Aromatic polycarbonate resin composition and molded resin

A polycarbonate resin and aromatic technology, applied in the field of acid butyl, can solve the problems of high titanium content, insufficient polycondensation catalyst, and reduced heat resistance of the resin composition, and achieve the effect of excellent physical property balance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0237] Examples are shown below to describe the present invention more specifically, but the present invention is not limited to the following examples unless the gist is exceeded. In addition, in the following examples and comparative examples, the added amount refers to parts by weight.

[0238] When preparing each resin composition of an Example and a comparative example, the raw material shown below was prepared.

[0239]

[0240] PC-1: bisphenol A type aromatic polycarbonate produced by interfacial polymerization ("iupilon (upilon) S-3000FN" manufactured by Mitsubishi Engineering-Plastics Co., Ltd., Mv22500, terminal hydroxyl group concentration: 150ppm)

[0241] PC-2: Bisphenol A type aromatic polycarbonate produced by interfacial polymerization ("iupilon E-2000FN" manufactured by Mitsubishi Engineering-Plastics Corporation, Mv28000, terminal hydroxyl group concentration: 150ppm)

[0242] PC-3: bisphenol A type aromatic polycarbonate produced by the interfacial polyme...

manufacture example 1

[0244] Production example 1 (production of PBT-1):

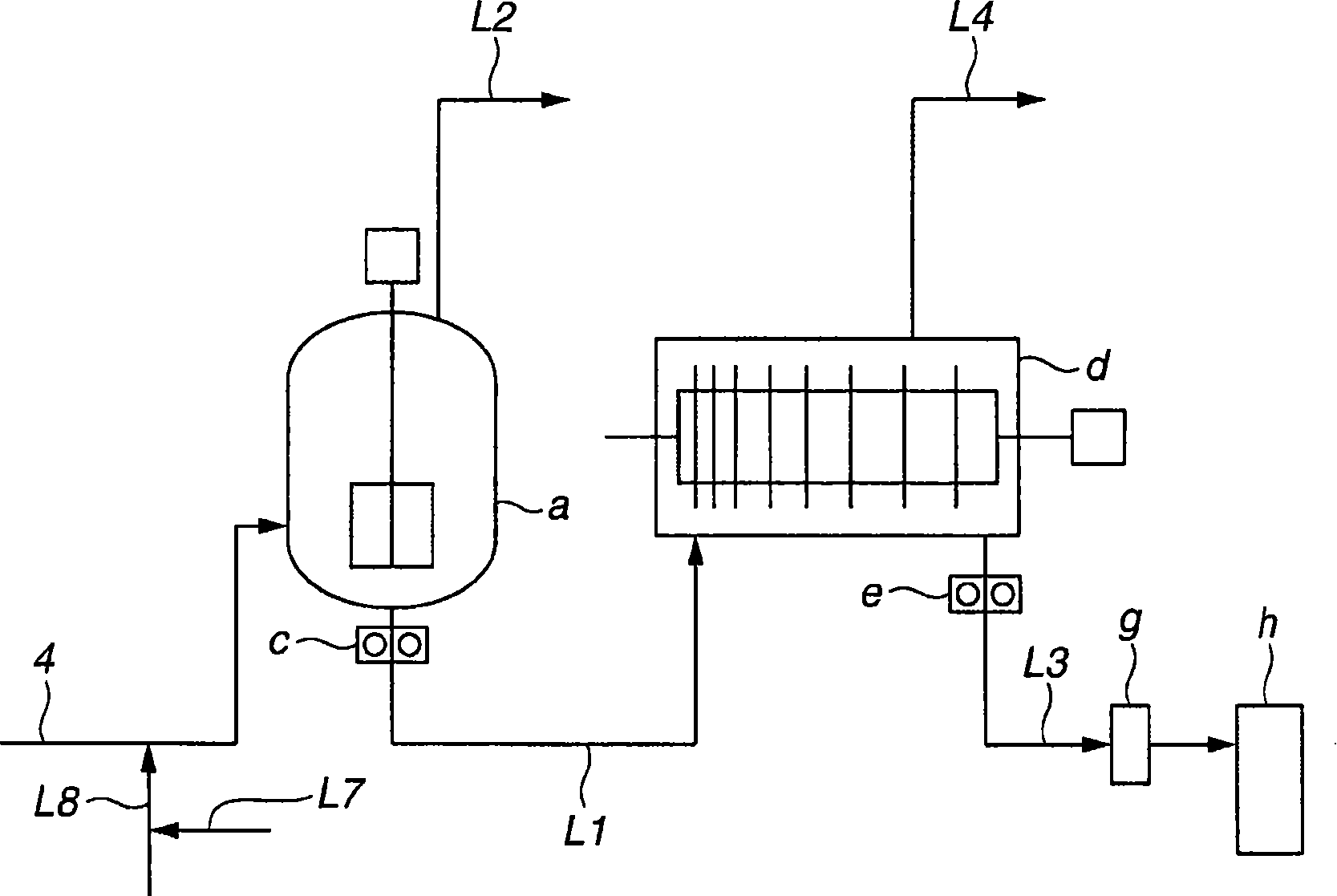

[0245] pass figure 1 In the esterification step shown and the polycondensation step shown in FIG. 3 , polybutylene terephthalate resin is produced in the following manner. First, a 60°C slurry mixed with 1.80 mol of 1,4-butanediol with respect to 1.00 mol of terephthalic acid was continuously fed at 40.0 kg / h from the slurry preparation tank through the raw material supply line (1). It was supplied to the reaction tank (A) for esterification which had the propeller type agitator filled with the polybutylene terephthalate oligomer of 99% of esterification rate beforehand.

[0246] At the same time, the bottom component of the rectification column (C) at 185° C. is supplied from the recirculation line (2) at 18.4 kg / h, and tetrabutylene at 65° C. is supplied as a catalyst at 127 g / h from the catalyst supply line (3). 6.0% by weight titanate solution in 1,4-butanediol (40 ppm relative to theoretical polymer yield). The water...

manufacture example 2

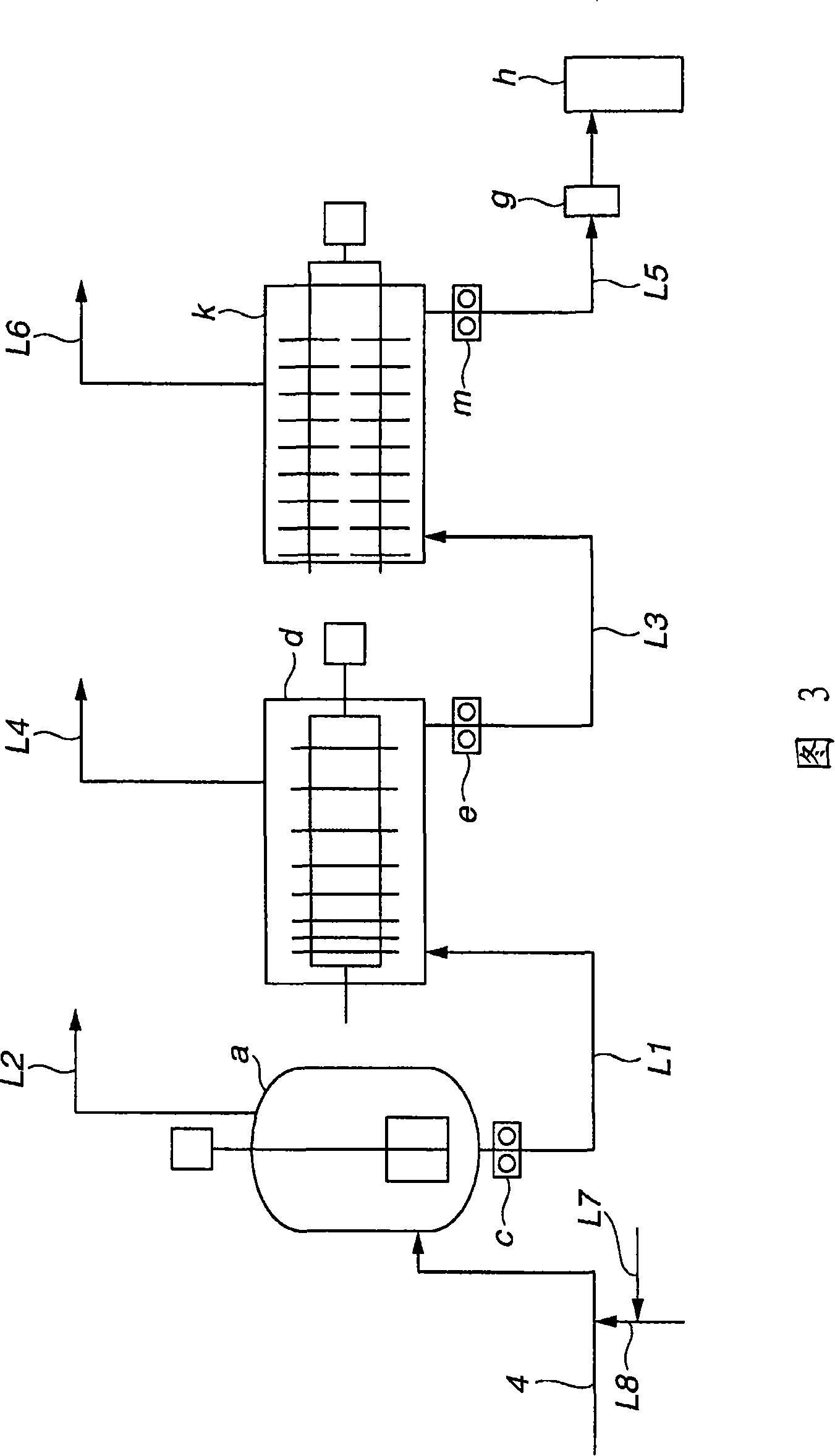

[0265] Production example 2 (production of PBT-2):

[0266] The esterification process in the reactor (A) is carried out in the same manner as PBT-1, and the polycondensation process uses figure 2 The procedure shown is carried out. The reaction conditions in the first polycondensation reaction tank (a) were the same as those of PBT-1, the internal temperature of the second polycondensation reaction tank (d) was 241° C., the pressure was 150 Pa, and the residence time was 70 minutes to obtain pellets. 50kg of the PBT pellets were solid-phase polymerized at 195°C under reduced pressure (below 0.133kPa) in a double-cone mixer (inner capacity 100L), and were taken out after a certain period of time to check the intrinsic viscosity. When the intrinsic viscosity is reached, the polymerization is stopped by cooling. The analytical values of the obtained PBT are summarized in Table 1. Hereinafter, the polybutylene terephthalate resin obtained in Production Example 2 is referred...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com