Experiment device for testing softening and dropping point of sinter

A technology of test experiment and drop point, which is applied in the investigation stage/state change, etc., can solve the problems that cannot meet the high-temperature softening drop detection requirements of high-basic sintered ore, and achieve the effect of convenient operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

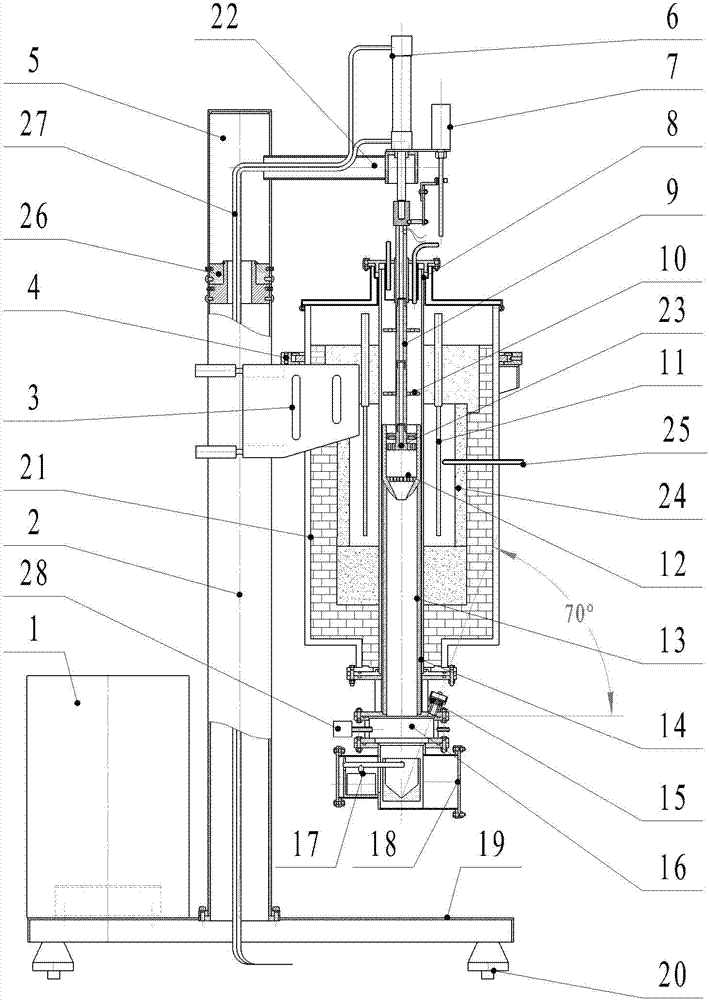

[0018] The experimental device for detecting sinter softening and dripping is realized in this way.

[0019] The specific implementation of the present invention is exactly the same as the content of the aforementioned invention, that is, the molybdenum disilicide heating element (11) is used as the heat source, and the power is supplied by a high-current transformer (1) whose power is 1.4-2.0 times greater than that of the heating element, so that the furnace body can The temperature in the high-temperature zone reaches 1650°C, and the constant temperature section in the high-temperature zone is not less than 120mm, thus meeting the actual needs of high-temperature performance testing of iron ore and high-alkalinity sintered ore.

[0020] The supporting furnace body structure adopts the furnace body chassis (19) to fix the furnace body fixing column (2), the furnace body chassis (19) is equipped with furnace body casters (20), and the high-current transformer (1) is installed ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com