Supersonic spray coating method of crystallizer copper plate

A crystallizer copper plate, supersonic spraying technology, applied in the direction of coating, molten spraying, metal material coating process, etc., can solve the problems of frequent copper plate replacement, low performance and price, low bonding strength, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

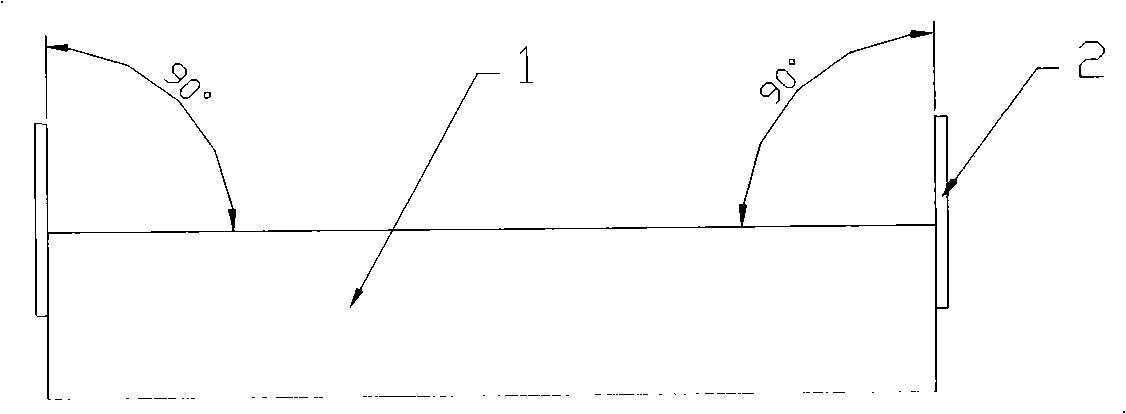

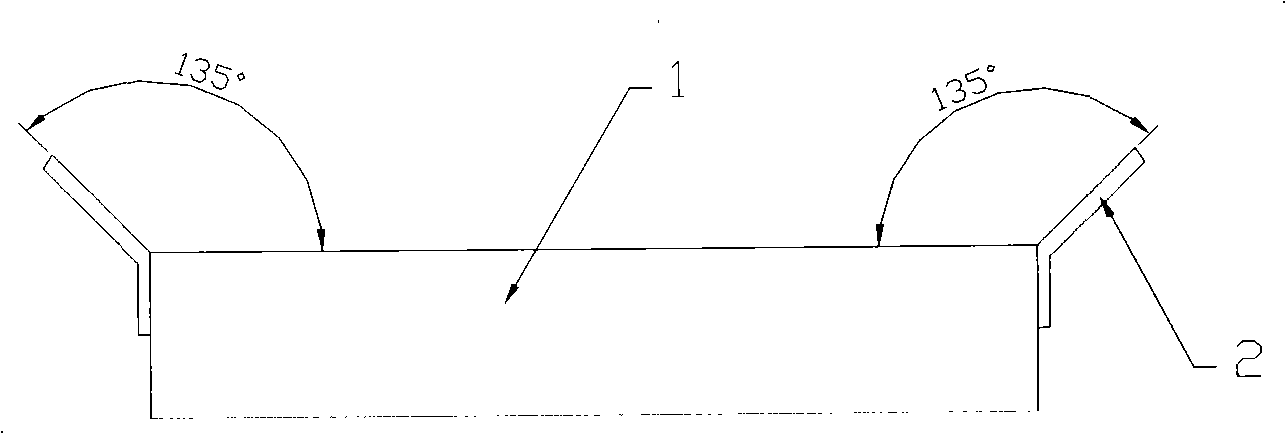

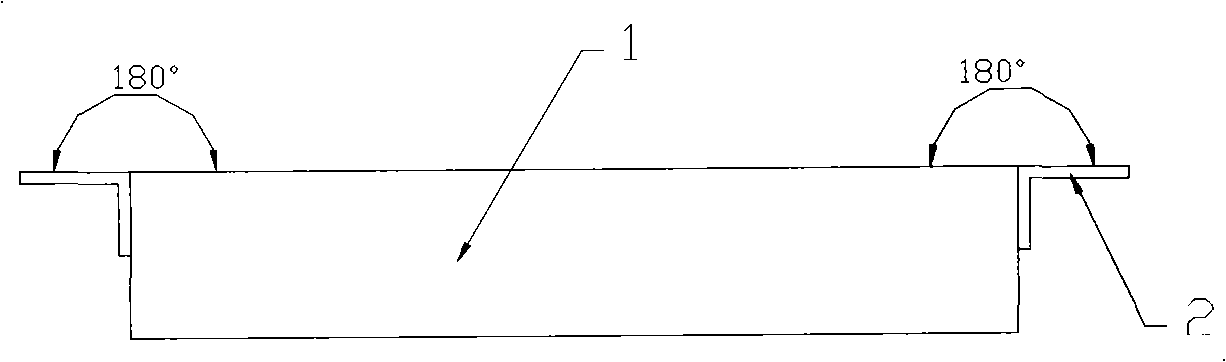

[0014] The supersonic spraying method of the crystallizer copper plate is carried out according to the following steps: first, the surface of the mold copper plate is cleaned and sandblasted with the conventional cleaning process; ° guards, such as figure 1 , 2 , The angle between the copper plate working surface and the guard plate shown in 3 can be 90 °, 135 ° or 180 °; then the nickel-based alloy powder spray coating such as NiCrBSi alloy powder is packed into the supersonic flame spraying equipment, and the crystallization is carried out according to the conventional procedure The surface of the copper plate of the crystallizer is sprayed; finally, after spraying the copper plate of the crystallizer, it is kept at 800°C-950°C for 0.5-3 hours for melting and diffusion vacuum heat treatment, so that the coating and the base material produce a miscible diffusion layer, which is formed by the original mechanical bonding. It is transformed into interpenetrating and miscible me...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com