Formulation of high-manganese cupronickel brazing filler metal and production process of high-manganese cupronickel brazing filler metal

A technology of cupronickel and brazing material, which is applied in the direction of manufacturing tools, metal processing equipment, welding/cutting media/materials, etc., can solve the problems of expensive brazing material, high price, high welding cost of electron tubes, etc., and achieve simple production process Ease of implementation, high profit and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0029] A kind of formula of high manganese nickel-nickel brazing filler metal, comprising components and percentages are:

[0030] Ni: 10.5%;

[0031] Mn: 36.5%;

[0032] Cu: 53%.

[0033] Preferably, the physical and mechanical properties of the high-manganese-nickel-nickel solder are: solidus 912°C, liquidus 925°C, tensile strength 600MPa, elongation 35%, Brinell hardness HB180 and density 7.73kg / dm 2 ;

[0034] Preferably, the high-manganese-nickel-nickel solder is used for welding electron tubes.

[0035] Preferably, the high-manganese-nickel-nickel solder is a round wire.

[0036] Preferably, the diameter of the high-manganese-nickel-nickel solder of the round wire is 0.8-4.0 mm.

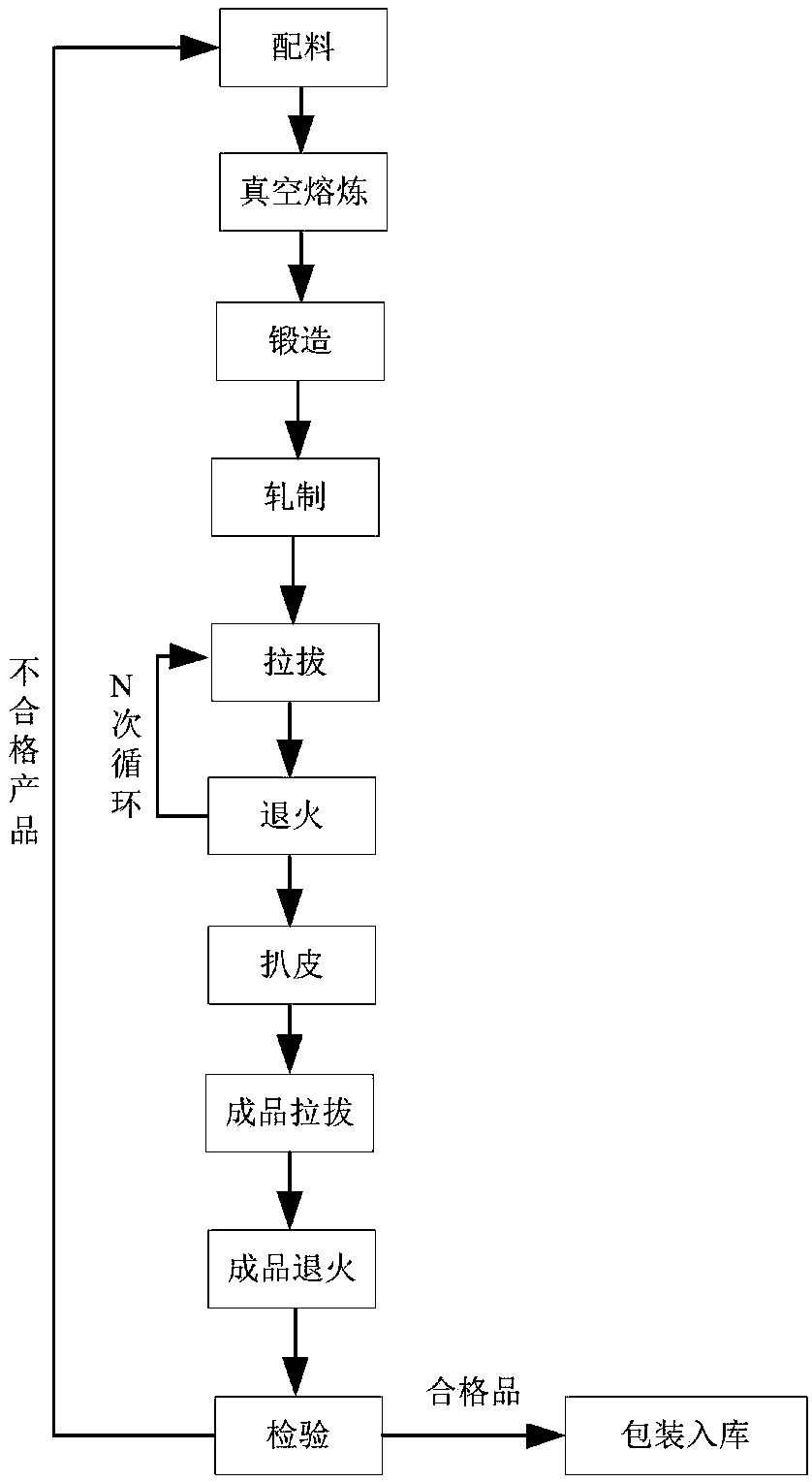

[0037] A kind of production technology of high manganese white copper brazing filler metal, the steps comprising include:

[0038] (1) batching: batching is carried out according to the formula of described a kind of high manganese white copper solder, 50 kilograms of every batches;

...

Embodiment 2

[0047] A kind of formula of high manganese nickel-nickel brazing filler metal, comprising components and percentages are:

[0048] Ni: 8.5%;

[0049] Mn: 38.5%;

[0050] Cu: 53%.

[0051] Preferably, the physical and mechanical properties of the high-manganese white copper solder are: solidus 902°C, liquidus 915°C, tensile strength 500MPa, elongation 45%, Brinell hardness HB160 and density 7.67kg / dm 2 ;

[0052] Preferably, the high-manganese-nickel-nickel solder is used for welding electron tubes.

[0053] Preferably, the high-manganese-nickel-nickel solder is a round wire.

[0054] Preferably, the diameter of the high-manganese-nickel-nickel solder of the round wire is 0.8-4.0 mm.

[0055] A kind of production technology of high manganese white copper brazing filler metal, the steps comprising include:

[0056] (1) batching: batching is carried out according to the formula of described a kind of high manganese white copper solder, 50 kilograms of every batches;

[0...

Embodiment 3

[0065] A kind of formula of high manganese nickel-nickel brazing filler metal, comprising components and percentages are:

[0066] Ni: 9.5%;

[0067] Mn: 37.5%;

[0068] Cu: 53%.

[0069] Preferably, the physical and mechanical properties of the high-manganese white copper solder are: solidus 907°C, liquidus 920°C, tensile strength 550MPa, elongation 40%, Brinell hardness HB170 and density 7.7kg / dm 2 ;

[0070] Preferably, the high-manganese-nickel-nickel solder is used for welding electron tubes.

[0071] Preferably, the high-manganese-nickel-nickel solder is a round wire.

[0072] Preferably, the diameter of the high-manganese-nickel-nickel solder of the round wire is 0.8-4.0 mm.

[0073] A kind of production technology of high manganese white copper brazing filler metal, the steps comprising include:

[0074](1) batching: batching is carried out according to the formula of described a kind of high manganese white copper solder, 50 kilograms of every batches;

[007...

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

| Brinell hardness | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com