Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

48results about How to "Excellent balance of physical properties" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Scratch-Resistant Flameproof Thermoplastic Resin Composition with Improved Compatibility

Disclosed herein is a scratch-resistant flameproof thermoplastic resin composition, the resin composition comprising a base resin including (A) about 50 to about 90% by weight of a polycarbonate resin; (B) about 1 to about 50% by weight of a methacrylic copolymer resin with a refractive index of about 1.495 to about 1.590; and (C) about 0 to about 49% by weight of a (meth)acrylic resin, and (D) about 5 to about 40 parts by weight of a flame retardant, based on about 100 parts by weight of the base resin comprising (A)+(B)+(C). The resin composition of the present invention can have good flame retardancy, scratch resistance, colorability, and good appearance due to its improved compatibility. The resin composition of the invention can be used to produce plastic molded articles which can exhibit better physical properties than products produced using conventional resin compositions.

Owner:LOTTE ADVANCED MATERIALS CO LTD

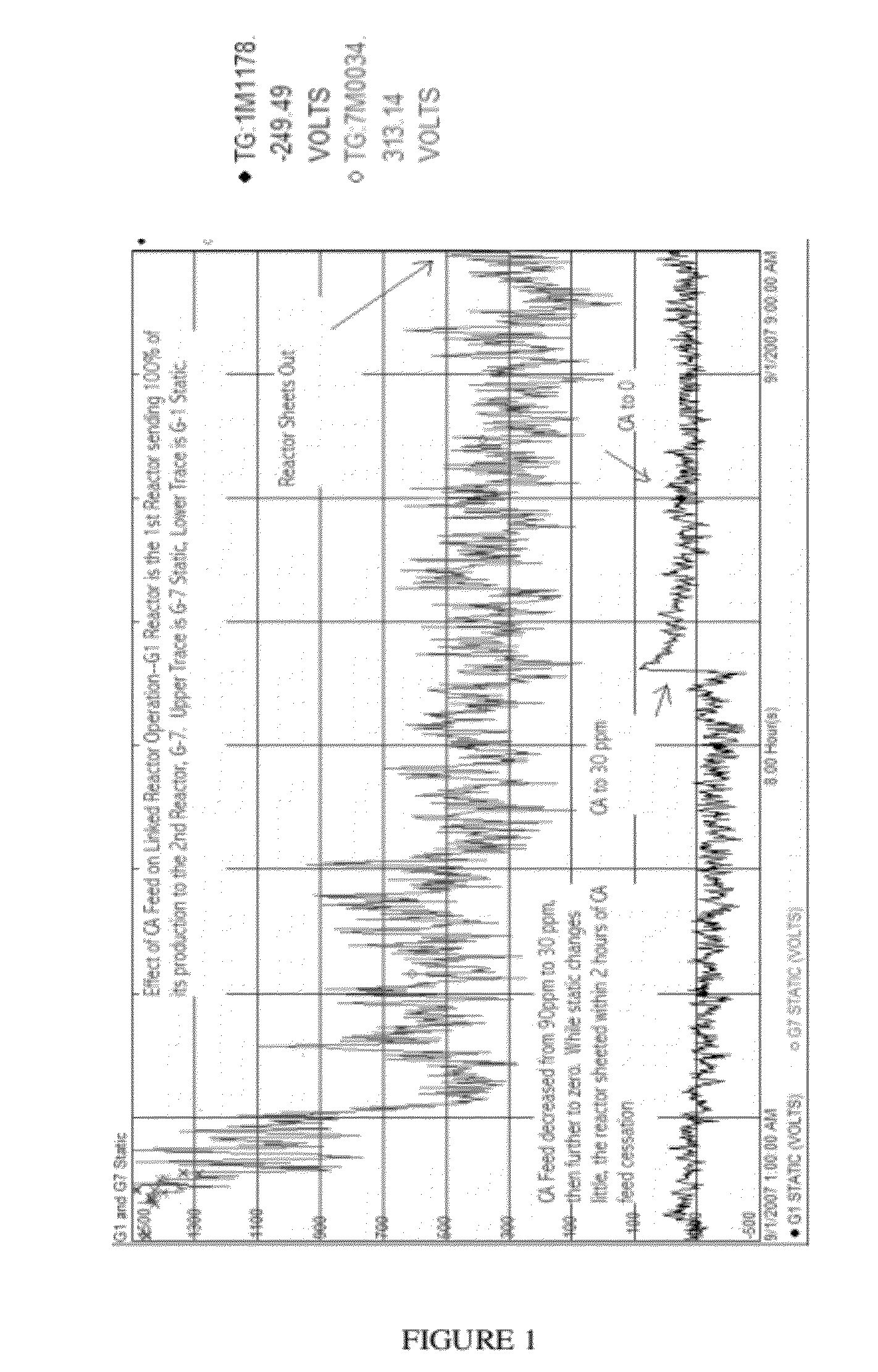

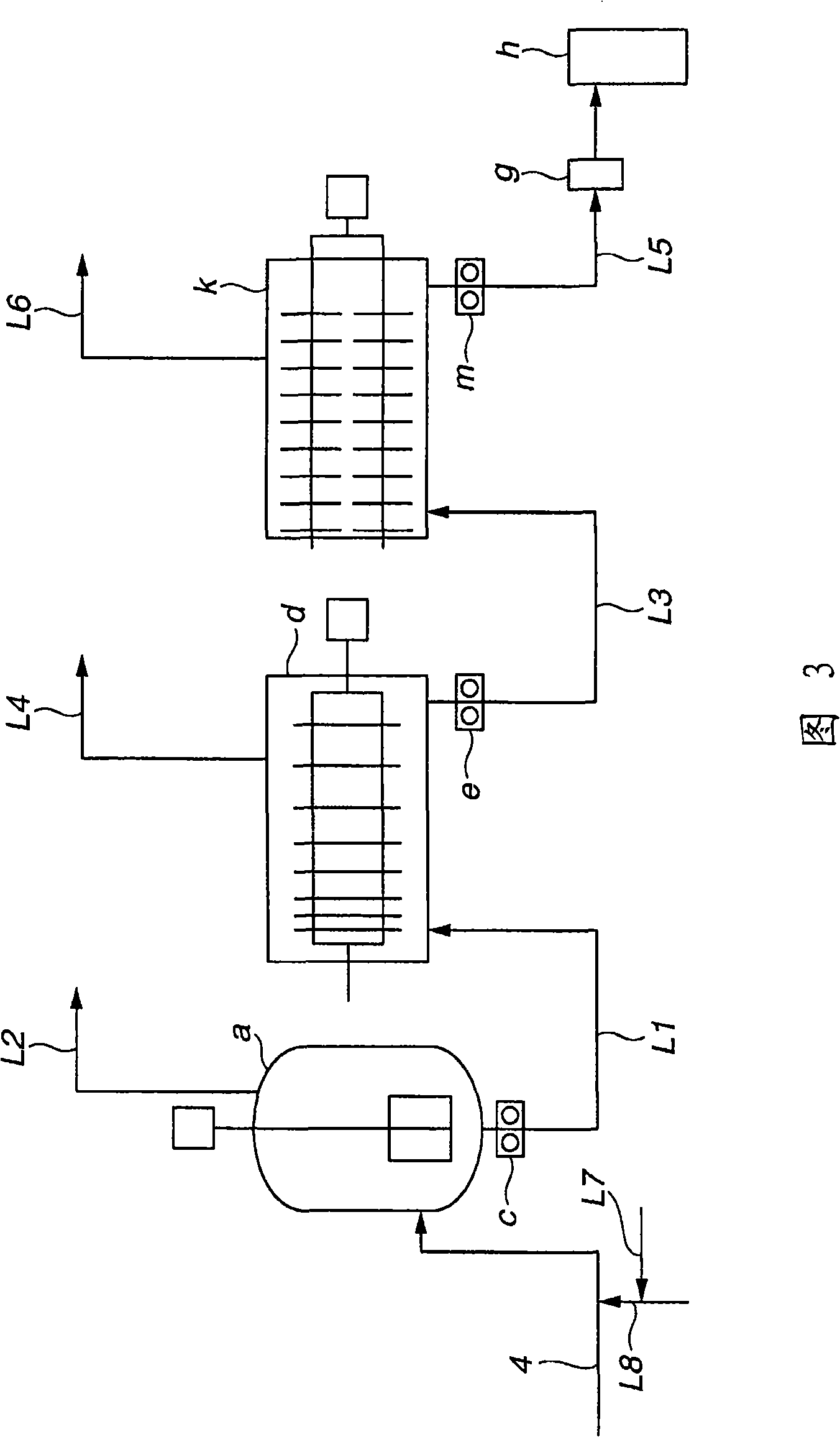

Ethylene copolymers, film and polymerization process

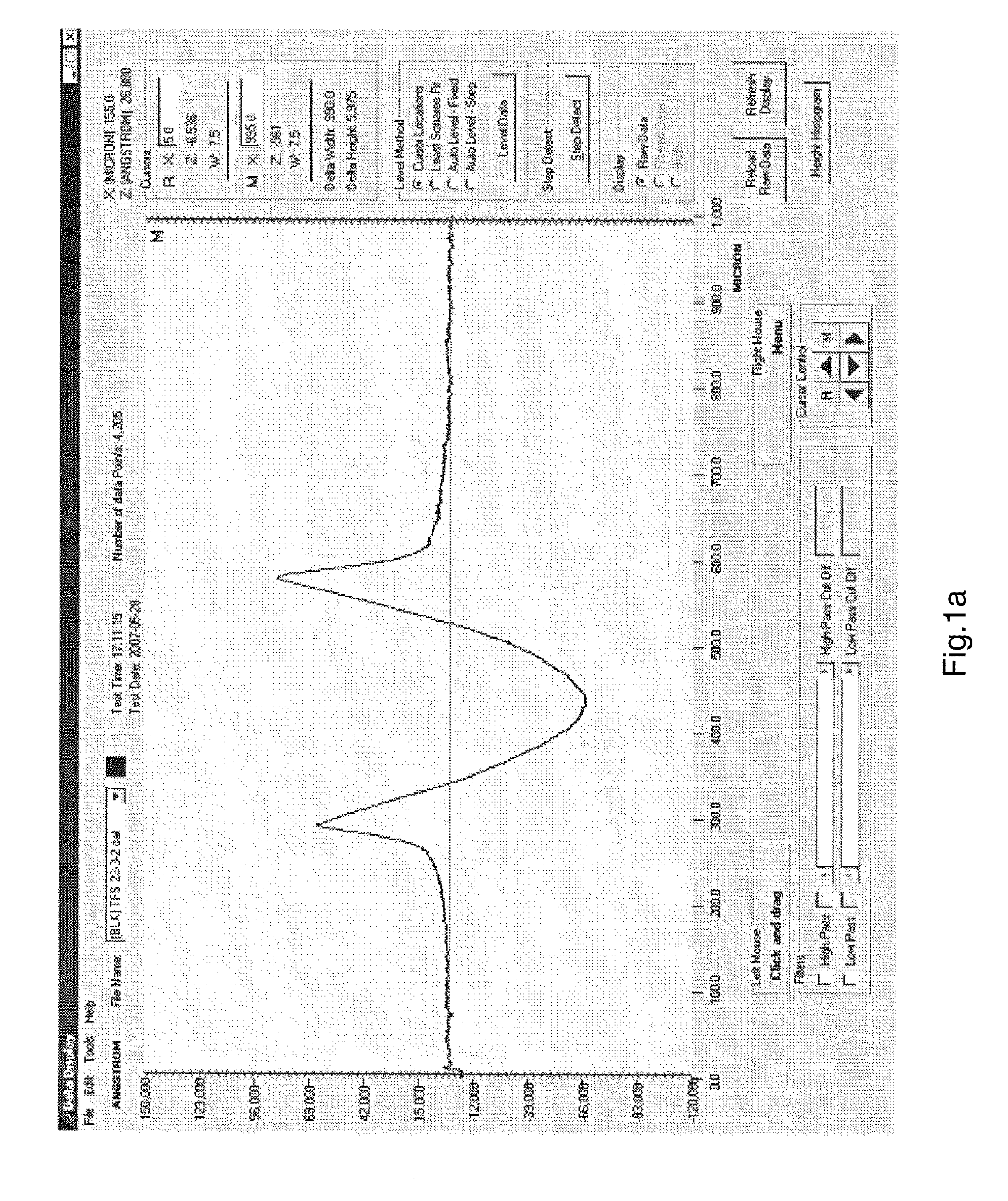

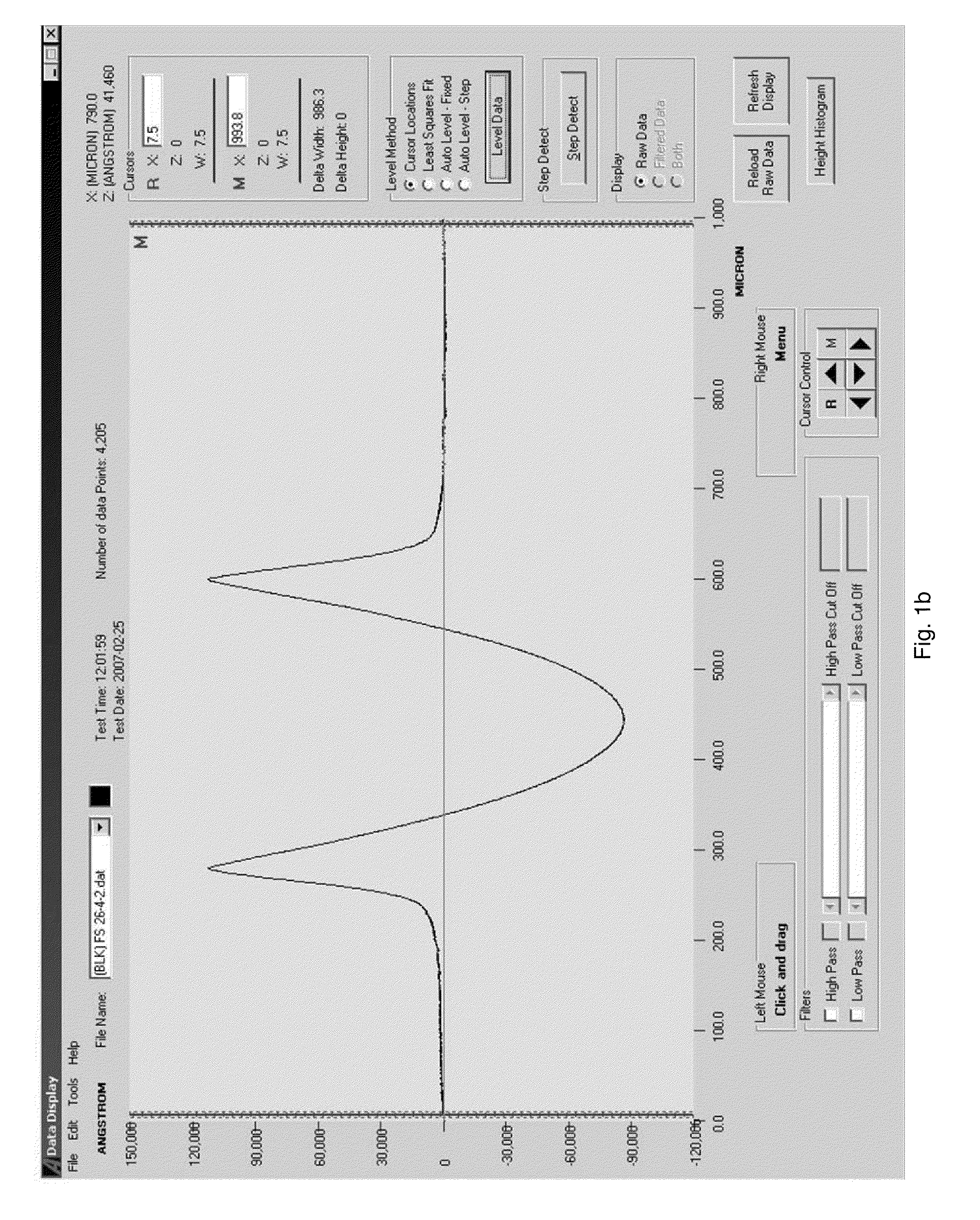

ActiveUS9079991B2Easy to processExcellent balance of physical propertiesSynthetic resin layered productsPolymer scienceFractionation

Ethylene copolymers having a relatively high melt flow ratio and a multimodal profile in a temperature rising elution fractionation (TREF) plot are disclosed. The copolymers can be made into film having good dart impact values and good stiffness properties under decreased extruder pressures.

Owner:NOVA CHEM (INT) SA

Molded article for interior parts of a car

ActiveUS6964997B2Good formabilityGloss and scratch resistanceLayered productsConductive materialShell moldingAlpha-olefin

The present invention relates to interior parts of a car comprising a new propylene resin composition. The present resin composition has good molding abilities and a good balance of physical properties as well as a good appearance, lower gloss and scratch resistance. Specifically, the present invention relates to a molded article for interior parts of a car comprising a polypropylene resin composition comprising the following components; a crystalline homopolypropylene having MFR of 500 to 3,000 g / 10 min.; a polypropylene consisting of a crystalline homopolypropylene and an ethylene-propylene copolymer rubber having 45 to 80% by mass of a ethylene content; a polypropylene consisting of a crystalline homopolypropylene and an ethylene-propylene copolymer rubber having 25% by mass or more to below 45% by mass of a ethylene content; and an ethylene-α-olefin copolymer rubber.

Owner:NISSAN MOTOR CO LTD

Resin Composition Having Good Scratch Resistance

ActiveUS20090043047A1Improve scratch resistanceExcellent balance of physical propertiesMeth-Core shell

A resin composition having good scratch resistance includes about 5 to about 50 parts by weight of core-shell graft resin (A) and about 95 to about 50 parts by weight of resin (B) which includes about 40 to about 100% by weight of (meth)acrylic acid alkyl ester. The outer shell of the core-shell graft resin (A) comprises (meth)acrylic acid alkyl ester.

Owner:LOTTE ADVANCED MATERIALS CO LTD

Ethylene-based polymer compositions, methods of making the same, and articles prepared from the same

The invention provides a composition comprising a blend, which comprises a high molecular weight ethylene-based polymer, and a low molecular weight ethylene-based polymer, and wherein the high molecular weight ethylene-based polymer has a density less than, or equal to, 0.955 g / cm3, and wherein the blend has a high load melt index (I21) greater than, or equal to, 15 g / 10 min, and wherein the blend has a molecular weight distribution (Mw / Mn) greater than, or equal to, 15. The invention also provides a composition comprising a blend, which comprises a high molecular weight ethylene-based polymer and a low molecular weight ethylene-based polymer, and wherein the high molecular weight ethylene-based polymer component has a density less than, or equal to, 0.945 g / cm3, and a melt index (I2) less than, or equal to, 0.1 g / 10 min, and wherein the blend has a high load melt index (I21) less than, or equal to, 15 g / 10 min, and a melt index (I5) less than, or equal to 1 g / 10 min, and a molecular weight distribution (Mw / Mn) greater than, or equal to, 15. Additional compositions are disclosed.

Owner:DOW GLOBAL TECH LLC

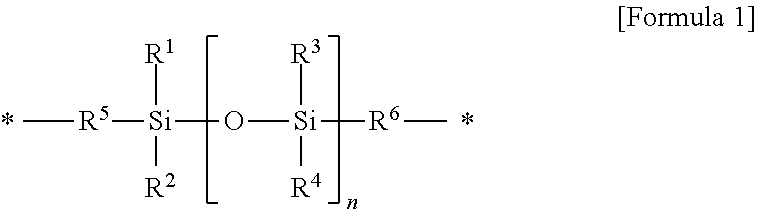

Polycarbonate-Polysiloxane Copolymer, and Method for Preparing Same

The present invention relates to a polycarbonate-polysiloxane copolymer containing a polysiloxane unit. The polycarbonate-polysiloxane copolymer of the present invention includes an aliphatic terminal having a specific carbon number, thereby having excellent impact properties at low temperature, and high transparency.

Owner:CHEIL IND INC

Thermoplastic resin composition

InactiveUS7282535B2Excellent balance of physical propertiesMaintain propertiesAcrylic polymerPolymer chemistry

A thermoplastic resin composition comprising a thermoplastic resin (a) and a block copolymer (b) containing a methacrylic polymer block (A) and an acrylic polymer block (B).

Owner:KANEKA CORP

Molded inorganic-fiber object and process for producing same

ActiveCN103781954AImprove thermal shock resistanceExcellent balance of physical propertiesExhaust apparatusSilencing apparatusHazardous substanceShock resistance

Provided is a molded inorganic-fiber object which is characterized by being extremely lightweight, being reduced in flying of fibers or a particulate substance from the surface thereof, and being free from problems concerning environmental pollution, such as generation of a harmful substance. The molded object is excellent in terms of thermal shock resistance and mechanical shock resistance and of resistance to high-speed wind erosion, has an excellent balance among material properties, and can be used in various heat insulator applications. The molded inorganic-fiber object comprises inorganic fibers and inorganic binder particles and has at least a pair of regions, a high-fiber-density region and a low-fiber-density region, wherein the ratio of the content of the binder particles in the high-fiber-density region to the content thereof in the low-fiber-density region, as determined by a given method, is 0.5:1 to 5:1 and the inorganic binder particles in the outermost surface of the molded object have a number-average particle diameter, as determined by a given method, of 20-35 [mu]m, the number of the inorganic binder particles therein being less than 15.

Owner:MAFTEC CO LTD

Thermoplastic resin composition

A thermoplastic resin composition which comprises a thermoplastic resin (a) and a block copolymer (b) comprising a methacrylic polymer block (A) and an acrylic polymer block (B).

Owner:KANEKA CORP

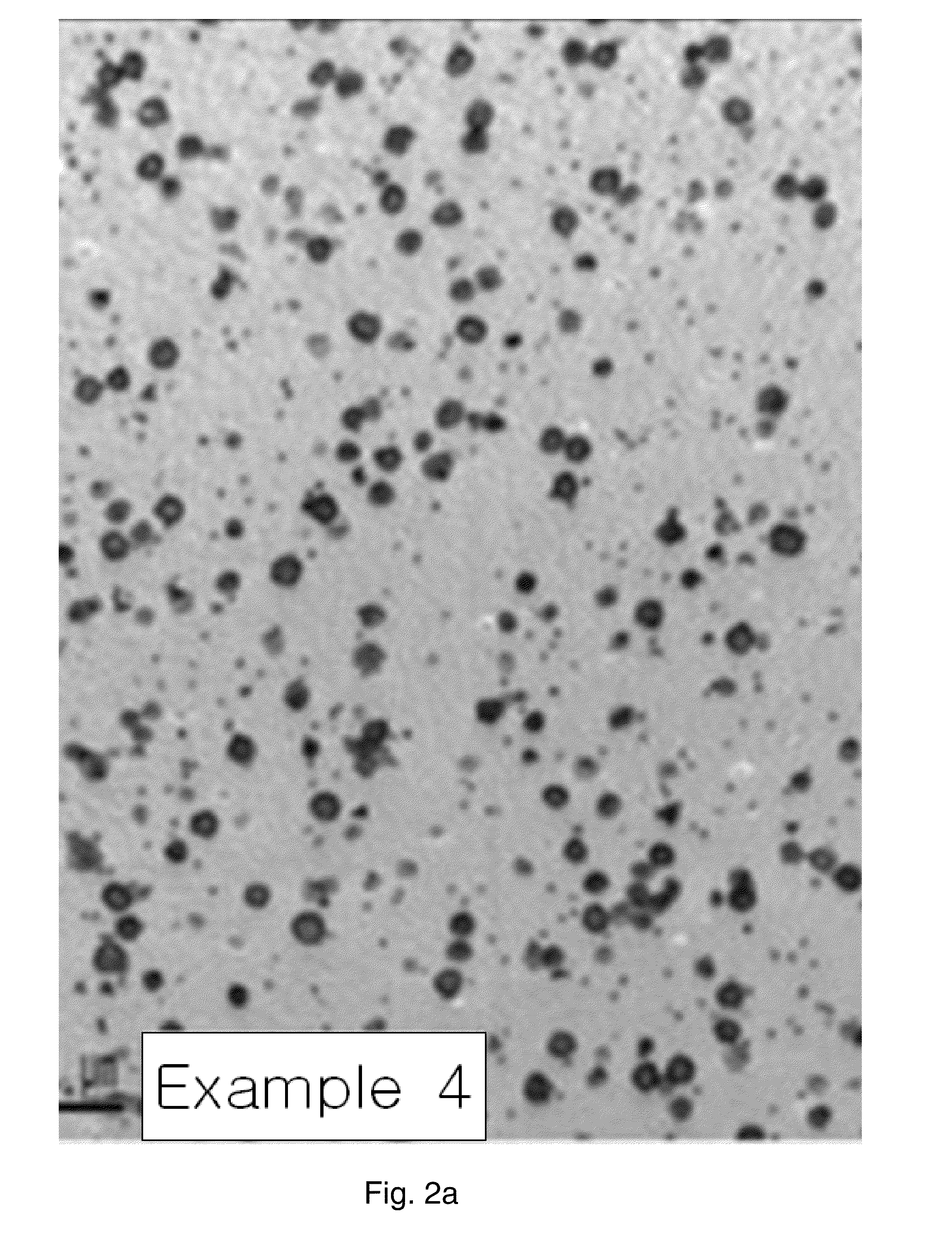

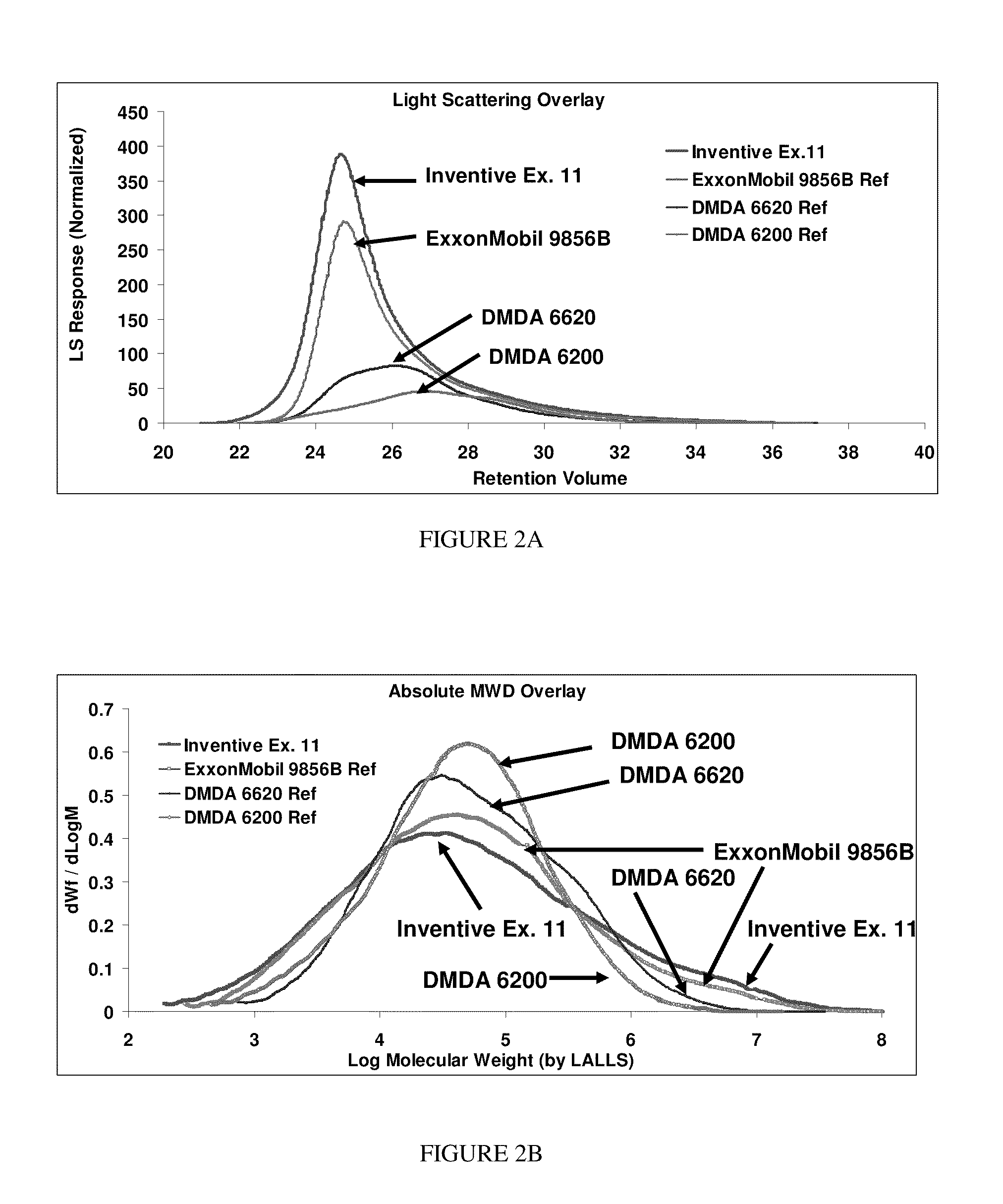

Ethylene-based polymer compositions, methods of making the same, and articles prepared from the same

ActiveUS9175111B2Easy to processExcellent balance of physical propertiesVolumetric Mass DensityHigh load

The invention provides a composition comprising a blend, which comprises a high molecular weight ethylene-based polymer, and a low molecular weight ethylene-based polymer, and wherein the high molecular weight ethylene-based polymer has a density less than, or equal to, 0.955 g / cm3, and wherein the blend has a high load melt index (I21) greater than, or equal to, 15 g / 10 min, and wherein the blend has a molecular weight distribution (Mw / Mn) greater than, or equal to, 15. The invention also provides a composition comprising a blend, which comprises a high molecular weight ethylene-based polymer and a low molecular weight ethylene-based polymer, and wherein the high molecular weight ethylene-based polymer component has a density less than, or equal to, 0.945 g / cm3, and a melt index (I2) less than, or equal to, 0.1 g / 10 min, and wherein the blend has a high load melt index (I21) less than, or equal to, 15 g / 10 min, and a melt index (I5) less than, or equal to 1 g / 10 min, and a molecular weight distribution (Mw / Mn) greater than, or equal to, 15. Additional compositions are disclosed.

Owner:DOW GLOBAL TECH LLC

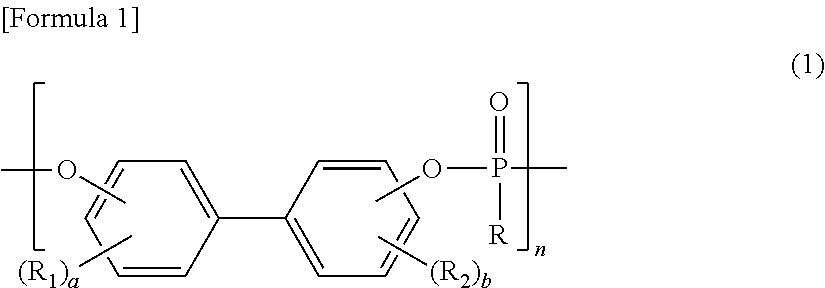

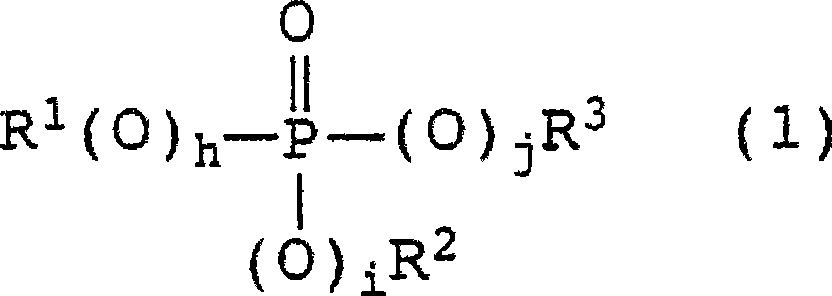

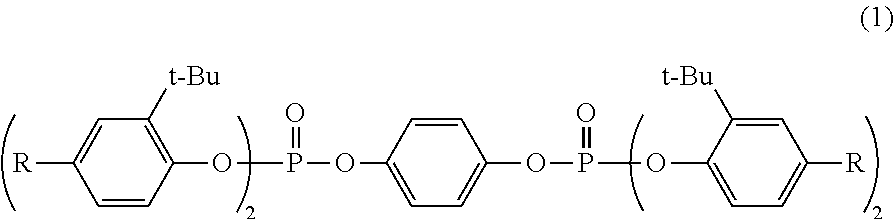

Biphenyl Polyphosphonate, Method for Preparing the Same and Thermoplastic Resin Composition Including the Same

Disclosed herein is a biphenyl polyphosphonate. The biphenyl polyphosphonate is represented by Formula 1:wherein R is hydrogen, substituted or unsubstituted C1-C5 alkyl, substituted or unsubstituted C2-C5 alkenyl, substituted or unsubstituted C5-C6 cycloalkyl, substituted or unsubstituted C5-C6 cycloalkenyl, substituted or unsubstituted C6-C20 aryl, or substituted or unsubstituted C6-C20 aryloxy, R1 and R2 are the same or different and are each independently substituted or unsubstituted C1-C6 alkyl, substituted or unsubstituted C5-C6 cycloalkyl, substituted or unsubstituted C6-C12 aryl, or halogen, a and b are the same or different and are each independently an integer from about 0 to about 4, and n is an integer from about 4 to about 500.

Owner:CHEIL IND INC

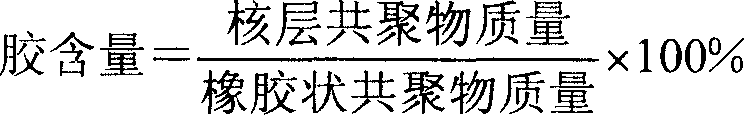

Transparent rubber modified thenylethylene resin composition

The invention discloses a rubber particle discontinuous phase and transparent rubber modified styrene resin compound, which is characterized by the following: forming rubber particle discontinuous phase with rubber copolymer; comprising 10-50 rubber particle discontinuous phase and 90-50 wt base blending copolymer; setting the rubber particle discontinuous phase as 20-80 wt core layer copolymer and 80-20 wt shell layer copolymer; setting the core layer copolymer as 5-50 wt styrene monomer and 95-50 wt diene monomer; setting the shell layer copolymer as 10-70 wt styrene monomer and 90-30 wt (metyl group) acrylic ester monomer; setting the base blending copolymer as 20-80 wt polymethyl methacryate resin and 80-20 wt styrene-acrylonitrile copolymer resin; setting the grain diameter of the core layer copolymer at 100-1000nm. This product possesses good transparency, shockproof property and chemical medicine resistance property.

Owner:BC P INC CHINA NAT PETROLEUM CORP +1

Thermoplastic resin composition and resin molding

Disclosed is a thermoplastic resin composition which comprises: an aromatic polycarbonate resin (component A) (which may comprise an aromatic polycarbonate resin (component A1) and a thermoplastic resin other than an aromatic polycarbonate resin (component A2)); a granulated talc (component B) which comprises a talc having an average particle diameter of 0.1 to 10 [mu]m, wherein the talc is so granulated as to have a bulk density of 0.4 to 1.5 g / ml; a rubbery polymer (component C, an optional component); a flame retardant (component E, an optional component); and a fluorinated polyolefin (component F, an optional component); wherein the granulated talk (component B) has such a grain size that the ratio of granules trapped on a 500 [mu]m-mesh sieve is 55% by weight or more. Also disclosed is a resin molded article formed by molding the thermoplastic resin composition. The thermoplastic resin composition and the resin molded article are excellent in extrusion moldability, stiffness, flame retardancy, impact resistance and thermal stability and show excellent balance among physical properties.

Owner:MITSUBISHI ENG PLASTICS CORP

Toughness reinforcing phenylethylene resin composition of transparent rubber and method for preparing the same

The invention discloses a preparing method of rubber toughening styrene transparent pitch compound, which is characterized by the following: forming rubber particle discontinuous phase with 50-90 wt copolymer continuous phase and 50-10 wt rubber-like polymer; mixing; getting the product; setting the rubber particle discontinuous phase as 20-80 wt core layer copolymer and 80-20 wt shell layer copolymer; proceeding suspension polymerization with 30-60 wt styrene monomer, 20-60 wt (metyl group) acrylic ester monomer, 5-30 wt acrylic nitrile or methacrylonitrile monomer; getting the copolymer continuous phase. This pitch possesses better transparency, shockproof property and chemical medicine resistance property.

Owner:BC P INC CHINA NAT PETROLEUM CORP +1

Thermoplastic resin composition having excellent chemical resistance and easy vacuum formability

InactiveUS20040054077A1Good physical propertiesGood vacuum formabilityDomestic articlesCyanide compoundEmulsion polymerization

The resin composition according to the present invention comprises (A) a graft polymer prepared by grafting in emulsion polymerization 100 parts by weight of monomer mixture comprising 20-30% by weight of vinyl cyanide compound and 70-80% by weight of vinyl aromatic compound to 20-60 parts by weight of diene rubber, (B) a graft polymer prepared by grafting in emulsion polymerization 100 parts by weight of monomer mixture comprising 20-30% by weight of vinyl cyanide compound and 70-80% by weight of vinyl aromatic compound to 20-60 parts by weight of acrylic rubber, (C) a linear copolymer prepared by polymerizing 40-50% by weight of vinyl cyanide compound and 50-60% by weight of vinyl aromatic compound, and (D) a branched copolymer prepared by 30-35% by weight of vinyl cyanide compound and 65-70% by weight of vinyl aromatic compound.

Owner:CHEIL IND INC

Aromatic polycarbonate resin composition and molded resin

ActiveCN101346430ASatisfy mobilityMeet the rigidityProductsReagentsPolytetramethylene terephthalatePolybutylene terephthalate

An aromatic polycarbonate resin composition which comprises an aromatic polycarbonate resin (ingredient (A)) and a polybutylene terephthalate resin (ingredient (B)) and optionally further contains a rubbery polymer and / or an inorganic filler, characterized in that the amounts of the aromatic polycarbonate resin (ingredient (A)) and the polybutylene terephthalate resin (ingredient (B)) are 51-99 parts by weight and 1-49 parts by weight, respectively, per 100 parts by weight of the sum of the aromatic polycarbonate resin (ingredient (A)) and the polybutylene terephthalate resin (ingredient (B)) and that the polybutylene terephthalate resin (ingredient (B)) has a titanium compound content of 1-75 ppm, excluding 1 ppm, in terms of titanium atom amount and a terminal carboxy group content of 39 [mu]eq / g or lower. This aromatic polycarbonate resin composition has an excellent balance among various properties, i.e., is satisfactory in all of flowability, rigidity, impact resistance, chemical resistance, fatigue characteristics, heat resistance, thermal stability in residence, and suitability for recycling.

Owner:MITSUBISHI ENG PLASTICS CORP

Resin composition having good scratch resistance

A resin composition having good scratch resistance includes about 5 to about 50 parts by weight of core-shell graft resin (A) and about 95 to about 50 parts by weight of resin (B) which includes about 40 to about 100% by weight of (meth)acrylic acid alkyl ester. The outer shell of the core-shell graft resin (A) comprises (meth)acrylic acid alkyl ester.

Owner:LOTTE ADVANCED MATERIALS CO LTD

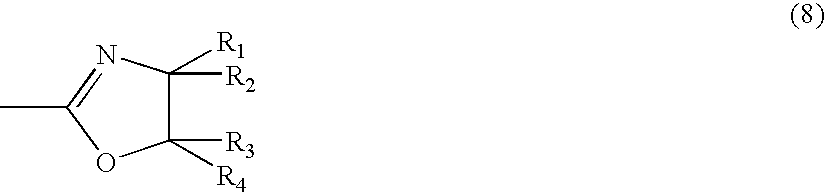

Cross-linked Polyphosphonate, Method of Preparing the Same, and Flame Retardant Thermoplastic Resin Composition Including the Same

InactiveUS20120172547A1Improve flame retardant performanceHigh impact strengthCross-linkHeat resistance

A cross-linked polyphosphonate and a thermoplastic resin composition including the cross-linked polyphosphonate are disclosed. The composition may have excellent flame retardancy and mechanical strength and superior appearance and heat resistance.

Owner:CHEIL IND INC

Copolymer for polymer blend compatibilizer and resin composition

ActiveUS20180134820A1Good physical propertiesImprove liquidityVehicle componentsHeat resistanceToughness

An object of the present invention is to provide a copolymer for a compatibilizer capable of increasing impact resistance strength, heat resistance and toughness without lowering fluidity. The copolymer for a compatibilizer contains polyamide resin and at least one resin selected from ABS resin, SAN resin, ASA resin, AES resin. A resin composition comprising 0.5 to 11 mass % of copolymer (A) for a polymer blend compatibilizer, 25 to 60 mass % of polyamide resin(B), and 29 to 74.5 mass % of resin (C) is formed. The resin (C) is at least one resin selected from ABS resin, SAN resin, ASA resin, and AES resin. The copolymer (A) for a polymer blend compatibilizer has 30 to 60 mass % of a maleimide-based monomer unit, 35 to 69 mass % of a styrene-based monomer unit, 1 to 5 mass % of unsaturated dicarboxylic anhydride monomer unit, and has a weight average molecular weight (Mw) of 60,000 to 125,000.

Owner:DENKA CO LTD

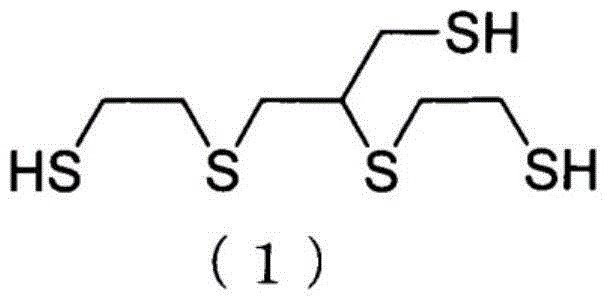

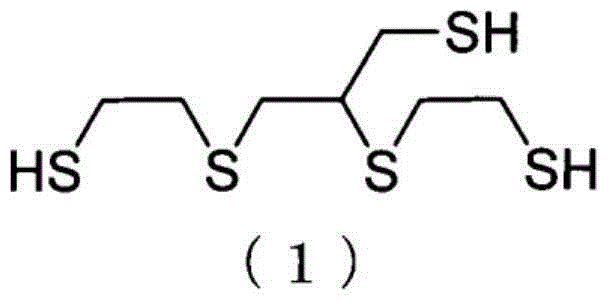

Composition for optical material

InactiveCN105102496AExcellent balance of physical propertiesImprove productivityOrganic chemistryOptical elementsOrganic chemistryChemistry

Owner:MITSUBISHI GAS CHEM CO INC

Flame Retardant Expandable Polystyrene-based Polymerized Beads, and Preparation Method Thereof

InactiveUS20130150469A1Improve flame retardant performanceIncrease production capacityPolymer sciencePolystyrene

A method of making flame retardant expandable polystyrene-based polymerized beads includes: mixing (a) about 70 to about 95 wt % of a styrene monomer, (b) about 1 to about 10 wt % of a char-generating thermoplastic resin, and (c) about 4 to about 29 wt % of inorganic foam particles to prepare a dispersion; and polymerizing the dispersion. The method of the present invention can eliminate further processing steps, can exhibit excellent productivity, and can allow easy control of the size of the beads.

Owner:CHEIL IND INC

Flame-retardant aromatic polycarbonate resin composition

The present invention relates to a polycarbonate resin composition having an excellent balance between various properties such as flame retardancy, transparency, hue and thermal stability. The flame-retardant aromatic polycarbonate resin composition comprises 100 parts by weight of an aromatic polycarbonate resin; and 0.001 to 0.5 parts by weight of a non-halogen-based aromatic sulfonic acid metal salt compound represented by the following general formula (1): wherein R 1 is a hydrogen atom or an alkyl group having 1 to 10 carbon atoms; R 2 is a hydrogen atom, an alkyl group having 1 to 7 carbon atoms, an aralkyl group having 6 to 20 carbon atoms or an aryl group having 5 to 15 carbon atoms; and M is rubidium (Rb), cesium (Cs) or francium (Fr).

Owner:MITSUBISHI ENG PLASTICS CORP

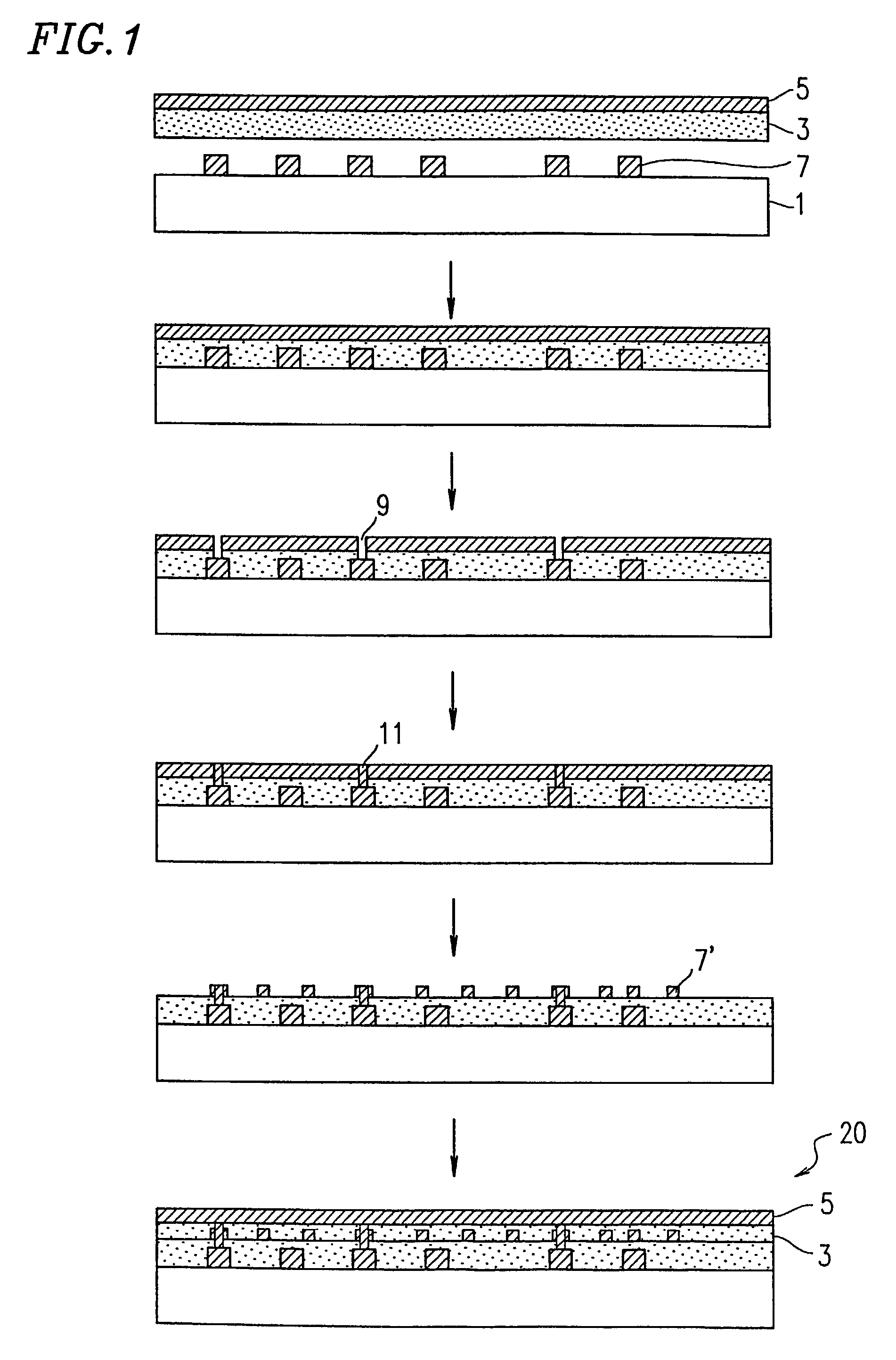

Multilayer structure and multilayer wiring board using the same

InactiveUS7252881B2Improve heat resistanceUniform thicknessInsulating substrate metal adhesion improvementSynthetic resin layered productsElectricityElectrical conductor

A multilayer structure comprising a conductor layer, an adhesive layer, and a polymer film layer interposed between the conductor layer and the adhesive layer. The multilayer structure can be used to provide a multilayer wiring board having excellent electrical properties and an excellent balance of physical properties, high heat resistance, a narrow pitch wiring pattern, a small-diameter via, uniform insulating layer thickness, an appropriately low coefficient of linear expansion, and stable adhesiveness between a metal and the polymer film. The polymer film layer may contain at least one repeating unit represented by formula (1) in the molecule. The present invention also provides a multilayer wiring board obtained from the multilayer structure.

Owner:KANEKA CORP

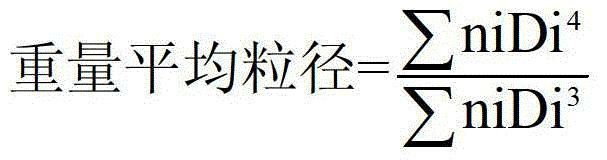

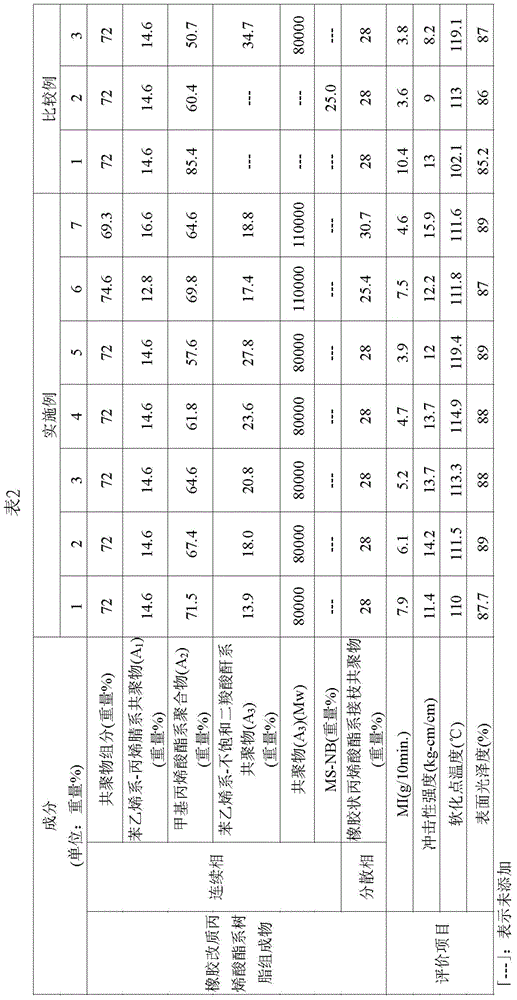

Rubber modification methacrylate resin composition

The invention relates to a rubber modification methacrylate resin composition including a continuous phase formed by 60-85% by weight of copolymer (A) and a dispersion phase formed by 15-40% by weight of acrylate rubber grafted copolymer (B). The copolymer (A), base on the total of 100% by weight, comprises 2-27% of acrylonitrile-styrene copolymer (A1), 42-80% of methyl-acrylate polymer (A2), and 8-32% of styrene-unsaturated dicarboxylic anhydride copolymer (A3).

Owner:CHI MEI CORP

Impact Modifier, Method for Preparing the Same and Scratch Resistant Methacrylate Resin Composition Using the Same

Disclosed herein is an impact modifier formed by graft polymerizing about 45 to about 70% by weight of a rubber polymer with about 30 to about 55% by weight of a methacrylate-based monomer, wherein said rubber polymer is prepared by polymerizing about 0.1 to about 1 part by weight of an antioxidant with about 100 parts by weight of a monomer mixture comprising about 30 to about 45% by weight of a diene-based monomer and about 55 to about 70% by weight of alkyl acrylate. The methacrylate-based resin composition of the present invention using the aforementioned impact modifier may have improved transparency, impact resistance and a good appearance.

Owner:LOTTE ADVANCED MATERIALS CO LTD

Novel Phosphorus Compound, Method of Preparing the Same and Flame Retardant Thermoplastic Resin Composition Including the Same

ActiveUS20120165444A1Improve hydrolysis resistanceImprove thermal stabilityPhosphorus organic compoundsHydrogenPolymer chemistry

Disclosed herein is a phosphorus compound represented by Formula 1:wherein each R is the same or different and is independently hydrogen, C1-C6 alkyl or C6-C12 aryl.

Owner:LOTTE ADVANCED MATERIALS CO LTD

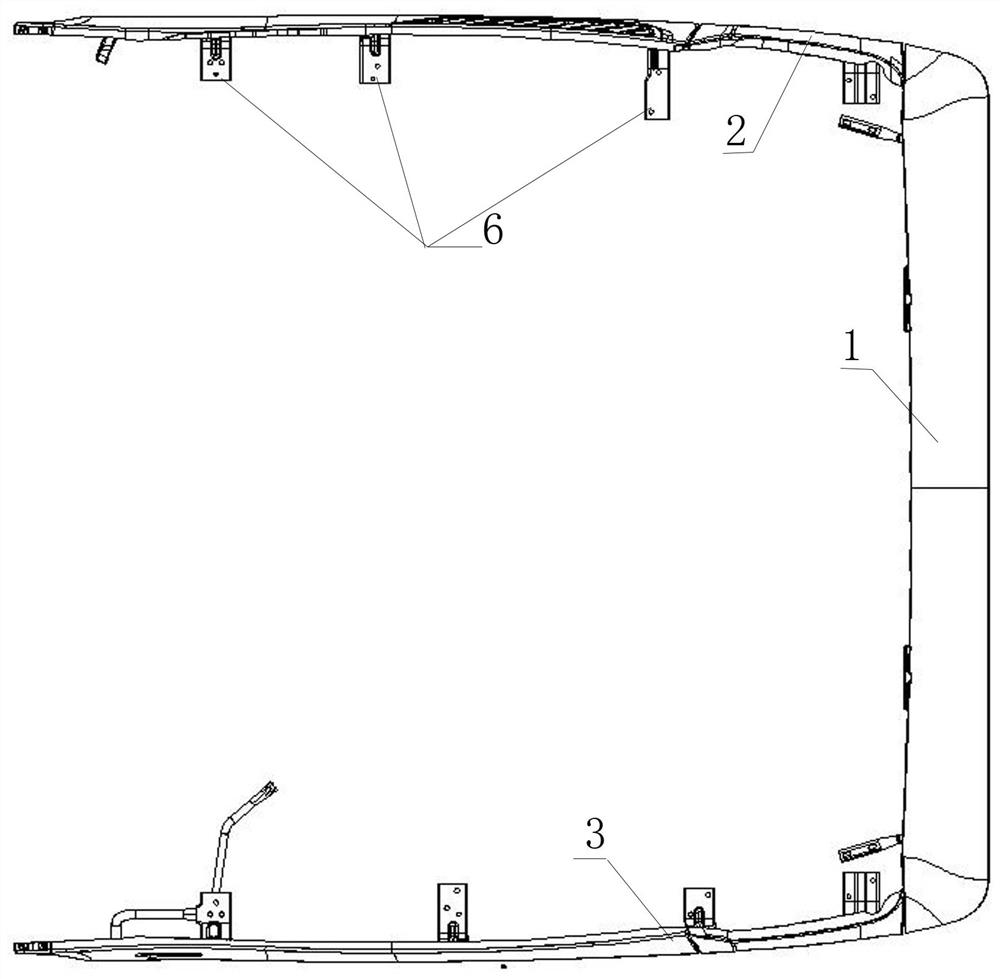

Commercial vehicle full-surrounding turbulent flow cover

PendingCN112319633AHigh strengthReduce weightComponent optimizationVehicle body streamliningAlkeneMechanical engineering

The invention discloses a commercial vehicle full-surrounding turbulent flow cover, and the outer surfaces of the top, the left portion and the right portion of the spoiler cover are common surfaces;reinforcing ribs are arranged on the inner surfaces of the top, the left portion and the right portion of the spoiler cover, a plurality of fixed bases are evenly arranged on the inner surfaces of thetop, and the left portion and the right portion of the spoiler cover at intervals in advance, wherein screw holes are formed in the fixed bases in advance. The outer surface or the inner surface of the fixed base is covered with an n-shaped component, and the n-shaped component forms a hollow channel in the two side edges and the middle of the inner surfaces of the top, the left portion and the right portion of the spoiler cover. The top, the left portion, the right portion and the n-shaped component of the turbulent flow cover are made of DCPD materials. Because the DCPD resin is brand-new olefin cross-linked thermosetting resin taking dicyclopentadiene as a main raw material, the DCPD resin is a new material capable of producing large-sized or complex-shaped molded workpieces in an extremely short time. The high-pressure RIM machine is used for pouring the DCPD material, polymerization reaction is carried out in a mold for forming, the method is suitable for large-scale, medium-scale and small-scale wide-range production, and the requirements for energy saving, resource saving and the like are met.

Owner:DONGFENG SHIYAN AUTOMOBILE HEAT EXCHANGER +1

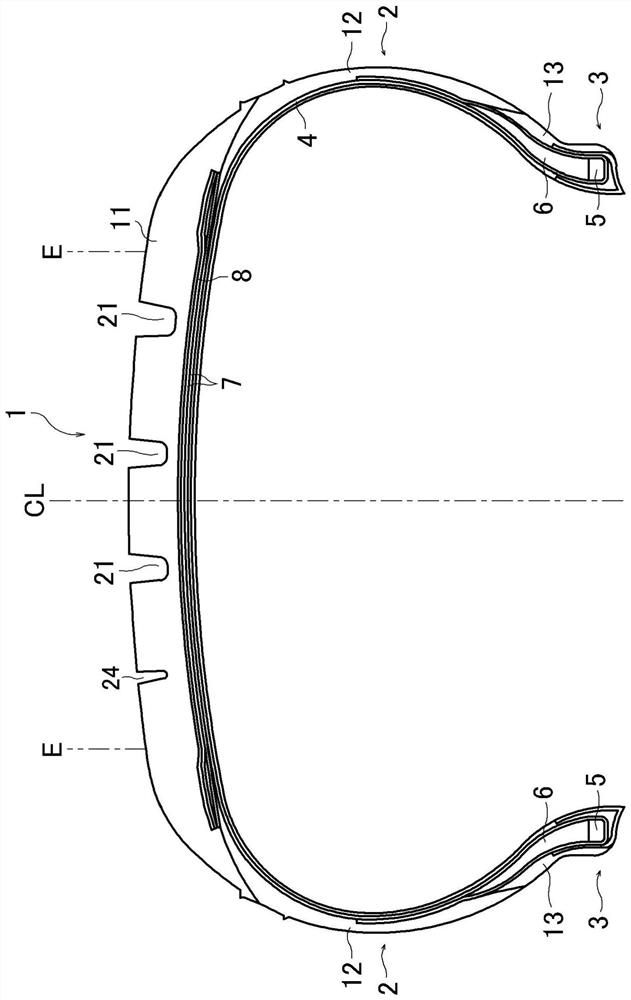

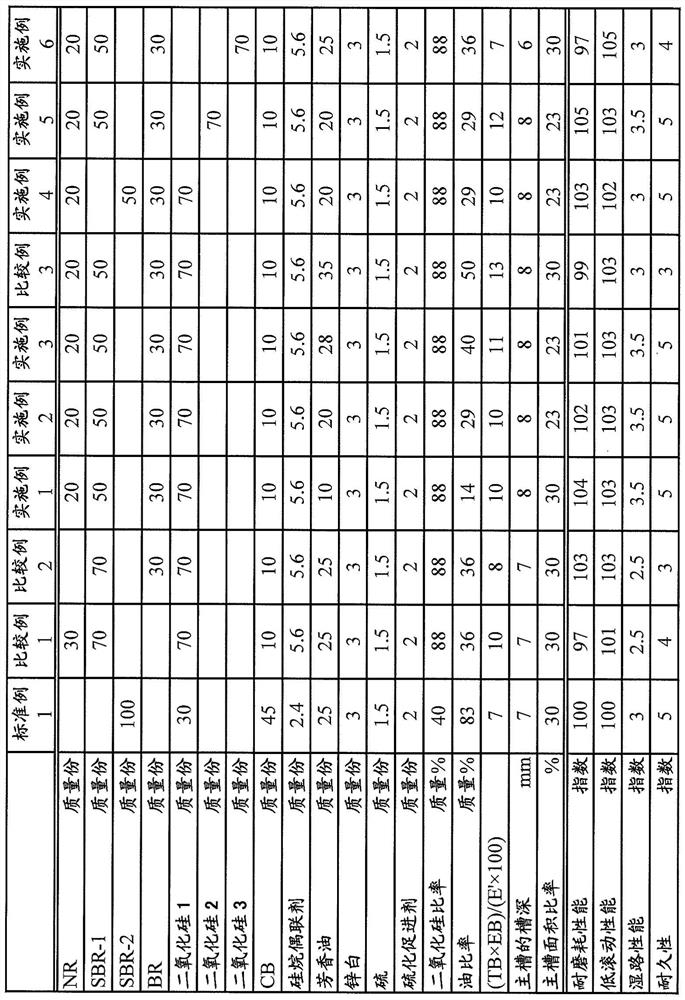

Pneumatic tire

ActiveCN111655510ALow handling stabilityGuaranteed durabilitySpecial tyresTyre tread bands/patternsButadiene DioxideGlass transition

Provided is a pneumatic tire that can improve wear resistance, low rolling performance, and wet road surface steering stability without sacrificing durability. A pneumatic tire that comprises a treadpart (1) and a main groove (21). The groove depth of the main groove (21) is 7-11 mm. The tread part (1) is constituted by a tread rubber composition that includes, as rubber components, natural rubber, a styrene butadiene rubber, and a butadiene rubber, the average glass transition temperature Tg of the rubber components being no greater than -50 DEG C. The tread rubber composition also includes50-100 parts by mass of silica per 100 parts by mass of the rubber components, the amount of silica being at least 80 mass% of the total amount of silica and carbon black. The tread rubber compositionalso includes no more than 40 mass% of an aromatic oil relative to the amount of silica.

Owner:THE YOKOHAMA RUBBER CO LTD

Thermoplastic resin composition for vehicular lamp housing

InactiveUS20110224355A1Improve propertiesSuppress generationMaterial nanotechnologyVehicle headlampsMeth-Physical property

The present invention provides a thermoplastic resin composition for a vehicular lamp housing, which is excellent in balance of physical properties with regard to such as impact resistance and fluidity, and of which hot plate weldability, vibration weldability and laser weldability are improved when a vehicular lamp housing is welded with other members.A thermoplastic resin composition for a vehicular lamp housing, comprising a graft copolymer (A) and a (co)polymer (C) is provided, whereinthe graft copolymer (A) is obtained by emulsion graft polymerization of an acrylic acid ester-based rubbery polymer having a weight average particle diameter of 70 to 250 nm with at least one monomer selected from the group consisting of an aromatic vinyl-based monomer, a vinyl cyanide-based monomer, a (meth)acrylic acid ester-based monomer and a maleimide-based monomer, wherein the acrylic acid ester-based rubbery polymer is obtained by emulsion polymerization of 60 to 95% by weight of an acrylic acid ester-based monomer in the presence of 5 to 40% by weight of an aromatic vinyl-based polymer having a weight average particle diameter of 10 to 150 nm;the (co)polymer (C) is obtained by polymerization of at least one monomer selected from the group consisting of an aromatic vinyl-based monomer, a vinyl cyanide-based monomer, a (meth)acrylic acid ester-based monomer and a maleimide-based monomer.

Owner:NIPPON A & L INC

Polypropylene resin composition and molded product thereof

ActiveUS20180258274A1Improve impact resistanceImprove rigidityBumpersThermoplastic elastomerFlexural modulus

A polypropylene resin composition includes a base resin, a thermoplastic elastomer, and an inorganic filler. The base resin is a polypropylene-based mixed resin including a first resin, a second resin, a third resin, and a fourth resin. The first resin is a homopolypropylene resin. The second resin, the third resin, and the fourth resin are each a polypropylene-based block copolymer resin. A melt index of the second resin measured at a temperature of 230° C. and under a load of 2.16 kg is higher than a melt index of each of the third resin and the fourth resin measured under the same condition. A flexural modulus of the third resin measured in accordance with ASTM D790 is lower than a flexural modulus of the fourth resin measured under the same condition.

Owner:HYUNDAI MOTOR CO LTD +3

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com