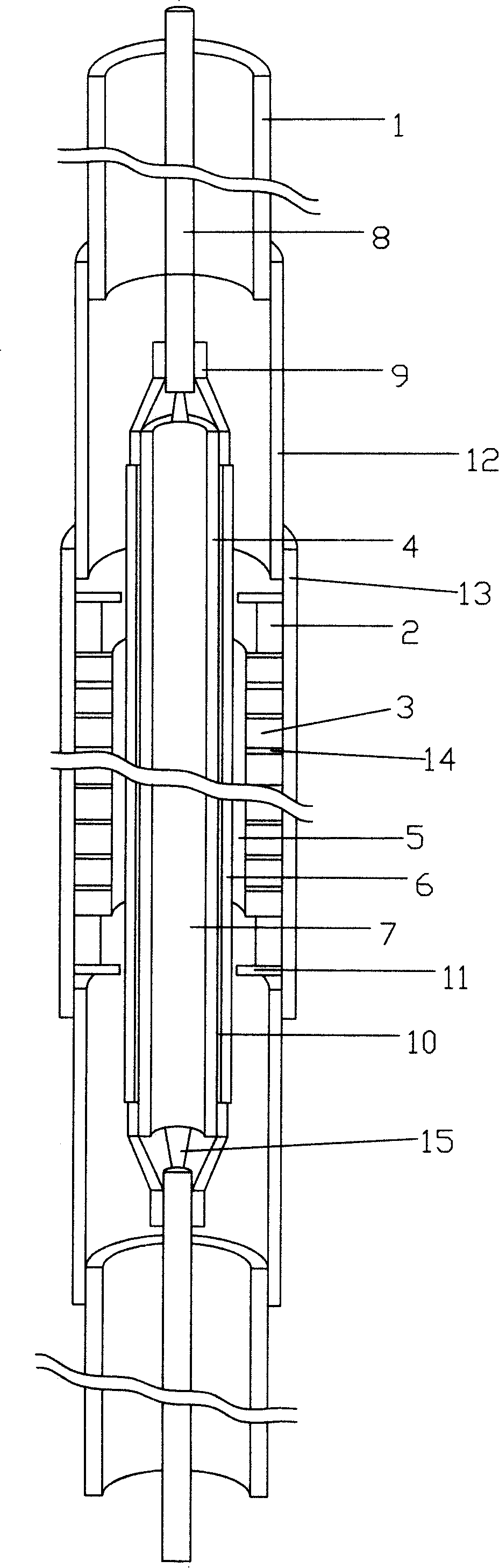

[0030] The present invention will be described in detail below in conjunction with the accompanying drawings.

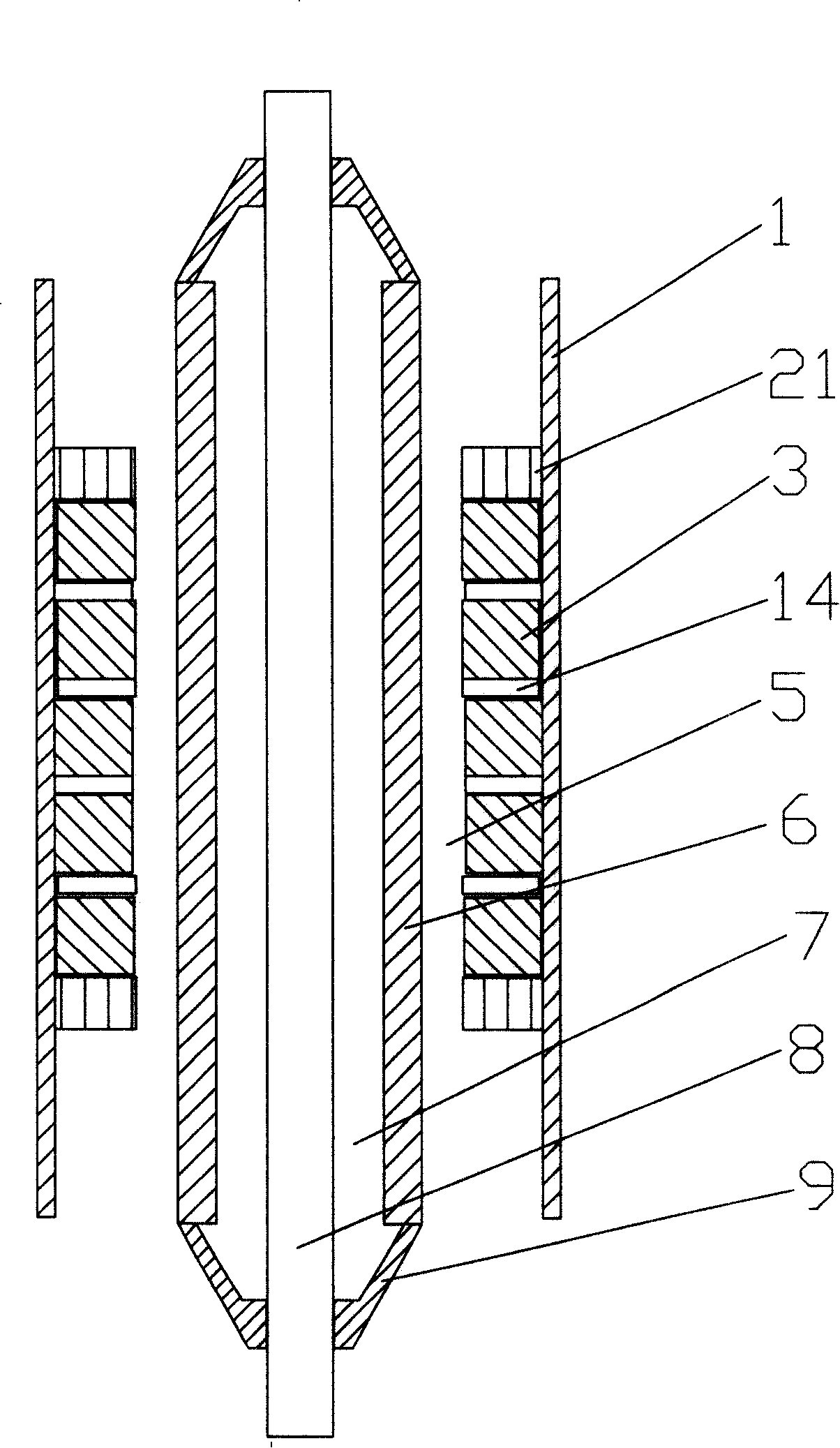

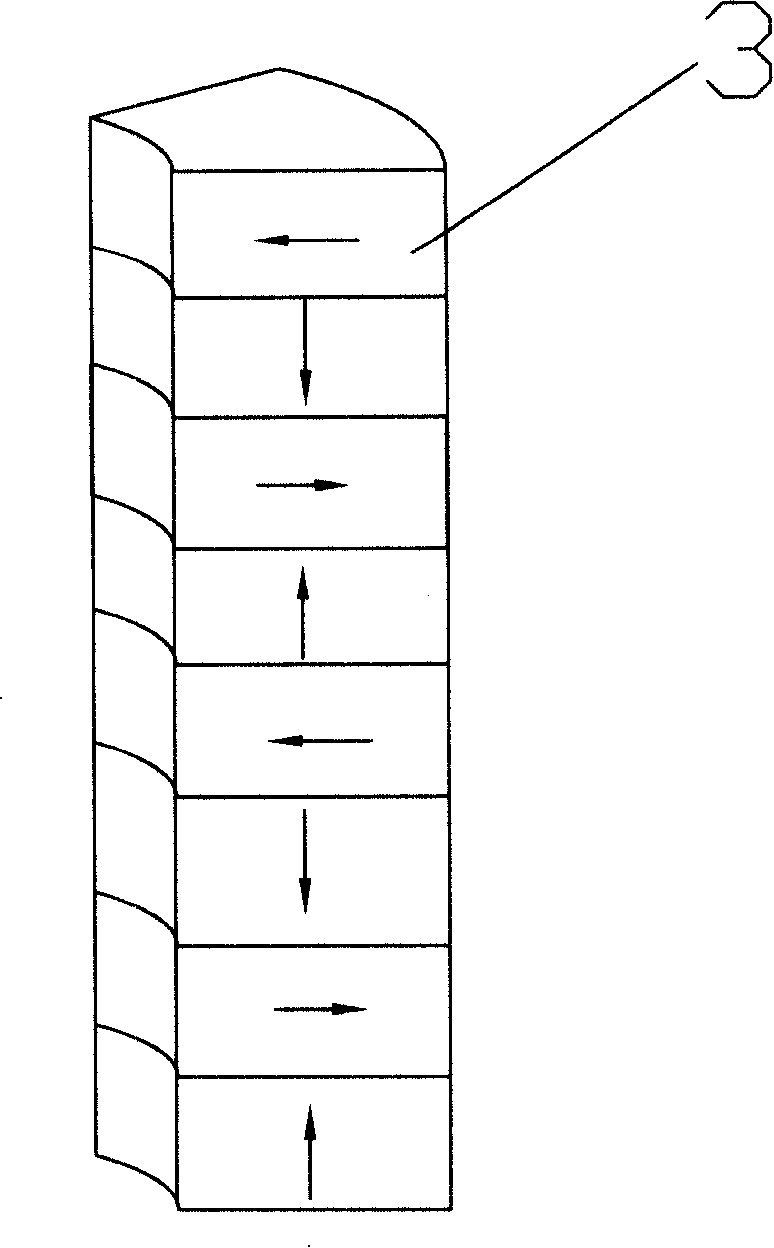

[0031] Such as figure 2 As shown, the present invention includes a ring-shaped magnetic steel 3 fixed on the inner wall of the outer pipe (thickened oil pipe 13 ) and a heating pipe 6 fixed on the hollow sucker rod 4 . It can be seen from the figure that the hollow sucker rod 4 of the present invention is only located in the oil pipe section where the heating pipe part is arranged. The hollow sucker rod 4 is fixedly connected (may be welded) to a conventional sucker rod (solid structure) 8 through ribs 15 . The ring magnets 3 are separated by ring fillers 14, and the two ends of these spaced ring magnets 3 and fillers 14 are fixed by ring yokes 2. The central, high-permeability material that guides the flux lines through to reduce flux loss, can be soft magnets, pure iron, or mild steel. The magnets 3 in the present invention are neodymium-iron-boron magnets, and...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com