Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

231results about How to "Improves sprayability" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

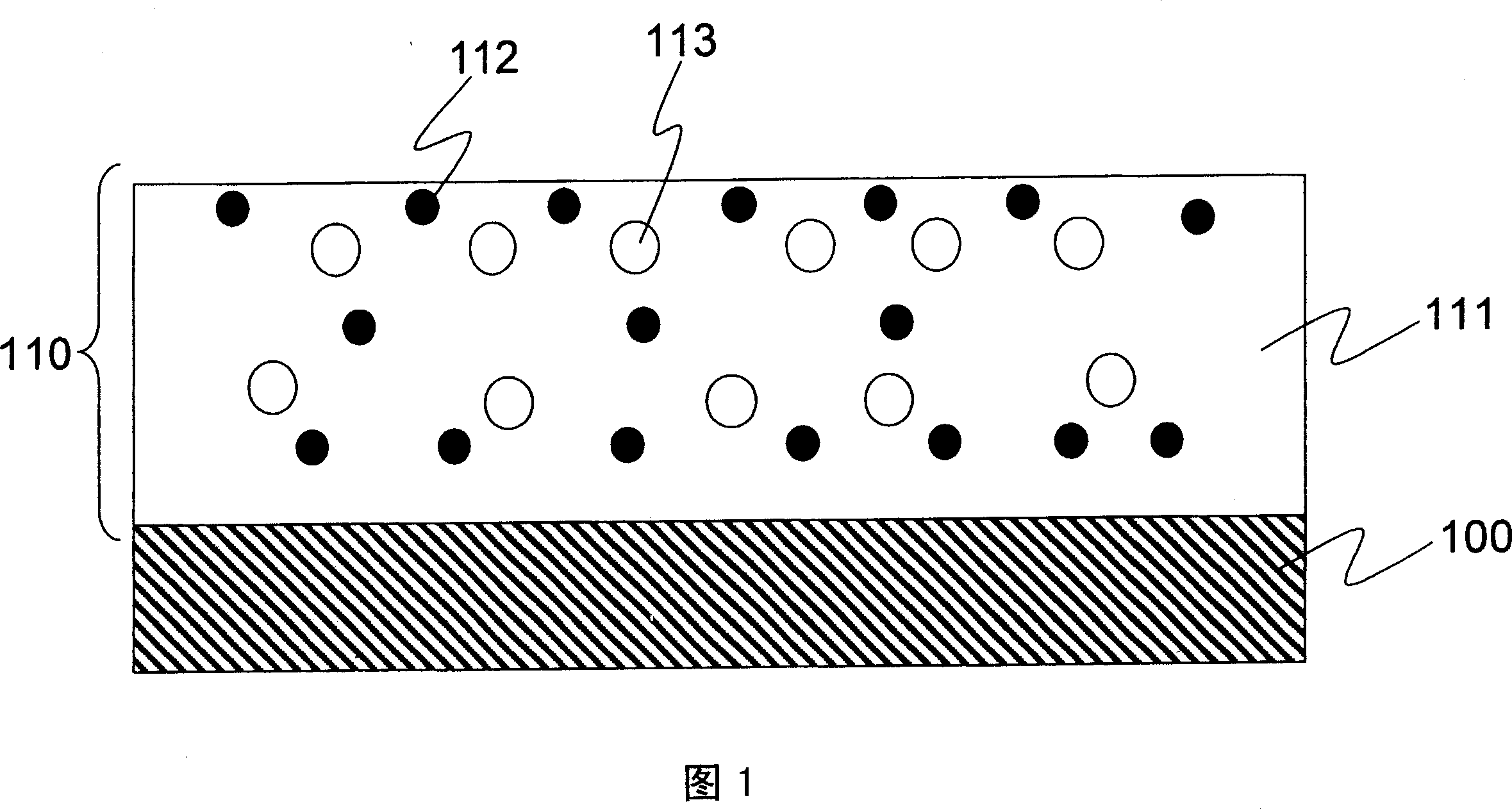

High temperature insulating mould coating

The invention relates to a high temperature insulating coating, comprising thermal- resistant resin, solvent, and nano-porous packing material and hollow microsphere inorganic packing material. The thermal- resistant resin comprises more than one thermal- resistant polymer, nano-porous packing material possesses nano- micropore structure, and the hollow microsphere inorganic packing material is hollow sphere.

Owner:IND TECH RES INST

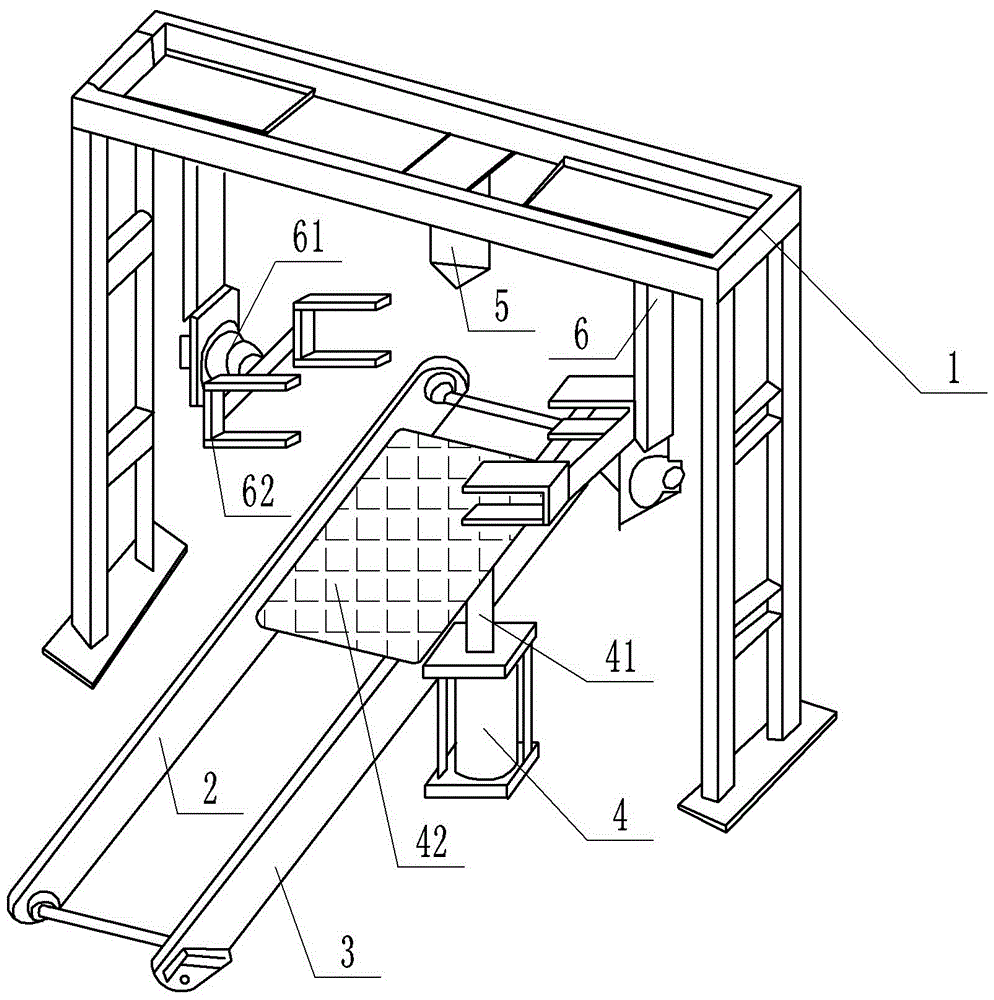

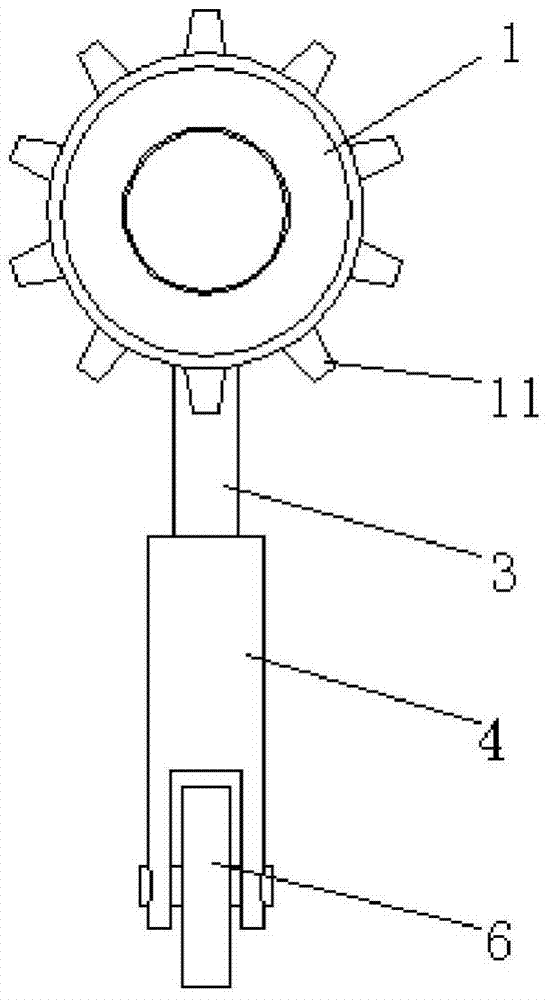

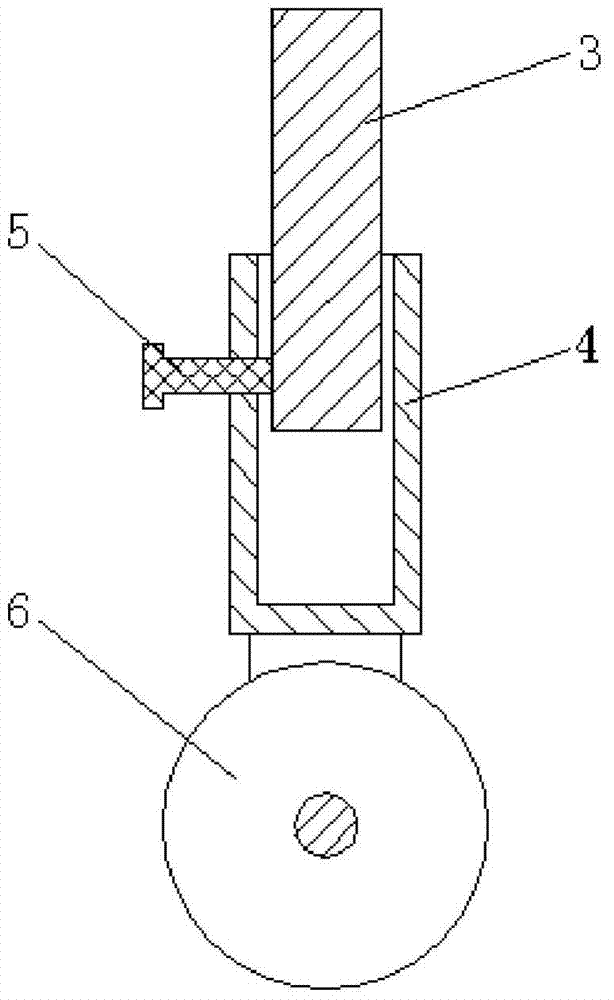

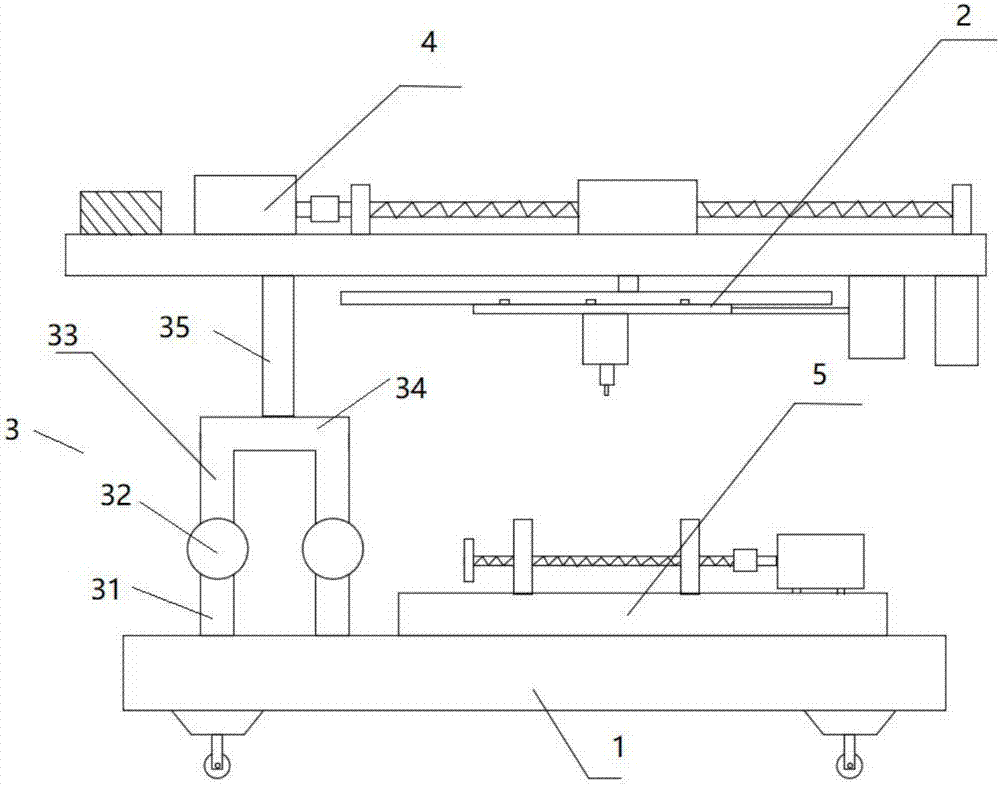

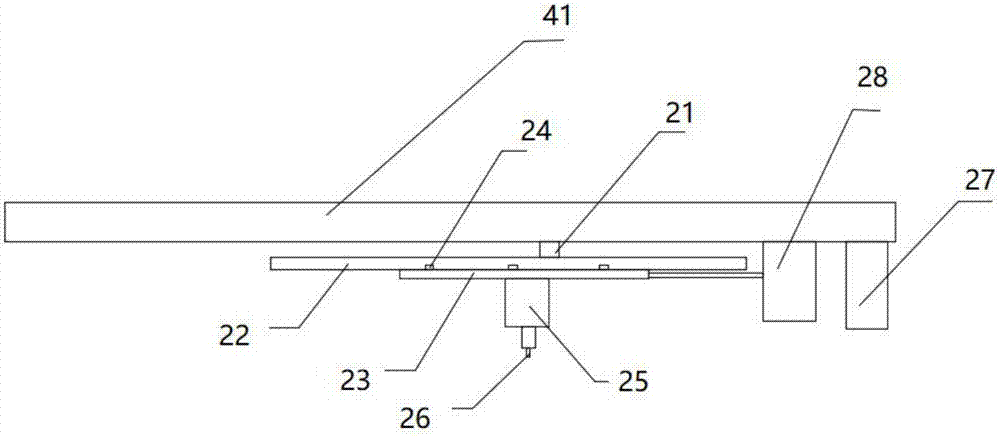

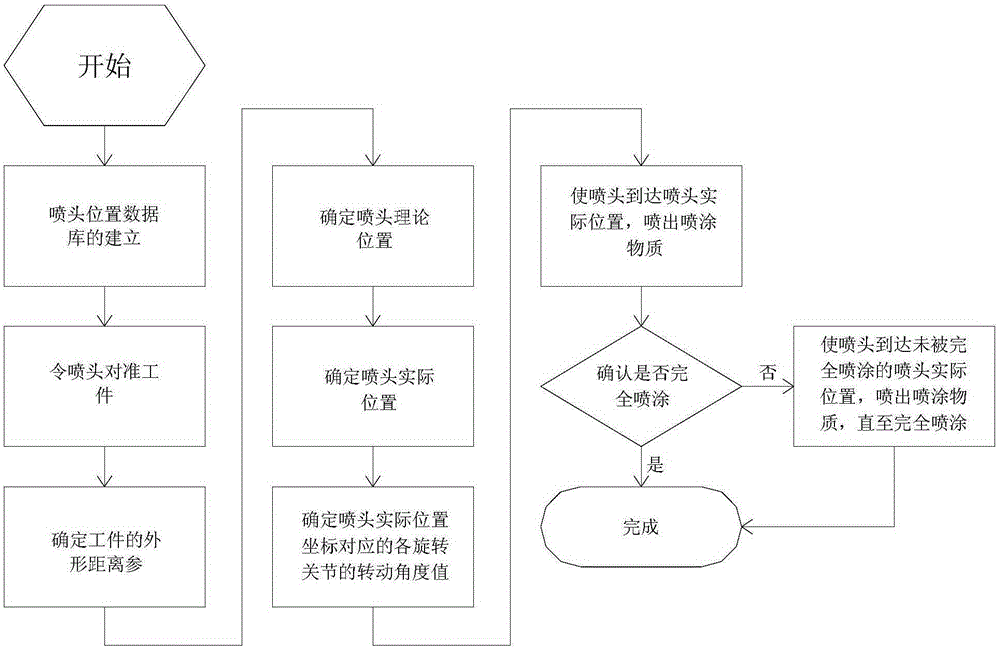

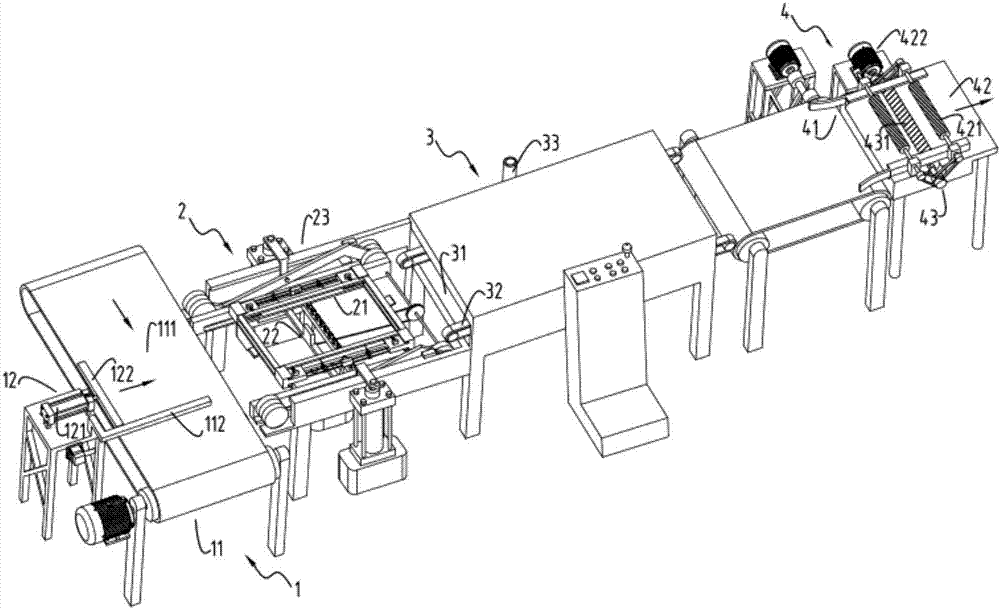

Automatic device for paint spraying of wood door

InactiveCN106423652ARealize all-round paintingReduce labor intensitySpraying apparatusUltimate tensile strengthAutomation

The invention relates to the technical field of paint spraying equipment, in particular to an automatic device for the paint spraying of a wood door. The automatic device comprises a bracket, a conveying device, a lifting device and an automatic paint spraying device, wherein the bracket is located at one side of the transporting direction of the conveying device; the conveying device comprises a left conveying chain and a right conveying chain; the lifting device is located between the left conveying chain and the right conveying chain; a clamping rotating device is arranged above the lifting device, and the clamping rotating device is fixed to the bracket; and the automatic paint spraying device is fixed to the bracket and located above the lifting device. By adopting the technical scheme, the all-dimensional paint spraying of the wood door can be realized, the automation degree is high, the labor intensity of workers is reduced, and the paint spraying efficiency is increased; and as paint spraying is carried out by the machine without depending on the experience of the workers, paint spraying is even, and the spraying effect is great.

Owner:遵义市美呈美居工贸有限公司

Nano magnetic pigment and preparation thereof

InactiveCN101205421AControl spray effectImproves sprayabilityInorganic pigment treatmentOrganic dyesNanometrePigment

The invention relates to a nano magnetic controlled pigment and a preparation method thereof, belonging to an application of magnetic nano-materials in the coating field. The preparation of the nano magnetic controlled pigment is mixing the magnetic nano-materials with other pigments after surface treatment of the magnetic nano-materials, adding the obtained magnetic controlled pigment into other coatings, and stirring completely before obtaining the nano magnetic controlled coating. The nano magnetic controlled pigment prepared by the invention has directional movement or the tendency of directional movement under the effect of magnetic field; the nano magnetic controlled coating can achieve the effect of controlling pattern spray through controlling magnetic lines of force; the coating is easy to prepare and operate.

Owner:NANJING UNIV OF TECH

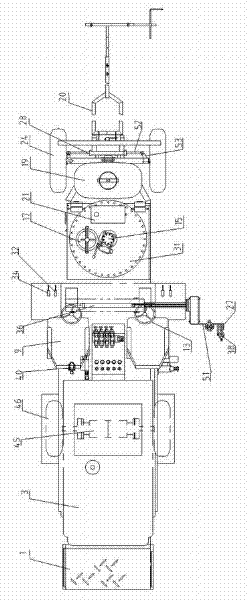

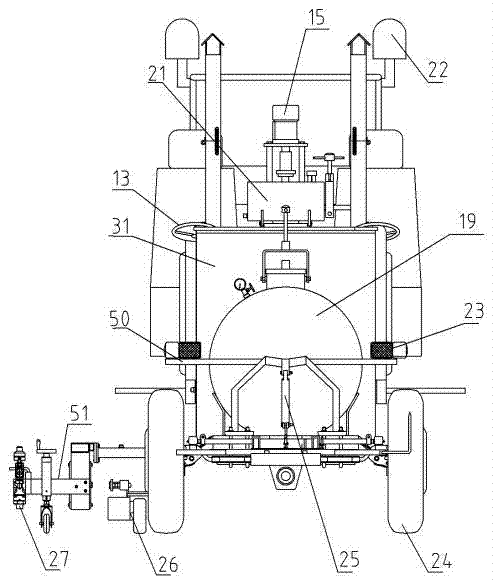

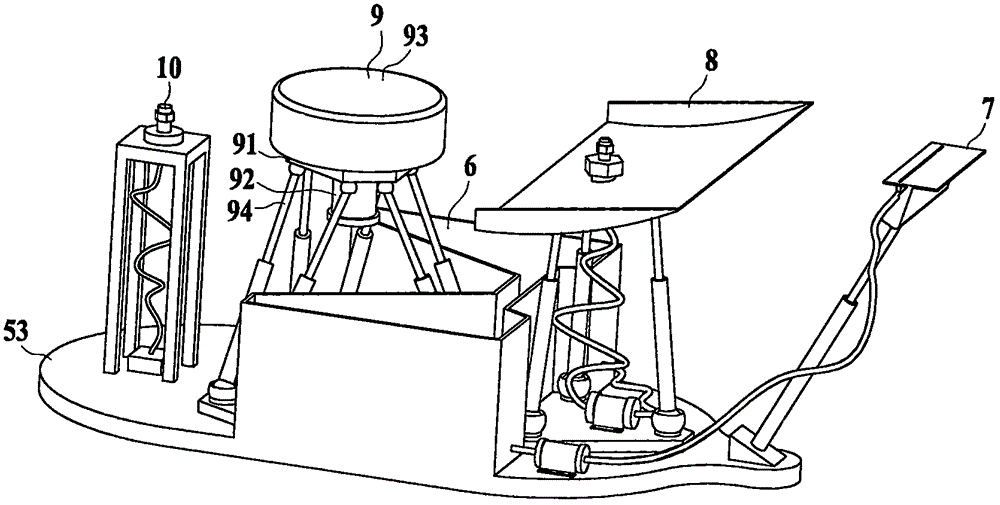

Ride-on Hot Melt Spray Marking Machine

ActiveCN102268855AImprove atomization effectReduce burrsRoads maintainenceHeating systemHeating efficiency

The invention discloses a drive type hot-melt spraying marking machine, which comprises a rack, and the rack is provided with a power-driven system, a heating system, a marking system, a travel system, a hydraulic control system, a pneumatic control system and a steering system, wherein the power-driven system is in drive connection with the travel system, the hydraulic control system and the pneumatic control system respectively; the hydraulic control system is in drive connection with the steering system; and the marking system is in drive connection with the hydraulic control system and the pneumatic control system respectively. In the invention, a hot-melt spraying coating is heated to be a molten condition through an infrared heating system and a heat-conduction-oil heat preservationcyclic system, and then is sprayed to specified positions through a hot-melt gun, and the like. The drive type hot-melt spraying marking machine has the advantages of high marking efficiency, no needof removing existing lines for redintegration, adjustable width and thickness of marking lines, high heating efficiency, sufficiency for combustion and flexible control of flames.

Owner:天途路业集团有限公司

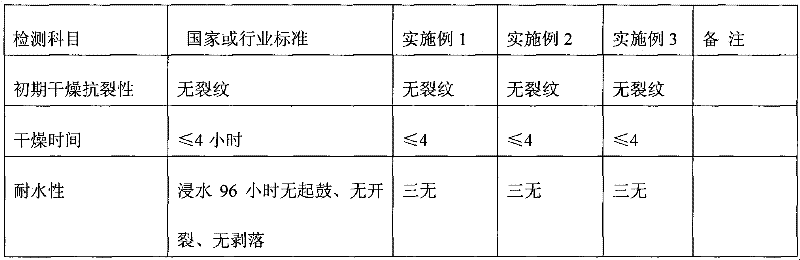

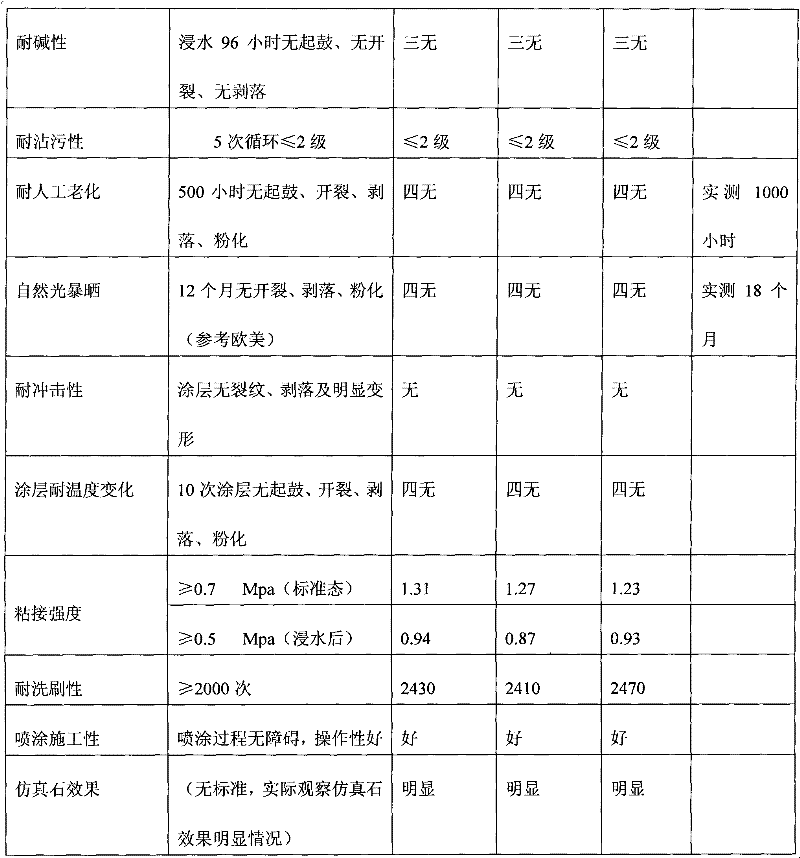

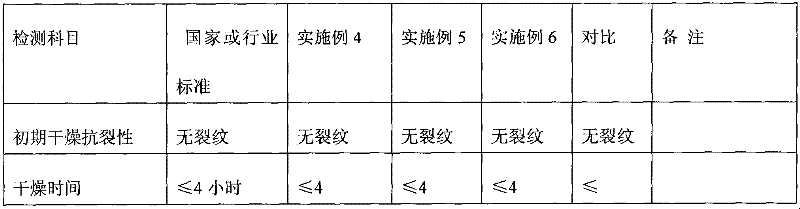

Sand textured two-component plaster mortar composition

The invention provides a sand textured two-component plaster mortar composition. The composition consists of the following components in parts by weight: 20 to 30 parts of white cement, 40 to 60 parts of silicon carbide, 0.5 to 1.5 parts of gelatin powder, 0.1 to 0.3 part of xanthan gum, 0.1 to 0.2 part of cellulose ether, 3 to 7 parts of lithopone, 1.5 to 3 parts of fire retardant, 0.1 to 0.5 part of sodium tripolyphosphate, 0.1 to 0.5 part of hardening agent, 0.1 to 0.3 part of defoaming agent, 40 to 50 parts of modified polyurethane emulsion, and 1 to 3 parts of dipropylene glycol methyl ether. A filmed polyurethane adhesive film has hydrophobic nature better than an adhesive film copolymerized from pure acrylic acid, styrene-acrylate or vinyl acetate, so that the mortar spraying effect is excellent, and the effect of simulating stones rivals that of stones; and the composition has good effects in adhesive strength, water resistance, stain resistance, light and weather resistance.

Owner:苏州盛泽科技创业园发展有限公司

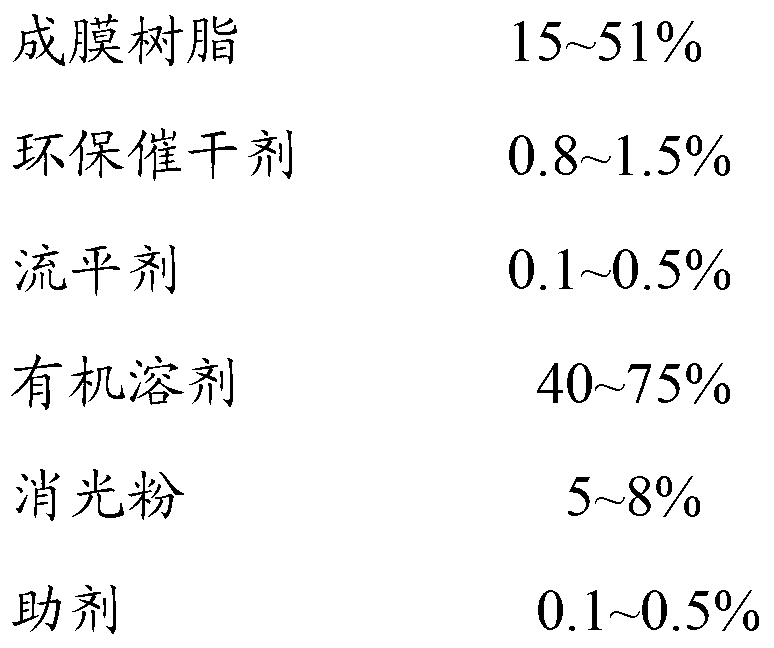

Environment-friendly elastic feeling paint and using method thereof

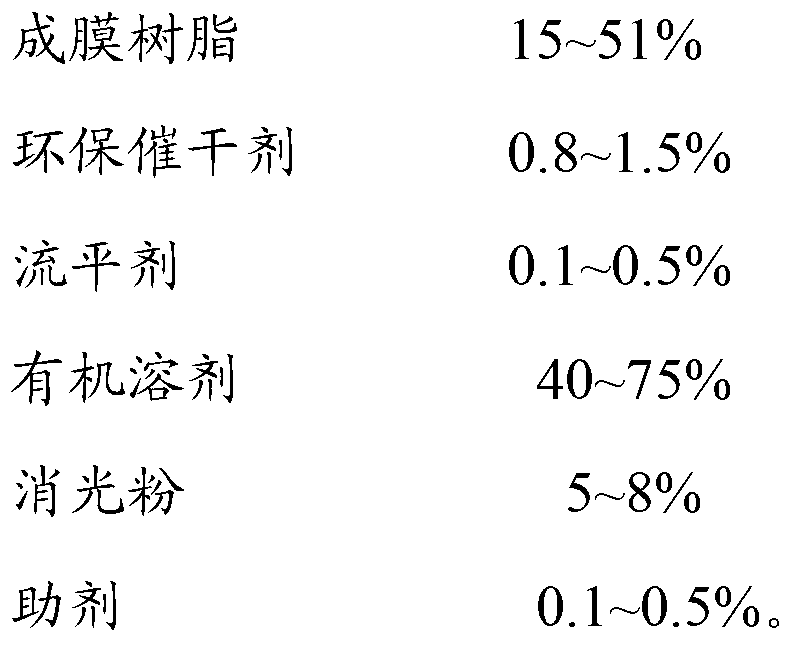

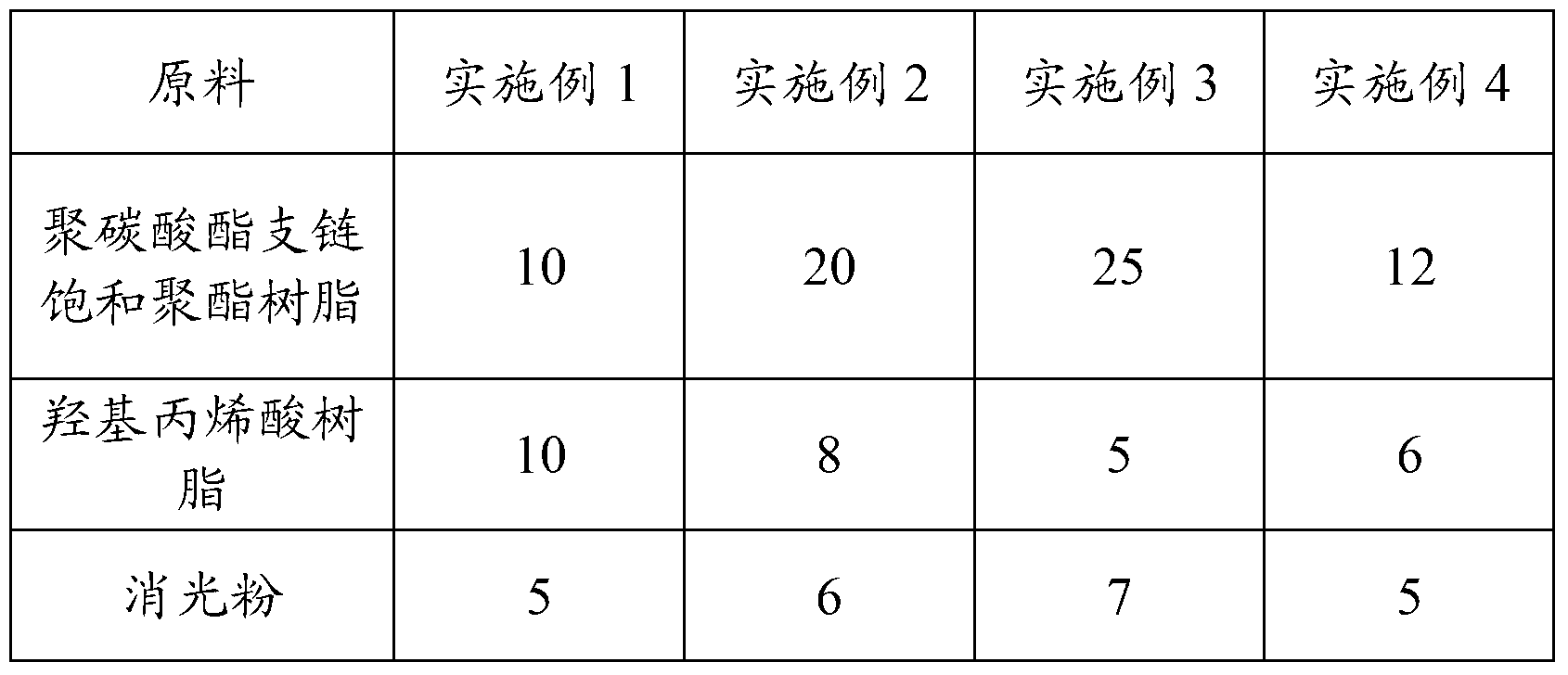

ActiveCN103319992AMeet performance requirementsImprove stabilityPolyester coatingsOrganic solventButyl acetate

The invention discloses environment-friendly elastic feeling paint and a using method thereof. The environment-friendly elastic feeling paint comprises a component A, and the component A comprises the following formula components in percentage by weight: 15-51% of film-forming resin, 0.8-1.5% of environment-friendly dryer, 0.1-0.5% of leveling agent, 40-75% of organic solvent, 5-8% of matting powder and 0.1-0.5% of auxiliary, wherein the organic solvent comprises butyl acetate, the auxiliary is amine phosphate, and the environment-friendly dryer is a bismuth-containing type or organic titanium dryer. The environment-friendly elastic feeling paint has the advantages of environment-friendly and wear-resistant properties, high drying performance and good stability. Simultaneously, the using method of the feeling paint is simple to operate and easy to control, other complex equipment is not required, and the spraying effect is good.

Owner:CHINA PAINT MFG CO SHENZHEN

(POLY)oxyalkylene block silyl ester copolymer, antifouling coating composition, antifouling coating formed from antifouling coating composition, antifouling method using antifouling coating composition and hull or underwater structure covered with antifouling coating

InactiveUS6828030B2Reduce usageImprove performanceAntifouling/underwater paintsPretreated surfacesSilyleneHydrolysis

A (poly)oxyalkylene block silyl ester copolymer comprising silyl ester copolymer block units (A) and block units (B), the block units (a) comprising (a) component units derived from a polymerizable unsaturated carboxylic acid silyl ester, and (b) polymerizable unsaturated monomer units other than the component units (a), the block units (B) derived from particular mercapto compounds, and an antifouling paint comprising the (poly)oxyalkylene block silyl ester copolymer. The copolymer enables the formation of an antifouling coating film which exhibits less cracking tendency, excellent adherence, less peeling tendency and controlled hydrolysis rate resulting in excellent antifouling performance and properties.

Owner:CHUGOKU MARINE PAINTS

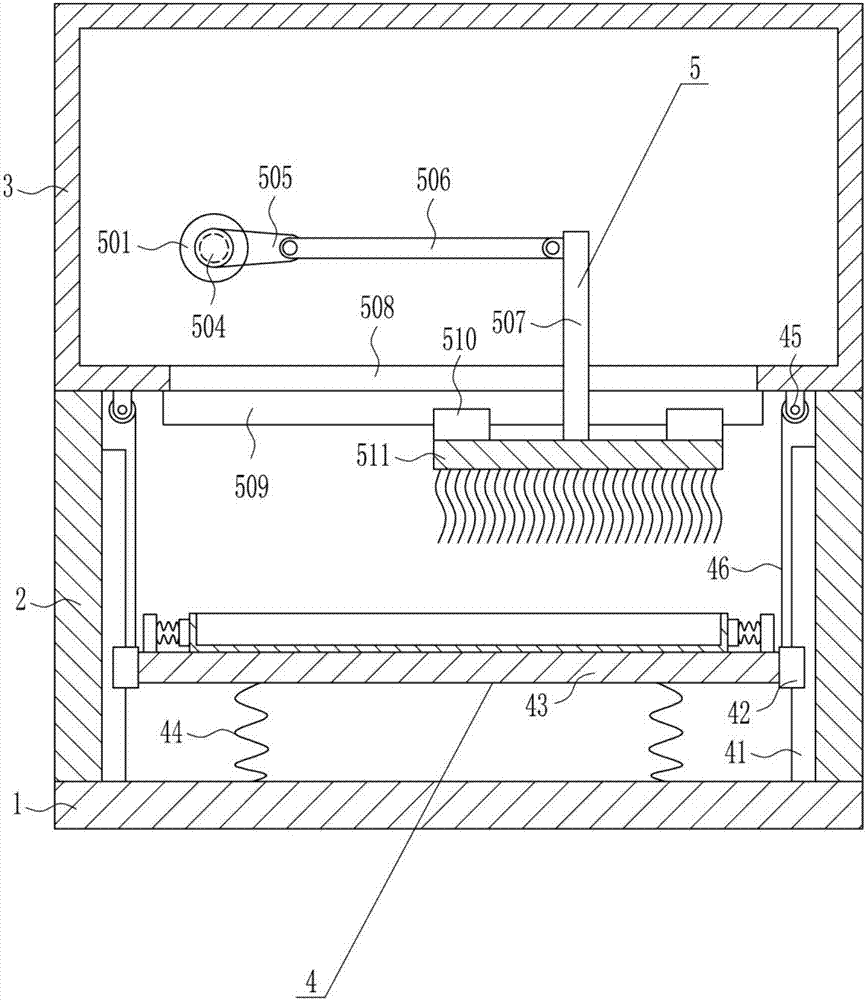

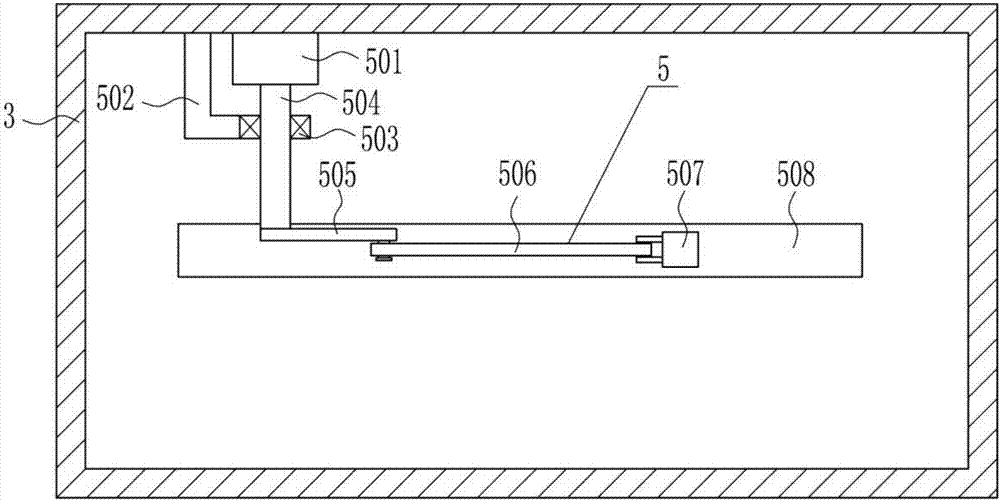

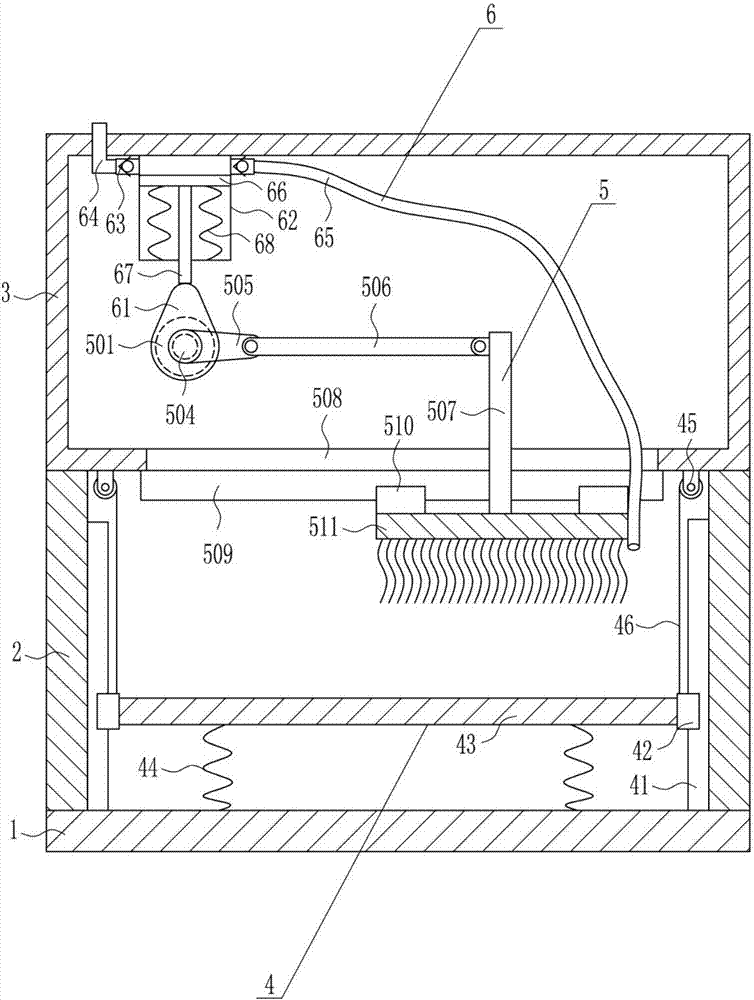

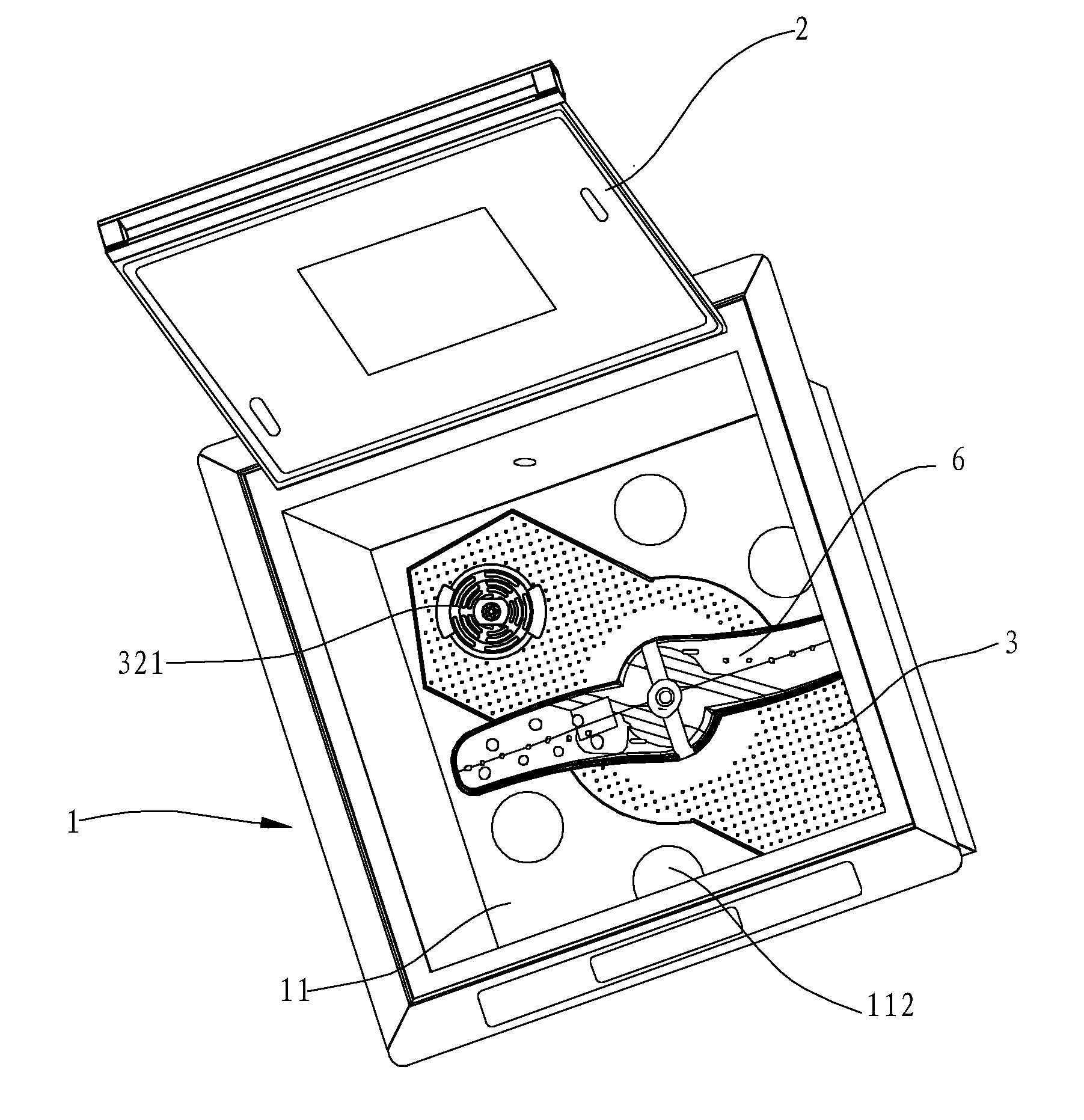

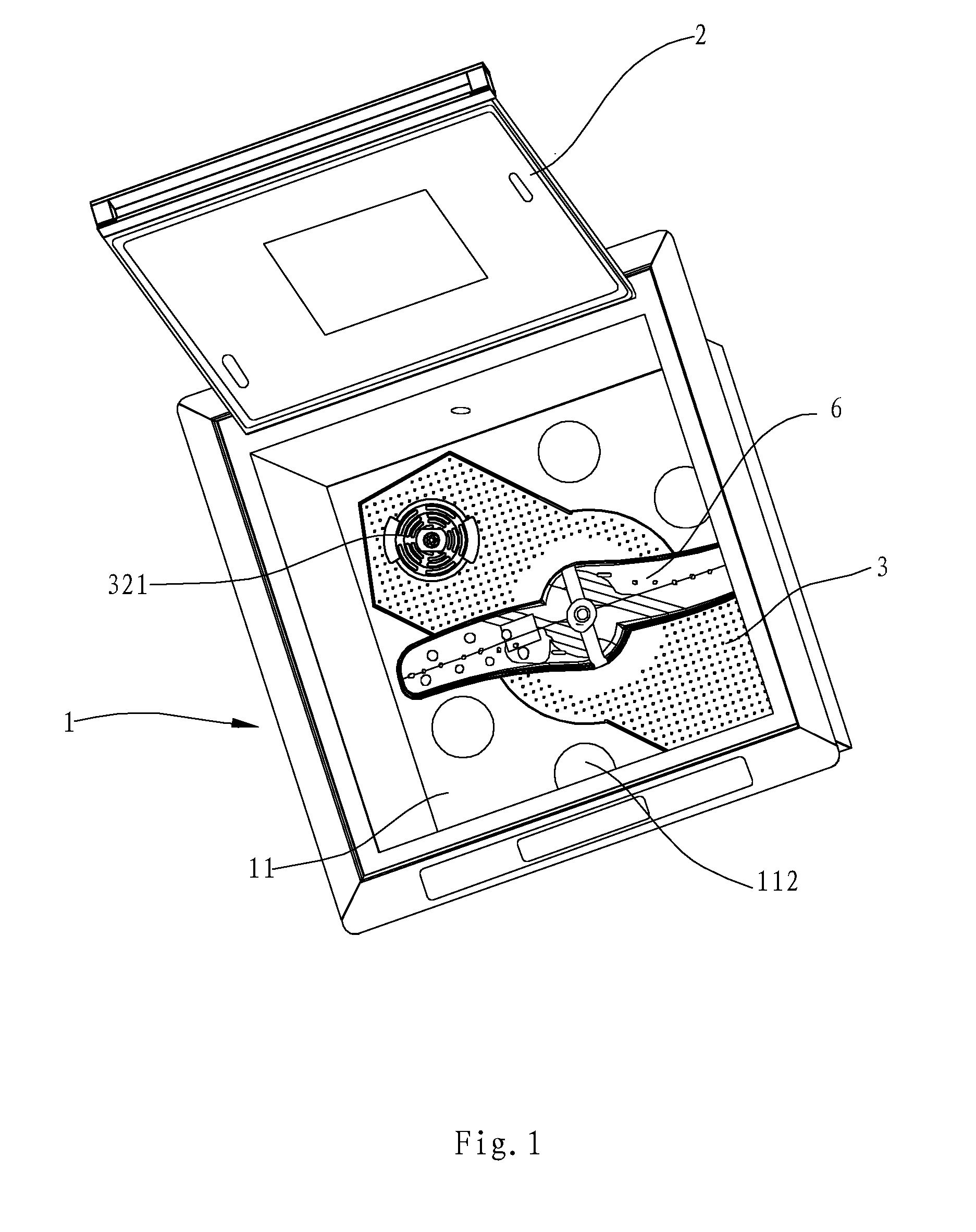

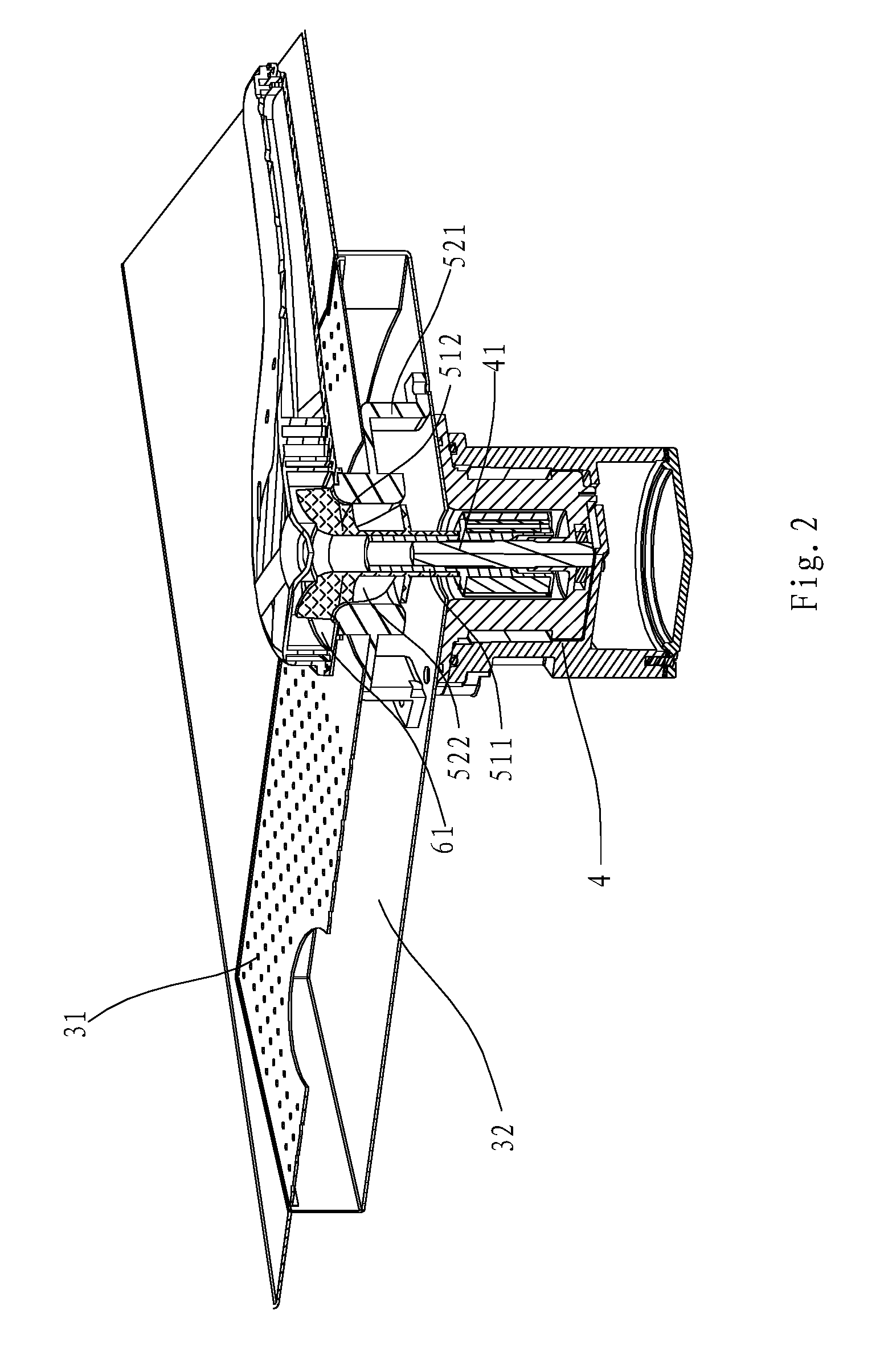

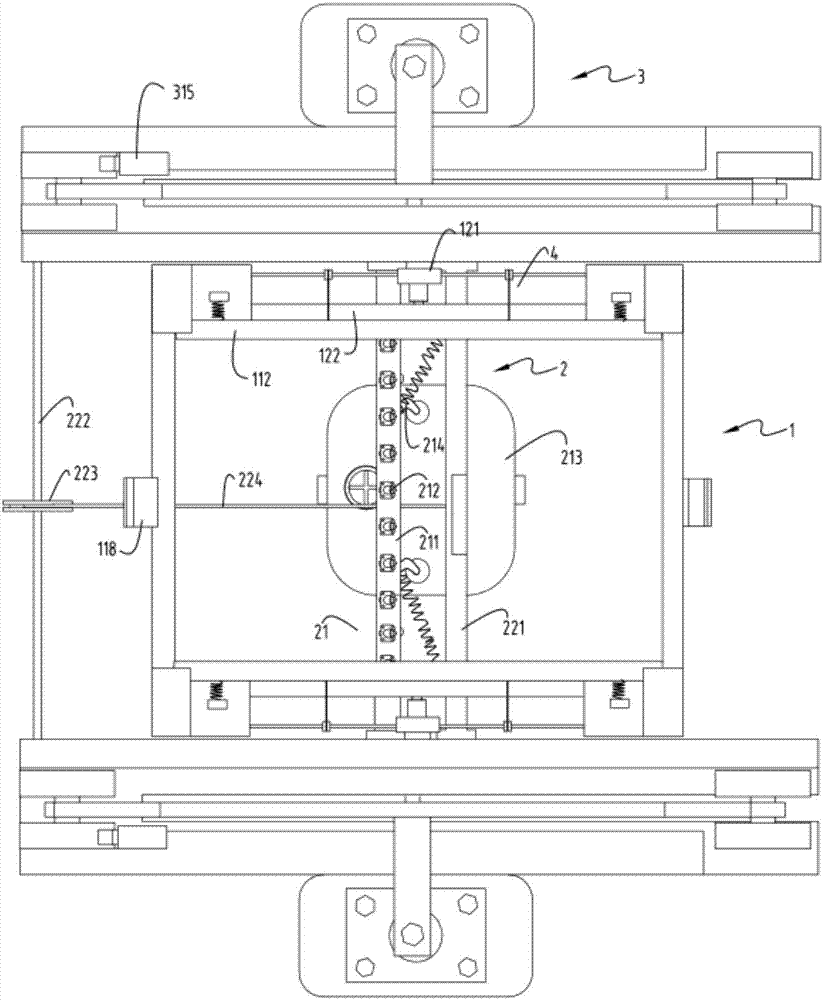

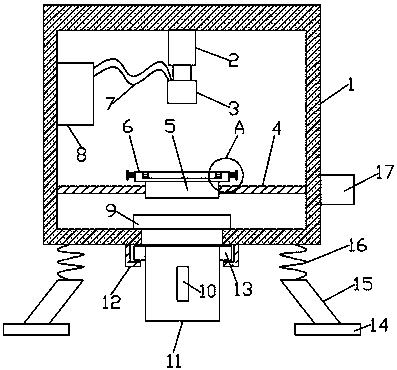

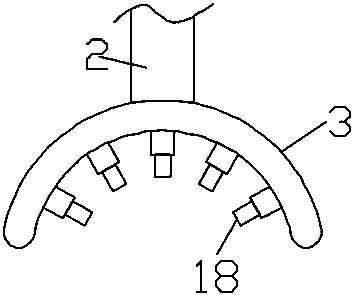

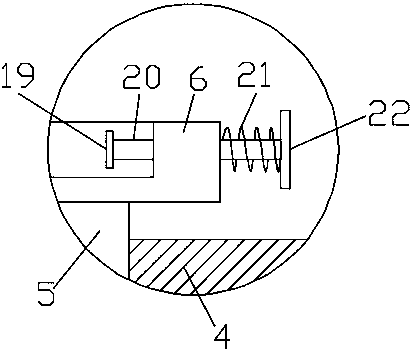

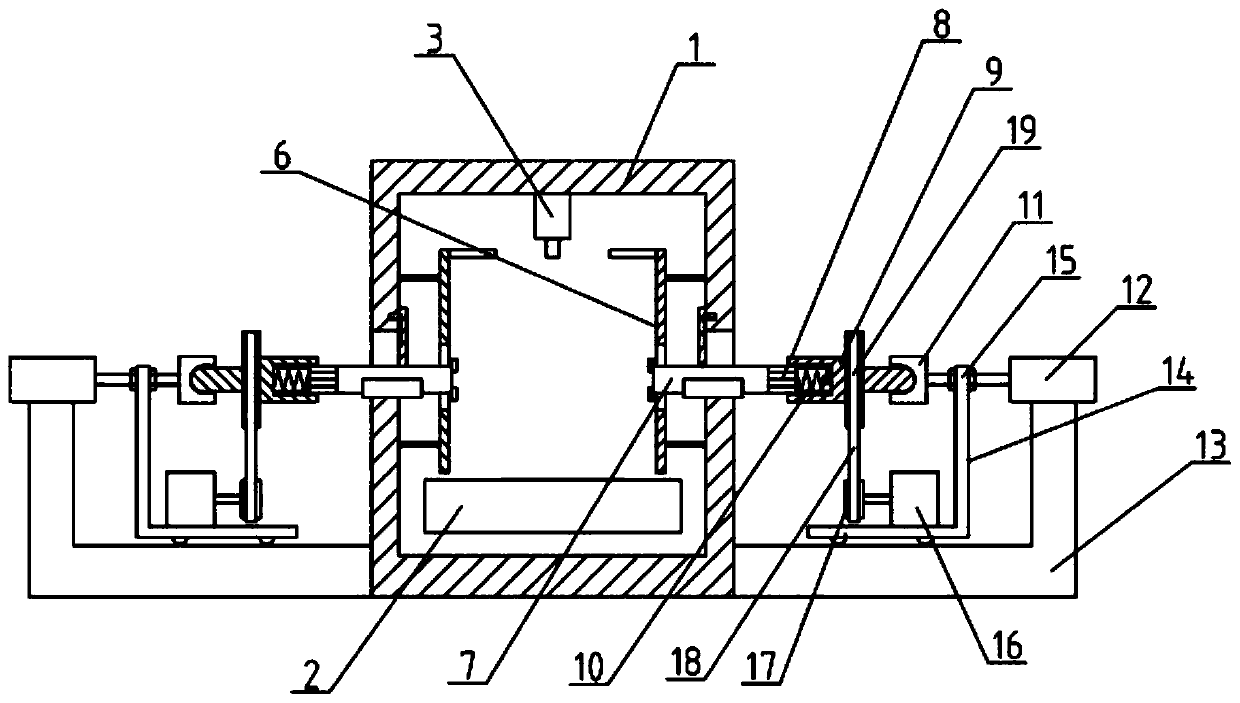

Antirust oil coating equipment for maintenance of injection mold

InactiveCN107876294AImproves sprayabilityImprove smudge effectLiquid surface applicatorsCoatingsBiochemical engineeringCoating

The invention relates to coating equipment, in particular to antirust oil coating equipment for maintenance of an injection mold. The antirust oil coating equipment for maintenance of the injection mold is high in coating efficiency and good in coating effect. The antirust oil coating equipment for maintenance of the injection mold comprises a bottom plate and the like, supporting plates are vertically installed on the left portion and the right portion of the top of the bottom plate, and a box is installed at the tops of the two supporting plates; and a lifting device is arranged between thetwo supporting plates, the box is internally provided with a coating device, and a coating part of the coating device is located at the outer bottom of the box and located above a lifting part of thelifting device. According to the antirust oil coating equipment for maintenance of the injection mold, the position of the mold is adjusted through the lifting device, the mold is coated through the coating device, and a paint spraying device enhances the coating effect of antirust oil, thus the effects of being high in coating efficiency and good in coating effect are achieved.

Owner:深圳市群创电子有限公司

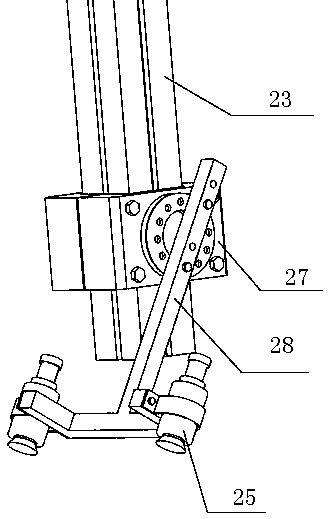

Height-adjustable pipe inner wall spraying equipment

InactiveCN104209214AImprove surface qualitySpray evenlySpraying apparatusEngineeringMechanical engineering

The invention discloses height-adjustable pipe inner wall spraying equipment and belongs to the field of spraying equipment. The height-adjustable pipe inner wall spraying equipment comprises a spraying head, a spraying pipe, a height adjusting device and a walking device, wherein the spraying head is mounted at one end of the spraying pipe and is communicated with the spraying pipe; the height adjusting device comprises a support rod, a connecting bushing and an adjusting screw; the connecting bushing is hollow inside and the side wall of the connecting bushing is provided with a thread hole; one end of the support rod extends into the connecting bushing; the adjusting screw extends into the connecting bushing via the thread hole for propping the support rod on the inner wall of the connecting bushing, and the other end of the support rod is fixedly connected to the part, near the spraying head, of the spraying pipe, and is perpendicular to the spraying pipe; the walking device is mounted at the bottom of the height adjusting device and can drive the spraying pipe to move in the axial direction of a pipe. The spraying equipment has the advantages of stable and reliable operation, good spraying effect, high efficiency and low cost and is suitable for inner walls of various small-diameter pipes, in particular for the inner walls of ultralong small-diameter pipes.

Owner:常州冯士节能环保科技有限公司

Wear-resisting foil type dynamic pressure thrust gas bearing and manufacturing method

ActiveCN104214205AReduce friction damageImprove the lubrication effectMolten spray coatingSliding contact bearingsStart stopMicrometer

The invention relates to a wear-resisting foil type dynamic pressure thrust gas bearing and a manufacturing method. The gas bearing is composed of bottom plates, wave foil and top fold, and the top foil is made of nickel-base superalloy. The top foil is coated with a nickel package graphite micro particle lubricating coating, the thickness of the coating is 0.050 mm to 0.055 mm, the mass fraction of nickel and graphite in nickel package graphite micro particles is 5 to 8:5 to 2, and the granularity of the nickel package graphite micro particles is 60 micrometers to 80 micrometers. The spraying process of the nickel package graphite micro particle lubricating coating of the top foil comprises the steps that (1) particles in the nickel package graphite micro particles are put into an oven to be dried for two hours to four hours at the temperature of 150 DEG C; (2) the top foil is put into an ultrasonic cleaning machine to be cleaned for 5 minutes to 20 minutes, and is preheated to 150 DEG C to 180 DEG C; (3) the nickel package graphite micro particles are sprayed on the upper surface of the top foil through an oxygen-acetylene flame powder spraying method. The nickel package graphite micro particle lubricating coating is sprayed on the surface of the top foil, and the start-stop service life of the foil type gas bearing is prolonged. The oxygen-acetylene flame powder spraying method is utilized for spraying, and the wear-resisting foil gas bearing meeting the quality requirement can be manufactured.

Owner:SHIJIAZHUANG KINGSTON BEARING TECH

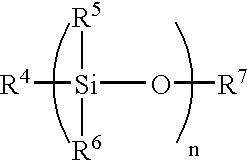

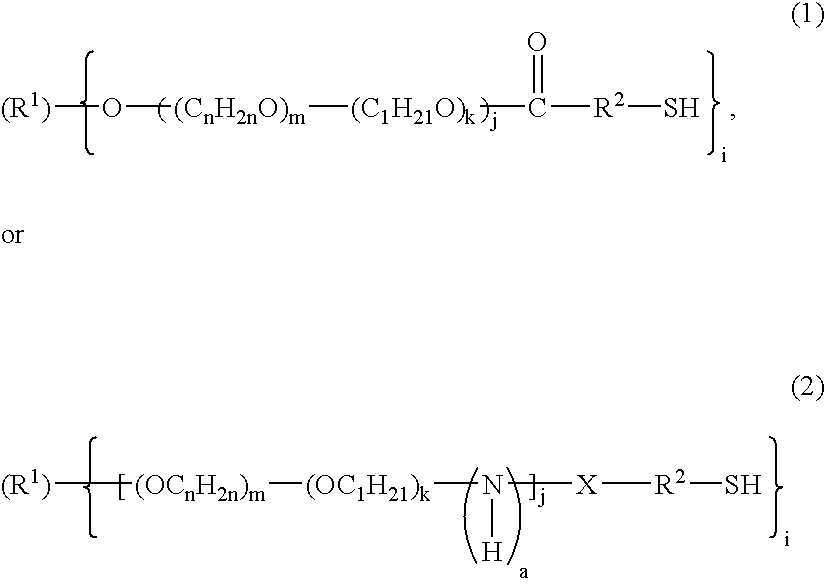

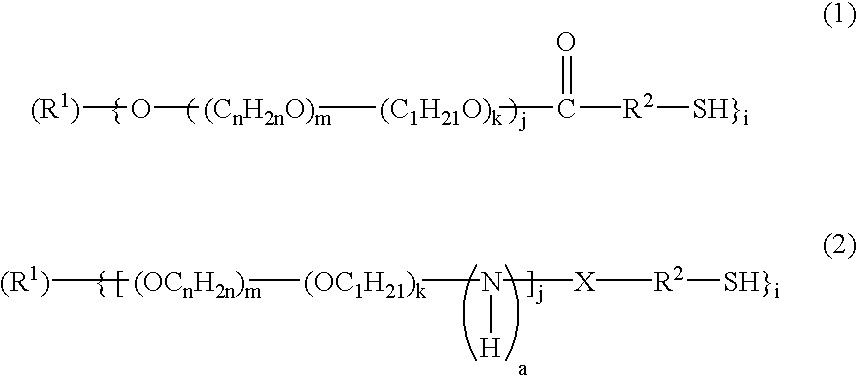

Novel (poly)oxyalkylene block silyl ester copolymer, antifouling coating composition, antifouling coating formed from antifouling coating composition, antifouling method using antifouling coating composition and hull or underwater structure covered with antifouling coating

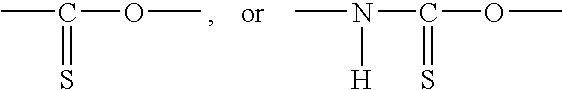

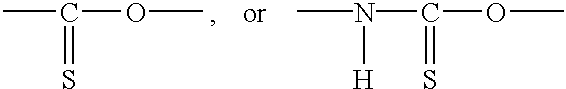

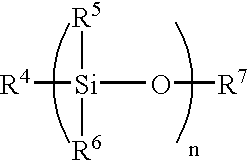

InactiveUS20020156224A1Reduce usageImprove coating efficiencyAntifouling/underwater paintsLayered productsSilyleneEther

A (poly)oxyalkylene block silyl ester copolymer comprising silyl ester copolymer block units (A) and block units (B), the silyl ester copolymer block units (A) comprising (a) component units derived from a polymerizable unsaturated carboxylic acid silyl ester, and (b) polymerizable unsaturated monomer units other than the component units (a), the block units (B) derived from a mercapto compound represented by the following formula (1) or (2), and further an antifouling paint comprising the (poly)oxyalkylene block silyl ester copolymer. wherein R1 represents a hydrocarbon group or ether-bond-containing hydrocarbon group having a valency of 1 or higher and having 1 to 30 carbon atoms; R2 represents a bivalent hydrocarbon group having 1 to 30 carbon atoms or a group of the formula -CH(R3)-wherein R3 represents a group of the formula R4-O-R5, R4 representing a bivalent hydrocarbon group having 1 to 30 carbon atoms, and R5 representing a monovalent hydrocarbon group having 1 to 30 carbon atoms; X represents: ; n is an integer of 1 to 5; m is an integer of 1 to 100; l is an integer of 1 to 5; k is an integer of 0 to 100; a is an integer of 0 or 1; j is an integer of 1 to 50; and i is the valency of R1. The present invention enables forming an antifouling coating film which exhibits less cracking tendency, excellent adherence so as to ensure less peeling tendency and desirably controlled hydrolysis rate so as to be excellent in antifouling performance (antifouling activity), antifouling properties, in particular, antifouling properties in highly fouling environment and long-term antifouling properties.

Owner:CHUGOKU MARINE PAINTS

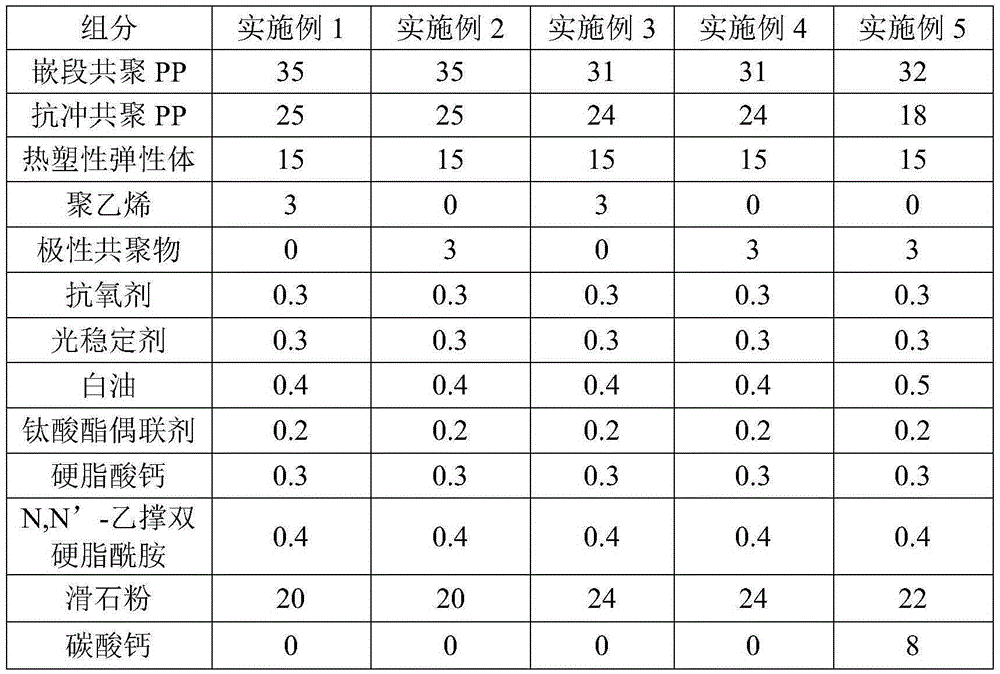

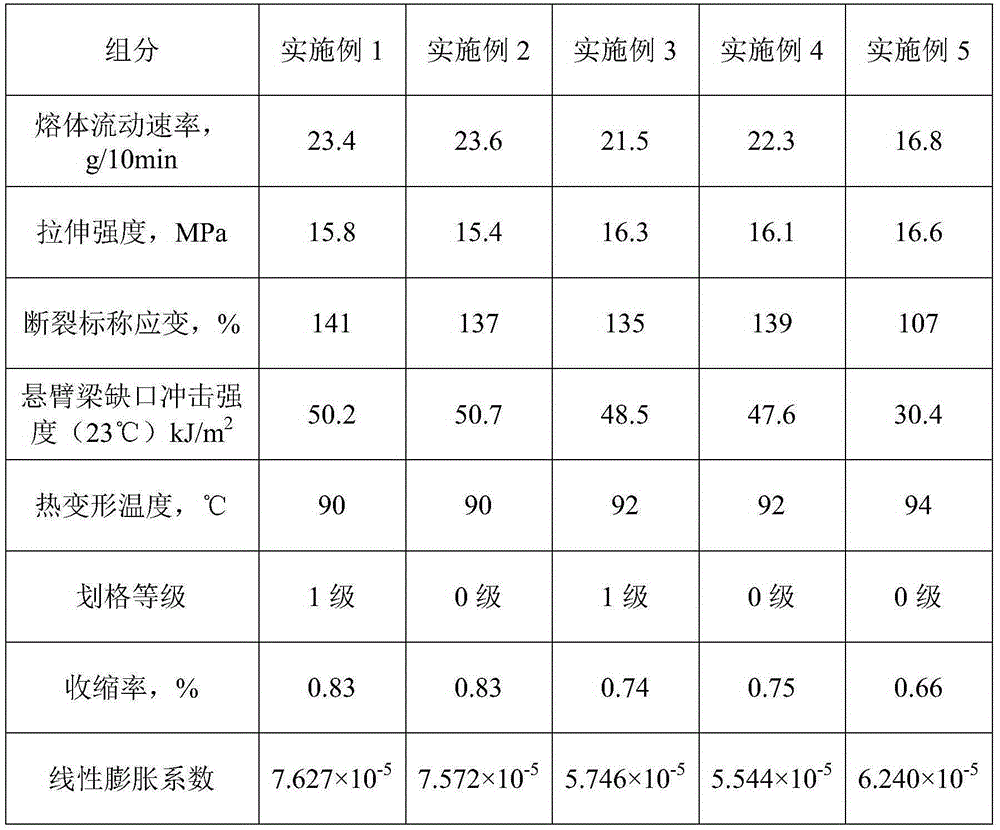

Easily-sprayed polypropylene composite material and preparation method and application thereof

ActiveCN106752633AWide processing temperature rangeImprove impact resistanceCoatingsPolypropylene compositesLow speed

The invention relates to an easily-sprayed polypropylene composite material which can be used for automobile parts and a preparation method and application thereof. The easily-sprayed polypropylene composite material is mainly prepared by mixing the following ingredients (by weight): 40-65 parts of polypropylene, 10-18 parts of a thermoplastic elastomer, 0-3 parts of polyethylene, 0-3 parts of a polar copolymer, 20-30 parts of a mineral filler and a few amount of an anti-oxidant, a light stabilizer and other functional aids. The preparation method comprises the following steps: successively adding polypropylene, the thermoplastic elastomer, polyethylene, the polar copolymer, the mineral filler, the anti-oxidant, the light stabilizer and other functional aids into a low speed mixer and mixing for at least 2 min; adding the mixture into a twin-screw extruder and mixing, setting the extrusion temperature to be 170-240 DEG C, extruding and granulating, and uniformly mixing to obtain the product. The easily-sprayed polypropylene composite material can be used for preparation of automobile bumper products and has comprehensive properties such as excellent impact resistance, fluidity, rigidity, heat stability, dimensional stability, sprayability, etc.

Owner:株洲时代工程塑料科技有限责任公司

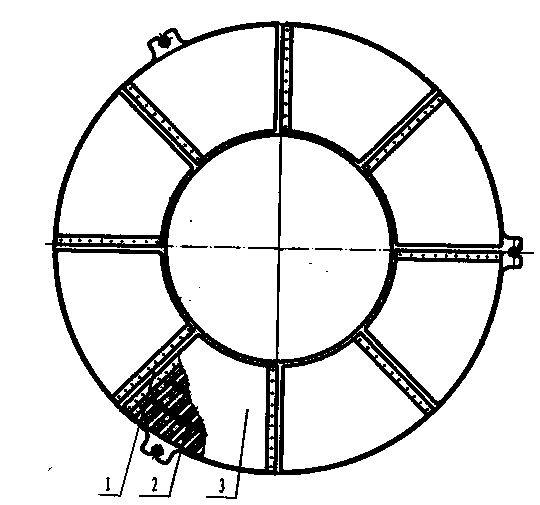

Rotating spray wall used in washing appartus and application thereof

ActiveUS20160324393A1Improves sprayabilityEasy to replaceTableware washing/rinsing machine detailsMechanical engineeringEngineering

A rotary spray arm for a washing device and a washing device, the rotary spray arm comprises a pair of an upper cover and a lower cover attached to the upper cover; a flow channel disposed between the upper cover and the lower cover, the water outlets are disposed on the upper cover an upper chamber in communication with the flow channel is formed at a center of the lower cover; the flow channel is located at two sides of the upper chamber, and a hole matching to the upper chamber is formed on a bottom surface of the lower cover. The rotary spray arm is provided with a chamber for accommodating the water outlet portion of the water pump and the chamber is communicated to the water outlets, therefore, the rotary spray arm can be manufactured independently of the water pump, and both processing and mounting are very convenient.

Owner:NINGBO FOTILE KITCHEN WARE CO LTD

Lifting type coating device

The invention provides a lifting type coating device. The lifting type coating device comprises a main base and a turnover assembly arranged on the right side of the upper surface of the main base. A lifting type supporting assembly is further fixed to the left side of the upper surface of the main base. A horizontal displacement assembly is fixed to the top of the lifting type supporting assembly. A coating assembly is further connected to the lower end of the horizontal displacement assembly. The turnover assembly is located on the left side of the lifting type supporting assembly. According to the lifting type coating device, a to-be-treated part is fixed to the turnover assembly, the coating assembly is firstly used for single face spraying, and coating adjustability is high; after single face spraying is carried out, the to-be-treated part is controlled by a servo motor to rotate, and therefore spraying of the second face is carried out; and the production efficiency can be improved easily, and the spraying effect is good.

Owner:嘉善蓝欣涂料有限公司

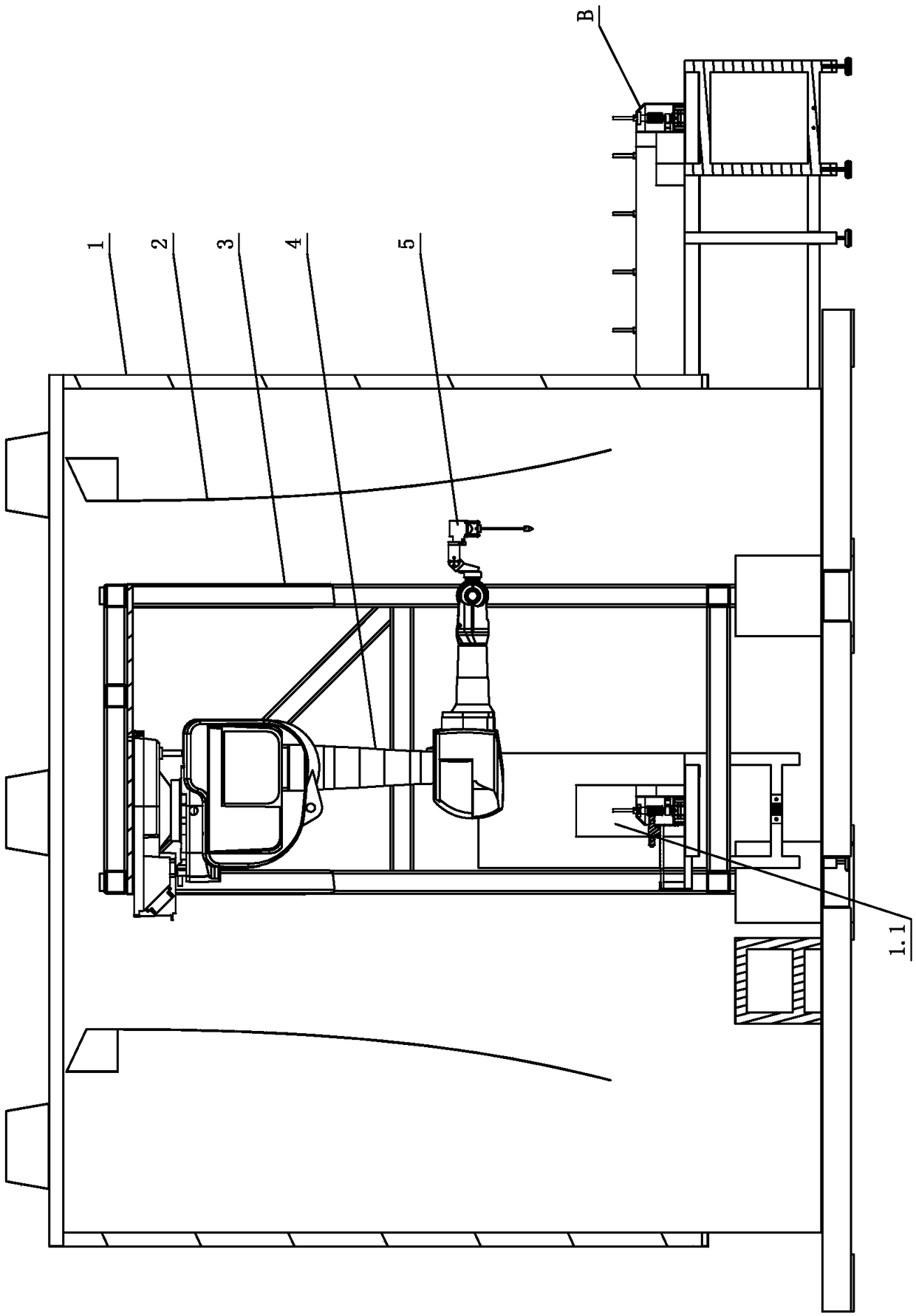

Automatic spraying line for golf club head

The invention relates to an automatic spraying line for a golf club head. The automatic spraying line comprises spraying equipment and conveying equipment, wherein at least one spraying equipment is arranged along the conveying equipment; the conveying equipment is annually arranged and penetrates through at least one spraying equipment; the spraying equipment comprises a water curtain cabinet, asupporting portal frame and a multi-shaft robot, the supporting portal frame and the multi-shaft robot are covered with the water curtain cabinet, the multi-shaft robot is arranged on the supporting portal frame in an upside down manner, and a spraying gun is arranged on the multi-shaft robot; and the conveying equipment comprises a conveying mechanism and a plurality of club head tool assemblies,the conveying mechanism comprises a conveying strip and a conveying driving assembly, the conveying belt is annularly arranged, the conveying driving assembly is used for driving the conveying stripto work, the conveying strip penetrates through the water curtain cabinet through a conveying opening in the water curtain cabinet, the multi-shaft robot is located above the conveying strip which penetrates through the inner side of the water curtain cabinet, and the club head tool assemblies are distributed on the conveying strip. The automatic spraying line is simple and reasonable in structure, high in degree of automation and spraying efficiency, good in spraying quality, high in finished rate and applicable to multiple spraying procedures, and the clean working environment is guaranteed.

Owner:GUANGDONG LXD ROBOTICS CO LTD

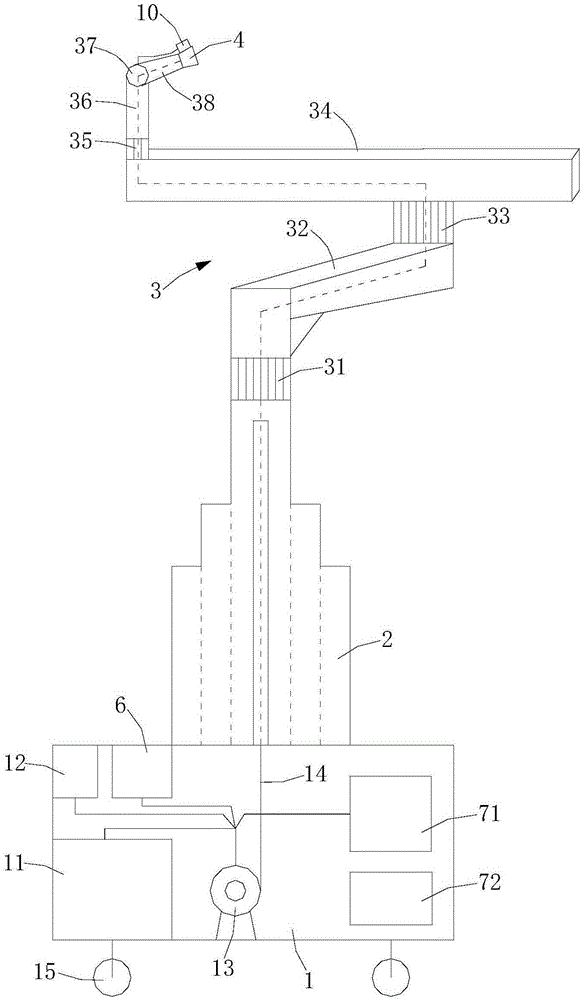

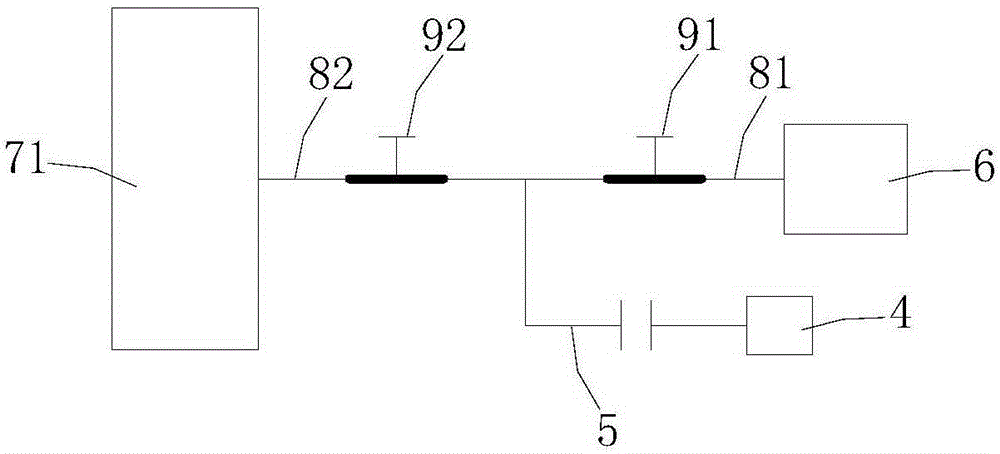

Spraying system with electric lifting function

The invention provides a spraying system with the electric lifting function. The spraying system comprises a base, a lifting rod, a mechanical arm and a sprayer. The lifting arm is arranged on the base. The mechanical arm is arranged on the lifting rod. The sprayer is arranged on the mechanical arm and connected with a spray pipe for conveying spray materials. The lifting rod is an electric telescopic mast. A storage box, an air pump and an electromotor are arranged in the base. The storage box is connected with the spray pipe through a first pipeline, and the air pump is connected with the spray pipe through a second pipeline. The first pipeline is provided with a first electromagnetic valve. The second pipeline is provided with a second electromagnetic valve. The spraying system is simple in structure and convenient to operate; the sprayer can reach different heights through the lifting rod, the sprayer can be quickly moved to any position around a workpiece by means of controlling the mechanical arm, and therefore the spraying system can meet the spraying requirements of different positions of the workpiece at different height positions, and then the workpiece is sprayed in an omni-bearing manner; and the spraying effect is remarkable, and manual climbing spraying work can be completely replaced.

Owner:STATE GRID ANHUI ULTRA HIGH VOLTAGE CO +1

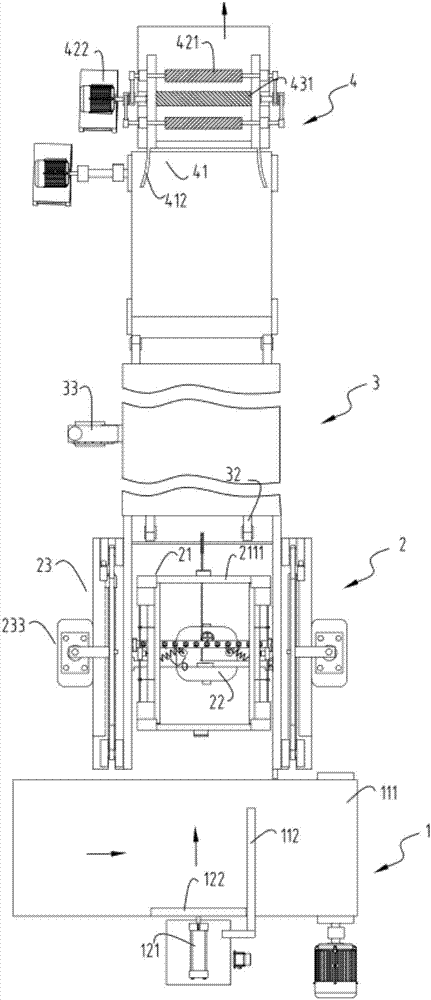

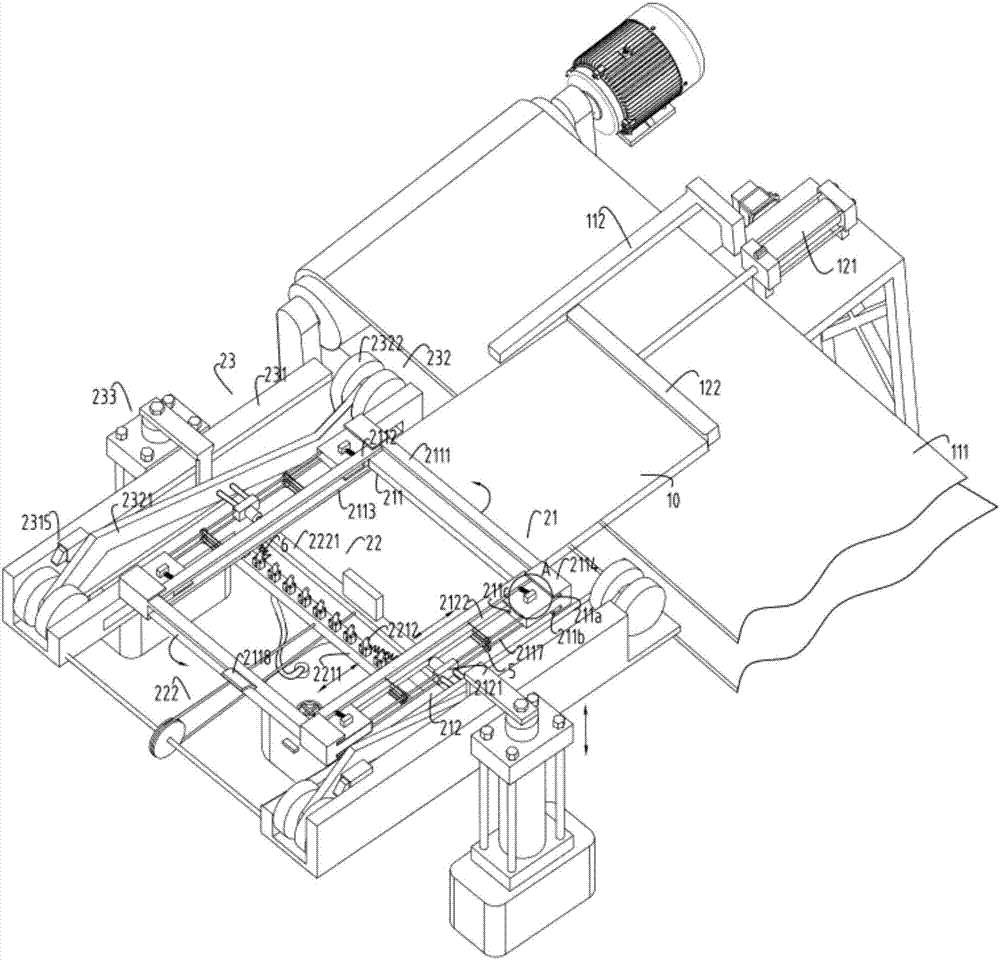

Ceramic tile surface waxing treatment production line

InactiveCN106938227AWaxes quickly and evenlyDry fastSpraying apparatusPretreated surfacesProduction lineWax treatment

The invention relates to a tile surface waxing treatment production line, which includes a positioning feeding part, the positioning feeding part is used to position and push the delivered tiles backward; a turning waxing part is arranged on the Positioning the rear end of the feeding part, the turning waxing part is used to wax the tiles pushed by the positioning feeding part; the drying part, the drying part is arranged at the rear end of the turning waxing part, and the drying part is used for It is used to dry the ceramic tiles output after being waxed by the turned waxing part; the polishing part is arranged at the rear end of the drying part, and the polishing part is used to perform surface waxing on the ceramic tiles output after the drying process of the drying part Polishing of the first layer; it overcomes the problems of tile waxing and wax surface polishing that do not have the function of integrated continuous processing, low efficiency and labor-intensive waxing process and uneven waxing.

Owner:湖州裕尚卫浴有限公司

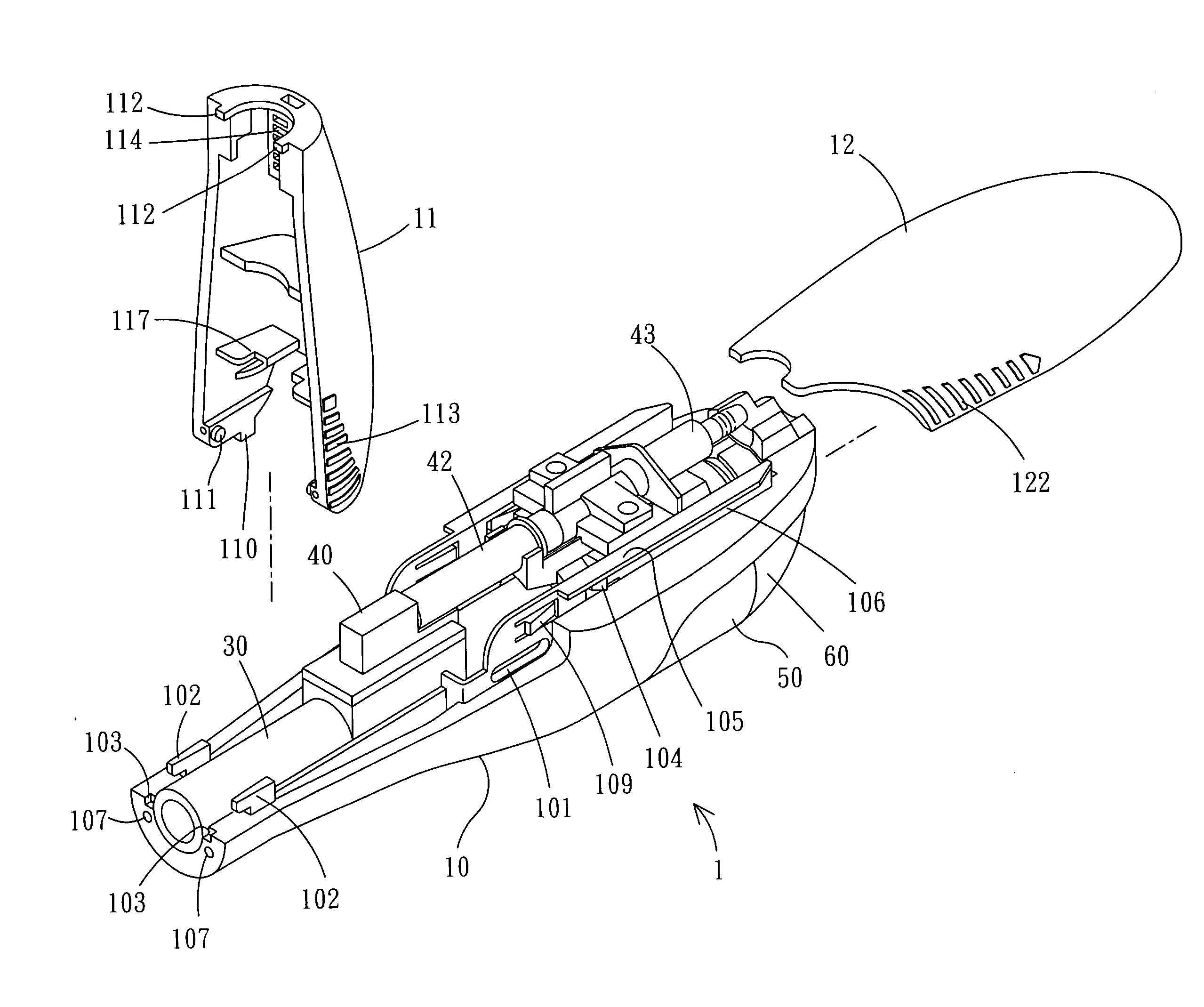

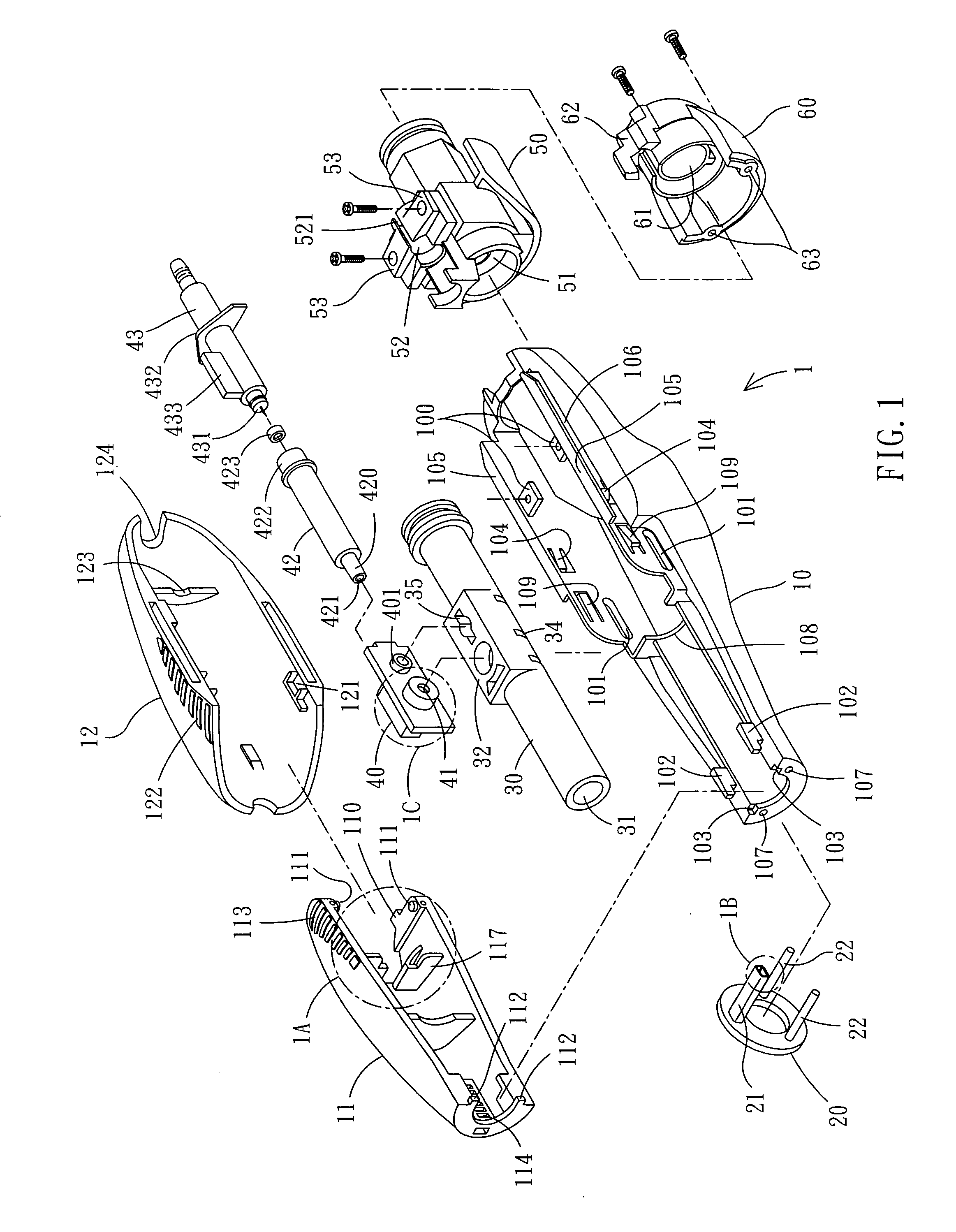

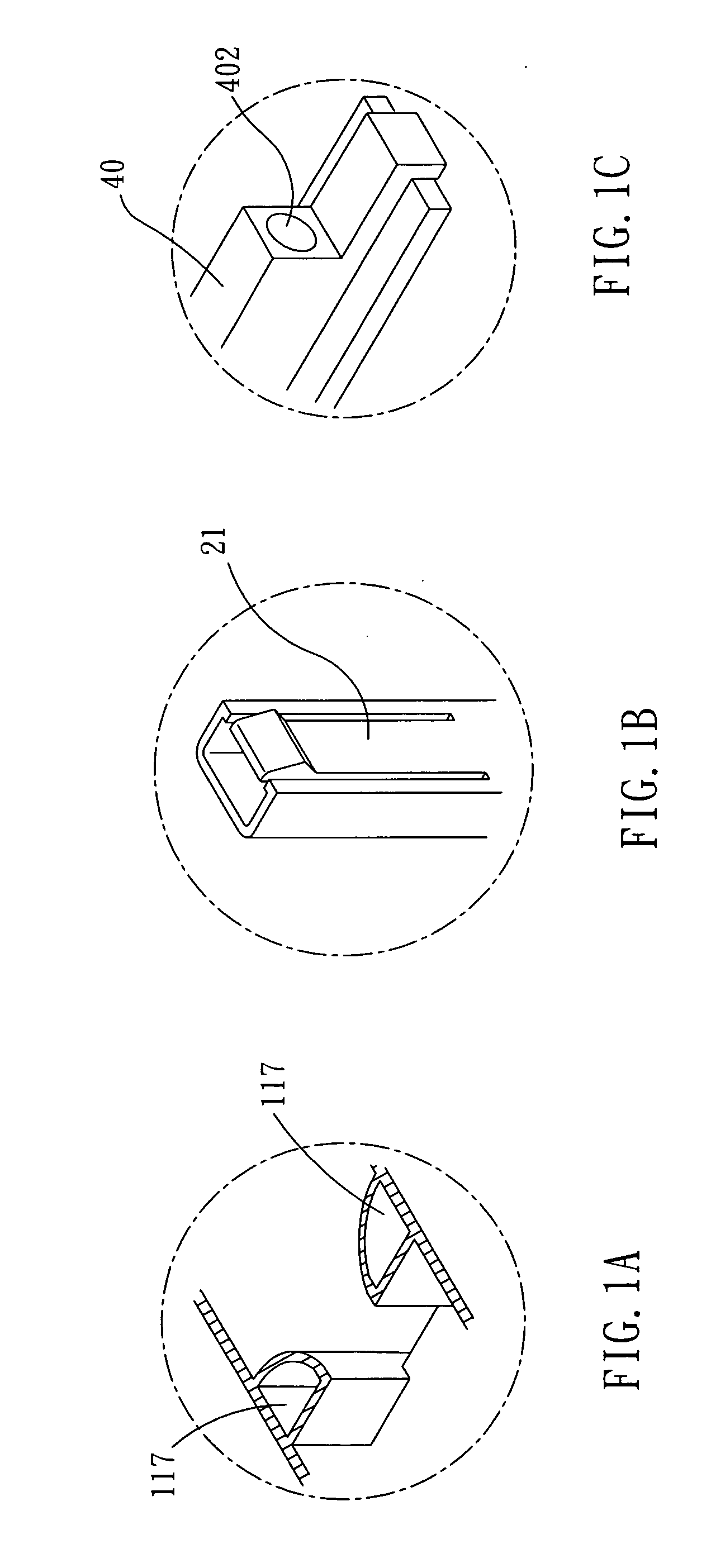

Drug delivery device

InactiveUS20110137281A1Promote atomizationImproves sprayabilityAmpoule syringesJet injection syringesBiomedical engineeringGas pressure

A drug delivery device mainly has a housing, which can be easily held and operated. The housing has one end formed with an adjustment seat capable of adjusting a range distance, and the other end connected to a gas pressure control source for providing mainstream and substream gas pressures. Disposed in the housing are a drug delivery pressuring tube, an embedded drug-can connecting seat or an external drug-can connecting seat, a replaceable drug-can container and a gas communication tube. According to this design, the minor liquid drug can be controlled, the drug-can can be replaced and the continuous quantitative injection of drug can be made. Also, all damaged or dirty members of the invention may be disassembled, cleaned or replaced.

Owner:GOLD NANOTECH

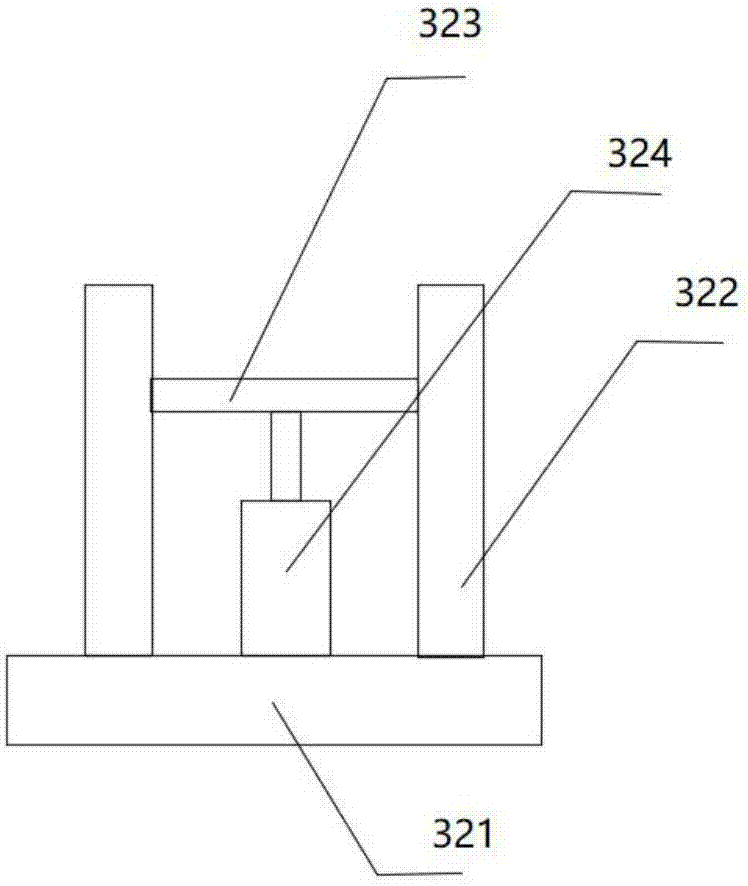

Ceramic tile turnover and automatic waxing equipment

InactiveCN106914362ASpray wax quickly and evenlyNo chance of dripping onto tilesSpraying apparatusWaxMaterials science

The invention relates to ceramic tile turnover and automatic waxing equipment which comprises a clamping and locating part, a sliding wax spray part and a rotating part. The clamping and locating part comprises a supporting mechanism used for locating and supporting ceramic tiles to be turned over and waxed, and a clamping mechanism used for clamping the ceramic tiles. The sliding wax spray part is used for waxing the surfaces of the ceramic tiles and comprises a wax spray mechanism and a transmission mechanism. The rotating part is used for driving the clamping and locating part and the ceramic tiles to be turned over together and meanwhile driving the wax spray mechanism through the transmission mechanism to move in the front-and-back direction to wax the ceramic tiles. The rotating part comprises a supporting seat, a turnover device fixedly connected with the supporting mechanism and a lifting device used for driving the turnover device to slide and be turned over along the supporting seat. The wax spray mechanism comprises a wax spray seat and multiple wax spray heads. The problems that ceramic tile waxing cannot be automatic and continuous, waxing efficiency is low, manpower is consumed, wax is prone to dripping onto the ceramic tiles, and waxing is not uniform are solved.

Owner:湖州裕尚卫浴有限公司

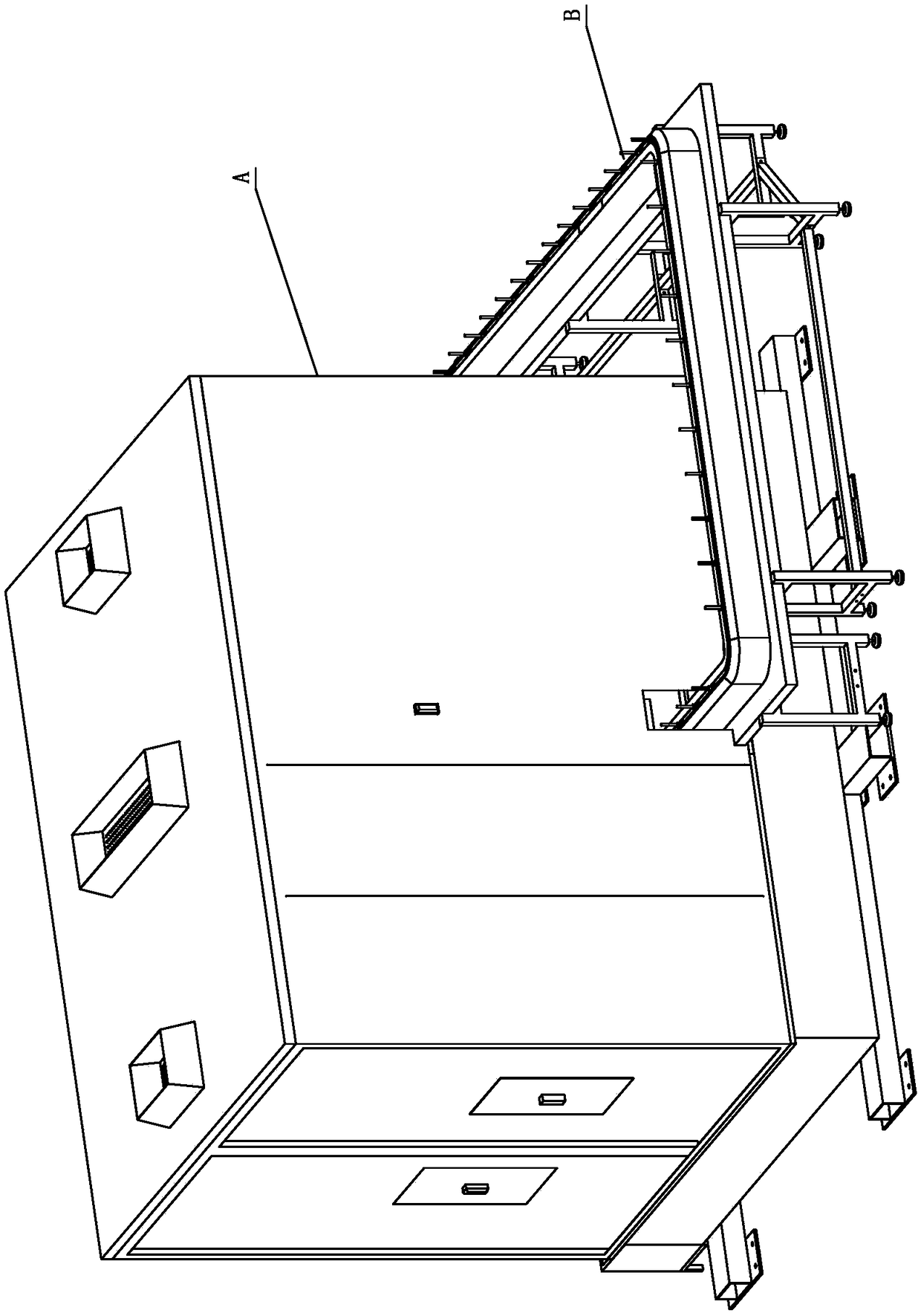

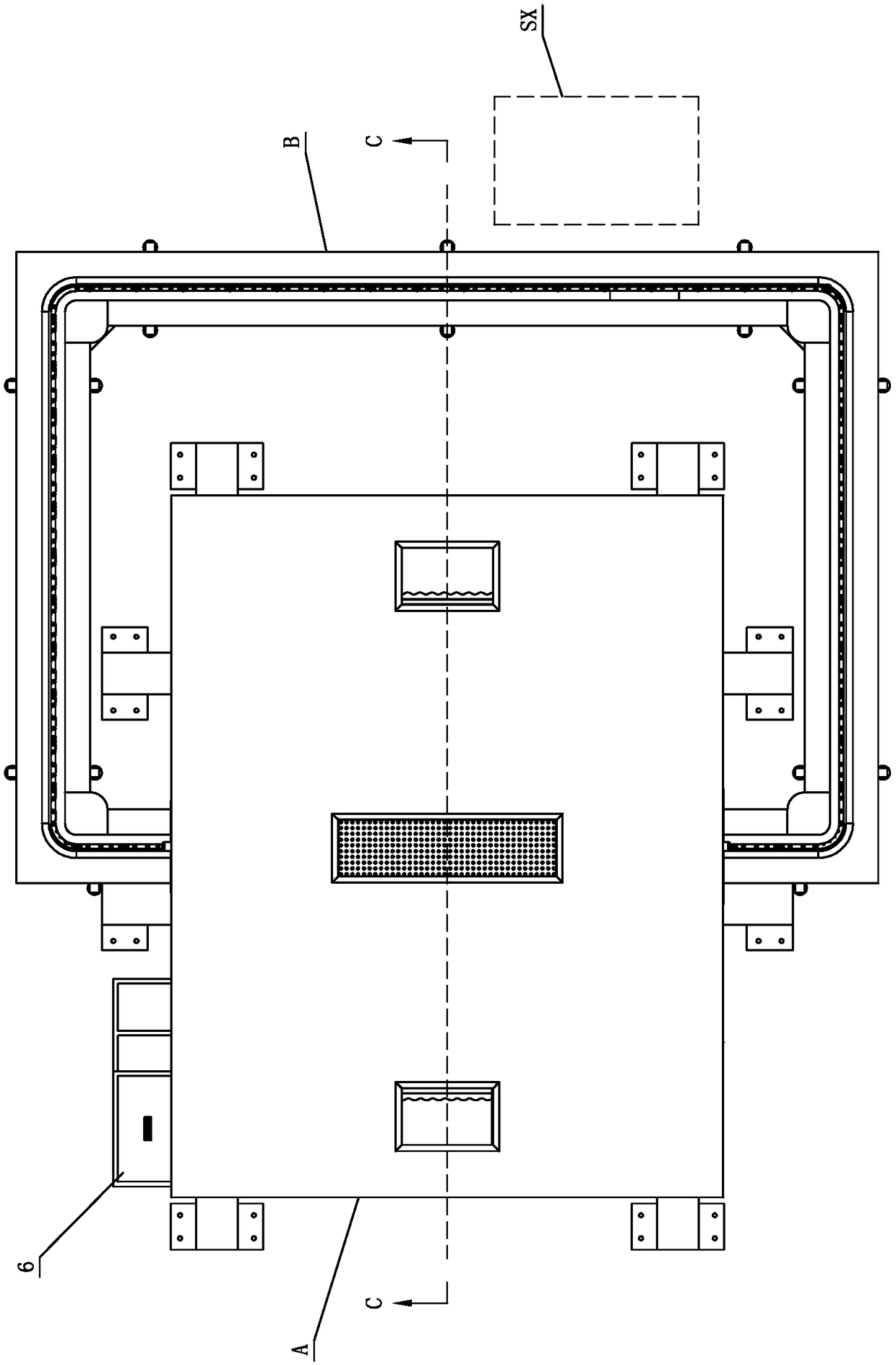

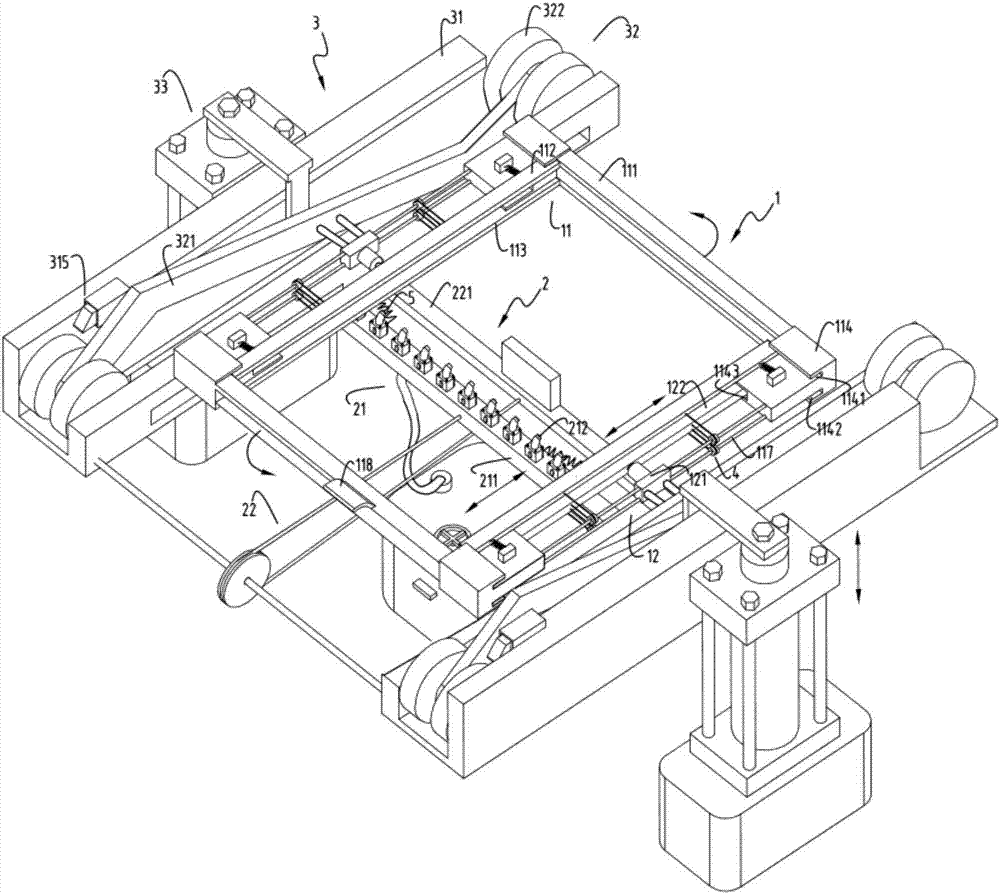

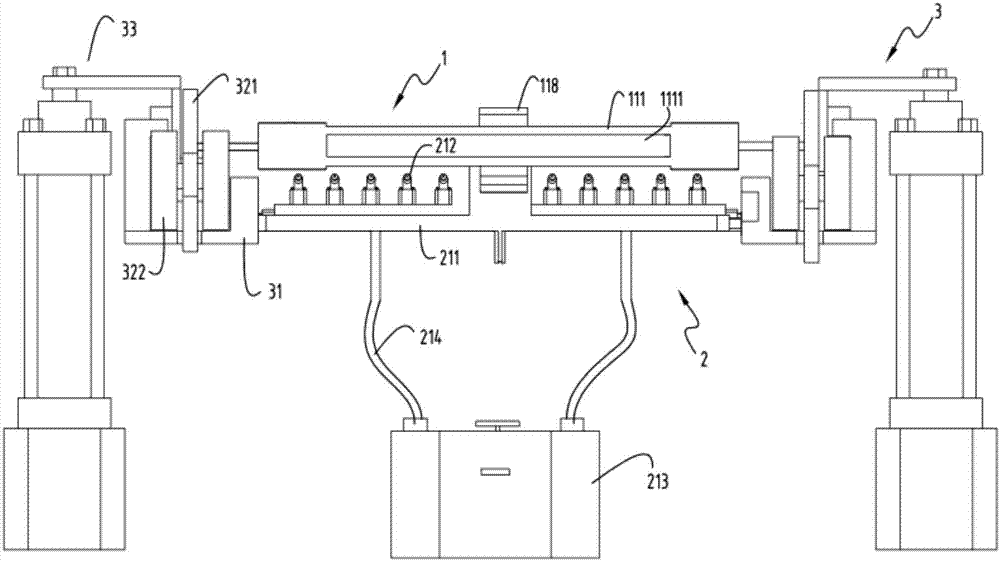

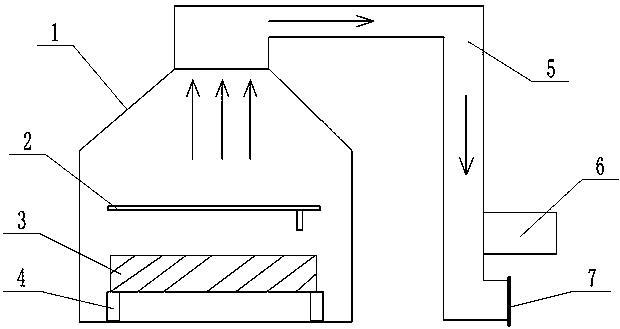

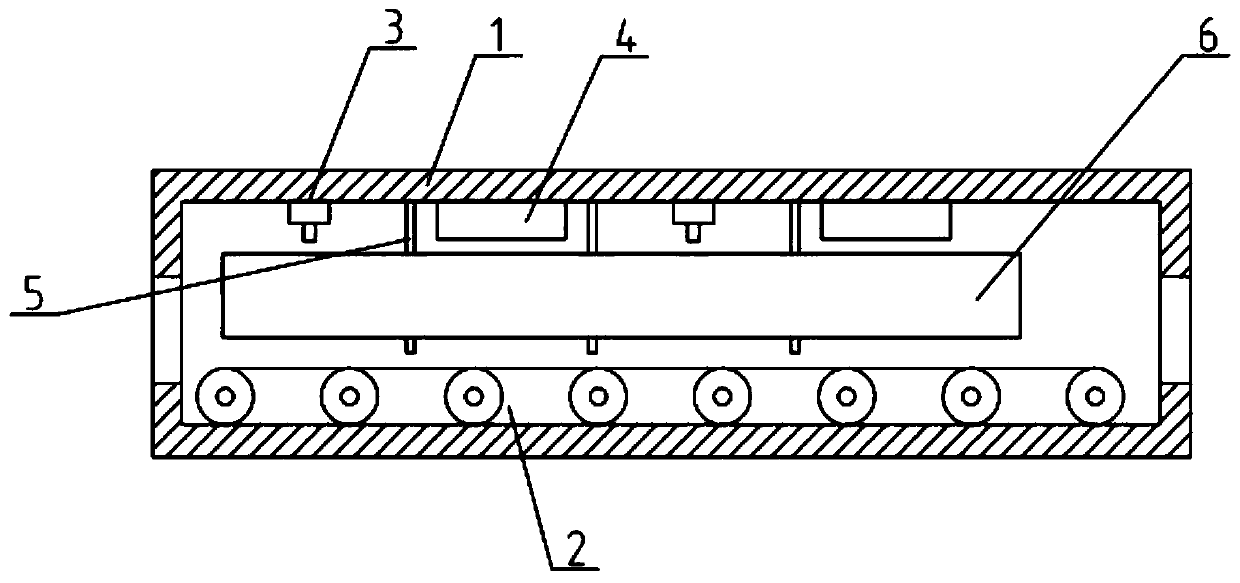

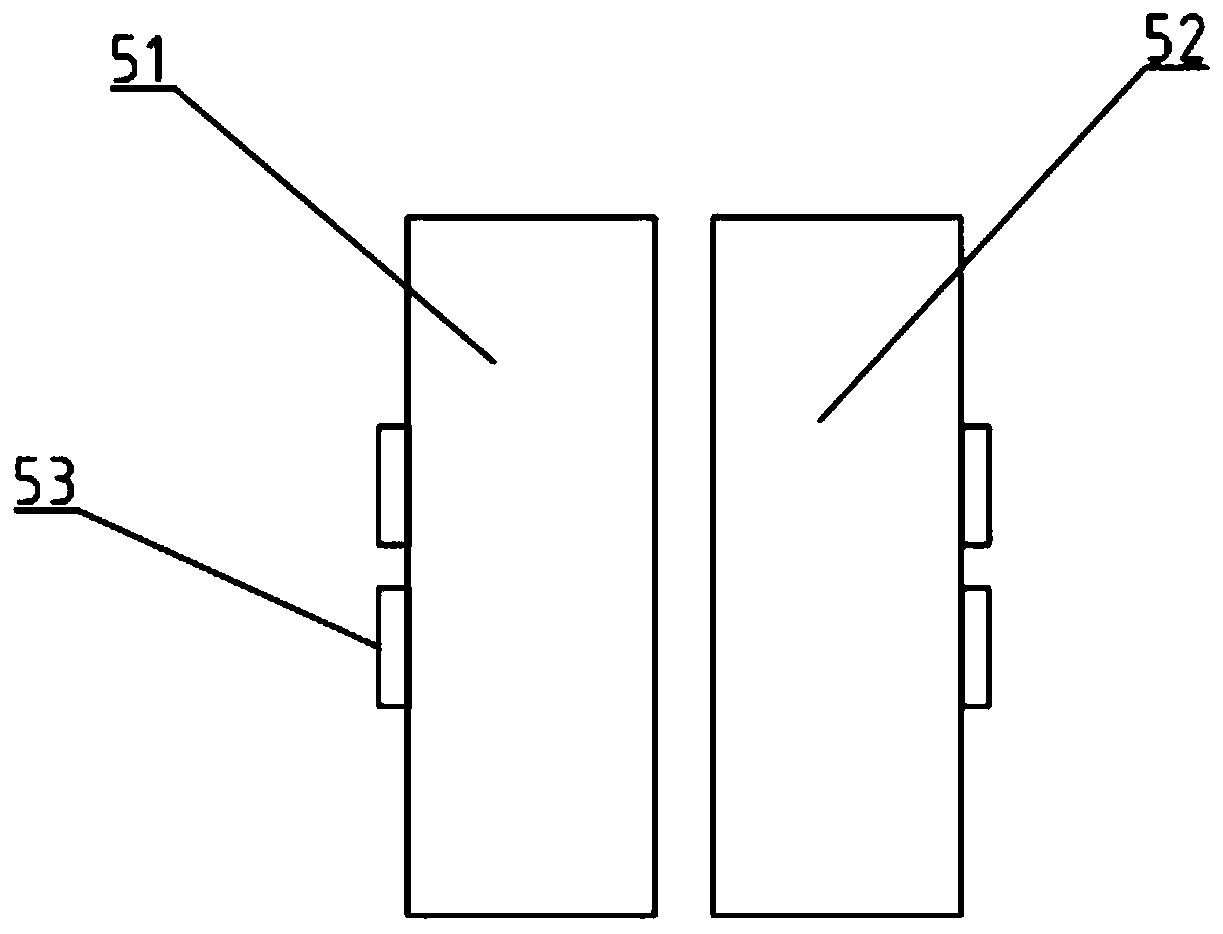

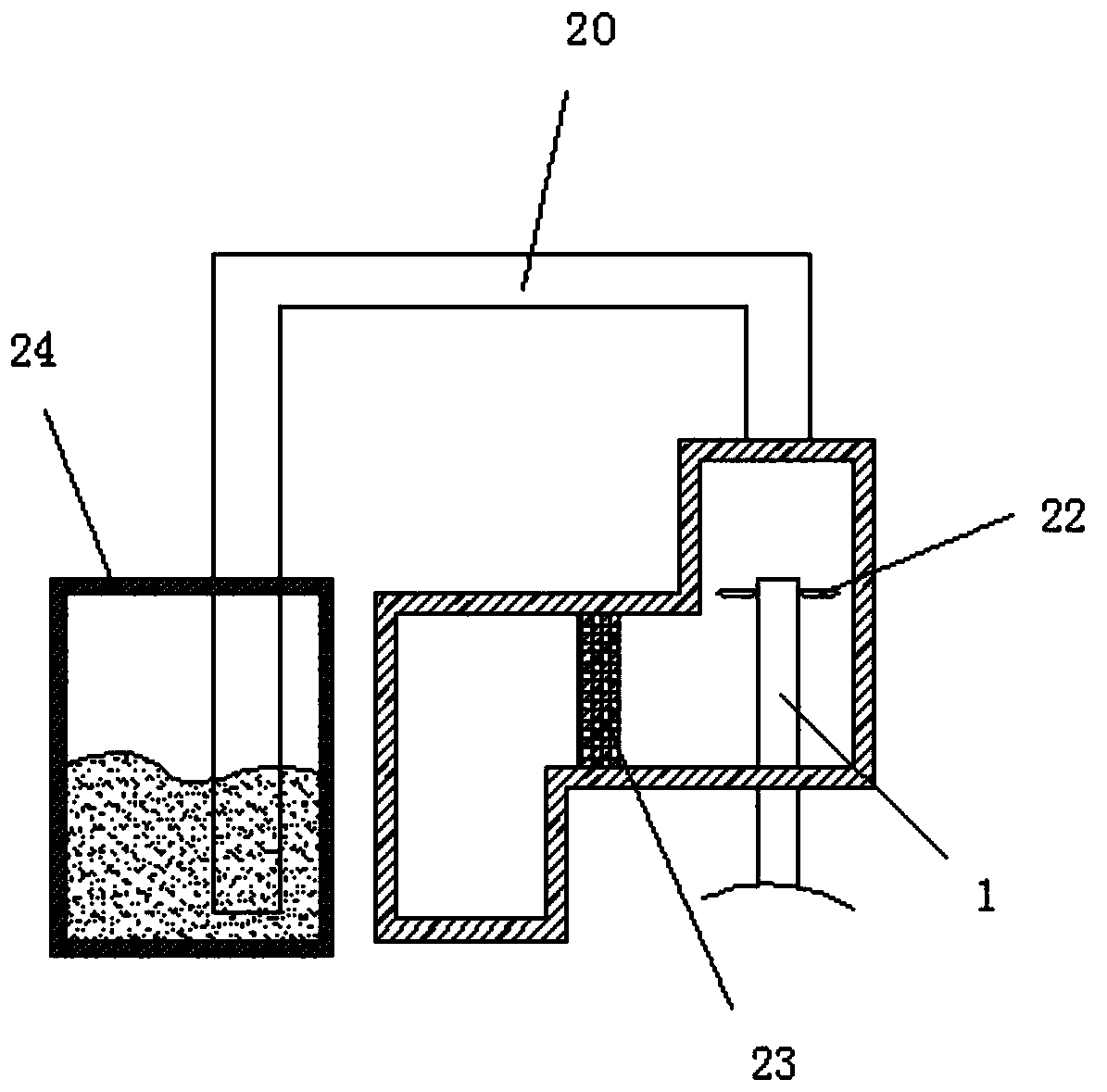

Double-block type automatic spray coating system of sleeper prefabricated de-molding agent

PendingCN108722710ASave Spraying TimeImprove spray uniformityLiquid spraying apparatusDiaphragm pumpProgrammable logic controller

The invention provides a double-block type automatic spray coating system of a sleeper prefabricated de-molding agent and belongs to the technical field of production of railway engineering ballastless tracks. Aiming at solving the technical problems, the invention provides the double-block type automatic spray coating system of the sleeper prefabricated de-molding agent, which has the effects ofimproving the spray coating quality and shortening the spray coating time and has a good spray coating effect. The double-block type automatic spray coating system is characterized by comprising a pumping and discharging system, a spray coating system and an oil gas supplying system, wherein the pumping and discharging system comprises a sealed space composed of a sealing cover, a pumping and discharging pipeline, an exhaust fan set and an oil dirt filtering screen; the pumping and discharging system is used for pumping and discharging waste gas and waste materials, which are produced in a spray coating process of the de-molding agent, and filtering and discharging oil dirt out of a spray coating field; the spray coating system comprises a PLC (Programmable Logic Controller), a servo motorand a spraying gun; the spray coating system is used for spraying and coating the de-molding agent on a sleeper mold on a plane formed by two parallel longitudinal tracks along the movement of the servo motor; the oil gas supplying system comprises a gas pressure pump station, a storage tank and a diaphragm pump; the oil gas supplying system is used for providing the de-molding agent and air power to the spray coating system.

Owner:CHINA RAILWAY NO 3 GRP CO LTD +1

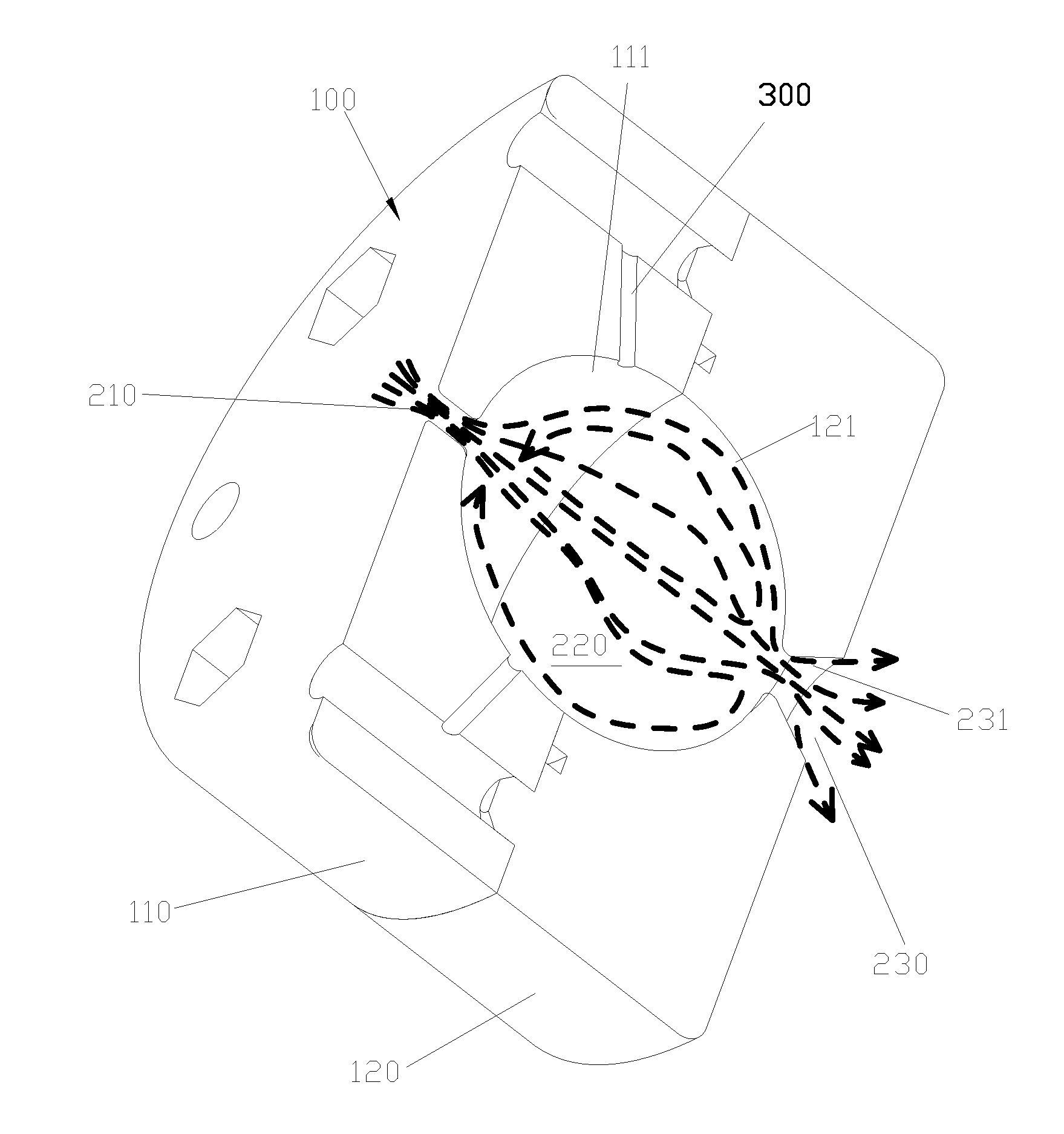

Device that can make pulsed water

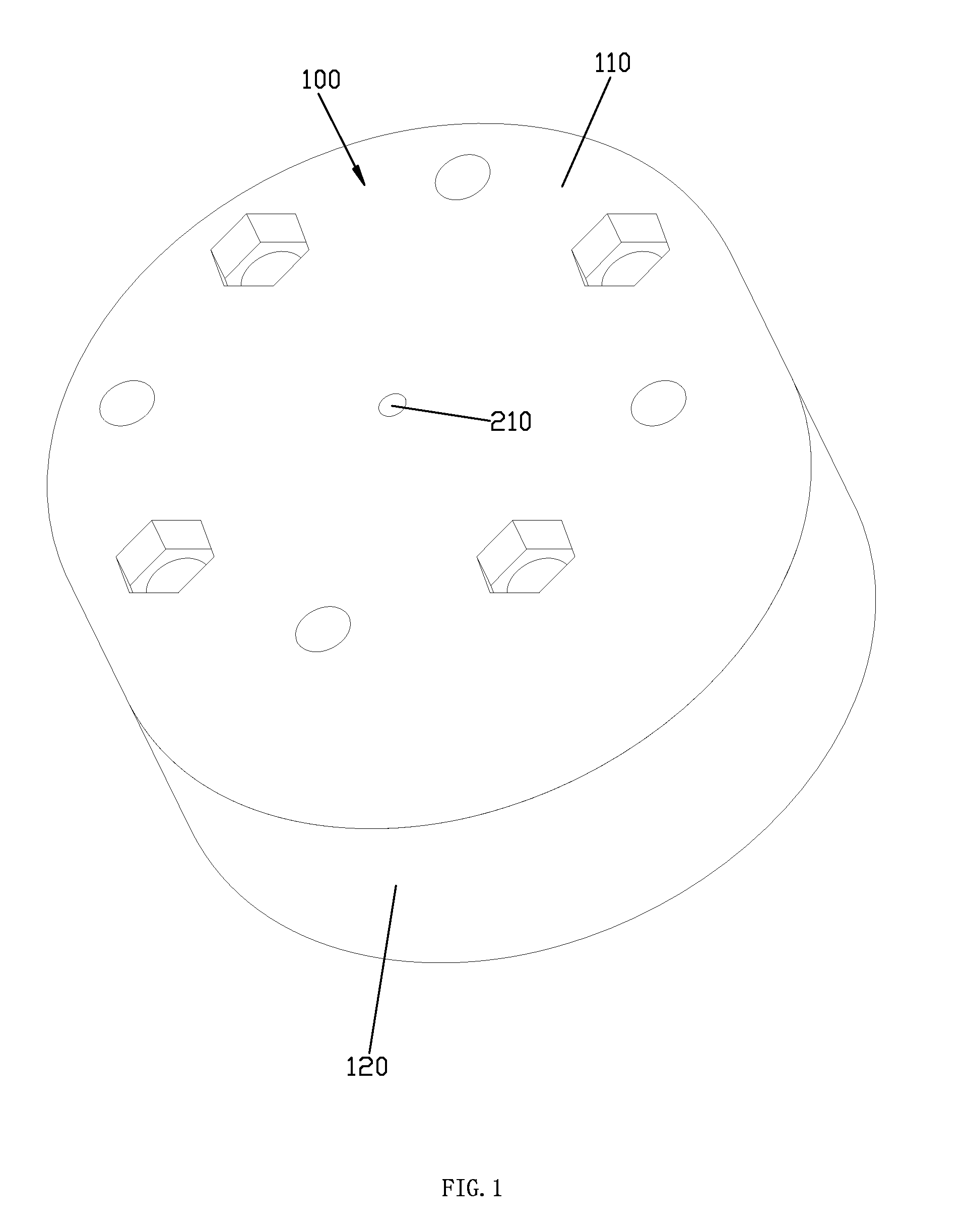

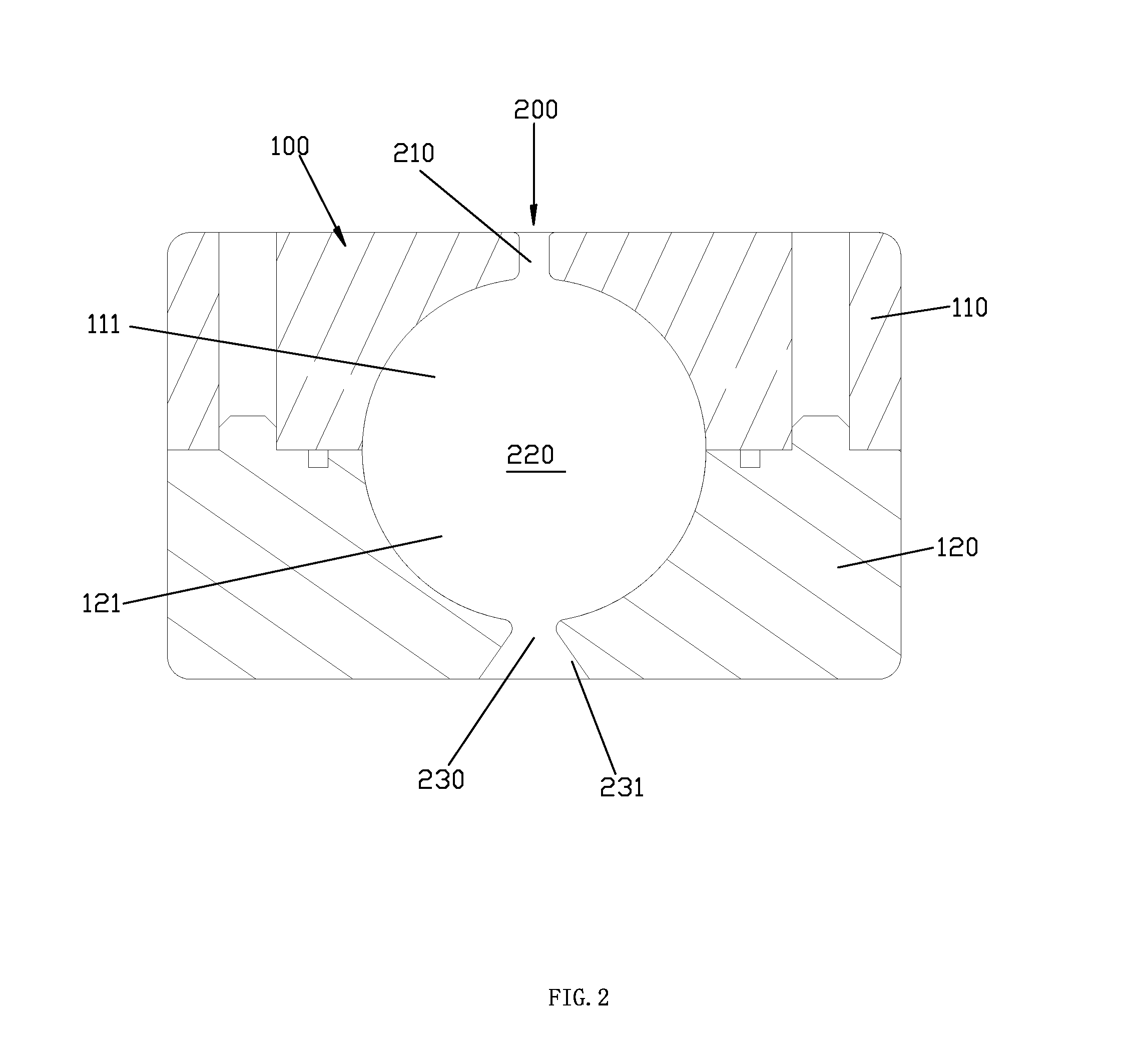

The present invention provides a device that can make pulsed water, including a base 100 equipped with a waterway 200. The waterway 100 consists of an inlet 210, an outlet 230 and a spherical cavity 220 forming between the inlet 210 and the outlet 230. The diameter of the spherical cavity 220 is larger than the caliber of the inlet 210, or that of the outlet 230. Some water flowing from the inlet to the spherical cavity will disperse, and others flows directly downwards. Some water hits the inwall of the spherical cavity and then reflects back to be reflection water. The reflection water impacts other water to turn to the side flowing down along the wall of the outlet. Due to the unstability of effluent, the water stream is along one place, turning to another side the next moment. So that the water sprays as a periodic and circumferential pulsed water.

Owner:XIAMEN SOLEX HIGH TECH IND CO LTD +1

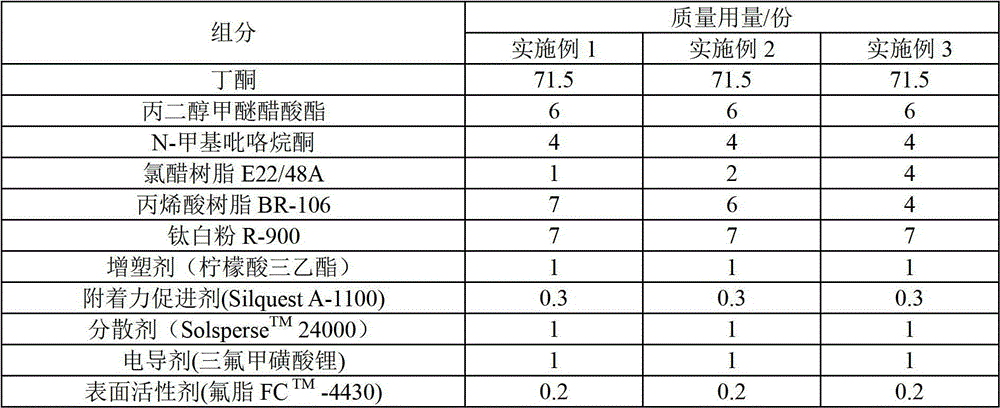

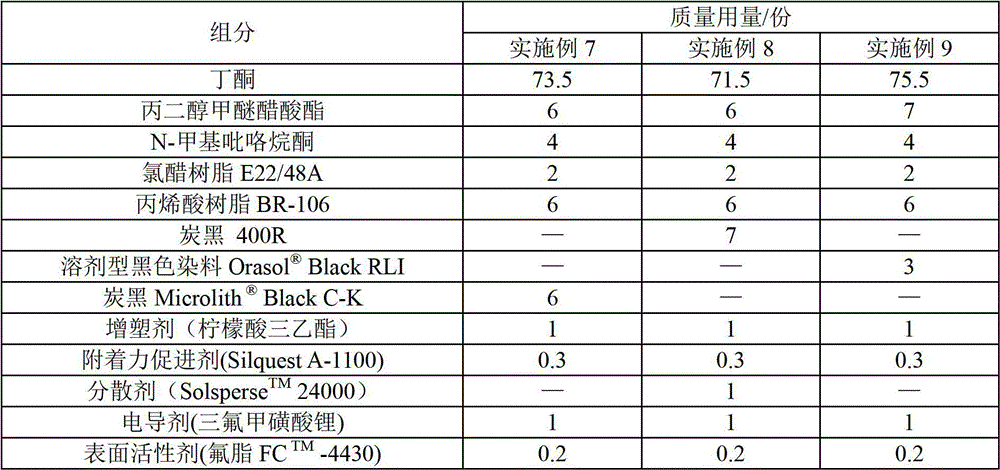

Special jet ink for PVC (polyvinyl chloride) cable

The invention discloses a special jet ink for PVC (polyvinyl chloride) cables, which consists of the following components by weight portions: 60-90 portions of organic solvent mixture, 5-12 portions of binder resin, 1-10 portions of colorant, 0.1-2.0 portions of plasticizer, 0.1-2.0 portions of adhesion promoter, 0.1-2.0 portions of surfactant, 0.2-5.0 portions of dispersing agent and 0.1-2.0 portions of conductance agent. The special jet ink for PVC cables disclosed by the invention is suitable for PVC substrate printing and has small particle size and good sprayability. The jet ink can quickly dry on the surface of the PVC substrate, having the advantages of stain resistance, scratch resistance, strong adhesion and good printing quality, printing stability, ink dryness and storage stability. The jet ink does not block the nozzle during printing and has good adhesion to PVC cables and good durability.

Owner:HANGZHOU HIWETECH CHEM TECH CO LTD

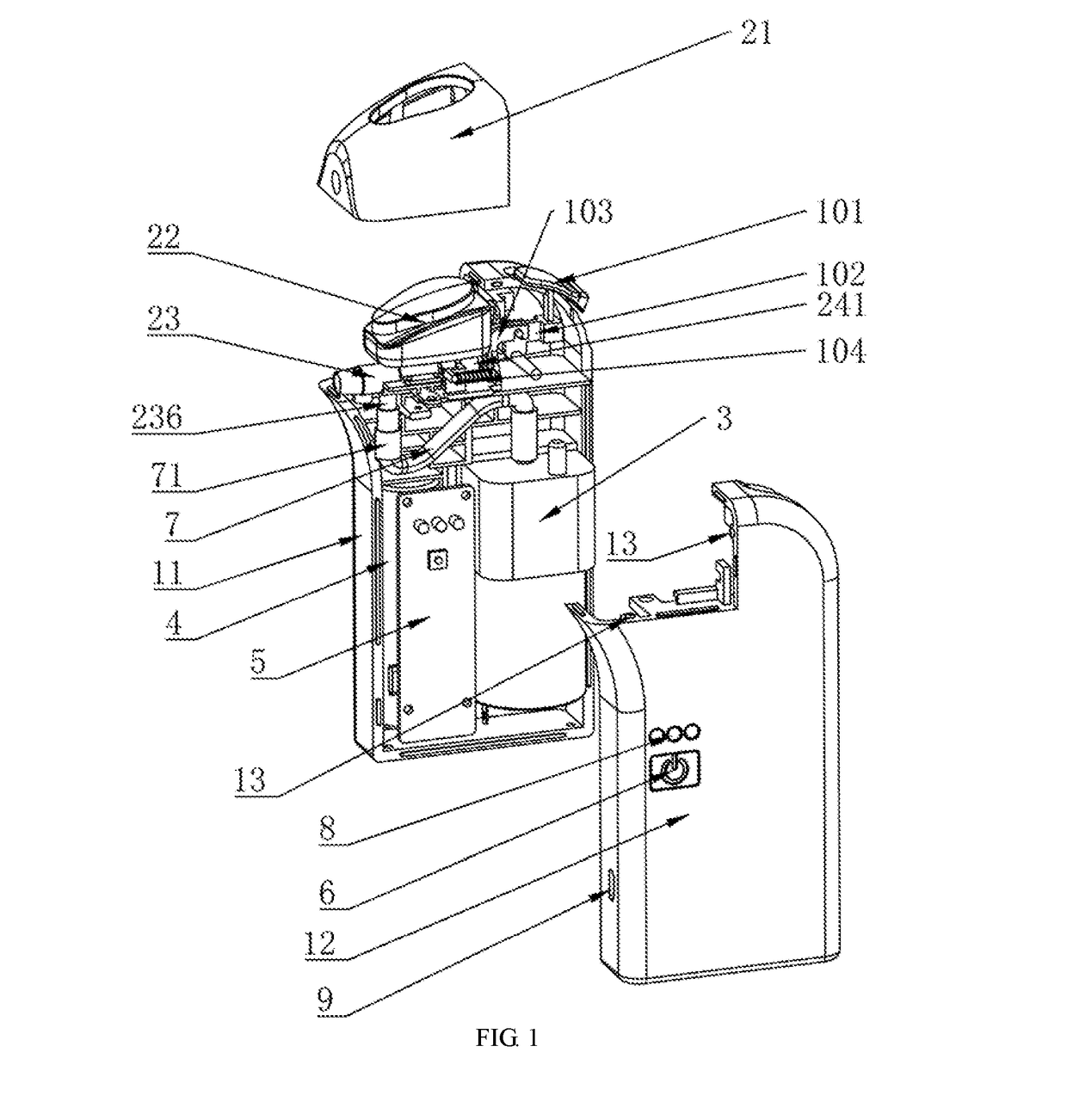

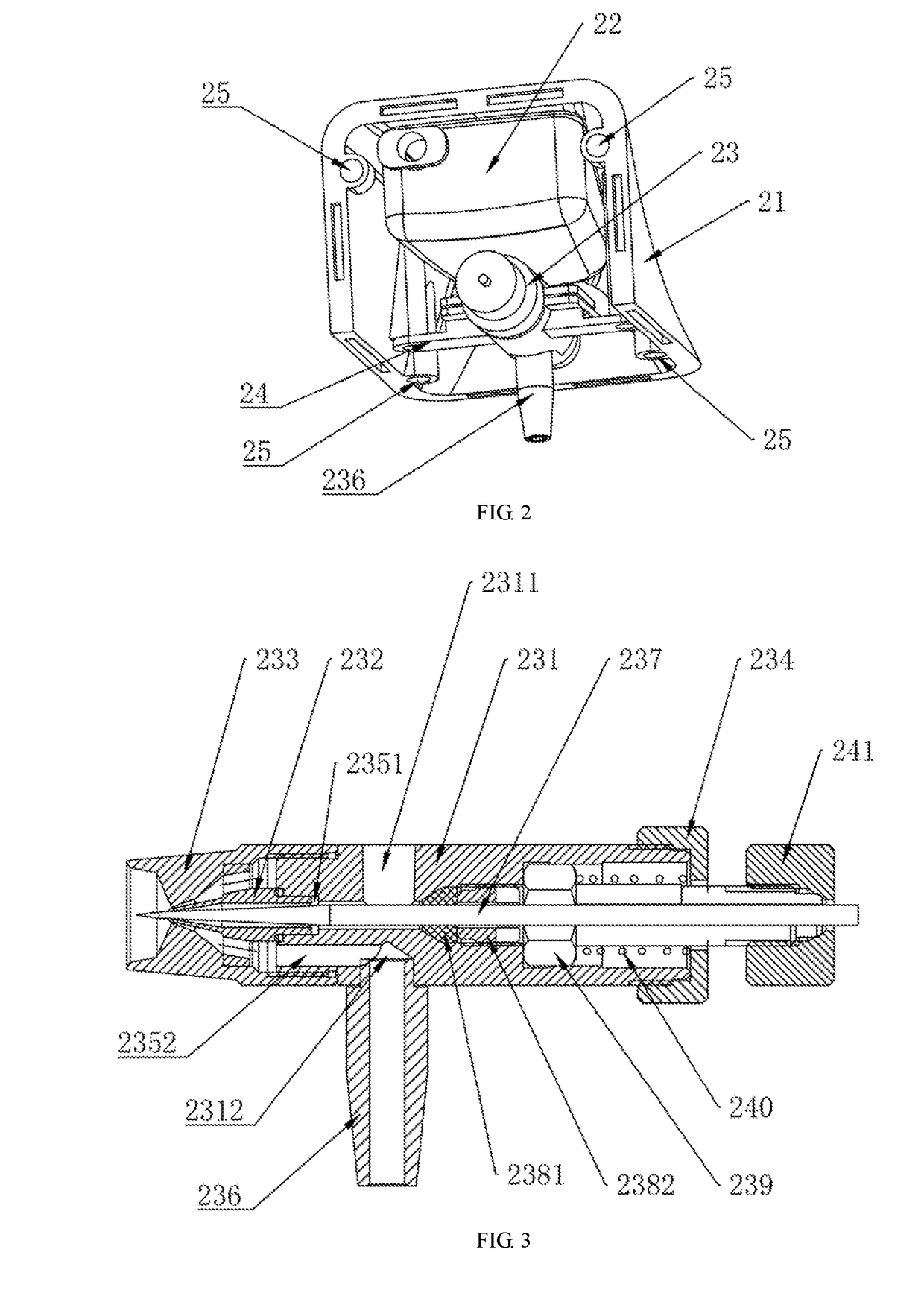

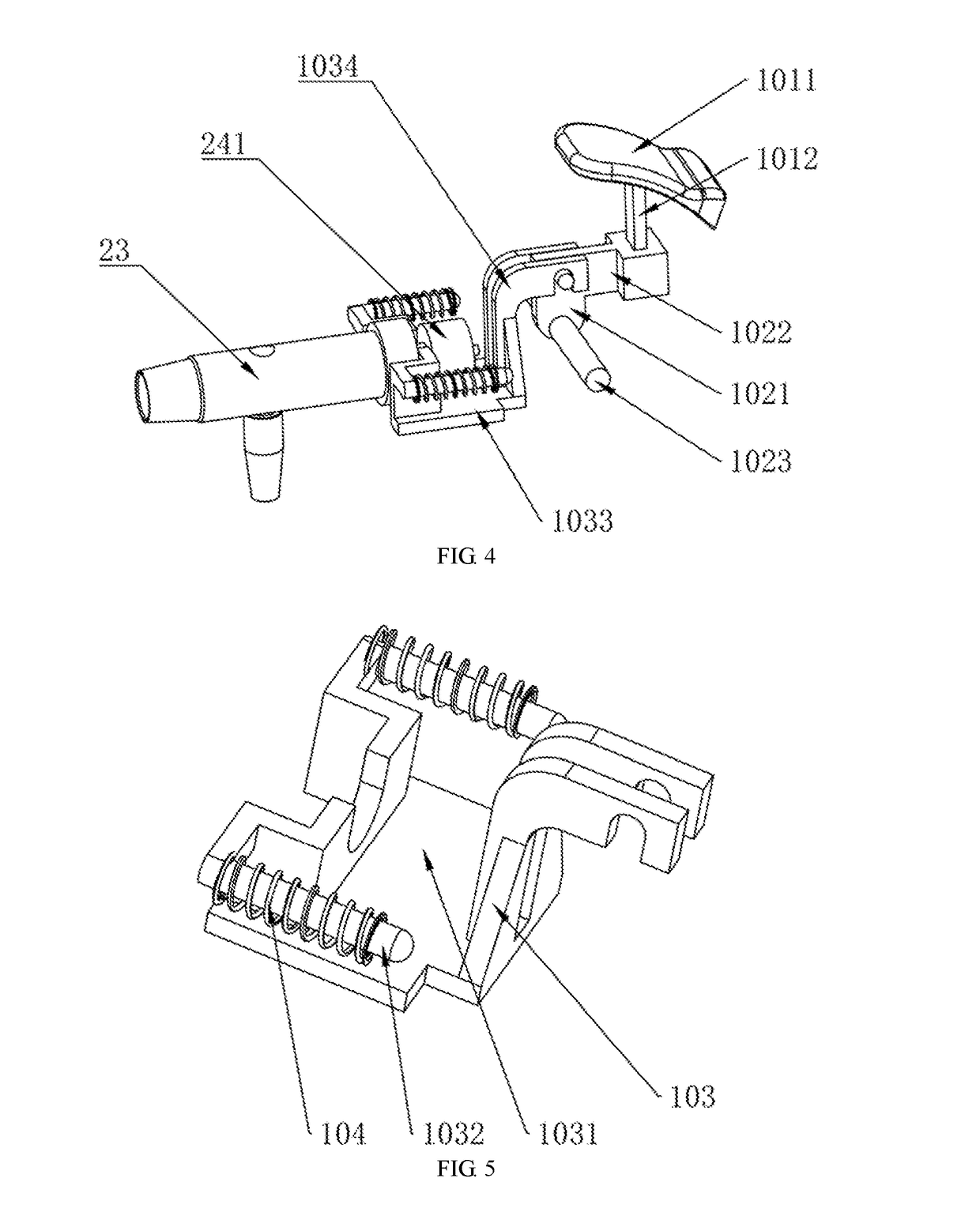

Integrated spray machine

ActiveUS20190022688A1Mount be convenient and fastSimple structurePackaging toiletriesPackaging cosmeticsEngineeringSprayer

Disclosed is an integrated spray machine which comprises a shell, a sprayer assembly, an air pump motor assembly, a battery, a circuit board and a switch, wherein the sprayer assembly comprises a housing, a container and a spray mechanism; the housing is matched with the shell, the container and the spray mechanism are mounted in the housing correspondingly, and the container communicates with a liquid inlet of the spray mechanism; the air pump motor assembly, the battery and the circuit board are all arranged in the shell, the switch is arranged on the wall of the shell, the air pump motor assembly, the battery and the switch are all electrically connected with the circuit board, and an air outlet of the air pump motor assembly communicates with an air inlet of the spray mechanism through an air pipe.

Owner:FENGHUA BIDA MASCH MFG CO LTD

Colorless transparent conductive ink as well as preparation method and application thereof

ActiveCN102286226AGood sprayabilityImprove reliabilityInksMetallic pattern materialsSolventEngineering

The invention discloses a colorless transparent conductive ink. The ink is prepared from the following raw materials by weight percent: 12%-21% of silver salt, 36%-53% of solvent, 27%-43% of additive and 0.1%-2.1% of dispersant. The ink has the advantages of good spraying property, good reliability, good image quality and good safety and can be used in the common home piezoelectric ink jet printer to prepare an electric circuit; and the common flat-plate printer can be utilized to prepare silver conductive patterns on different substrates. The invention also discloses a preparation method of the colorless transparent conductive ink. The method comprises the following steps: placing the silver salt in the organic solvent, performing ultrasonic vibration for 1-5 minutes; and adding the additive under stirring, stirring for 5-20 minutes, then adding the dispersant, stirring for 5-30 minutes and filtering to obtain the colorless transparent conductive ink. The method has the advantages ofsimple preparation technology, mild reaction conditions, good controllability, short preparation period, low production cost and the like.

Owner:宁波森利电子材料有限公司

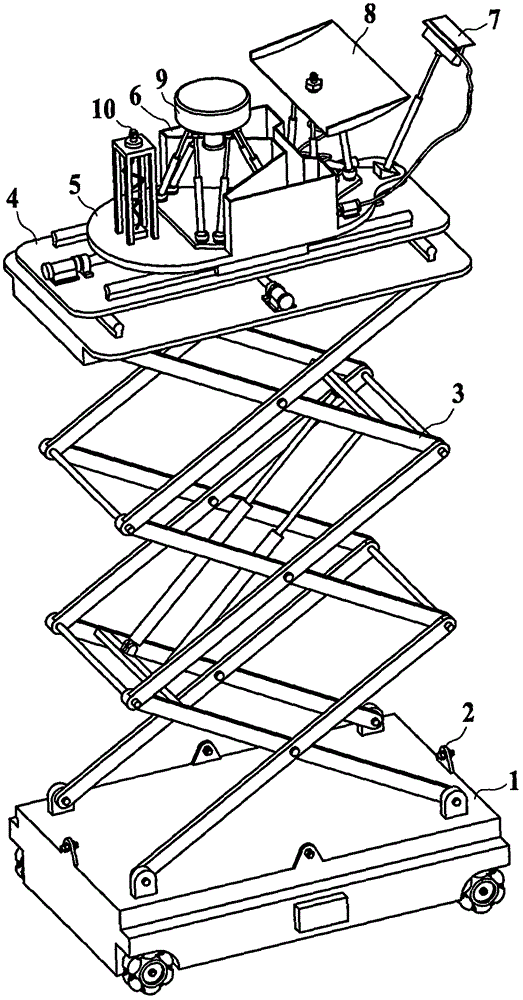

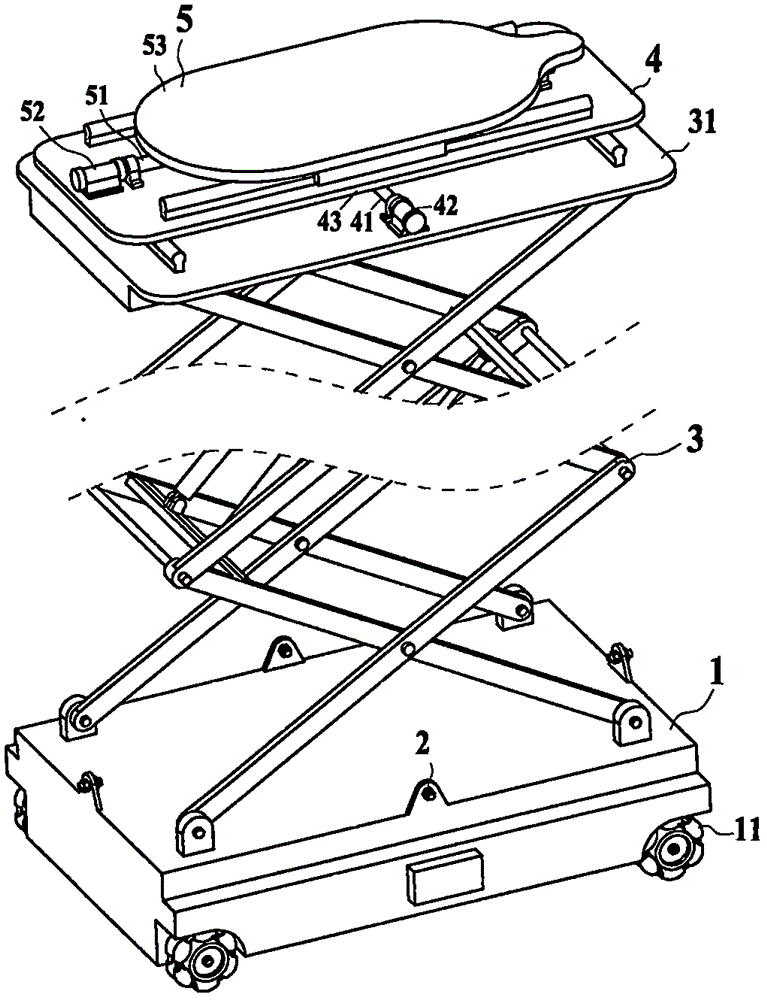

Scissor type upper wall processing robot and electrical system thereof

InactiveCN105908952ARealize integrated operationReduce health risksBuilding constructionsHealth riskEmulsion

The present invention relates to the field of building machinery, and specifically discloses a scissor type upper wall processing robot and an electrical system thereof. The robot main body comprises a bottom travelling device, distance sensors, an elevating device, a back and forth moving platform, a left and right moving platform, a reservoir, a plastering device, a paint spraying device, a polishing device and a photoelectric sensor. The electrical system comprises a programmable controller, a sensor unit, a hydraulic unit, a servo motor unit and a servo controller. Integrated operations of polishing, putty plastering and emulsion paint spraying on an upper wall can be achieved without workers and multiple equipment, manpower is saved, health risks of the workers are reduced, efficiency is improved, economic benefits are increased, and polishing, plastering and paint spraying effects are better compared with traditional equipment.

Owner:HUAINAN NORMAL UNIV

Aluminum alloy machined part environment-friendly spraying device

The invention discloses an aluminum alloy machined part environment-friendly spraying device. The aluminum alloy machined part environment-friendly spraying device comprises a device body, a hydraulicoil cylinder is fixedly connected to the inner top of the device body, an arc plate is fixedly connected to the telescopic end of the hydraulic oil cylinder, multiple sprayers are fixedly connected to the inner wall of the arc plate at equal intervals, a coating tank is fixedly connected to the inner wall of the device body, a delivery pipe is fixedly connected to the side wall of the coating tank, the output end of the delivery pipe is fixedly connected with the sprayers, and a driving motor is fixedly connected to the side wall of the device body. By means of the aluminum alloy machined part environment-friendly spraying device, through the arrangement of a negative pressure draught fan and a storage bucket, particles generated in the spraying process are collected into the storage bucket, and the environment pollution is reduced; through second springs, the vibration inertia of the device is reduced, dynamic loads transmitted to a foundation are reduced, then the device more stablyruns, and the spraying effect is better; the sprayers are aslant arranged below the arc plate, so that the spraying range is wider, corners of an aluminum alloy workpiece can be sprayed, and the product quality is improved.

Owner:昆山力维拓工业自动化科技有限公司

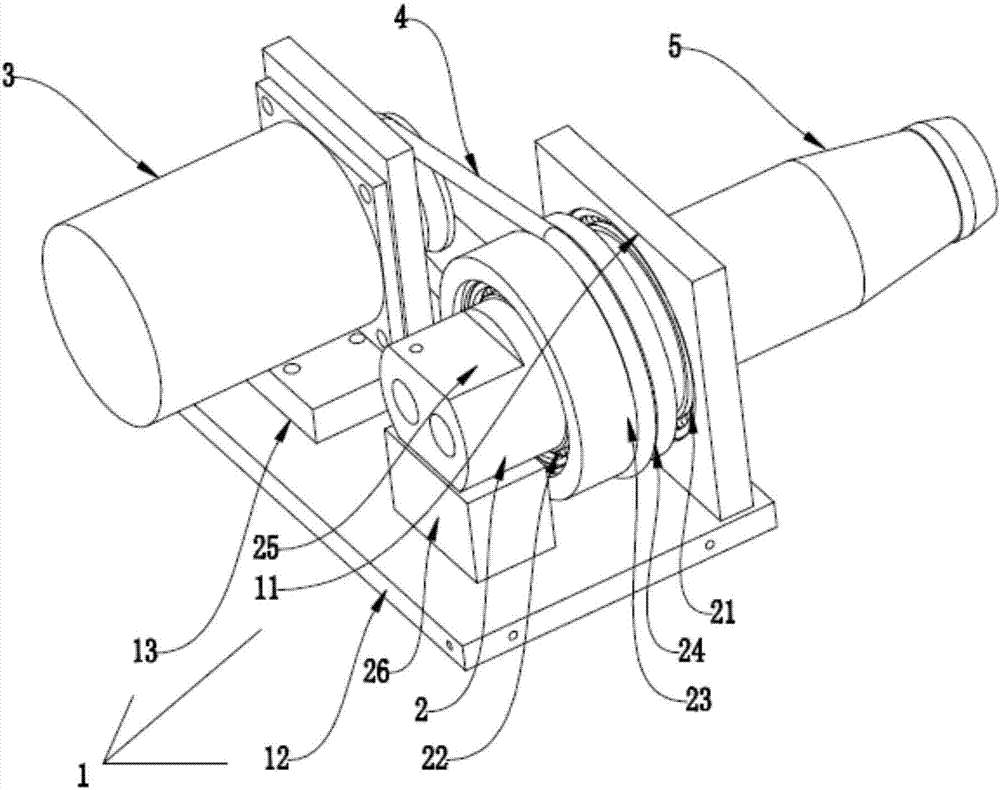

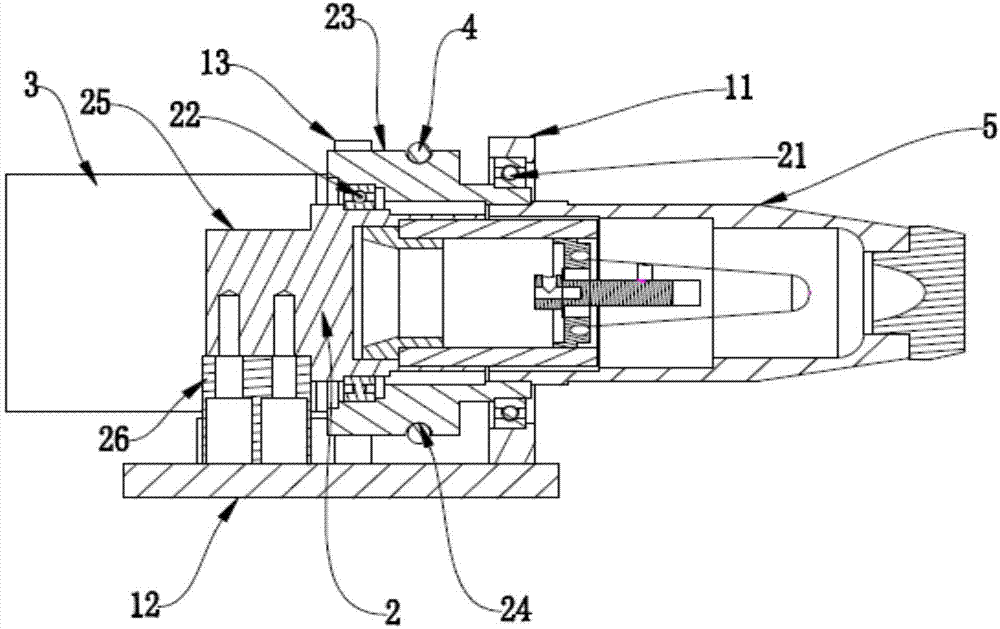

Plasma gun rotating device

InactiveCN103796410ANot prone to vibrationExpand the spraying rangePlasma techniqueMotor driveEngineering

A plasma gun rotating device comprises a rack, a motor, a conveyor belt, a plasma gun and a shaft core. The motor is fixed on the rack. The motor drives, through the conveyor belt, the shaft core to rotate. The plasma gun is arranged at the tail end of the shaft core. A bearing is arranged on the middle back portion of the shaft core. The shaft core is provided with a rotating shell. The bearing is arranged between the shaft core and the rotating shell. A spray head of the plasma gun is arranged in an inclined mode. The motor drives, through the conveyor belt, the plasma gun to rotate. The plasma gun rotating device expands the spraying range, improves spraying efficiency, reinforces the stability of the plasma gun in the spraying process, and realizes a better spray effect.

Owner:广东韦达尔传媒有限公司

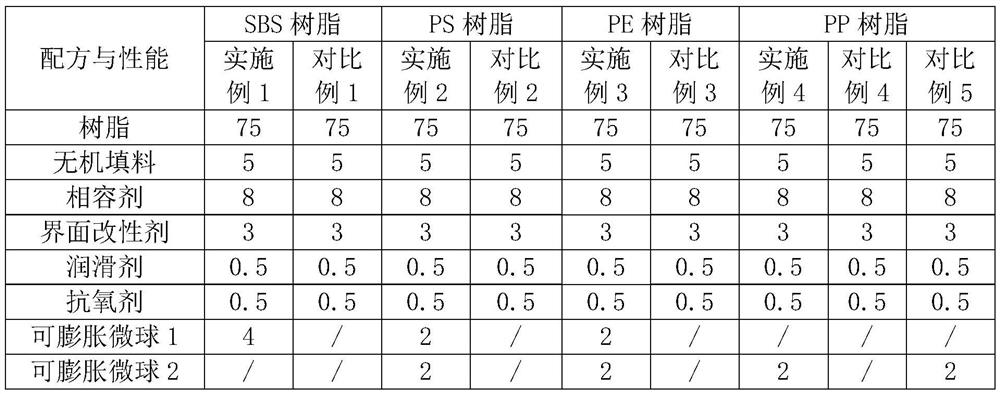

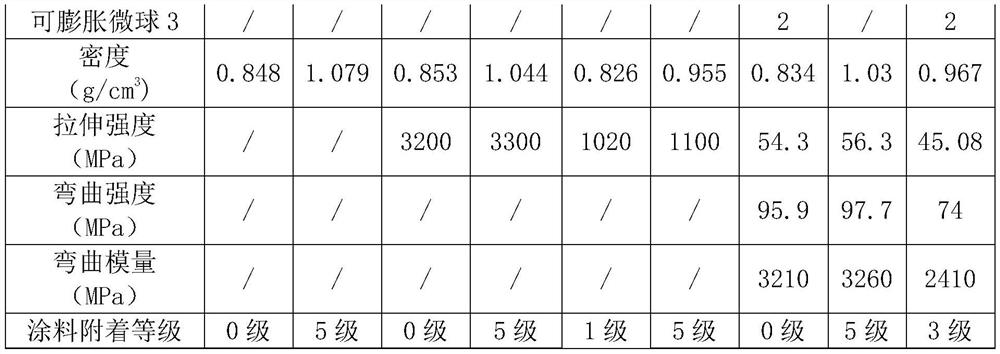

Polymer material and preparation method thereof

The invention discloses a polymer material and a preparation method thereof. The polymer material comprises polymer material particles, expandable microspheres, inorganic filler and the like. The preparation method comprises the following steps: uniformly mixing the polymer material particles, the inorganic filler, a compatilizer, ane interface modifier, a lubricant and an antioxidant in proportion, and extruding and bracing the mixture through a twin-screw extruder to obtain modified polymer master batch; and blending the modified polymer particles with expandable microspheres, and preparingthe low-density sprayable polymer composite material by using a single-screw injection molding machine. Under the condition of ensuring the strength of the polymer material, the buckling deformation and the density of the polymer material are effectively improved so that the surface of the material becomes rougher, the wetting ability is improved, and the sprayability is enhanced. More active groups exist on the surfaces of the expandable microspheres, and the hyperbranched interface modification aid is combined so that the surface polarity of the polymer is increased, and the sprayability ofthe polymer is improved.

Owner:CRERAX SCI & TECH CO LTD

Transformer spraying equipment and spraying process thereof

InactiveCN111495641AImproves sprayabilityGuarantee the quality of sprayingPretreated surfacesCoatingsTransformerMechanical engineering

The invention discloses transformer spraying equipment. The transformer spraying equipment comprises a supporting body, a containing cavity is formed in the supporting body, guide grooves are formed in the upper side wall and the lower side wall of the containing cavity in the horizontal direction, adjusting devices are connected into the guide grooves in a sliding mode, each adjusting device comprises a sliding part and a supporting part, the sliding parts are located at the outer ends of the containing cavity to be perpendicularly connected with the supporting parts, and the supporting partsextend in the center direction of the supporting body from the perpendicular connecting position. According to the transformer spraying equipment, before a spraying assembly is used for spraying a transformer shell, the transformer shell is clamped firstly and then is rotated, so that the spraying effect is good and more in place, the overall spraying quality is guaranteed, the automation degreeof the operation process is high, manpower is saved, and the operation process is safer.

Owner:台州市振泰机电有限公司

High-efficiency spraying device for electric vehicle accessories

The invention discloses a high-efficiency spraying device for electric vehicle accessories. The high-efficiency spraying device comprises a box body and a fixed plate, the fixed plate is fixedly installed at the bottom of an inner cavity of the box body, electric push rods are correspondingly installed on the two sides of the top of the fixed plate, fixed blocks are installed at the tops of the electric push rods, and a spraying mechanism is installed at the top of the inner cavity of the box body; and the spraying mechanism comprises a screw rod, a motor, a screw rod nut, a sprayer, a limit sliding groove and a limit sliding block, the motor is installed on the left side wall of the box body, a transmission shaft of the motor penetrates through the left side wall of the box body, and is fixedly connected with one end of the screw rod, the other end of the screw rod is movably connected with the inner wall of the box body through a bearing, and the screw rod nut is installed on the outer wall of the screw rod in a sleeving mode. According to the high-efficiency spraying device, the screw rod is driven by the motor to rotate, thus the sprayer is driven for reciprocating spraying, thus spraying is even, meanwhile a stirring rod is driven to stir coating, thus the coating is even, thus the spraying effect is better, and the situation that spraying is uneven due to deposition is avoided.

Owner:XUZHOU JIULONG ELECTRONICS IND CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com