Burner assembly for cooking equipments

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

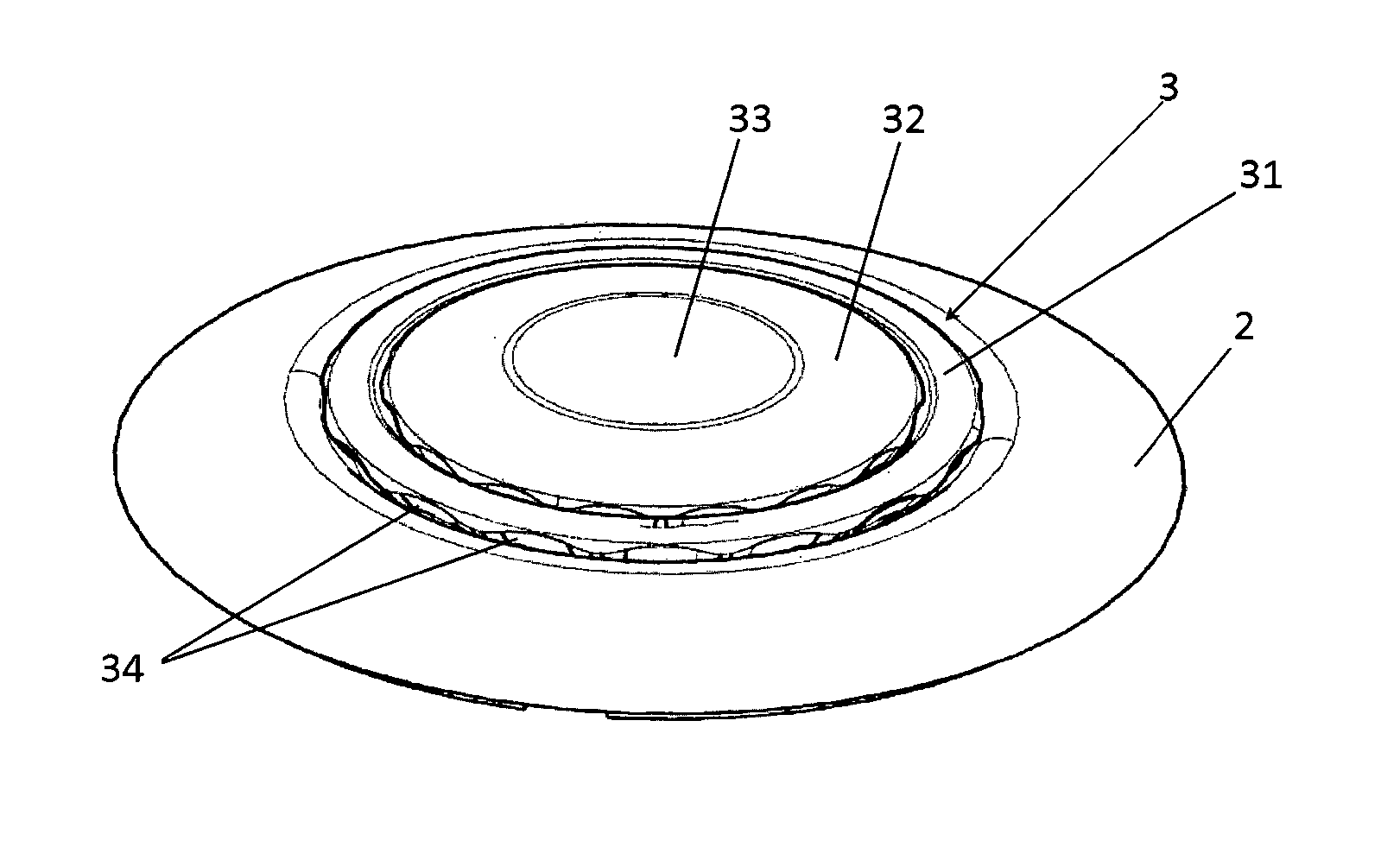

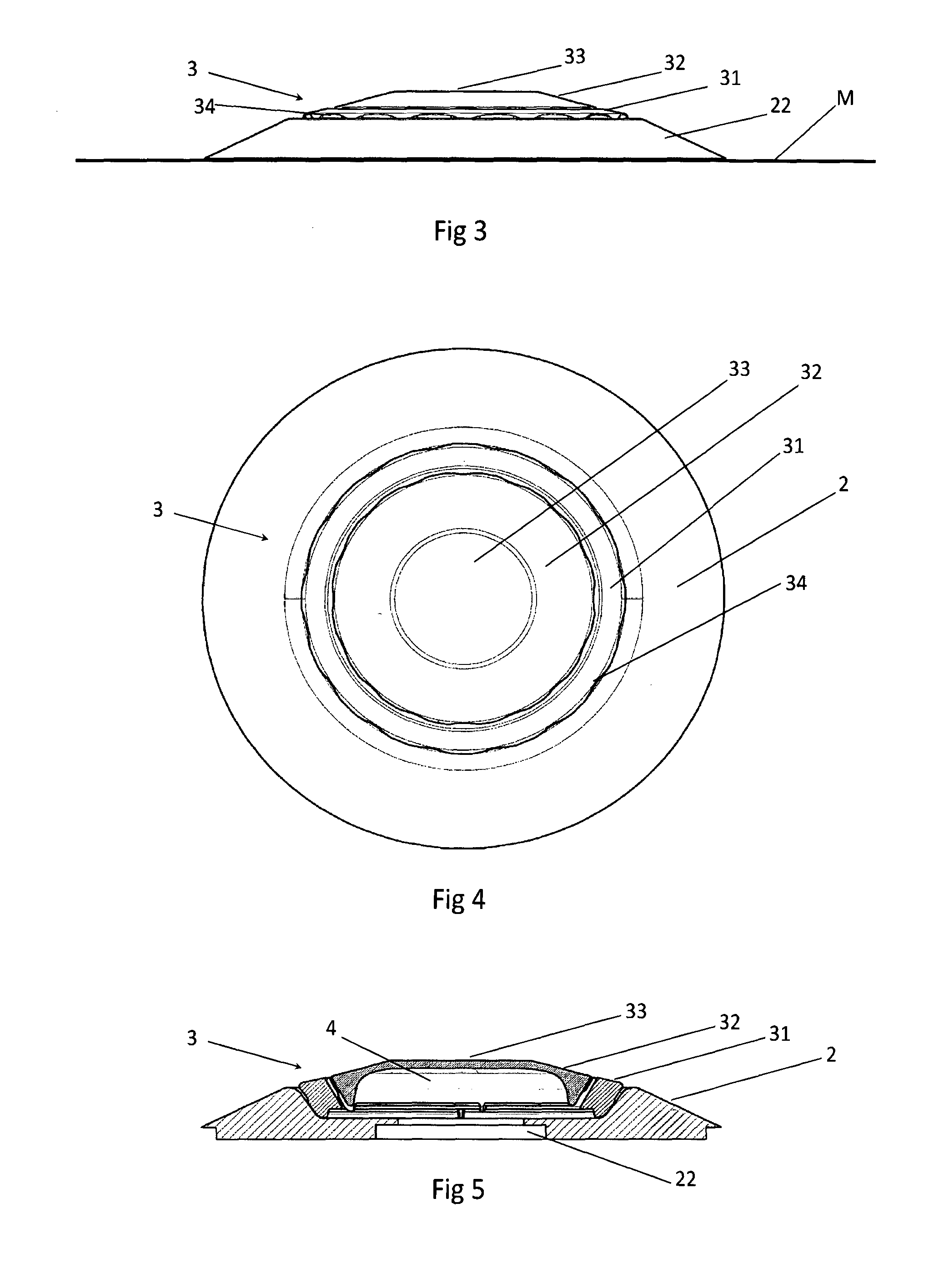

[0030]The accompanying FIG. 1 shows a general view of burner assembly constructed according to a preferred embodiment of the present invention allowing visualization of the base 2 which, in general, rests on the cooking table M which may also have lower prolongations (not shown) for connection to the internal components for interconnection with the supply source of gas and air.

[0031]In the embodiment shown—which, it should be noted, is illustrative and not restrictive, since the piece can present other aesthetic configurations without thereby escaping from the scope of protection claimed in the present application—the base 2 has a substantially frustoconical format comprising, in its internal region, a central orifice 22 for the coupling of system for feeding air-fuel mixture (not shown).

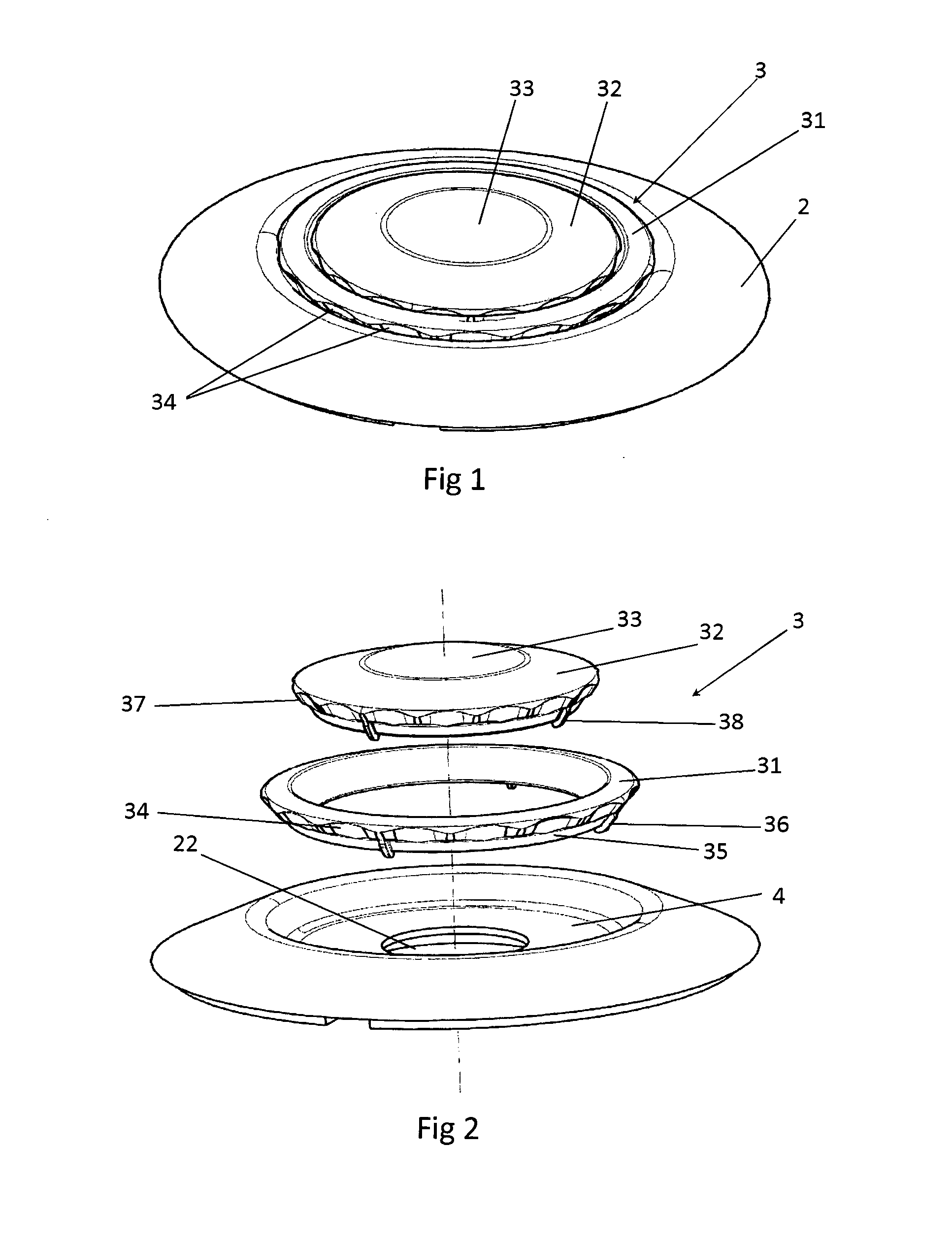

[0032]A spreading cover 3—better shown in FIG. 2—is, in the exemplary embodiment shown in the appended figures, consisting of a perimeter ring 31 to the center from which it couples a disc 32 with p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com