Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

295results about How to "Guarantee the quality of spraying" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Layered spraying track planning method used for spraying robot

InactiveCN102831306AEfficient sprayingImprove spraying efficiencySpecial data processing applicationsEconomic benefitsTrajectory optimization

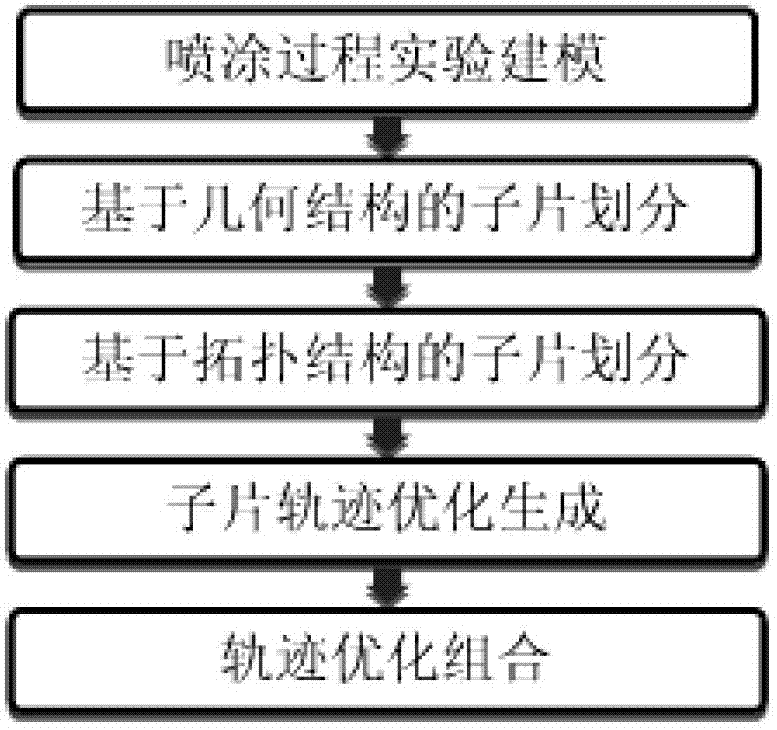

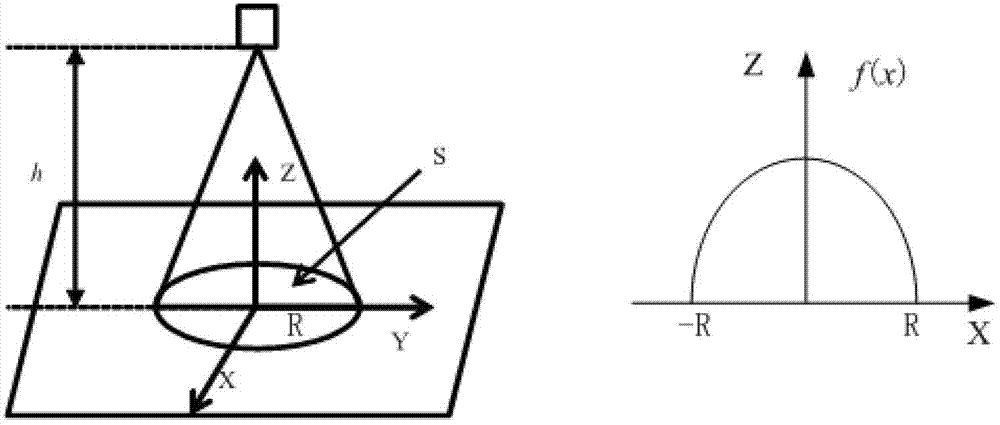

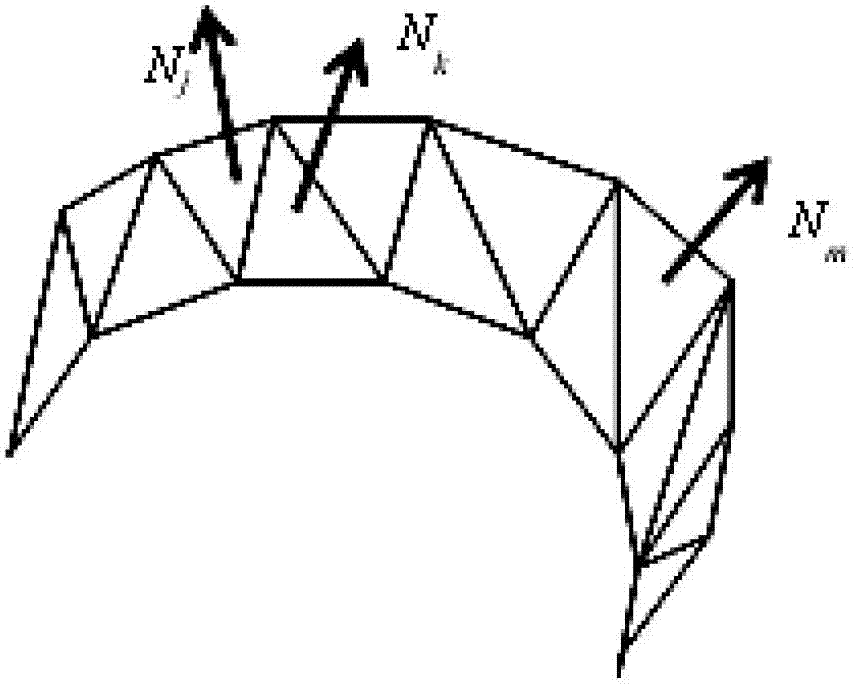

The invention discloses a layered spraying track planning method used for a spraying robot. The layered spraying track planning method comprises the steps of: firstly, designing an experiment method to build a model for the spraying process and fitting a coating distribution condition by introducing Gaussian and coating accumulative rate model; then adopting a layered track planning method and dividing a complex curve into a plurality of simple sub-curves by respectively applying a double deviation angle method and a projection method based on geometric and topological characteristics of a work-piece, establishing a corresponding spraying track optimization model and obtaining a travel parameter by adopting a numerical method so as to generate a spraying track in each sub-sheet; and finally, adopting an estimation of distribution algorithm to perform optimized combination on the track of each sub-sheet. The layered spraying track planning method used for the spraying robot, disclosed by the invention, has the advantages of improving the spraying production technology of the spraying robot, realizing track optimized generation of the spraying robot on each complex work-piece surface, improving distribution uniformity under the precondition of satisfying expected thickness of the coating, reducing paint waste, and thereby facilitating to improve production efficiency and economic benefits of the spraying manufacturing industry.

Owner:SOUTHEAST UNIV

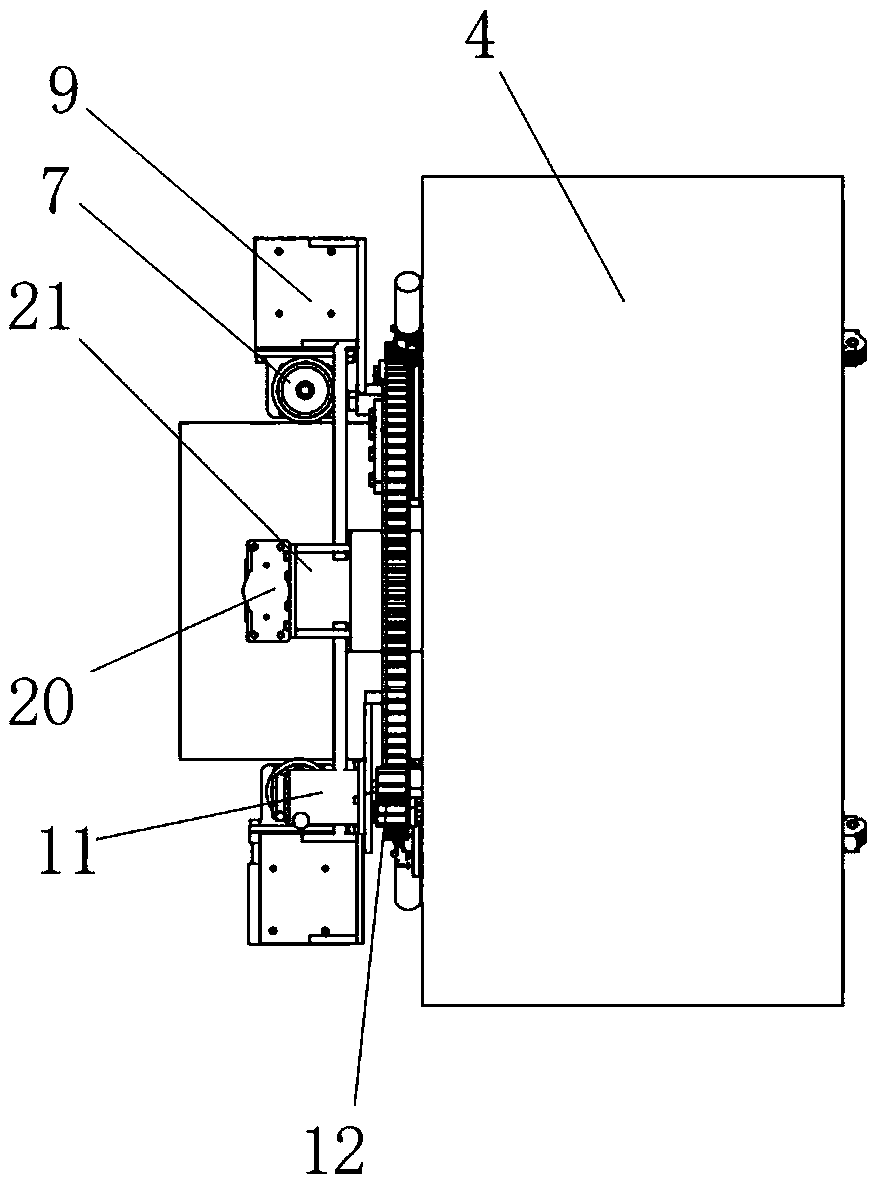

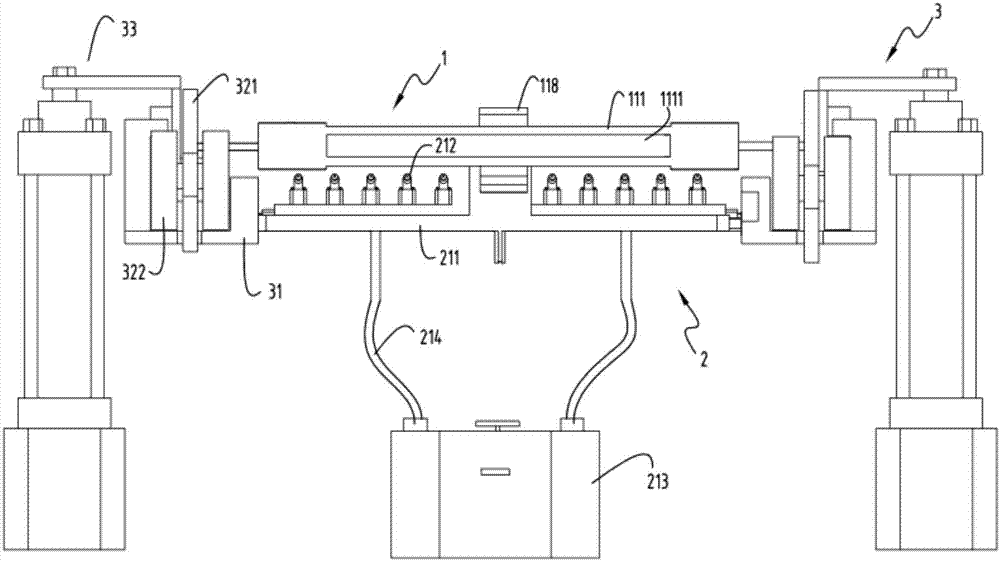

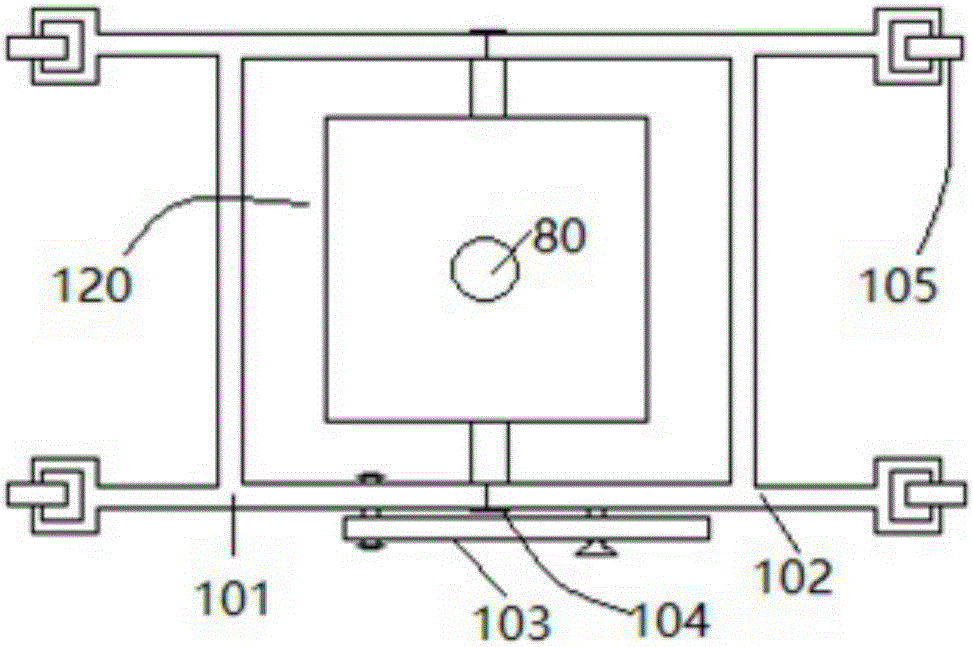

Racket automatic spraying system

ActiveCN106622771AAvoid mutual interferenceReduce movement distanceSpraying apparatusPretreated surfacesProduction lineControl signal

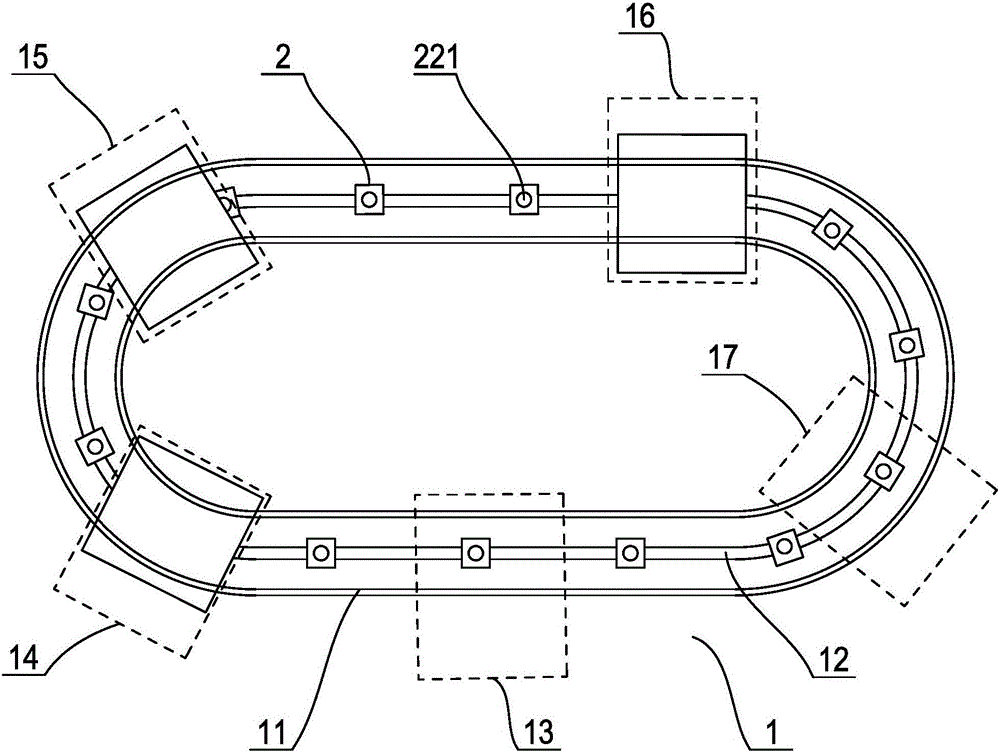

The invention discloses a racket automatic spraying system. The racket automatic spraying system comprises a loading station, a spraying station, a curing station and an unloading station arranged on a conveying production line in sequence; a driving chain of the conveying production line is provided with multiple racket fixed sleeves for inserting rackets; the spraying station is provided with a spraying manipulator; the spraying manipulator is provided with a combined spraying gun, a racket driving mechanism and a position detecting device; when the racket fixed sleeves move beside the spraying manipulator, the position detecting device sends a control signal; the spraying manipulator and the racket fixed sleeves keep synchronous movement; the combined spraying gun is controlled to automatically spray one surfaces of the rackets; after the combined spraying gun sprays one surfaces of the rackets, the racket driving mechanism acts to rotate the rackets on the racket fixed sleeves; and at this time, the combined spraying gun automatically sprays the other surfaces of the rackets by procedures. The racket automatic spraying system can realize full-automatic racket spraying to prominently improve the production efficiency, reduce the labor intensity of staff and effectively improve the spraying quality of the rackets.

Owner:杭州诚兴体育用品有限公司

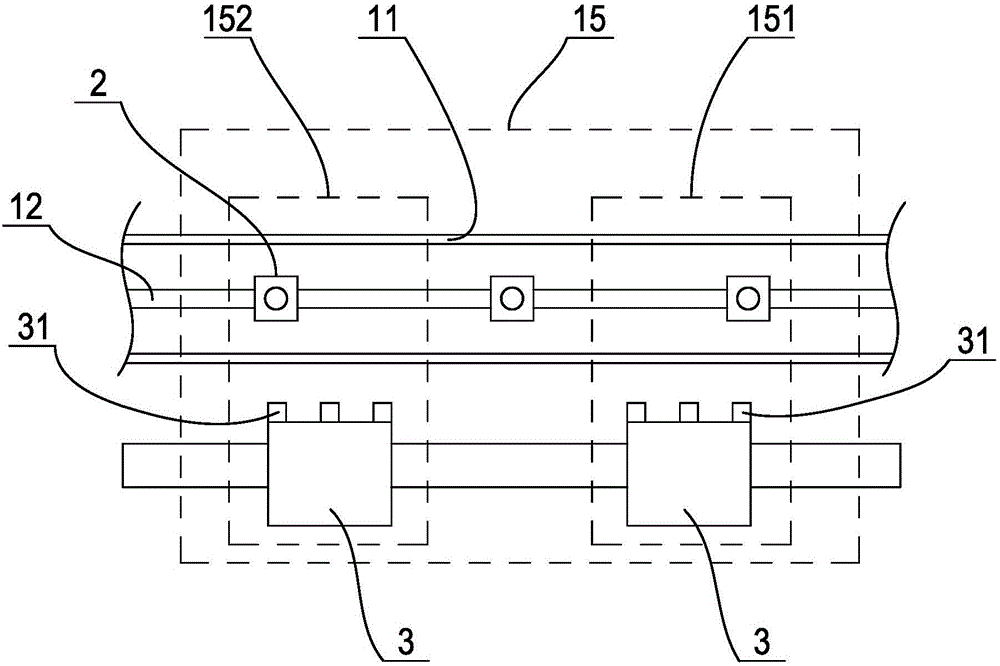

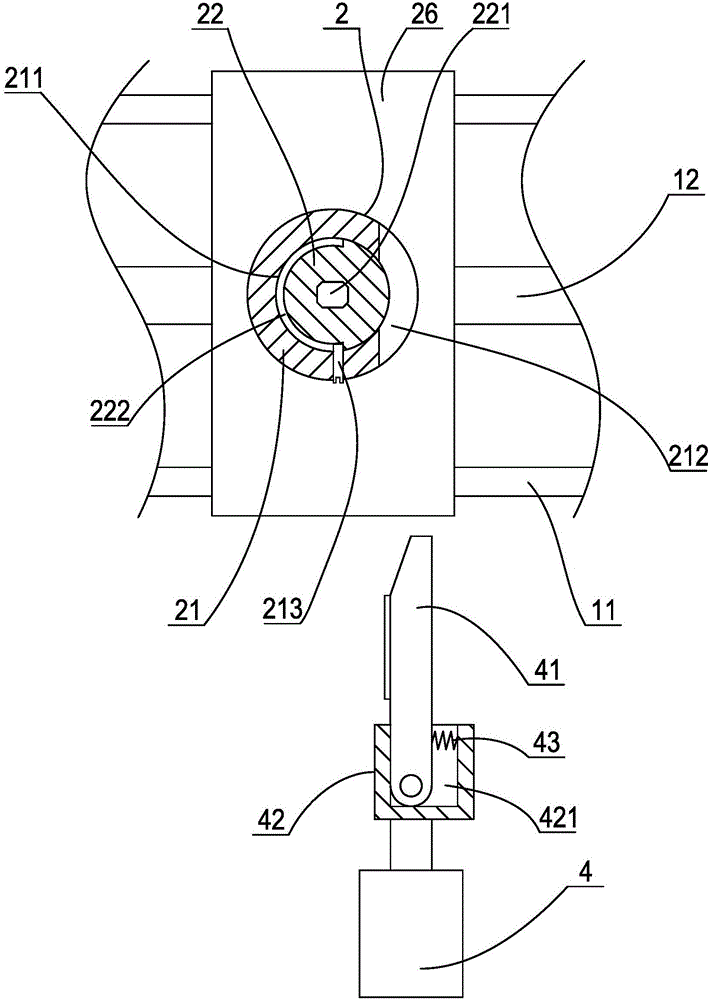

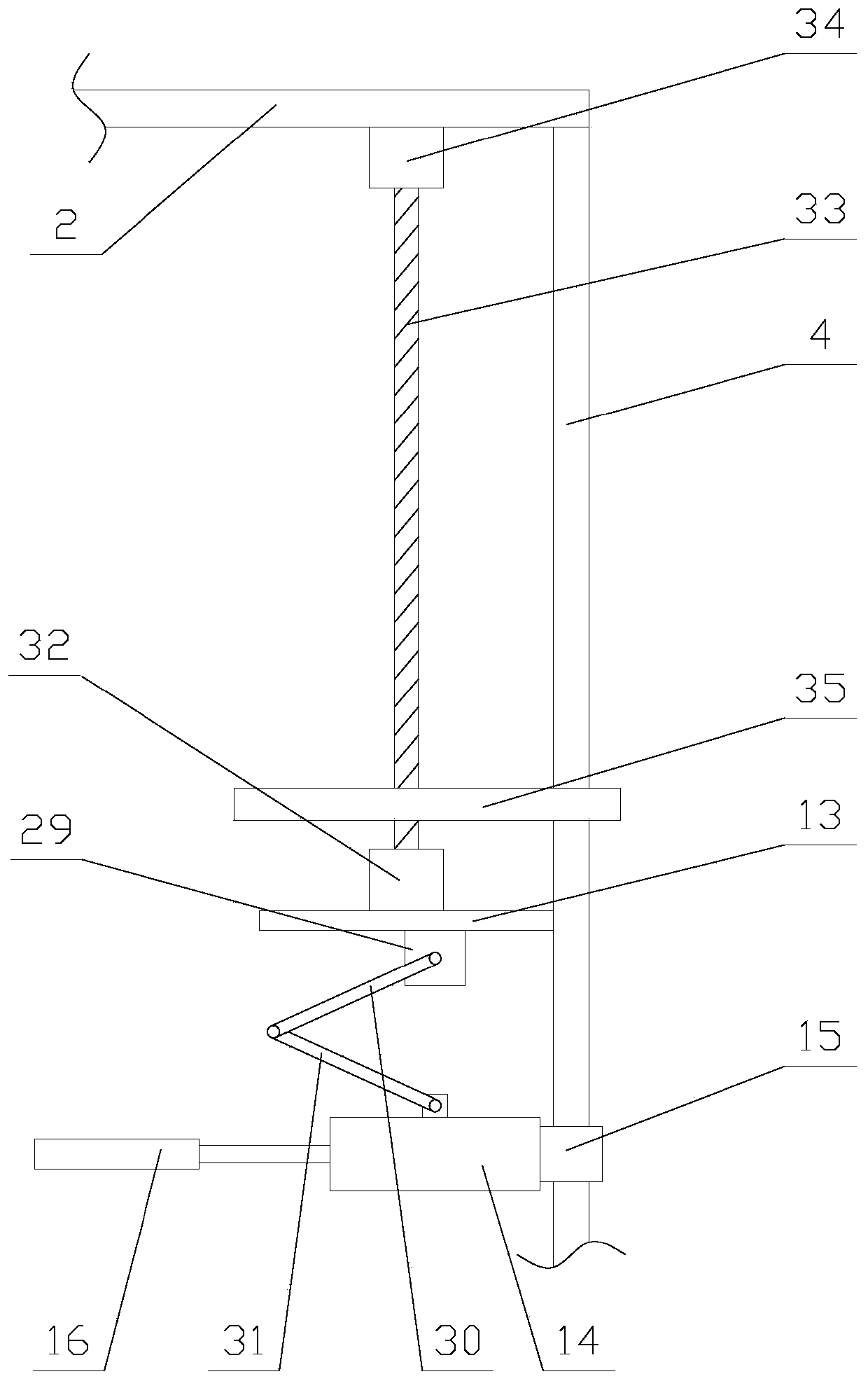

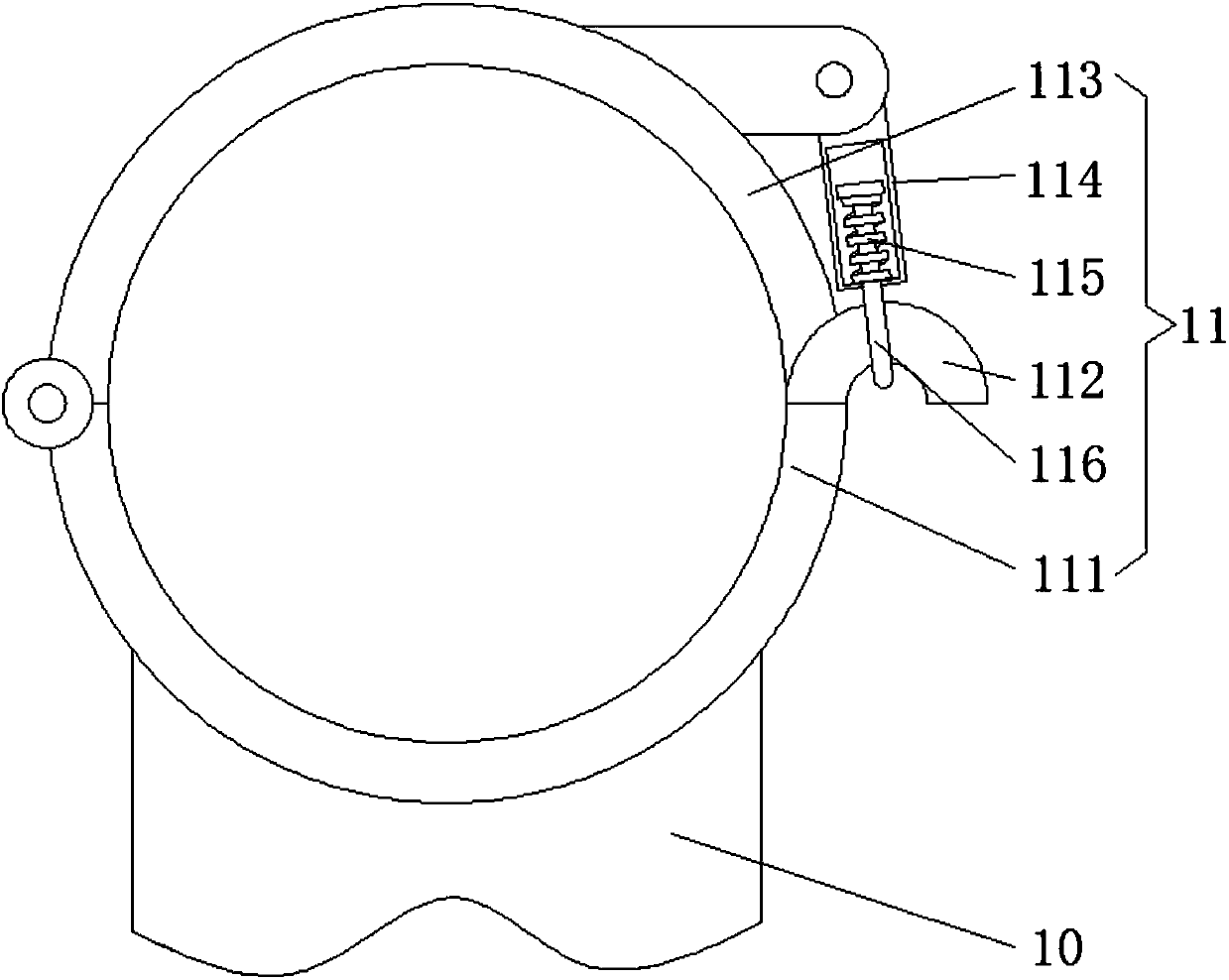

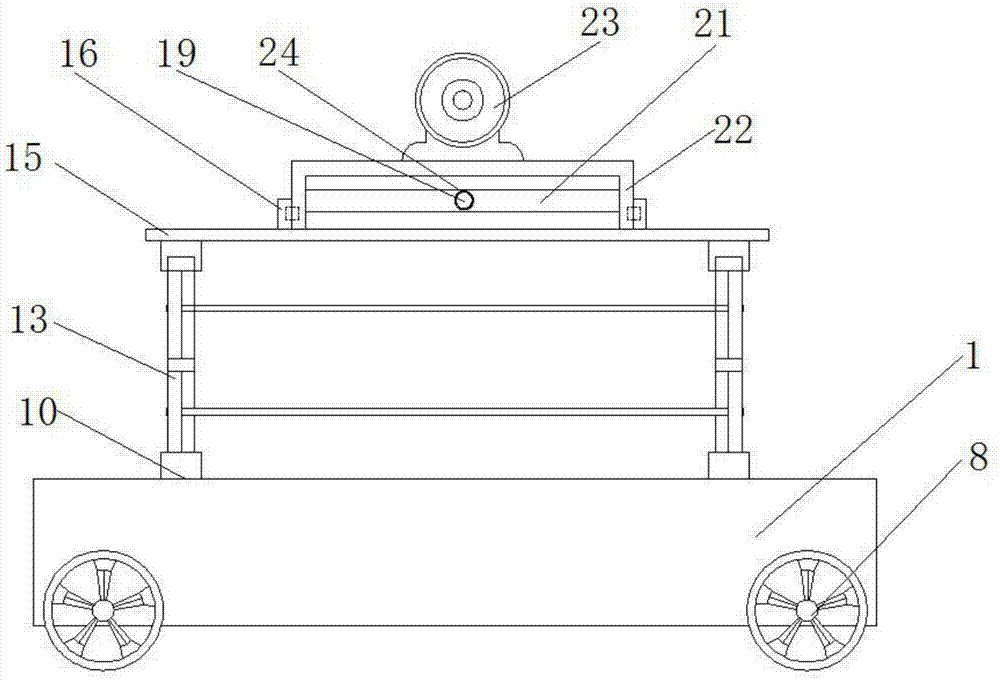

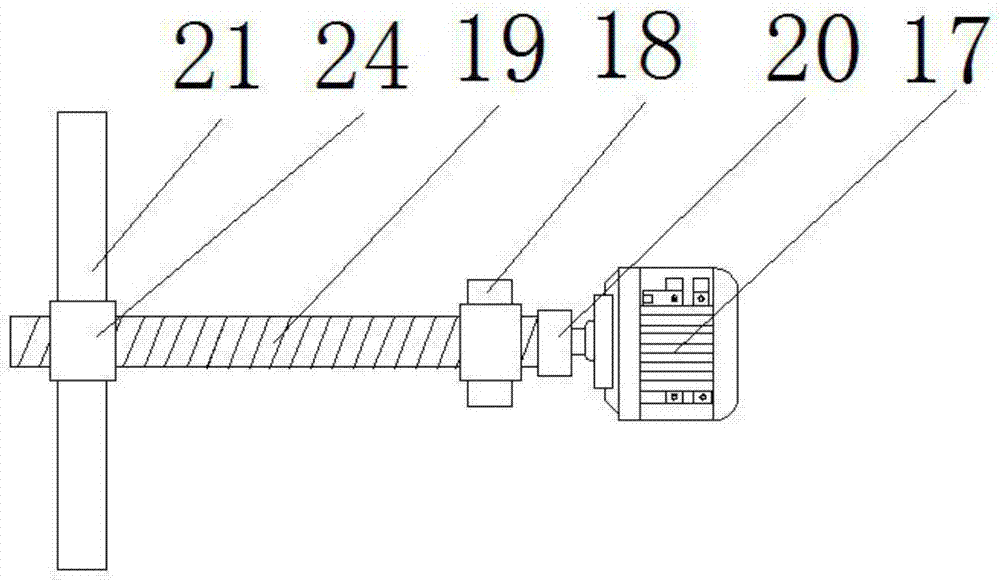

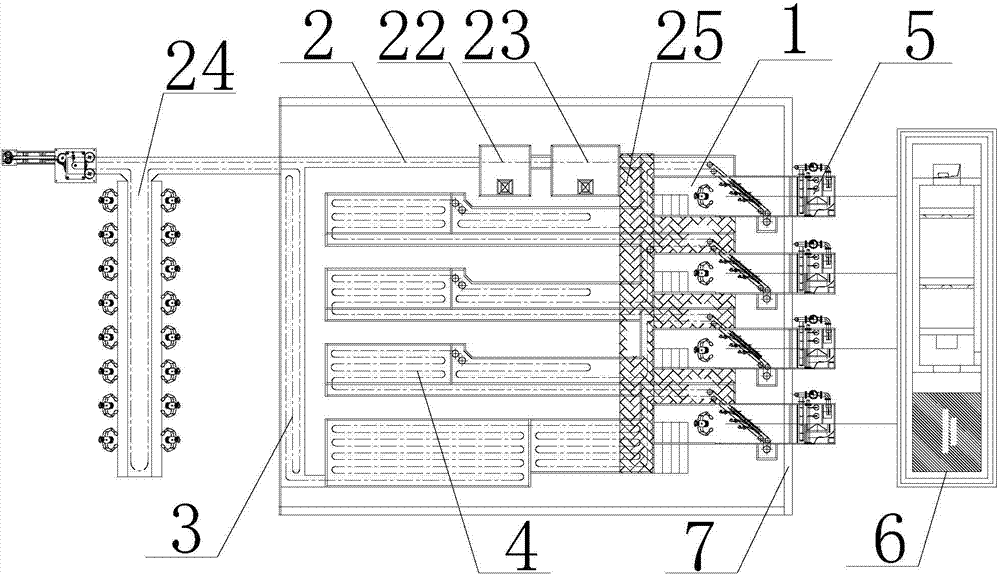

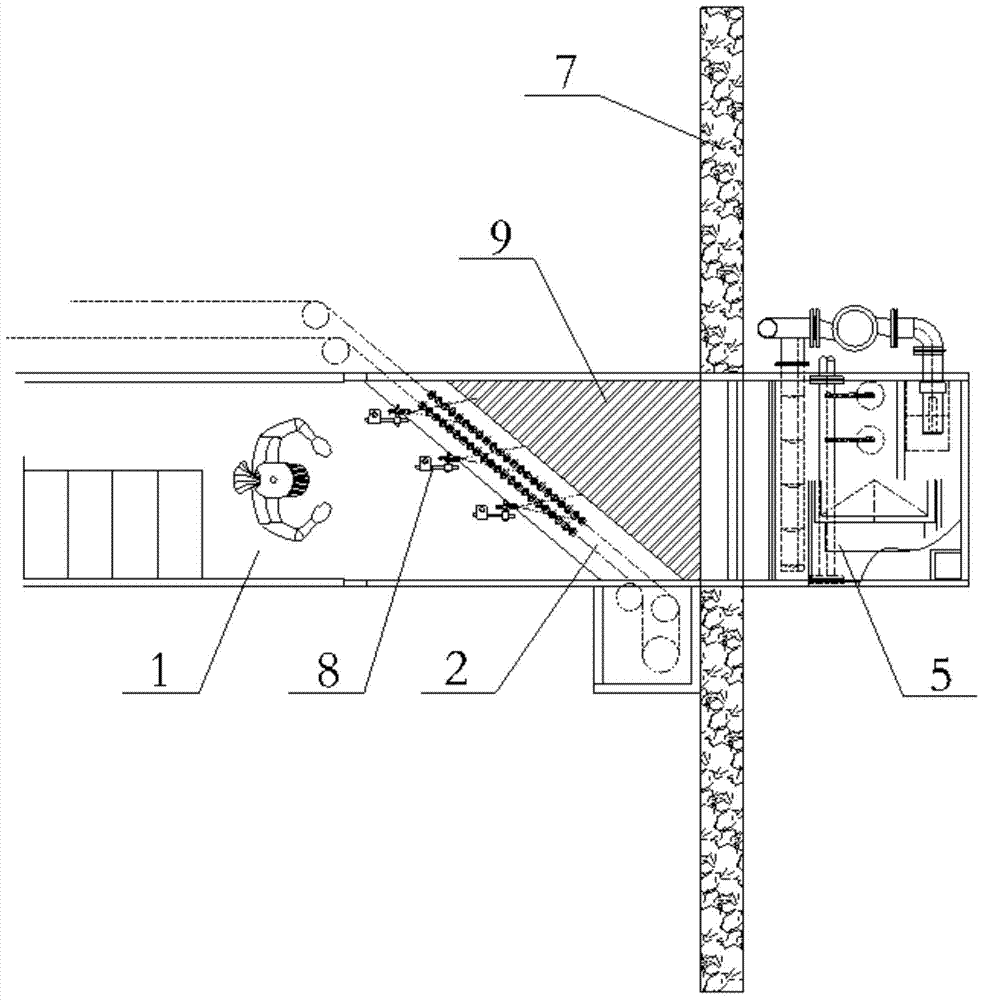

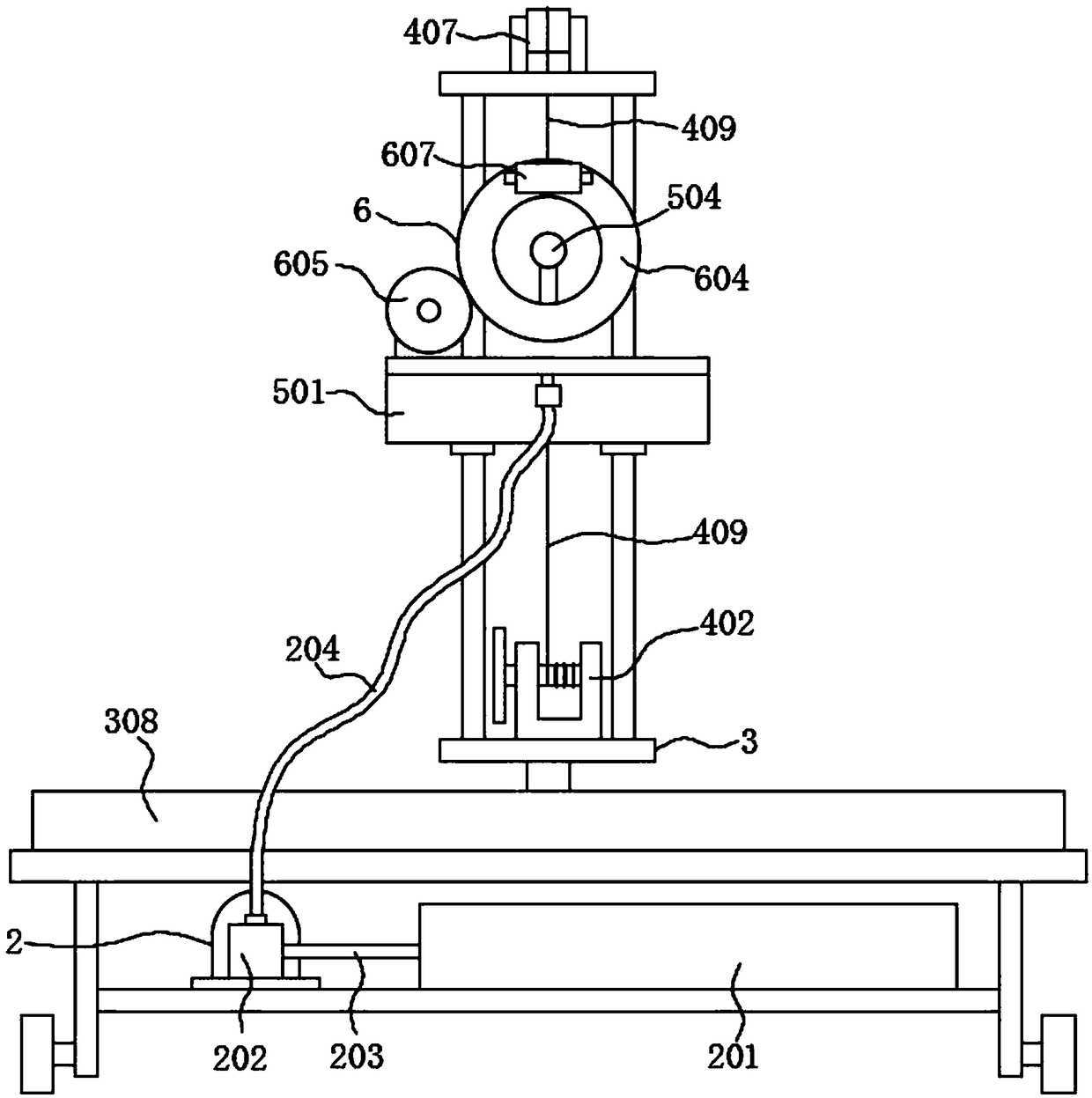

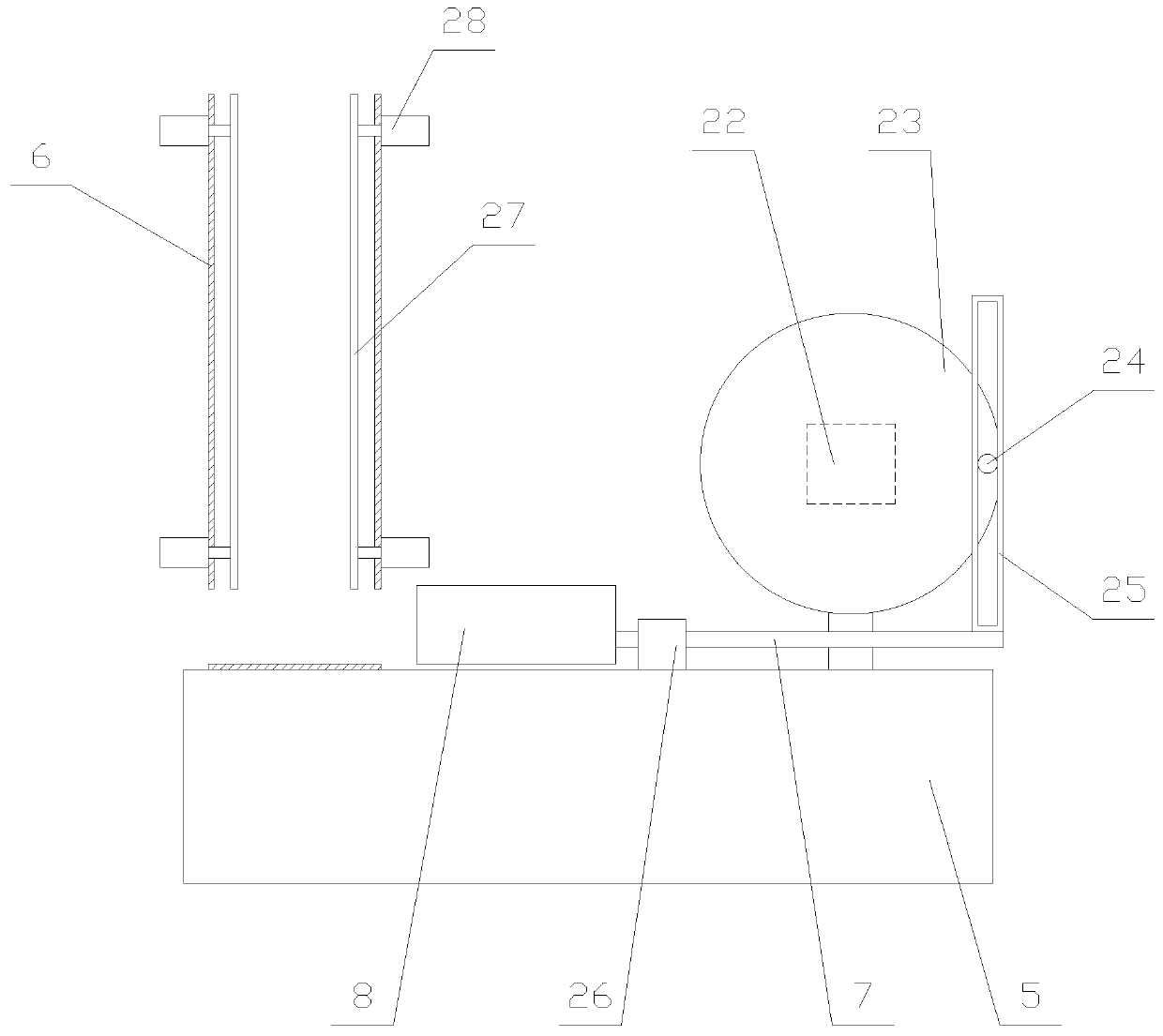

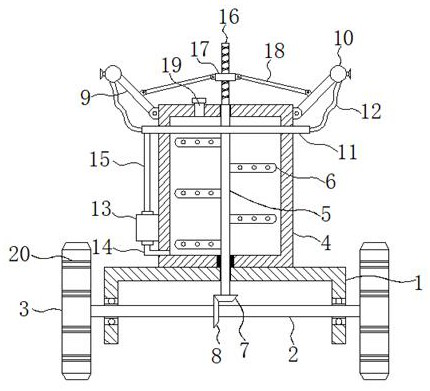

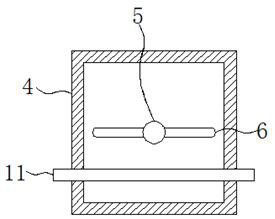

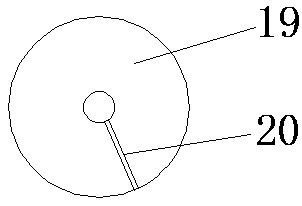

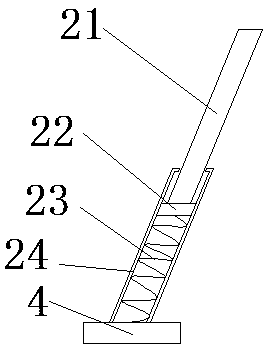

Automatic spraying device for lime washing of trunk

ActiveCN105127036AGuaranteed neutral requirementsAppropriate distanceSpraying apparatusSprayerUtilization rate

The invention discloses an automatic spraying device for lime washing of a trunk. The device comprises a frame traveling mechanism, an upright opening-closing mechanism, three sprayer clamp positioning mechanisms, three sprayer clamp up-down moving mechanisms and a hydraulic spraying mechanism, wherein the upright opening-closing mechanism is arranged on the left, middle and right parts of the frame traveling mechanism; the three sprayer clamp positioning mechanisms and the three prayer clamp up-down moving mechanisms are all arranged on the upright opening-closing mechanism; and the hydraulic spraying mechanism, an electronic control mechanism and an auxiliary mechanism are all arranged on the frame traveling mechanism. According to the automatic spraying device, a manual spraying mode is changed to an automatic spraying mode, and the sprayer clamp positioning mechanisms are used for ensuring that a proper distance is kept between sprayers and the trunk and simultaneously ensuring the centering requirement of the sprayers and the trunk when the diameter of a tree is changed; and the upright opening-closing mechanism is used for enabling the sprayer clamp positioning mechanisms to enclose a circle and enabling the sprayers to be uniformly distributed at the periphery of the trunk, so that the spraying quality is ensured, the utilization rate of paint is increased, the spraying stability is improved, and the trunk lime washing work is high in efficiency and stable.

Owner:浙江知多多网络科技有限公司

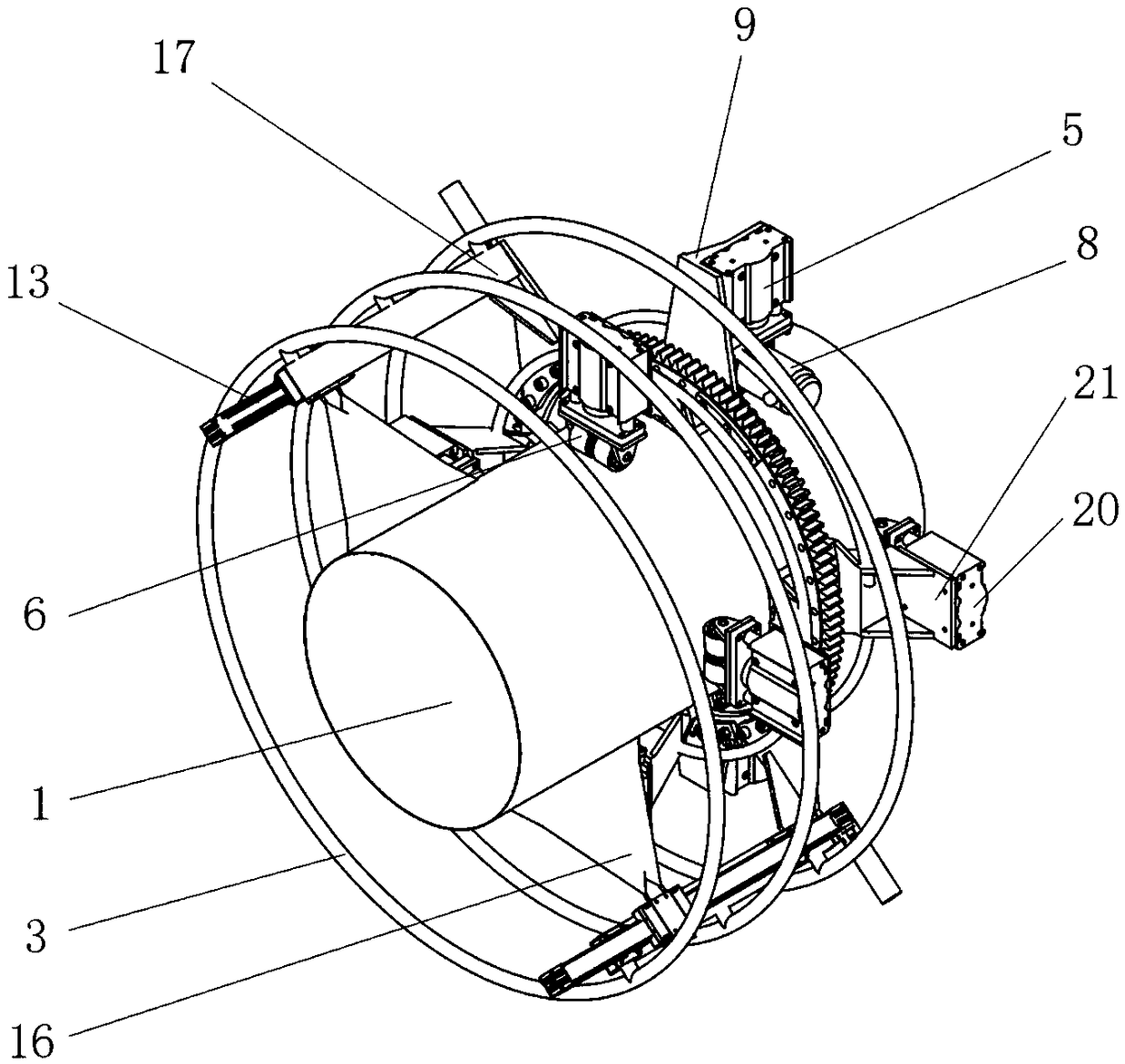

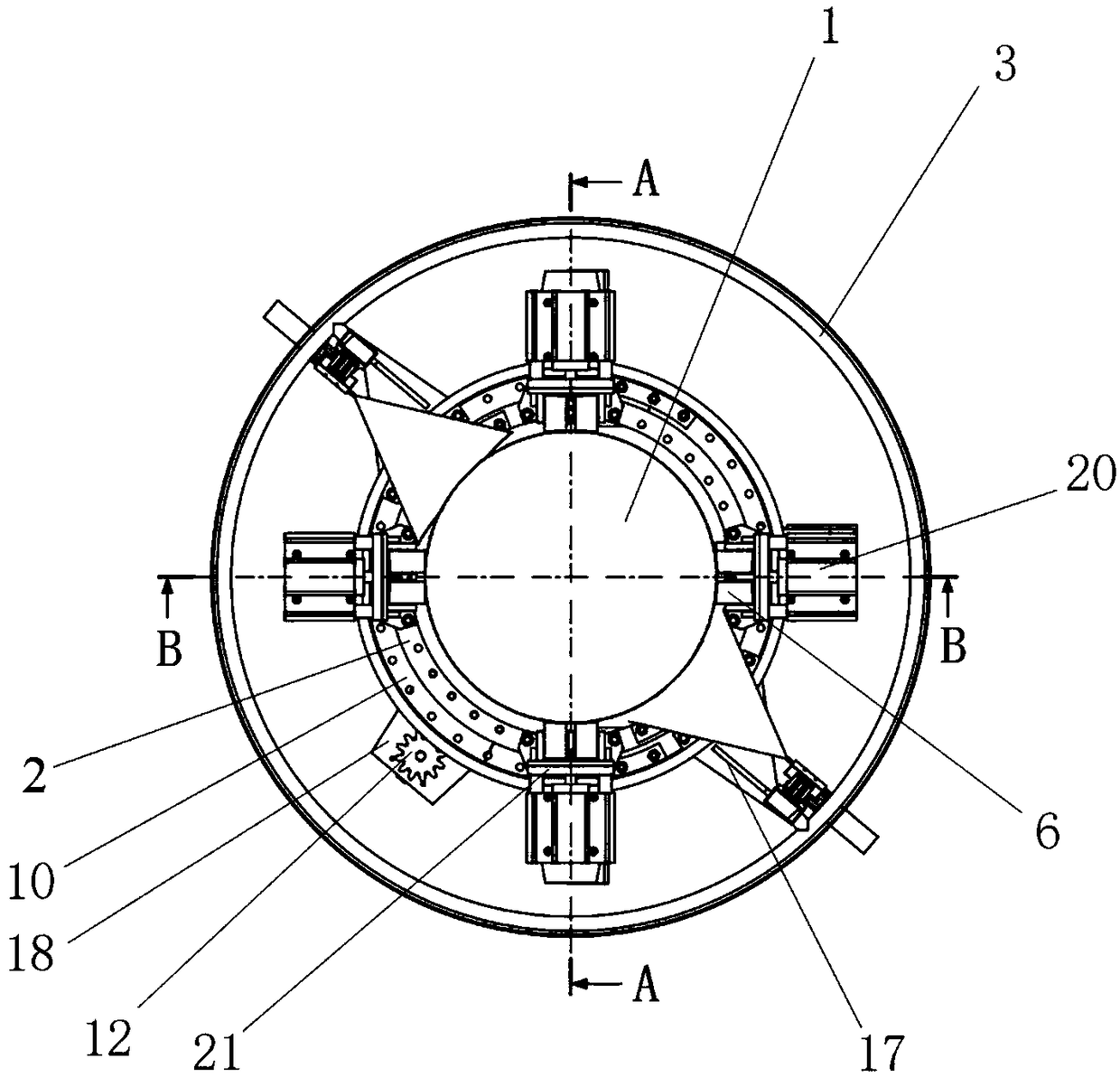

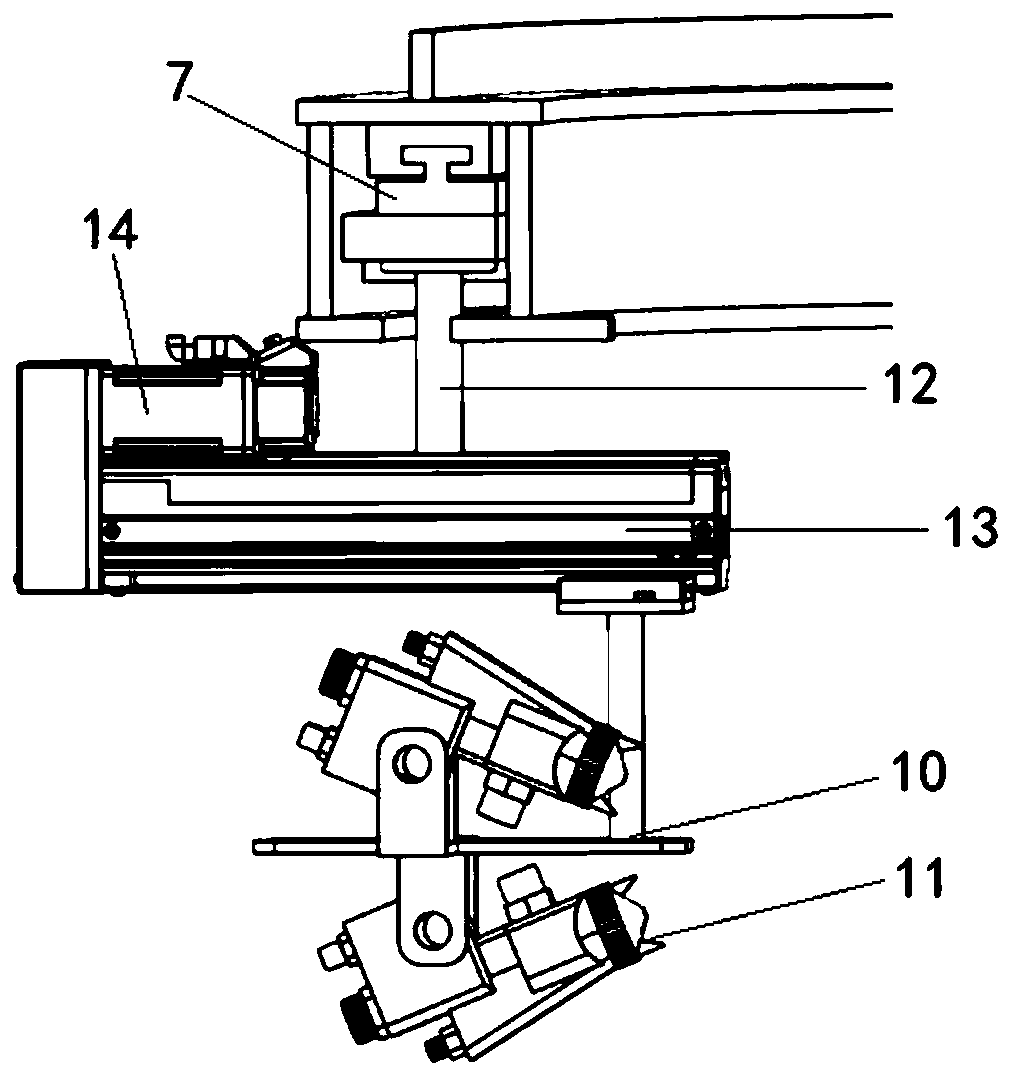

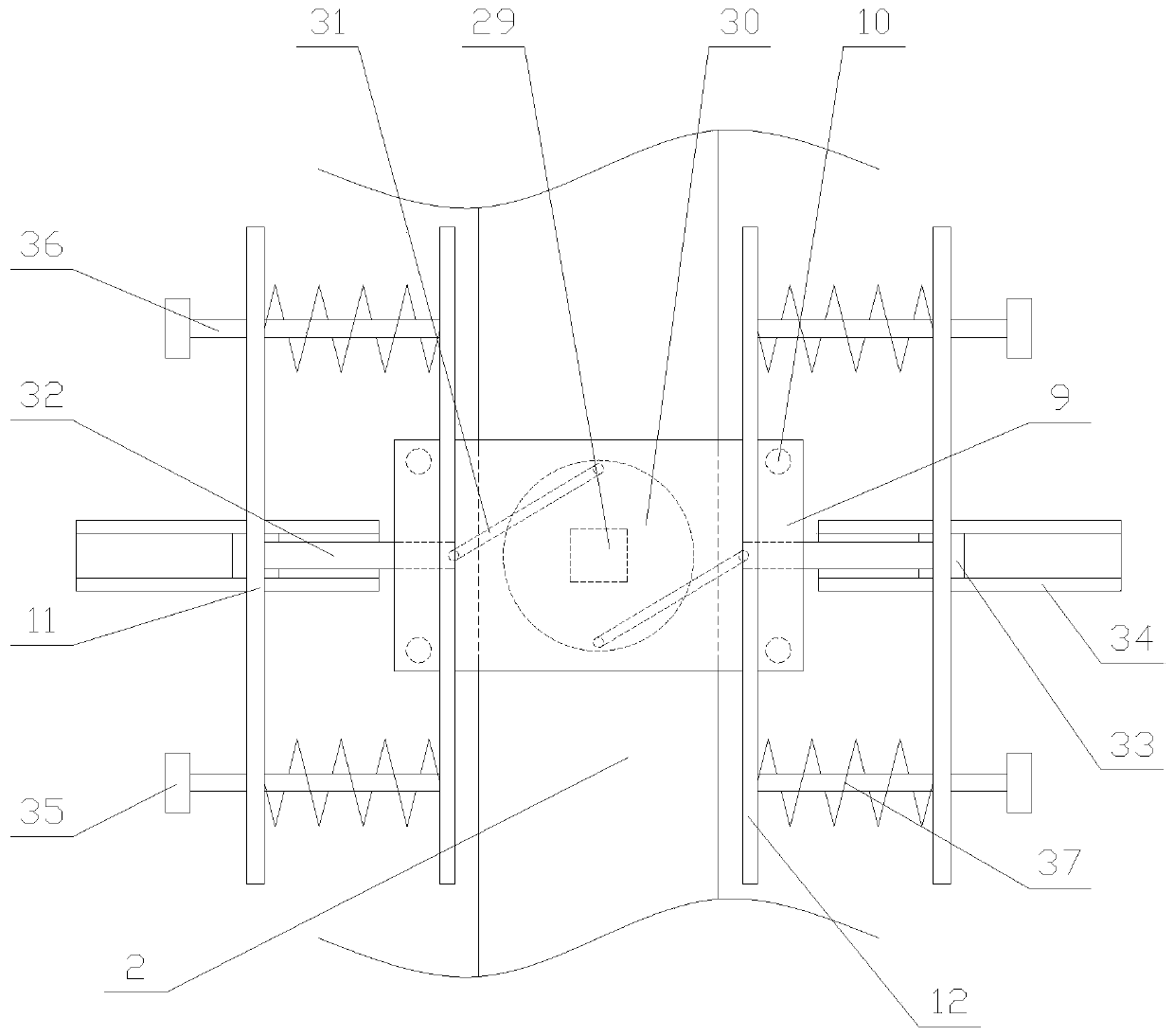

Cable rope coating spraying device and method

PendingCN109395942AImprove spraying efficiencyGood spray effectSpraying apparatusSpray nozzleElectric machinery

The invention provides a cable rope coating spraying device and method and relates to the technical field of coating spraying. A gas pump, a supporting and rotating mechanism, a spraying mechanism, atravelling mechanism and a wireless receiving controller are included. An inner ring formed by connecting semicircular rings in a lap joint manner is a supporting mechanism around a cable rope; an outer gear ring is combined with the outer diameter of the inner ring through a ball to form a rotating mechanism; the connection end of a track support is fixed to the outer gear ring through a bolt; the cantilever side face of the track support is provided with linear guide rails in clearance fit with a slider; the shaft end of a spraying motor is provided with a synchronous belt wheel, and a spraynozzle and the slider are fixed to form the spraying mechanism; according to the travelling mechanism, the 45 degree included angle position of the outer side of the inner ring and the track supportis uniformly provided with four cylinder supporting frames, the 45 degree included angle positions of the lower left of the inner ring and the cylinder supporting frames are provided with motor supports, and the end portion of an output shaft of a driving motor is provided with a power gear engaged with the outer gear ring; and the 45 degree included angle position of the inner side of the inner ring and the track support is uniformly provided with four cylinder supporting frames, and a travelling wheel is arranged below each cylinder.

Owner:SOUTHWEST JIAOTONG UNIV

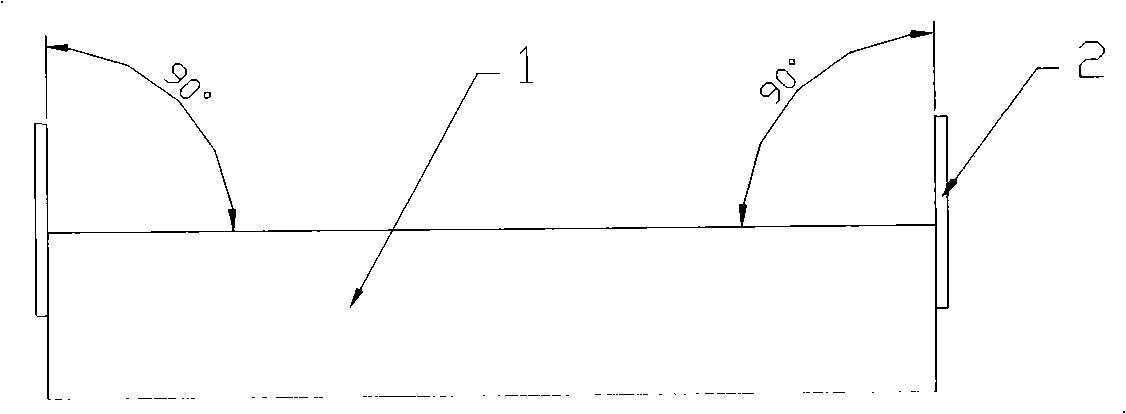

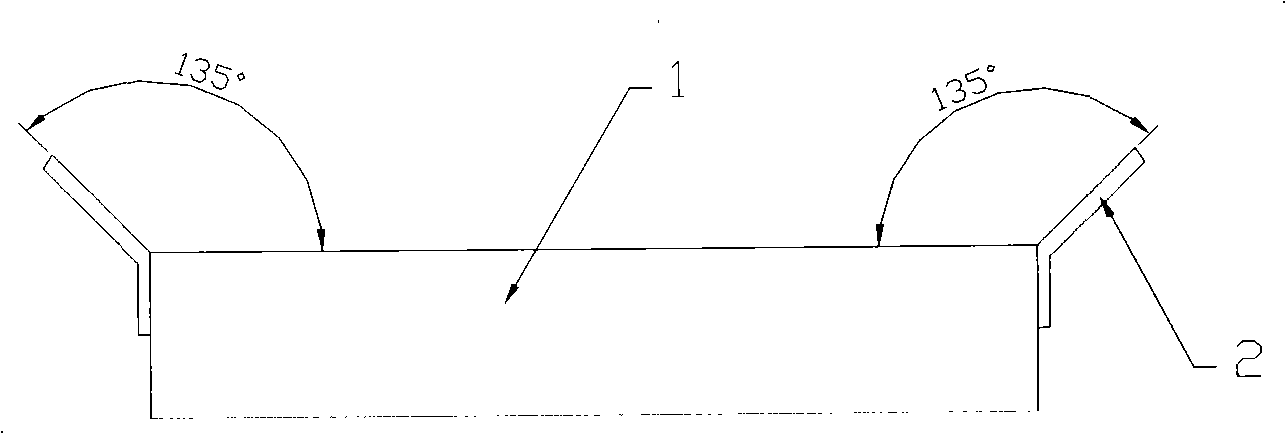

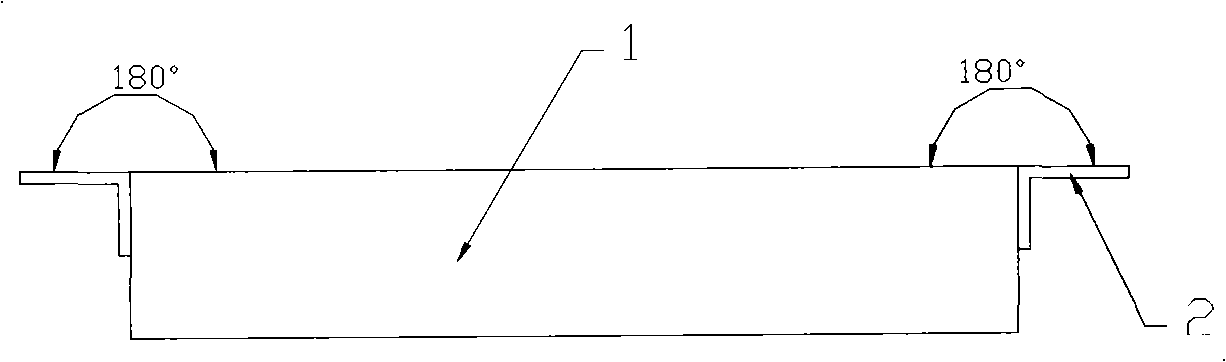

Supersonic spray coating method of crystallizer copper plate

ActiveCN101302619AImprove bindingGuarantee the quality of sprayingMolten spray coatingFurnace typesSand blastingSpray coating

The invention discloses a supersonic spraying method for crystal implement copper plates, which is characterized in that the operation of the method is carried out according to the following steps that: firstly, cleaning and sand blasting treatments are carried out to the surface of a crystal implement copper plate through a conventional cleaning process; secondly, four peripheries of thecrystal implement copper plate are provided with protective plates at an angle of between 90 and 180 degrees with a working surface of the copper plate; thirdly, nickel-base alloy powder spraying paint is put into a supersonic flame spraying device so as to spray the surface of the crystal implement copper plate through a conventional process; fourthly, after spraying, the crystal implement copper plate is insulated at a temperature of between 800 and 950 DEG C for 0.5 to 3 hours for melting-diffusing vacuum heat treatment, and then is cooled through nitrogen, argon or helium; fifthly, the cooled crystal implement copper plate is subject to aging treatment at a temperature of between 400 and 500 DEG C for 1 to 3 hours. The supersonic spraying method is simple in the whole spraying process and uniform in spraying thickness, saves spraying material, and is strong in coating binding capacity and is wearproof.

Owner:XIXIA LONGCHENG SPECIAL MATERIALS CO LTD

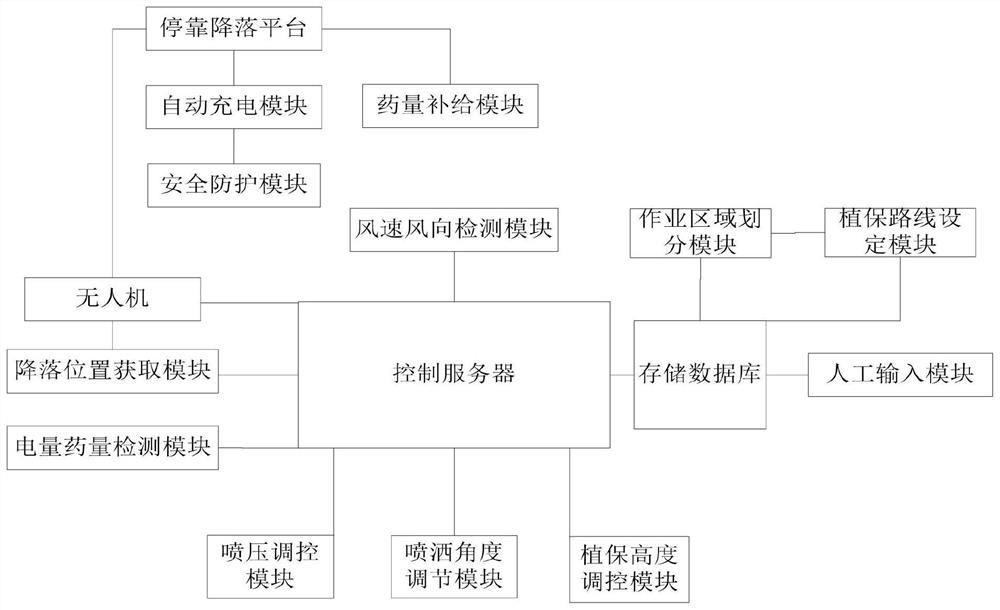

Agricultural planting plant protection operation intelligent management system based on big data internet of things

InactiveCN111665864AGuarantee the quality of sprayingIncrease profitShort-circuit testingContinuity testingAgricultural scienceAgricultural engineering

The invention discloses an agricultural planting plant protection operation intelligent management system based on big data internet of things. The system comprises an unmanned aerial vehicle, an operation area division module, a plant protection route setting module, a manual input module, a wind speed and direction detection module, a spraying angle adjustment module, a spraying pressure regulation and control module, a plant protection height regulation and control module, an electric quantity and pesticide quantity detection module, a landing position acquisition module, a parking landingplatform, an automatic charging module, a control server, a storage database and a pesticide quantity supply module. The pesticide spraying angle, the spraying pressure and the operation height of theunmanned aerial vehicle during plant protection operation are regulated and controlled according to the detected wind speed and wind direction data of the plant protection day, and meanwhile, whetherthe unmanned aerial vehicle needs return supply or not is judged by detecting the electric quantity and pesticide quantity during plant protection of the unmanned aerial vehicle, so that the plant protection pesticide application quality is guaranteed, the spraying efficiency and the agricultural resource utilization rate are improved, the labor cost is reduced, and intelligent management of an agricultural planting plant protection system is embodied.

Owner:张玉红

Pipeline inner wall coating machine

PendingCN107008606AWalking smoothlyWalk; through the spray evenlySpraying apparatusJackhammerIndustrial engineering

The invention discloses a pipeline inner wall coating machine and belongs to the field of pipeline equipment. Travelling wheels are connected to a driving device output shaft. Nozzles are at least arranged on the coating machine and are evenly distributed on the periphery of the inner wall of a pipeline. A jackhammer, an illuminating device and a camera device are arranged on the upper portion of the front portion of the pipeline. An automatic take-up wheel is arranged behind the pipeline. A coaxial compression air pipe roller is arranged beside the take-up wheel. A steel wire rope traction hole is further formed in the rear portion of the coating machine. The nozzles and the jackhammer are arranged on rotary plates correspondingly. Through the pipeline inner wall coating machine, obstacles in the pipeline can be cleared, smooth flowing of liquid in the pipeline can be ensured, the labor intensity of painters is relieved, physical discomfort of workers due to the harsh paint environment is avoided, automatic operation is achieved, the paint efficiency is improved, and the health of the workers is ensured.

Owner:ANYANG GUOLONG MACHINERY

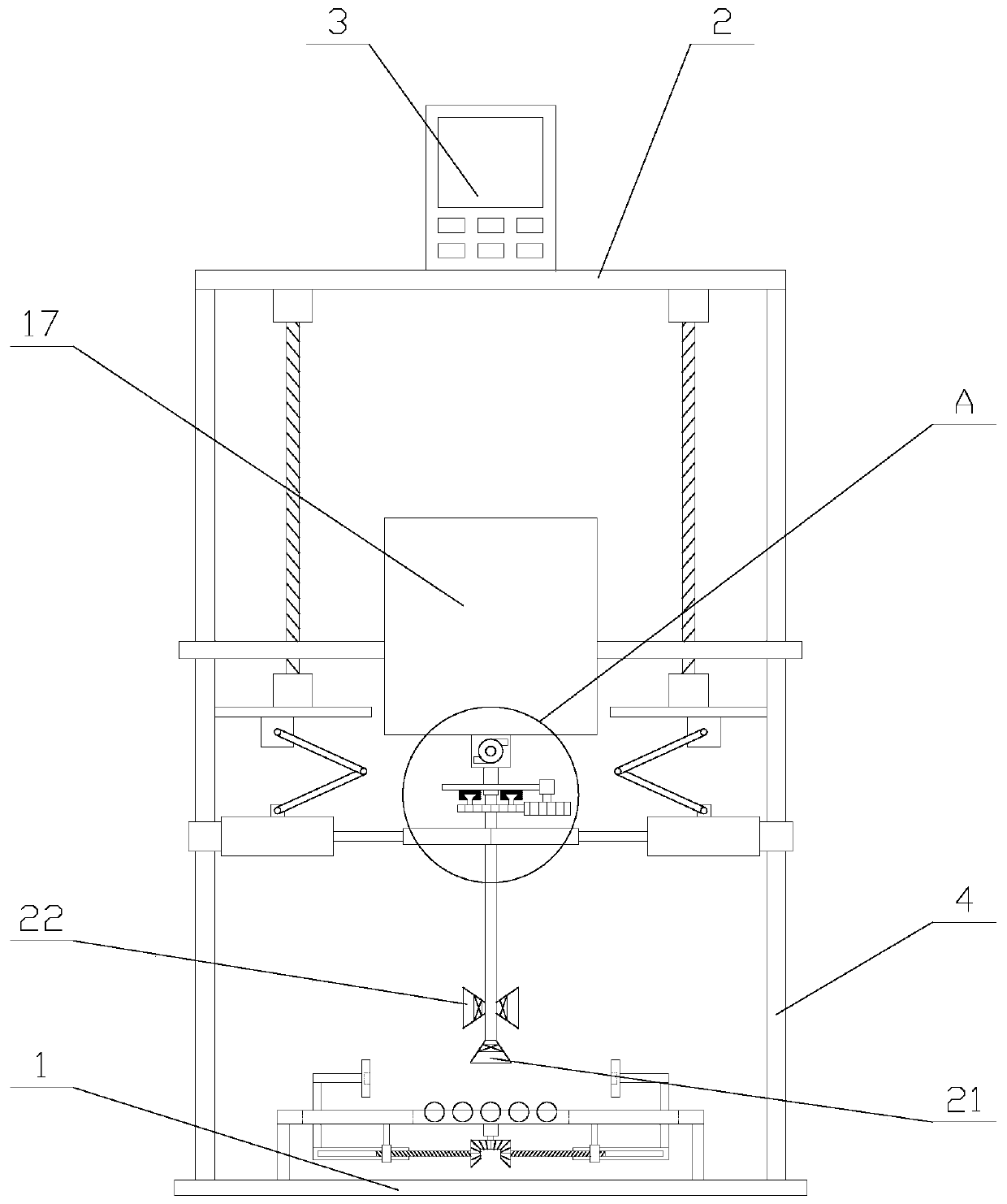

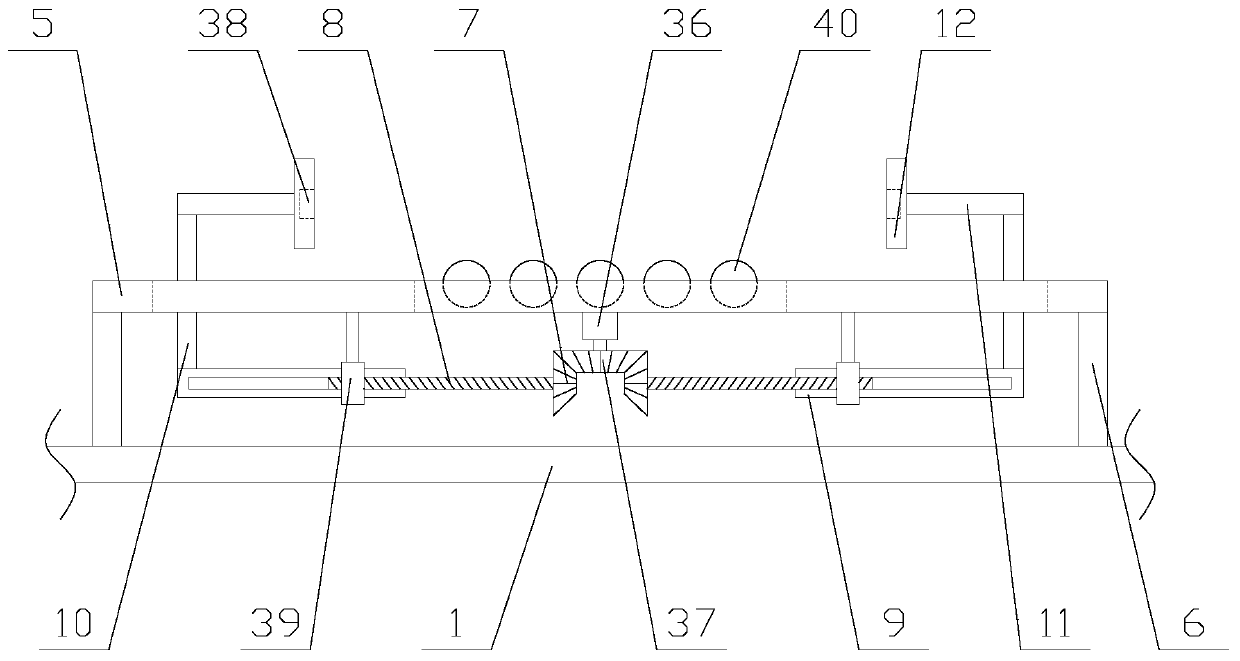

Spraying device for processing inner wall of cylindrical container

ActiveCN110394261AAffects respiratory healthSpray evenlySpraying apparatusRespiratory healthEngineering

The invention relates to a spraying device for processing the inner wall of a cylindrical container. The device comprises a base, a top plate, a controller, a placing mechanism, a spraying mechanism,two vertical rods and two sealing mechanisms, wherein the placing mechanism comprises a platform, a driving assembly, a plurality of positioning assemblies and a plurality of supporting legs, the positioning assemblies comprise strip-shaped openings, transmission bevel gears, screw rods, translation blocks, movable plates, cross rods and clamping plates, the sealing mechanisms comprise side plates, lifting assemblies, telescopic assemblies, air cylinders, sleeve rings and sealing plates. According to the spraying device for processing the inner wall of the cylindrical container, the position of the container is adjusted conveniently through the placing mechanism, so that a spray pipe in the spraying mechanism and the axis of the container are positioned on the same straight line, uniform spraying is facilitated, and the spraying quality is ensured, moreover, a bottle opening of the container can be sealed by the sealing mechanisms in a spraying process, so that the situation that paintis diffused to the outside of the container to influence the respiratory health of a user is prevented, the spraying safety is guaranteed, and the practicability of the device is improved.

Owner:临沂文衡信息技术有限公司

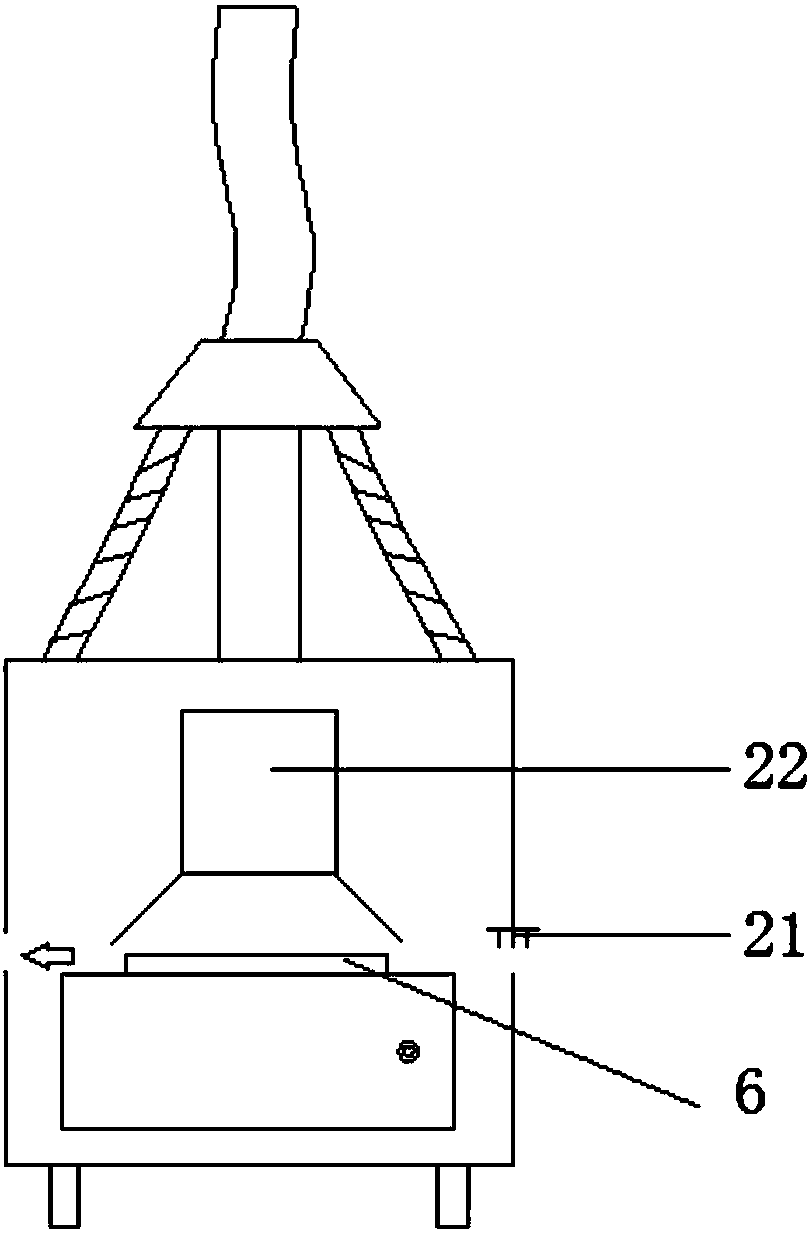

Coating and heating device of large-caliber plastic-coated composite steel pipe

ActiveCN103920620AIncrease productivityGuarantee the quality of sprayingPretreated surfacesCoatingsHeating furnaceCoating

The invention relates to a coating and heating device of a large-caliber plastic-coated composite steel pipe. The coating and heating device comprises a primary heating furnace, coating mechanisms, a conduction frame and a secondary heating furnace, as well as a buffering conduction frame, wherein the conduction frame is arranged behind the primary heating furnace, two sides of the conduction frame are respectively provided with the coating mechanism, the secondary heating furnace is arranged behind the conduction frame, and the coating and heating device is characterized in that the coating mechanisms are double-directional inner adsorption coating mechanisms, and the buffering conduction frame is arranged between the conduction frame and the secondary heating furnace. The coating and heating device is scientific and reasonable in structure design, and has the advantages that high production efficiency and uniformity coating can be realized, the quality of a produced composite pipe is high, production cost is lowered, long-term development of the enterprise is facilitated, and high innovation performance is achieved.

Owner:TIANJIN CITY FUSHUNDE IND CO LTD

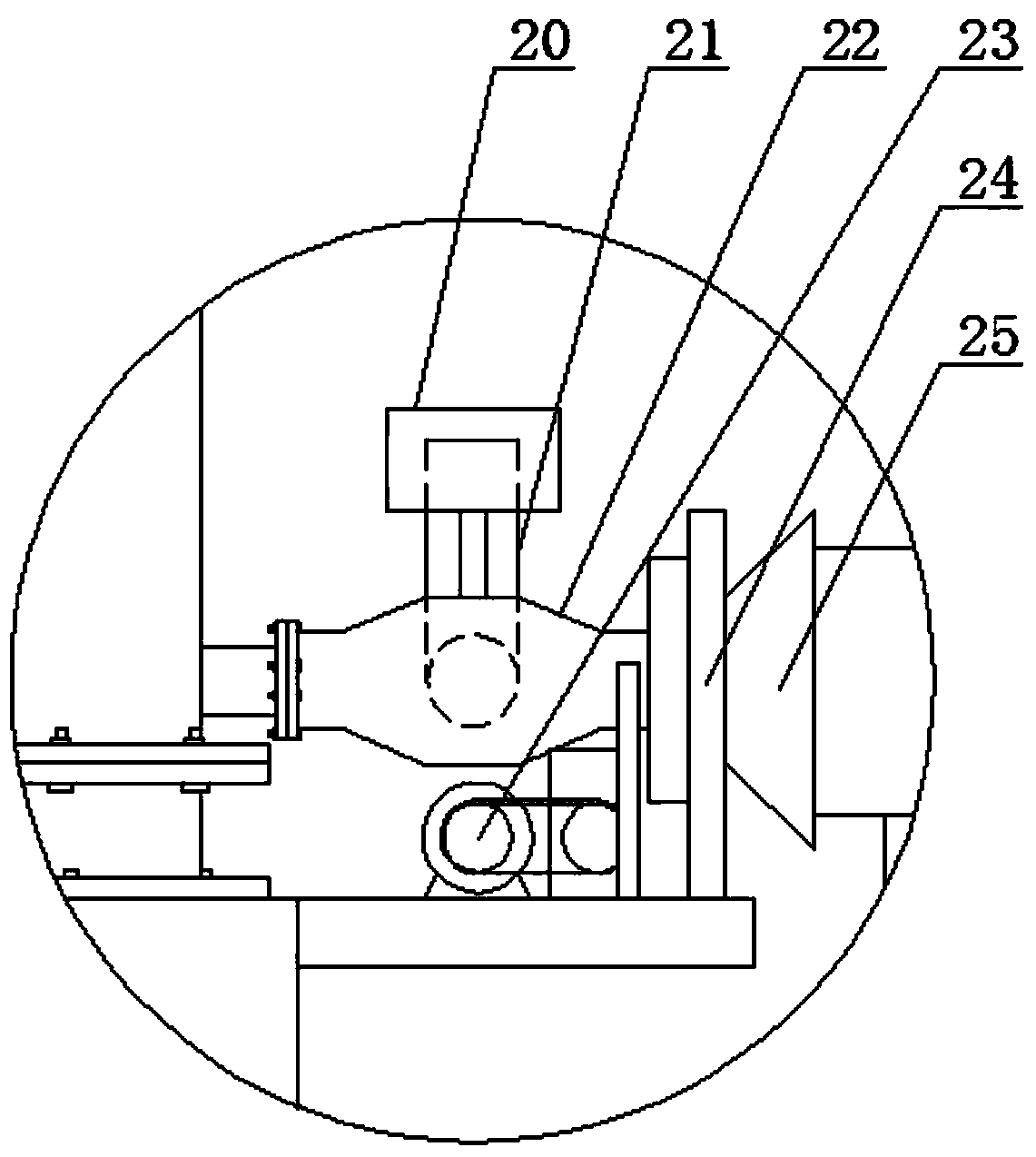

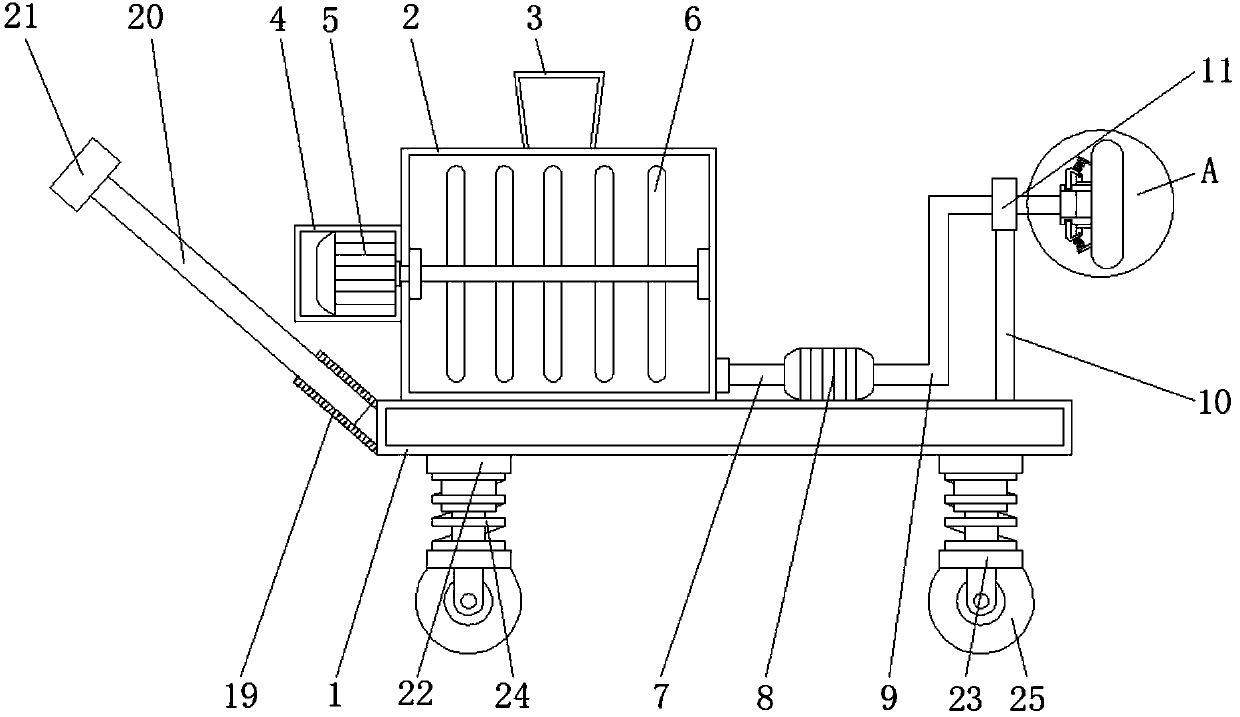

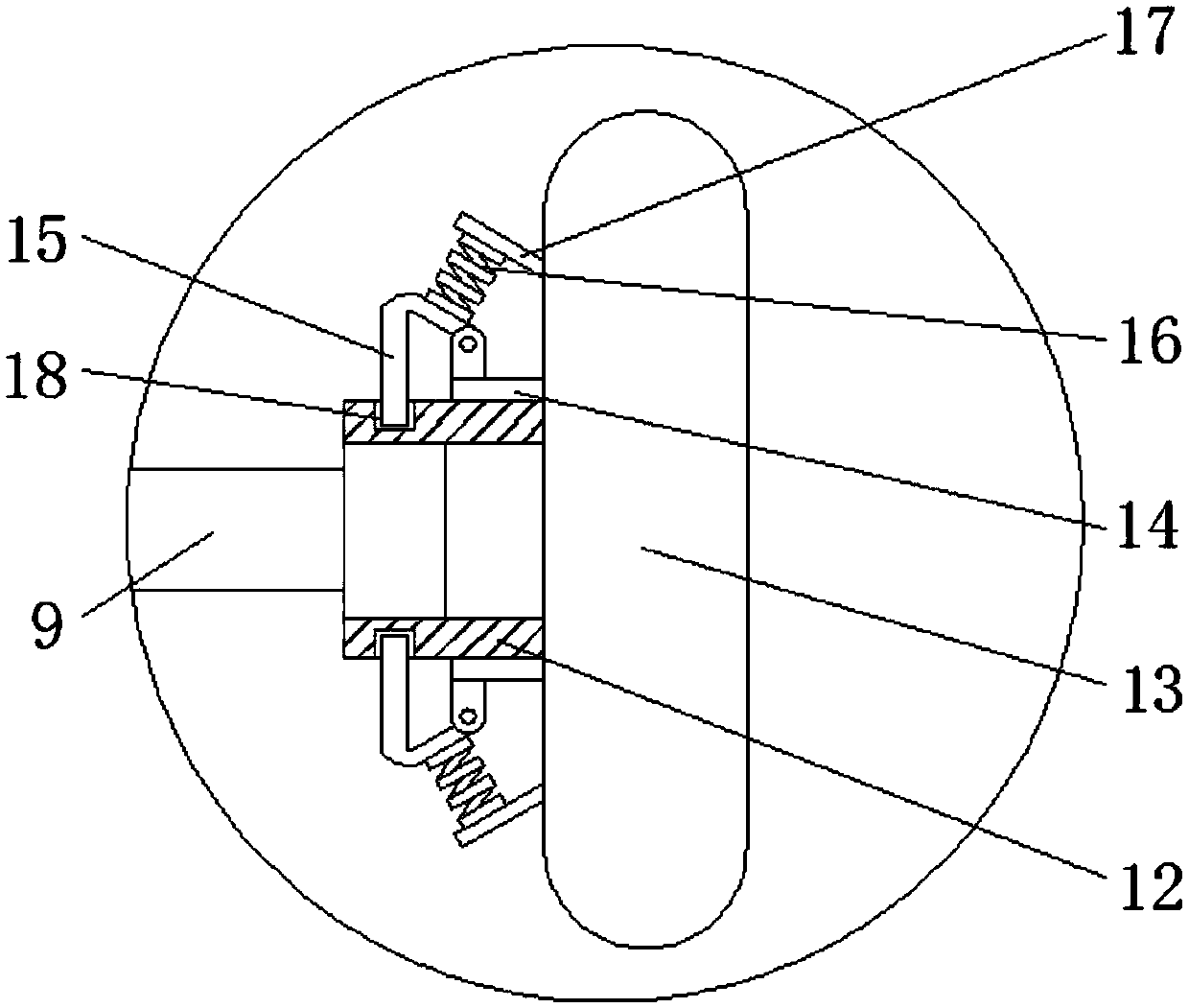

Spraying machine applied to small-scale agricultural land

InactiveCN107897151AEasy to disengagePlace stableInsect catchers and killersAgricultural landAgricultural engineering

The invention discloses a spraying machine applied to small-scale agricultural land. The machine comprises a supporting plate, an outer shell is fixedly installed at one side of the top of the supporting plate, a water outlet pipe is fixedly installed at the water outlet position located at one side of the outer shell, one end of the water outlet pipe is fixedly connected with a water pump, a water outlet located at one side of the water pump is fixedly connected with a connection water pipe, and a supporting rod is welded on the other side of the top of the supporting plate; and a connectioncircular ring is fixedly installed at the top of the supporting rod, one end of the connection water pipe passes through the connection circular ring and extends to one side of the connection circularring to be connected with a connection sleeve pipe, and a spray nozzle sleeves one end of the connection sleeve pipe. According to the spraying machine applied to the small-scale agricultural land provided by the invention, the connection water pipe can be placed into the connection circular ring through the arrangement of the connection circular ring, the spray nozzle can be set up in midair, sothat people spray the agricultural land without holding the connection water pipe and the spray nozzle by hands, the spray nozzle can automatically spray a pesticide to the agricultural land to killinsects, thereby saving use of manpower.

Owner:CHANGZHOU COLLEGE OF INFORMATION TECH

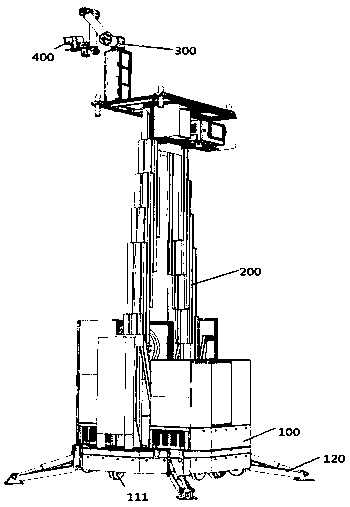

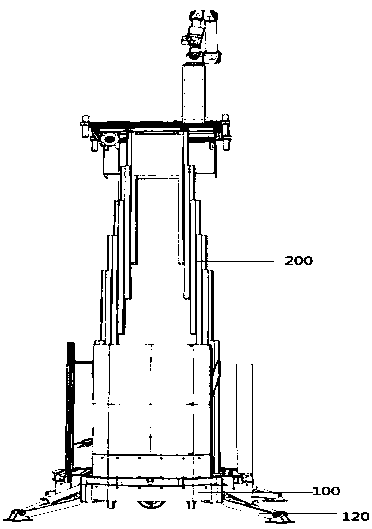

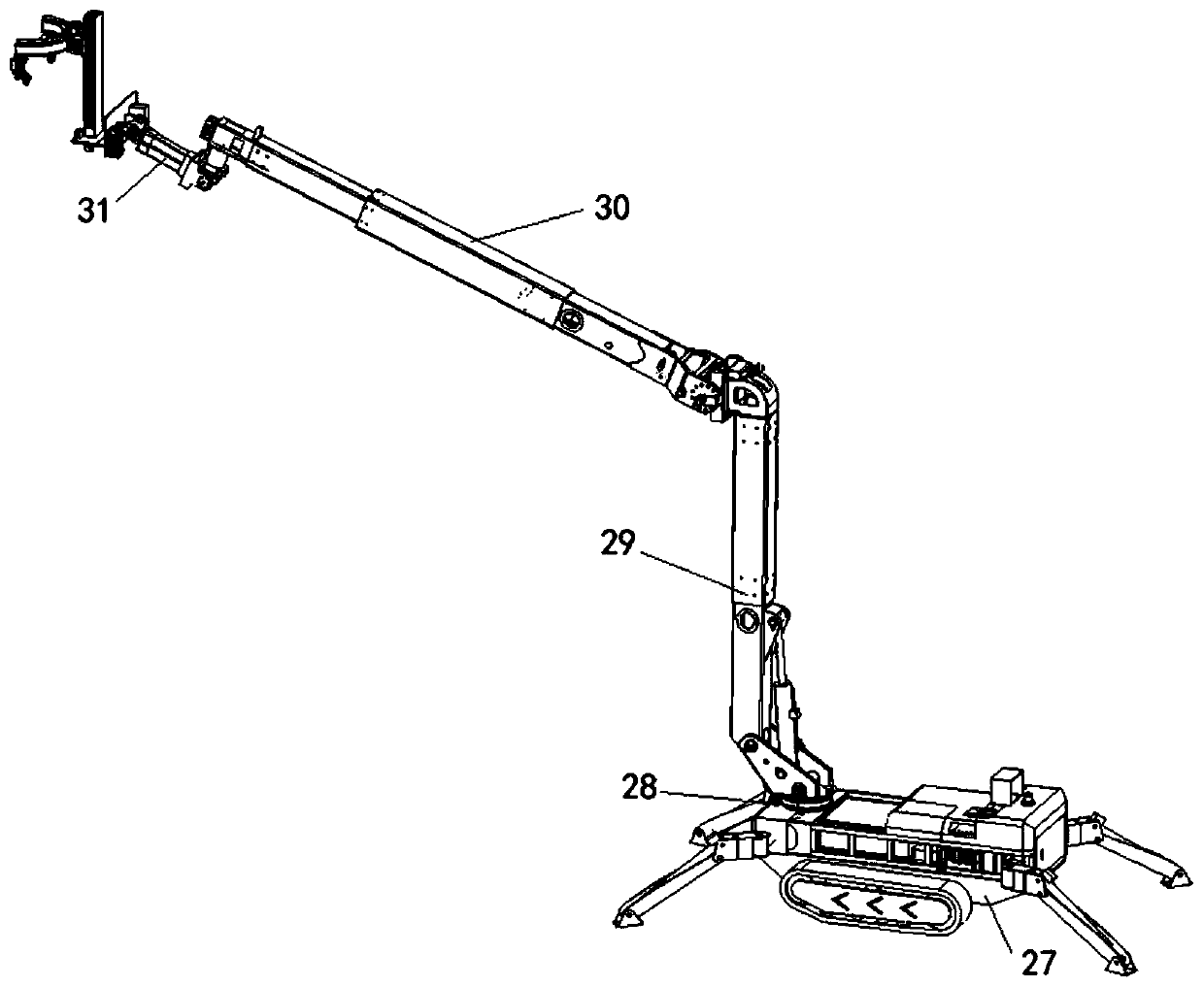

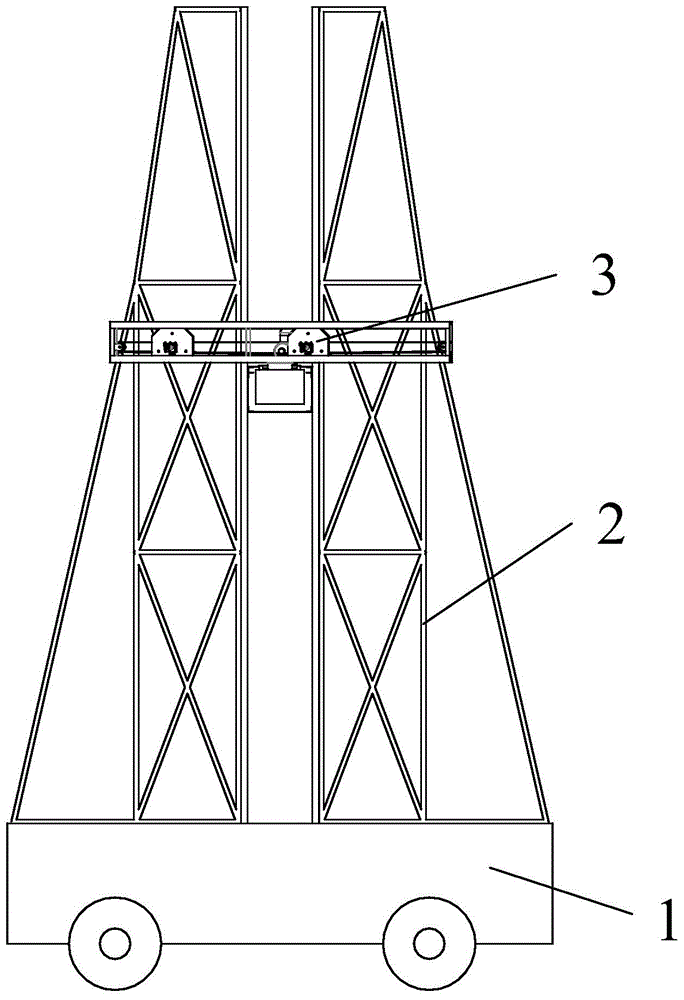

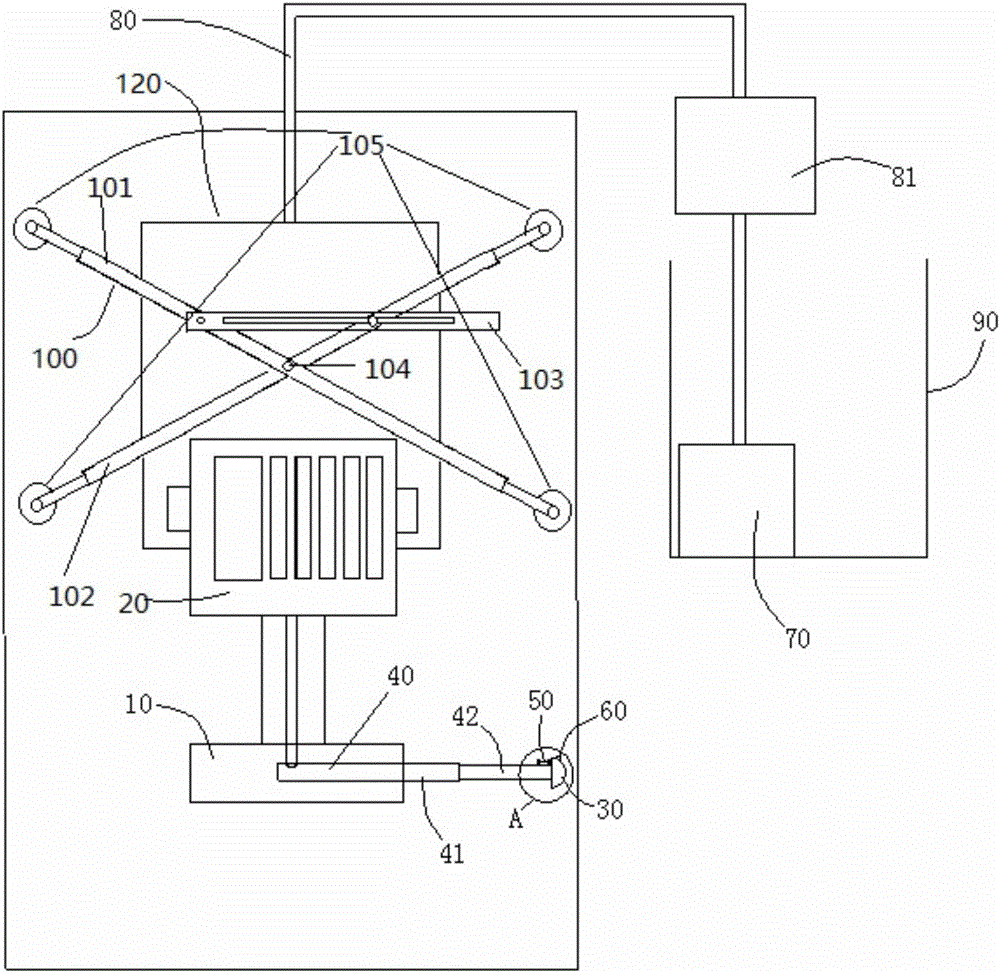

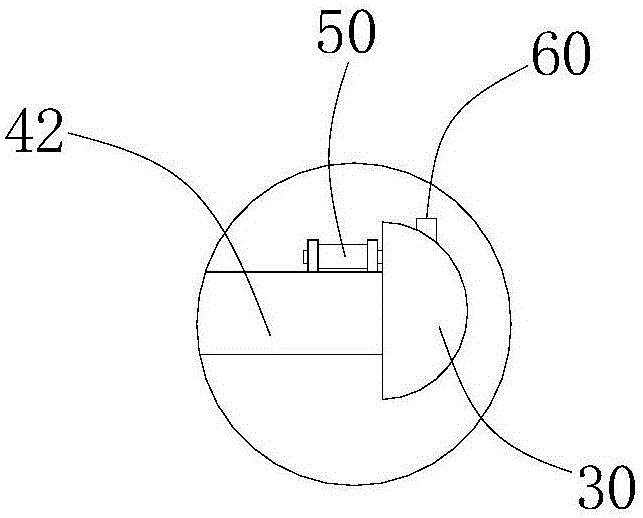

High-wall surface painting system and method for industrial buildings

InactiveCN109306794AReduce generationReduce Risk of Exposure to Harmful Coating ChemicalsBuilding constructionsIndustrial constructionHuman exposure

The invention discloses a high-wall surface painting system and method for industrial buildings. A moving base is arranged to drive the whole high-wall surface painting system for the industrial buildings to achieve autonomous navigation and movement in a work space, a two-bar telescopic lifting mechanism is used for driving a mechanical arm to ascend and descend for painting of a high-rise region, the mechanical arm drives a spray gun to achieve multiple degree-of-freedom angle and position adjustment so as to meet the requirements of different painted positions; the whole painting process isautomatically completed by the high-wall surface painting system for the industrial buildings, time and labor are saved, the efficiency is high, the high-wall surface painting system for the industrial buildings can achieve painting of the top of an area up to 13 meters, and the painting requirements of high-rise areas are met. The thickness of paint is accurate and uniform, the painted surface is evenly distributed, and the quality of painting is ensured. The high-wall surface painting system for the industrial buildings can obviously reduce paint dust produced in the painting process, thusreducing the risk of human exposure to harmful paint chemicals.

Owner:TRANSFORMA ROBOTICS PTE LTD

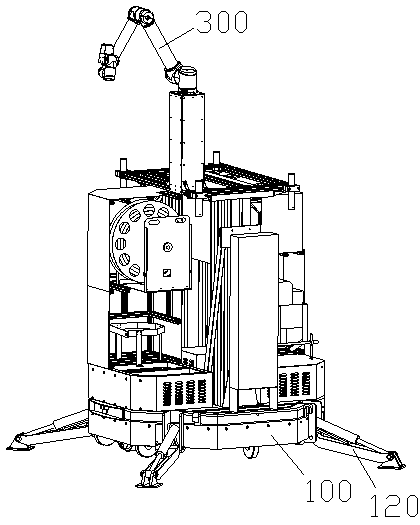

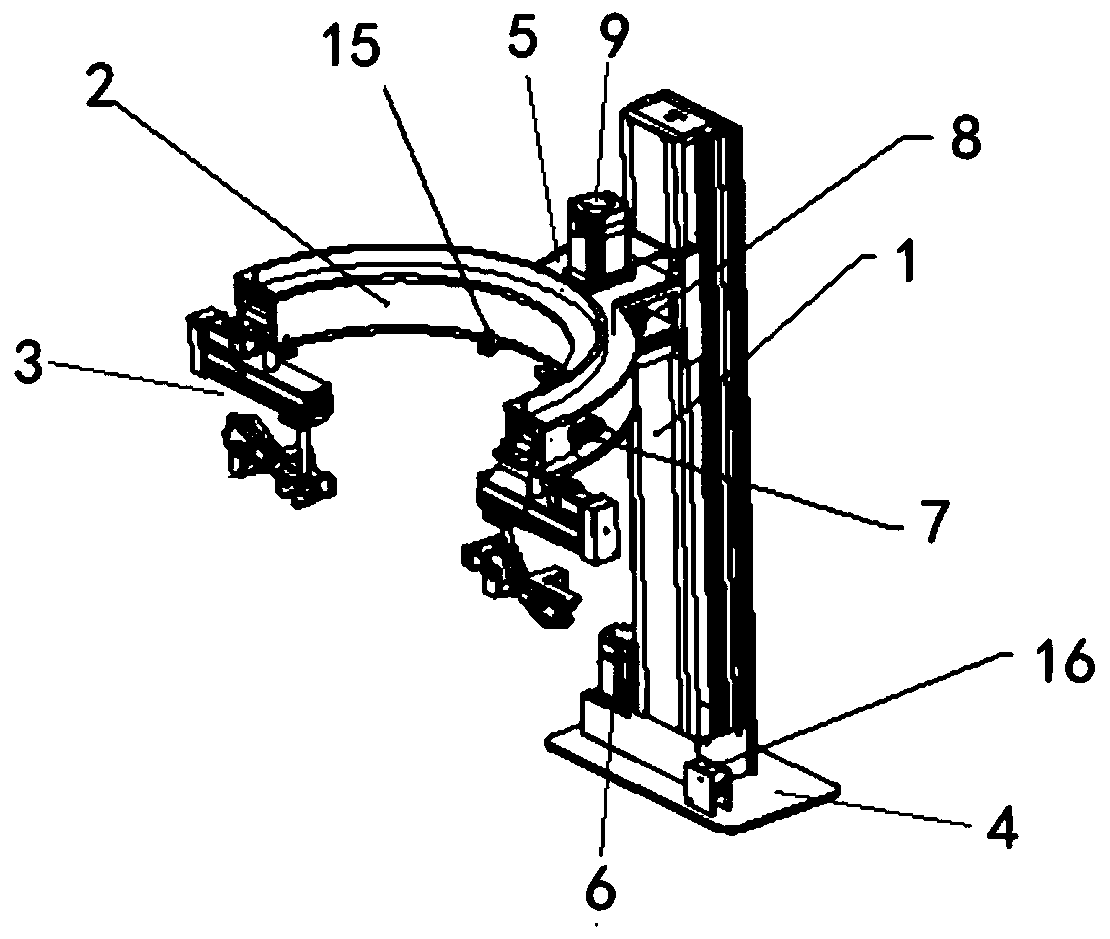

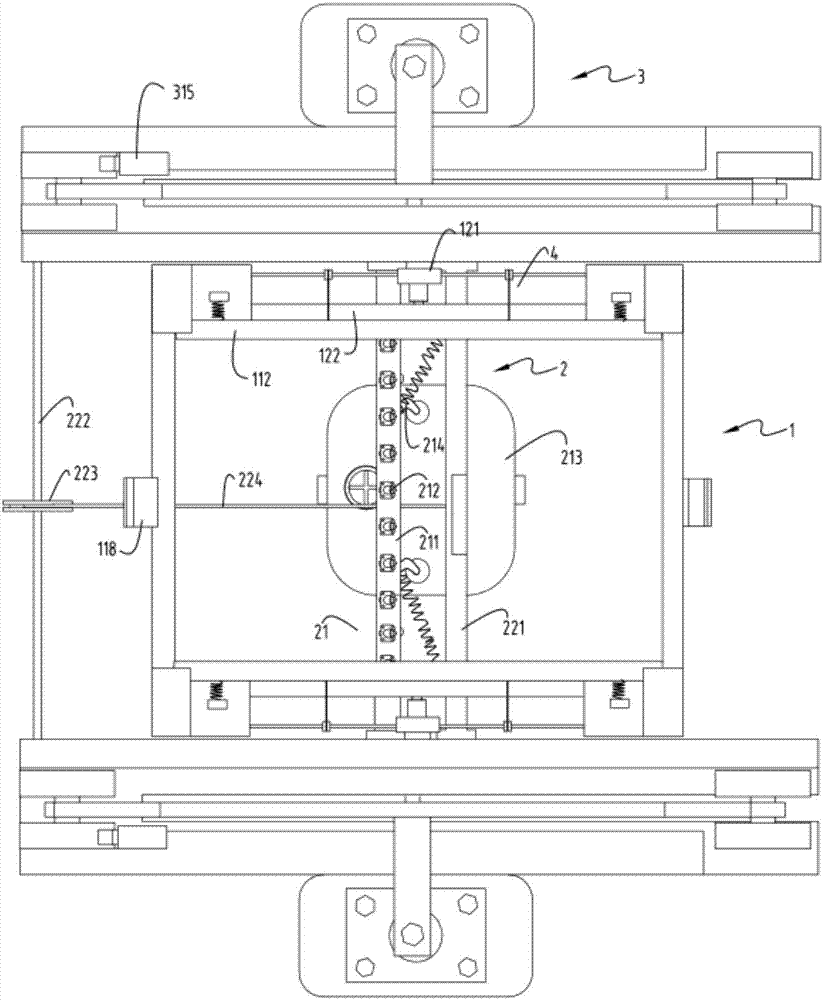

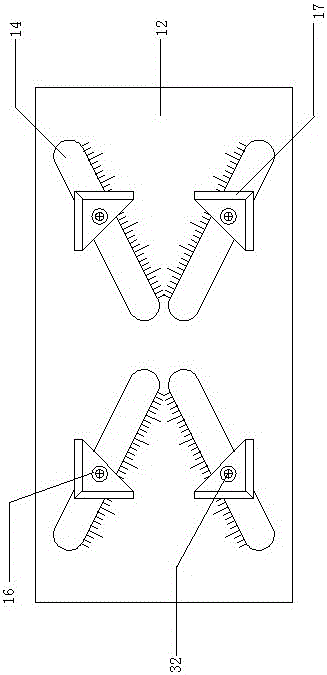

Robot system for spraying anti-pollution flashover coatings on substation insulators and spraying method

ActiveCN110899027AAll-round three-dimensional spraying realizationSolve the dead angle of sprayingSpraying apparatusControl engineeringStructural engineering

The invention discloses a robot system for spraying anti-pollution flashover coatings on substation insulators and a spraying method. The robot system is characterized by comprising a robot body and aspraying tool, wherein the robot body comprises a lifting mechanism, and the spraying tool is arranged at the front end of the lifting mechanism; the spraying tool comprises a supporting mechanism, asurrounding mechanism and at least one spraying mechanism; the surrounding mechanism is connected with the supporting mechanism and can carry out vertical lifting movement relative to the supportingmechanism; the surrounding mechanism comprises an annular inner chamber and an annular component which can move along the annular inner chamber, and an annular opening is formed in the lower part of the annular inner chamber; and at least one spraying mechanism is arranged under the supporting mechanism, is connected with the annular component and can move along with the annular component along the annular opening. The robot system can realize uniform spraying for the insulators.

Owner:STATE GRID INTELLIGENCE TECH CO LTD

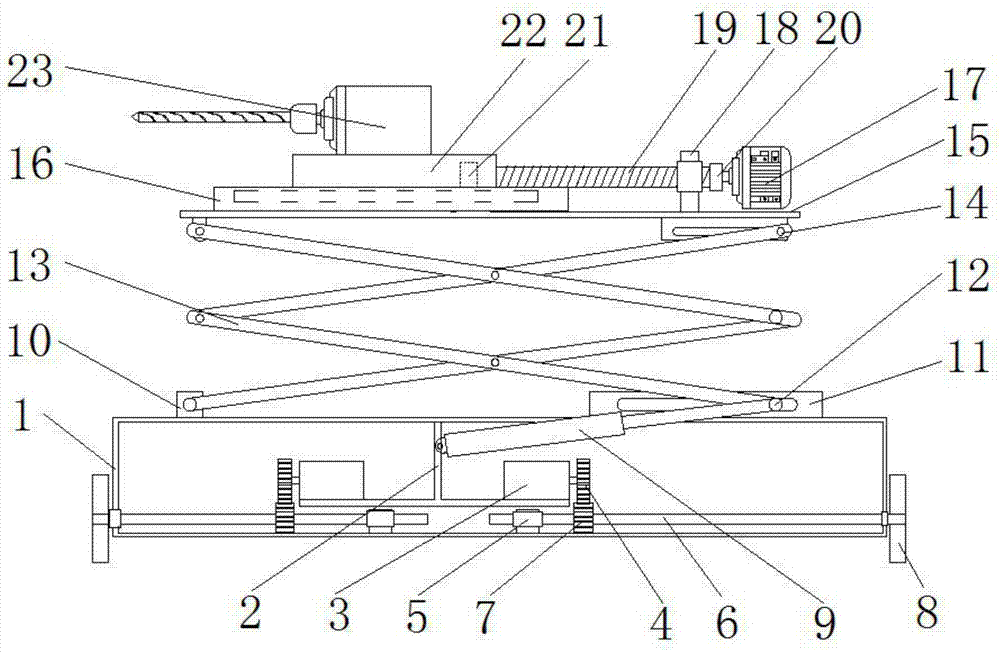

Automatic wall face drilling device

InactiveCN107378057AAvoid health effectsAvoid influencePortable power-driven toolsFeeding apparatusDrive wheelDrive shaft

The invention discloses an automatic wall drilling device, which comprises a box body, first motors are fixedly connected to both sides of the top of a T-shaped fixed plate on the inner wall of the box, and a shaft seat is fixedly connected to the bottom of the inner wall of the box, and the shaft seat rotates. A drive shaft is connected, one end of the drive shaft is fixedly connected to the drive wheel, the first motor is connected to the drive wheel through gear transmission, one side of the T-shaped fixed plate is connected to the hydraulic rod, and the top of the box is connected to the lifting frame in rotation. The top is rotatably connected with a lifting platform, one side of the top of the lifting platform is fixedly connected with a support plate, the support plate is slidingly connected with a moving frame, the top of the moving frame is fixedly connected with a drilling device, and the top of the lifting platform is fixedly connected with a second motor. One end of the output shaft of the second motor is fixedly connected with a screw rod. The invention relates to the field of electromechanical tools. The wall surface automatic drilling device realizes automatic feeding, improves hole quality and work efficiency, and protects the safety of construction personnel.

Owner:合肥恩腾电子科技有限公司

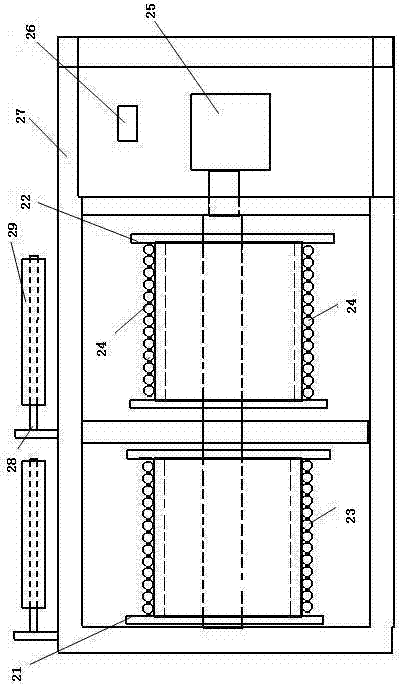

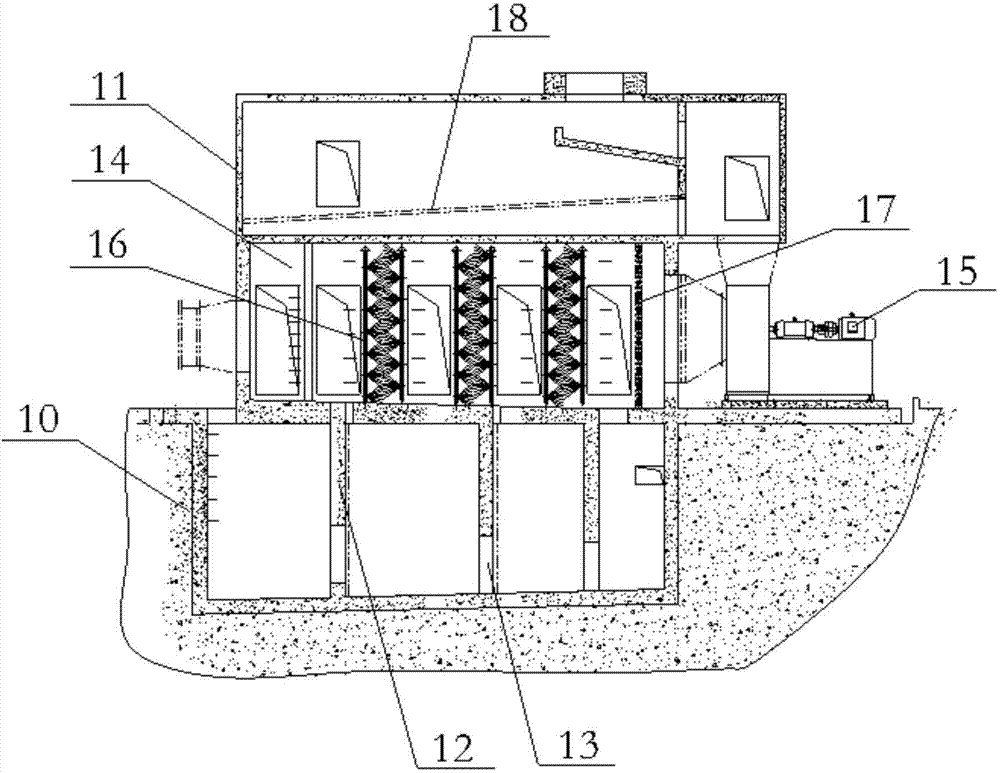

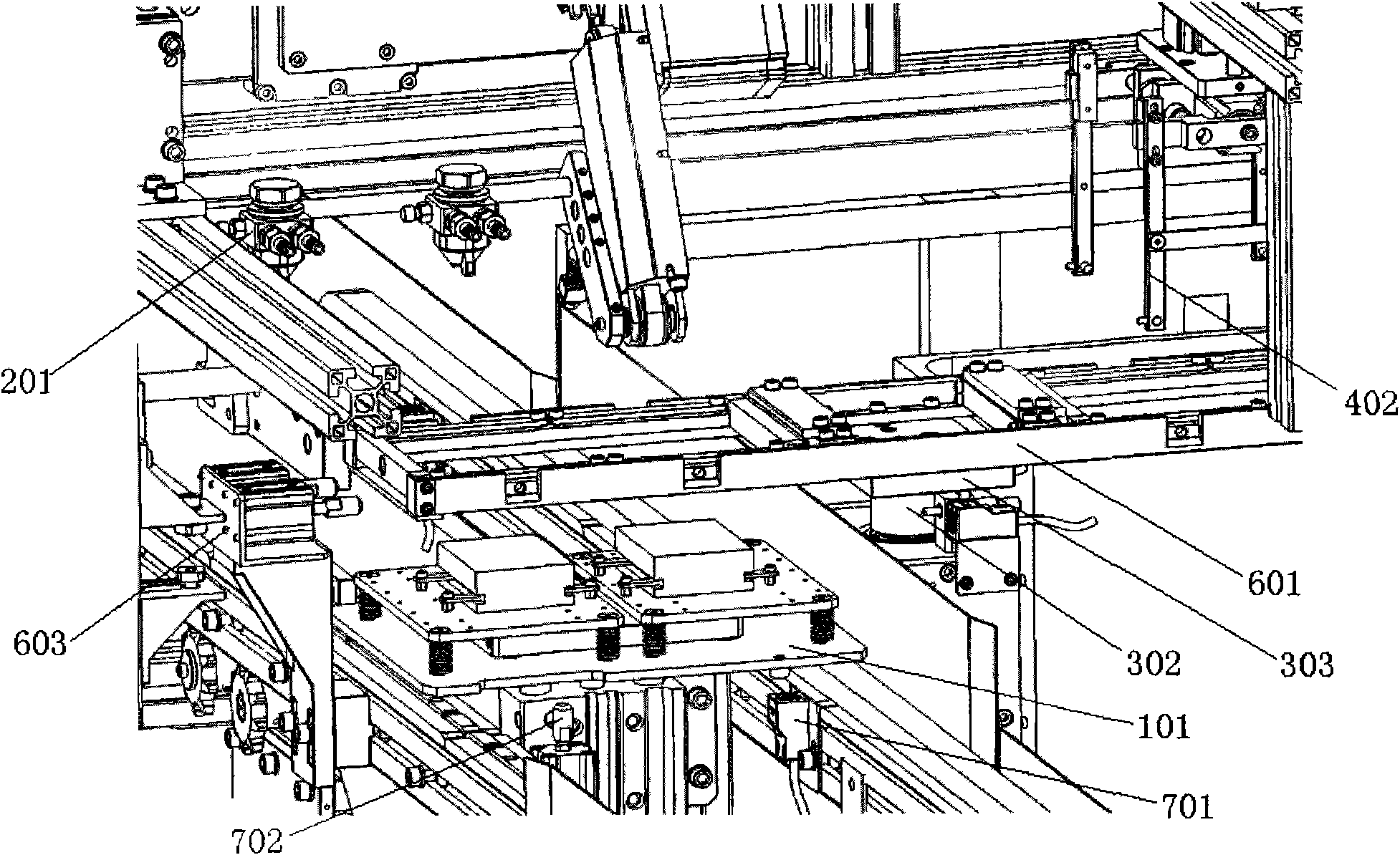

Continuous type coating production line

ActiveCN104492643AEasy to cleanImprove cleanlinessSpraying apparatusPretreated surfacesProduction lineTransmitted power

The invention discloses a continuous type coating production line, which comprises spray rooms, a conveying belt, a cooling section, drying rooms, water and gas supply and exhaust systems, a slag removal system and a human and material flow supply platform, wherein the spray rooms, the conveying belt, the cooling section and the drying rooms are arranged in a room, the water and air supply and exhaust systems and the slag removal system are arranged outside the room, the spray rooms are arranged near a partition, and are connected with the water and air supply and exhaust systems outside the partition, the water and air supply and exhaust systems convey waste water and waste gas to the slag removal system, the spray rooms and the drying rooms arranged in the room are connected in series to form a production line, the drying room at the final section is connected with the cooling section, a to-be-processed workpiece which is conveyed on the conveying belt sequentially passes through each spray room, each drying room and the cooling section, and the human and material flow supply platform is in charge of supplying coating for each spray room. The continuous type coating production line has the advantages that the spraying processing is separated form the slag removal treatment, the spray rooms are separated from the air and water supply and exhaust systems by the partition, the cleanliness and coating quality of the spray rooms are improved, the transmitting power consumption is decreased, and the treatment efficiency is improved.

Owner:SICHUAN LONGXIN TECH PACKING

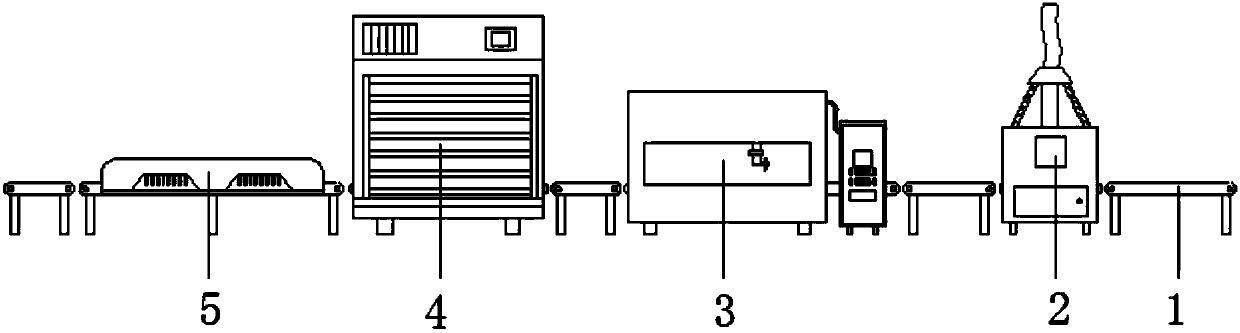

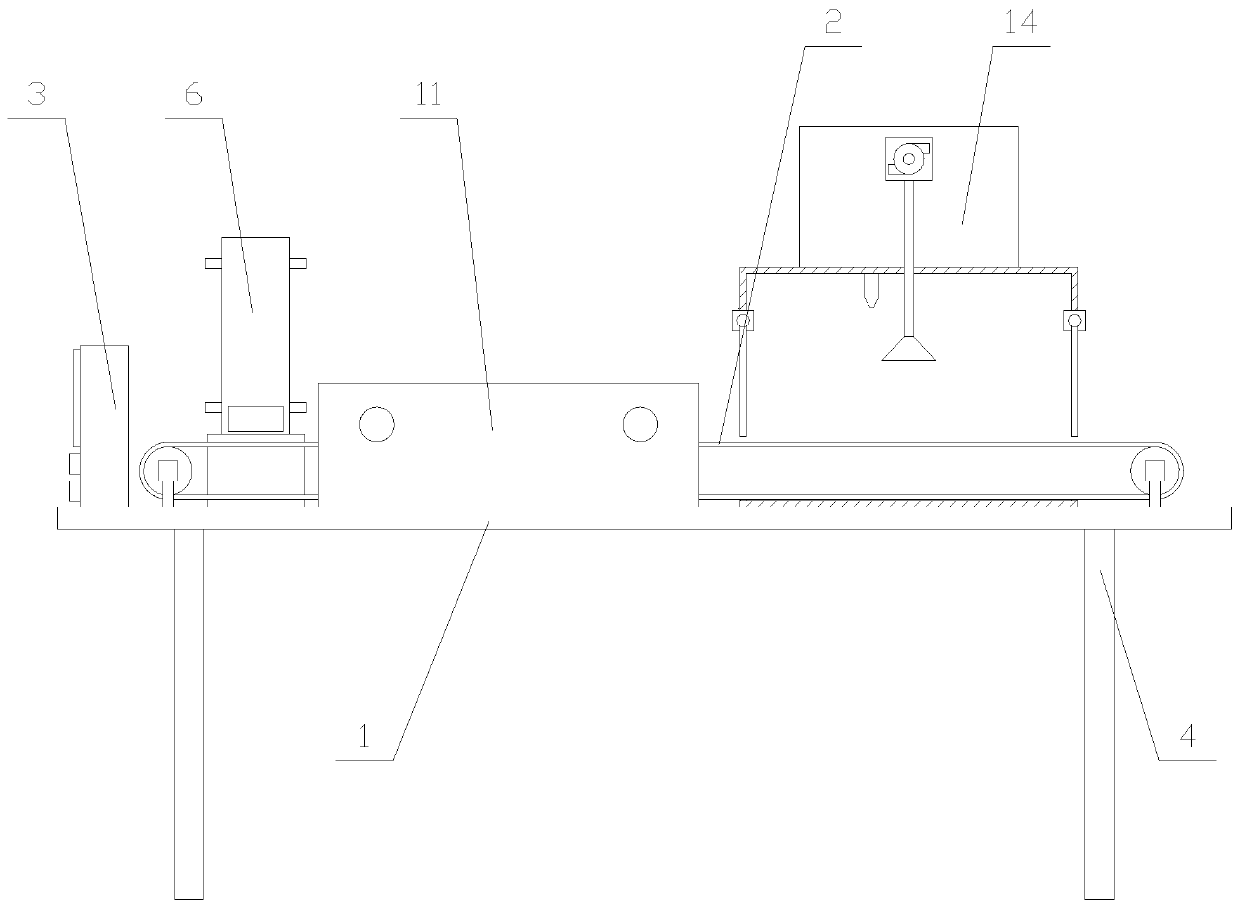

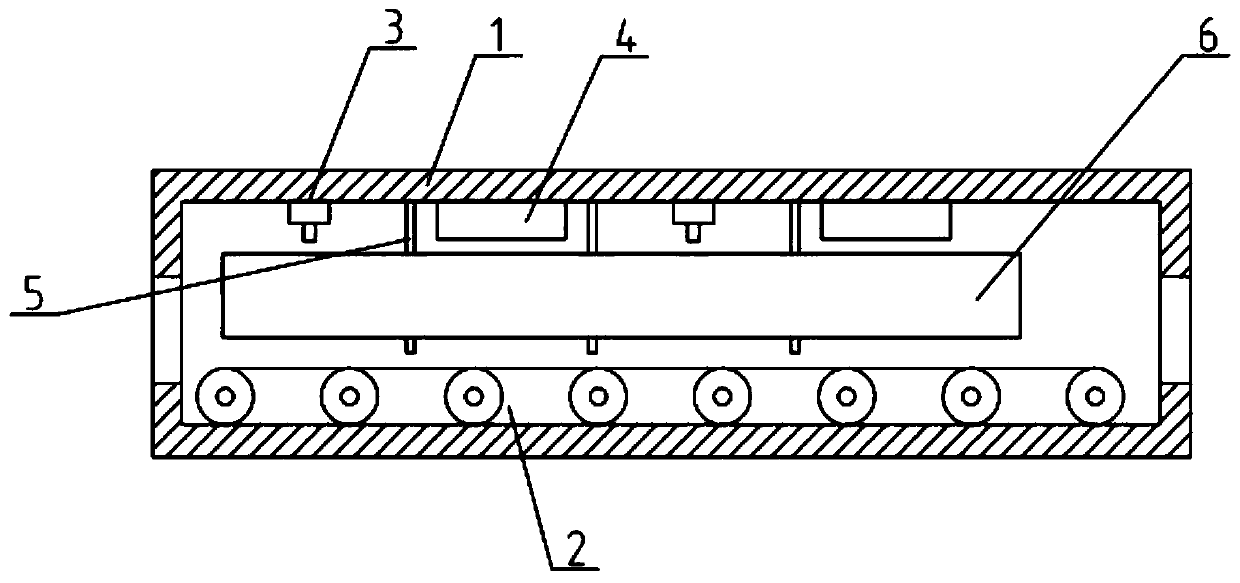

Full-automatic paint spraying production line for furniture plates

PendingCN109967297AReduce labor costsContinuous production cyclePretreated surfacesCoatingsProduction lineQuality control

The invention relates to a full-automatic paint spraying production line for furniture plates. The full-automatic paint spraying production line comprises a dust removal device, a paint spraying device, a primary drying device and a secondary drying device which are sequentially connected, wherein the production line is provided with a belt conveying mechanism used for conveying the furniture plates, the belt conveying mechanism penetrates through the whole assembly line, surface dust of the furniture plates is removed through the dust removal device, the furniture plates are sprayed with paint through the paint spraying device, are solidified and dried through a primary drying device, and are further solidified and dried through a secondary drying device, and the whole paint spraying process is completed in a full-automatic mode. Compared with the prior art, the full-automatic paint spraying process does not need to participate in the paint spraying process, the labor cost is saved, the production rhythm is continuous and compact, the production efficiency is high, the product quality control is strict, and the paint spraying quality is effectively guaranteed; the paint spraying device only sprays the paint on the upper area of the plates, so that the paint waste is reduced; and a multi-layer three-dimensional structure is adopted by the drying device, so that the occupied area is small, the continuous production is realized, and the production rhythm is fast.

Owner:AURORA CHINA

Wall spraying device for building decoration and method thereof

ActiveCN108252492AMeet the needs of spraying areaAvoid moving back and forthBuilding constructionsEngineeringMaterial storage

The invention discloses a wall spraying device for building decoration and a method thereof, and relates to the technical field of building construction equipment. The wall spraying device comprises amachine frame, a bottom plate is arranged at the bottom of the machine frame, a feeding device is arranged on the bottom plate, and the feeding device comprises a material storage box. A feeding pumpis arranged on the side, located on the bottom plate, of the material storage box, the feeding end of the feeding pump is connected with the material storage box through a first feed delivery pipe, and a feeding pipe is arranged at the discharging end of the feeding pump. The machine frame is provided with a horizontal moving mechanism, the horizontal moving mechanism is provided with a verticalmoving mechanism, and the vertical moving mechanism is provided with a spraying mechanism. The different position adjustment of the spraying mechanism can be realized by arranging the horizontal moving mechanism and the vertical moving mechanism, so that the entire device is prevented from being moved back and forth when a wall is sprayed, and requirements of wall painting areas are met; and thenthe spraying efficiency is improved, the spray quality is guaranteed, and the spray uniformity is improved.

Owner:江西鸿盛建设有限公司

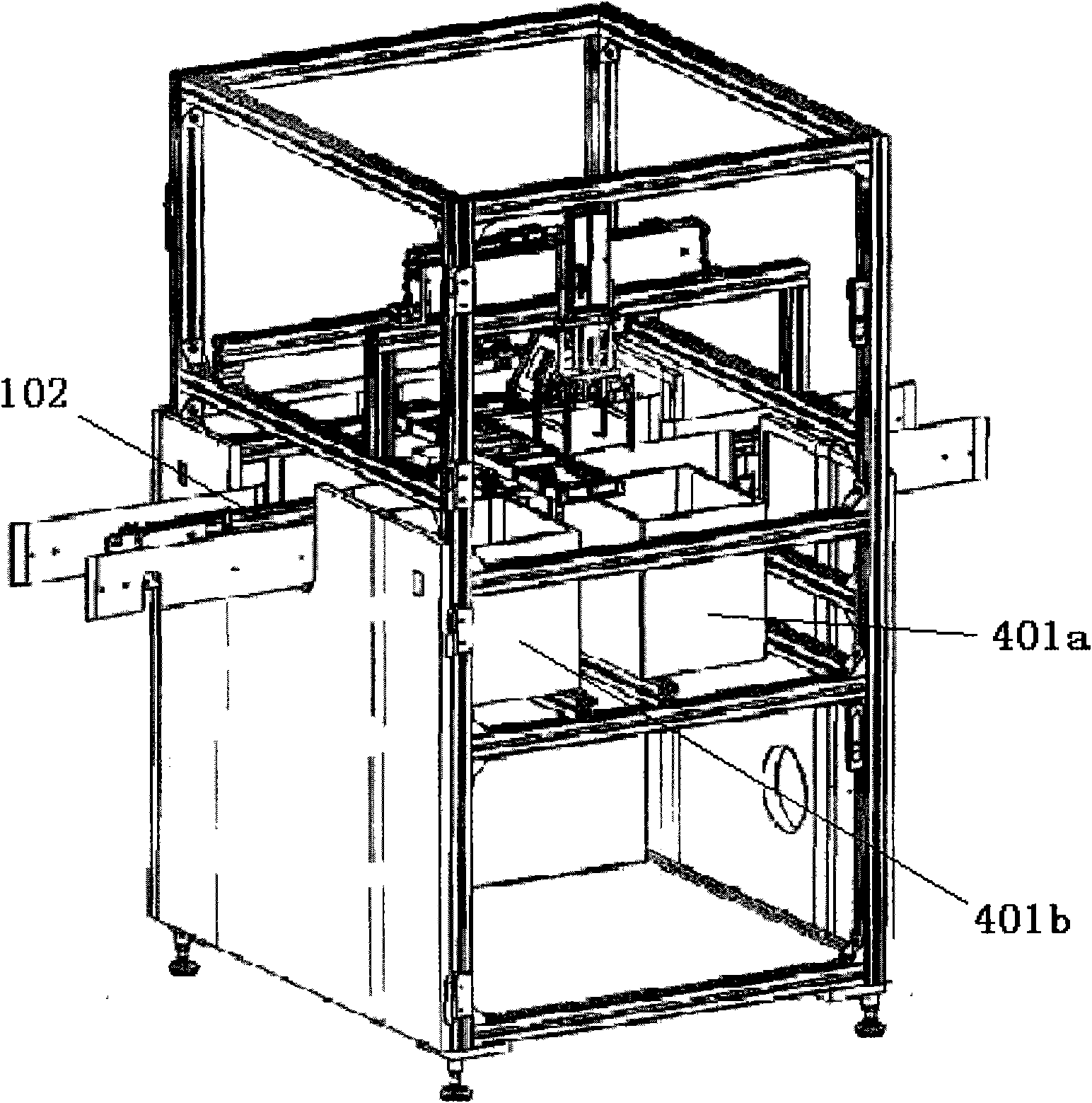

Automatic spraying equipment

InactiveCN101829643AFully automatedSuitable for spray productionLiquid surface applicatorsCoatingsControl unitProduction planning

The invention aims to provide automatic spraying equipment suitable for toy production characteristics. The automatic spraying equipment comprises a rubber part transfer component for transferring a rubber part, a spray gun component used for spraying, a template fixing component for fixing a template, a template cleaning component for moving and cleaning the template, a mantling and locating component for mantling the rubber part and the template and a control unit, wherein each component realizes automatic operation of procedures including charging, mantling, spraying, demoulding, blanking and mould cleaning in toy spraying operation under the control of the control unit, and therefore, the invention can enhance the production efficiency, ensure the spraying quality, promote the production planning target standard-reaching rate, accurately control the paint dose, lower the production material cost, effectively lower the labor intensity and is suitable for spraying production of a product such as a toy and the like.

Owner:中扩实业集团有限公司

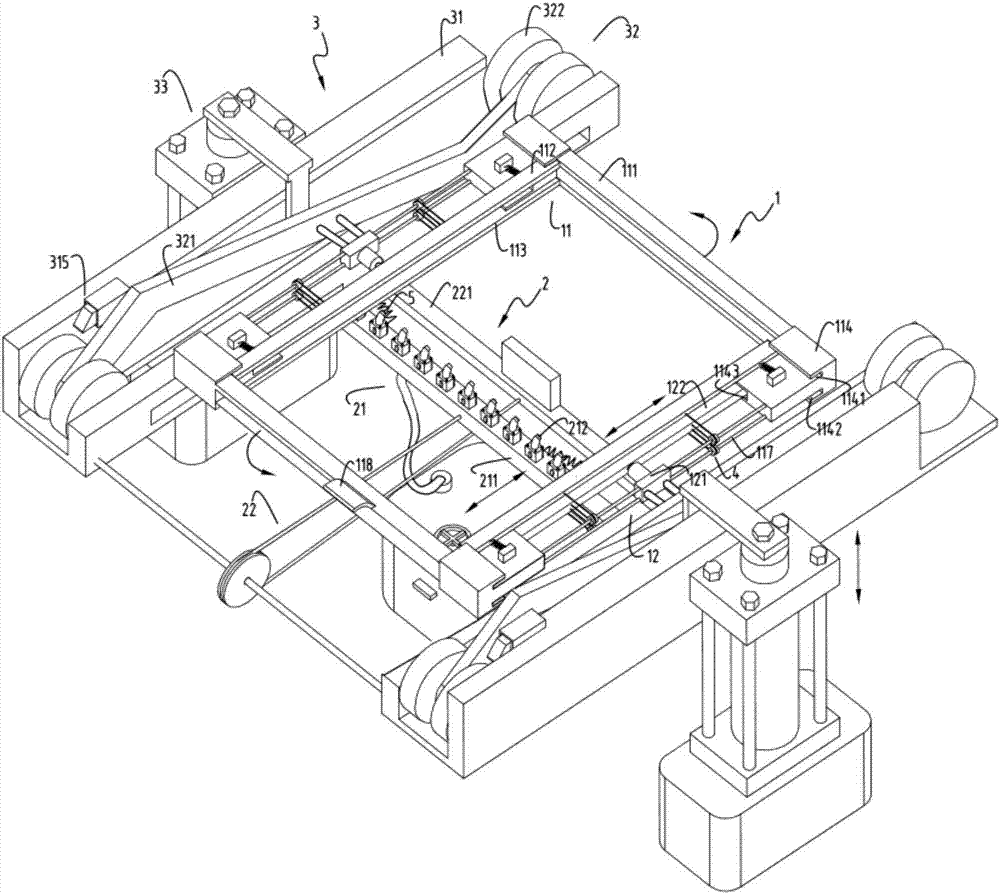

Ceramic tile turnover and automatic waxing equipment

InactiveCN106914362ASpray wax quickly and evenlyNo chance of dripping onto tilesSpraying apparatusWaxMaterials science

The invention relates to ceramic tile turnover and automatic waxing equipment which comprises a clamping and locating part, a sliding wax spray part and a rotating part. The clamping and locating part comprises a supporting mechanism used for locating and supporting ceramic tiles to be turned over and waxed, and a clamping mechanism used for clamping the ceramic tiles. The sliding wax spray part is used for waxing the surfaces of the ceramic tiles and comprises a wax spray mechanism and a transmission mechanism. The rotating part is used for driving the clamping and locating part and the ceramic tiles to be turned over together and meanwhile driving the wax spray mechanism through the transmission mechanism to move in the front-and-back direction to wax the ceramic tiles. The rotating part comprises a supporting seat, a turnover device fixedly connected with the supporting mechanism and a lifting device used for driving the turnover device to slide and be turned over along the supporting seat. The wax spray mechanism comprises a wax spray seat and multiple wax spray heads. The problems that ceramic tile waxing cannot be automatic and continuous, waxing efficiency is low, manpower is consumed, wax is prone to dripping onto the ceramic tiles, and waxing is not uniform are solved.

Owner:湖州裕尚卫浴有限公司

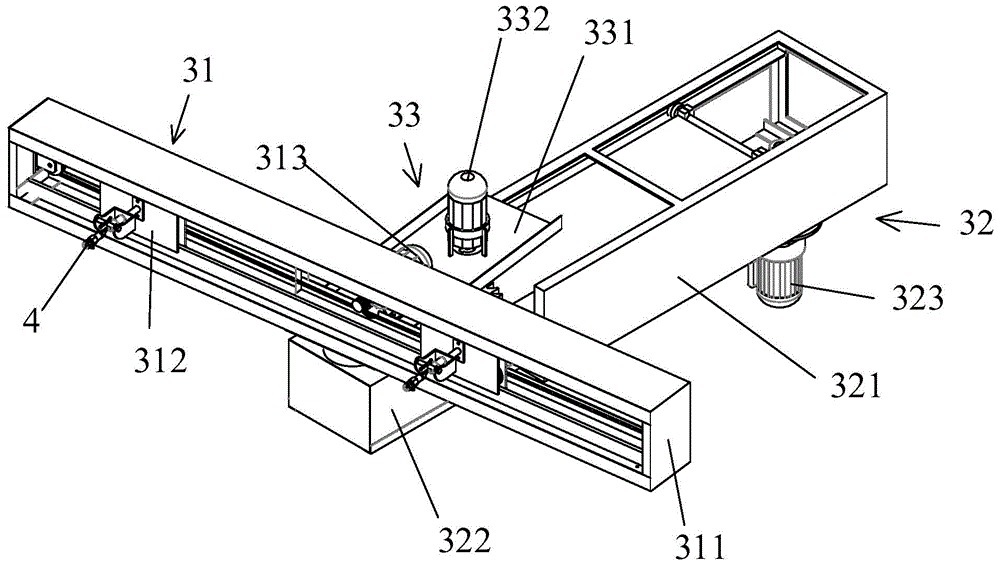

Automatic painting robot for shipbuilding coating

The invention discloses an automatic painting robot for shipbuilding coating. The automatic painting robot for shipbuilding coating comprises a painting movement mechanism, a PLC and a spray gun; the painting movement mechanism comprises a side-to-side movement mechanism, a front-to-back movement mechanism and a rotational movement mechanism; the side-to-side movement mechanism comprises a first shell, a sliding block and a first motor, the first motor drives the sliding block to move from side to side, the spray gun is fixedly arranged on the sliding block, and the first shell is provided with a distance measuring sensor; the front-to-back movement mechanism comprises a second shell, an inner shell and a second motor, and the inner shell moves back and forth in the second shell; the rotational movement mechanism comprises a support plate, a third motor and a fixed gear wheel, the side-to-side movement mechanism and the support plate are connected with the inner shell through a bearing, the third motor drives the side-to-side movement mechanism to rotate around the bearing, and the distance measuring sensor, the first motor, the second motor and the third motor are electrically connected with the PLC. According to the automatic painting robot for shipbuilding coating, the work efficiency is improved, the labor cost is reduced, the construction period is shortened, the evenness of a paint coating is good, and the quality of the paint coating is improved.

Owner:SHANGHAI WAIGAOQIAO SHIP BUILDING CO LTD

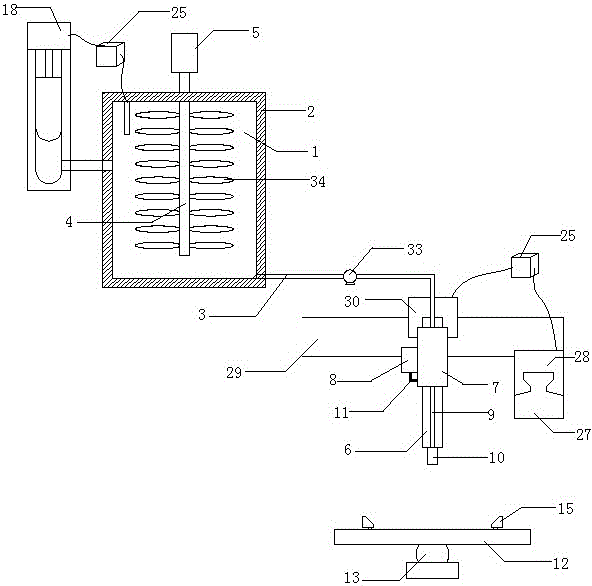

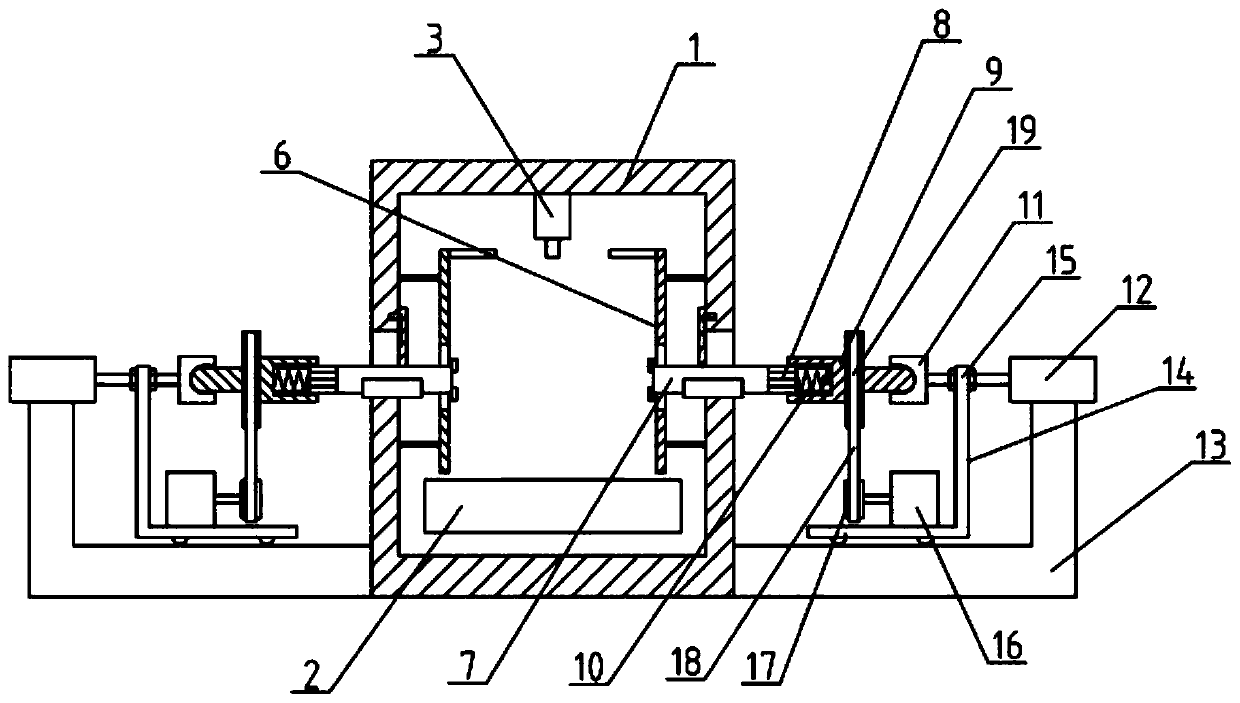

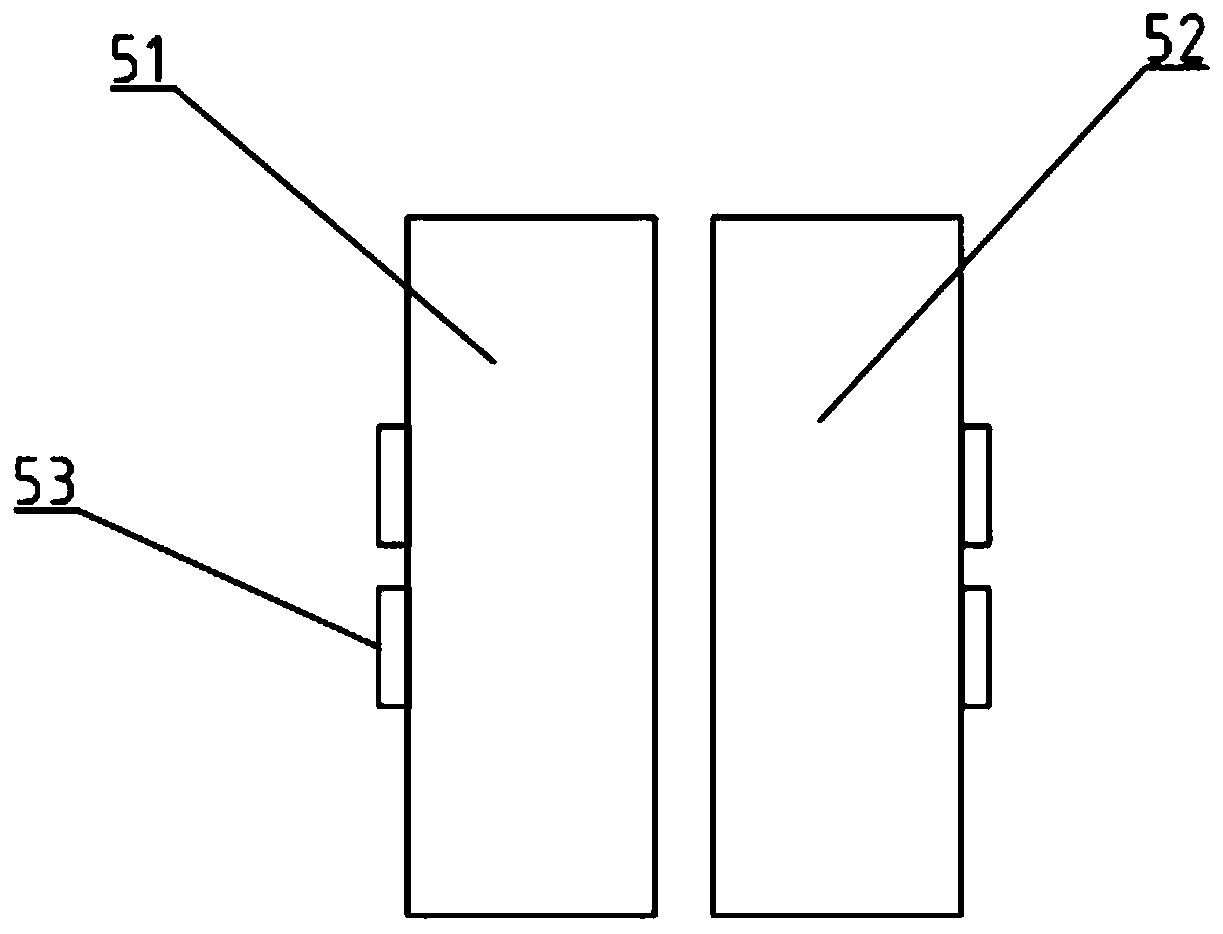

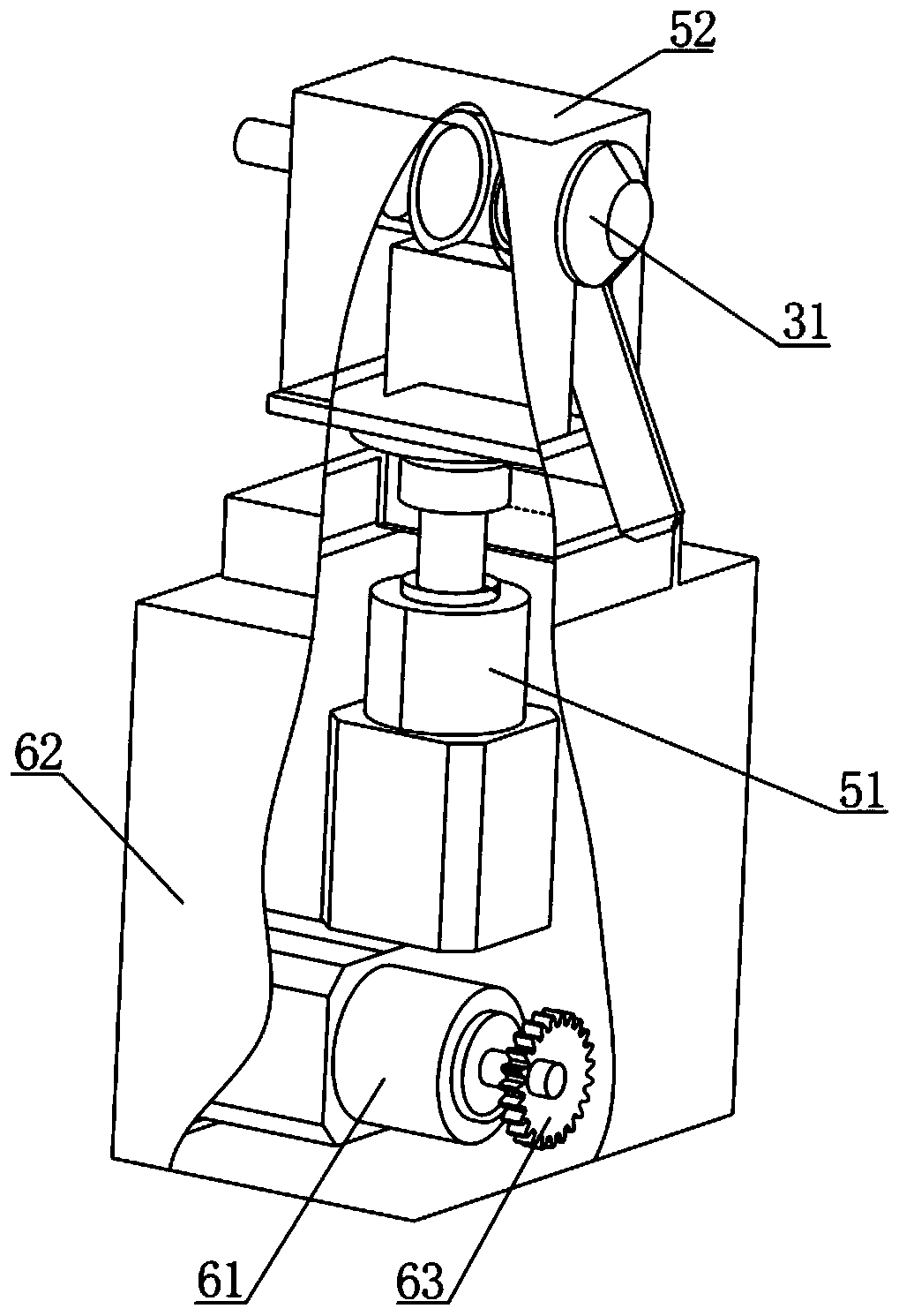

Polyurethane black material spraying equipment

ActiveCN105728236AAll-round sprayingSpray evenlySpray nozzlesLiquid spraying apparatusEngineeringPressurized spray

The invention provides polyurethane black material spraying equipment. The polyurethane black material spraying equipment comprises a black material extracting part, a black material spraying part and a plate clamping part, wherein the black material extracting part comprises a black material storage barrel and a black material stirring device; a cooling sandwich layer is arranged on the lateral wall of the black storage barrel, and a black material extracting pipe is connected to the bottom of the black material storage barrel; the black material stirring device comprises a stirring shaft and a stirring motor; the black material spraying part comprises a spraying gun, a to-be-sprayed black material storage tank and a pressurizing spraying device; the plate clamping device comprises a clamp plate and a universal ball. The polyurethane black material spraying equipment has the advantages that omnibearing and even spraying of the plate can be achieved, the storage quality of polyurethane black materials during storage and use can be guaranteed, and spraying quality and effect are further guaranteed; the polyurethane black material spraying equipment is efficient in spraying and capable of lowering spraying cost favorably.

Owner:上海林馨科技有限公司

Automatic spraying system with correcting function for workpiece processing

The invention relates to an automatic spraying system with a correcting function for workpiece processing. The system comprises a workbench, a supply mechanism, a correcting mechanism, a spraying mechanism, a conveying belt, a controller and four supporting legs; the supply mechanism comprises a fixed block, a supply pipe, a pushing assembly and two adjusting assemblies, wherein the pushing assembly comprises a driving unit, a reciprocating rod and a pushing block; and the correcting mechanism comprises a supporting block, a power assembly, two correcting assemblies and four supporting rods, wherein the power assembly comprises a moving plate, a correcting plate and two buffering units. According to the automatic spraying system with the correcting function for workpiece processing, workpieces are automatically placed on the conveying belt one by one through the supply mechanism, and operators do not need to manually place the workpieces, so that the working time of the workers is shortened, and the labor cost is reduced; and moreover, the position of the workpieces on the conveying belt can be corrected through the correcting mechanism, thus facilitating the accurate spraying of nozzles, ensuring the spraying quality, and improving the practicability of the system.

Owner:扬州健松涂装材料有限公司

Evenly-spraying device of nanometer self-cleaning coating for coke oven crude gas ascension pipe

ActiveCN106540831AUniform thicknessGuaranteed stabilityLiquid spraying apparatusCoated surfaceEngineering

The invention discloses an evenly-spraying device of nanometer self-cleaning coating for a coke oven crude gas ascension pipe. The evenly-spraying device comprises a center-adjusting support, a rotary suspending support and a shell. The center-adjusting support comprises a first center-adjusting support body, a second center-adjusting support body, a diameter-adjusting device and pulleys. A material spraying head is suspended on the rotary suspending support, a spraying pipe is arranged between the rotary suspending support and the material spraying head, and the spraying pipe is assembled on the rotary suspending support and horizontally arranged. The evenly-spraying device further comprises a material spraying pump, a material conveying pipe connected with the material spraying pump, an image detector and an image calculating module connected with the image detector. The material conveying pipe communicates with the spraying pipe through a hollow cavity of the rotary suspending support, and the image calculating module is in electric connection with a controller. According to the evenly-spraying device of the nanometer self-cleaning coating for the coke oven crude gas ascension pipe, the coating sprayed from the material spraying head is scanned through the image detector, the data are sent to the image calculating module, and thickness evenness of a coating is judged by the image calculating module according to the coating surface change; and the material spraying pump and a double-acting air cylinder are controlled by the controller to adjust the thicknesses of the coating.

Owner:江苏龙冶节能科技有限公司

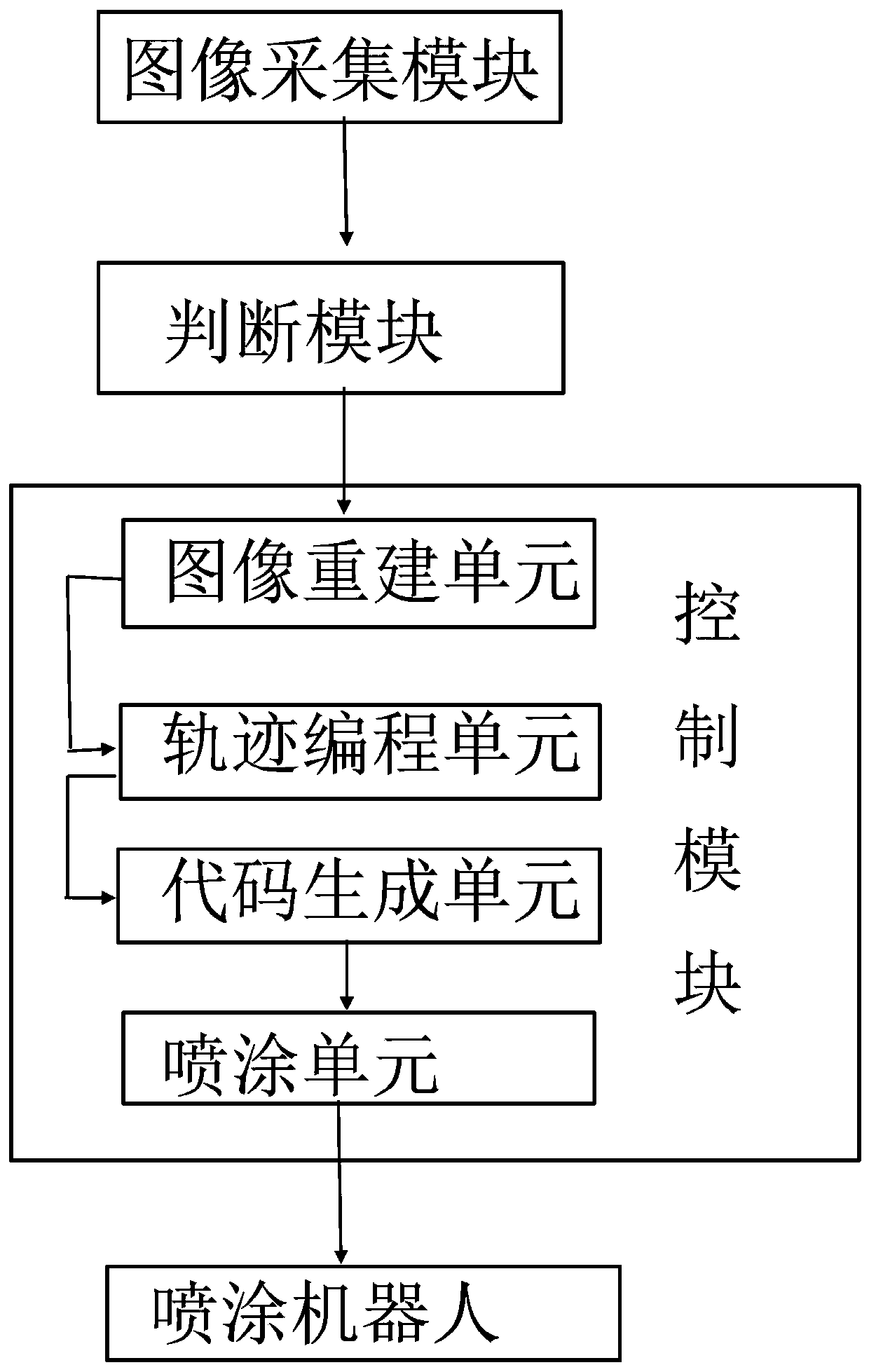

Spraying robot control system and control method

InactiveCN111013857ALow technical experience requiredGuarantee the quality of sprayingSpraying apparatusControl systemControl engineering

The invention provides a spraying robot control system and control method, and belongs to the technical field of spraying robots. An image acquisition module acquires a spraying photograph of a sprayed workpiece; the spraying photograph is analyzed through a model to determine whether the spraying photograph meets the spraying standard or not, and the geometric information of the spraying photograph which does not meet the spraying standard is acquired; the model is obtained from multiple groups of data through machine learning training, and each group of data in the multiple groups of data comprises the spraying photograph of the sprayed workpiece and standard identification information used for identifying the spraying photograph; and a control module is used for controlling the sprayingrobot to carry out spraying. According to the spraying robot control system and control method, a method based on machine learning is adopted, a corresponding spraying area model is automatically established for the sprayed workpiece, the sprayed position can be detected in real time, and the spraying quality is guaranteed; manual intervention is not needed, and technical experience requirementsof spraying operators are lowered.

Owner:BEIJING DONGFANG HOWAIL IND EQUIP

Environment-friendly type special adhesion primer for nonferrous metal surface

InactiveCN101693802AStrong support abilityLess consumption per unit areaAnti-corrosive paintsPolyvinyl butyralPolyvinyl alcohol

The invention relates to an environment-friendly type special adhesion primer for nonferrous metal surface which is exclusively used for the surface of nonferrous metal, such as stainless steel, aluminum alloy and the like, to serve as the primer. The environment-friendly type special adhesion primer for nonferrous metal surface comprises a component A and a component B, wherein the formula of the component A comprises the following components: 1-20 parts of zinc chrome yellow, 1-5 parts of talcum powder, 2-20 parts of polyvinyl butyral, 5-70 parts of isopropanol and 1-25 parts of butanol; the formula of the component B comprises the following components: 1-30 parts of phosphoric acid, 10-40 parts of purified water and 30-70 parts of isopropanol. A coating is ultrathin and has strong matching property, wide use range, little consumption of unit area and high drying speed; and the thickness of a dry film is only 5-20 microns, and subsequent matching paint can be sprayed after 10-20 minutes. The polyvinyl butyral and the zinc chrome yellow which are innoxious and inodorous are used as main raw materials, the properties of high transparence and superior flexibility and deflection of the polyvinyl butyraldehyde after being dissolved in alcohol solvents and the like are utilized, the adhesion force is increased, the zinc chrome yellow and the phosphoric acid generate a phosphating reaction on the surface of the metal to act as the functions of phosphatization and passivation, the bonding force between the paint and a substrate of the metal is improved, and the environment-friendly type special adhesion primer for nonferrous metal surface has a certain corrosion-prevention function and effect.

Owner:袁泉利

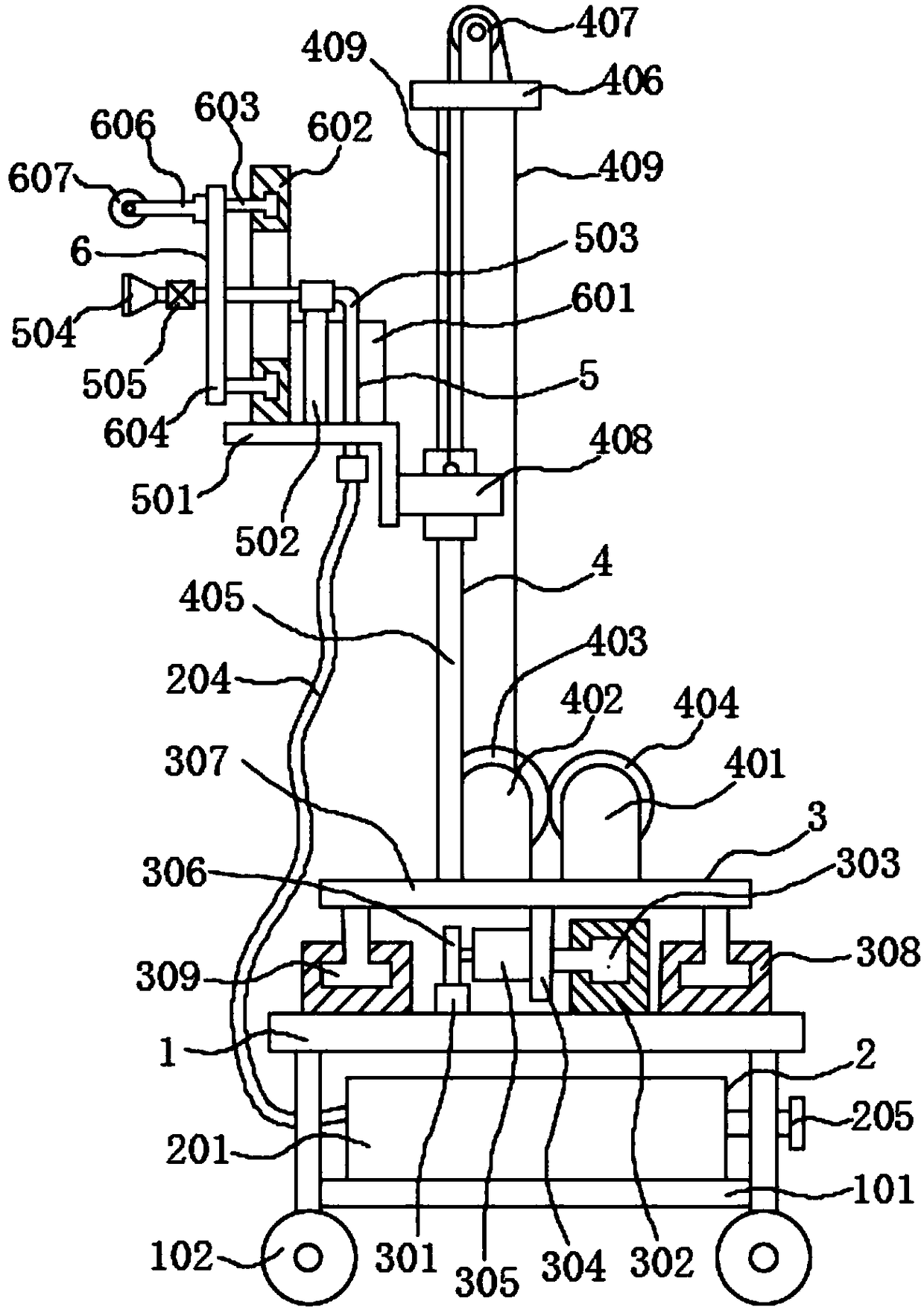

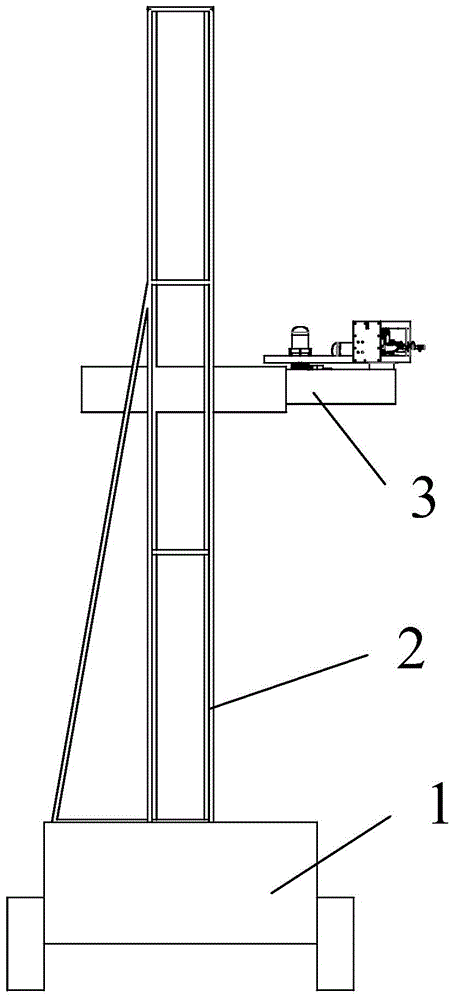

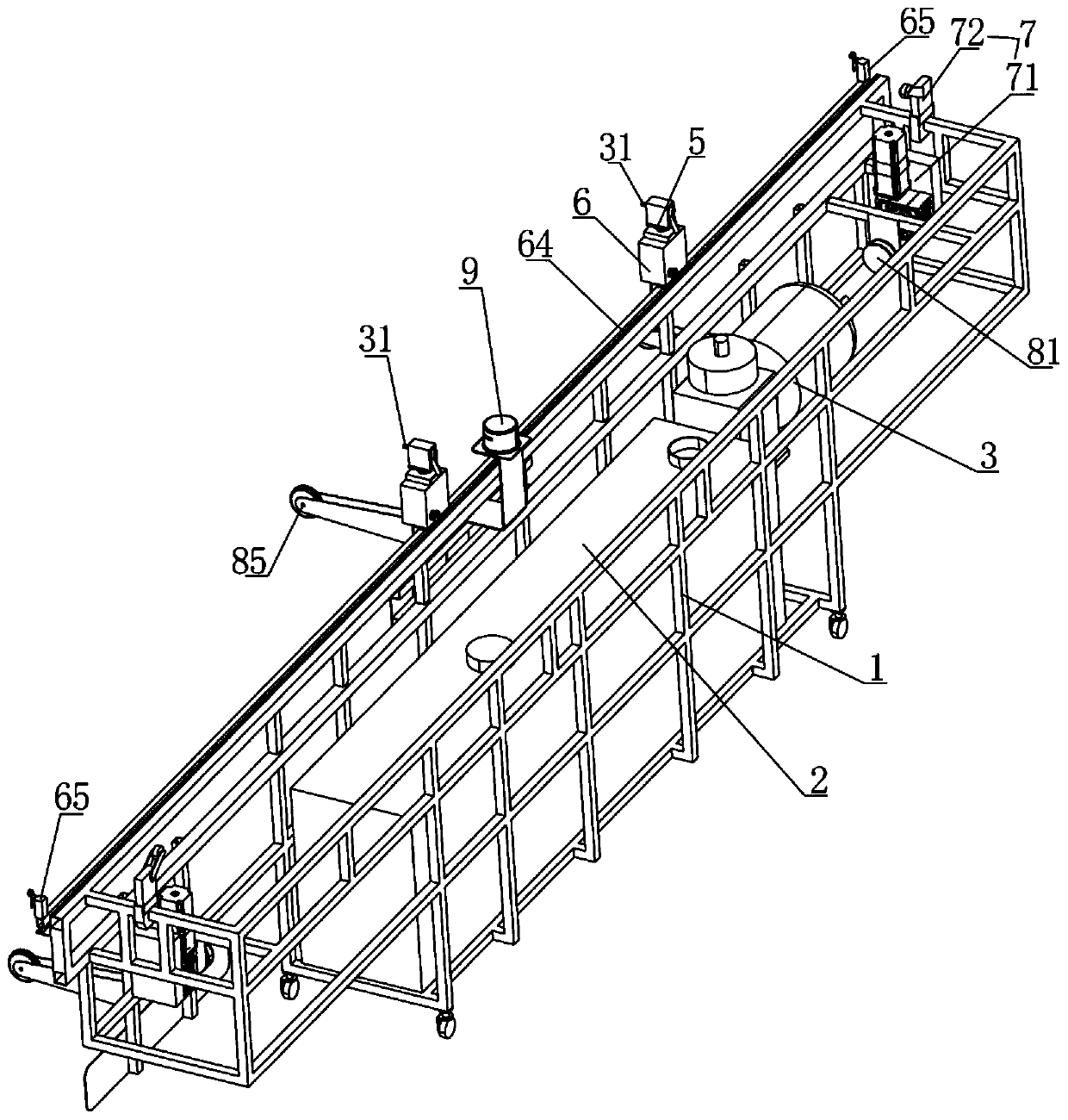

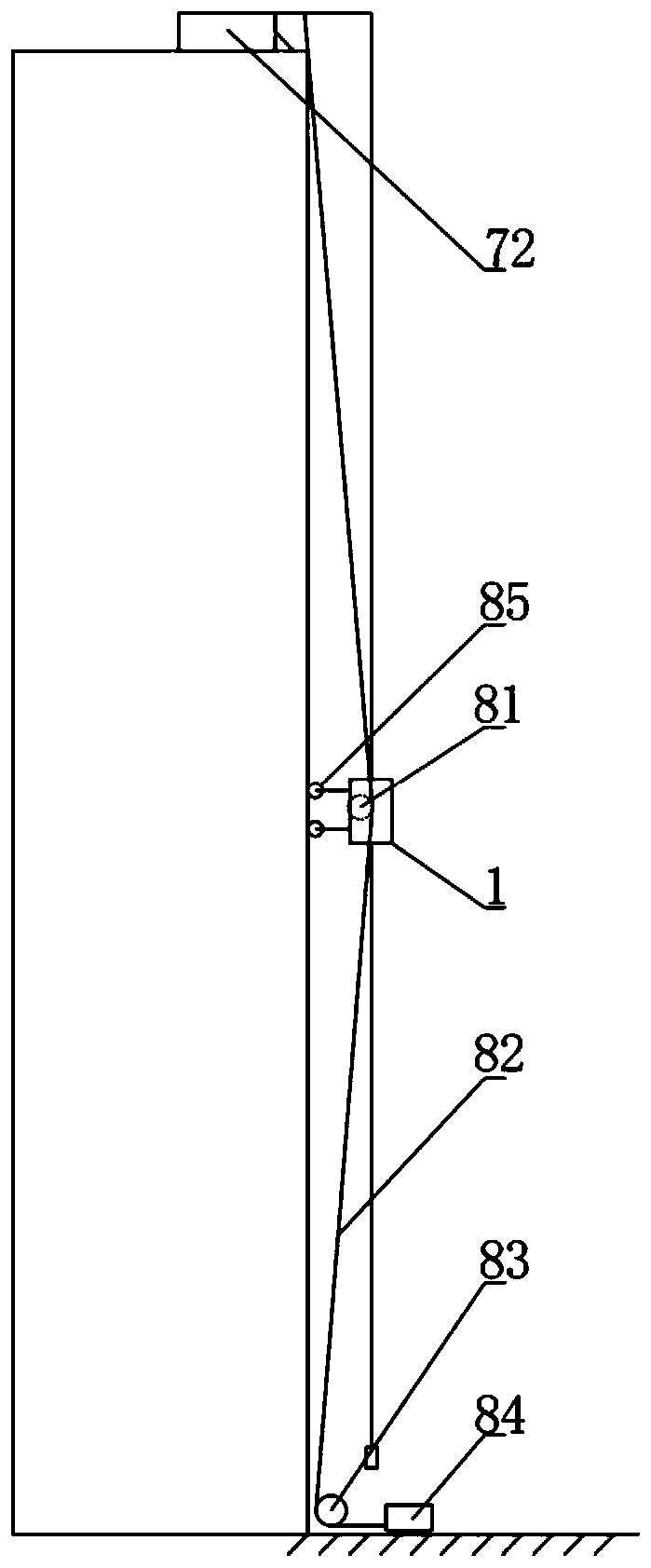

Automatic metal thermal spraying device

InactiveCN101884966AAchieve sprayingTo achieve the purpose of sprayingLiquid surface applicatorsSpraying apparatusThermal sprayingReciprocating motion

The invention discloses an automatic metal thermal spraying device. The automatic metal thermal spraying device applied to the technical field of coating comprises a rail, a trolley, a stand column and a spray gun base, wherein the trolley is arranged on the rail; the stand column is vertically fixed on the trolley; the spray gun base is arranged on the stand column and can move up and down along the stand column; a spray gun is arranged on the spray gun base; a fixed pulley is arranged at the top end of the stand column and wound with a steel wire rope; one end of the steel wire rope is connected with the spray gun base, while the other end is suspended with a balance weight; the surface of the stand column is provided with a rack in vertical direction; the spray gun base is provided with a lifting motor; and a gear which is engaged with the rack is arranged on the lifting motor. The trolley which can reciprocate and the spray gun base adopted by the invention fulfill the aim of automatic metal thermal spraying for a workpiece in a large area, thereby achieving the effects of improving working efficiency and guaranteeing thermal spraying quality.

Owner:SHANGHAI HUNENG ANTI CORROSION & HEAT INSULATION ENG

Transformer spraying equipment and spraying process thereof

InactiveCN111495641AImproves sprayabilityGuarantee the quality of sprayingPretreated surfacesCoatingsTransformerMechanical engineering

The invention discloses transformer spraying equipment. The transformer spraying equipment comprises a supporting body, a containing cavity is formed in the supporting body, guide grooves are formed in the upper side wall and the lower side wall of the containing cavity in the horizontal direction, adjusting devices are connected into the guide grooves in a sliding mode, each adjusting device comprises a sliding part and a supporting part, the sliding parts are located at the outer ends of the containing cavity to be perpendicularly connected with the supporting parts, and the supporting partsextend in the center direction of the supporting body from the perpendicular connecting position. According to the transformer spraying equipment, before a spraying assembly is used for spraying a transformer shell, the transformer shell is clamped firstly and then is rotated, so that the spraying effect is good and more in place, the overall spraying quality is guaranteed, the automation degreeof the operation process is high, manpower is saved, and the operation process is safer.

Owner:台州市振泰机电有限公司

Building outer wall spraying robot and control method thereof

ActiveCN110370296AImprove spray qualityGuarantee personal safetyBuilding constructionsManipulatorControl engineeringStructural engineering

The invention provides a building outer wall spraying robot and a control method thereof, and relates to the technical field of building robots. The building outer wall spraying robot comprises a machine frame, a material storage box and a spraying machine, wherein the material storage box and the spraying machine are arranged on the machine frame, a spraying gun of the spraying machine is provided with a rotating mechanism capable of changing a spraying direction, and the spraying gun is fixed on a horizontal moving device capable of sliding in the horizontal direction of the machine frame; and the machine frame is provided with a lifting mechanism for enabling the machine frame to move in the direction of a plumb bob, and a stability maintaining mechanism for adjusting the movement stability of the machine frame, an outer wall recognition device for identifying a spraying region is further arranged on the machine frame, and the outer wall recognition device, the rotating mechanism, the horizontal moving device and the lifting mechanism are electrically connected to a controller. According to the robot and the method, the problems that in the prior art, manual building outer wallspraying is dangerous, the efficiency is low, and the spraying quality is not stable are solved.

Owner:UNIV OF ELECTRONICS SCI & TECH OF CHINA

Agricultural mechanical equipment for herbicide spraying

InactiveCN112167232AEasy to stir and mixEasy accessSpraying apparatusWeed killersAgricultural scienceAgricultural engineering

The invention relates to the technical field of agricultural machinery, and discloses agricultural machinery equipment for herbicide spraying. The agricultural machinery equipment comprises a U-shapedplate and a rotating rod penetrating through the U-shaped plate. The rotating rod is rotatably connected with the side wall of the U-shaped plate through a ball bearing, walking wheels are fixedly mounted at the two ends of the rotating rod, a liquid storage tank is fixedly mounted in the center of the top of the U-shaped plate, a stirring rod is arranged in the liquid storage tank, a plurality of stirring blades which are evenly distributed in a staggered mode are welded to the outer rod wall of the stirring rod, the bottom end of the stirring rod sequentially penetrates through the bottom of the liquid storage tank and the U-shaped plate and is fixedly connected with a driven bevel gear, the stirring rod is rotationally connected with the bottom of the liquid storage tank through a sealing bearing, and the stirring rod is rotationally connected with the U-shaped plate. According to the agricultural machinery equipment for herbicide spraying, reciprocating swing spraying of herbicideliquid medicine is convenient, the herbicide liquid medicine is conveniently stirred, precipitation of the herbicide liquid medicine is avoided, and therefore the spraying quality is effectively improved.

Owner:西安汇龙中鼎机械设备有限公司

Anti-pollution-flashover paint spraying device for power transmission and transformation equipment

InactiveCN107813936ARealize remote controlGuarantee personal safetyAircraft componentsRemote controlled aircraftElectric power transmissionSpray coating

The invention discloses an anti-pollution-flashover paint spraying device for power transmission and transformation equipment, and belongs to the technical field of electric maintenance equipment. Thedevice includes an unmanned aerial vehicle, and the two sides of the bottom surface of a rack of the unmanned aerial vehicle are provided with support frames respectively; the rack of the unmanned aerial vehicle is provided with a spray mechanism, a wireless remote control device and an image collection and transmission device; the spray mechanism includes a material box, a power supply, a compressor, a discharge pipe and a spray-coating rod; the power supply and the compressor are arranged at the bottom of a material box, the power supply is connected with the compressor, one end of the discharge pipe is connected with an outlet of the material box, the other end of the discharge pipe is fixedly connected with a connecting rod, the connecting rod is connected with the spray-coating rod through a rotary joint, the rotary joint is connected with a drive motor, the side wall of the spray-coating rod is connected with several nozzles, and an electromagnetic valve is arranged at the connection portion of each nozzle and the spray-coating rod; the image collection and transmission device includes a camera and an image transmitter. According to the device, construction personnel do notneed to climb power transmission equipment for manual spray coating, the intensity of construction work is greatly reduced, and the safety of the construction personnel is ensured.

Owner:STATE GRID HENAN ELECTRIC ZHOUKOU POWER SUPPLY +1

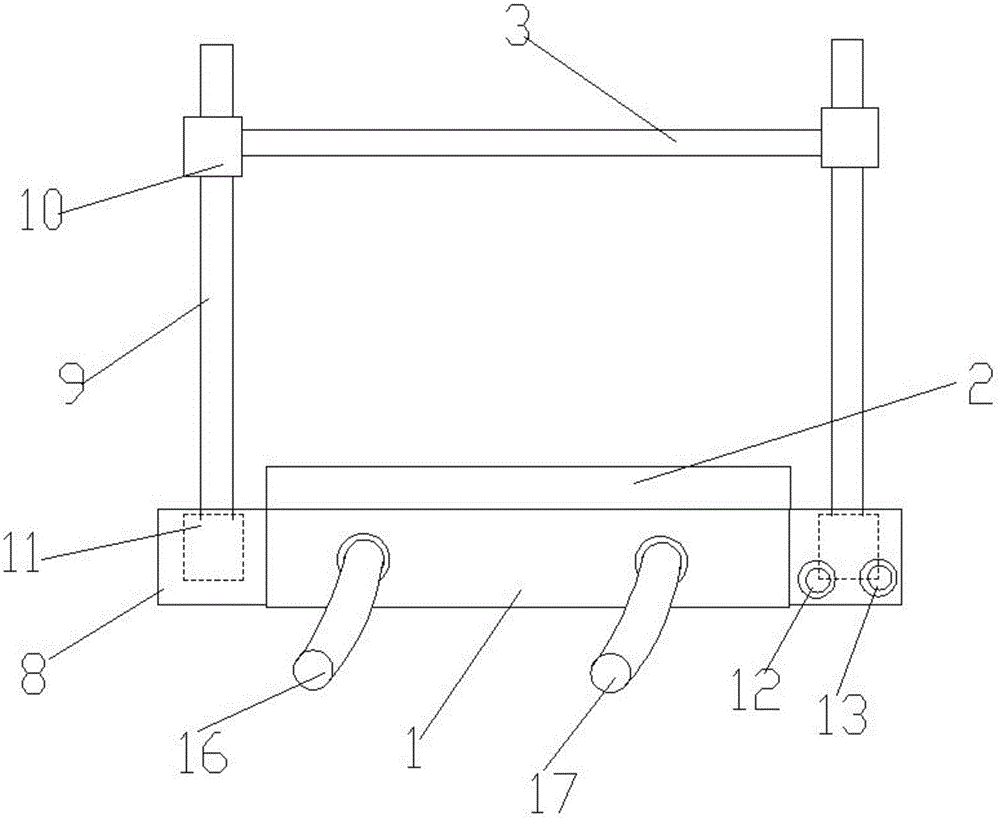

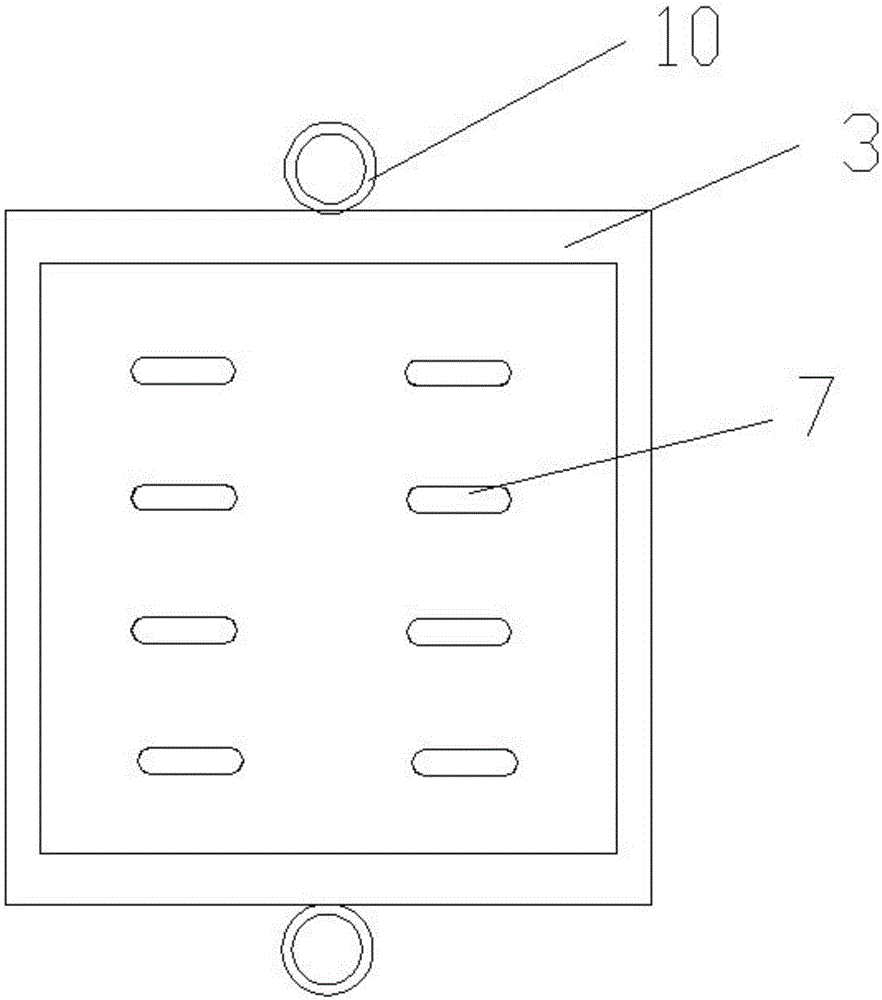

Locally spraying fixture

InactiveCN105032658AImprove spraying efficiencyAvoid shakingSpraying apparatusMechanical engineeringEngineering

Owner:SUZHOU BOAO PLASTIC ELECTRONICS

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com