Polymer material and preparation method thereof

A polymer material and polymer technology, applied in the field of plastic modification, can solve the problems of poor surface adhesion and poor sprayability, and achieve the effect of maximizing the guarantee, improving the wetting ability and increasing the polarity.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

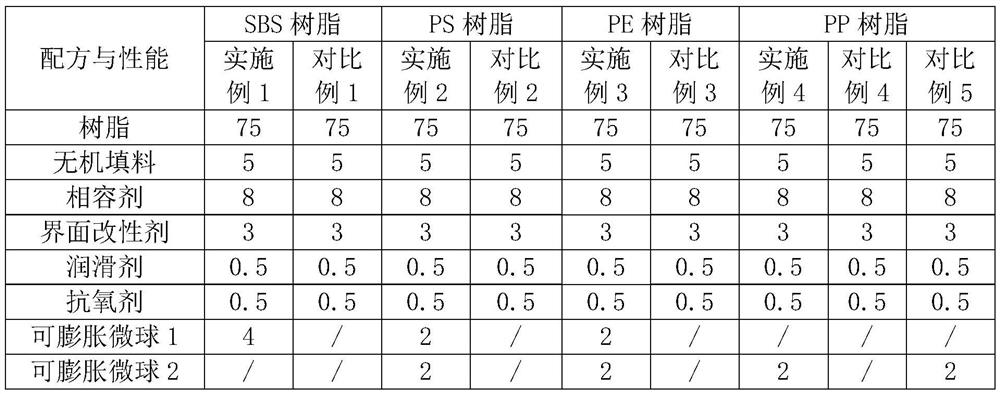

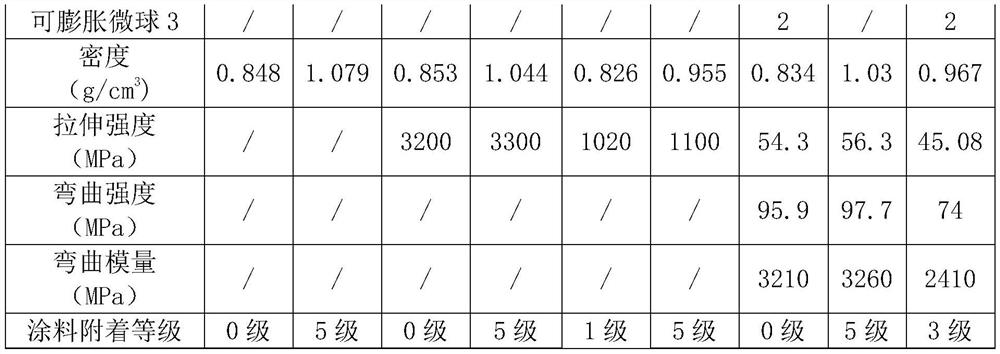

Embodiment 1

[0028] A preparation method of modified styrene thermoplastic elastomer material:

[0029] With the styrene thermoplastic elastomer resin of 75 mass parts, the inorganic filler calcium carbonate of 5 mass parts, the polypropylene PP-g-MAH of the compatibilizer maleic anhydride graft of 8 mass parts, the interfacial modifier of 3 mass parts Hydroxyl-terminated "hyperbranched" polyolefin, 0.5 parts by mass of lubricant polyethylene wax, and 0.5 parts by mass of antioxidant 1010 are mixed evenly, and then added to the feed port of the twin-screw extruder, and the temperature of the extruder is controlled at 120 Between -160°C, prepare styrene thermoplastic elastomer resin modified masterbatch. The styrene thermoplastic elastomer material modified by expandable microspheres can be obtained by blending and injecting 4 parts of expandable microspheres 1 with the above-mentioned masterbatch. The material is injection molded into products in the range of 160-180°C, and the product-re...

Embodiment 2

[0031] A preparation method of modified polystyrene material:

[0032] 75 parts of polystyrene resin, 5 parts of inorganic filler quartz powder, 8 parts of PS grafted with maleic anhydride, 3 parts of interfacial modifier carboxyl-terminated "hyperbranched" polyolefin, 0.5 parts of Lubricant ERS and 0.5 parts of antioxidant 168 are mixed evenly, and then added to the feeding port of the twin-screw extruder. The temperature of the extruder is controlled between 120-180°C to prepare polystyrene modified masterbatch. 2 parts of expandable microspheres 1 and 2 parts of expandable microspheres 2 are blended with the above-mentioned masterbatch for injection molding to obtain a polystyrene material modified by expandable microspheres. The material is injection molded into products in the range of 160-190°C, and the product-related performance test results are shown in Table 1.

Embodiment 3

[0034] A preparation method of modified polyethylene material:

[0035]75 parts of polyethylene resin, 5 parts of inorganic filler talcum powder, 8 parts of polyethylene PE-g-MAH grafted with maleic anhydride, 3 parts of interface modifier "hyperbranched" polyolefin with terminal hydroxyl groups, 0.5 parts Lubricant erucamide and 0.5 parts of antioxidant 1076 are mixed evenly, and then added to the feed port of a twin-screw extruder, and the temperature of the extruder is controlled between 120-180°C to prepare polyethylene modified master batches. 2 parts of expandable microspheres 1 and 2 parts of expandable microspheres 2 are blended and injected with the above-mentioned masterbatch to obtain a polyethylene material modified by expandable microspheres. The material is injection molded into products in the range of 160-220°C, and the product-related performance test results are shown in Table 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thermal resistance | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com