Monomer for hardmask composition, hardmask composition including monomer, and pattern forming method using hardmask composition

一种硬掩模、组合物的技术,应用在用于光机械设备的光敏材料、对表面涂布液体的装置、图纹面的照相制版工艺等方向,能够解决难以提供具有优异轮廓精细图案等问题

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

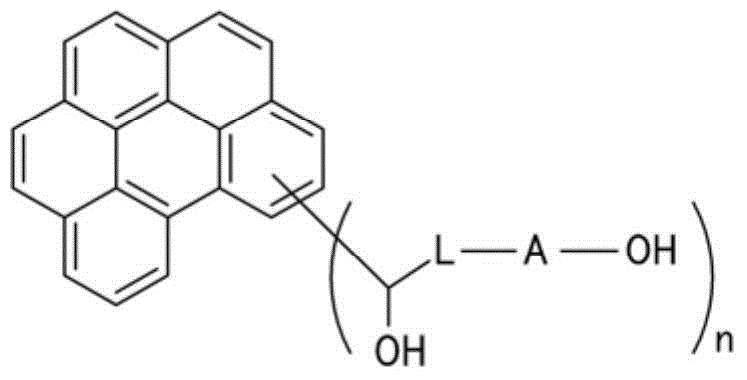

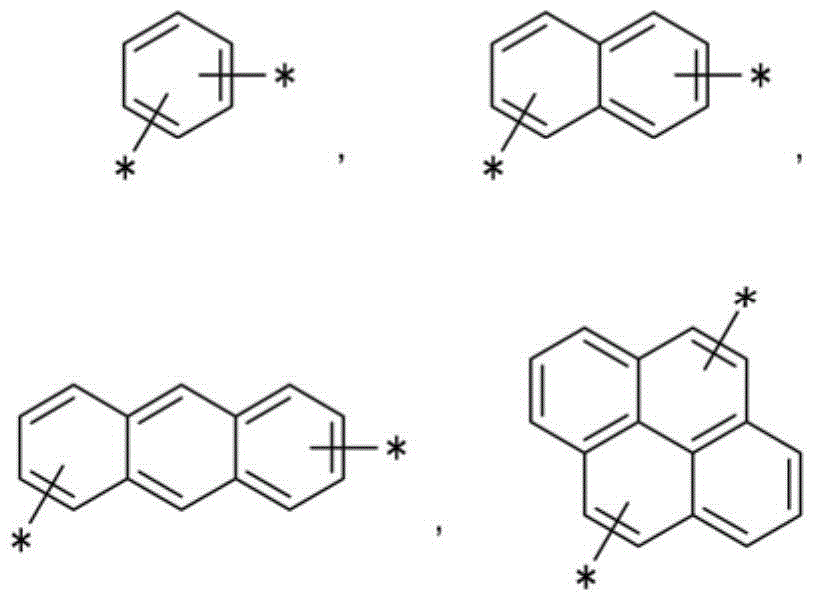

Method used

Image

Examples

Synthetic example 1

[0107] Introduce 27.6g (0.1mol) of benzoperylene and 22.1g (0.1mol) of methoxynaphthoyl chloride together with 500g of chloroform / dichloromethane mixed solution into a 2L three-necked flask, and stir with a stir bar. Then, the reaction was carried out while gradually adding 24.5 g (0.1 mol) of aluminum trichloride. The reaction was stirred at room temperature for 2 hours. After the completion of the reaction, 52.88 g (0.31 mol) of methoxybenzoyl chloride was added to the reactant and stirred, and the reaction was carried out while gradually adding 85.7 g (0.35 mol) of aluminum trichloride.

[0108] After reacting for 5 hours, aluminum trichloride was removed using water to provide reactant powder. The reactant powder, 60 g (1 mol) of acetic acid and 48.5 g (0.6 mol) of hydrogen bromide were introduced into a 500 mL three-necked flask and reacted at 130°C. After 6 hours, it settled in water to provide powder. The powder was washed several times and dissolved in tetrahydrofuran ...

Synthetic example 2

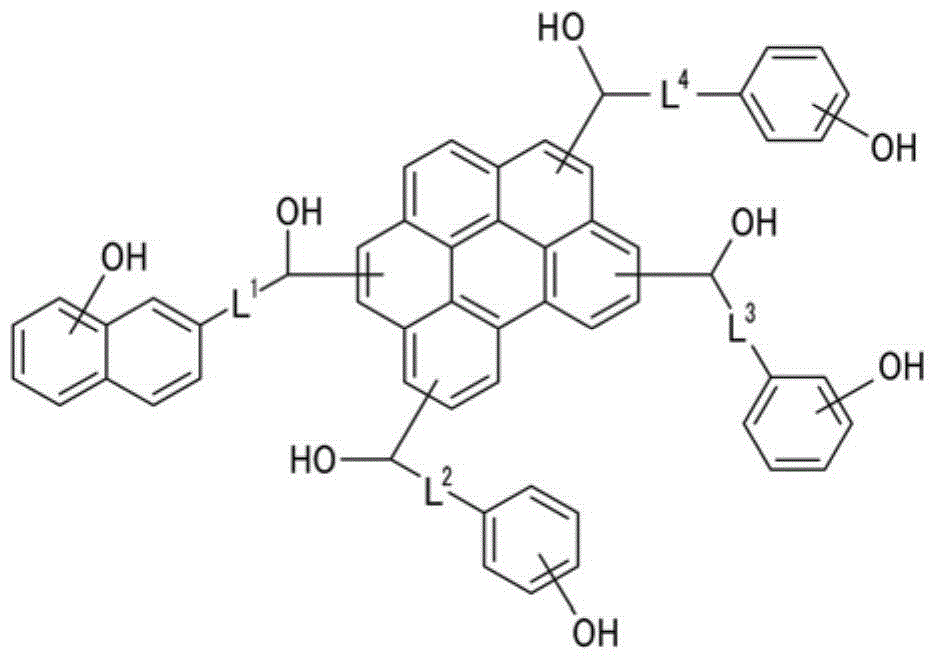

[0112] The monomer represented by the following chemical formula 1bb was obtained according to the same procedure as in Example 1, except that 91.14 g of 0.1 mol of methoxy pyrenyl chloride was used instead of 0.1 mol of methoxy naphthalene Formyl chloride.

[0113] [Chemical formula 1bb]

[0114]

Synthetic example 3

[0116] Introduce 27.6g (0.1mol) of benzoperylene and 68.4g (0.32mol) of methoxynaphthoyl chloride together with 500g of chloroform / dichloromethane mixed solution into a 2L three-necked flask, and stir with a stir bar. And the reaction was performed while gradually adding 85.7 g (0.35 mol) of aluminum trichloride. After the reaction is completed, the aluminum trichloride is removed using water to provide reactant powder. The reactant powder, 60 g (1 mol) of acetic acid and 48.5 g (0.6 mol) of hydrogen bromide were introduced into a 500 mL three-necked flask and reacted at 130° C. for 6 hours. It precipitates in water to provide powder. The powder was washed several times and dissolved in tetrahydrofuran (THF), and the reaction was carried out with gradually adding 18.98 g (0.5 mol) of lithium aluminum hydride. After the reaction is completed, side reactants are removed using a water / methanol mixture to provide a monomer represented by the following chemical formula 1cc.

[0117...

PUM

| Property | Measurement | Unit |

|---|---|---|

| molecular weight | aaaaa | aaaaa |

| weight-average molecular weight | aaaaa | aaaaa |

| weight-average molecular weight | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com