Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

96 results about "Rubber toughening" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

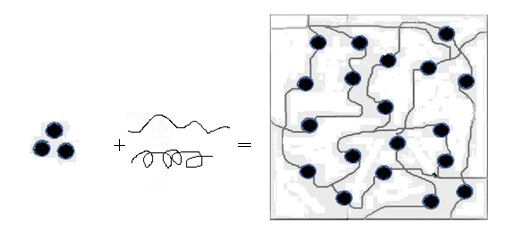

Rubber toughening is a process in which rubber nanoparticles are interspersed within a polymer matrix to increase the mechanical robustness, or toughness, of the material. By "toughening" a polymer it is meant that the ability of the polymeric substance to absorb energy and plastically deform without fracture is increased. Considering the significant advantages in mechanical properties that rubber toughening offers, most major thermoplastics are available in rubber-toughened versions; for many engineering applications, material toughness is a deciding factor in final material selection.

Saloon car bumper special material capable of direct spray coating

The invention discloses a special material for direct spray coating of a bumper, which is prepared by mixing of polypropylene, a rubber toughening agent, a crosslinking agent, grafted polypropylene, inorganic filler, black master bath, an antioxidant and a light stabilizer in proportion, preparation of the master bath, dynamic vulcanization, secondary extrusion, multi-monomer fusing and grafting, etc. The polarity of the special material for the bumper is changed by multi-monomer fusing and grafting modification of methyl methacrylate and so on, and the surface activity of the special material for the bumper is increased; and spray coating paint of the bumper comprises a plurality of chemical compositions, the appetency of various compositions and given functional groups is insufficient, a plurality of active functional groups are formed on the surface of the material by activation of a plurality of functional groups and can simultaneously form physical absorption or chemical bonding with the various chemical compositions in the paint, thereby the special material can perform direct spray coating without flame treating, achieves the optimum spray coating effect, and has good processing fluidity and high toughness.

Owner:CHANGCHUN UNIV OF TECH

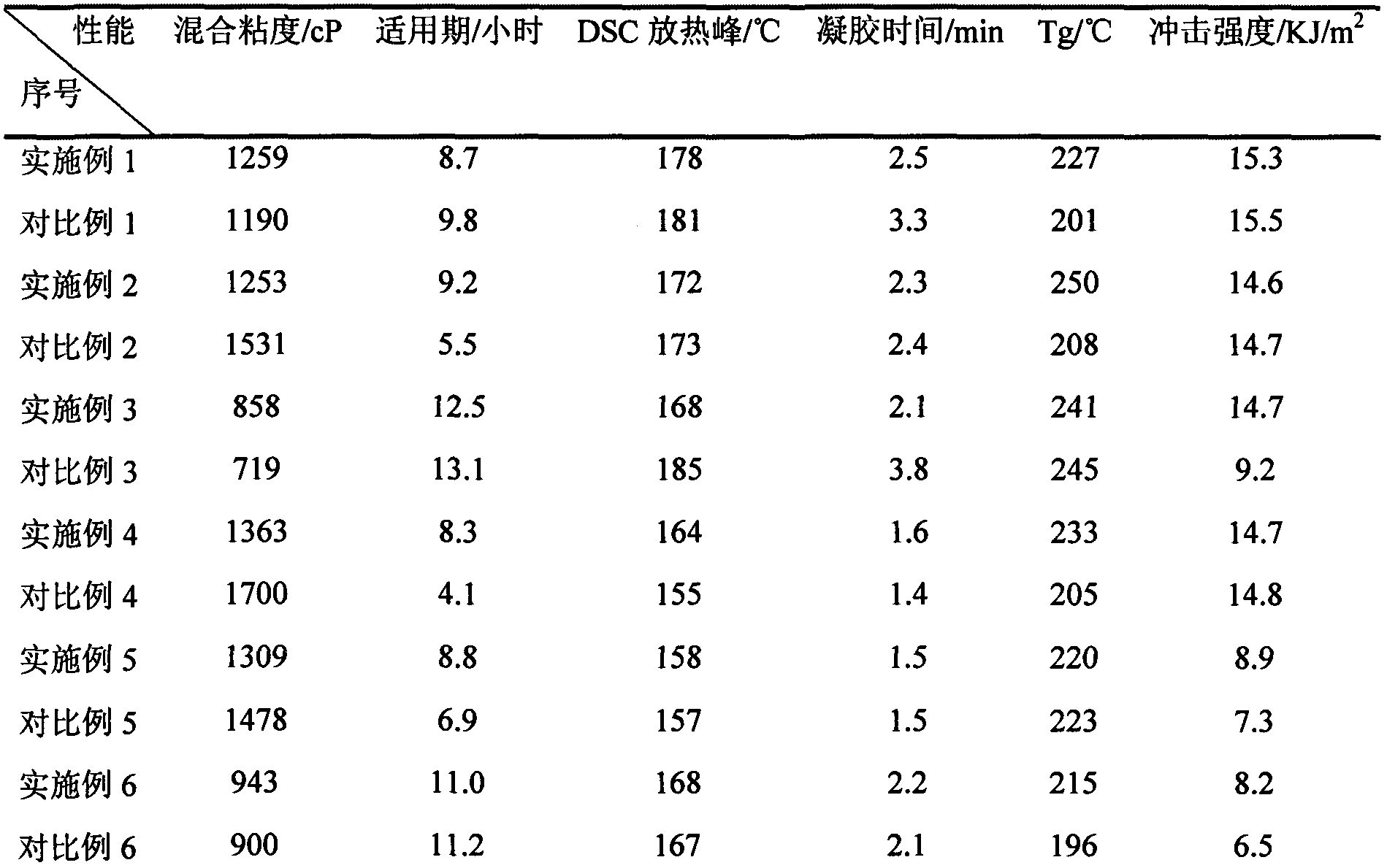

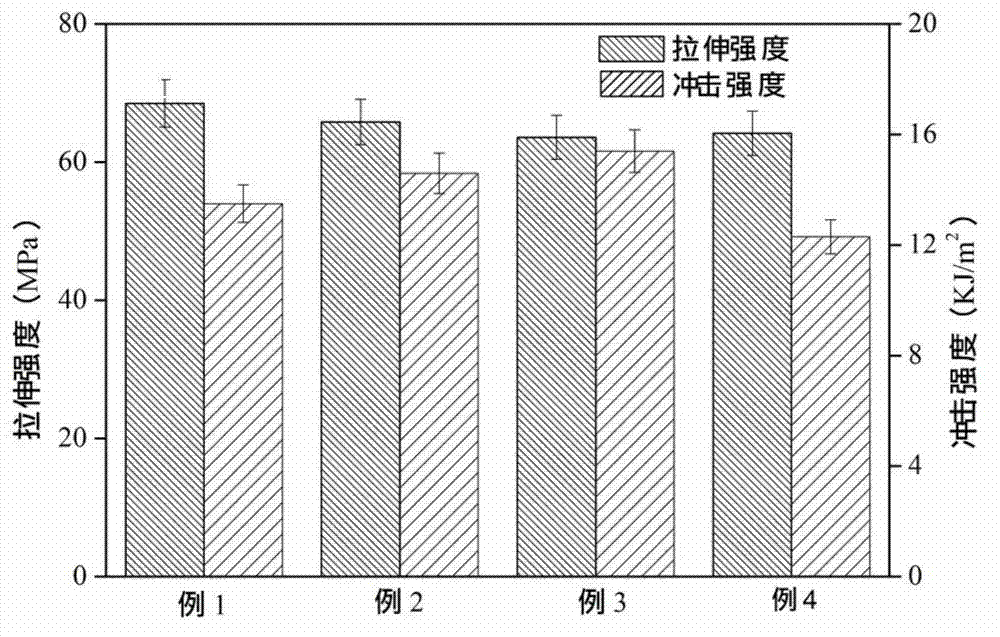

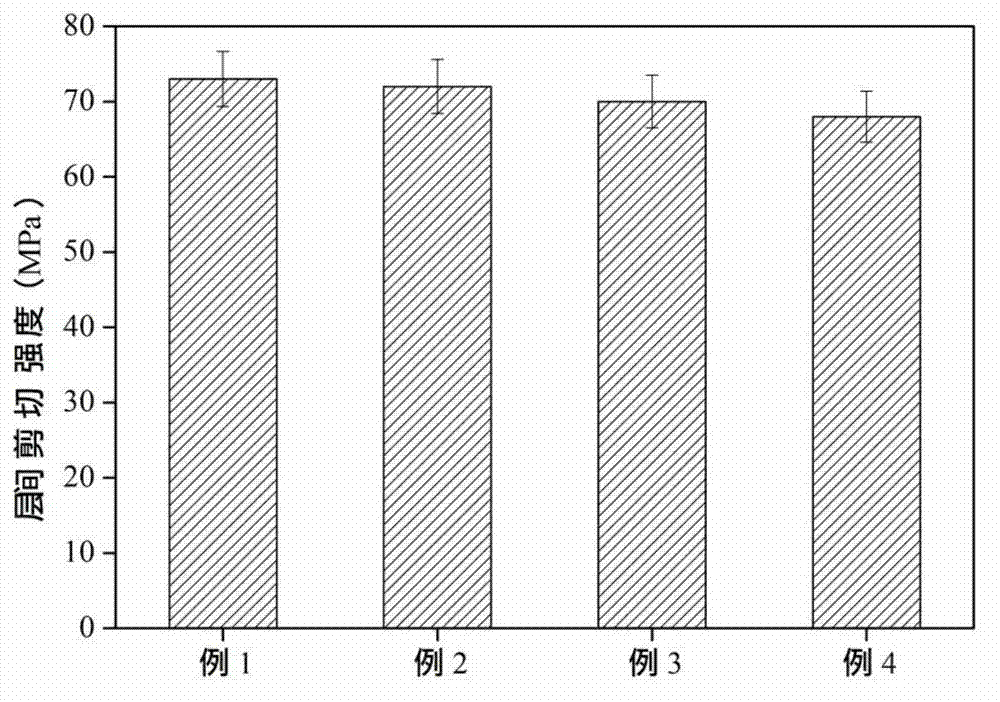

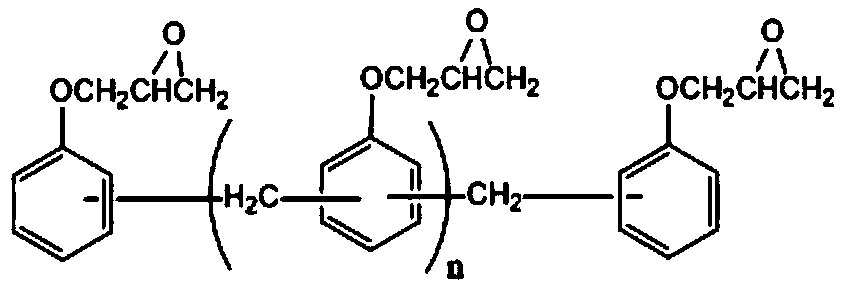

High temperature-resistant epoxy resin composition for pultrusion and preparation method

The invention provides a high temperature-resistant epoxy resin composition for pultrusion and a preparation method. The high temperature-resistant epoxy resin composition for pultrusion comprises A and B components, wherein the A component comprises glycidyl ether epoxy resin, cycloaliphatic epoxy resin and an epoxy resin active diluents, the B component comprises cycloaliphatic anhydride, aromatic hydrocarbon polyanhydride, a thermoplastic phenolic resin curing agent, a maleic anhydride grafted rubber toughening agent, a polysiloxane toughening modifier, and an epoxy resin curing accelerator, and the ratio of the A component to the B component, by weight of the components, is 100:50-250. The composition of the invention has excellent high temperature resistance, and also maintains balance between processing properties, impact toughness and comprehensive performance. The prepared products can be used for a long time in rigorous wild high temperature environment.

Owner:江苏绿材谷新材料科技发展有限公司

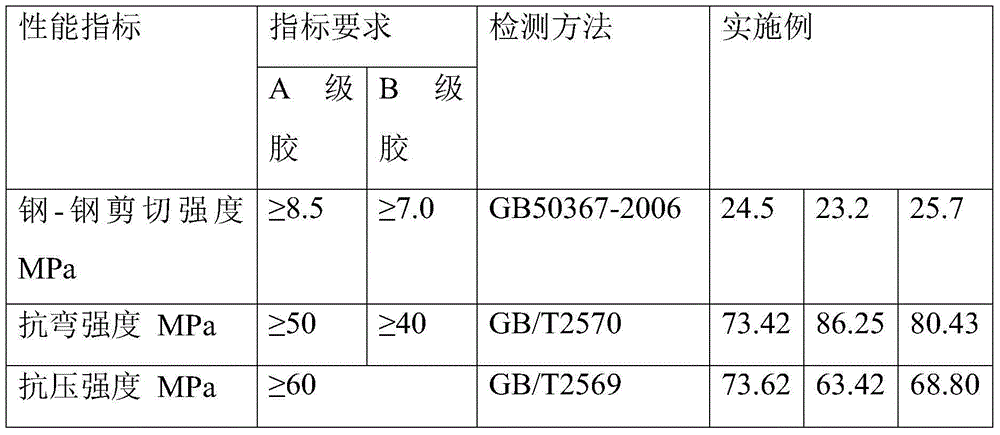

Modified bisphenol-A epoxy resin inserted bar glue in complete underwater environment and preparation method

ActiveCN104789178AGood seawater resistanceStrong acid and alkali corrosion resistanceNon-macromolecular adhesive additivesEpoxy resin adhesivesRubber tougheningRebar

The invention discloses modified bisphenol-A epoxy resin inserted bar glue in the complete underwater environment and a preparation method. The inserted bar glue comprises the following ingredients by weight ratio: ingredients A: 10-15 parts of bisphenol-A epoxy resin, 1.5-2.5 parts of a rubber toughening agent and 5-10 parts of a spherical filler with the degree of sphericity being 0.8-1; ingredients B: 3-5 parts of a modified base amines curing agent and 5-15 parts of a spherical filler with the degree of sphericity being 0.8-1. The ingredients A and the ingredients B are mixed for construction according to the ratio of 1:1. According to the inserted bar glue and the preparation method, steel bars can be inserted and screw rods can be embedded on the surfaces of substrates completely underwater; the inserted bar glue can be cured at ordinary temperature in the complete underwater environment, and the steel-steel shearing strength can reach to over 23 MPa after curing.

Owner:DALIAN UNIV OF TECH

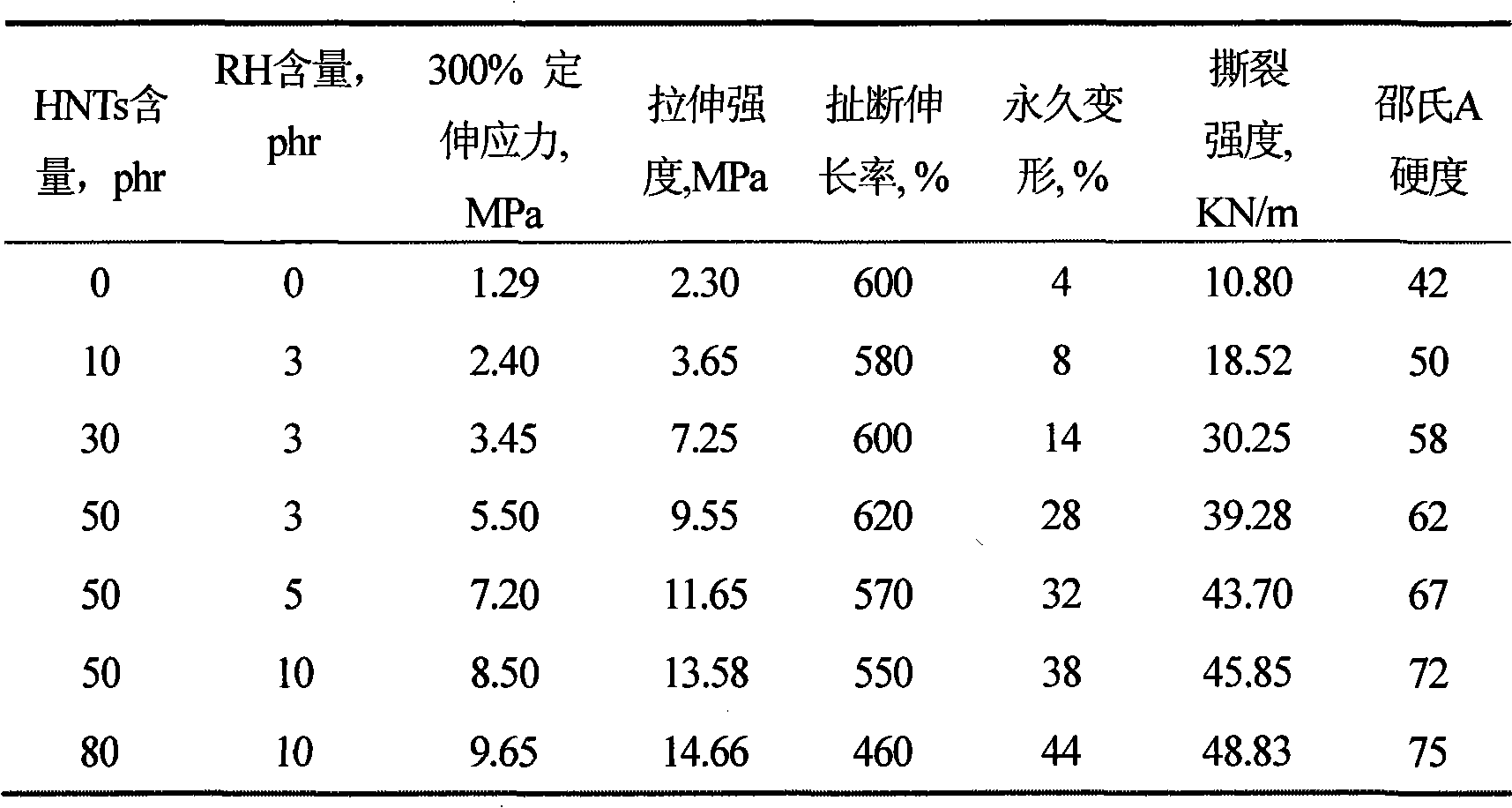

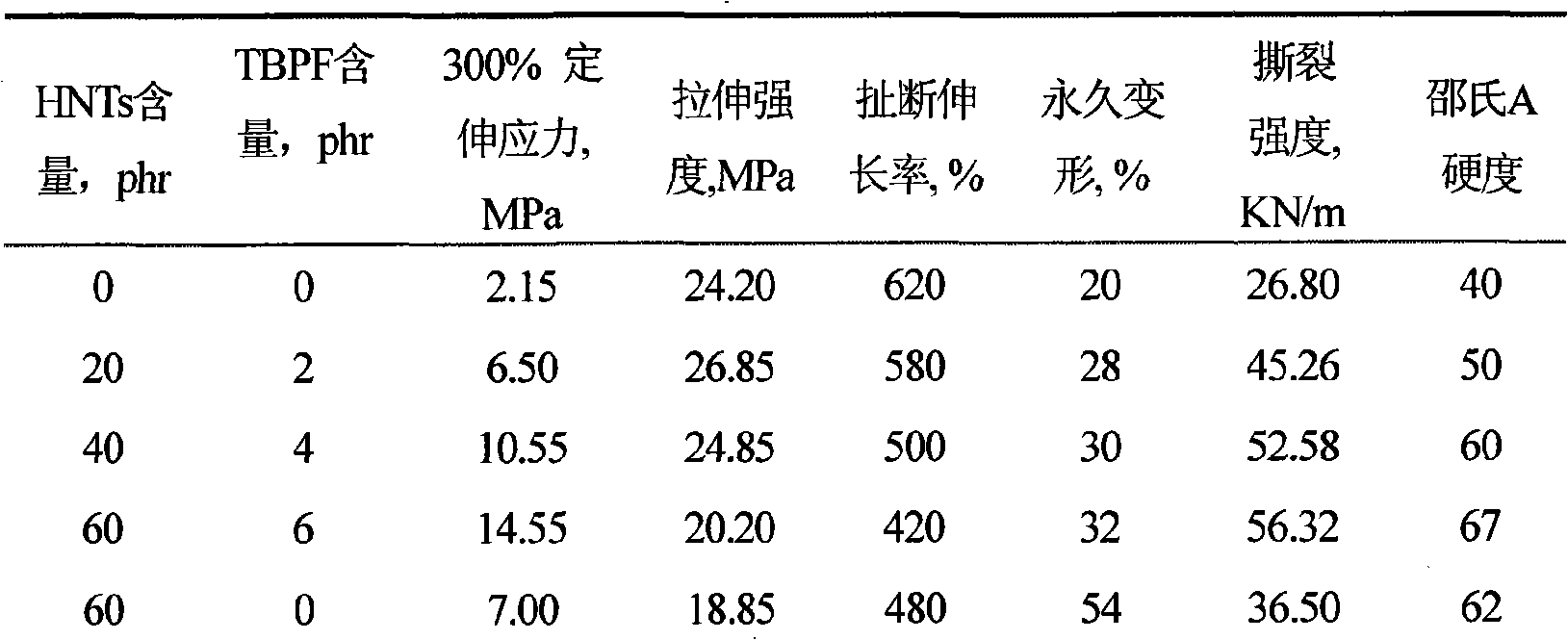

Preparation method for rubber/keramite nano-tube nano-composite material

The invention relates to preparation method of rubber / halloysite nanotube nano-composite material, the invention adopts the preparation method that the rubber, the halloysite nanotube and modifying agent are mixed according to the mass ratio of 100:5 to 100 : 0.5-20 through the ordinary rubber pugging equipment and technique, then the sulphation is performed through the ordinary sulphidizing process and equipment to realize the in-situ modification, and finally, the rubber / halloysite nanotube nano-composite material with nano-dispersion, good interfacial bonding and good performance. Wherein, the modifying agent comprises compound in-situ generated phenolic resin, alkyl phenolic resin, modified rubber, methacrylic acid metal salt and one or more than one mixture (s) in the sulfur-containing organosilane coupling agent. The preparation method of rubber / halloysite nanotube nano-composite material has the advantages that the defects that the rubber / halloysite nanotube nano-composite material is difficult to be dispersed, the interfacial bonding is not good, the performance can not be improved observably can be overcome, and the preparation method can be applied in a variety of rubber products, rubber toughening plastics and binding agents and the like.

Owner:SOUTH CHINA UNIV OF TECH

Preparation method of dimer acid modified epoxy resin toughened carbon fiber prepreg

The invention provides a preparation method of a dimer acid modified epoxy resin toughened carbon fiber prepreg, which comprises the following steps: by taking a component of which the molecular structure is similar to that of a carbon fiber sizing agent as toughener, preparing a dimer acid modified epoxy resin through a pre-reaction method; adding reactants into the mixed epoxy resin, adding a latent curing agent, and evenly mixing to obtain a resin system for the prepreg; and coating the resin system through a film coating machine, and then compounding with carbon fibers or a fabric made therefrom to prepare the moderate-temperature curing prepreg having fine operability and adhesivity. Compared with the traditional rubber toughened prepreg, the invention can enhance the wettability of the resin system on carbon fibers, reduce the moisture permeability of the prepreg and simultaneously improve the toughness and impact resistance of the composite material, thus being suitable for manufacturing of a prepreg for winding formation.

Owner:中威北化科技有限公司

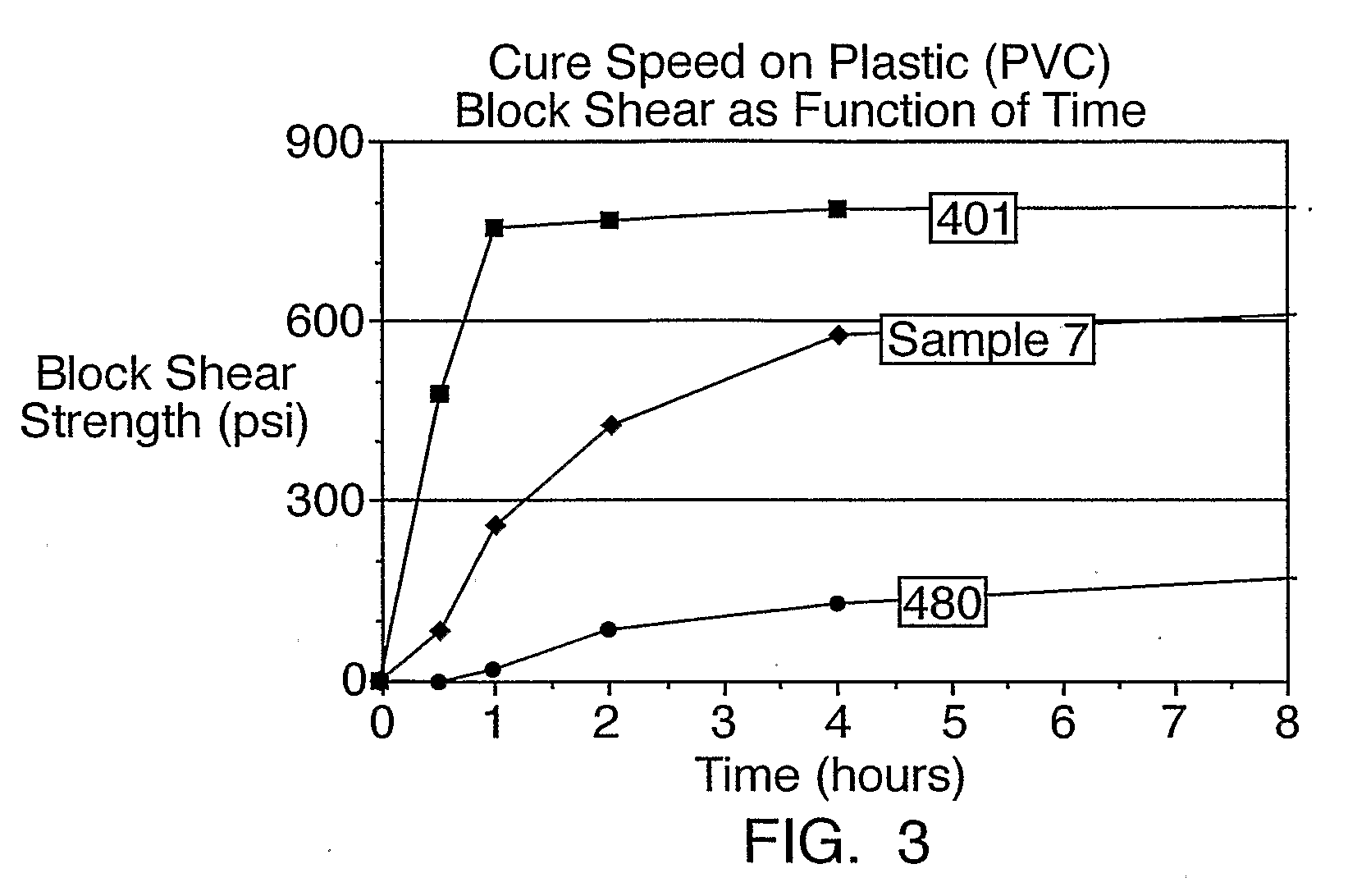

Toughened Cyanoacrylate Compositions

InactiveUS20080314519A1Extended shelf lifeIncrease speedAdhesive processesNon-macromolecular adhesive additivesPolymer scienceRubber toughening

This invention relates to cyanoacrylate-containing compositions that include, in addition to the cyanoacrylate component, a rubber toughening component, which is substantially clear and colorless and which is substantially free of release agents and anti-oxidants known to impair the fixture speeds and shelf life stability of cyanoacrylate compositions to which they are added. As a result, the inventive rubber cyanoacrylate adhesive compositions demonstrate improved properties, such as fixture speed, strength and shelf life under accelerated aging conditions.

Owner:HENKEL IP & HOLDING GMBH

Bottom filling glue for packaging inverted chip type semiconductor

ActiveCN102002209AExcellent performance indexImprove moisture resistanceSemiconductor/solid-state device detailsSolid-state devicesEpoxyThermal expansion

The invention discloses bottom filling glue for packaging an inverted chip type semiconductor, which is prepared from the following raw materials in percentage by weight: 5.8-59 percent of liquid epoxy resin, 2-10 percent of rubber toughening agent, 5.8-59 percent of modified organic silicon resin, 0.5-14.8 percent of multifunctional epoxy resin, 1.5-10.5 percent of epoxy diluent, 0.5-14.8 percent of aromatic amine curing agent, 1.1-10.8 percent of silane coupling agent, 20-59 percent of silicon micropowder and 0-6 percent of pigment. The invention has the advantages of low viscosity, proper flow property, no defect, no bubble and good heat resistance of resin condensate, low thermal expansion coefficient, low modulus, small internal stress, less warping degree, high bonding strength, low halogen content and high insulating performance, can maintain favorable bonding reliability and curing performance during thermal cycling treatment and improve the seal performance and the operating performance of the surface of a silicon wafer containing photosensitive polyimide and a silicon nitride film, can be widely used for the technical field of inverted chip packaging and is especially suitable for the field of high-end devices in a Flip-chip process and high-density packaging.

Owner:深圳市库泰克电子材料技术有限公司

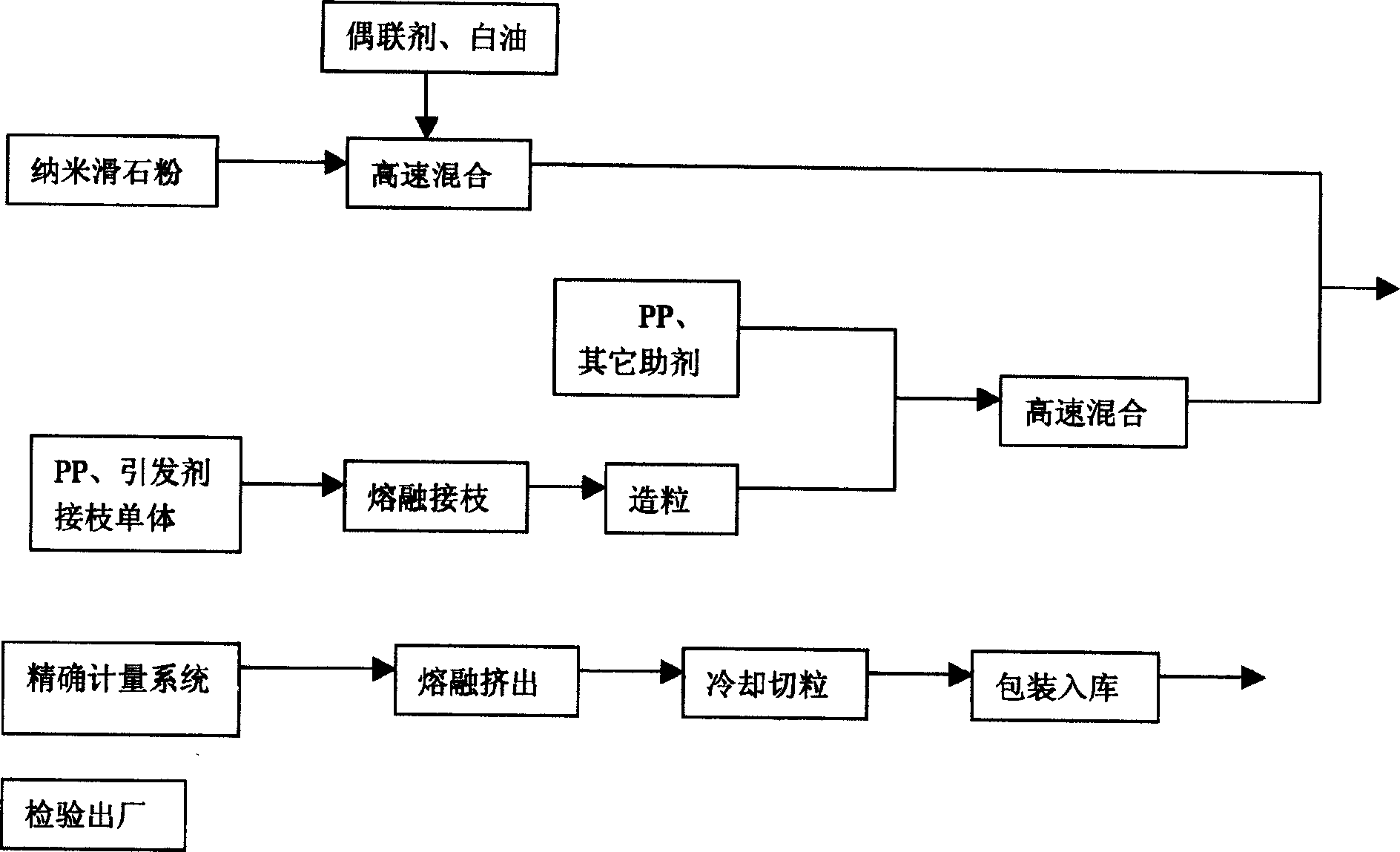

High fluidity nano talcum powder modified polypropylene composite material and its preparation method

InactiveCN1569945AHigh impact strengthImprove low temperature toughnessPolypropylene compositesRubber toughening

The invention discloses a high fluidity nano talcum powder modified polypropylene composite material and its preparation method, wherein the material is prepared from polypropylene resin, grafted and modified polypropylene resin, rubber toughening agent, coupling agent and nanometer talcum powder through blending and extrusion by screw rod extrusion machine set.

Owner:横店集团得邦工程塑料有限公司

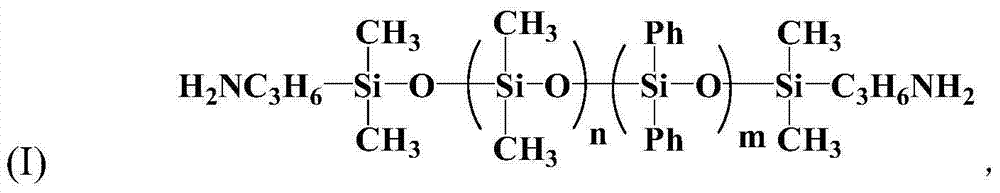

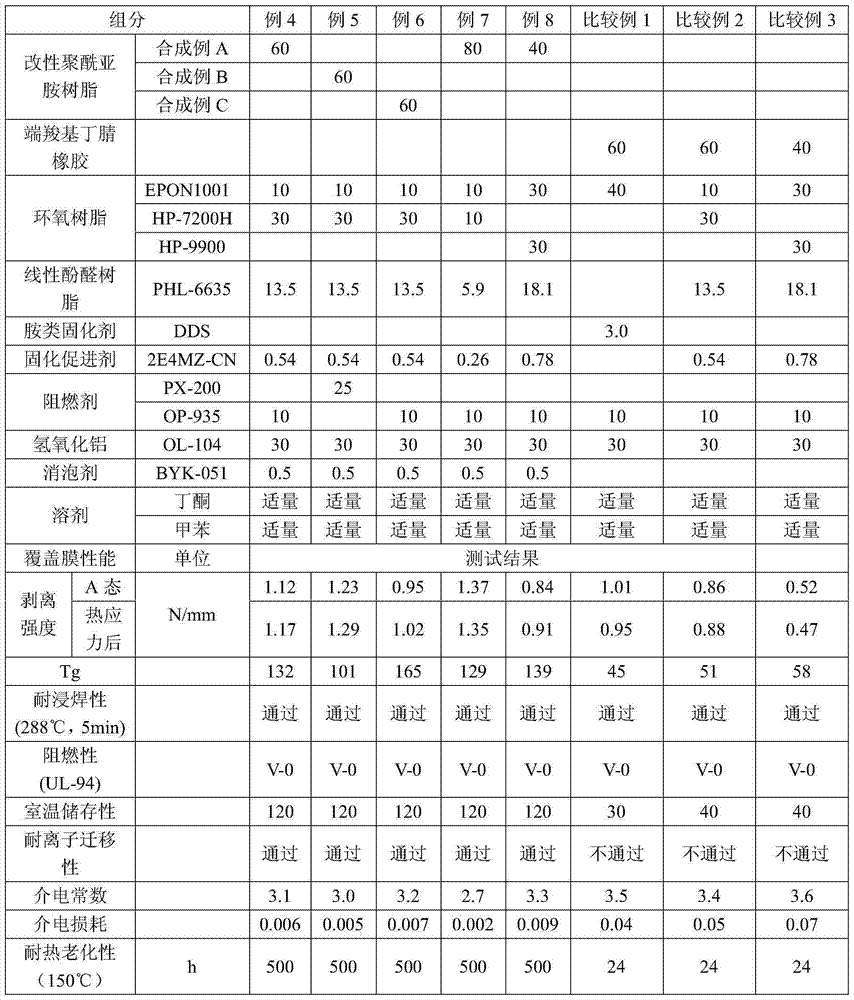

Modified polyimide resin, adhesive composition containing modified polyimide resin and covering film containing adhesive composition

ActiveCN103483586AImprove adhesionImprove heat resistanceNon-macromolecular adhesive additivesFilm/foil adhesivesThermal ageingVitrification

The invention provides modified polyimide resin. A molecular structure of the modified polyimide resin comprises the repeated units of the following chain segments: polysiloxane polyimide chain segments, cycloaliphatic polyimide chain segments and aromatic polyimide chain segments, wherein the molar contents of the polysiloxane polyimide chain segments, the cycloaliphatic polyimide chain segments and the aromatic polyimide chain segments in a chemical formula of the modified polyimide resin are 20-40%, 20-50% and 30-60% respectively. The modified polyimide resin can be used as a toughening agent of an epoxy resin adhesive and is more excellent in characteristics such as higher thermal ageing resistance, higher glass-transition temperature and the like in comparison with a buna-n rubber toughened epoxy adhesive agent.

Owner:GUANGDONG SHENGYI SCI TECH

Thermosetting rubber film for flexible circuit assembly and its preparing method

InactiveCN1580171AFast curingHigh peel strengthEpoxy resin adhesivesConjugated diene hydrocarbon adhesivesEpoxyPolymer science

It is about hot set rubber film for flexibility circuit assemblage and its preparation methods. This -can be used in ---circuit construction. It is made from epoxy resin, butadiene acrylonitrile rubber toughening agent, fixing tanning agents of imidazole derivates and solvent by form them into liquid cement and application. The binding strength and tenacity can be advanced by the combination of epoxy resin. The curing speed in the high temperature can be improved by the complex fixing tanning agents of aromatic polyamines and imidazole derivates. The whole process can finish within decades of seconds in temperature of 180 degree. So it is propitious to snap couple flexible electric. Compared with the exiting technique, the invention can keep the film of rubber stable in normal temperature and can fast set in high temperature and hot pressing without excessive glue and uncover.

Owner:SHENZHEN DANBOND TECH

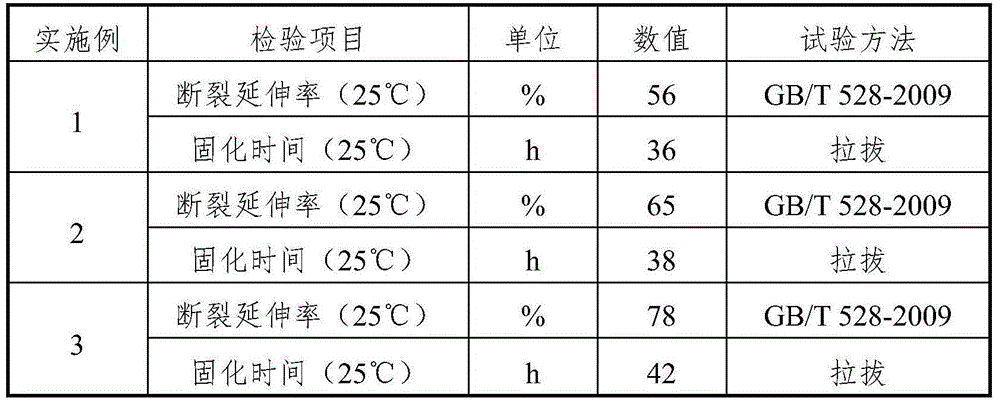

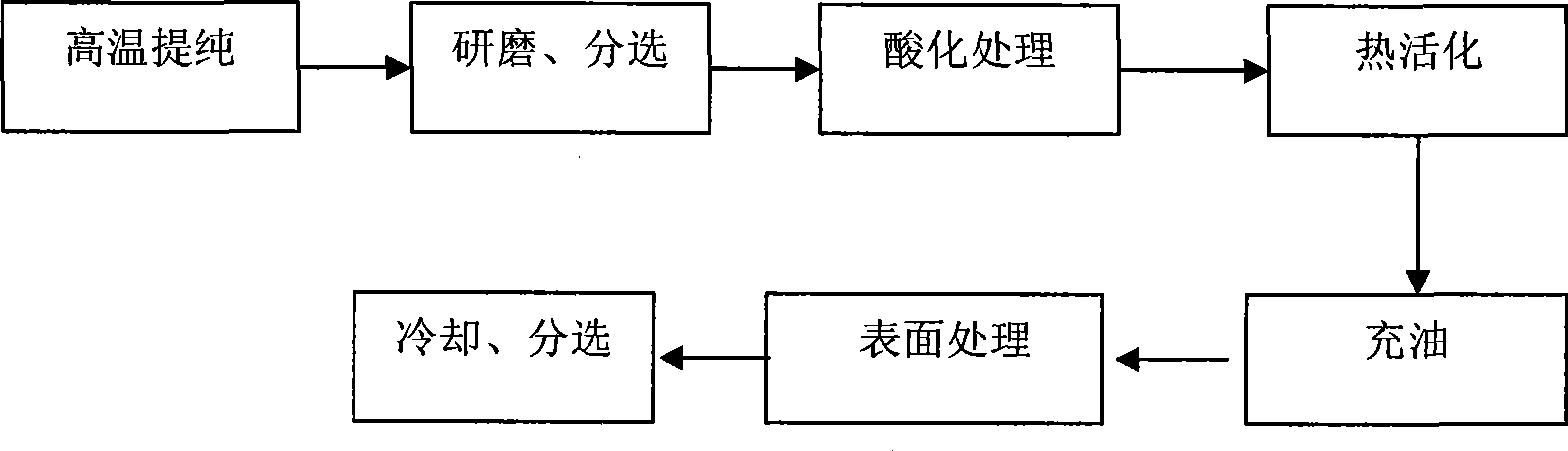

High-toughness cold-mixing modified resin material for paving roads and bridges and preparation method of high-toughness cold-mixing modified resin material

InactiveCN105038141AGood compatibilityProlong mixing reaction timeClimate change adaptationBuilding insulationsEpoxyDiluent

The invention discloses a high-toughness cold-mixing modified resin material for paving roads and bridges and a preparation method of the high-toughness cold-mixing modified resin material. The high-toughness cold-mixing modified resin material is composed of a component A and a component B, wherein the mass ratio of the component A to the component B is 10:(8-13); the component A comprises 10-20 parts of epoxy resin, 1-5 parts of a diluent and 1-5 parts of an active toughening agent; and the component B comprises 5-15 parts of a normal-temperature flexible curing agent, 1-5 parts of asphalt, 3-8 parts of a solubilizer and 1-3 parts of filler. The invention provides the high-toughness cold-mixing modified resin material for paving roads and bridges; the high-toughness cold-mixing modified resin material is more convenient to construct and is not needed to be heated, the raw materials are mainly softened by using compound toughening materials including a rubber toughening agent, toughening filler and a flexible curing agent, and the performances of the high-toughness cold-mixing modified resin material are same as those of hot-mixed or warm-mixed epoxy asphalt, so that the high-toughness cold-mixing modified resin material provides a technical reference for specially paving bridge decks, airfield pavements and the like.

Owner:JIANGSU SINOROAD TRANSPORTATION SCI & TECH CO LTD

Low temperature curable adhesives and use thereof

InactiveUS20170349795A1Unique/acceptable mechanical propertiesMacromolecular adhesive additivesEpoxy resin adhesivesCore shellLiquid rubber

An epoxy adhesive composition having a higher level (at or above 5 wt %) of a blocked tertiary amine catalyst, a urethane toughener, an epoxy resin modified with liquid rubber, a core shell rubber toughener and a combination of liquid and solid epoxy resins and the making thereof.

Owner:DOW GLOBAL TECH LLC

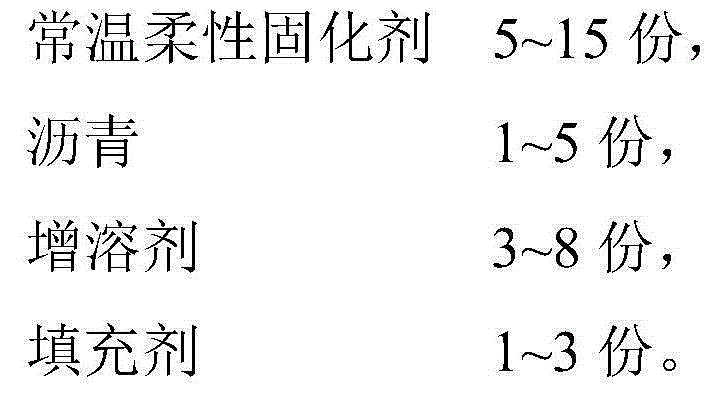

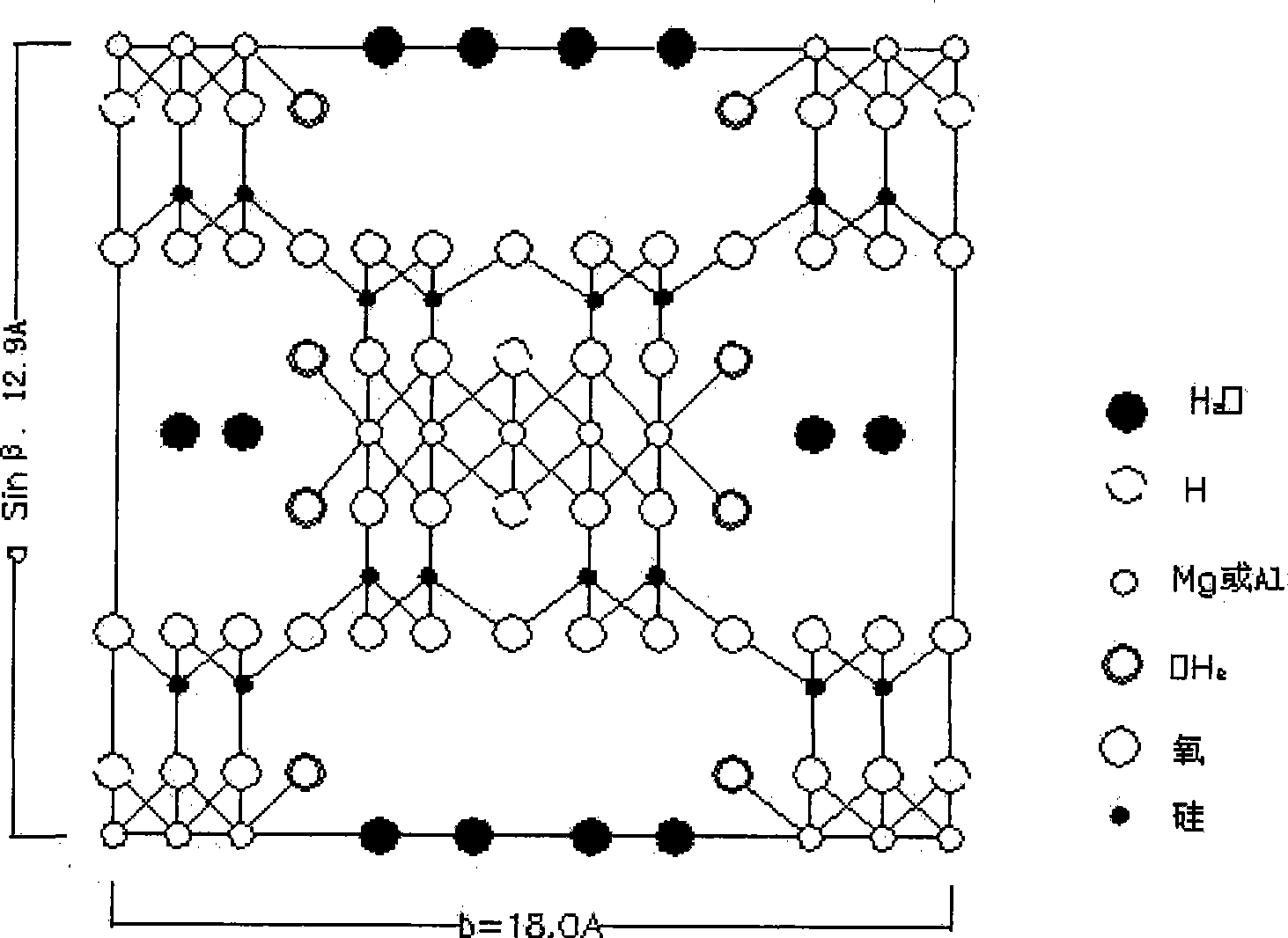

Inorganic high molecular plastics and rubber toughening agent

The invention provides an inorganic polymer rubber-plastic toughener using attapulgite clay as a main raw material, which is evenly dispersed in a high polymer matrix, and has good compatibility with high polymer. The method for preparing the inorganic high polymer rubber-plastic toughener comprises the following steps: (1) purifying the attapulgite clay at a high temperature; (2) grinding and sorting; (3) acidizing; (4) thermal activating; (5) oil charging; and (6) surface treating. The toughener uses the property of fibrous microcellular structure of the attapulgite clay, modifies fibrous pore canals of inner layers of particles, improves the compatibility of the toughener with the high polymer on the premise that the fibrous structure of the attapulgite clay is maintained, has unique modification function, not only replaces toughener resin, but also proves that compared with the prior combination of padding / toughener resin, a plastic product blended by the inorganic high polymer rubber-plastic toughener and a plurality of synthetic resins has preferable aging resistance and physical property through a plurality of applied tests.

Owner:NANJING YADONG AOTU MINING

Normal-temperature curing flexibility epoxy resin waterproof binder for roads and bridges and preparation method of normal-temperature curing flexibility epoxy resin waterproof binder

InactiveCN110373143AGood flexibilityImprove stabilityMacromolecular adhesive additivesEpoxy resin adhesivesGlycidyl ethersRoom temperature

The invention discloses a normal-temperature curing flexibility epoxy resin waterproof binder for roads and bridges. The normal-temperature curing flexibility epoxy resin waterproof binder is characterized in that the waterproof binder is prepared from a component A and a component B, the component A is prepared form bisphenol A glycidyl ether epoxy resin, a toughening agent a, namely a rubber toughening agent, and an active diluent, and the component B is prepared form a polyamide curing agent and polyether amine curing agent mixed curing agent, a toughening agent b, namely a reacting toughening agent, and an amine accelerant, wherein the mass ratio of the component A to the component B during using is (100:35) to (100:50). The epoxy resin binder can be cured within 24 hours at the room temperature environment, and has high strength and high elasticity.

Owner:HUNAN YUNZHONG REGENERATION TECH CO LTD

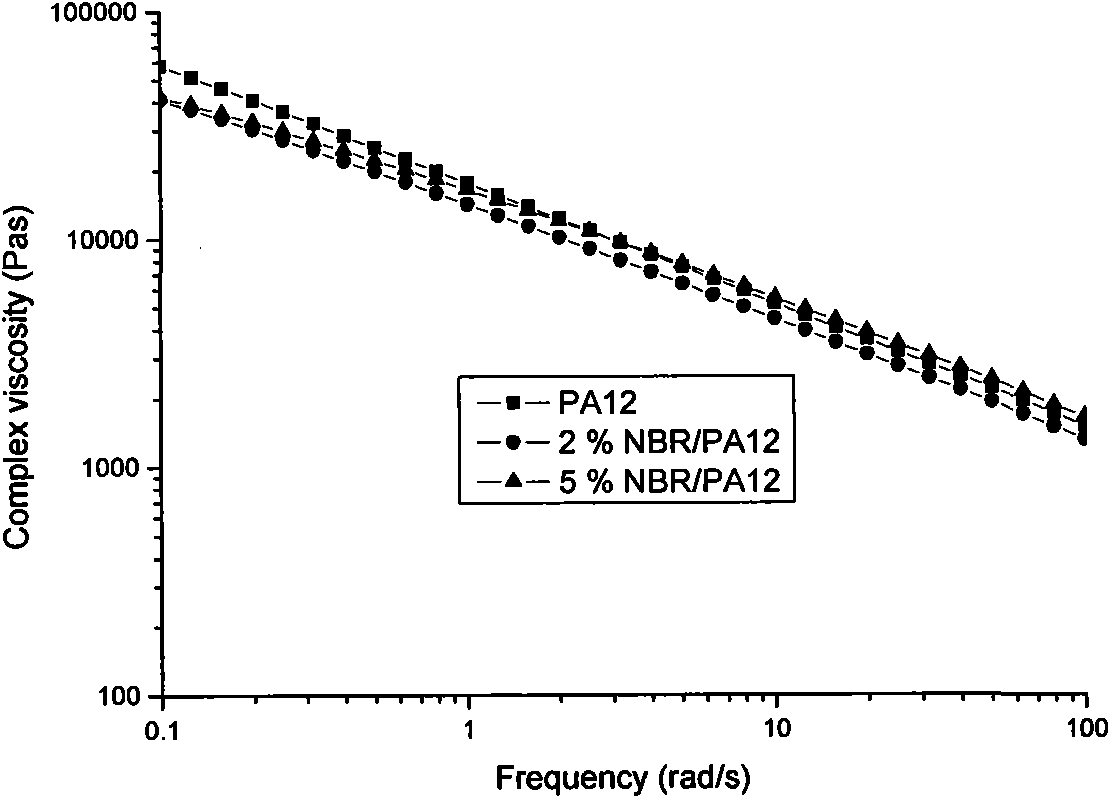

Nylon composite material with high transparency and low temperature cracking resistance and preparation method thereof

The invention relates to a nylon composite material with high transparency and low temperature cracking resistance and a preparation method thereof. The composite material comprises the following components in parts by weight: 53-99 parts of nylon, 1-47 parts of polar liquid rubber toughening agent, 0.2-1 part of nucleating agent, 0.2-0.5 part of lubricant and 0.2-0.5 part of antioxidant; the preparation method comprises the following steps: uniformly mixing the nylon with the polar liquid rubber toughening agent in the formula in advance, adding other additives in the premix for co-mixing, adding the mixture into a double-screw extruder, and extruding to prepare the nylon composite material with high transparency and low temperature cracking resistance. Compared with the prior art, the product provided by the invention has the advantages of wide material selection, excellent low temperature cracking resistance, high rigidity retaining rate, good transparency, excellent appearance and the like, and is particularly suitable for application in some products with higher requirements on the low temperature cracking resistance and appearance transparency of materials, for example, spectacles, buckles, ribbons, etc.

Owner:FINE BLEND COMPATILIZER JIANGSU CO LTD

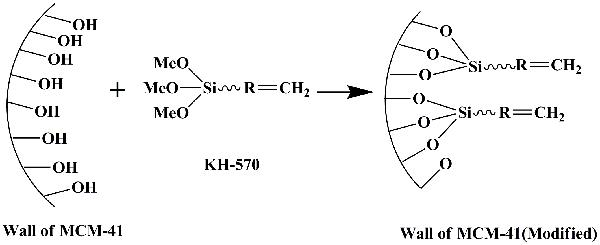

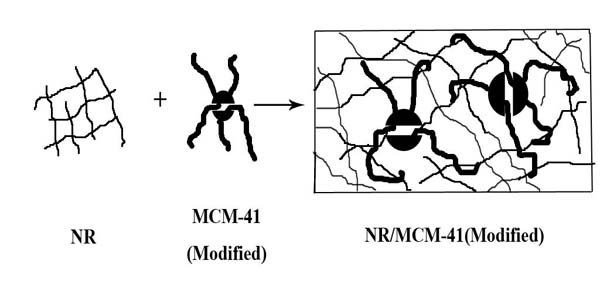

Preparation method of rubber/mesoporous molecular sieve nanocomposite

The invention provides a preparation method of a rubber / mesoporous molecular sieve nanocomposite and relates to the technical field of nanocomposites. The preparation method comprises the following steps of: blending rubber, mesoporous molecular sieves and a modifier in a mass ratio of 100:0.5-20:0.5-10 by mixing equipment and process; and vulcanizing the mixture by the common vulcanization process and equipment to realize in-situ modification so as to obtain the rubber / mesoporous molecular sieve nanocomposite with nano-scale dispersion, good interfacial bonding and high performance. The mesoporous molecular sieves are nano-scale mesoporous molecular sieve particles with special structures. The modifier comprises one or a mixture of more than one of methacrylate series, surfactant series and coupling agent series. The preparation method can overcome the defects of dispersion difficulty, poor interfacial bonding and difficulty in obviously improving the performance of the rubber / mesoporous molecular sieve nanocomposite and can be applied to various rubber products, rubber toughening plastic, binding agents and the like.

Owner:SHENYANG INSTITUTE OF CHEMICAL TECHNOLOGY

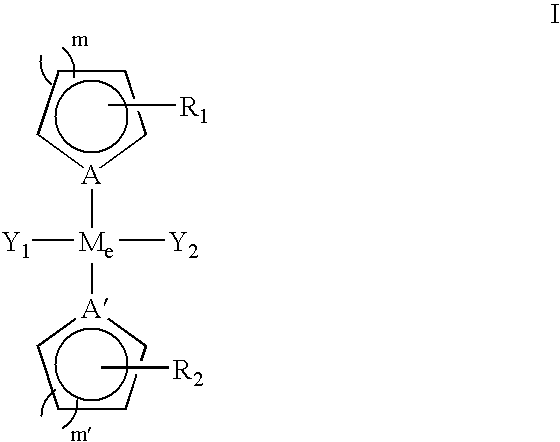

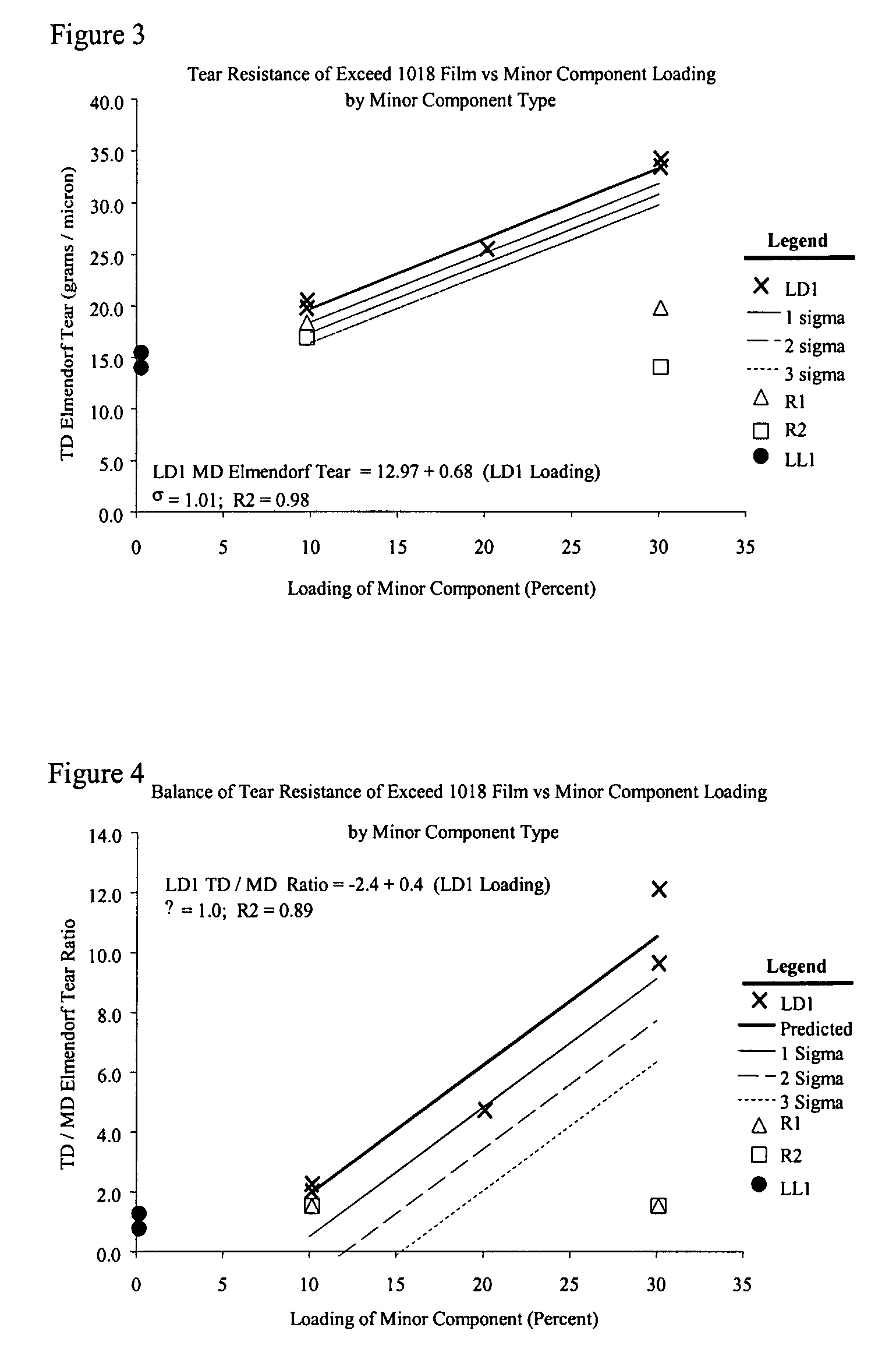

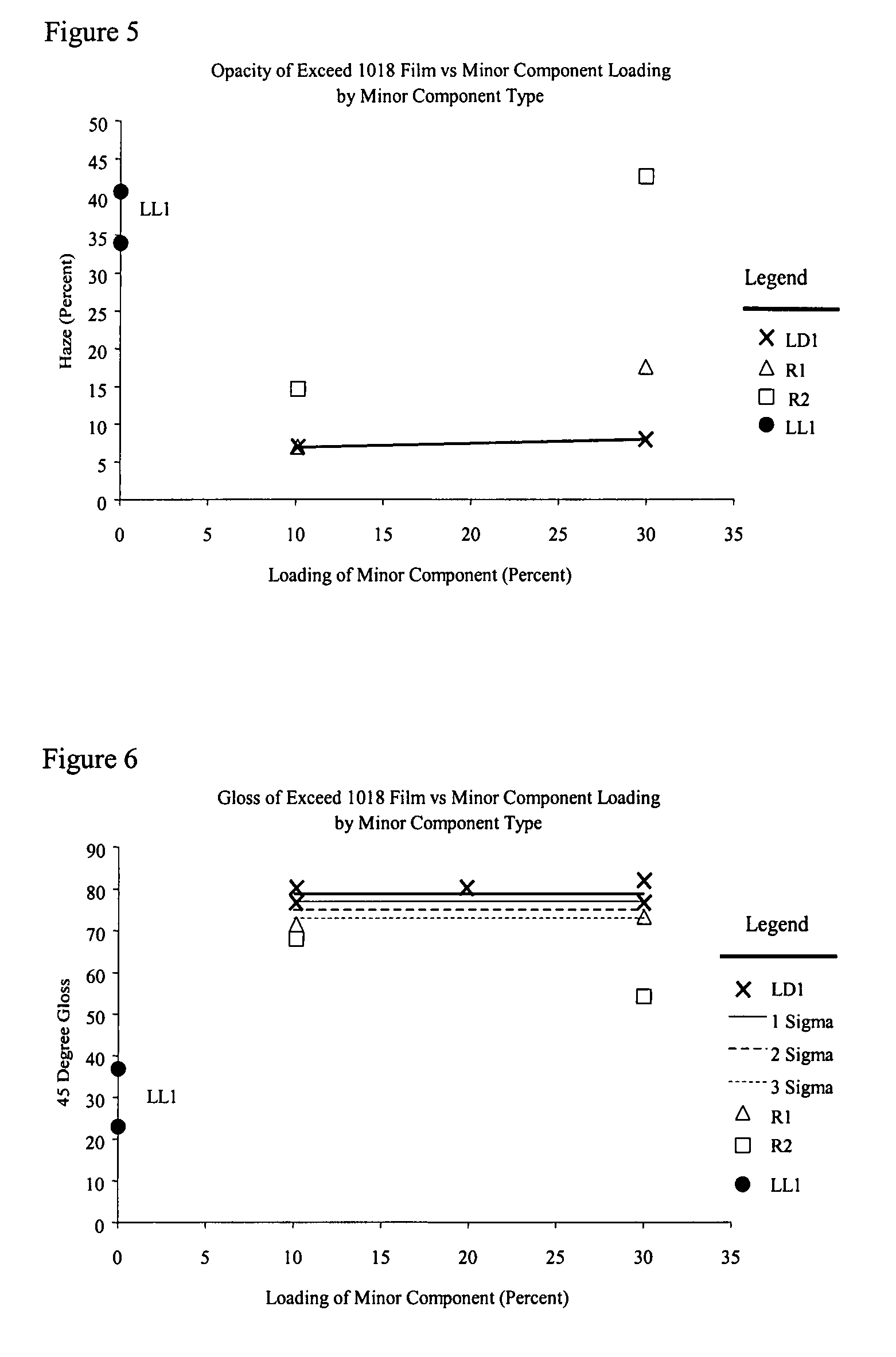

Rubber toughened compositions, articles, films, and methods of making the same

ActiveUS7985804B2Synthetic resin layered productsHollow wall articlesPolymer scienceRubber toughening

Owner:EXXONMOBIL CHEM PAT INC

Bamboo-charcoal slow rebounding pillow

InactiveCN102764020AReduce the overall heightWeak elasticityPillowsOther chemical processesActive agentEngineering

The invention relates to a pillow, in particular to a bamboo-charcoal slow rebounding pillow. The pillow comprises a pillow body and a pillow case, the pillow body comprises a high-elastic sponge pillow core, an air bag and a bamboo-charcoal slow rebounding sponge pillow core, the bamboo-charcoal slow rebounding sponge pillow core wraps the air bag, the air bag wraps the high-elastic sponge pillow core, one end of an air pipe is arranged on the air bag, the other end of the air pipe is connected with an air valve and arranged outside the bamboo-charcoal slow rebounding sponge pillow core, and the bamboo-charcoal slow rebounding sponge comprises, by weight, 1 to 8 parts of bamboo-charcoal powders with a particle size of 1500 to 2500 meshes, 20 to 85 parts of first polyatomic alcohol, 10 to 90 parts of second polyatomic alcohol, 8 to 30 parts of diphenylmethane diisocyanate (MDI), 0.2 to 0.8 part of silicone rubber toughening agents, 3 to 6 parts of foaming agents, 0.5 to 1 part of catalysts, 0.3 to 0.9 part of surface active agents and 0.2 to 0.5 part of fire retardants. The bamboo-charcoal slow rebounding pillow has the advantages that the elasticity and height can be adjusted, smooth flowing of blood in human body neck can be achieved, and an antibacterial effect can be achieved.

Owner:ZHEJIANG JIANZHONG BAMBOO IND

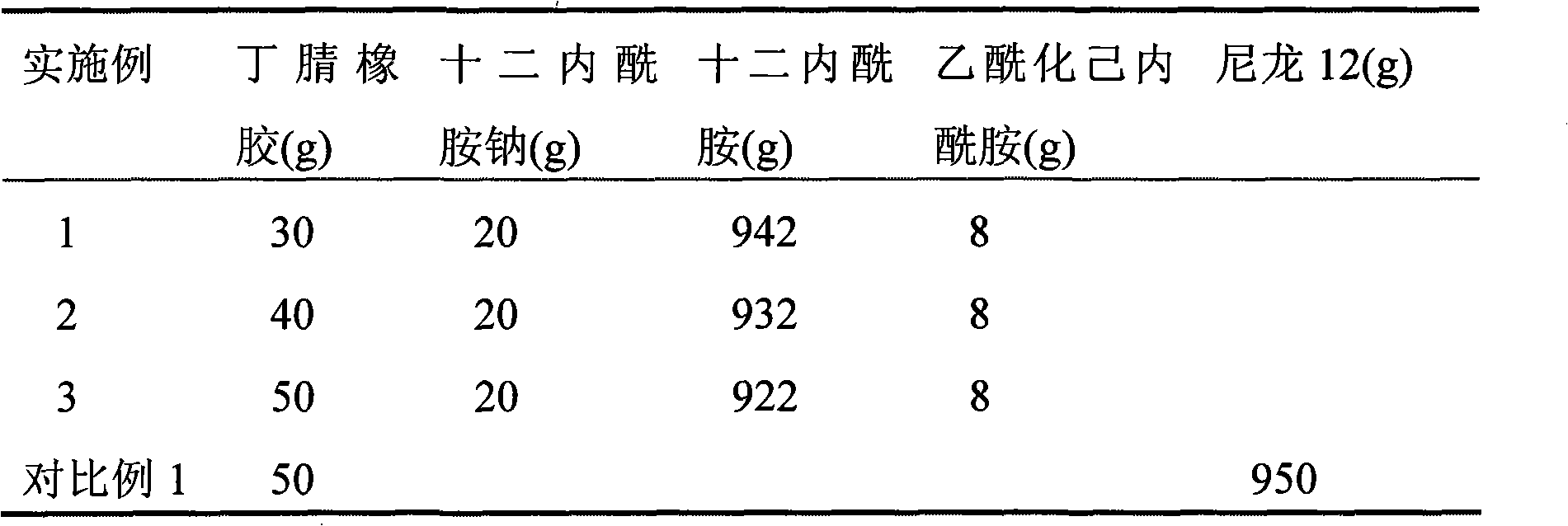

Preparation method of nano rubber toughening nylon material

The invention relates to a preparation method of nano rubber toughening nylon material. By an in-situ polymerization method, 3 to 10 weight percent of nano rubber, 81.8 to 96.93 weight percent of matrix nylon, 0.05 to 8 weight percent of anionic polymerization initiator and 0.02 to 0.2 weight percent of activating agent are premixed and directly fed into a synthesis device for anionic ring opening polymerization reaction at the synthesis temperature of 150-300 DEG C and extruded into granules to obtain nylon alloy. Compared with the prior art, the invention has the advantages of excellent shock resistance, simple process flow, little consumption, environment protection, no pollution, and the like.

Owner:SHANGHAI GENIUS ADVANCED MATERIAL (GRP) CO LTD

High-temperature-resistant phenolic carrier glue film and preparation method thereof

InactiveCN108485555AImprove heat resistanceImprove toughnessFilm/foil adhesivesMacromolecular adhesive additivesFiberEpoxy

The invention discloses a preparation method of a high-temperature-resistant phenolic carrier glue film. The prepared glue film is applicable to the bonding among honeycomb core sandwich materials, metal, ceramic and C-C composite materials. Particularly at high-temperature environment, good bonding performance is still maintained. The high-temperature-resistant phenolic carrier glue film providedby the invention is prepared by using modified phenolic glue liquid as matrix resin and using fiber fabric as a framework material by a hot melting film coating method; the modified phenolic glue liquid is prepared from the following ingredients in parts by mass: 100 mass parts of phenolic resin, 10 to 50 mass parts of rubber toughening agents, 50 to 80 mass parts of epoxy resin and 5 to 10 massparts of diluents. The prepared high-temperature-resistant phenolic carrier glue film has the characteristics that the preparation process is simple; the application is convenient and fast; the heat resistance and bonding performance are good, and the like.

Owner:WUHAN UNIV OF TECH

Epoxy structure adhesive applied to aramid fiber honeycomb composite materials and preparation method thereof

InactiveCN107556954AHigh bonding strengthImprove temperature resistanceNon-macromolecular adhesive additivesMacromolecular adhesive additivesEpoxyRubber toughening

The invention discloses an epoxy structure adhesive applied to aramid fiber honeycomb composite materials and a preparation method thereof. The epoxy structure adhesive is prepared from the followingcomponents: matrix epoxy resin, heat-resistant epoxy resin and a rubber toughening agent, wherein the mass ratio of the matrix epoxy resin to the heat-resistant epoxy resin and the rubber toughening agent is 1 to (1.5-3) to (2-5). The epoxy structure adhesive of the technical scheme is mainly applied to connection between aramid fiber honeycomb materials; the mass ratio of the matrix epoxy resin to the heat-resistant epoxy resin and the rubber toughening agent is optimized to obtain an equilibrium value, so that the prepared epoxy structure adhesive has relatively high adhesion strength and better temperature resistance after the epoxy structure adhesive is cured under normal temperature; meanwhile, the preparation method is simple to operate; the epoxy structure adhesive is cured under normal temperature and is used under high temperature; the peeling strength of the adhesive material is improved.

Owner:SICHUAN YUNTONG CHEM IND CO LTD

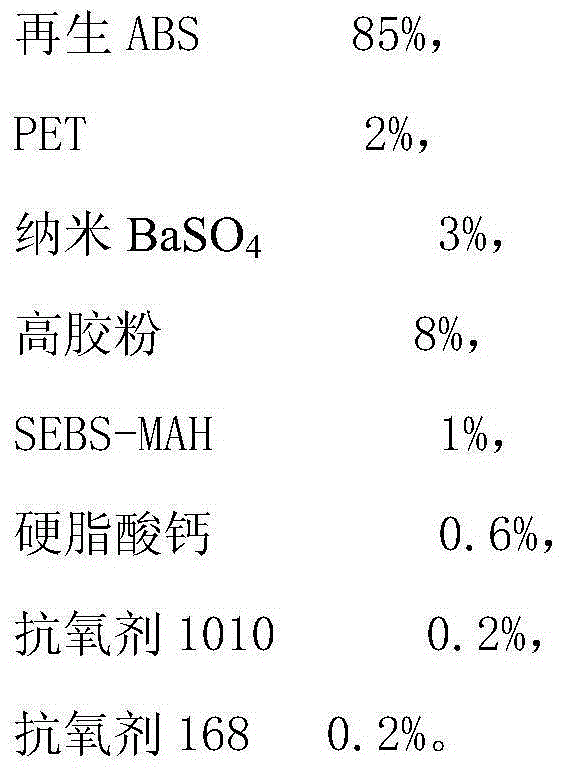

High-impact greasy-dirt-resistant modified regenerated ABS material and preparation method thereof

InactiveCN105199303AImprove impact resistanceImprove oil stain resistancePolymer scienceRubber toughening

The invention discloses a high-impact greasy-dirt-resistant modified regenerated ABS material and a preparation method thereof. The modified regenerated ABS material is prepared from, by weight, 78%-85% of regenerated ABS, 2%-5% of PET, 8%-10% of ABS, 1%-2% of compatilizer, 0.3%-0.8% of lubricating agent, 0.4%-0.8% of antioxygen and 2%-5% of filler. The PET resin, nano BaSO4 and ABS of the specific content are added, the impact resistance and greasy dirt resistance of the ABS material are improved, the use requirement of the ABS material as a high-impact greasy-dirt-resistant storage battery shell is met, impact strength is improved due to rubber toughening of the ABS, and the PET resin and nano BaSO4 achieve the functions of improving the surface polarity of the ABS material and reducing surface microdefects of the ABS material.

Owner:GUANGDONG TIANBAO NEW MATERIALS CO LTD

Room temperature controllable curing building adhesive and preparation method thereof

ActiveCN101265400ALow viscosityLong operating timeNon-macromolecular adhesive additivesEpoxy resin adhesivesAlkaneAdhesive

The invention relates to a room temperature controllable curing construction adhesive and the preparation method thereof, which belong to the adhesive used for bonding and anchoring of building elements, and the preparation field thereof. The room temperature controllable curing construction adhesive is a bi-component room temperature curing adhesive composed of first adhesive liquid and second adhesive liquid, the components and the contents (mass percent) of the first adhesive liquid are as follows: bisphenol A epoxy resin 30 to 95 percent, bisphenol F epoxy resin 0 to 95 percent, ester thinner 5 to 20 percent, and long-chain fatty alkane 5 to 25 percent; the components and the contents (mass percent) of the second adhesive liquid are as follows: fatty amines 15 to 65 percent, rubber toughening agent 10 to 50 percent, curing accelerant 2 to 15 percent, and coupling agent of KH series 2 to 8 percent. The construction adhesive has the advantages that the construction adhesive has environmental protection (without contaminants of formaldehyde,etc.) urgently needed by the building market, small viscosity, long operating time, larger amount of adhesive distribution, higher operating temperature range and controllable curing speed, thereby meeting the requirements of construction and operation under differnet conditions, and solving the problem of the requirement of the building market to the room temperature controllable curing environment-friendly building structural adhesive.

Owner:DALIAN UNIV OF TECH

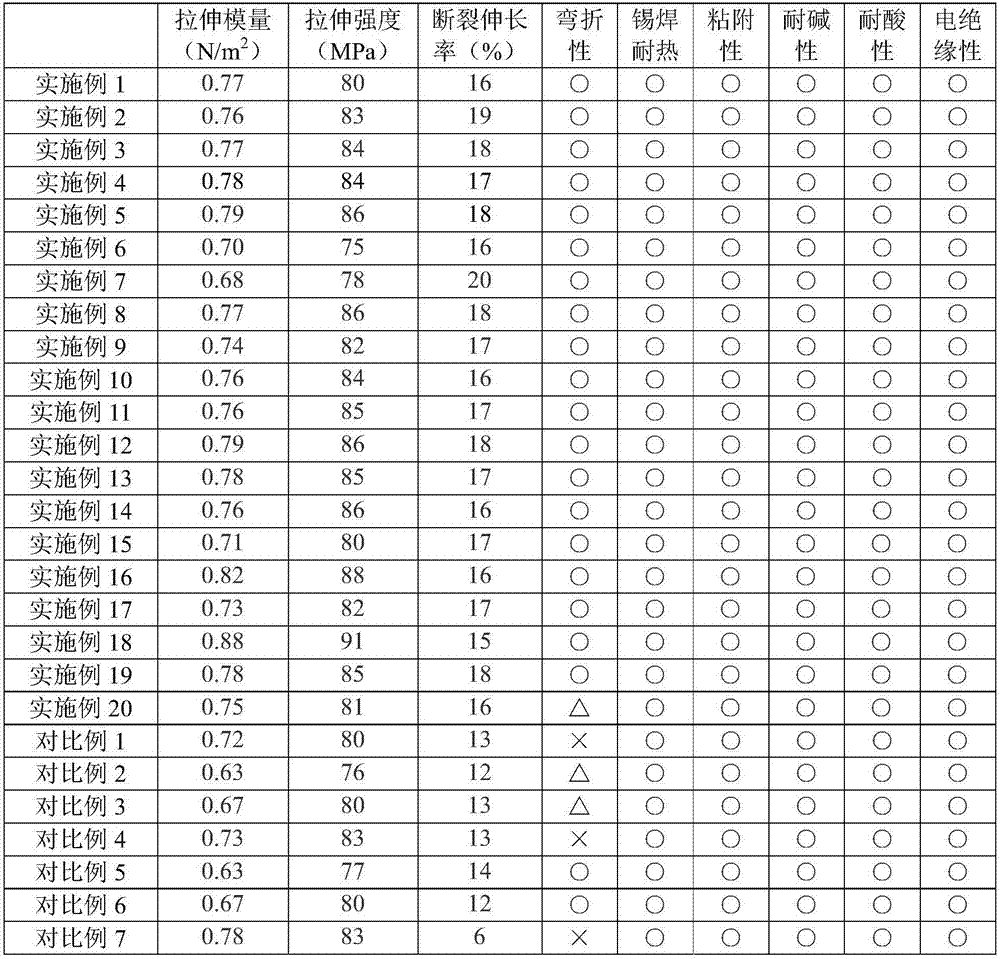

High-toughness photosensitive epoxy acrylic resin composition capable of developing in weakly basic water and preparation method of epoxy acrylic resin composition

ActiveCN107450269AImprove toughnessEvenly dispersedPhotosensitive materials for photomechanical apparatusAcrylic resinOxygen

Owner:HANGZHOU FIRST ELECTRONIC MATERIAL CO LTD

Heat conducting adhesive and preparation method and application thereof

ActiveCN104817985AAchieve a tight bondImprove performanceNatural rubber adhesivesNon-macromolecular adhesive additivesPolymer scienceAdhesive

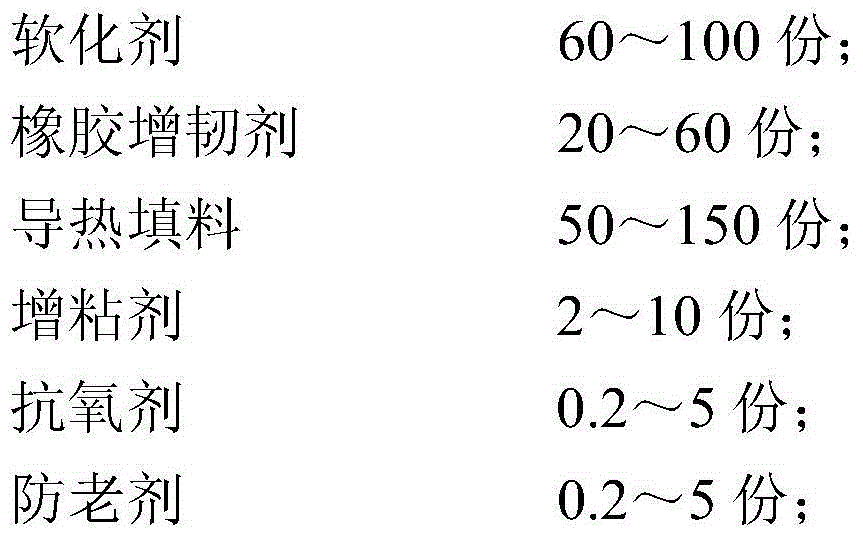

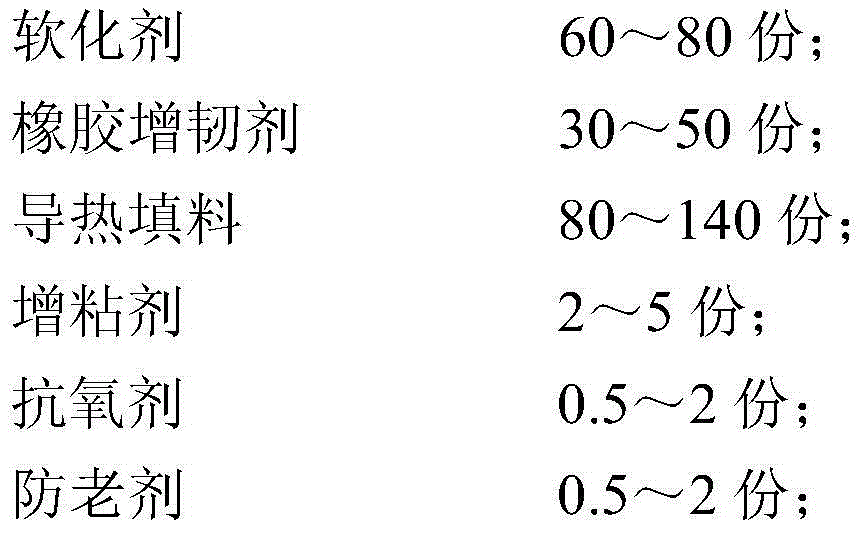

The invention relates to a macromolecular heat conducting composite material, in particular to a heat conducting adhesive and a preparation method and application thereof. The heat conducting adhesive is made of, by weight, 60-100 parts of softener, 20-60 parts of rubber flexibilizer, 50-150 parts of heat conducting filler, 2-10 parts of tackifier, 0.2-5 parts of antioxidant and 0.2-5 parts of antiager. The preparation method includes the steps: rolling the rubber flexibilizer, sequentially adding the softener, the heat conducting adhesive, the tackifier, the antioxidant and the antiager, and mixing for 1-2h at the temperature of 80-150 DEG C to obtain the heat conducting adhesive. The heat conducting adhesive has the advantages of freeness of curing, convenience in processing, excellent adhesion performance, high heat conductivity and the like. Close adhesion of devices can be realized only by application of a proper pressure at the normal temperature, and the heat conducting adhesive is cheap and environment friendly.

Owner:国科广化(南雄)新材料研究院有限公司 +1

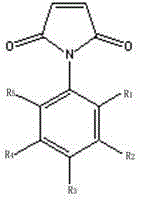

Heat-resistant, flame resistant and anti-brittle fracture modified epoxy resin adhesive and preparation method thereof

InactiveCN103059790AGood anti-brittle performanceHigh Response FlexibilityMacromolecular adhesive additivesEpoxy resin adhesivesGlycidyl methacrylateHeat stability

The invention belongs to the technical field of epoxy resin adhesives, and particularly relates to a heat-resistant, flame resistant and anti-brittle fracture modified epoxy resin adhesive and a preparation method thereof. The adhesive is prepared from the substances in parts by weight as follows: 50-60 parts of low-viscosity bisphenol A type epoxy resin, 25-30 parts of bromo-phenyl maleimide / styrene / glycidyl methacrylate terpolymer, 15-30 parts of a curing agent, 2-8 parts of a nuclear shell type rubber toughening agent, 26-29 parts of a diluting agent and 3-7 parts of a curing accelerator. The heat-resistant, flame resistant and anti-brittle fracture modified epoxy resin adhesive improves heat stability and flame resistance thereof efficiently, reduces brittleness of cured products, has a simple process, low cost and convenience in operation, can finish the preparation process thereof in a universal device and has a very high practical value for the development of the adhesive industry, and has a wide application foreground in the fields such as electronics, microelectronics and the like.

Owner:ZHENGZHOU UNIV

Modified polypropylene composite material with high adhesive property as well as preparation method and application thereof

ActiveCN112724537AIncrease surface tensionHigh bonding strengthPolypropylene compositesRubber toughening

The invention discloses a modified polypropylene composite material with high bonding performance as well as a preparation method and application thereof. The modified polypropylene composite material comprises the following components: 40-80 parts of polypropylene, 20-50 parts of talcum powder, 1-10 parts of a rubber flexibilizer, 0.5-1.5 parts of a compatilizer, 0.1-1.5 parts of an antioxidant, 0.1-3 parts of a coupling agent, 0.1-1.5 parts of a lubricant and 0.1-2 parts of a polar additive, wherein the particle size of the talcum powder is 3-15 [mu] m; and the polar additive is diethanol amine with a long carbon chain structure, and the long carbon chain structure is a carbon chain structure with more than 10 carbon atoms. The preparation method comprises the following steps: mixing all the raw materials, carrying out melt extrusion, cooling and granulating. The modified polypropylene material has the advantages of favorable mechanical properties, favorable surface state and excellent bonding effect, and has favorable bonding application effect when being used for plastic back doors.

Owner:DONGFENG MOTOR CORP HUBEI

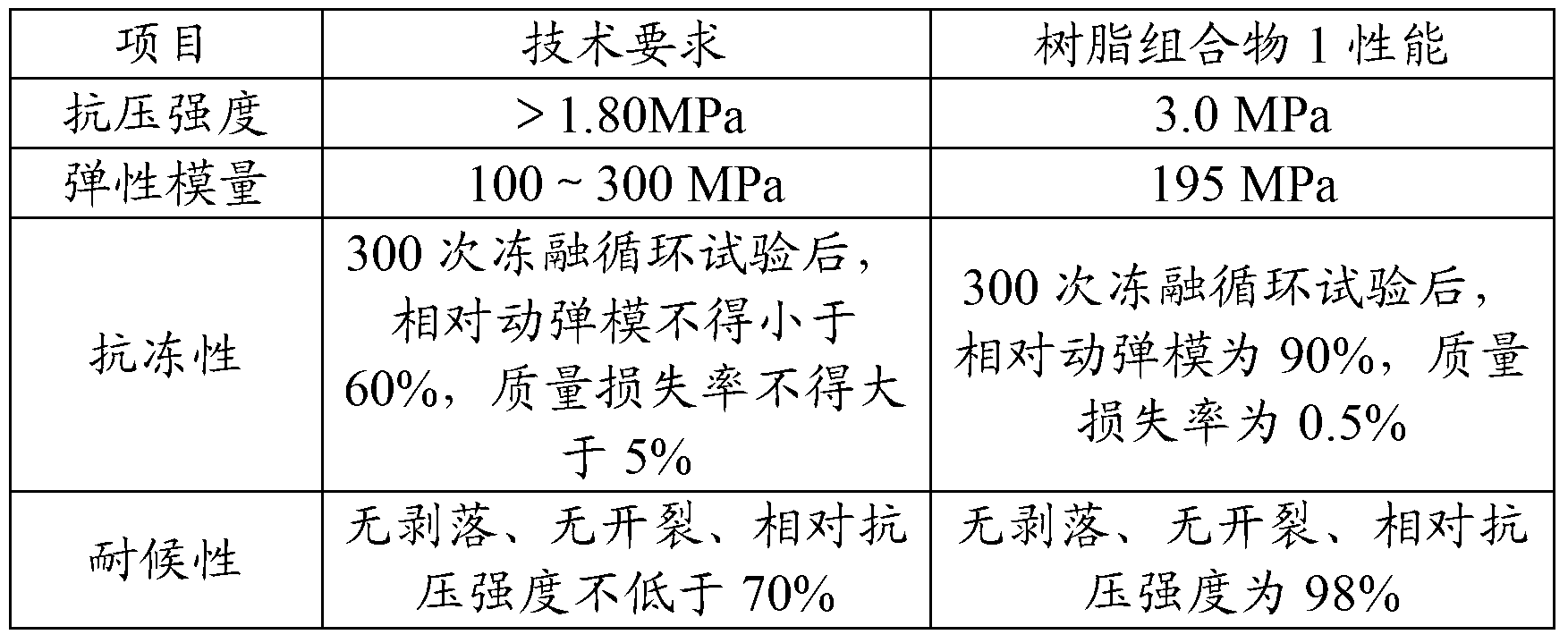

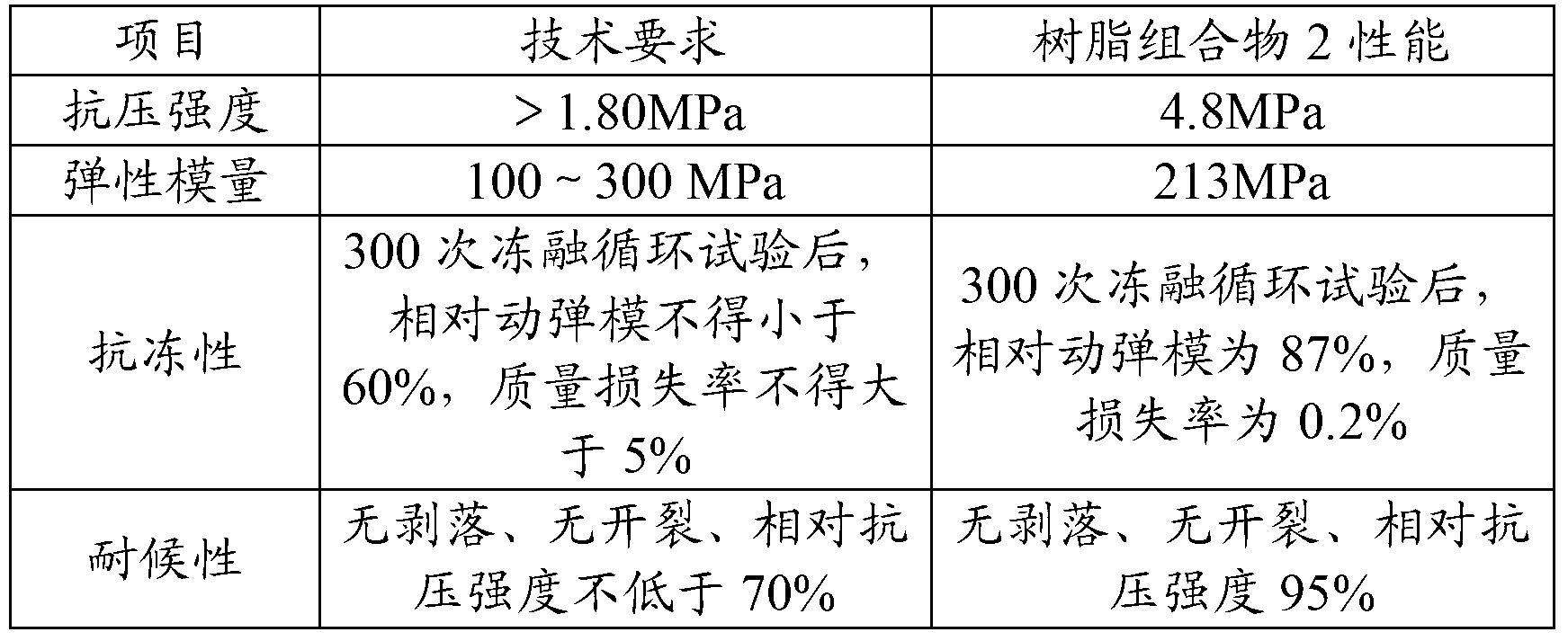

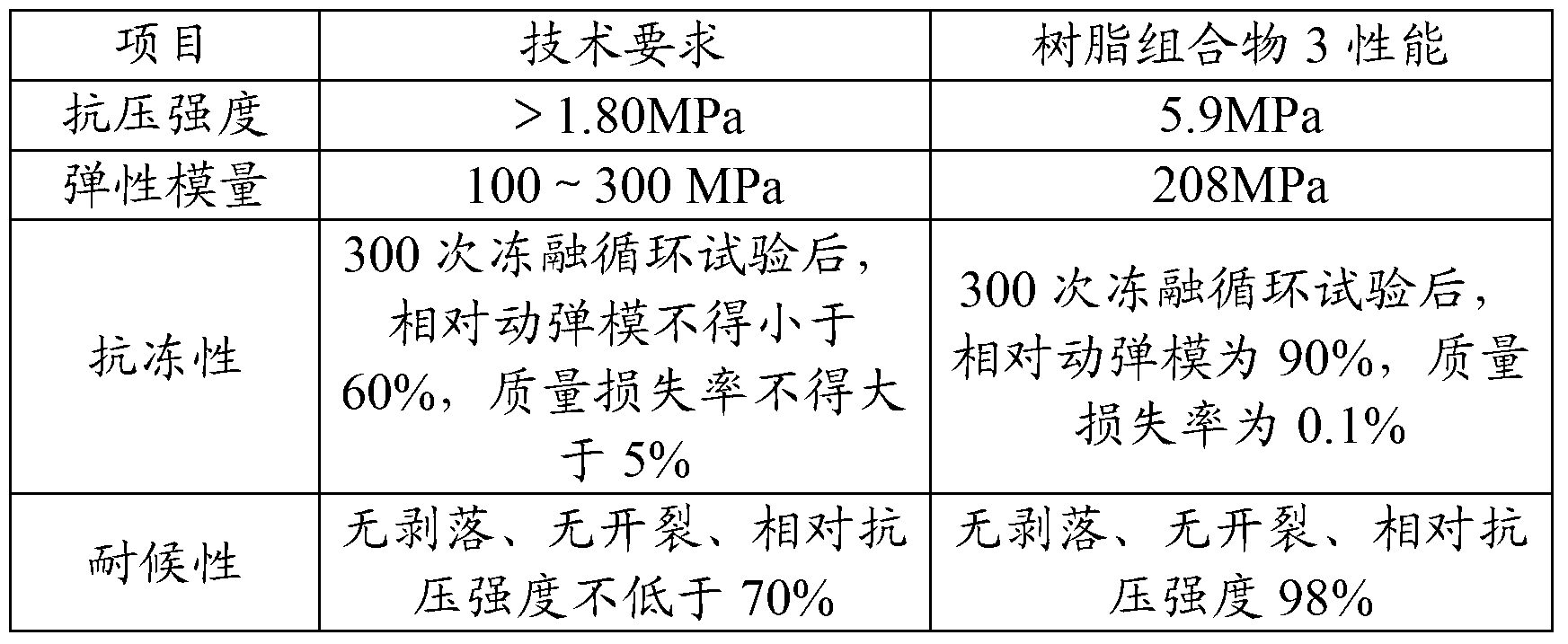

Resin composition for CRTS (China Rail Traffic Summit) I type slab ballastless track and preparation method of resin composition

The invention provides a resin composition and a preparation method of the resin composition. The resin composition comprises a component A, a component B and a component C, wherein the component A comprises the following substances in parts by weight: 70-200 parts of vinyl ester resin composition, 0-20 parts of active diluting agent, 0-50 parts of non-rubber toughening agent, 0-30 parts of rubber toughening agent, 0-20 parts of catalyst, 0-5 parts of ultraviolet absorber, 0-5 parts of light stabilizer, 0-5 parts of antioxidant, 0-5 parts of coupling agent and 0-50 parts of thixotropic agent; the component B comprises the following substance in parts by weight: 1-100 parts of peroxide initiator; the component C comprises the following substances in parts by weight: 120-500 parts of quartz sand and 0-200 parts of rubber particle; and the vinyl ester resin composition comprises vinyl ester resin polymer. The resin composition is matched with a CA mortar layer in performance and is previously prepared, a line with subgrade differential settlement of being over 30 mm can be conveniently and quickly maintained within actual maintenance skylight time, and the original line track structure is restored after the skylight is finished, and the traffic safety is guaranteed.

Owner:METALS & CHEM RES INST CHINA ACAD OF RAILWAY SCI +2

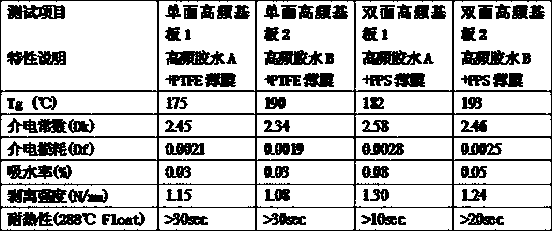

High-frequency glue and high-frequency flexible copper-clad laminate applying high-frequency glue

InactiveCN110982489ALow dielectric constantLow dielectric lossSynthetic resin layered productsElectrical equipmentPolymer scienceDielectric loss

The invention provides a high-frequency glue and a high-frequency flexible copper-clad laminate applying the high-frequency glue, and mainly relates to the field of copper-clad laminate preparation. The high-frequency glue is prepared from the following components in parts by mass: 10-15 parts of an epoxy resin, 10-30 parts of a DCPD modified benzo resin or 8-18 parts of a polyphenylene oxide resin (PPO), 2-8 parts of a BMI resin, 5-10 parts of an SMA anhydride curing agent, 2-8 parts of a low-dielectric phosphazene flame retardant, 5-10 parts of a low-dielectric rubber toughening agent and 25-45 parts of butanone. The high-frequency flexible copper-clad laminate is bonded by using the high-frequency glue. According to the invention, by preparing the high-frequency glue, the AiP antenna material with low dielectric constant, low dielectric loss and low water absorption is obtained by applying the high-frequency glue to a copper-clad laminate so as to provide the hardware support for application of 5G technology.

Owner:SHANDONG JINDING ELECTRONICS MATERIALS CO LTD

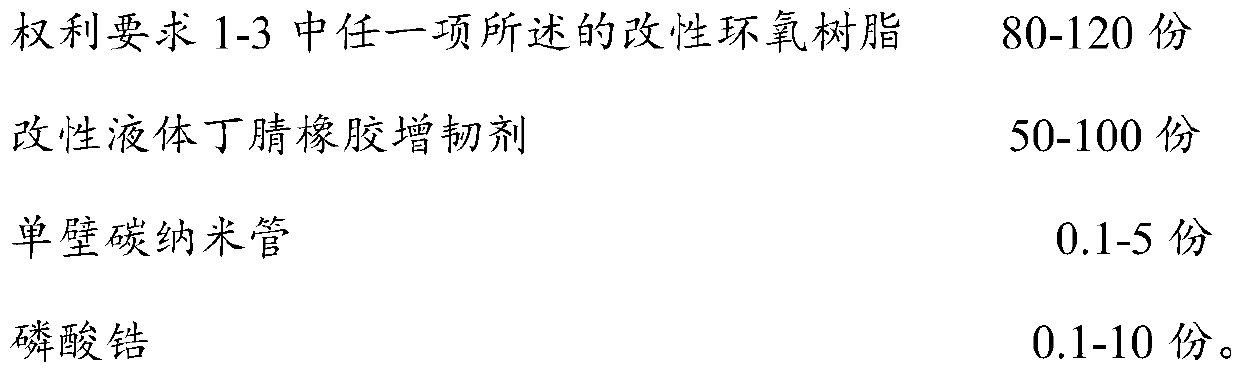

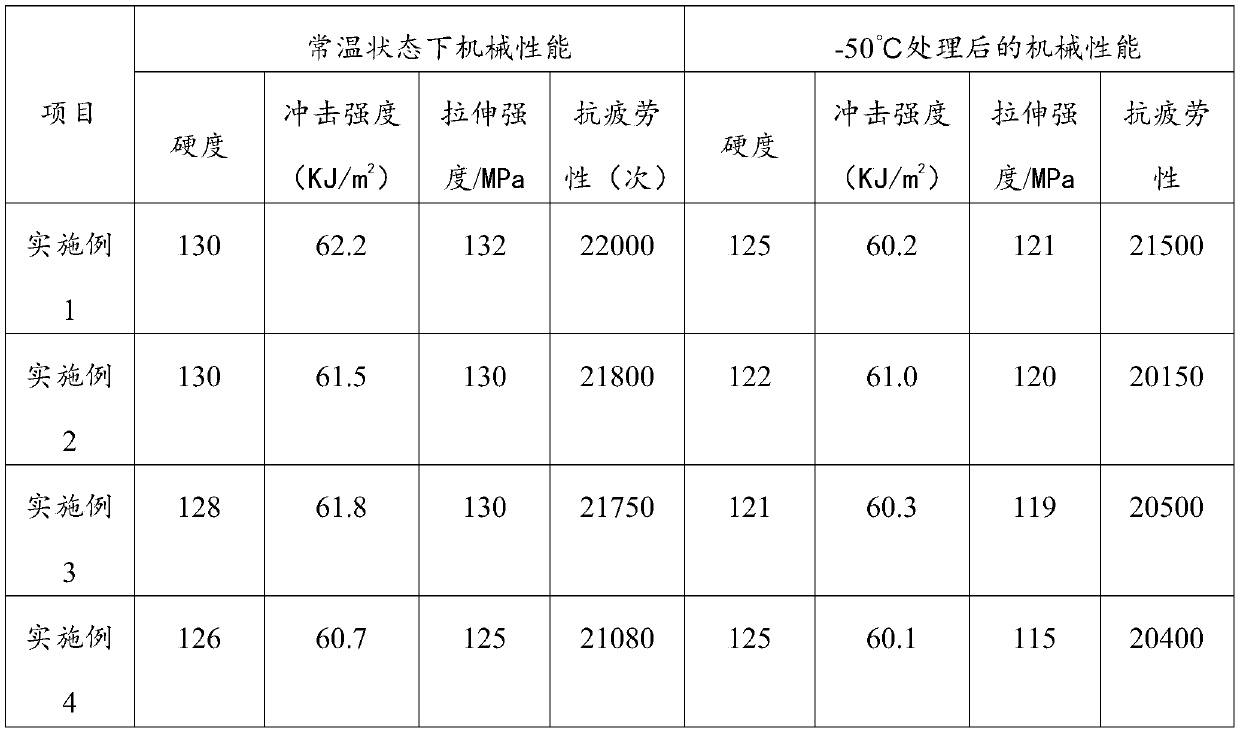

Modified epoxy resin composition, adhesive film and preparation method thereof

InactiveCN111393653ALarge specific surface areaHigh strengthAntifouling/underwater paintsPaints with biocidesEpoxyPolymer science

The invention belongs to the field of materials, and discloses modified epoxy resin, which is mainly obtained by jointly modifying epoxy resin with an organic silicon copolymer and an acrylate oligomer. The organic silicon copolymer is obtained by polymerizing SiO2 and an organic silicon monomer, and the organic silicon monomer is silane containing phenyl and alkoxy; and the molecular weight of the acrylate oligomer is 1000-10000. The invention also discloses a modified epoxy resin composition, which comprises the modified epoxy resin, a modified liquid nitrile butadiene rubber flexibilizer, asingle-walled carbon nanotube and zirconium phosphate. The adhesive film prepared from the modified epoxy resin composition has excellent weather resistance, mechanical properties and good wave permeability, and can be used in the field of stealth technology or radio. Meanwhile, the modified epoxy resin composition also has remarkable antibacterial and bacteriostatic performance and is not proneto being polluted by microorganisms in the production process, and the prepared epoxy resin adhesive film has antibacterial performance and can be used in severe environments.

Owner:江门市瑞祥复合材料研究院有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com