Automatic spraying equipment

An automatic spraying and equipment technology, applied in the field of automation, can solve the problems of restricting the development of the toy industry, achieve the effect of increasing the target compliance rate, improving air quality, and reducing the cost of production materials

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

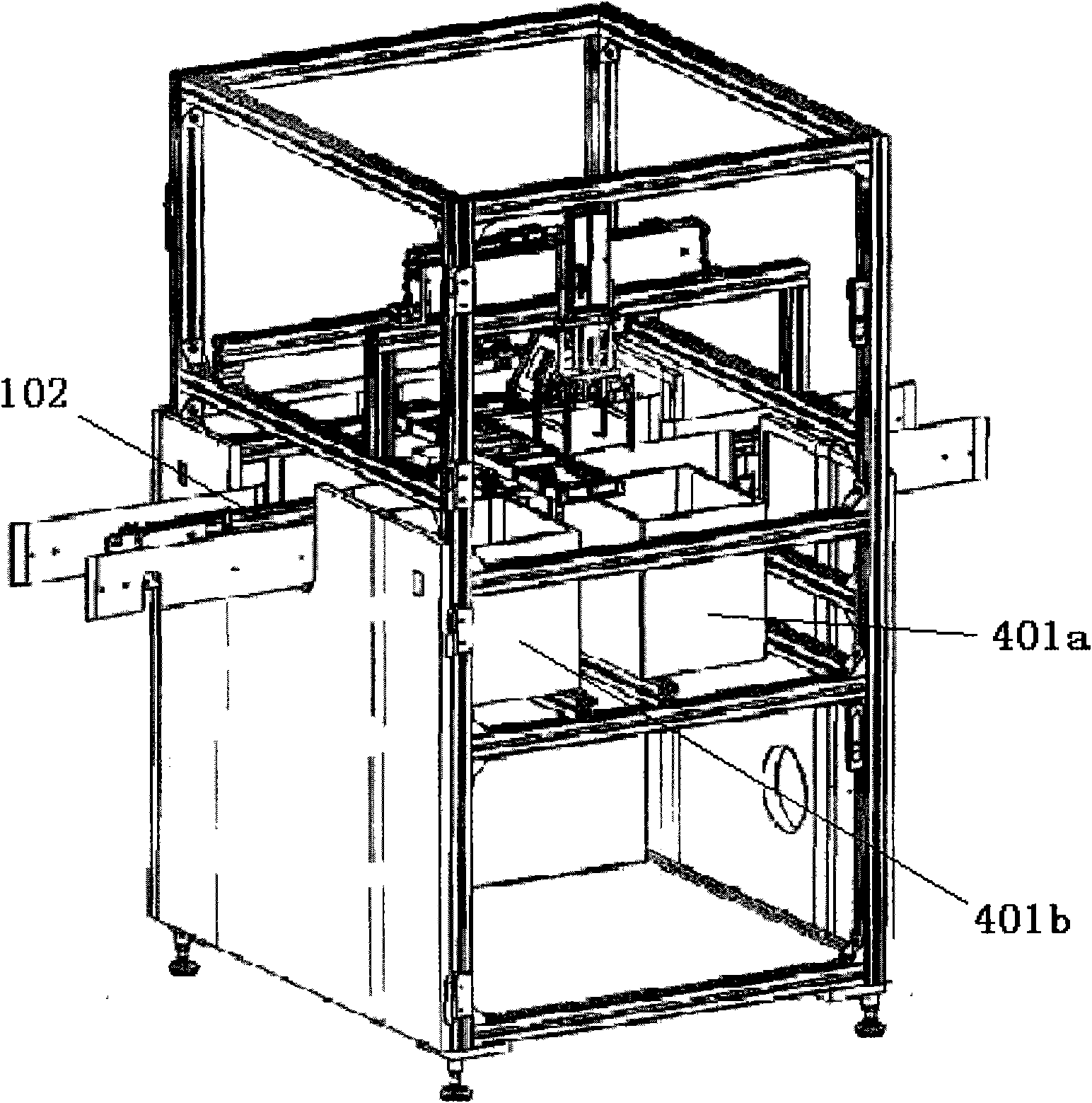

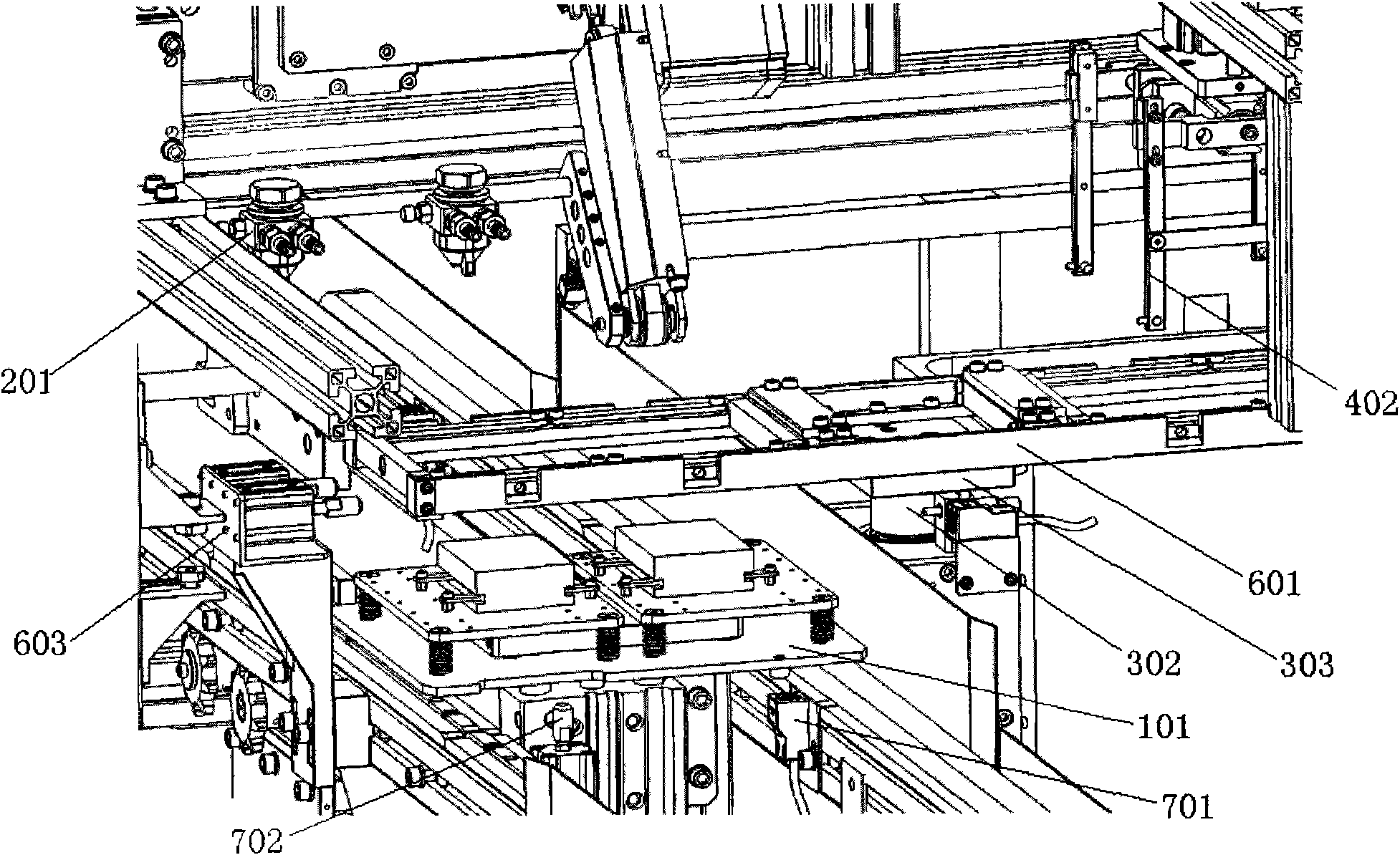

[0049] As shown in the figure, the automatic spraying equipment of this embodiment includes a glue delivery component, a spray gun component, a template fixing component, a template cleaning component, a mold positioning component and a control unit, wherein:

[0050] The glue delivery assembly includes a glue fixing plate 101 and a conveyor belt 102 for conveying the glue fixing plate 101. The middle of the conveyor belt 102 is hollowed out, and both ends of the glue fixing plate 101 are movable on the conveyor belt. On both sides of 102, there are protruding metal cylinders 103 under the bottom side of the glue fixing plate 101, and the conveyor belt 102 is driven by a motor 109 below it.

[0051] The rubber parts transmission assembly also includes a bottom mold fixing plate 104, and the bottom mold fixing plate 101 is provided with a plurality of mounting holes to flexibly install the bottom mold 108. The bottom mold 108 is used to fix the glue parts, and the glue parts of ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com