Spraying robot control system and control method

A spraying robot and control system technology, applied in the direction of spraying devices, etc., can solve problems such as heavy programming workload, high site requirements, and inability to guarantee spraying quality, and achieve the effect of reducing technical experience requirements and ensuring spraying quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

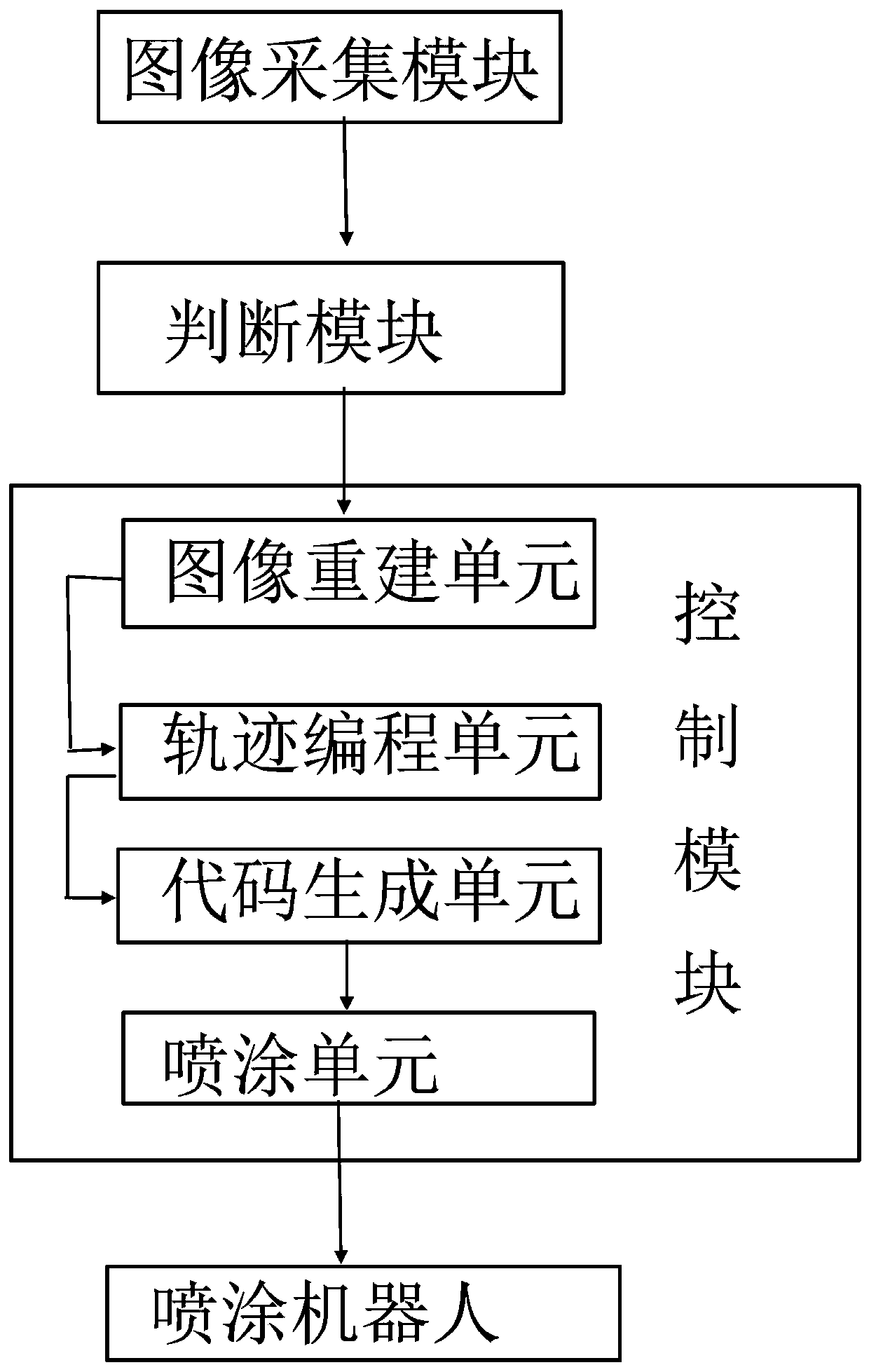

[0053] Such as figure 1 As shown, Embodiment 1 of the present invention provides a spraying robot control system, the system includes: an image acquisition module, a judgment module and a control module;

[0054] The image acquisition module is used to scan the sprayed workpiece in real time according to the preset scanning path, so as to collect the sprayed photos of the sprayed workpiece; in Embodiment 1 of the present invention, the image acquisition module can use an industrial camera.

[0055] The judgment module is used to analyze the sprayed photos through the model, determine whether the sprayed photos meet the spraying standards, and obtain the geometric information of the sprayed photos that do not meet the spraying standards; wherein, the model uses machine learning through multiple sets of data Obtained by training, each set of data in the multiple sets of data includes a sprayed photo of the sprayed workpiece and standard identification information used to identif...

Embodiment 2

[0070] Embodiment 2 of the present invention provides a spraying robot control method, the method comprising:

[0071] Obtain spraying photos of sprayed workpieces;

[0072] Analyze the sprayed photos through the model, determine whether the sprayed photos meet the spraying standards, and obtain the geometric information of the sprayed photos that do not meet the spraying standards; wherein, the model is obtained by using machine learning training through multiple sets of data, so Each set of data in the above multiple sets of data includes a spraying photo of the sprayed workpiece and standard identification information used to identify the spraying photo;

[0073] Optimize the geometric information to generate a three-dimensional model of the sprayed workpiece, and generate the positional relationship between the workpiece and the spraying robot, automatically identify the spraying area and calculate the spraying trajectory according to the three-dimensional model of the wor...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com