A method of in-situ heating and mining oil shale with microwave step-down

A microwave heating, stepped technology, applied in the production of fluids, earthwork drilling, wellbore/well components, etc., can solve engineering problems, wellbore material failure, overheating and other problems, to improve efficiency, maintain heating efficiency, and high efficiency Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0031] A method for in-situ heating and exploitation of oil shale by microwave step-down, comprising the following steps:

[0032] (1) A microwave heating well is set on the oil shale ore layer, and the microwave heating well is located at the center of the oil and gas outlet fracture;

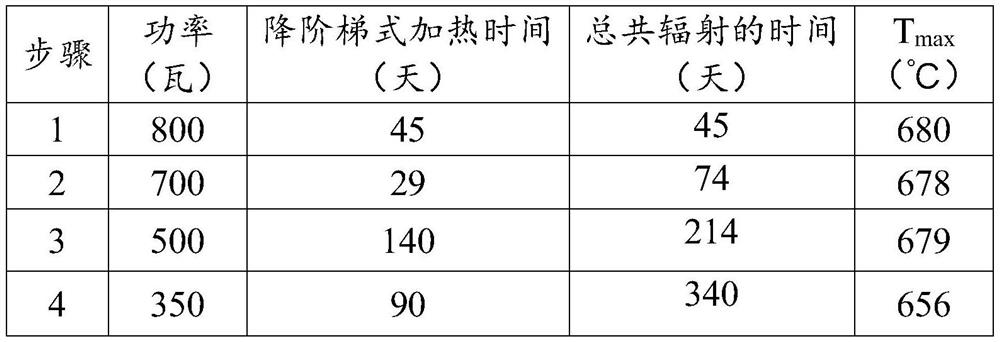

[0033] (2) Set the upper limit value of the temperature sensor to 700°C, turn on the microwave source through the control room, the power of the microwave source is 800W, and continuously radiate the formation for 45 days. When the monitoring temperature reaches 680°C, reduce the power to 700W at this time , continue to radiate for 29 days, and the monitoring temperature reaches 678°C; at this time, reduce the power to 500W, and continue to radiate for 140 days, when the monitoring temperature reaches 679°C; at this time, reduce the power to 350W, continue to radiate the formation for 126 days, and then monitor The temperature reaches 656° C. (see Table 1 for specific steps).

[0034] Assumin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com