Novel high-efficiency dedusting and desulphurization integrated system process for coke-tamping, coaling and coke-discharging ground station

A ground station and coal charging technology, which is applied in the fields of climate change adaptation, human health protection, chemical instruments and methods, etc., can solve the problem of not being able to effectively solve high-temperature tar paste cloth bags, failing to meet environmental protection emission requirements, and short operating life of cloth bags. and other problems, to achieve the effect of reduced labor intensity of workers, small footprint, and fewer operators

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

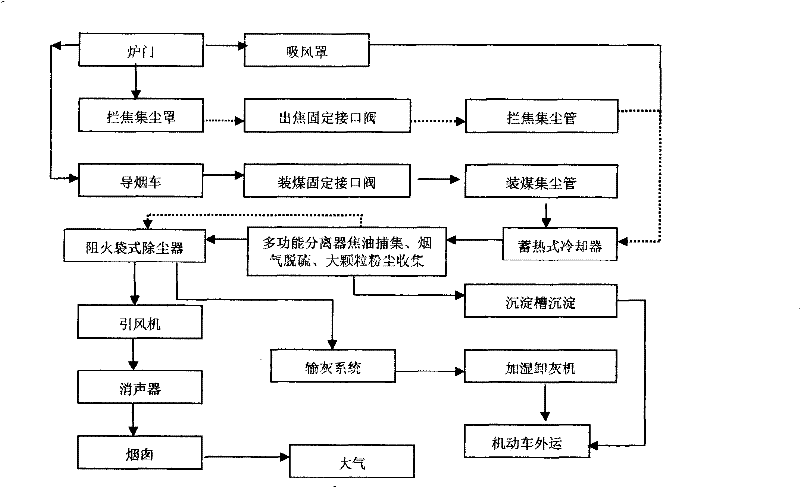

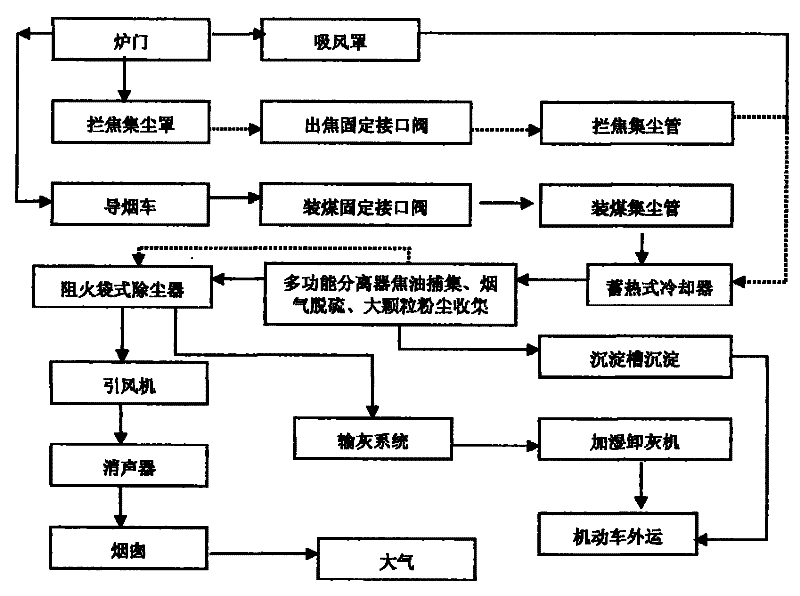

[0016] Such as figure 1 As shown, a new type of high-efficiency dust removal and desulfurization integrated system process for tamping coke charging, coal charging and coke discharge ground station, including the following steps:

[0017] (1) The upper part of the furnace door on both sides of the machine coke is equipped with a suction hood. If there is smoke occasionally at a certain furnace door, the butterfly valve here can be opened to suck the smoke into the main flue, preventing the dispersion and diffusion of the smoke. When coal is added, the soot gas emitted by the coke oven enters the regenerative cooler through the coal charging fixed interface valve and the coal charging dust collection pipe from the furnace top smoke guiding vehicle, and is cooled to below 120 ° C; The soot gas enters the regenerative cooler from the suction hood on the upper part of the furnace door through the coal charging dust collection pipe, and is cooled to below 120°C; The coke fixed in...

PUM

| Property | Measurement | Unit |

|---|---|---|

| dust removal efficiency | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com