Industrial electromagnetic heating process, apparatus and use

A heating method and electromagnetic induction heating technology, which are applied in the application field of the aforementioned method and device, can solve the problems of strong coil magnetic field interference, low heating power density, and the inability to install and use circular electromagnetic induction heating coils, etc., and achieve wide application range, The effect of increasing the heating power density

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

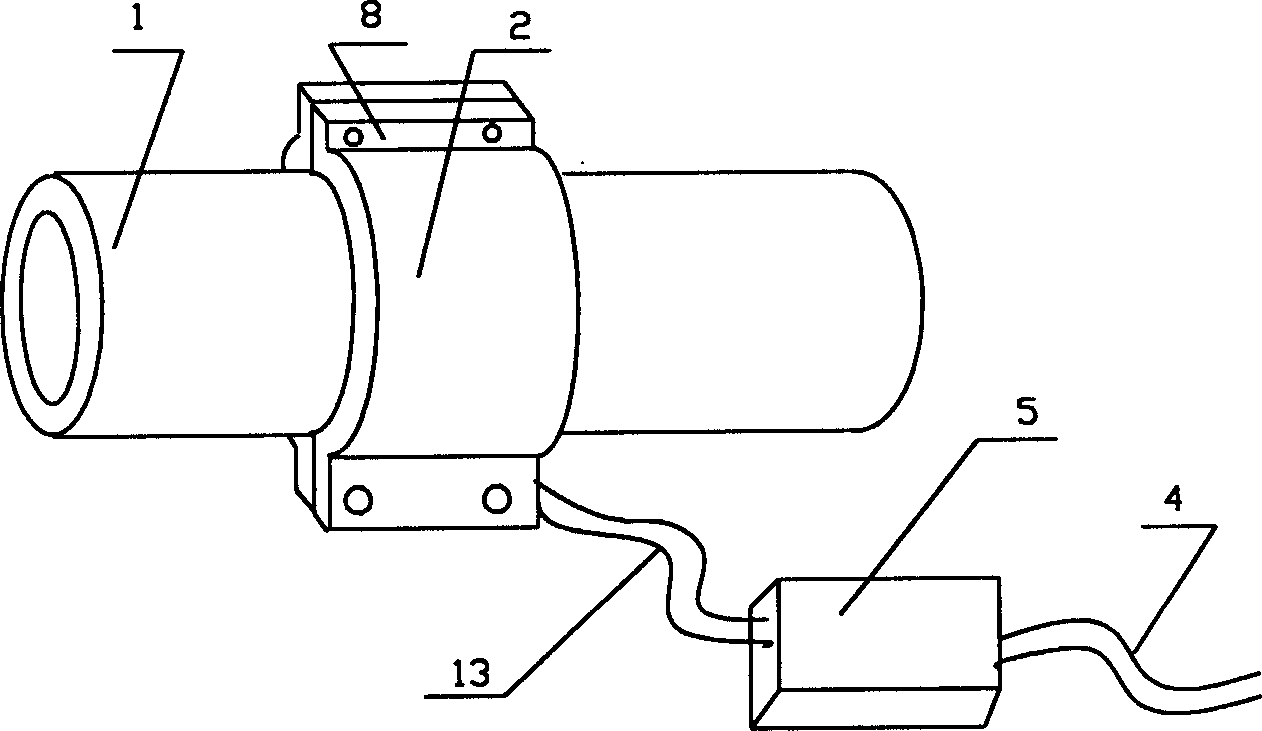

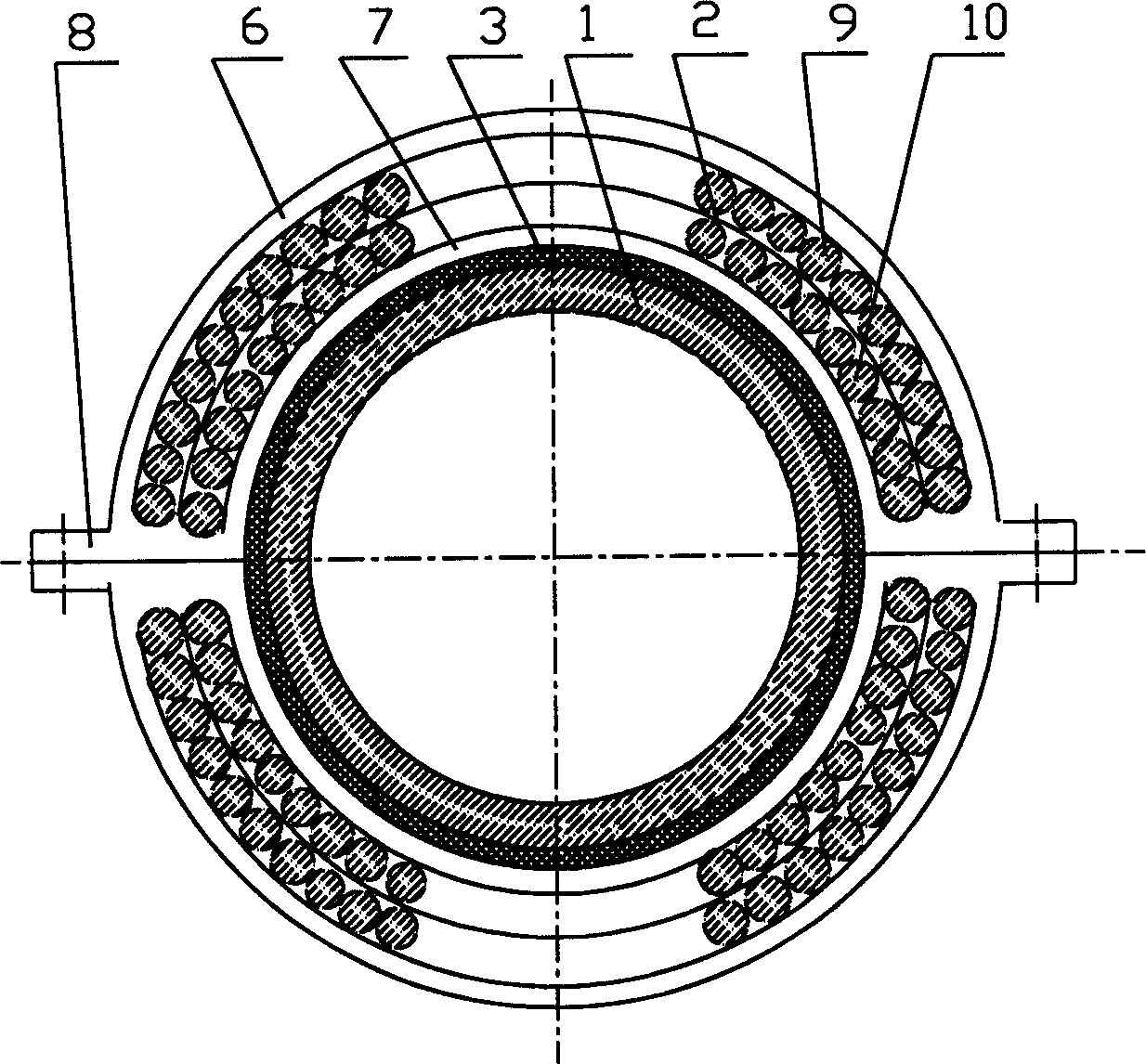

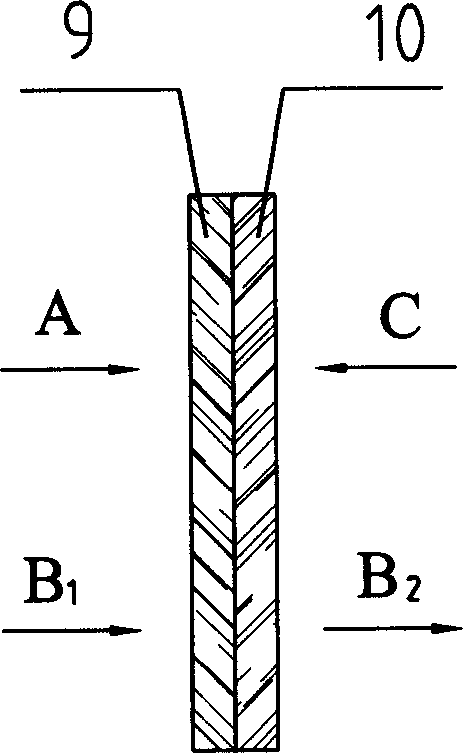

[0031] From attached figure 1 and figure 2 It can be seen that the present invention is a composite laminated electromagnetic induction heating coil, comprising a composite laminated electromagnetic induction heating coil 2, the composite laminated electromagnetic induction heating coil 2 is installed on the outside of the metal pipe 1 and communicated with the electromagnetic controller through a wire 13 5 phases, and the electromagnetic controller 5 is connected to the external power supply through the power line 4. The composite laminated electromagnetic induction heating coil 2 has no magnetic core, and a heat insulating material layer 3 is provided between its inner surface and the outer surface of the metal pipe 1. It is characterized in that: the composite laminated electromagnetic induction heating coil 2 is electrically The magnetic induction heating method is heated by double-layer stacked electromagnetic induction heating coils. A composite laminated electromagn...

Embodiment 2

[0033] The principle of embodiment 2 is the same as that of embodiment 1. The laminated composite laminated electromagnetic induction heating coil is also a double-layer electromagnetic heating coil, but the shape of the composite laminated electromagnetic induction heating coil is made according to the shape of the applied pipeline. It has an arc-shaped structure and is composed of multiple arc-shaped composite laminated electromagnetic induction heating coils to form a complete circle. Each double-layer composite laminated electromagnetic induction heating coil is wrapped by an outer jacket and an inner jacket made of insulating materials, and A connector for connecting the composite laminated electromagnetic induction heating coils of each arc-shaped structure is provided at the junction of the outer jacket and the inner jacket of each section of the composite laminated electromagnetic induction heating coil, and the composite laminated electromagnetic induction heating coils...

Embodiment 3

[0035] Embodiment 3 is a planar composite laminated electromagnetic induction heating coil. The number of coils laminated by each composite laminated electromagnetic induction heating coil is four layers, and the coils of each layer are made of plane spiral winding and then laminated. Together, the coils are connected in series, and the wires of each adjacent coil are connected end to end; that is, the upper coil is spirally wound from the outside to the inside, the wire tail is located at the innermost coil, and the next coil The wire ends of the coil are spirally wound from the inside to the outside, so the wire ends of the next layer of coils just meet the wire ends of the upper layer of coils. And the four coils are made by winding a wire. The composite laminated electromagnetic induction heating coil is also wrapped by an insulating material, and a connector for fixing the composite laminated electromagnetic heating coil can be arranged outside the insulating material. T...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com